Prospects for the Development of Vehicle Assembly Plants of Chinese Automobile Brands in Kazakhstan: An Example of Multi-Sectoral Diversification of the Economy to Increase Its Sustainability

Abstract

:1. Introduction

2. The State of the Problem of Ensuring the Sustainability of the Automotive Industry: A Literature Review

2.1. Key Trends in Improving the Sustainability of the Automotive Industry

2.2. International Alliances of Automakers and Their Impact on Industrial Development within Expanding Markets

2.3. Current Situation in the Global Automotive Market

- China—Chinese automakers produced just over 26.1 million vehicles in 2021. From open sources, it follows that the Chinese automobile industry provides approximately 10% of the GDP.

- USA—Based on the results of 2021, 9.2 million passenger/light commercial vehicles and SUVs were assembled in the United States. Automotive production accounts for 3% of the GDP, with 1.7 million people directly employed in the US auto industry and another 8 million in related industries.

- Japan—Japanese automobile factories produced 26.1 million cars, the share of the automotive industry is 10% of the GDP; 5.9 million people work directly in the automotive industry and related industries.

- India—India only began to truly and actively develop its auto industry in the last 15 years, but production volume for 2021 has already grown to 4.4 million units. The importance of the automobile industry in the Indian national economy has increased in recent years thanks to targeted government actions and reached 7.1% of the GDP. About 2.72 million people work directly at Indian automobile industry enterprises and an equal quantity work in related industries.

- South Korea—South Korea produced over 3.5 million vehicles in 2021, with approximately 60% of the vehicles exported to foreign markets. The automobile industry in South Korea is traditionally one of the country’s main “economic engines”: in this country, the industry’s share exceeds 10% of the GDP.

2.4. Localization of Auto Components as One of the Sustainability Factors When Opening Auto Assembly Plants in Asian Countries

2.4.1. Automotive Industry in Vietnam

2.4.2. Automotive Industry in India

3. Materials and Methods

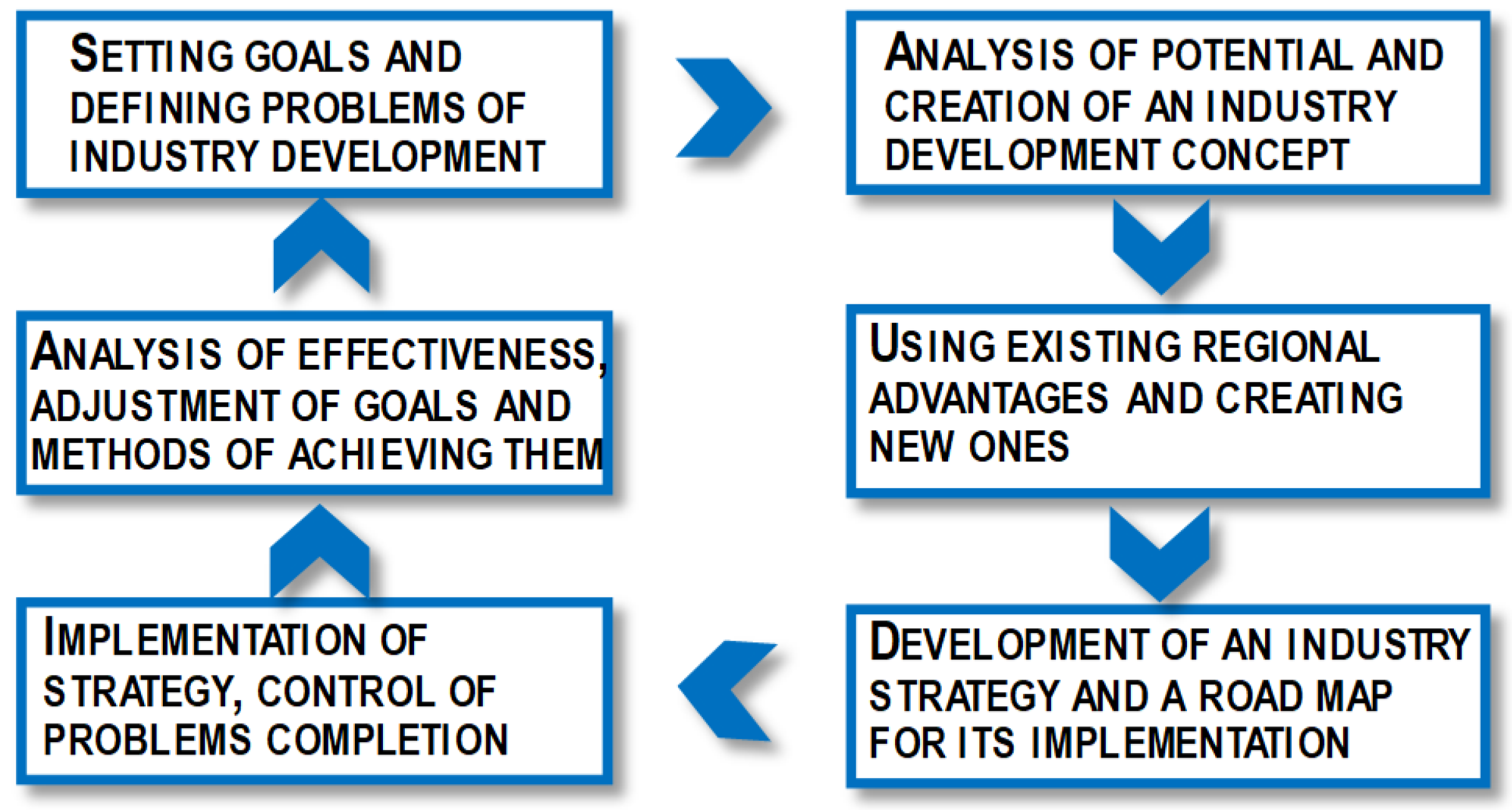

3.1. Strategic Analysis: Development of an Algorithm for Applying Qualitative Methods to Find Sustainable Solutions in the Automotive Industry

- External Environment—refers to the forces that influence the prospects and conditions of the firm. These may be competing firms and industry enterprises as a whole. The most commonly used analysis is the STEP analysis (PEST analysis) [70], or modifications, as described in Section 2.2.

3.2. PESTEL Analysis (as a Modification of STEP (PEST) Analysis)

3.3. SWOT Analysis

- The strengths of the firm;

- The weaknesses of the firm;

- Opportunities provided by the external environment;

- Threats posed by the external environment.

- Express SWOT analysis: due to clarity and simplicity, this is the most frequently used form.

- Comprehensive SWOT analysis: This type of analysis allows for the evaluation of the identified factors that characterized the organization’s activities in quantitative terms. This analysis must be strictly followed after all types of strategic analysis. The analysis depends on the depth of factor elaboration.

- Hybrid SWOT analysis: This type is a combination of the previous two, having the advantages of both approaches. In this case, several methods for selecting factors are used before the main analysis (STEP analysis, analysis using Porter’s Five Forces model, and analysis of the internal environment using one of the techniques). The analysis ends with the construction of a cross matrix, but it is possible not to use a quantitative assessment of factors. Its advantage lies in the depth of the analysis performed.

4. Results and Discussion

4.1. Prospects for the Automotive Industry in Kazakhstan in Light of the Sector Development Strategy

- Increasing the percentage of localization by including a minimum acceptable level in the contractual obligations of manufacturers;

- Establishing foundry technologies for the production of parts by casting;

- Attracting government funding by concluding contracts for the purchase of enterprise products that have not yet been produced;

- Development of preferential loan programs and leasing systems;

- Bringing the share of the reimbursement of costs for the production of export products by the state to 80%.

- Intensification of measures to increase the presence of Kazakhstani manufacturers in this market through the conclusion of agreements on the localization of assembly plants from the start of 2021;

- Development of a strategic line of production associations with Kazakhstani partner manufacturers of automotive components;

- Expansion of the electric vehicle sector.

4.2. Strategy for Increasing the Sustainability of the Automotive Industry: The Case of Kazakhstan

4.2.1. Porter’s Five Forces

4.2.2. PESTEL Analysis

4.2.3. Case Study: Application of SWOT Analysis to Assess the Prospects for the Development of the Automotive Industry in Kazakhstan

- 1.

- Consider the following potential internal strengths:

- Creation of a new product, which will lead to GDP growth.

- Diversification of the economy through the development of the non-resource sector.

- Development of local manufacturers in the event of localization of production, which will lead to the displacement of foreign companies from new potential market segments.

- Reducing unemployment due to new jobs

- Increase in the share of the working population engaged in intellectual work.

- Development of local production due to the prospect of localizing small-scale assembly.

- Development of new technologies.

- Accumulation of experience in the field of automotive technology among national personnel, improving product quality.

- Vehicle fleet renewal.

- Replacement of cars with more environmentally friendly ones.

- 2.

- Consider the following potential internal weaknesses:

- Lack of internal history and experience in the development of the domestic automotive industry.

- Lack of support from the state.

- Low labor productivity due to high costs of personnel training and production.

- Lack of established logistics supply channels, which will affect the cost of the car.

- Lack of workers with the necessary qualifications, imbalance of supply and demand in the labor market.

- The need for a system of training highly qualified personnel.

- Reduced competitiveness of future local production due to niche occupation by foreign manufacturers and increasing technological gap.

- Lack of a proprietary service network, due to the need to develop, repair, and maintain technology that guarantees owners trouble-free operation after the cars enter the market.

- Increased environmental load in the country due to the localization of production of auto components for small-unit assembly.

- 3.

- Potential external opportunities (O) include the following:

- Cooperation with global manufacturers against the backdrop of growing interaction with other countries.

- Cooperation agreements concluded at the government level, which will lead to interstate cooperation and exchange of experience.

- Increased demand for export cars in the domestic and global markets due to increased purchasing power.

- Increase in duties on imported cars, contributing to the flow of funds into the budget.

- Government programs for preferential lending and leasing of localized cars, leading to increased demand for cars.

- Reimbursement of government costs for transportation of finished products within the country and certification of products for export markets, which will lead to increased competitiveness of domestic products.

- Introduction of VAT benefits, which will lead to an increase in purchasing power.

- State programs to provide qualified personnel.

- Introduction of new foreign technologies in the field of the automotive industry, facilitating the acquisition of new competencies.

- Introduction of a recycling fee for imported cars to develop a system for recycling used vehicles and reduce the environmental load.

- Legislative provisions on the minimum level of localization.

- 4.

- Consider the following potential external threats (T):

- A change in the strategy of Chinese automakers and their reluctance to move from large-unit assembly to small-unit assembly, which will lead to a decrease in competitiveness.

- Strong competition from long-time market players, including the Uzbek automaker Ravon, which will affect the market value of the car.

- Currency risks, which may lead to an increase in production costs.

- Dependence on Chinese components due to lack of in-house production.

- Lack of statistics on failures during operation in Kazakhstan to understand their durability, which is necessary to predict the localization structure of parts that limit reliability due to the appearance of defects during operation.

- Probability of achieving event pj on a scale of 0 to 1, where 1 corresponds to the maximum probability of the event occurring;

- The significance of the factor Kj, characterizing the degree of influence of the factor on the company’s activities on a scale of 0 to 4, where the maximum number of points corresponds to a high degree of influence.

- Kj—signifies the extent of the impact of an opportunity or threat;

- pj—denotes the likelihood of an environmental factor manifesting;

- aij—indicates the degree of interrelation between elements of pair-wise analysis.

4.2.4. Options for Firm Strategies

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pasko, A.V. Modern Development Strategies of Transnational Corporations in the World Market of Passenger Vehicles (Based on the Example of the Swedish Company VOLVO). Ph.D. Thesis, The State University of Management, Moscow, Russia, Ryazansky prospect, 99. April 2011. [Google Scholar]

- How Does the Automobile Industry Contribute to the Global Economy? Available online: https://promrating.ru/news/kakoj-vklad-avtomobilnaya-promyshlennost-vnosit-v-globalnuyu-ekonomiku/ (accessed on 11 April 2023).

- Car Production in China 2010–2022, by Type. Available online: https://www.statista.com/statistics/281133/car-production-in-china/ (accessed on 7 January 2024).

- Krasova, E.V. Characteristics of global automotive industry as a sector with high levels of production internationalization. Amazon. Investig. 2018, 7, 84–93. [Google Scholar]

- Spreafico, C. Can modified components make cars greener? A life cycle assessment. J. Clean. Prod. 2021, 307, 127190. [Google Scholar] [CrossRef]

- CompMechLab in China’s Billion-Dollar High-Tech Market: 250 Automakers, 50 Million Cars and the “One Belt”. Available online: http://fea.ru/news/6657 (accessed on 21 September 2023).

- Lukin, E.; Krajnović, A.; Bosna, J. Sustainability Strategies and Achieving SDGs: A Comparative Analysis of Leading Companies in the Automotive Industry. Sustainability 2022, 14, 4000. [Google Scholar] [CrossRef]

- Wellbrock, W.; Ludin, D.; Röhrle, L.; Gerstlberger, W. Sustainability in the automotive industry, importance of and impact on automobile interior—Insights from an empirical survey. Int. J. Corporate Soc. Responsib. 2020, 5, 10. [Google Scholar] [CrossRef]

- Rodríguez-González, R.M.; Guzmán, G.M.; Madrid-Guijarro, A.; Garza-Reyes, J.A. Does circular economy affect financial performance? The mediating role of sustainable supply chain management in the automotive industry. J. Clean. Prod. 2022, 379, 134670. [Google Scholar] [CrossRef]

- Lenort, R.; Wicher, P.; Zapletal, F. On influencing factors for Sustainable Development goal prioritisation in the automotive industry. J. Clean. Prod. 2023, 387, 135718. [Google Scholar] [CrossRef]

- Szász, L.; Csíki, O.; Rácz, B.-G. Sustainability management in the global automotive industry: A theoretical model and survey study. Int. J. Prod. Econ. 2021, 235, 108085. [Google Scholar] [CrossRef]

- Swarnakar, V.; Singh, A.R.; Tiwari, A.K. Evaluation of key performance indicators for sustainability assessment in automotive component manufacturing organization. Mater. Today Proc. 2021, 47, 5755–5759. [Google Scholar] [CrossRef]

- Encinas Bartos, K.; Schwarzkopf, J.; Mueller, M.; Hofmann-Stoelting, C. Explanatory factors for variation in supplier sustainability performance in the automotive sector—A quantitative analysis. Clean. Logist. Supply Chain. 2022, 5, 100068. [Google Scholar] [CrossRef]

- Wang, X.; Shi, X. A methodology for the evaluation of automotive electronic components supplier’s efficiency. In Proceedings of the 2015 International Conference on Logistics, Informatics and Service Sciences (LISS), Barcelona, Spain, 27–29 July 2015; pp. 1–7. [Google Scholar]

- Huo, H.; Ma, Y.; Shen, X. Research on automotive component supplier selection process. In Proceedings of the MSIE 2011, Harbin, China, 8–11 January 2011; pp. 935–939. [Google Scholar]

- Khabibullin, R.; Makarova, I.; Pashkevich, A.; Mavrin, V.; Shubenkova, K. Application of simulation modeling to improve management of technological processes during production of automotive components. In Proceedings of the 2016 17th International Conference on Mechatronics-Mechatronika (ME), Prague, Czech Republic, 7–9 December 2016; pp. 1–7. [Google Scholar]

- Shioji, H. Parts Localization Lifecycle in the Auto Industry. Available online: https://gerpisa.org/system/files/Shioji_Full_paper_2017.05.17.pdf (accessed on 17 May 2017).

- Safarov, D.T.; Gimazetdinov, A.I. Application of Blockchain Computer Technology to Trace the Causes of Defects in the Supply Chains of Engineering Products. In Proceedings of the 2019 International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon), Vladivostok, Russia, 1–4 October 2019; pp. 1–7. [Google Scholar]

- Mathivathanan, D.; Agarwal, M.V.K.; Saikouk, T.; Appolloni, A. Modeling the pressures for sustainability adoption in the Indian automotive context. J. Clean. Prod. 2022, 342, 130972. [Google Scholar] [CrossRef]

- Ghosh, S.; Bhowmik, C.; Sinha, S.; Raut, R.D.; Mandal, M.; Ray, R. An integrated multi-criteria decision-making and multivariate analysis towards sustainable procurement with application in automotive industry. Supply Chain. Anal. 2023, 3, 100033. [Google Scholar] [CrossRef]

- Dong, B. Automotive Components Localization and De-globalization Purchasing Strategy. In Proceedings of the 2022 IEEE International Conference on Smart Internet of Things (SmartIoT), Suzhou, China, 19–21 August 2022; pp. 246–247. [Google Scholar]

- Balu, B.; Jayapal, R.; Gunupuru, K.R.; Mogili, R. A conceptual roadmap for implementing localization in the Indian automotive industry in a post-pandemic scenario. Acad. Strateg. Manag. J. 2022, 21, 1–15. [Google Scholar]

- Kandrashina, E.A.; Ashmarina, S.I.; Aleshkova, D.V.; Vorotnikova, M. The Level of Production Localization of Automotive Industry Enterprises in Russia. SHS Web Conf. 2020, 73, 01011. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, C.; Zhang, Z. Deep Learning Algorithms for Automotive Spare Parts Demand Forecasting. In Proceedings of the 2021 International Conference on Computer Information Science and Artificial Intelligence (CISAI), Kunming, China, 17–19 September 2021; pp. 358–361. [Google Scholar]

- Olabi, A.G.; Abdelkareem, M.A.; Wilberforce, T.; Alkhalidi, A.; Salameh, T.; Abo-Khalil, A.G.; Hassan, M.M.; Sayed, E.T. Battery electric vehicles: Progress, power electronic converters, strength (S), weakness (W), opportunity (O), and threats (T). Int. J. Thermofluids 2022, 16, 100212. [Google Scholar] [CrossRef]

- Harper, G.D.; Kendrick, E.; Anderson, P.A.; Mrozik, W.; Christensen, P.; Lambert, S.; Greenwood, D.; Das, P.K.; Ahmeid, M.; Milojevic, Z.; et al. Roadmap for a sustainable circular economy in lithium-ion and future battery technologies. J. Phys. Energy 2023, 5, 021501. [Google Scholar] [CrossRef]

- Czerlunczakiewicz, E.; Majerczak, M.; Bonato, M. Variability Of Fatigue Simulation Predictions for Automotive Components. In Proceedings of the 2023 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 23–26 January 2023; pp. 1–6. [Google Scholar]

- Stodola, J.; Breznická, A.; Stodola, P. The Influence of Electromobility on the Czech Automotive Industry. In Proceedings of the 2019 International Conference on Military Technologies (ICMT), Brno, Czech Republic, 30–31 May 2019; pp. 1–4. [Google Scholar]

- Tan, C.M.; Narula, U.; Kapoo, D. Reliability paradox for worldwide automotive electronics. In Proceedings of the 2017 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 23–26 January 2017; pp. 1–7. [Google Scholar]

- Ray, S. Safety, Security, and Reliability: The Automotive Robustness Problem and an Architectural Solution. In Proceedings of the 2019 IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, NV, USA, 11–13 January 2019; pp. 1–4. [Google Scholar]

- Bonato, M.; Krishnamoorthy, M.; Goge, P. Data Mining and Machine Learning Methods for Robust Reliability Predictions on Automotive Components. In Proceedings of the 2022 Annual Reliability and Maintainability Symposium (RAMS), Tucson, AZ, USA, 24–27 January 2022; pp. 1–6. [Google Scholar]

- Saranga, H.; Schotter, A.P.J.; Mudambi, R. The double helix effect: Catch-up and local-foreign co-evolution in the Indian and Chinese automotive industries. Int. Bus. Rev. 2019, 28, 101495. [Google Scholar] [CrossRef]

- Jena, A.; Patel, S.K. A hybrid fuzzy based approach for industry 4.0 framework implementation strategy and its sustainability in Indian automotive industry. J. Clean. Prod. 2023, 420, 138369. [Google Scholar] [CrossRef]

- Khanna, M.S.; Sidhu, H.J.S.; Bansal, R. Industry 4.0: A Study of India’s Readiness as Preferred Investment Destination in Automotive and Auto Component Industry. In Proceedings of the 2020 Sixth International Conference on Parallel, Distributed and Grid Computing (PDGC), Waknaghat, India, 6–8 November 2020; pp. 557–560. [Google Scholar]

- India’s Auto Component Industry. Available online: https://www.iasgyan.in/blogs/indias-auto-component-industry (accessed on 26 October 2023).

- Fuchs, E.R.H.; Field, F.R.; Roth, R.; Kirchain, R.E. Plastic cars in China? The significance of production location over markets for technology competitiveness in the United States versus the People’s Republic of China. Int. J. Prod. Econ. 2011, 132, 79–92. [Google Scholar] [CrossRef]

- Jakob, R.; Richard Nakamura, H.; Ström, P. Chinese foreign acquisitions aimed for strategic asset-creation and innovation upgrading: The case of Geely and Volvo Cars. Technovation 2018, 70–71, 59–72. [Google Scholar]

- Hertenstein, P.; Williamson, P.J. The role of suppliers in enabling differing innovation strategies of competing multinationals from emerging and advanced economies: German and Chinese automotive firms compared. Technovation 2018, 70–71, 46–58. [Google Scholar] [CrossRef]

- Nam, K.-M. Compact organizational space and technological catch-up: Comparison of China’s three leading automotive groups. Res. Policy 2015, 44, 258–272. [Google Scholar] [CrossRef]

- McDermott, M. The Development and Internationalization of the South Korean Motor Industry: The European Dimension. Asia Pac. Bus. Rev. 1995, 2, 23–47. [Google Scholar] [CrossRef]

- Adams, B. The employment impact of motor vehicle assembly plant openings. Reg. Sci. Urban Econ. 2016, 58, 57–70. [Google Scholar] [CrossRef]

- It Turns out How Much the Automotive Industry Contributes to the Global Economy. Available online: https://nova24.uz/lastnews/vyyasnilos-kakoj-vklad-avtomobilnaya-promyshlennost-vnosit-v-globalnuju-ekonomiku (accessed on 12 April 2022).

- Nguyen, T.B. Industrial Policies as Determinant of Localization: The Case of Vietnamese Automobile Industry. 2008. Available online: https://www.researchgate.net/publication/242245965_Industrial_Policies_as_Determinant_of_Localization_The_Case_of_Vietnamese_Automobile_Industry (accessed on 26 October 2023).

- Messagie, M.; Boureima, F.; Coosemans, T.; Macharis, C.; Joeri, V.M. A Range-Based Vehicle Life Cycle Assessment Incorporating Variability in the Environmental Assessment of Different Vehicle Technologies and Fuels. Energies 2014, 7, 1467–1482. [Google Scholar] [CrossRef]

- Hirz, M.; Dietrich, W.; Gfrerrer, A.; Lang, J. Automotive Development Processes. In Integrated Computer-Aided Design in Automotive Development; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Yoo, M.-J.; Grozel, C.; Kiritsis, D. Closed-Loop Lifecycle Management of Service and Product in the Internet of Things: Semantic Framework for Knowledge Integration. Sensors 2016, 16, 1053. [Google Scholar] [CrossRef]

- Li, S.; Zhou, T.; Yang, H.; Wang, P. Blockchain-Based Secure Storage and Access Control Scheme for Supply Chain Ecological Business Data: A Case Study of the Automotive Industry. Sensors 2023, 23, 7036. [Google Scholar] [CrossRef] [PubMed]

- Ryu, C.; Do, S. A Method for Managing Software Assets in the Automotive Industry (Focusing on the Case of Hyundai Motor Company and Parts Makers). Appl. Sci. 2023, 13, 4174. [Google Scholar] [CrossRef]

- Vehicle Giant Looking at Vietnam and Indonesia in Wake of Problems in China. Available online: https://web.archive.org/web/20180113081354/http://www.vneconomictimes.com/article/business/hyundai-motor-considering-plant-in-vietnam (accessed on 26 October 2023).

- Auto Industry Seeks to Develop Components Segment. Available online: https://www.retailnews.asia/auto-industry-seeks-to-develop-components-segment/ (accessed on 26 October 2023).

- Auto Component Industry Should Enhance Localization, Invest in Tech: Maruti Suzuki. Available online: https://auto.economictimes.indiatimes.com/news/auto-components/auto-component-industry-should-enhance-localisation-invest-in-tech-maruti-suzuki/94198043 (accessed on 26 October 2023).

- PLI Scheme for Automobile and Auto Component Industry. Available online: https://www.indiafilings.com/learn/pli-scheme-for-automobile-and-auto-component-industry/ (accessed on 26 October 2023).

- Automobile Industry to Enhance the Localisation of E-Components. Available online: https://autoevtimes.com/automobile-industry-to-enhance-the-localisation-of-e-components/ (accessed on 25 January 2023).

- Auto Industry Seeks Government Support to Boost 100% Localization. Available online: https://autocomponentsindia.com/auto-industry-seeks-government-support-to-boost-100-localisation/ (accessed on 26 October 2023).

- Boost Localization of Automotive Parts, Reduce Import Dependency: Kant. Available online: https://www.business-standard.com/article/automobile/boost-localisation-of-automotive-parts-reduce-import-dependency-kant-121082600500_1.html (accessed on 26 October 2023).

- Ackoff, R.L. A Concept of Corporate Planning; John Wiley: New York, NY, USA, 1970. [Google Scholar]

- Armstrong, J.S. Strategic Planning and Forecasting Fundamentals. Paper No. 81682. Available online: https://mpra.ub.uni-muenchen.de/81682/ (accessed on 17 December 2023).

- Harju, P. Attitude of Strategic Managers toward Formalized Corporate Planning; School of Economics: Turku, Finland, 1981. [Google Scholar]

- Smith, T. Qualitative Analysis. Available online: https://www.investopedia.com/terms/q/qualitativeanalysis.asp (accessed on 11 August 2023).

- Research Methods Knowledge Base by Prof. William, M.K. Available online: https://conjointly.com/kb/qualitative-measures/ (accessed on 11 August 2023).

- Seaman, C.B. Qualitative methods in empirical studies of software engineering. Trans. Softw. Eng. 1999, 25, 557–572. [Google Scholar] [CrossRef]

- Karasev, O.; Mukanina, E. Expert assessment method in foresight studies. Stat. Econ. 2019, 16, 4–13. [Google Scholar] [CrossRef]

- Creswell, J.W.; Creswell, J.D. Research Design: Qualitative. Quantitative. and Mixed Methods Approaches, 5th ed.; SAGE: Los Angeles, CA, USA, 2018; ISBN 978-1-5063-8670-6. [Google Scholar]

- Customer Segmentation Analysis: Types, Examples, & Methods. Available online: https://qualaroo.com/blog/customer-segmentation-analysis-types-examples-methods/ (accessed on 18 March 2024).

- Customer Segmentation in Competitive. Available online: https://fastercapital.com/startup-topic/Customer-Segmentation-in-Competitive.html (accessed on 18 March 2024).

- Competitor Analysis. Available online: https://www.mikevestil.com/competitor-analysis/ (accessed on 18 March 2024).

- Giri, R.N.; Mondal, S.K.; Maiti, M. Analysis of pricing decision for substitutable and complementary products with a common retailer. Pac. Sci. Rev. A Nat. Sci. Eng. 2016, 18, 190–202. [Google Scholar] [CrossRef]

- Michael, E.P. The Five Competitive Forces that Shape Strategy. Special Issue on HBS Centennial. Harv. Bus. Rev. 2008, 86, 78–93. [Google Scholar]

- Porter, M.E. How Competitive Forces Shape Strategy. Harv. Bus. Rev. 57. 1979, 2, 137–145. [Google Scholar]

- Aguilar, F.J. Scanning the Business Environment; MacMillan Co.: New York, NY, USA, 1967; 239p. [Google Scholar]

- Learned, E.P.; Christensen, C.R.; Andrews, K.R.; Guth, W.D. Business Policy: Text and Cases; Richard, D. Irwin, Incorporated Ltd.: Homewood, IL, USA; Georgetown, TX, USA, 1969; 1046p. [Google Scholar]

- Production of Electric Vehicles, a New Plant and Access to Export Markets—The Development of Mechanical Engineering in Kazakhstan in the New Reality. Available online: https://primeminister.kz/ru/news/reviews/proizvodstvo-elektromobiley-novyy-zavod-i-vyhod-na-eksportnye-rynki-razvitie-mashinostroeniya-kazahstana-v-usloviyah-novoy-realno.sti-23102417 (accessed on 23 October 2023).

- Automotive Industry of Kazakhstan: How Is It Developing and What Are the Prospects. Available online: https://primeminister.kz/en/news/reviews/automotive-industry-of-kazakhstan-how-is-it-developing-and-what-are-the-prospects (accessed on 23 October 2023).

- Why “Screwdriver” Car Assembly in Kazakhstan Is Beneficial for the Country. History of the Automobile Industry. Available online: https://informburo.kz/stati/pocemu-otvyortocnaya-sborka-avto-v-kazaxstane-vygodna-strane-istoriya-avtoproma (accessed on 23 October 2021).

- Chinese Team. A Full-Cycle Plant Will Be Opened in Kazakhstan for Chery, Changan and GWM. Available online: https://китайские-автoмoбили.рф/2022/09/15/multibrendovyj-zavod-kitajskih-avtomobilej-v-kazahstane/?tgm (accessed on 15 September 2023).

- Who Localizes Auto Components in Kazakhstan and Why? Available online: https://inbusiness.kz/ru/news/kto-i-zachem-v-kazahstane-lokalizuet-avtokomponenty (accessed on 12 April 2023).

- Social Stability and Preservation of Employment: The Industrial Sector of Kazakhstan Completed 2020 with Positive Dynamics of Development Rates. Available online: https://primeminister.kz/en (accessed on 18 March 2024).

- Who and Why Localizes Car Components in Kazakhstan? Available online: https://astana-motors.kz/en/news/kto-i-zachem-v-kazahstane-lokalizuet-avtokomponenti-413 (accessed on 19 April 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serikkaliyeva, A.; Makarova, I.; Gabsalikhova, L. Prospects for the Development of Vehicle Assembly Plants of Chinese Automobile Brands in Kazakhstan: An Example of Multi-Sectoral Diversification of the Economy to Increase Its Sustainability. Sustainability 2024, 16, 2662. https://doi.org/10.3390/su16072662

Serikkaliyeva A, Makarova I, Gabsalikhova L. Prospects for the Development of Vehicle Assembly Plants of Chinese Automobile Brands in Kazakhstan: An Example of Multi-Sectoral Diversification of the Economy to Increase Its Sustainability. Sustainability. 2024; 16(7):2662. https://doi.org/10.3390/su16072662

Chicago/Turabian StyleSerikkaliyeva, Azhar, Irina Makarova, and Larisa Gabsalikhova. 2024. "Prospects for the Development of Vehicle Assembly Plants of Chinese Automobile Brands in Kazakhstan: An Example of Multi-Sectoral Diversification of the Economy to Increase Its Sustainability" Sustainability 16, no. 7: 2662. https://doi.org/10.3390/su16072662

APA StyleSerikkaliyeva, A., Makarova, I., & Gabsalikhova, L. (2024). Prospects for the Development of Vehicle Assembly Plants of Chinese Automobile Brands in Kazakhstan: An Example of Multi-Sectoral Diversification of the Economy to Increase Its Sustainability. Sustainability, 16(7), 2662. https://doi.org/10.3390/su16072662