Evolutionary Game Analysis of Low-Carbon Incentive Behaviour of Power Battery Recycling Based on Prospect Theory

Abstract

1. Introduction

2. Literature Review

2.1. Research on Power Battery Recycling

2.2. Research on Evolutionary Games in the Field of Recycling

2.3. Research on Prospect Theory

3. Three-Party Evolutionary Game Model Based on Prospect Theory

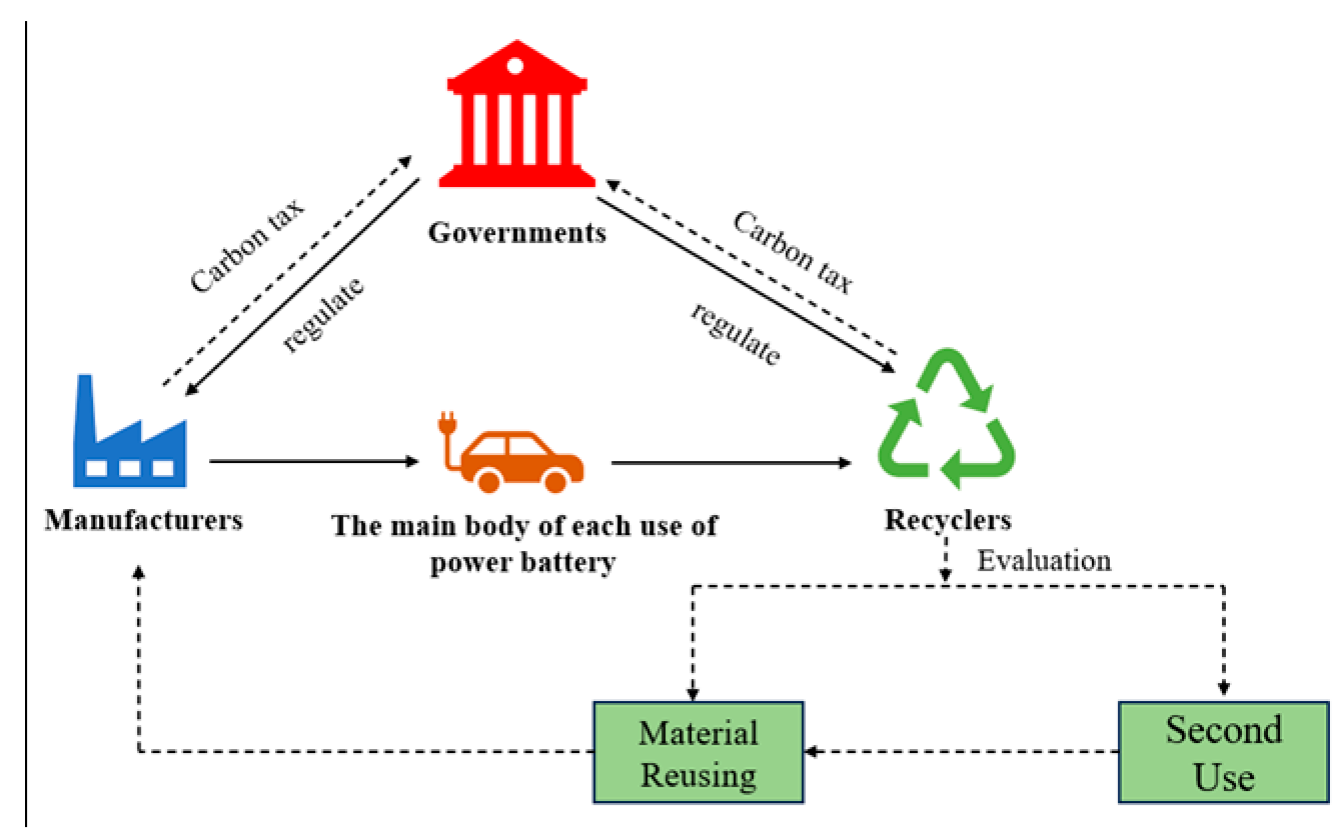

3.1. Description of the Model

3.2. Game Model Assumptions

3.3. Construction of Payoff Matrix

4. Model Resolution and Stability Strategy Analysis

4.1. Dynamic Equations and Stability Analysis of Replication in Government

4.2. Dynamic Equations and Stability Analysis of Replication in Manufacturers

4.3. Dynamic Equations and Stability Analysis of Replication in Recyclers

4.4. System Stability Analysis of Three-Party Game

5. Simulation and Analysis

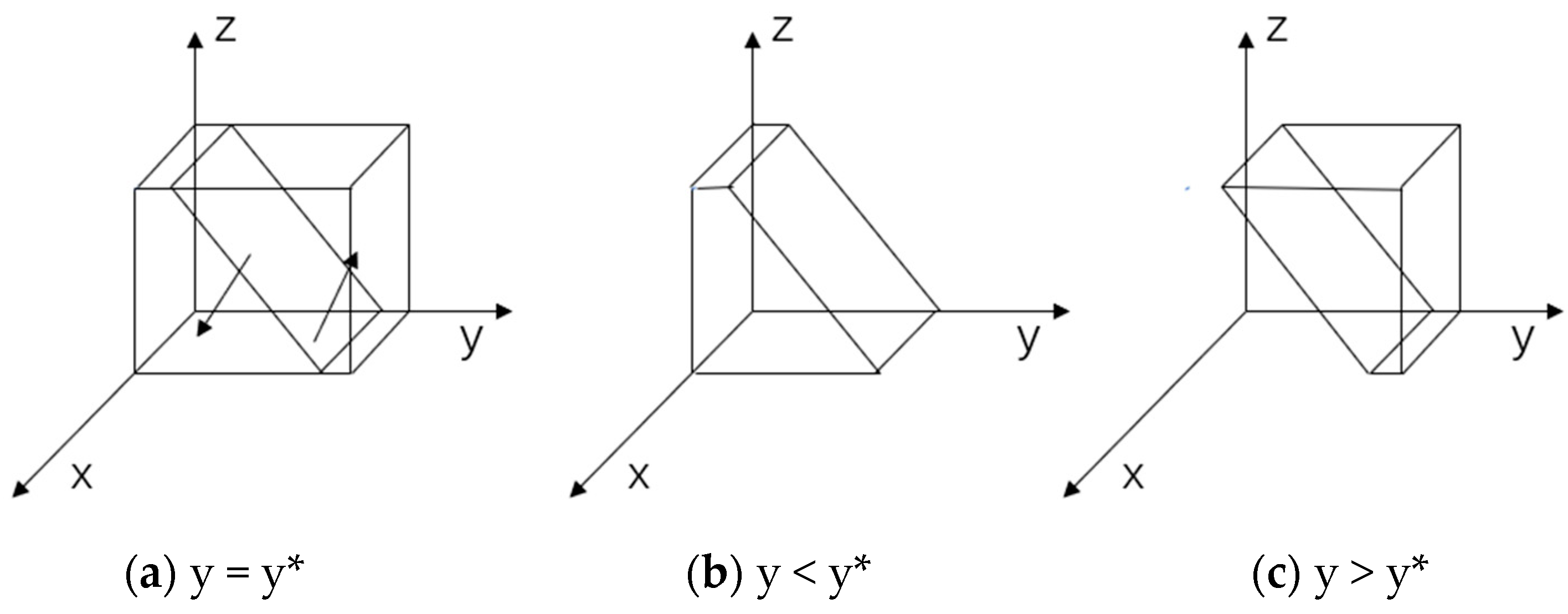

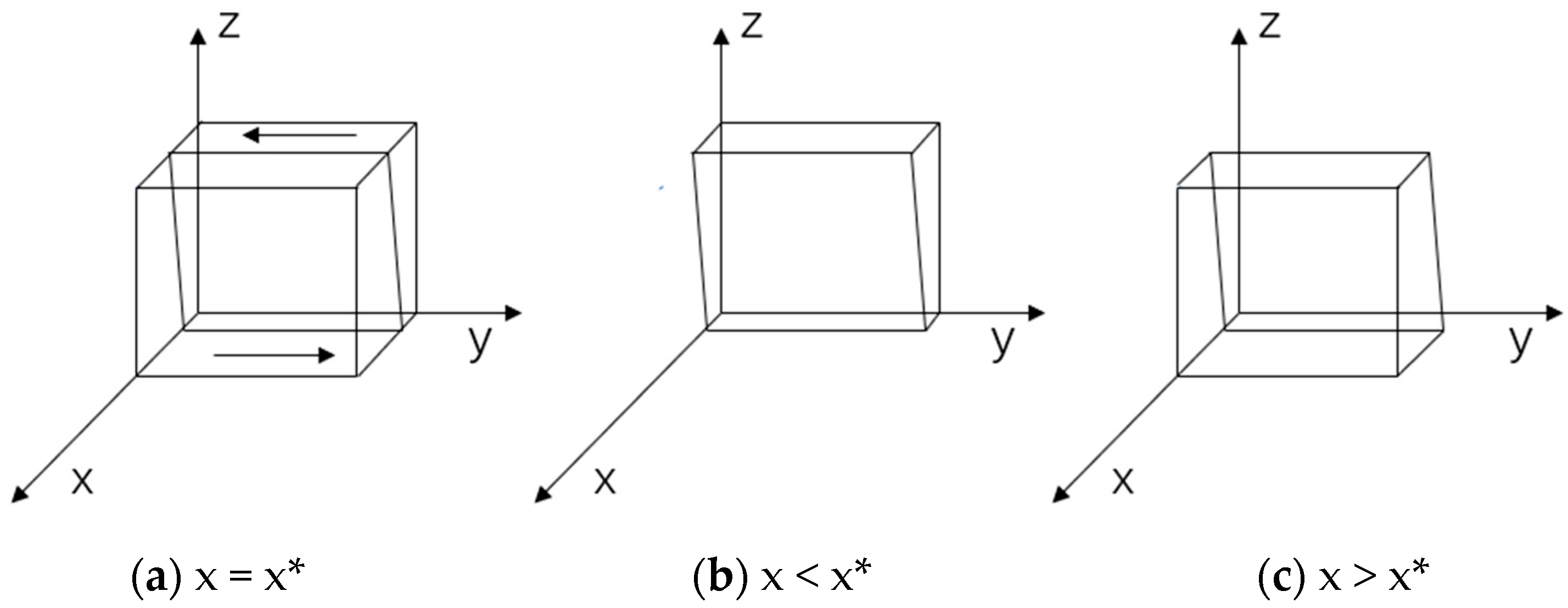

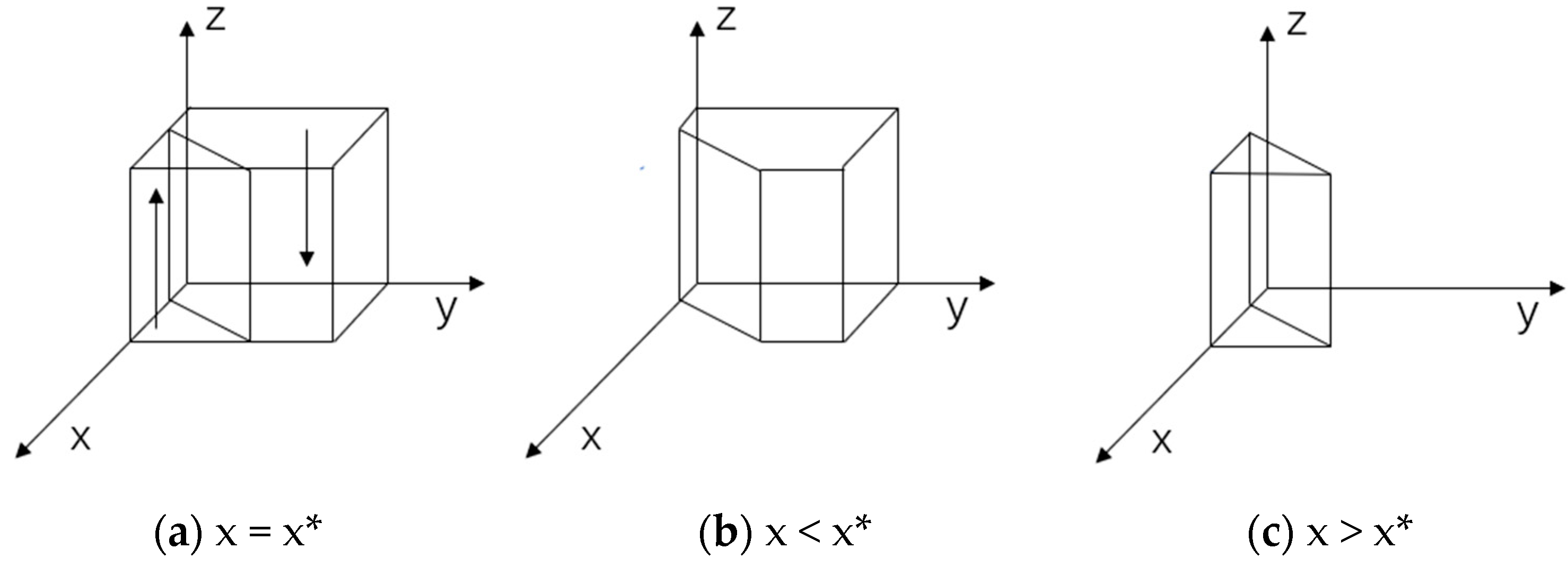

5.1. Initial Evolutionary Paths Analysis

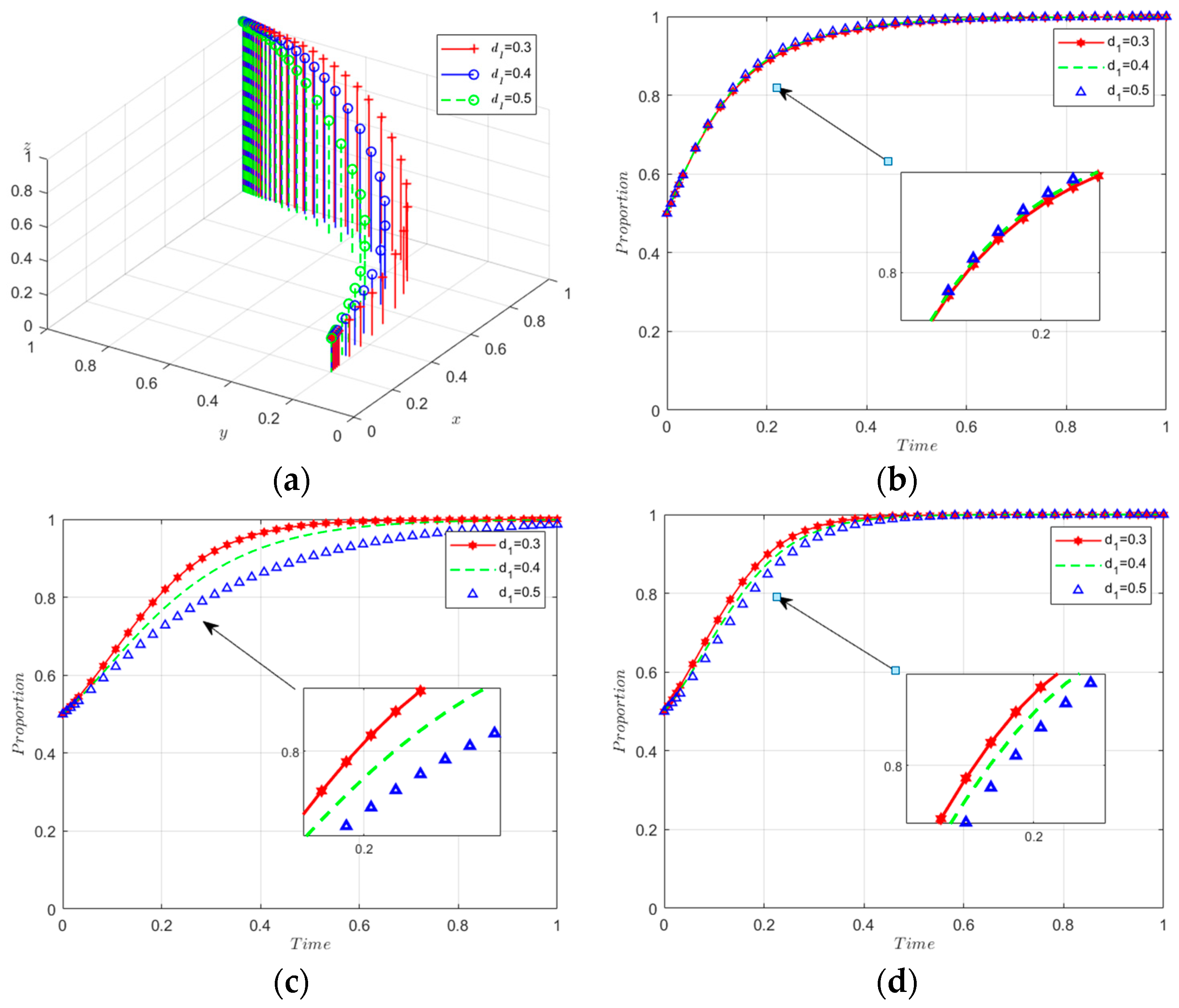

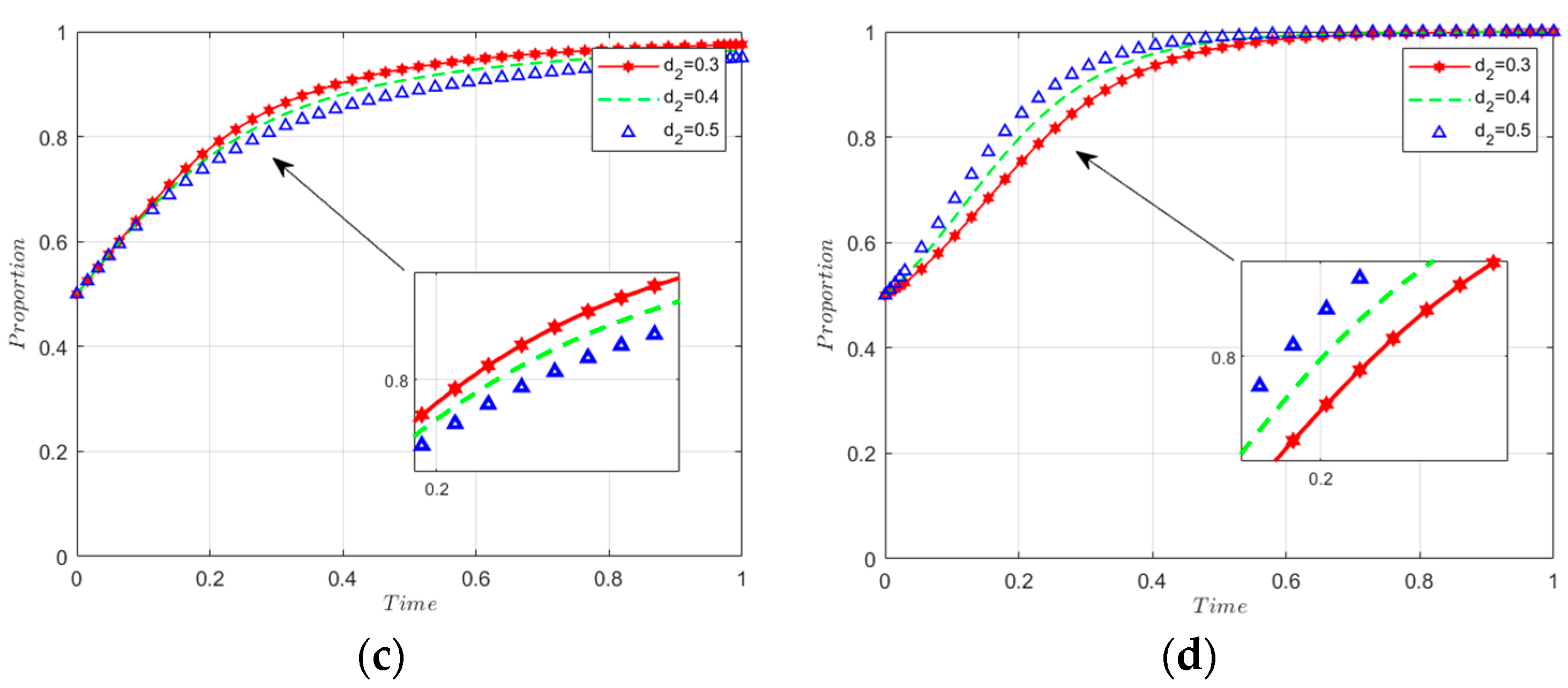

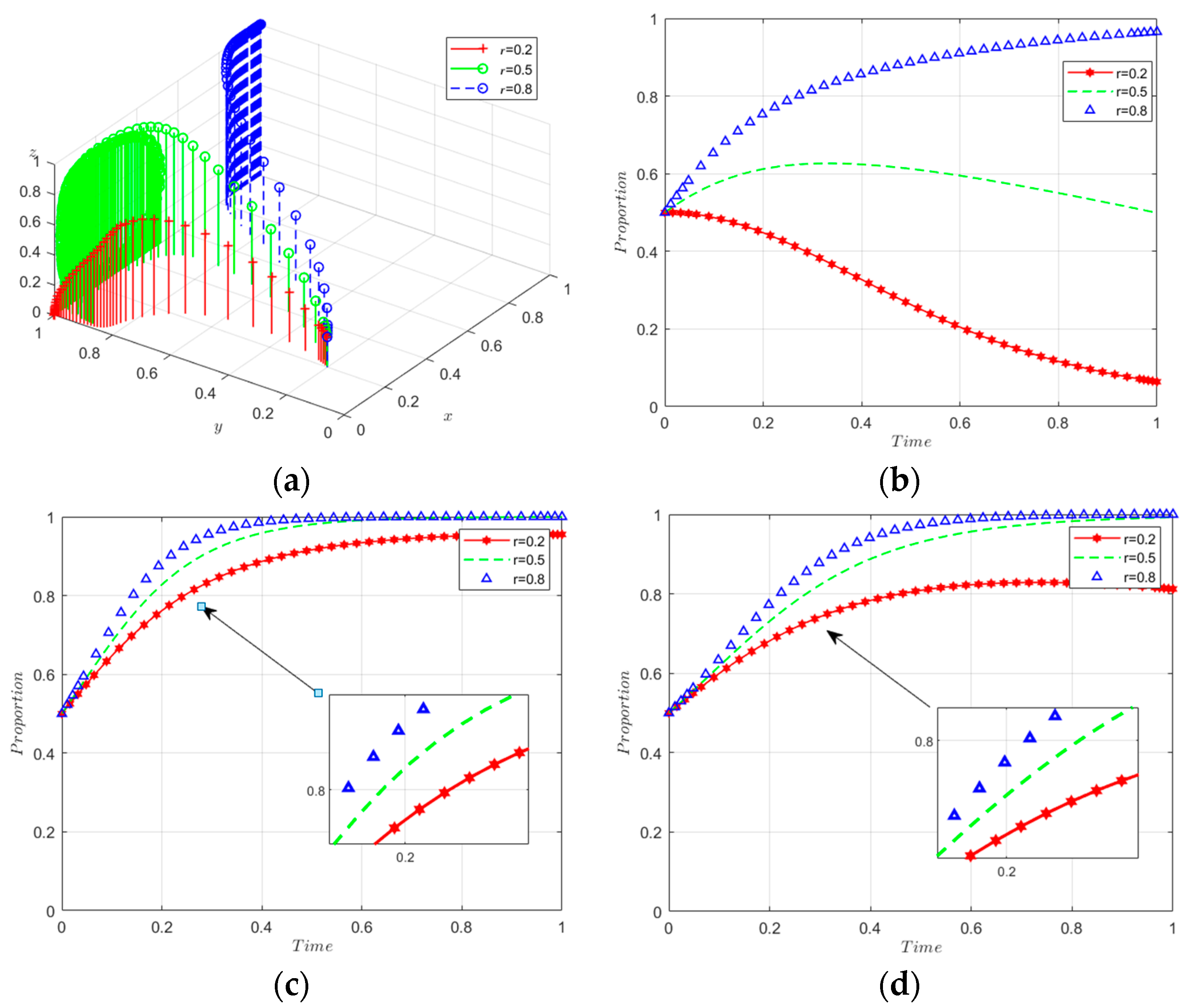

5.2. Sensitivity Analysis

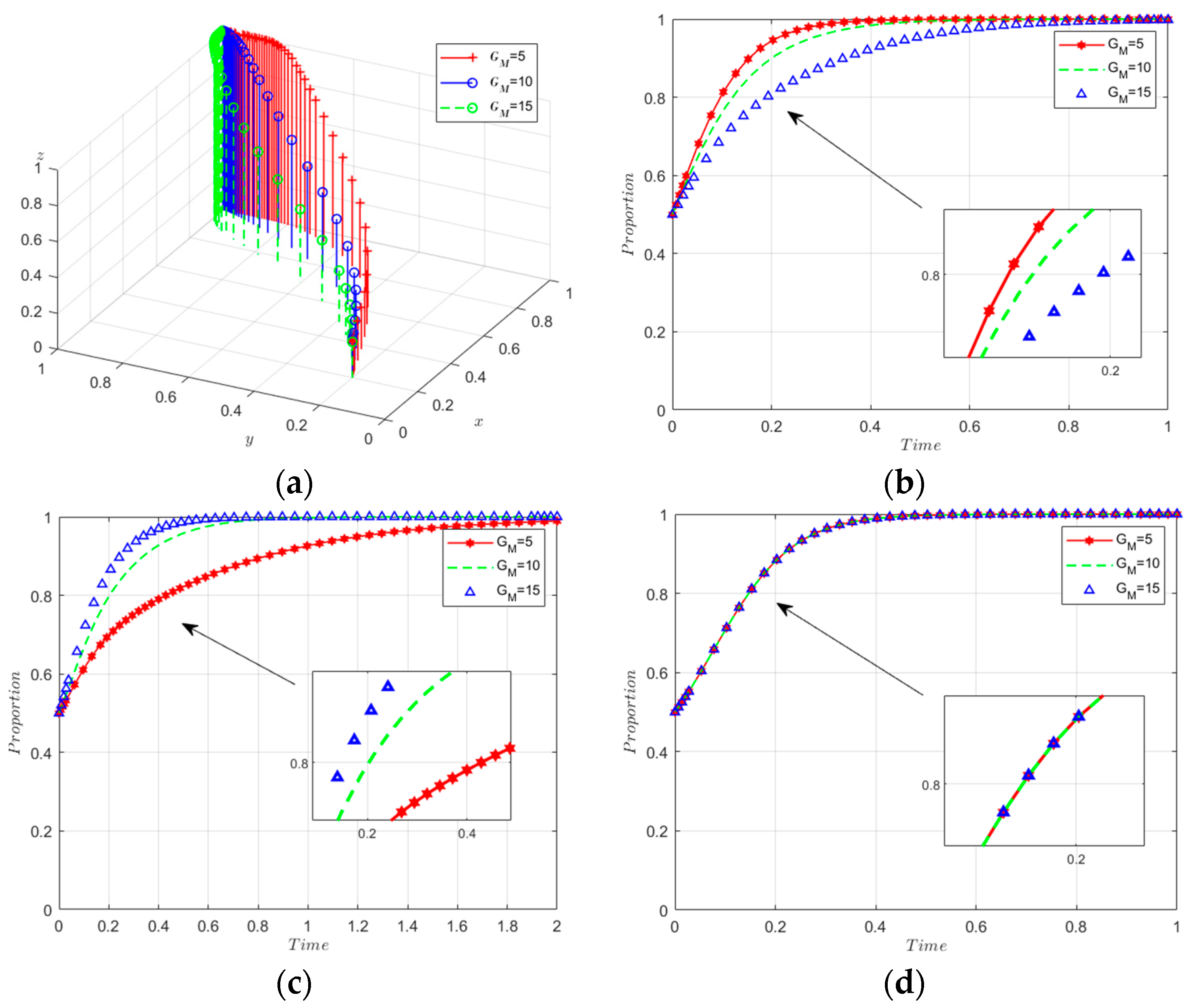

5.2.1. Sensitivity Analysis of Government Incentives

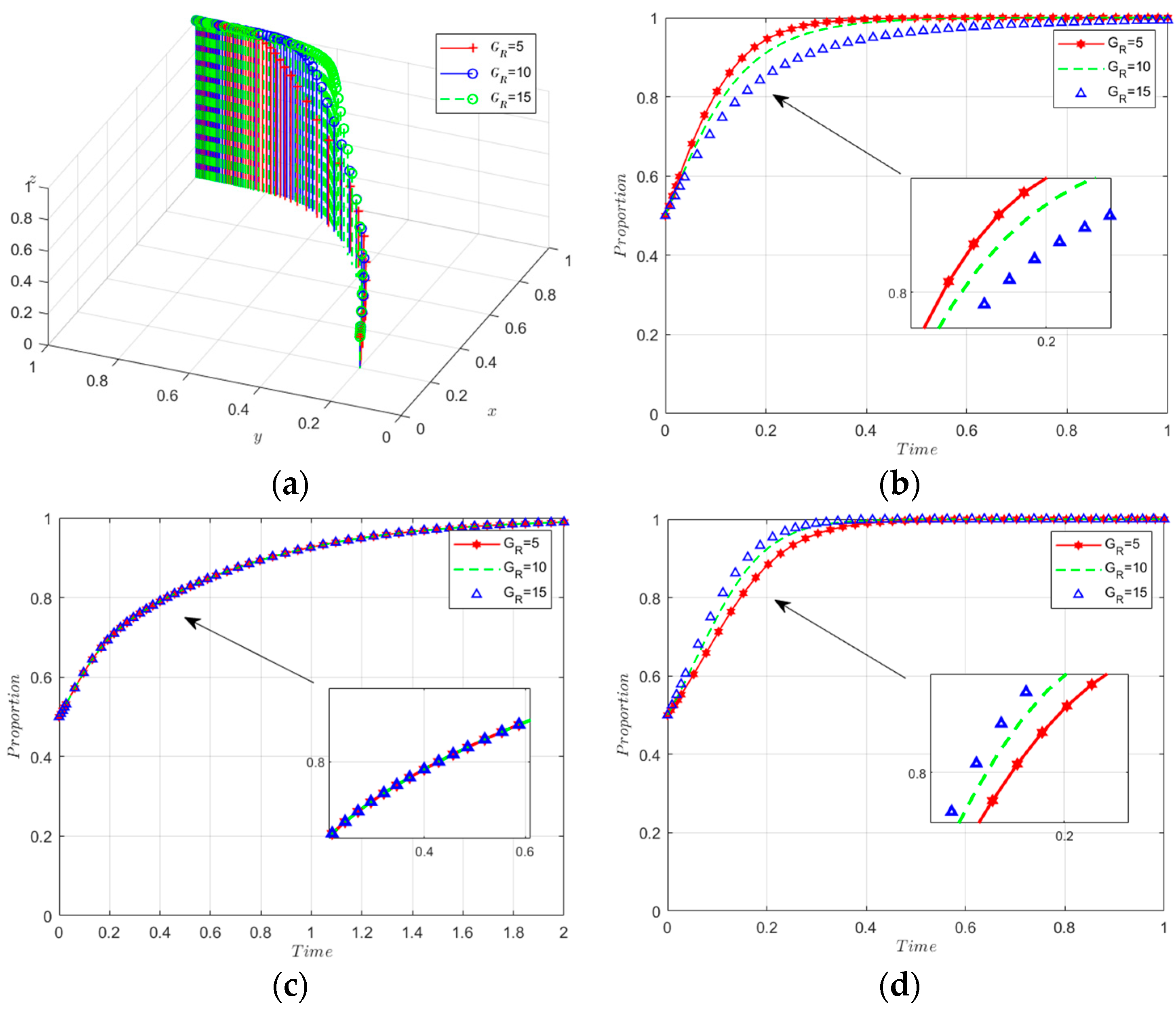

5.2.2. Sensitivity Analysis of Government Penalties

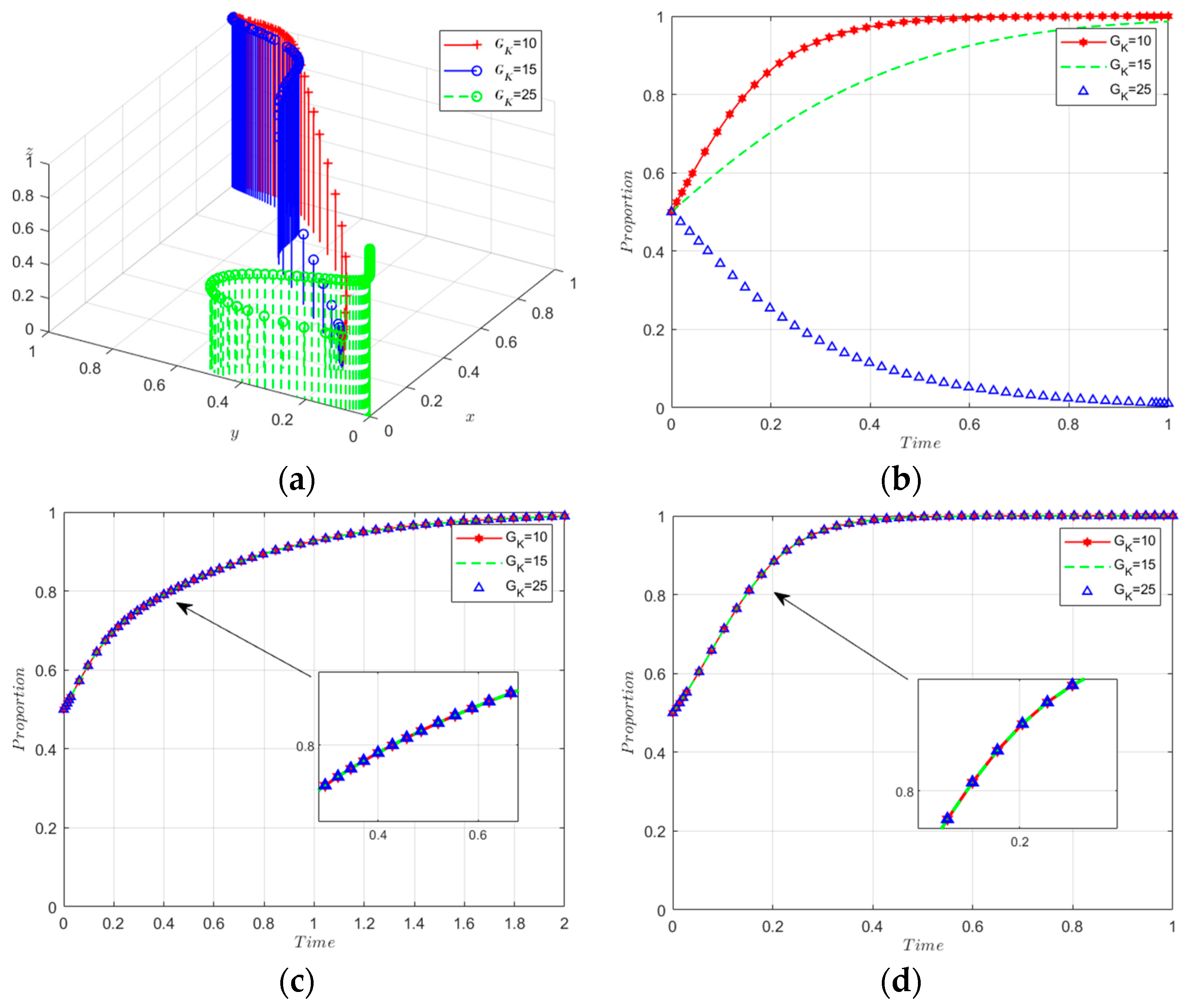

5.2.3. Sensitivity Analysis of Co-Benefit Sharing Coefficient and Cost-Sharing Coefficient

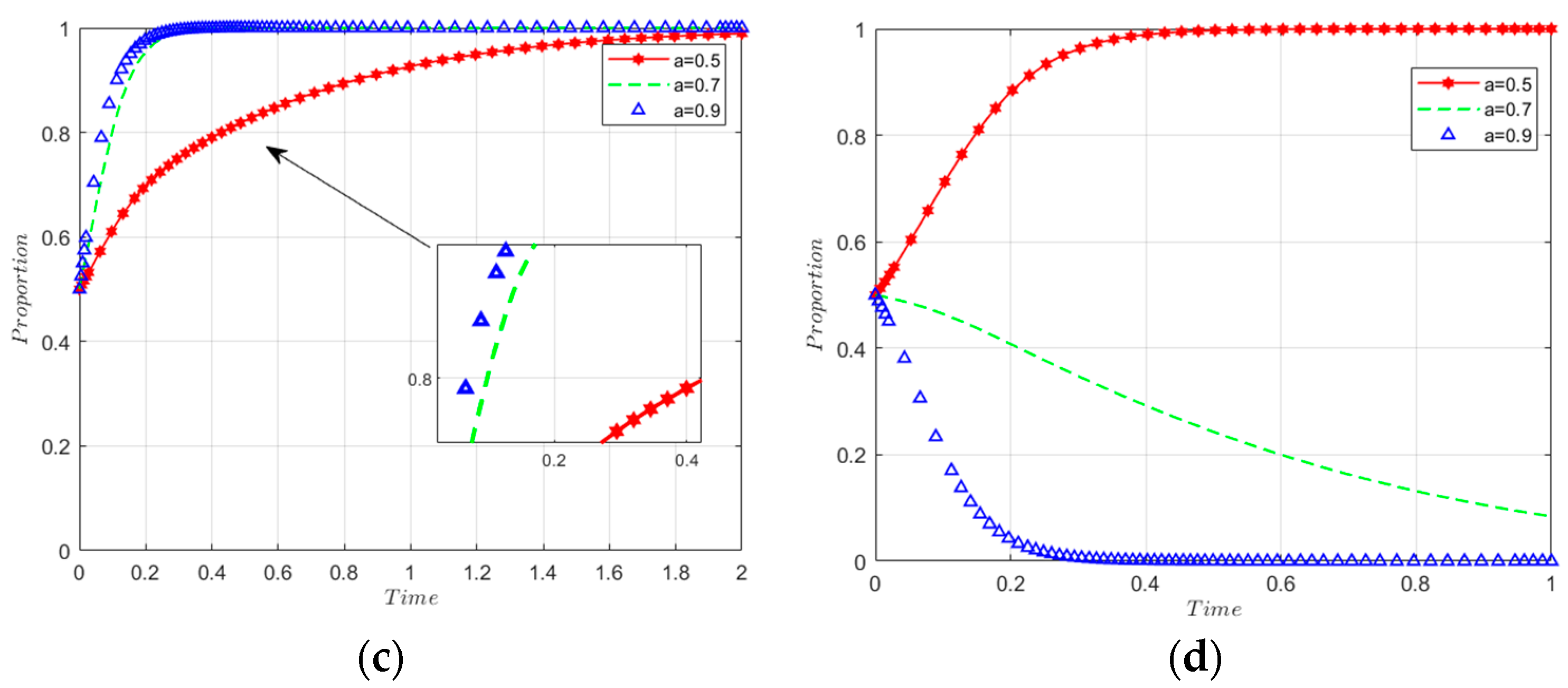

5.2.4. Sensitivity Analysis of Spillover Effects

5.2.5. Sensitivity Analysis of Carbon Tax Rates

6. Conclusions and Recommendations

6.1. Conclusions

- (1)

- The analysis reveals that the shared goal of maximizing benefits under bounded rationality guides all stakeholders—governments, producers, and recyclers—toward a unified low-carbon innovation strategy. This approach aligns with environmental goals and confers competitive advantages by enhancing efficiency and adhering to escalating environmental standards, thereby fostering a collective incentive for sustainable development.

- (2)

- Government incentives, though not the primary driver, significantly influence the engagement of manufacturers and recyclers in low-carbon initiatives. An increase in subsidies boosts their willingness to innovate sustainably, whereas rising regulatory costs tend to deter strict enforcement by the government.

- (3)

- Adjustments in benefit and cost-sharing coefficients significantly influence the innovation willingness of manufacturers and recyclers. A higher benefit share for manufacturers boosts their innovation drive, whereas greater cost responsibility reduces it, affecting recyclers inversely. These coefficients minimally impact government decision making.

- (4)

- Technology spillovers, while not drastically changing decision-making dynamics, show discernible effects; enhanced spillovers result in a transient reduction in stakeholders’ low-carbon innovation activities.

- (5)

- A higher carbon tax rate propels manufacturers and recyclers towards more active low-carbon innovation participation by enhancing the cost-effectiveness of reducing emissions, potentially leading to decreased government regulatory measures as the tax itself incentivizes eco-friendly practices.

6.2. Recommendations

- (1)

- In the pursuit of low-carbon innovations within the power battery recycling sector, adopting a refined approach to policy enhancement and economic incentives is crucial. This involves creating performance-oriented government incentives and regulatory frameworks designed to motivate compliance and drive innovation among all stakeholders, while avoiding excessive financial strains. Additionally, the adoption of flexible carbon tax schemes, which can be adjusted based on technological progress and economic shifts, is vital. Such schemes are intended to encourage eco-friendly practices and ensure the sector’s competitive edge and sustainability. Furthermore, establishing collaborations across various sectors is essential for resource sharing, knowledge exchange, and strategy synchronization on low-carbon innovation. Encouraging cooperative synergies between governments, industry, academia, and NGOs paves the way for a sustainable, efficient, and competitive recycling industry, in harmony with overarching goals of environmental conservation and sustainable development.

- (2)

- Within the scholarly discussion on sustainable practices in power battery recycling, the focus on technological innovation and collaboration stands out as a key theme. Promoting focused research and development investments in areas with potential for technological spillovers is crucial, highlighting the importance of creating an ecosystem that nurtures innovation and leverages the secondary benefits of these advancements. Moreover, the creation of platforms for collaborative innovation is recommended to enable the fluid exchange of breakthroughs, research outcomes, and best practices among a wide range of stakeholders. These platforms aim not only to accelerate the adoption of innovative, sustainable technologies but also to establish channels for knowledge sharing that extend beyond conventional industry limits. This strategy advocates for a unified effort to adopt sustainable technologies, utilizing the collective synergy of shared objectives and expertise to propel the industry toward enhanced environmental responsibility and innovation efficacy.

- (3)

- In the academic analysis of low-carbon initiatives within the power battery recycling industry, the strategic handling of benefits and costs is identified as a crucial factor. Developing innovative mechanisms for sharing benefits is essential, aiming to guarantee a fair distribution of advantages among all stakeholders, thus enhancing their long-term commitment to low-carbon innovation. Furthermore, crafting detailed strategies for cost management and sharing is vital, possibly through creating cooperative platforms or forming joint ventures. These methods seek to mitigate the financial hurdles linked to innovation, promoting a more inclusive setting for stakeholders to participate in and contribute to the low-carbon economy. This viewpoint supports a balanced approach to managing financial risks and rewards, underlining the significance of strategic financial planning and collaboration to address the fiscal obstacles encountered in shifting toward more sustainable industrial practices.

6.3. Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sporkmann, J.; Liu, Y.; Spinler, S. Carbon emissions from European land transportation: A comprehensive analysis. Transp. Res. Part D Transp. Environ. 2023, 121, 103851. [Google Scholar] [CrossRef]

- Li, S.J.; Liu, J.G.; Wu, J.J.; Hu, X.Y. Spatial spillover effect of carbon emission trading policy on carbon emission reduction: Empirical data from transport industry in China*. J. Clean. Prod. 2022, 371, 123906. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, K.; Dong, X.; Dong, K. Is smart transportation associated with reduced carbon emissions? The case of China. Energy Econ. 2022, 105, 105715. [Google Scholar] [CrossRef]

- Carbon Dioxide Emissions in China 1960–2022. Available online: https://www.statista.com/statistics/239093/co2-emissions-in-china/#statisticContainer (accessed on 16 March 2024).

- Zhu, C.; Wang, M.; Yang, Y. Analysis of the Influencing Factors of Regional Carbon Emissions in the Chinese Transportation Industry. Energies 2020, 13, 1100. [Google Scholar] [CrossRef]

- Hussain, Z.; Khan, M.K.; Xia, Z.Q. Investigating the role of green transport, environmental taxes and expenditures in mitigating the transport CO2 emissions. Transp. Lett. Int. J. Transp. Res. 2023, 15, 439–449. [Google Scholar] [CrossRef]

- Huo, H.; Wang, M.; Johnson, L. Projection of Chinese motor vehicle growth, oil demand, and CO2 emissions through 2050. Transp. Res. Rec. 2007, 2038, 69–77. [Google Scholar] [CrossRef]

- Zou, R.; Liu, Q. Current situation and Countermeasures of power battery recycling industry in China. Conf. Ser. Earth Environ. Sci. 2021, 702, 012013. [Google Scholar] [CrossRef]

- He, H.; Hu, S.; Wang, P. A Prediction Model for Recycling Amount of Recycled Metal from Waste Power Battery. J. Phys. 2023, 2463, 012056. [Google Scholar] [CrossRef]

- Wang, D. Research on policies of power batteries recycle in China from the perspective of life cycle. J. Environ. Eng. Landsc. Manag. 2021, 29, 135–149. [Google Scholar] [CrossRef]

- Hu, L.; Wei, X.; Ma, J. Research on Power Battery recovery Mode of New Energy Electric vehicles in China under Circular economy. Conf. Ser. Earth Environ. Sci. 2021, 651, 042029. [Google Scholar] [CrossRef]

- Sun, Y. Lithium-Ion Battery Recycling: Challenges and Opportunities. Highlights Sci. Eng. Technol. 2023, 58, 365–370. [Google Scholar] [CrossRef]

- Zorin, A.; Song, T.; Gastol, D. Acid-Assisted Separation of Cathodic Material from Spent Electric Vehicle Batteries for Recycling. Metals 2023, 13, 1276. [Google Scholar] [CrossRef]

- Cattaneo, P.; Callegari, D.; Merli, D. Sorting, Characterization, Environmentally Friendly Recycling, and Reuse of Components from End-of-Life 18650 Li Ion Batteries. Adv. Sustain. Syst. 2023, 7, 2300161. [Google Scholar] [CrossRef]

- Wang, M.; Liu, K.; Yu, J. Challenges in Recycling Spent Lithium-Ion Batteries: Spotlight on Polyvinylidene Fluoride Removal. Glob. Chall. 2023, 7, 2200237. [Google Scholar] [CrossRef] [PubMed]

- Zheng, S.; Wang, X.; Gu, Z. Advances and challenges on recycling the electrode and electrolyte materials in spent lithium-ion batteries. Mater. Lab. 2022, 1, 220036-1–220036-17. [Google Scholar]

- Li, Y.; Guo, R.; Zhang, Y. Study on Reuse of Power Lithium Ion Battery Recycling. Adv. Mater. Res. 2014, 937, 515-519. [Google Scholar] [CrossRef]

- Ganter, M.; Landi, B.; Babbitt, C. Cathode refunctionalization as a lithium ion battery recycling alternative. J. Power Sources 2014, 256, 274–280. [Google Scholar] [CrossRef]

- Liu, J.; Ye, J.; Yang, C. Power Battery Recycling Mode and Decision-making Model for New Energy Vehicles Under the Background of Dual Carbon. Strateg. Plan. Energy Environ. 2022, 41, 457–476. [Google Scholar] [CrossRef]

- Li, X.; Du, J.; Liu, P. Optimal choice of power battery joint recycling strategy for electric vehicle manufacturers under a deposit-refund system. Int. J. Prod. Res. 2023, 61, 7281–7301. [Google Scholar] [CrossRef]

- Zan, X.; Zhang, D. Analysis on the optimal recycling path of Chinese lead-acid battery under the extended producer responsibility system. Sustainability 2022, 14, 4950. [Google Scholar] [CrossRef]

- Chen, P.; Wu, M.; Wang, P. Suggestions and Effect Evaluation Model for Automobile Manufacturers’ Deployment of Power Battery Recycling and Utilization under the Dual-Carbon Target. In Proceedings of the 2022 IEEE International Conference on Electrical Engineering, Big Data and Algorithms (EEBDA), Changchun, China, 25–27 February 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 257–260. [Google Scholar]

- Zhang, Q. Gain Competitive Advantage in the Recycling Industry with Technology and Supply Chain-Based on a Case Study of GEM. J. Syst. Manag. 2023, 1–11. Available online: http://kns.cnki.net/kcms/detail/31.1977.N.20230821.1512.002.html (accessed on 17 March 2024).

- Wang, W.; Zhang, Y.; Zhang, K. Reward–penalty mechanism for closed-loop supply chains under responsibility-sharing and different power structures. Int. J. Prod. Econ. 2015, 170, 178–190. [Google Scholar] [CrossRef]

- Chang, X.; Wu, J.; Li, T. The joint tax-subsidy mechanism incorporating extended producer responsibility in a manufacturing-recycling system. J. Clean. Prod. 2019, 210, 821–836. [Google Scholar] [CrossRef]

- Ren, M. Optimal Designment of Incentive Mechanism Based on the Implementation of Extended Producer Responsibility of Electronic Manufacturer. Syst. Eng. 2009, 27, 116–120. [Google Scholar]

- Richter, J.; Koppejan, R. Extended producer responsibility for lamps in Nordic countries: Best practices and challenges in closing material loops. J. Clean. Prod. 2016, 123, 167–179. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, Q.; Hu, S. Evaluation of a new extended producer responsibility mode for WEEE based on a supply chain scheme. Sci. Total Environ. 2020, 726, 138531. [Google Scholar] [CrossRef] [PubMed]

- Mailath, G.J. Introduction: Symposium on evolutionary game theory. J. Econ. Theory 1992, 57, 259–277. [Google Scholar] [CrossRef]

- Li, X.; He, J. Evolutionary mechanism of green product certification behavior in cement enterprises: A perspective of herd behavior. Environ. Technol. Innov. 2024, 33, 103508. [Google Scholar] [CrossRef]

- Jamali, M.B.; Rasti-Barzoki, M.; Khosroshahi, H. An evolutionary game-theoretic approach to study the technological transformation of the industrial sector toward renewable electricity procurement: A case study of Iran. Appl. Energy 2022, 318, 119083. [Google Scholar] [CrossRef]

- Hargreaves-Heap, S.; Varoufakis, Y. Game Theory: A Critical Introduction; Routledge: London, UK, 2004. [Google Scholar]

- Qi, J.; Sun, B.; Feng, M. Research on Evolutionary Game Model of Waste Electronic Product Recycling Behavior from the Perspective of Competition and Cooperation. In Proceedings of the 5th International Conference on Control, Robotics and Cybernetics (CRC), Wuhan, China, 16–18 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 76–80. [Google Scholar]

- Yang, J.; Long, R.; Chen, H. A comparative analysis of express packaging waste recycling models based on the differential game theory. Resour. Conserv. Recycl. 2021, 168, 105449. [Google Scholar] [CrossRef]

- Yao, S.; Wu, L.; Yu, D. Synergy between Electric Vehicle Manufacturers and Battery Recyclers through Technology and Innovation: A Game Theory Approach. Sustainability 2023, 15, 13726. [Google Scholar] [CrossRef]

- Li, X.; Mu, D.; Du, J. Multi-channel recycling decisions of electric vehicle battery based on SD-dynamic game model. In Proceedings of the 15th International Conference on Service Systems and Service Management (ICSSSM), Hangzhou, China, 21–22 July 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar]

- Yao, J.; Venkitasubramaniam, P. Stochastic games of end-user energy storage sharing. In Proceedings of the IEEE 55th Conference on Decision and Control (CDC), Las Vegas, NV, USA, 12–14 December 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 4965–4972. [Google Scholar]

- Kai-Ineman, D.; Tversky, A. Prospect theory: An analysis of decision under risk. Econometrica 1979, 47, 363–391. [Google Scholar]

- Leoneti, A.; Gomes, L.F.A.M. Comparative analysis of the todim method adherence to prospect theory. Indep. J. Manag. Prod. 2021, 12, 1935–1947. [Google Scholar] [CrossRef]

- Lang, G. Review of route choice based on prospect theory. Conf. Ser. Earth Environ. Sci. 2020, 545, 012036. [Google Scholar] [CrossRef]

- Werner, K.M.; Zank, H. A revealed reference point for prospect theory. Econ. Theory 2019, 67, 731–773. [Google Scholar] [CrossRef]

- Friedman, D. On economic applications of evolutionary game theory. J. Evol. Econ. 1998, 8, 15–43. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, C.; Deng, X. Evolutionary game analysis of the utilization of construction waste resources based on prospect theory. Sustainability 2023, 15, 2577. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Wu, J. Evolutionary game analysis of government and residents’ participation in waste separation based on cumulative prospect theory. Int. J. Environ. Res. Public Health 2022, 19, 14589. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Meng, Y.P. Research on the evolutionary game of port emission reduction based on prospect theory. In Advances in Energy, Environment and Chemical Engineering; CRC Press: Boca Raton, FL, USA, 2022; Volume 1, pp. 137–145. [Google Scholar]

- Sun, H.; Gao, G.; Li, Z. Evolutionary game analysis of enterprise carbon emission regulation based on prospect theory. Soft Comput. 2022, 26, 13357–13368. [Google Scholar] [CrossRef]

- Tversky, A.; Kahneman, D. Advances in prospect theory: Cumulative representation of uncertainty. J. Risk Uncertain. 1992, 5, 297–323. [Google Scholar] [CrossRef]

- Hu, J.; Wang, T. Strategies of Participants in the Carbon Trading Market—An Analysis Based on the Evolutionary Game. Sustainability 2023, 15, 10807. [Google Scholar] [CrossRef]

- Zhang, J.; Guan, J. The time-varying impacts of government incentives on innovation. Technol. Forecast. Soc. Chang. 2018, 135, 132–144. [Google Scholar] [CrossRef]

- Li, H.; Qi, H.; Cao, H.; Yuan, L. Industrial Policy and Technological Innovation of New Energy Vehicle Industry in China. Energies 2022, 15, 9264. [Google Scholar] [CrossRef]

- Gerlagh, R.; Lise, W. Carbon taxes: A drop in the ocean, or a drop that erodes the stone? The effect of carbon taxes on technological change. Ecol. Econ. 2005, 54, 241–260. [Google Scholar] [CrossRef]

| Governments | Manufacturers | Recyclers | |

|---|---|---|---|

| PI(z) | NI(1 − z) | ||

| Strict supervision(x) | PI(y) | V(GR1) − GK1 − mV(GM) − nV(GR) | V(GR1) − GK1 − mV(GM) + rQR |

| CR1 + aV(ΔR)-b(C1 + C2 − 2S) + mV(GM) | CR1 + mV(GM) − (C1-S) + V(R1) | ||

| SR1 + (1 − a)V(ΔR) − (1 − b)(C1 + C2 − 2S) + nV(GR) | SR1 − rQR + d2V(R1) | ||

| NI(1 − y) | V(GR1) − GK1 − nV(GR) + rQM | rQM + rQR − GK1 | |

| CR1 − rQM + d1V(R2) | CR1 − rQM | ||

| SR1 + nV(GR) − (C2 − S) + V(R2) | SR1 − rQR | ||

| Unregulated(1 − x) | PI(y) | ηV(GR1) | ηV(GR1) + rQR |

| CR1 + aV(ΔR) − b(C1 + C2) | CR1 + V(R1) − (C1 − S) | ||

| SR1 + (1 − a)V(ΔR) − (1 − b)(C1 + C2) | SR1 + d2V(R1) − rQR | ||

| NI(1 − y) | ηV(GR1) + rQM | 0 | |

| CR1 + d1V(R2) − rQM | CR1 | ||

| SR1 + V(R2) − (C2 − S) | SR1 | ||

| Equilibrium Point | Eigenvalue λ1 | Eigenvalue λ2 | Eigenvalue λ3 |

|---|---|---|---|

| E1(0,0,0) | −V(R1)d2 − bC2 − bC1 | C1b − C2 − C1 + C2b − d1V(R2) | V(GR1) − GK1 + rQM + rQR − tV(GR1) |

| E2(1,0,0) | GK1–V(GR1) − rQM − rQR+ tV(GR1) | bS − bC2 − bC1 + d1V(R2) − rQM + mV(GM) | S − C2 − C1 + bC1 + bC2 − bS + d2V(R1)+ nV(GR) |

| E3(0,1,0) | bC1 + bC2 + d2V(R1) | V(GR1) − GK1 + rQM − mV(GM) + rQR − tV(GR1) | V(ΔR) − C2 − R2 − C1 + bC1 + bC2 − aV(ΔR) + rQM − rQR |

| E4(0,0,1) | C1 + C2 − bC1 − bC2 + d1R2 | aV(ΔR) − R1 − bC1 − bC2 − C1 | V(GR1) − GK1 + rQM + rQR − nV(GR) − tV(GR1) |

| E5(1,0,1) | GK1 − V(GR1) − rQM − rQR +nV(GR) + tV(GR1) | bS − R1 − bC1 − bC2 − C1 + rQM + mV(GM) +aV(ΔR) | C1 + C2 − S − bC1 − bC2 + bS − d2R1 − nV(GR) |

| E6(1,1,0) | bC1 + bC2 − bS − d1V(R2) + rQM − mV(GM) | GK1 − V(GR1) − rQM + mV(GM) − rQR + tV(GR1) | S − C2 − R2 − C1 + b(C1+ C2) − bS + (1 − a)V(ΔR) + rQM − rQR + nV(GR) |

| E7(0,1,1) | C1 + R1 + bC1 + bC2 − aV(ΔR) | V(GR1) − GK1 + rQM − mV(GM) + rQR − nV(GR) − tV(GR1) | C1 + C2 + R2 − V(ΔR) − bC1 − bC2 +aV(ΔR) − rQM + rQR |

| E8(1,1,1) | GK1 − V(GR1) − rQM + mV(GM) − rQR + nV(GR) + tV(GR1) | C1 − V(R1) + bC1 + bC2 − bS − aV(ΔR) + rQM − mV(GM) | (1 − b)(C1 + C2 − S) − R2 − (1 − a)V(ΔR) − rQM +rQR − nV(GR) |

| Equilibrium Point | Real Symbol | Stabilisation | Prerequisite |

|---|---|---|---|

| E1(0,0,0) | (−,−,−) | ESS | ① |

| E2(1,0,0) | (−,−,−) | ESS | ②③④ |

| E3(0,1,0) | (+,×,×) | Instability point | \ |

| E4(0,0,1) | (+,−,×) | Instability point | \ |

| E5(1,0,1) | (−,×,×) | Instability point | \ |

| E6(1,1,0) | (×,×,×) | Instability point | \ |

| E7(0,1,1) | (+,×,×) | Instability point | \ |

| E8(1,1,1) | (−,−,−) | ESS | ②⑤⑥ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhang, J. Evolutionary Game Analysis of Low-Carbon Incentive Behaviour of Power Battery Recycling Based on Prospect Theory. Sustainability 2024, 16, 2793. https://doi.org/10.3390/su16072793

Li Y, Zhang J. Evolutionary Game Analysis of Low-Carbon Incentive Behaviour of Power Battery Recycling Based on Prospect Theory. Sustainability. 2024; 16(7):2793. https://doi.org/10.3390/su16072793

Chicago/Turabian StyleLi, Yan, and Jiale Zhang. 2024. "Evolutionary Game Analysis of Low-Carbon Incentive Behaviour of Power Battery Recycling Based on Prospect Theory" Sustainability 16, no. 7: 2793. https://doi.org/10.3390/su16072793

APA StyleLi, Y., & Zhang, J. (2024). Evolutionary Game Analysis of Low-Carbon Incentive Behaviour of Power Battery Recycling Based on Prospect Theory. Sustainability, 16(7), 2793. https://doi.org/10.3390/su16072793