Abstract

The paper uniquely assesses the relationship between the main elements of the sustainability of the supply chain and the performance of Romanian enterprises. To identify dimensions of supply chain sustainability, a sample survey was conducted on a structured questionnaire basis among a sample of 385 Romanian enterprises represented by supply chain managers and practitioners. The hypothesis testing and the validation of the proposed construct model were achieved by using the modeling of the equation with the smallest partial squares (SEM-PLS) and multigroup analysis (PLS-MGA). The results suggest a positive and significant relationship between supply chain sustainability practices and business performance. This study provides original evidence to Romanian managers that business performance can be maximized by focusing on increasing the economic, social, and environmental sustainability of the supply chain. The results of this quantitative marketing research add to the existing literature and have far-reaching theoretical and practical implications for enterprises in the Romanian economy.

1. Introduction

In recent years, the discourse on sustainability has evolved from being a mere corporate social responsibility initiative to a fundamental driver of business strategy and performance. Small- and medium-sized enterprises (SMEs) play a pivotal role in the global economy, contributing significantly to job creation, innovation, and economic growth. As awareness of environmental and social issues continues to rise, SMEs increasingly recognize the importance of integrating sustainability practices into their operations and value chains. This shift is not only driven by ethical considerations but also by the growing recognition of the tangible benefits that sustainability can bring to business performance [1].

Sustainable practices in the supply chain can lead to the development of unique resources and capabilities that offer a competitive advantage to SMEs. By integrating sustainability into their operations, SMEs can enhance resource efficiency, reduce costs, improve product quality, and strengthen their reputation among stakeholders, ultimately leading to improved financial performance. On the other hand, engaging in sustainable practices can improve relationships with stakeholders, build trust, and generate goodwill, which can positively influence SME performance through increased customer loyalty, enhanced supplier relationships, higher employee morale and productivity, and reduced regulatory risks. Institutional pressures, such as societal norms, regulations, and industry standards, can shape organizations’ adoption of sustainability practices. SMEs may adopt sustainable practices in response to institutional pressures to meet societal expectations, comply with regulations, or gain legitimacy in the market. Aligning with institutional norms and expectations can enhance an SME’s reputation, reduce risks, and open market access and financing opportunities, thereby positively impacting performance [2].

While theoretical frameworks provide valuable insights into these potential effects, there are several aspects that require deeper exploration. For example, many theoretical models simplify the relationships between sustainability practices and SME performance. In reality, these are highly complex and multifaceted, influenced by socio-demographic factors such as industry, firm size, geographical location, and organizational culture. Many theoretical frameworks briefly address how elements such as innovation and product design; emerging technologies like AI, the Internet of Things, and automation; value creation for stakeholders; and economic visibility contribute to improving SME performance. The theoretical understanding of how the implementation of worker rights and fair employment practices, promotion of human rights, engagement in partnerships and social projects, and cultivation of fair relationships with supply chain stakeholders lead to increased SME performance remains insufficient. Furthermore, how initiatives aimed at minimizing resource consumption, optimizing material resource efficiency, promoting energy efficiency, managing water resources, reducing harmful emissions, efficiently managing waste, promoting responsible recycling and disposal, and optimizing packaging design along the supply chain influence SME performance have not been adequately addressed in existing models. Additionally, moderating and mediating factors such as organizational capabilities, market conditions, regulatory environments, and stakeholder involvement can variably influence the effectiveness of sustainability practices. Identifying and understanding these contextual factors can contribute to a better understanding of how specific practices translate into performance outcomes. It should not be forgotten that both sustainability practices and performance outcomes evolve over time and are influenced by changes in the micro and macro environments. Therefore, dynamic perspectives should be incorporated into theoretical models to better capture the iterative process of adoption, implementation, and adaptation of sustainability practices in SME value chains [3].

Our study aims to fill a gap in the existing literature by developing a new construct model that emphasizes the interconnection of economic, environmental, and social dimensions of sustainability. By incorporating sustainability practices into their supply chain activities, SMEs can create value not only in terms of financial performance but also in terms of environmental management and social responsibility. Addressing this theoretical gap can contribute to enriching the understanding of the complex relationship between sustainability practices and SME performance, informing both academic research and practical decision-making in enterprises striving for sustainable development [4].

Enhancing competitiveness, efficient risk management, market expansion, efficient resource utilization, and enhancing reputation and brand value are some of the reasons highlighting the importance of studying the effect of sustainability practices in the supply chain on SME performance. Enterprises have become increasingly aware of the need to integrate sustainable practices that can enhance their competitiveness by improving resource efficiency, reducing costs, and enhancing reputation. Furthermore, these practices can also contribute to mitigating risks associated with environmental regulations, supply chain disruptions, and changing consumer preferences. By adopting these practices, enterprises can better meet stakeholder expectations and capitalize on growing market opportunities for eco-friendly products and services. Additionally, energy and water conservation, waste reduction, and recycling can improve resource efficiency and reduce operational costs for SMEs. Understanding how sustainability practices influence performance can help SMEs enhance brand image, increase customer loyalty, ensure employee satisfaction, and differentiate themselves in the market [5].

Given the aspects mentioned above, the following decision problem arises: what is the effect of the determinants of economic, social, and environmental sustainability on business performance? Specifically, how do these factors correlate with business performance, and what are the differences between small enterprises (SE) and medium-sized enterprises (ME) regarding these proposed correlations within the construct model?

In recent years, supply chains have faced frequent disruptions, intensified by the COVID-19 pandemic, the Russia–Ukraine war, and climate changes. The COVID-19 pandemic has disrupted supply chains around the world, leading to production activities being interrupted, transport suspension, temporary physical distribution activities being blocked, border closures, a decrease in workforce availability due to a large number of sick people, lockdowns and restrictions on the movement of persons, etc. [6].

The Russian–Ukrainian war and sanctions imposed on the Russian Federation continue to generate threats to both Russian and European supplying lines. Moreover, the effects of this conflict are felt globally. These are amplified by a lack of funding for different types of transport, port congestion, reduced access to some natural resources, and limited labor. These shortcomings and limitations will increase further as supply routes in Eastern Europe become unavailable, causing increasing pressure on the global supply of chains. Therefore, we observe how a conflict unfolded in an area of limited and medium amplitude produces major effects worldwide [7]. The increase in the price of energy and gas resources had a strong impact on supply chains, especially in the case of food chains. At the same time, there were numerous interruptions in the supply of goods and materials, especially cereals (wheat, corn, etc.), which affected the market for consumer goods and, to a certain extent, food security.

Romania, located in proximity to these countries, has been and continues to be impacted by the negative economic effects of this conflict. Most industries were affected by the energy crisis, grow up of inflation, the tightening of financial conditions, the cost of rising for fuels, the lack of raw materials and storage facilities, workforce availability, the congestion of Constanta port due to containers of goods not being picked up on time, etc. Overall, all these factors contributed to rising costs for final consumers [8].

Recently, climate change has been generating more and more threats to supply chains. Heat waves, droughts, fires, destructive storms, and violent floods have had severe repercussions on world economies and supply chains. Europe faced its newest hot summer in 2023, in addition to the energy crisis and the consequences of the war in Ukraine. Fires, temperatures, extreme weather, and drought have severely compromised many agricultural crops in European countries, including Romania. The progressive increase in the average air temperature in Romania produces negative effects on the quality of life, economic and social services, and supply chains in all sectors of activity [9].

To cope with all these disruptions, supply chains need to become sustainable, i.e., take into account economic, social, and environmental impacts at the level of all operations. Embracing economic responsibility would involve efficient management of financial obligations that enterprises have towards all economic stakeholders, such as customers, suppliers, and other supply chain partners. Then, social responsibility would assume applying strategies related to ethical sourcing; purchasing materials from ethical sources; prioritization of fair-trade suppliers; ensuring conditions for secure work; negotiating adequate wages in line with inflation; compliance with human rights; promotion of diversity, equality, and inclusion, etc. These actions could contribute to creating social responsibility for enterprises, as well as improving society as a whole. In close correlation with the other elements, environmental responsibility would require efficient management of waste generated by enterprises, reduction in energy and water consumption, use of sustainable materials, sustainable transport, impact monitoring and reporting on the environment, and others. Consequently, the absorption of sustainability practices by enterprises integrated into supply chains could lead to an improvement in long-term business performance.

This study makes valuable contributions to the field of supply chain management. First, it addresses a current topic related to the relationship analysis of key elements of supply chain sustainability and performance. Business management and sustainable supply chain practices affect business performance in different ways, such as transparency, visibility, control costs, competitive advantages, risk management, flexibility of relations with parties involved, customer satisfaction, and more. For example, a sustainable supply chain could help reduce operational costs and optimize the levels of inventory while minimizing waste, reducing emissions, and streamlining processes [10]. Second, the study proposes and develops a new construct model that is sufficiently robust and valid and can be expanded in the future by joining latent variables related to technology, communication, legislation, and others. Thirdly, the study contributes to theoretical and empirical research on sustainable management of supply chains in secondary emerging countries, such as Romania. In recent years, the attention of managers and researchers has generally focused on the economic sustainability of the supply chain and its effect on financial performance [11,12,13,14,15]. This research focuses equally on the three elements of supply chain sustainability and practices that should be improved to cope with future disruptions, as well as to strengthen the performance of enterprises from this system.

This study aims to assess the relationship between the main elements of supply chain sustainability and business performance in Romania. This study includes several objectives: identifying items specific to latent variables—Economic Sustainability Supply Chain (ECSC), Social Sustainability Supply Chain (SOSC), and Environmental Sustainability Supply Chain (ENSC)—and impact assessment of common business performance (BP) (Q1); identifying differences significant between the small enterprises (SE) and medium-sized enterprises (ME) groups for proposed correlation pathways (ECSC → BP, SOSC → BP and ENSC → BP) (Q2).

Section 2 illustrates a review of the relevant literature, presents statistical assumptions, and reveals the main reasons why enterprises pay more attention to the sustainability of supply chains. Section 3 presents the data collection in stages and procedures, measures, bias, and data analysis methods. Section 4 presents the results of PLS - SEM and MGA analyses. Section 6 introduces a discussion of the implications for research and practice of the study. Section 7 includes limitations and future research directions. The conclusions can be found in Section 8.

2. Literature Review

Sustainability supply chain management (SSCM) is the process that incorporates economic, environmental, and social considerations; governance principles; and corporate mechanisms, from obtaining raw materials to converting them into products and delivering them on the market [16]. According to [17], SSCM is a movement in the framework of undertakings involving efficient management of economic impact, environment, and social and encouraging good governance practices throughout the life of goods and services performed. In contrast, ref. [18] demonstrates the necessity and benefits of integrating the SSCM in order to reduce pressures on the environment, society, and economy and contribute to sustainable development. It highlights that a balance must be created between economic growth, the environment, and social responsibility.

In recent years, due to global warming, businesses have come under pressure to create, protect, and increase economic, environmental, and social value in the long term for all stakeholders involved in supply chains with goods. More recently, enterprises can be held accountable for their actions, which leads most people to focus more than ever on sustainability. Sustainable supply chains offer market-involved enterprises the opportunity for long-term visibility, the development of new business models, and continuity in future operations [19].

Today, businesses’ commitments to sustainability across the board national savings mean taking on responsibilities and risks that go beyond the boundaries of national markets or the place where the product or service is purchased, produced, or delivered. That is why enterprises at the forefront of the sustainability of the supply chains adopt appropriate strategies and tactics aimed at innovation and development of the entire life cycle of the product, from manufacture, transport, and delivery to use, recycling, and disposal. To achieve their objectives for sustainability, the companies have to face the constraints due to the VUCA world, which is concerned with green investments of any kind [20].

Many reasons lead enterprises to pay more attention to the sustainability of supply chains. The first reason is related to consumers who are better informed and more aware of unethical practices within the many supply chains, such as child labor, forced labor, and gender discrimination. More and more consumers choose to buy products only from integrated into sustainable supply chains that actively manage and effective social and environmental impact. The second reason is climate change and global disruption. Pollution, noise, deforestation, waste, etc., affect the whole and have an immediate negative impact on workers’ health and the community. That is why more educated consumers consume the products and services offered by enterprises that want to build a more sustainable world. The third reason relates to building resilience across supply chains. A chain of more sustainable supply leads, in vulnerable times, to less impact on the availability, capacity, and resilience of the workforce and ensures continuity and business efficiency. The fourth reason relates to the amendment of international law on the sustainability of supply chains. In order to maintain quality and product safety, more and more countries have harmonized their legislation with international standards on supply chain sustainability. Moreover, the governments have started to require businesses to demonstrate sustainability and report due diligence in their supply chain.

The existing literature indicates three main elements of the sustainability supply chain: economic, environmental, and social. It should be highlighted that each element is important in itself, but at the same time, it is also interconnected with others.

2.1. Economic Sustainability of the Supply Chain (ECSC)

Economic sustainability of the supply chain is the practice of preserving financial and non-financial resources to create long-term financial stability. A supply chain that is sustainable can deal more easily with vulnerabilities of the market in the future, generating minimal negative impacts. For supply chains to be sustainable, they must first be profitable. But achieving long-term profitability is not the only argument in what it concerns, the economic pillar, and cannot go beyond the other two pillars—social and environmental. In recent years, the development of economic sustainability practices at the level of supply chains has involved the integration of compliance practices, adequate governance, and risk management, although these are not a global standard.

Ref. [21] demonstrated that sustainable practices socially applied in Sri Lankan clothing supply chains positively affect the performance of economic sustainability. Ref. [22] analyzed the economic sustainability of the supply chain in terms of costs and showed that, together with the integration of social and political concerns, it contributes to increasing enterprise performance. Developing an end-to-end model for a chain loop sourcing, ref. [23] demonstrated that the implementation of an effective return policy; new, innovative, and easy product refurbishing; improving technologies; and redesigning products contribute alongside intensive marketing efforts to consumer acceptance of products and increasing enterprise performance. Therefore, economic sustainability includes both financial and non-financial practices, many of which are addressed in a limited manner or not at all. Investigating the financial sustainability of food businesses, [14] noted that there is a positive link between financial performance and financial balance indicators. The results of his research indicate that undertakings with financial balance and a performance situation are acceptable and enjoy good financial sustainability. Analyzing the integration of supply chain operations and financial aspects of the enterprise, [12] recommended that divisions within the undertaking should not compete with each other for limited capital and resources, and managers should make decisions that ensure future sustainability by maximizing long-term business value. Ref. [15] showed that the steady intensification of the aspect of economic sustainability leads both to an increase in the level of technical efficiency of undertakings producing milk as well as the general improvement of the life of the whole community. Ref. [13] noted that, due to increased external pressures, enterprises are forced to implement sustainable practices for their supply chain. Moreover, to share the benefits and “success stories” of sustainable management practices of supply chain enterprises integrated into the system, they must communicate and collaborate with each other for a better knowledge of specific concepts. Ref. [11] noted that some aspects of the economic pillar received more attention from businesses due to interest in the growth of employee profit or performance. In his opinion, sales and net profit represent the most influential factors of sustainability.

The existing literature indicates a lack of studies focusing on economic sustainability in supply chains [24,25]. Most studies focus on the joint integration of the three elements of sustainability and pay less attention to size economic sustainability [26,27]. Existing studies highlight that many researchers have focused on tight financial issues, such as direct or indirect costs related to the product, return on capital, and profit [21,22,28]. This study expands the literature on economic sustainability by including non-financial, such as innovation and product design; development of technologies such as AI, IoT, and automation; streamlining processes; and creating value and visibility for all stakeholders of the supply chain (See Table A1 in Appendix A).

2.2. Social Sustainability of the Supply Chain (SOSC)

Economic sustainability of the supply chain is the practice of preserving financial and non-financial resources to create long-term financial stability. A supply chain that is sustainable can deal more easily with vulnerabilities of the market in the future, generating minimal negative impacts.

The social sustainability of the supply chain is called “People” or “Ethical sustainability”. It is just as important—if not more important—than economic and environment sustainability. The existence of a solid structure based on ethics and social values within the supply chains competes to maintain the other two elements of sustainable development in the future. As in any system and supply chain, the priority falls on people, with the rest of the elements being in symbiosis with them. The practice of social sustainability describes how businesses integrated into supply chains are organized, managerial, and control issues related to rights and working conditions, human well-being, human rights and fundamental freedoms, safety, health, hygiene, education, and more [29]. However, we must ensure that the overall objective of sustainability remains the coverage of current human needs without compromising those of future generations.

A recent study looked at businesses’ thinking and practices about how to ensure working conditions and respect for workers’ rights in a supply chain. The results showed that despite systematic convergence in codes of conduct for enterprises, the practical application of approaches to the social sustainability of the supply chain is often not achieved [30]. Ref. [31] showed that due to sustainability reporting, businesses have started to deepen research into social sustainability and implicitly on quantitative social indicators allocated along the three levels of main supply chains—upstream, middle, and downstream.

From a social point of view, some authors have noted that there are numerous problems in the development of the field of management of supply chains. Moreover, the current literature indicates a limited amount of research addressing the dimension of social sustainability for supply chains. Most are focused on social regulations and large enterprises in the fields of clothing, food, and electronics. In this context, the main social problems of supply chains are related to the low importance given to this branch in relation to the others, lack of managerial support, lack of necessary resources and internal programs, lack of communication and cooperation between chain partners on socially sustainable practices, and others [32,33]. Social aspects in previous studies have been related to child labor, forced labor, and corporal punishment; lack of occupational safety and welfare; use of subjects unclean and unsafe premiums; and others [34,35,36]. Ref. [37] observed that businesses use strategies, different management systems, and tools for solving social problems along their supply chains. Ref. [38] showed that implementing social sustainability practices in relations with suppliers and customers contributes to improving business performance at processed-based levels, both upstream and downstream of the supply chain. Ref. [30] pointed out that businesses in supply chains are responsible for supporting employees’ rights and welfare in their supply base. In addition, they observed that enterprises follow two distinct and cumulative approaches, based on transactions and relationships, to ensure supplier compliance and strengthen mutual capacity between them and their suppliers. Ref. [39] highlighted that downstream enterprises’ supply chains, compared to upstream, report higher expenses on social sustainability actions for the well-being of staff and social community spending. The current literature on social sustainability can be improved by including additional aspects, such as ensuring conditions safe and adequate work, respect for and promotion of human rights partnerships and social projects with local institutions, cultivating sustainable relationships with all parts of the supply chain to meet social responsibility, and ethical business practices.

2.3. Environmental Sustainability of the Supply Chain (ENSC)

A supply chain can only be sustainable if it applies environmentally friendly practices in each stage with the aim of protecting both people and the environment. Hence, environmental sustainability in the supply chain involves all the operations carried out by enterprises to protect the planet and society. Reporting sustainability has led to businesses researching and understanding the standards of the environment, as well as economic and social ones, as well as developing internal programs and environmentally friendly practices in all operations with suppliers, customers, stakeholders, and other business partners. Environmental standards or practices are nothing more than laws and environmental regulations accepted by society [40]. Enterprises must be prepared to comply with society’s environmental standards and meet objectives such as ensuring full regulatory compliance in vigor by reducing or eliminating the negative impact of operations and encouraging employee training and others. The ways to improve supply chain sustainability include reducing the carbon footprint in all areas, efficient management of water, waste reduction, halting deforestation, developing a friendly packaging environment, using ecolabels, and others [41,42].

Recently, ref. [43] demonstrated that education has a significant positive impact on the sustainability of supply chains. Moreover, it contributes to promoting environmental knowledge and increasing chain efficiency supply. Ref. [44] showed that the environmental, internal, and external orientation of enterprises produce strong effects on management practices of the sustainability of supply chains, contributing overall to the growth of environmental, social, and economic performance. Ref. [45] pointed out that despite existing challenges and barriers, such as high costs, limited stocks, cumbersome legislation, resistance to change, and complexity of documentation, enterprises need to effectively integrate sustainable materials to reduce the impact on the environment. Ref. [46] argues that joint implementation of environmental practices and Industry 4 (I4) technologies in supply chains help build a strong reputation, increasing customer satisfaction and the fulfillment of stakeholder requirements.

Ref. [47] conducted a critical analysis of gaps in the management of sustainable supply chains and found that environmental elements are dealt with in a very succinct way compared to the other branches. Analyzing the environmental impact of pharmaceutical supply chains, ref. [48] found that reducing the carbon footprint can only be ensured if producers could be incentivized to use environmentally friendly raw materials and purchase renewable energy. Meanwhile, in supply chains, energy footprints could be reduced by a careful selection of materials by allocating resources for the purchase of equipment and personal protection. Therefore, diversifying solutions remains the only strategy vital for improving sustainability and reducing the footprint on the environment [49].

As environmental issues become an increasing concern for both businesses and public organizations, ref. [50] considers it necessary to devise effective policies to mitigate environmental issues, guide entities towards sustainability, and more easily overcome the obstacles to the greening process. Despite the extensive literature on sustainability, environmental protection activities have received limited attention from enterprise managers and researchers. To reduce this gap, specific aspects were included, such as reducing resource consumption and optimizing their efficiency; the development of energy efficiency practices; responsible water management and reduction in harmful emissions; efficient waste management; promotion of responsible recycling, reuse, and disposal of waste; and implementation of ecological product packaging and optimization of packaging design.

2.4. Business Performance (BP)

Business performance (BP) is the ability to use resources efficiently and effectively and achieve the expected results. BP measures are often formulated in the form of predetermined goals and objectives at the level of enterprises integrated into the different chains. On this basis, both financial and non-financial performance are evaluated. Financial includes four main areas: financial processes, learning/growth, internal processes, and also those of attracting and retaining customers [51]. Obtaining good BP at the enterprise level can be the result of joint action of several factors, namely management style, management customer relations and quality of services provided, effectiveness of compensation schemes of incentives, and motivation of employees. BP is often closely related to commercial efficiency. This implies the ability to effectively implement objectives and strategies and provide useful and quality products or services that meet current and future customer expectations. Business performance is measured with the help of quantitative and qualitative indicators (key performance indicators). Enterprises use different types of indicators to measure their performance, such as sales, marketing, financial, operational, and customer-focused [52].

Supply chain performance depends on business performance integrated into this system. Therefore, the latter must be ensured by meeting the requirements of end customers; namely, ensuring the availability of products, proper management and storage, timely delivery, ensuring the necessary capacities, and others, to deliver that performance in a responsive way. They are of great importance for every aspect of the business—accounting, sales, employee satisfaction, and customers. Tracking specific performance indicators along the supply chain provides businesses with the information they need to improve and build a strong logistics system [53]. Enterprises should closely follow both their own performance indicators and those of the chain’s supply and constantly identify areas for improvement. The results of the supply chain analysis and distribution metrics enable supply managers of enterprises to develop new strategies for the considerable improvement of operations, streamlining logistics activities, increasing product quality, and delivering services.

Recent studies highlight the role of sustainable elements in creating performance affairs. Ref. [54] demonstrated that there is a positive relationship between constructs of environmental and business performance, if moderated by top management support, and knowledge sharing [55]. Ref. [56] highlights the role of social sustainability in increasing enterprise performance. In his opinion, enterprise management must balance the interests of business, customers, stakeholders, the environment, and society to help optimize social practices and increase competitiveness and sustainable development. Ref. [57] demonstrates that the manifestation of socially responsible behavior of the enterprises from supply chains helps improve business performance. This, coupled with the increased attention paid to each stakeholder group, constitutes a socially sustainable supply chain, which offers multiple benefits and also helps managers balance the expectations of all parties involved [58]. A study from China found that environmental orientations within the supply chain have a positive and significant impact on purchasing practices that are based on the environment and cooperation with the customers, allowing for a quick return on investment and significantly contributing to business performance [59]. The existing scientific literature dealing with business performance is completed by including in the items of the dependent variable, both financial and non-financial elements, such as increasing gross profit margin, net and operational, sales and market share, product/service quality, and customer satisfaction.

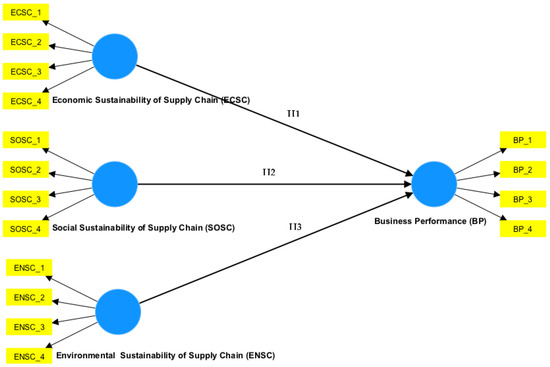

Building upon these studies, our research aims to contribute to the extant literature by addressing several gaps and expanding the understanding of economic sustainability within supply chains. Firstly, while existing studies have primarily focused on the joint integration of economic, social, and environmental sustainability elements, our research specifically emphasizes economic sustainability, filling a notable gap in the literature. By examining economic sustainability in greater depth and breadth, we aim to provide insights into the unique challenges, practices, and implications associated with preserving financial resources and achieving long-term financial stability within supply chains. Additionally, our study extends beyond traditional financial metrics, such as profit and cost reduction, to include non-financial aspects of economic sustainability, such as innovation, product design, and technology development. By incorporating these non-financial dimensions, we seek to offer a more comprehensive understanding of economic sustainability practices and their potential impact on supply chain performance. Through this research endeavor, we aspire to contribute valuable insights that can inform strategic decision-making and foster sustainable business practices within supply chains (Figure 1).

Figure 1.

A graphical representation of the theoretical model to be tested.

In relation to the two objectives of the research, six statistical hypotheses were formulated as follows:

Hypothesis 10 (H10).

Economic Sustainability of the Supply Chain (ECSC) has a positive effect on business performance (BP).

Hypothesis 20 (H20).

Social Sustainability of the Supply Chain (SOSC) has a positive effect on business performance (BP).

Hypothesis 30 (H30).

Environmental Sustainability of the Supply Chain (ENSC) has a positive effect on business performance (BP).

Hypothesis 40 (H40).

There are no significant differences between “small enterprises” (SE) and “medium-sized enterprises” (ME) groups in the construction of Economic Sustainability of the Supply Chain (ECSC) → business performance (BP).

Hypothesis 50 (H50).

There are no significant differences between “small enterprises” (SE) and “medium-sized enterprises” (ME) groups in the construction of Social Sustainability of the Supply Chain (SOSC) → business performance (BP).

Hypothesis 60 (H60).

There are no significant differences between “small enterprises” (SE) and “medium-sized enterprises” (ME) groups in the construction of Environmental Sustainability of the Supply Chain (ENSC) → business performance (BP).

3. Materials and Methods

3.1. Subsection Data Collection and Procedure

SMEs are essential for the health, stability, and sustainability of Romania’s economy. They are a major contributor to private sector GDP, heritage expansion, and job creation and have a strong social impact and also on the carbon footprint. In recent years, sustainability must be approached in an integrated manner in order to minimize the impact of economic activities on the environment and increase social responsibility at the SME level. The government has implemented Romania’s National Recovery and Resilience Plan, which includes 507 milestones and targets related to reforms and investments to be carried out in 2023–2027 at the level of Romanian SMEs [60]. The planned investments and reforms will help reduce pollution, increase social responsibility, and strengthen economic growth potential. The data required for the research were collected between December 2023 and February 2024. A list of 1560 small- and medium-sized enterprises (SMEs) acting in the main sectors of activities such as industry, construction, trade, and services was created from the useful database of the National Institute of Statistics [61]. SMEs were contacted by email in order to identify respondents and obtain agreement to participate in the survey. To avoid the common bias method, data were collected during the first two weeks of each month [62,63,64]. The open letters and questionnaire included information on the purpose of the research, the consent form for data processing, and the privacy statement. The questionnaire was structured in two blocks. Data related to demographic variables (number of employees, sector, age, annual revenue/asset size) were collected based on identification questions in the first block. The 16 content questions synthesized relevant aspects regarding the latent variables of the proposed construct model, namely economic, social, environmental sustainability, and enterprise performance. The same questionnaire was used to collect responses on demographic and latent variables in each round, a method otherwise supported by recent research [64]. In the three rounds, 132, 140, and 137 responses were collected, of which 24 questionnaires were eliminated due to incomplete or missing answers. Finally, 385 valid responses were used to test research hypotheses, obtaining a response rate of 74.04%. We collected the data using simple random sampling using the computerized method. Each sampling unit (undertaken) was assigned a unique code within the sampling frame.

Using the computer-based random number generation facility, 520 codes ranging from 1 to 1560 enterprises were randomly selected. In terms of size, 64.68% are small businesses, and 35.32% are middle-sized enterprises. The data show that 11.43% of SMEs are active in the industry, 9.87% in construction, 35.06% in trade, and 43.64% in services. The share of SMEs that are up to 15 years old on the market is 77.14%, and for those that exceed this threshold, it is 22.86% (see Table 1).

Table 1.

Demographic information of SMEs (n = 385).

3.2. Bias

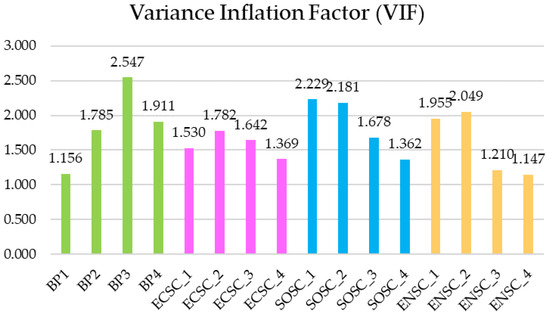

Based on this study, two modes of evaluating the common method bias (CMB) were employed. The results of the variance inflation factor (VIF) indicated a solid and strong correlation between the independent variables in the regression analysis, with their sizes being below the maximum allowable threshold of 4.00 [65]. Furthermore, all constructs exhibit correlations lower than the maximum threshold of 0.9, demonstrating the avoidance of CMB [66]. To address a potential issue related to the common method bias (CMB), the Harman single-factor test was applied. The result showed that the total variance for a single factor was 38.63%, below the maximum acceptable threshold of 50% [62] (see Table A3).

3.3. Measures

This study adapted the four specific items of ECSC from [67] and [68]. The SOSC variable included adapted items from [69,70,71]. The items of the ENSC variable were constructed based on the studies of [72,73,74]. Business performance (BP) was highlighted by the presence of four items taken from the studies of [75]. All items were evaluated on a Likert scale ranging from 1 to 7, where 1 represents “Total Disagree” and 7 represents “Total Agree”. The questionnaire was pretested in a pilot study (50 respondents) to verify the order and correctness of the questions, as well as the reliability of the scales (Cronbach’s Alpha CA > 0.5/0.6 Table 2) [61]. Due to insignificant results, 10 items were excluded: 3 from ECSC and ENSC and 2 each from SOSC and BP.

Table 2.

Construct reliability and validity.

This study utilized two methods of analysis. The first is structural equation modeling with partial least squares (PLS-SEM). This method of structural equation modeling allows for the estimation of complex cause–effect relationships between the path models of latent variables integrated into the proposed construct model [76,77]. PLS-SEM has become highly utilized in the field of marketing, with more and more researchers and statisticians approaching it to better understand the complex relationships between different latent variables. PLS-SEM modeling offers several advantages, making it a popular choice in certain research contexts. Among these advantages are suitability for small sample sizes and robustness in cases with limited data; reliability in modeling reflective latent constructs; an emphasis on predictiveness, making it ideal for exploratory research; and others. Numerous studies in the field of supply chain sustainability have utilized the PLS-SEM method to establish relationships between the constructs of different proposed multidimensional models [78,79,80].

The second method is multigroup analysis (MGA), which is ideal for testing and identifying significant differences in parameter estimates specific to predefined data groups. Through the SmartPLS4 v. 4.0.9.3 software, permutation MGA [81] and bootstrap MGA [82] can be generated. Permutation MGA includes the MICOM procedure, which highlights the existence or absence of statistically significant differences between parameter estimates specific to their group, such as outer weights, outer loadings, and path coefficients [76]. Bootstrap MGA calculates bias-corrected confidence intervals for group-specific parameter estimates in the PLS path model. Additionally, using the Parametric test and Welch–Satterthwaite test establishes the difference in PLS-SEM results specific to the group, including equal or unequal variations between groups. This latter method is also the subject of numerous studies in the field [83,84,85].

4. Results

4.1. Results PLS-SEM

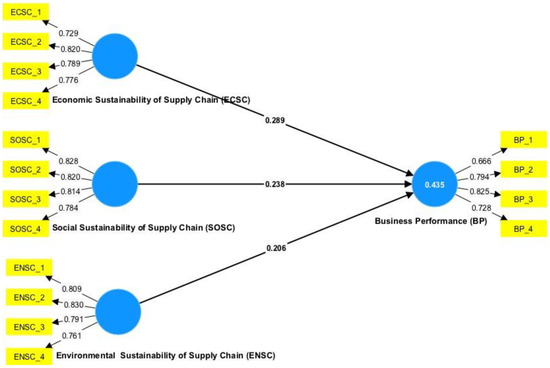

The path weight of 0.289 indicates that ECSC has a positive effect on BP. This is followed by SOSC at 0.238 and ENSC at 0.206, with both having a slightly more moderate positive effect. Given the measure of path coefficients, usually standardized, it can be said that the absolute magnitude of the effect of ECSC on BP is 40.2% greater than that of the ENSC variable. On the other hand, the absolute magnitude of the effect of SOSC on BP is 15.5% greater than that of the ENSC variable.

The R-square value of 0.435 for the endogenous variable BP means that about 43.5% of its variance is explained by the model construct. Outer model loadings are significant and greater than 0.70 [86], which demonstrates that the multidimensional model measurement is strong and reliable (See Figure 2).

Figure 2.

The results of construct model.

In the proposed construct model, the highest Composite Reliability (CR) value was obtained by the ECSC variable (0.867), while the lowest was by the ENSC (0.818). As all composite reliabilities measures were greater than 0.80 [87], we can state that the reflective model is good for exploratory research and meets the condition of convergent validity. The latent factors of BP, ECSC, and ENSC show Cronbach’s Alpha (CA) indicators above the acceptable level of 0.70 (0.754; 0.747; 0.700). In contrast, the SOSC latent factor tends towards 0.80 (0.795 > 0.70) [81]. The size of these indicators confirms that the multidimensional model is reliable and shows convergent validity (See Table 2).

The Average Variance Extracted (AVE) measures were calculated for the four latent variables ranging between 0.534 and 0.622. Since all AVE measures are greater than 0.50, according to [81,88], we can affirm that the proposed reflective model satisfies both the convergent and divergent validity conditions. For the latent variable BP, the square root of AVE is greater than its correlation with the latent variables ECSC, SOSC, and ENSC (0.599, 0.613, 0.565 > 0.756). Similarly, for the ECSC variable, the shared variance with its block of indicators (0.758) was higher than the variances shared with the other two variables, SOSC and ENSC (0.664 < 0.758 and 0.625 < 0.758). For SOSC, the square root of AVE was greater than its correlation with ENSC (0.789 > 0.752). Therefore, the obtained results indicate once again that the proposed reflective model meets the discriminant validity conditions (See Table 3).

Table 3.

Fornell–Larcker criterion.

The proposed model construct shows a good fit as the standardized root mean square residual (SRMR = 0.074) is less than 0.08 [89]. The ECSC variable demonstrates intended loadings greater than 0.7 [86]. In contrast, its cross-loadings with BP, SOSC, and ENSC range between levels 0.4 and 0.6. Because the other indicator variables also show lower correlations with the other latent variables than with themselves, we can state that the model construct satisfies the discriminant validity condition and is properly specified (see Table 4).

Table 4.

Cross loadings.

In the proposed model construct, all heterotrait correlations were lower than monotrait correlations, with the HTMT ratio indicating values below 0.90 [90]. For example, in the case of the ECSC, its correlations with the other variables indicate HTMT values of 0.753, 0.752, and 0.740, below the maximum allowed threshold of 0.90 (see Table 5). The results indicate that the discriminant validity condition was met in the reflective construct model.

Table 5.

Heterotrait–monotrait ratio (HTMT).

According to [91], the size of the variance inflation factor (VIF) should be in the range of 0.250–4.000. The highest VIF measure was obtained by BP_3 (2.547) and the lowest by ENSC_4 (1.147) (See Figure 3). Considering both the VIF magnitudes and the R-square value (0.435) obtained, we can state that there is multicollinearity in the structural model. Goodness-of-Fit (GoF) ranges towards 1 (0.501), which indicates a good fit between the collected sample data and the predicted data, showing a good validity or good fit of the reflective model [92].

Figure 3.

Outer VIF values.

Because the R-square value is 0.435, it follows that more than 40% of the variation in BP is explained by the joint action of the variables ECSC, SOSC, and ENSC. The small number of latent variables included in the construct model makes the adjusted R-square size (0.430) close to the unadjusted R-square (0.435). The f-square effect size measure is low in the case of the SOSC variable (0.029). In contrast, the f-square effects obtained by the ECSC (0.060) and ENSC (0.032) factors are average (average above 0.15 according to [93]. Therefore, the ECSC and ENSC latent variables have a larger positive effect on BP than the SOSC.

In Table 6, the results, run through the bootstrapping option, report that all paths are significant at a probability level of 0.50. The ECSC variable (β = 0.289, t = 3.874, p = 0.00) demonstrates the strongest and most significant impact on BP; therefore, the null hypothesis H10 was accepted. This is closely followed by the exogenous variable SOSC (β = 0.238, t = 2.446, p = 0.014). A positive, significant, but slightly more moderate influence on the endogenous variable BP is exerted by ENSC (β = 0. 206, t = 3.023, p = 0.003). Because the last two paths of the reflective model are also positive and significant, the hypotheses H20 and H30 are accepted (where t-value > 1.96 or p-value > 0.05 or 0.001 [76].

Table 6.

Results of the construct model.

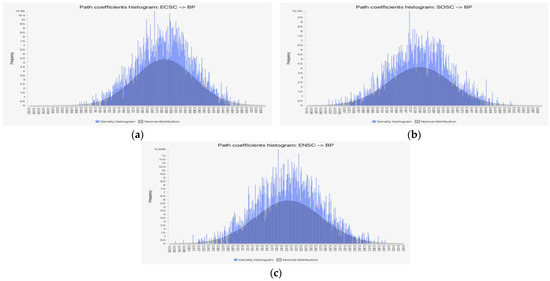

All histograms in Figure 4 show differences in the dispersion of the estimated values between the paths of the exogenous variables ECSC, SOSC, ENSC, and the endogenous variable BP. Histograms (a) and (c) reveal that the ECSC → BP and ENSC → BP iterations have a more complex distribution of path loading coefficients, in contrast to (b).

Figure 4.

Path Coefficients histograms: (a) the distribution of path loading coefficients from ECSC → BP; (b) the distribution of path loading coefficients from SOSC → BP; (c) the distribution of path loading coefficients from ENSC → BP.

4.2. Results Multi-Group Analysis (MGA)

Taking into account to the size of the enterprises, the sample was divided into two groups, namely “small enterprises” (SE) and “medium-sized enterprises” (ME). The identification of potential differences, significant or not, between the two groups was carried out using parametric multigroup analysis (MGA) using independent samples t-tests [94]. Three statistical hypotheses (H40, H50, and H60) were formulated, according to which there are no significant differences in the ECSC → BP, SOSC → BP, and ENSC → BP constructs between the “small enterprises” (SE) and “medium-sized enterprises” groups, respectively.

Table 7 presents the separate path coefficients for the “small-sized enterprises” (SE) and “medium-sized enterprises” (ME) groups, together with the estimated bootstrap standard deviations, t-value, p-value, and confidence intervals. The small enterprises (SE) group (0.337; 0.168; 0.225) had higher standardized path coefficients in the structural (interior) model than the medium-sized enterprises (ME) group (−0.019; 0.642; 0.127). The t-values obtained for the ECSC → BP and ENSC → BP paths were higher for the “small-sized enterprises” (SE) and “medium-sized enterprises” (ME) groups (t-value, 4.161 > 1.129; 2.998 > 0.775).

Table 7.

Result path coefficients: differences between groups “small enterprises” (SE) and “medium-sized enterprises” (ME).

For the ECSC → BP path, the confidence intervals overlap for the “small-sized enterprises” (SE) group (from 0.193 lower to 0.461 higher) (See Table 8). Note that 0 falls within the confidence limits of the “medium-sized enterprises” (ME) group in the “confidence intervals” columns (0 ⊂ [−0.304; 0.195]), so the intervals no longer overlap. Also, the confidence intervals for the path from SOSC to BP over-plot for both samples (SE, 0 ⊄ [0.013; 0.346] and ME, 0 ⊄ [0.320; 0.955]). For the ENSC → BP path, the confidence intervals overlap for the “small-sized enterprises” (SE) group (0 ⊄ [0.110; 0.357]). In contrast, the “medium-sized enterprises” (ME) group does not overlap (0 ⊄ [−0.178; 0.362]). Overlapping confidence intervals for the SOSC → BP path, at a significance level of 0.05, do not lead us to accept the null hypothesis H50. The results show that there is no difference in the path coefficients between the “small-sized enterprises” (SE) and “medium-sized enterprises” (ME) samples for the SOSC → BP construct. In contrast, the non-overlap of confidence intervals for the ECSC → BP and ENSC → BP constructs leads us to state that there is a difference between the path coefficients between the “small enterprises” (SE) and “medium-sized enterprises” (ME) samples. We, therefore, reject the null hypotheses H40 and H50 and accept the alternative ones.

Table 8.

Confidence intervals (bias corrected).

In order to check whether the differences identified between the “small-sized enterprises” (SE) and “medium-sized enterprises” (ME) samples are significant or not, three tests were applied, using the 0.05 significance level by default [95]. The first PLS-MGA non-parametric significance test indicates that there is a significant difference between the “small enterprises” (SE) and “medium-sized enterprises” (ME) groups for the ECSC → BP construct, as the p-value is less than 0.05 (p-value new = 0.021 < 0.050). In turn, the Parametric test and Welch–Satterthwait test confirm the same result (0.043 <0.050 and 0.020 < 0.050). The situation is different in the case of the ENSC → BP pathways, where although there is a clear difference between the two groups (SE vs. ME), it remains non-significant (PLS-MGA: p-value new = 0.305 > 0.05; Parametric test: p-value new = 0.307 > 0.05; Welch–Satterthwait test: p-value new = 0.292 > 0.05) (Table 9).

Table 9.

Differences between groups: “small enterprises” (SE) and “medium-sized enterprises” (ME).

5. Hypotheses Discussion

PLS-SEM analysis showed that ECSC is the strongest predictor of BP (Path Coeff. = 0.289; t-value = 3.874 and p-value = 0.000 < 0.05). The results show that Romanian small and medium enterprises are concerned about making investments in product innovation and design (ECSC_1, item loading = 0. 729), in new technologies (ECSC_2, item loading = 0.820), in creating value for stakeholders (ECSC_3, item loading = 0.789) and in ensuring transparency and accessibility of financial and economic information along the supply chain (ECSC_4, item loading = 0.776). Similar findings related to the items analyzed above have been the subject of recent studies by [96,97,98,99].

An almost equally strong effect on BP had the variable SOSC (Path Coeff. = 0.238; t-value = 2.446 and p-value = 0.014 < 0.05). The results of the research indicate that the enterprises analyzed respect labor rights and conditions (SOSC_1, item loading = 0. 828), human rights (SOSC_2, item loading = 0.820), carry out partnerships and social projects with local institutions (SOSC_3, item loading = 0.814) and try to cultivate fair and respectful relationships with all supply chain stakeholders (SOSC_4, item loading = 0.784). The findings of [100,101,102,103,104], who have studied various social issues in the supply chain and their effects on business performance, confirm the result of the current study. These studies suggested that social sustainability is an important factor that strongly influences the business performance of small- and medium-sized enterprises in the supply chain.

The impact of ENSC on BP was slightly more moderate compared to the other two latent variables (Path Coeff. = 0.206; t-value = 3.023 and p-value = 0.003 < 0.05). Reducing material resource consumption, developing energy efficiency practices, managing water and reducing carbon emissions, managing waste and promoting recycling, achieving environmentally friendly product packaging, and optimizing packaging design are priority concerns for small- and medium-sized enterprises in Romania. These results are also supported by the findings of other researchers [105,106,107,108,109]. The PLS-SEM results demonstrate that all correlation paths of the proposed model construct (ECSC → BP, 0.289; ECSC → BP, 0.238 ECSC → BP, 0.206) are positive and significant, for levels above the allowed thresholds t-value > 1.96 or p-value > 0.001 [76]. Therefore, the null hypotheses H10, H20, and H30 were accepted, and the first objective of the study (Q1) was met.

The values obtained for R-square (0.435), R-square adjusted value (0.430), and GoF (0.501) confirm that the proposed construct model is valid and robust. Approximately 43.5% of the variance of the endogenous variable BP is explained by the joint action of the exogenous variables ECSC, SOSC, and ENSC. Some studies demonstrate improved business performance as a result of applying sustainability practices to supply-chain-integrated enterprises [110,111,112,113].

PLS-MGA analysis was used to identify any significant or non-significant differences between the “small enterprises” (SE) and “medium-sized enterprises” (ME) groups for the proposed correlation paths (ECSC → BP, SOSC → BP and ENSC → BP), thus achieving the second objective (Q2). The first results indicated that the standardized path coefficients in the structural (interior) model are lower for the group “medium-sized enterprises” (ME) compared to “small enterprises” (SE), which is supported by lower obtained t-value measures. As the confidence intervals overlapped for both samples, in the case of the path from SOSC to BP, the null hypothesis H50 was accepted. For the other two constructs, ECSC → BP and ENSC → BP, it was found, based on non-overlapping confidence intervals, that there were differences in the case of the “medium-sized enterprises” (ME) sample. Therefore, the null hypotheses H40 and H50 were rejected, and the alternative ones were accepted. The results of PLS-MGA, Parametric test, and Welch–Satterthwait test analyses showed that there is a significant difference between the groups “small enterprises” (SE) and “medium-sized enterprises” (ME) for the ECSC → BP construct and insignificant for the ENSC → BP path.

6. Implications

6.1. Implications for Research

Our study implies a good understanding of the elements of supply chain sustainability and their impact on the performance of enterprises in Romania.

First, the research extends the literature on supply chain sustainability management. It highlights that businesses need to develop, maintain, and apply economically, socially, and environmentally sustainable practices that help society to lead healthy, productive lives now and in the future. Supply chain sustainability management involves three forms of accountability, which, through their joint action, influence business performance parameters. By balancing profitability with environmental stewardship and social responsibility, businesses can pursue long-term sustainable growth while maximizing value creation for all stakeholders. Businesses need to develop dynamic capabilities to adapt to changing market conditions, technological advances, and stakeholder expectations. Adopting supply chain sustainability management requires the development of dynamic capabilities such as product innovation and design, new technologies, collaboration, communication, transparency, and accessibility of information, cultivating fair and respectful relationships with all stakeholders, etc., enabling businesses to respond effectively to sustainability challenges and opportunities. It has been shown that there is a positive and significant relationship between supply chain sustainability practices and business performance in a similar manner to the study by [114]. Secondly, this research contributes to the improvement of Romanian enterprises by investigating the dimension of the integration of sustainability practices and the typology of the activities carried out. The results indicate a stronger focus on economic and environmental sustainability practices, while social elements are addressed to a lesser extent. The PLS-SEM analysis found that economic sustainability practices embedded in the supply chain, such as investments in AI, IoT technologies, value creation for stakeholders, product innovation and design, and ensuring transparency and accessibility of financial and economic information, lead to improved business performance. Similar business practices related to sustainable sourcing, green design, and integrating AI tools for creating circular supply chains that close the loop and improve business performance have been the subject of previous studies [115,116,117]. At the same time, environmental sustainability contributes to business performance through optimizing material resource efficiency, efficient waste management, use of environmentally friendly product packaging, efficient water and energy management, and reduction in carbon emissions from supply chain activities. Similar results have been determined separately in recent studies by [118,119,120]. From a sustainability perspective, the supply chain performance of an enterprise cannot be achieved if social aspects are not achieved simultaneously. Respecting working conditions, promoting human rights, and cultivating ethical relationships with all supply chain stakeholders have been the subject of studies by [30,121,122]. Third, the study develops a new multidimensional construct model that allows for a more comprehensive understanding of the factors that influence business performance by integrating the economic, social, and environmental dimensions of sustainability. This holistic approach recognizes the interconnectedness of these factors and their combined impact on organizational performance. By incorporating the three dimensions of sustainability, the model recognizes the complexity of modern business environments. The study reveals that business success cannot be attributed solely to economic factors but is also influenced by social and environmental considerations. The model construct encourages a system thinking approach, emphasizing interdependence and feedback loops between economic, social, and environmental elements. It recognizes that changes in one dimension of sustainability can have ripple effects across the whole system, impacting business performance in multiple ways. The model development then contributes to advancing sustainability theory, providing a framework for understanding the relationship between sustainability and business performance. It adds empirical evidence to support existing theoretical concepts and may lead to refining or extending current sustainability frameworks. Fourth, most research focuses on the study of supply chain management, with various aspects beyond sustainability being addressed, such as green procurement, inventory management, operations, information technology, and so on. In reality, little is known about the extent of implementation of sustainability practices in enterprises in emerging economies such as Romania. Our study contributes significantly to closing this gap in the literature. The association of the dimensions of supply chain sustainability with firm performance in emerging economies has been reported in studies by [123,124].

Finally, our study was conducted to measure changes in business performance under the influence of economic, social, and environmental sustainability elements, which have broad implications for research, practice, and policy related to sustainability and business management.

6.2. Implications for Practice

Implementing economic, social, and environmental sustainability practices has several practical implications. Our study demonstrates that the latent variables of the construct model are valid and relevant in the context of small- and medium-sized enterprises, not only large ones, as some research in the literature shows. The novel elements consist of the 12 distinct but significant items of the sustainability orientation of Romanian enterprises.

Based on the results of our study, governments could adopt policies and regulations to stimulate or oblige enterprises to adopt sustainability practices. Furthermore, they could allocate resources for sustainable projects (e.g., renewable energy systems, public transport, recycling, etc.), monitor enterprises’ compliance with sustainability regulations, apply sanctions for non-compliance with environmental conditions, promote sustainability awareness and carry out education campaigns to inform citizens about the importance of sustainable practices and encourage behavioral change.

In turn, employees of enterprises could contribute to the implementation of sustainability practices by participating in training and education programs, proposing innovative ideas and solutions, or becoming more engaged and motivated as they feel their work contributes to broader sustainability goals by boosting business performance.

Managers could develop strategic planning actions, integrating sustainability objectives into business activities, taking into account economic, social, and environmental factors. They could also establish sustainability-related key performance indicators to track their progress more easily in achieving the objectives. Given the results of our study, managers could invest in product innovation and design; the uptake of new technologies and process automation; contribute to value creation for all stakeholders; and practice better economic viability by providing clarity, transparency, and accessibility in the transmission of financial and economic information throughout the supply chain.

In order to improve social sustainability, managers should respect labor rights and fair employment practices, respect human rights, and carry out partnerships and social projects with local institutions. In addition, they could build fair and respectful relationships with all parties involved in the supply chain, ensuring compliance with social responsibility standards and ethical business practices. Enterprises that priorities social sustainability could contribute to the well-being and development of society by supporting local communities, promoting diversity and inclusion, and making it easier to address social challenges such as poverty and inequality. This could lead to tangible benefits such as job creation, skills development, and improved quality of life for community members.

Investment in community development projects (for example, educational pro-grams, healthcare initiatives, and infrastructure improvement) can help build a resilient community and contribute to long-term social and economic development. In terms of environmental sustainability, managers could aim to minimize resource consumption and optimize material resource efficiency; ethically source material; achieve environmentally friendly packaging of products; develop energy efficiency systems; manage water and reduce carbon emissions; effectively manage waste; and promote responsible recycling, reuse, and disposal of waste along the entire supply chain. Addressing climate change is a critical aspect of environmental sustainability.

Enterprises could contribute to climate resilience by adapting to changing environmental conditions, investing in renewable energy and clean technologies, and advocating for policies that mitigate climate-related risks.

Small- and medium-sized enterprises that prioritize sustainability can build trust and credibility with stakeholders (such as customers, employees, investors, and local communities) and enter into collaborative partnerships more easily. They are designed to stimulate innovation, address emerging problems, proactively address environmental and social risks, avoid potential conflicts, and mitigate reputational damage. Strong relationships with stakeholders, based on trust and open communication, could provide valuable support in times of crisis or uncertainty.

7. Limitations and Future Research Directions

The main limitations of this research were related to situational and time constraints. The study sample consisted only of Romanian enterprises. It is recommended that researchers approach wider geographical areas to generalize results. In this situation, the samples of selected enterprises from different countries could be larger, ensuring representativeness and contributing to a better synthesis of results. As for the latent variables of the construct model, they should be included in other future studies to identify potential differences between Romanian and foreign enterprises.

Also, when analyzing the sustainability of supply chain management, it would be important to investigate the common effect of other factors, such as legislative, risk, technological, etc., on business performance. Selections on the socio-demographic characteristics of enterprises, such as number of employees, length of service, turnover, industries, etc., should not be omitted. The results of future research could also be influenced by these characteristics, which, through their moderation effect in correlation pathways, would demonstrate notable differences between enterprises integrated into supply chains.

Our cross-sectional study was based on a simple questionnaire with a high degree of structuring. It is recommended to use horizontal or longitudinal research, which allows a broader measurement of the impact of these variables (ECSC, SOSC, ENSC, BP) in the short, medium, or long term. Diversifying the scales would also help increase the volume of information and expand analysis. The study addressed positive articles specific to ECSC, SOSC, ENSC, and BP factors.

Additionally, the unique role and specific characteristics of enterprises that make them effective and efficient in achieving performance within the supply chain should be considered. Our research, to some extent, overlooks the heterogeneity of actors within the supply chain, treating them as homogeneous entities. This simplification may fail to capture the diverse capabilities, motivations, and constraints of enterprises, leading to an incomplete understanding of their contributions to supply chain performance. Furthermore, our research adopts a static perspective, failing to account for the dynamic nature of relationships and interactions within the supply chain over time.

Future marketing tools should include barriers that businesses might face in the process of integrating the three elements of sustainability of supply chains. Investment in supply chain resilience, supplier development programs, circular economy practices, and supply chain financing for sustainability initiatives are just some of the aspects of economic sustainability that deserve more attention from researchers. Regarding social sustainability practices, some research should focus on new issues related to the implementation of the living wage, the development of mechanisms to promote the voice and representation of workers in supply chains (e.g., trade unions), ensuring ethical recruitment practices and protecting the rights of migrant employees, or investing in community development initiatives. Some researchers should address less-studied environmental sustainability practices, such as incorporating natural capital into supply chain decision-making, preserving biodiversity, sustainably managing water, and building loop supply chains.

Other studies should adopt a more nuanced approach, which acknowledges the heterogeneity of enterprises and considers their unique capabilities, motivations, and constraints. This could involve using qualitative research methods, such as case studies or interviews, to capture the complexity of interactions among actors within the supply chain. Researchers should examine how relationships and interactions between enterprises evolve over time in response to changes in the business environment. Longitudinal studies and dynamic modeling techniques could provide insights into the temporal dynamics of supply chain performance. Finally, methodological advancements, such as the use of advanced analytics techniques and real-time data monitoring, could enhance the rigor and validity of research results. By addressing these future research directions, scholars can contribute to a more comprehensive understanding of the role and characteristics of enterprises in implementing sustainability practices and driving supply chain performance.

8. Conclusions

This study conducted a PLS-SEM analysis to investigate the impact of economic, social, and environmental sustainability practices on business performance (BP) in Romanian small- and medium-sized enterprises (SMEs). The findings revealed that economic sustainability (ECSC) emerged as the strongest predictor of BP, with SMEs focusing on investments in product innovation, technology adoption, stakeholder value creation, and financial transparency throughout the supply chain. Similar results have been supported by recent studies. Additionally, social sustainability (SOSC) also exhibited a significant effect on BP, indicating that SMEs prioritize respecting labor and human rights, engaging in social projects, and fostering fair relationships in the supply chain. The impact of environmental sustainability (ENSC) on BP was slightly less pronounced but still notable, with SMEs emphasizing resource efficiency, waste management, and eco-friendly practices. The study confirmed the positive and significant correlation between the three elements of sustainability and BP. Furthermore, PLS-MGA analysis highlighted significant differences between small- and medium-sized enterprises, particularly in the relationship between economic sustainability and business performance, with those related to environmental sustainability being insignificant. Overall, the findings underscore the importance and contribution of sustainability practices in enhancing business performance and highlight areas of focus for SMEs in Romania.

Author Contributions

Conceptualization, M.C.T.; methodology, M.C.T.; software, M.C.T.; validation, M.C.T.; formal analysis, M.C.T.; investigation, M.C.T., C.-S.B., and L.S.; resources, M.C.T.; data curation, M.C.T.; writing—original draft preparation, M.C.T., C.-S.B., and L.S.; writing—review and editing, M.C.T., C.-S.B., and L.S.; visualization, M.C.T.; supervision, M.C.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study does not require ethical approval.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The author declares no conflicts of interest.

Appendix A

Table A1.

Measures of variables used in the research.

Table A1.

Measures of variables used in the research.

| Variable | Items |

|---|---|

| Economic sustainability of the supply chain (ECSC) | (ECSC_1) My company invests in product innovation and design, constantly trying to adapt to changing market demands and align with sustainable supply chain practices. |

| (ECSC_2) My enterprise invests in technologies such as AI, IoT, and automation, streamlines processes, improves accuracy, and reduces errors in inventory management, logistics, and fulfillment. | |

| (ECSC_3) My business helps create value for supply chain stakeholders, including shareholders, suppliers, and customers, by offering high-quality products or services at competitive prices. | |

| (ECSC_4) My business practices economic visibility by providing clarity, transparency, and accessibility of financial and economic information along the supply chain. | |

| Social sustainability of the supply chain (SOSC) | (SOSC_1) My company respects labor rights and fair employment practices by maintaining fair wages and safe working conditions and ensuring dignity and respect for all workers along the supply chain. |

| (SOSC_2) My company respects and promotes human rights, including the right to freedom of association, non-discrimination, and fair treatment, regardless of gender, race, ethnicity, or origin. | |

| (SOSC_3) My company carries out partnerships and social projects with local institutions, contributing positively to community development, education, and well-being. | |

| (SOSC_4) My business cultivates fair and respectful relationships with all stakeholders in the supply chain, ensuring they adhere to social responsibility standards and ethical business practices. | |

| Environmental sustainability of the supply chain (ENSC) | (ENSC_1) My business aims to minimize resource consumption and optimize material resource efficiency to reduce environmental impact along the supply chain. |

| (ENSC_2) My company develops practices on energy efficiency, water management, and reducing harmful emissions from supply chain activities. | |

| (ENSC_3) My company runs processes to manage waste efficiently and promote responsible recycling, reuse, and disposal of waste along the supply chain. | |

| (ENSC_4) My company carries out environmentally friendly packaging of products and tries to optimize packaging design to reduce environmental impact. | |

| Business performance (BP) | Implementing supply chain sustainability practices within my enterprise contributes to the following: |

| (BP_1) Increase in gross, net, and operating profit margin; | |

| (FP_2) Increase sales and market share; | |

| (BP_3) Product/service quality; | |

| (BP_4) Increasing customer satisfaction. |

Table A2.

Outer loadings.

Table A2.

Outer loadings.

| Variables | BP | ECSC | SOSC | ENSC |

|---|---|---|---|---|

| BP1 | 0.766 | |||

| BP2 | 0.794 | |||

| BP3 | 0.825 | |||

| BP4 | 0.728 | |||

| ECSC_1 | 0.729 | |||

| ECSC_2 | 0.820 | |||

| ECSC_3 | 0.789 | |||

| ECSC_4 | 0.776 | |||

| SOSC_1 | 0.828 | |||

| SOSC_2 | 0.820 | |||

| SOSC_3 | 0.814 | |||

| SOSC_4 | 0.784 | |||

| ENSC_1 | 0.809 | |||

| ENSC_2 | 0.830 | |||

| ENSC_3 | 0.791 | |||

| ENSC_4 | 0.761 |

Abbreviations: Economic Sustainability of the Supply Chain (ECSC); Social Sustainability of the Supply Chain (SOSC); Environmental Sustainability of the Supply Chain (ENSC); business performance (BP).

Table A3.

Total variance explained.

Table A3.

Total variance explained.

| Factor | Initial Eigenvalues | Extraction Sums of Squared Loadings | ||||

|---|---|---|---|---|---|---|

| Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | |

| 1 | 6.759 | 42.245 | 42.245 | 6.181 | 38.630 | 38.630 |

| 2 | 1.562 | 9.764 | 52.009 | |||

| 3 | 1.124 | 7.027 | 59.036 | |||

| 4 | 1.102 | 6.886 | 65.923 | |||

| 5 | 0.862 | 5.384 | 71.307 | |||

| 6 | 0.740 | 4.625 | 75.932 | |||

| 7 | 0.641 | 4.008 | 79.940 | |||

| 8 | 0.520 | 3.252 | 83.192 | |||

| 9 | 0.512 | 3.198 | 86.390 | |||

| 10 | 0.479 | 2.993 | 89.382 | |||

| 11 | 0.373 | 2.332 | 91.715 | |||

| 12 | 0.371 | 2.322 | 94.037 | |||

| 13 | 0.332 | 2.074 | 96.111 | |||

| 14 | 0.260 | 1.625 | 97.736 | |||

| 15 | 0.236 | 1.474 | 99.210 | |||

| 16 | 0.126 | 0.790 | 100.000 | |||