Technical Feasibility of a Hydrail Tram–Train in NA: Okanagan Valley Electric Regional Passenger Rail (OVER PR)

Abstract

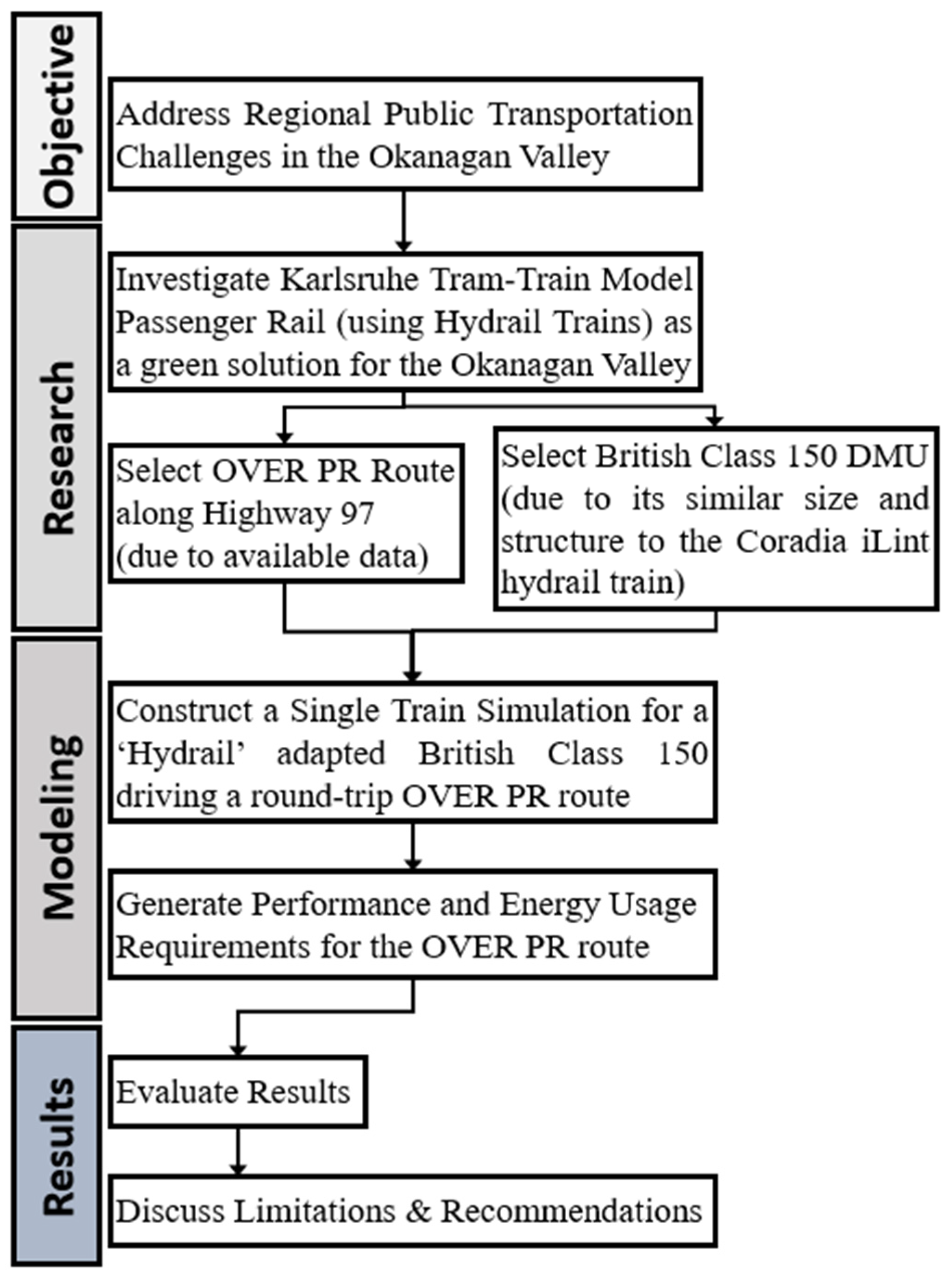

1. Introduction

- Confirm the technical feasibility of running a steel-wheeled, hydrail tram–train vehicle on rails along an alignment similar to Highway 97 between Osoyoos and Kamloops.

- Confirm the power requirements and hydrail power-train capacity to meet power requirements.

- Make recommendations on hydrail tram–train vehicle specifications to meet OVER PR needs.

2. Background

Interurban Passenger Rail and Hydrail Drive-Trains

- First, the constrained space available on existing roadways for track placement, compounded by the impracticality of procuring land for dedicated tracks, renders a locomotive-hauled solution challenging.

- Second, the connecting Valley route by definition crosses several existing highway bridges, including most significantly the Okanagan Lake floating bridge, which has specified weight limitations that requires self-powered, light-rail vehicle technology (e.g., KTTM tram–trains in Karlsruhe, Germany) comparable in weight to freight trucks, and precludes the use of heavier 150 ton (or more) locomotive vehicles to haul passenger trains (e.g., VIA rail in Canada).

- Third, the Karlsruhe Model promotes the use of public transportation as an attractive alternative to private vehicles by including key features such as synchronized transportation schedules, transit-oriented regional infrastructure, and intermodal fare integration. By emphasizing transportation intermodality, the KTTM intends to reduce traffic crashes and congestion while promoting sustainability [9,10]. Cities in central Europe have shown that it is feasible to integrate urban transit systems into cities which provide convenient and efficient transportation options for people who live in and/or visit urban and suburban regions, with tram–train ridership often more than quadrupling previous transit use levels as a result [11].

- Transport policy needs to be in place in order to help create the modal shift.

- Organization and integration of the entire public transport system must be conducted.

- The rail system should be an important instrument of urban renewal and revitalization of spatial and social structures.

3. Methods

3.1. Single-Train Simulation

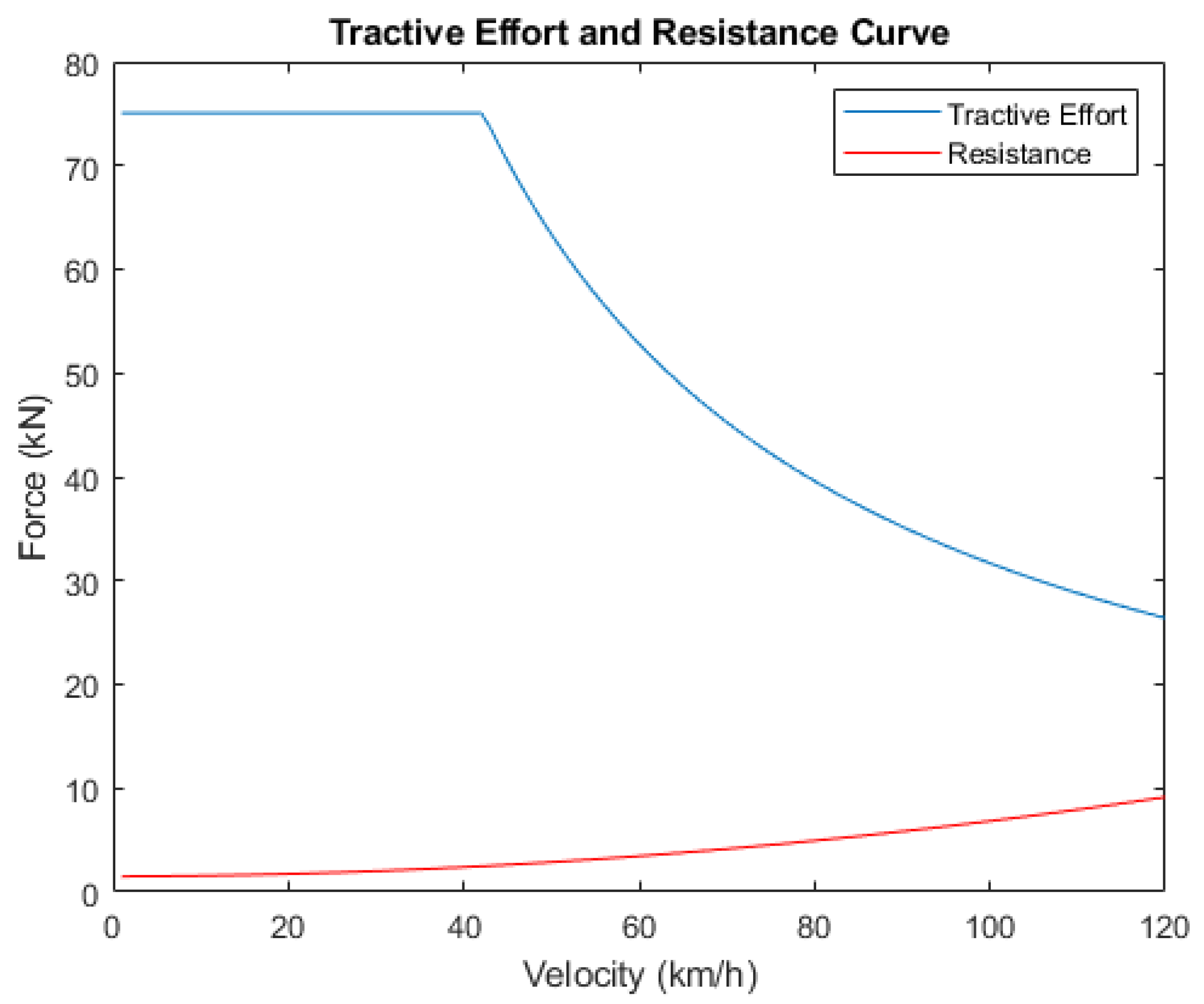

3.2. Vehicle Specifications

3.3. Selected (Highway 97) Route

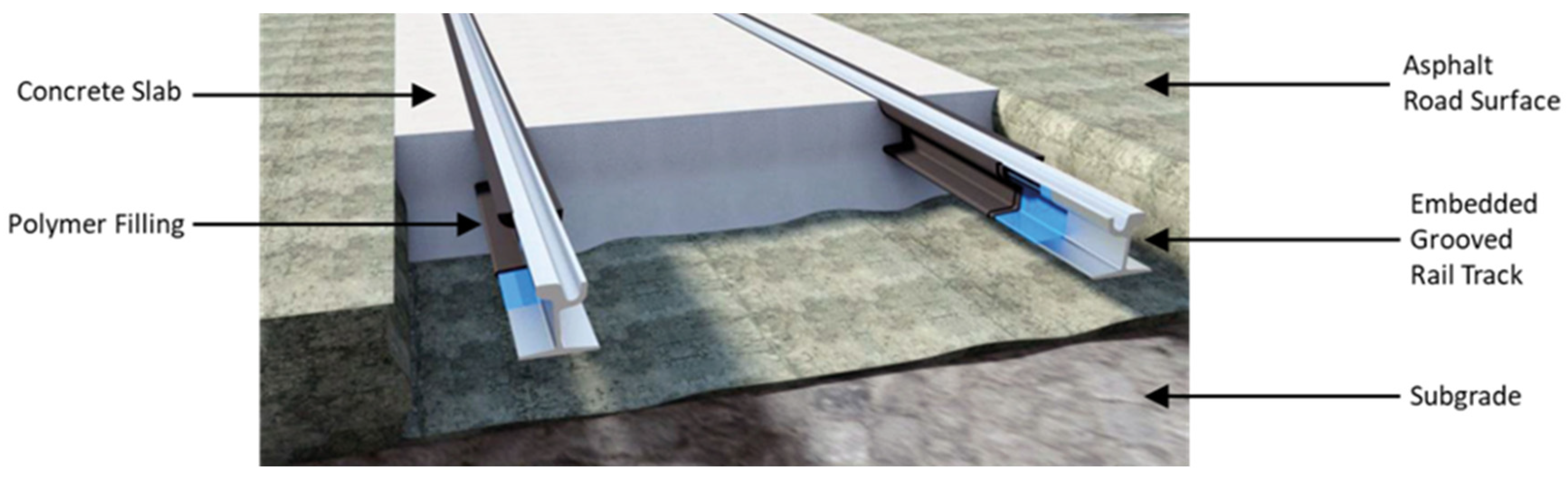

3.4. Track Structure

4. Results and Discussion

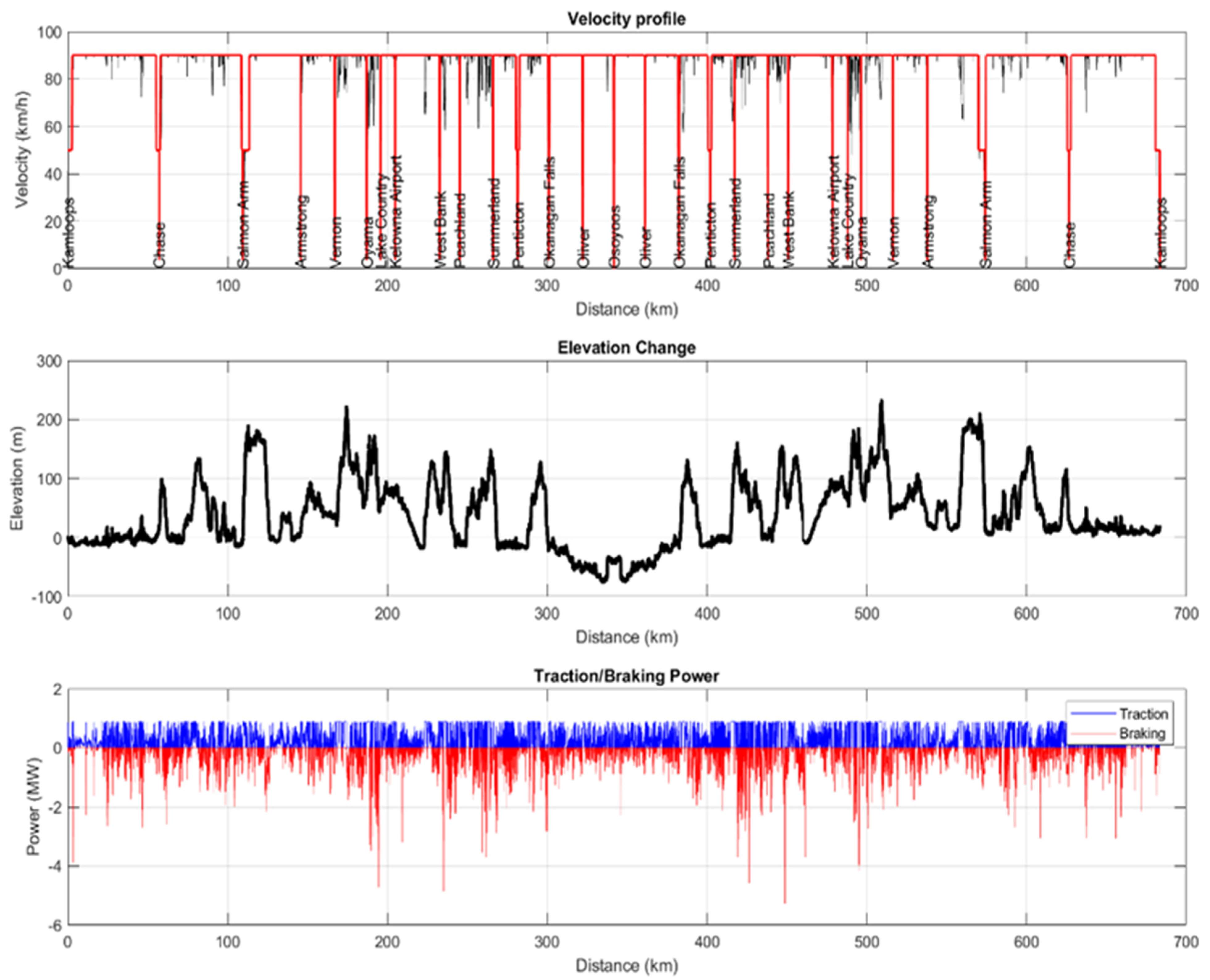

4.1. Performance and Energy Usage Modeling

4.2. Route Gradient Assessment for a Hydrail Tram–Train

- A larger battery bank (i.e., more battery packs added to the system), which may also consider different battery chemistries, such as Lithium Titanate Oxide (LTO) batteries, due to their improved safety and reliability.

- The addition of more hydrogen fuel cell modules in parallel to the battery system.

4.3. Limitations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

References

- Government of Canada. Producing Hydrogen in Canada—Clean Fuels. 2024. Available online: https://natural-resources.canada.ca/our-natural-resources/energy-sources-distribution/clean-fuels/producing-hydrogn-canada/23151 (accessed on 10 January 2024).

- Government of Canada. Provincial and Territorial Energy Profiles—British Columbia. 2024. Available online: https://www.cer-rec.gc.ca/en/data-analysis/energy-markets/provincial-territorial-energy-profiles/provincial-territorial-energy-profiles-british-columbia.html (accessed on 10 January 2024).

- Railway Association of Canada. Rail Trends 2020; Railway Association of Canada: Ottawa, ON, Canada, 2020. [Google Scholar]

- Railway Association of Canada. Canada’s Passenger Railways: Moving People. 2023. Available online: https://www.railcan.ca/101/canadas-passenger-railways-moving-people/ (accessed on 10 January 2024).

- TransLink. Rider Info—Schedules and Maps. 2023. Available online: https://www.translink.ca/schedules-and-maps (accessed on 10 January 2024).

- Steer Group. Feasibility of an East-West Intercity Passenger Rail System for Washington State; Final Report; Washington State Joint Transportation Committee Reference No. 23685001; Steer Group: Olympia, WA, USA, 2020. [Google Scholar]

- Karlsruhe, V. Karlsruhe Tram-Train Rider Information. 2023. Available online: https://www.vbk.info/service/kontakt.html (accessed on 10 January 2024).

- Albtal-Verkehrs-Gesellschaft mbH. Karlsruhe Tram-Train Schedule. 2023. Available online: https://www.avg.info/fahrplan.html (accessed on 10 January 2024).

- Perez, M. Karlsruhe Tram-Train Model. 2024. Available online: https://www.karlsruher-modell.de/en/index.html (accessed on 10 January 2024).

- Adamkiewicz, T. Possibilities and Conditions of Application of the Karlsruhe model in Selected Tramway Systems in Poland. Transp. Econ. Logist. 2019, 83, 141–152. [Google Scholar] [CrossRef]

- Kołoś, A.; Taczanowski, J. The feasibility of introducing light rail systems in medium-sized towns in Central Europe. J. Transp. Geogr. 2016, 54, 400–413. [Google Scholar] [CrossRef]

- Hegazi, M. Fuel Cell Battery Hybrid (Hydrail) Propulsion for Zero Emissions Freight Switching Locomotives: Duty Cycle Construction, Component Sizing, and Low Power Vehicle Prototyping. Ph.D. Thesis, University of British Columbia, Kelowna, BC, Canada, 1 December 2022. Available online: https://open.library.ubc.ca/soa/cIRcle/collections/ubctheses/24/items/1.0422235 (accessed on 10 January 2024).

- Din, T.; Hillmansen, S. Energy consumption and carbon dioxide emissions analysis for a concept design of a hydrogen hybrid railway vehicle. IET Electr. Syst. Transp. 2017, 8, 112–121. [Google Scholar] [CrossRef]

- Thorne, R.; Amundsen, A.; Sundvor, I. Battery Electric and Fuel Cell Trains—Maturity of Technology and Market Status; TØI report 1737/2019; Norwegian Centre for Transport Research—Institute of Transport Economics: Oslo, Norway, 2019; p. 46. [Google Scholar]

- Hoffrichter, A.; Miller, A.R.; Hillmansen, S.; Roberts, C. Well-to-wheel analysis for electric, diesel and hydrogen traction for railways. Transp. Res. Part D Transp. Environ. 2012, 17, 28–34. [Google Scholar] [CrossRef]

- Ahsan, N.; Hewage, K.; Razi, F.; Hussain, S.A.; Sadiq, R. A critical review of sustainable rail technologies based on environmental, economic, social, and technical perspectives to achieve net zero emissions. Renew. Sustain. Energy Rev. 2023, 185, 113621. [Google Scholar] [CrossRef]

- Alstom. Alstom’s Hydrogen Train Enters Regular Passenger Service in Austria. 2020. Available online: https://www.alstom.com/press-releases-news/2020/9/alstoms-hydrogen-train-enters-regular-passenger-service-austria (accessed on 10 January 2024).

- Train de Charlevoix. Hydrogen-Train. 2023. Available online: https://traindecharlevoix.com/en/hydrogen-train/ (accessed on 10 January 2024).

- Alstom. World Premiere: 14 Coradia iLint to Start Passenger Service on First 100% Hydrogen Operated Route, 24 August 2022. Photo Used with Permission. 2022. Available online: https://www.alstom.com/press-releases-news/2022/8/world-premiere-14-coradia-ilint-start-passenger-service-first-100 (accessed on 10 January 2024).

- Marin, G.D.; Naterer, G.F.; Gabriel, K. Rail transportation by hydrogen vs. electrification—Case study for Ontario Canada, I: Propulsion and storage. Int. J. Hydrogen Energy, 2010; 35, 6084–6096. [Google Scholar] [CrossRef]

- Marin, G.D.; Naterer, G.F.; Gabriel, K. Rail transportation by hydrogen vs. electrification—Case study for Ontario Canada, II: Energy supply and distribution. Int. J. Hydrogen Energy, 2010; 35, 6097–6107. [Google Scholar] [CrossRef]

- Logan, K.G.; Nelson, J.D.; McLellan, B.C.; Hastings, A. Electric and hydrogen rail: Potential contribution to net zero in the UK. Transp. Res. Part D Transp. Environ. 2020, 87, 102523. [Google Scholar] [CrossRef]

- Herwartz, S.; Pagenkopf, J.; Streuling, C. Sector coupling potential of wind-based hydrogen production and fuel cell train operation in regional rail transport in Berlin and Brandenburg. Int. J. Hydrogen Energy 2021, 46, 29597–29615. [Google Scholar] [CrossRef]

- United Nations Development Programme, Sustainable Development Goals. 2023. Available online: https://www.undp.org/sustainable-development-goals (accessed on 10 January 2024).

- Hegazi, M.A.; Markley, L.; Lovegrove, G. Examining the Influence of Battery Sizing on Hydrogen Fuel Cell-Battery Hybrid Rail Powertrains (Hydrail) for Regional Passenger Rail Transportation Using Dynamic Component Models. Can. J. Civ. Eng. 2021, 48, 512–521. Available online: https://www.nrcresearchpress.com/doi/abs/10.1139/cjce-2019-0464 (accessed on 10 January 2024).

- Jaekel, B.; Albrecht, T. Comparative analysis of algorithms and models for train running simulation. J. Rail Transp. Plan. Manag. 2014, 4, 14–27. [Google Scholar] [CrossRef]

- Zenith, F.; Raphael, I.; Hoffrichter, A.; Thomassen, M.S.; Moller-Holst, S. Techno-economic analysis of freight railway electrification by overhead line, hydrogen and batteries: Case studies in Norway and USA. J. Rapid Rail Transp. 2020, 234, 791–802. [Google Scholar] [CrossRef]

- R. Cooke. CLASS 150/0 & 150/1 Diesel Multiple Units. 2012. Available online: https://www.miac.org.uk/class1501.html (accessed on 10 January 2024).

- CBC News. No Criminal Charges Laid in Okanagan Bus Crash that Killed 4 People on Christmas EVE 2022. CBC News British Columbia, Chad Pawson, 20 December 2023. Available online: https://www.cbc.ca/news/Canada/british-columbia/2022-christmas-eve-bus-crash-okanagan-connector-no-criminal-charges-1.7065356 (accessed on 10 January 2024).

- Balfour Beatty Rail Technologies Ltd. Embedded Rail Slab Track, September 2006. 2006. Available online: https://balfourbeatty.com/media/29022/embedded-rail-system-datasheet.pdf (accessed on 10 January 2024).

- American Public Transportation Association. Rail Transit Track Inspection and Maintenance. 2022. Available online: https://www.apta.com/wp-content/uploads/Standards_Documents/APTA-RT-FS-S-002-02-Rev-1.pdf (accessed on 10 January 2024).

- Ling, L.; Han, J.; Xiao, X.; Jin, X. Dynamic behavior of an embedded rail track coupled with a tram vehicle. J. Vib. Control 2017, 23, 2355–2372. [Google Scholar] [CrossRef]

- PANDROL. Product Lines/Sustainable Resilient Systems. 2023. Available online: https://www.pandrol.com/product-lines/sustainable-resilient-systems/ (accessed on 10 January 2024).

- TRELLEBORG. Applied Technologies—Vector Embedded Rail System. 2023. Available online: https://www.trelleborg.com/en/applied-technologies/products-and-solutions/rail-systems/vector-embedded-rail-system (accessed on 10 January 2024).

- Gonzalez-Gil, A.; Palacin, R.; Batty, P. Sustainable urban rail systems: Strategies and technologies for optimal management of regenerative braking energy. Energy Convers. Manag. 2013, 75, 374–388. [Google Scholar] [CrossRef]

| Modified Specifications for Hydrail Commuter Train | |

|---|---|

| Vehicle Length, | 40.12 m |

| Vehicle Width, | 2.8 m |

| Vehicle Height, | 3.77 m |

| Tare Mass, | 76.5 tonnes |

| Davis Equation, | |

| Maximum Speed, | 90 km/h |

| Maximum Acceleration, | 0.981 m/s2 |

| Numbers of Powered-Axles, | 8 |

| Numbers of Available Seats, | 124 |

| Engine Power, | 1000 kW |

| Drive Train Efficiency (DC-bus to wheels), | 88% |

| OVER PR Energy Usage | |

|---|---|

| Roundtrip Time, TR | 8 h 34 m |

| Average Train Velocity, | 86 km/h |

| Peak Traction Power, | 880 kW |

| Average Traction Power, | 276.4 kW |

| Energy Consumed at Drivetrain Efficiency of 88%, | 2400 kWh |

| Consumed Energy with Regeneration, | 1950 kWh |

| Hydrogen Consumption of 16 Train Hydrail Fleet for 16 h day Transit Service, | 5 tonnes H2/day |

| Hydrogen Storage System Mass @ 35 MPa, | 1460 kg |

| Hydrogen Storage System Mass with Regeneration, | 1194 kg |

| Hydrogen Gas Used, | 144 kg |

| Hydrogen Gas Used with Regeneration @ 35 MPa, | 117 kg |

| Hydrogen Fuel Consumption Rate, | 0.21 kg/km |

| Hydrogen Fuel Consumption Rate with Regeneration, ΔfH2,reg | 0.17 kg/km |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boray, T.; Hegazi, M.; Hoffrichter, A.; Lovegrove, G. Technical Feasibility of a Hydrail Tram–Train in NA: Okanagan Valley Electric Regional Passenger Rail (OVER PR). Sustainability 2024, 16, 3042. https://doi.org/10.3390/su16073042

Boray T, Hegazi M, Hoffrichter A, Lovegrove G. Technical Feasibility of a Hydrail Tram–Train in NA: Okanagan Valley Electric Regional Passenger Rail (OVER PR). Sustainability. 2024; 16(7):3042. https://doi.org/10.3390/su16073042

Chicago/Turabian StyleBoray, Tye, Mohamed Hegazi, Andreas Hoffrichter, and Gord Lovegrove. 2024. "Technical Feasibility of a Hydrail Tram–Train in NA: Okanagan Valley Electric Regional Passenger Rail (OVER PR)" Sustainability 16, no. 7: 3042. https://doi.org/10.3390/su16073042

APA StyleBoray, T., Hegazi, M., Hoffrichter, A., & Lovegrove, G. (2024). Technical Feasibility of a Hydrail Tram–Train in NA: Okanagan Valley Electric Regional Passenger Rail (OVER PR). Sustainability, 16(7), 3042. https://doi.org/10.3390/su16073042