An Innovative Passive Noise Control Technique for Environmental Protection: An Experimental Study in Explosion Noise Attenuation

Abstract

1. Introduction

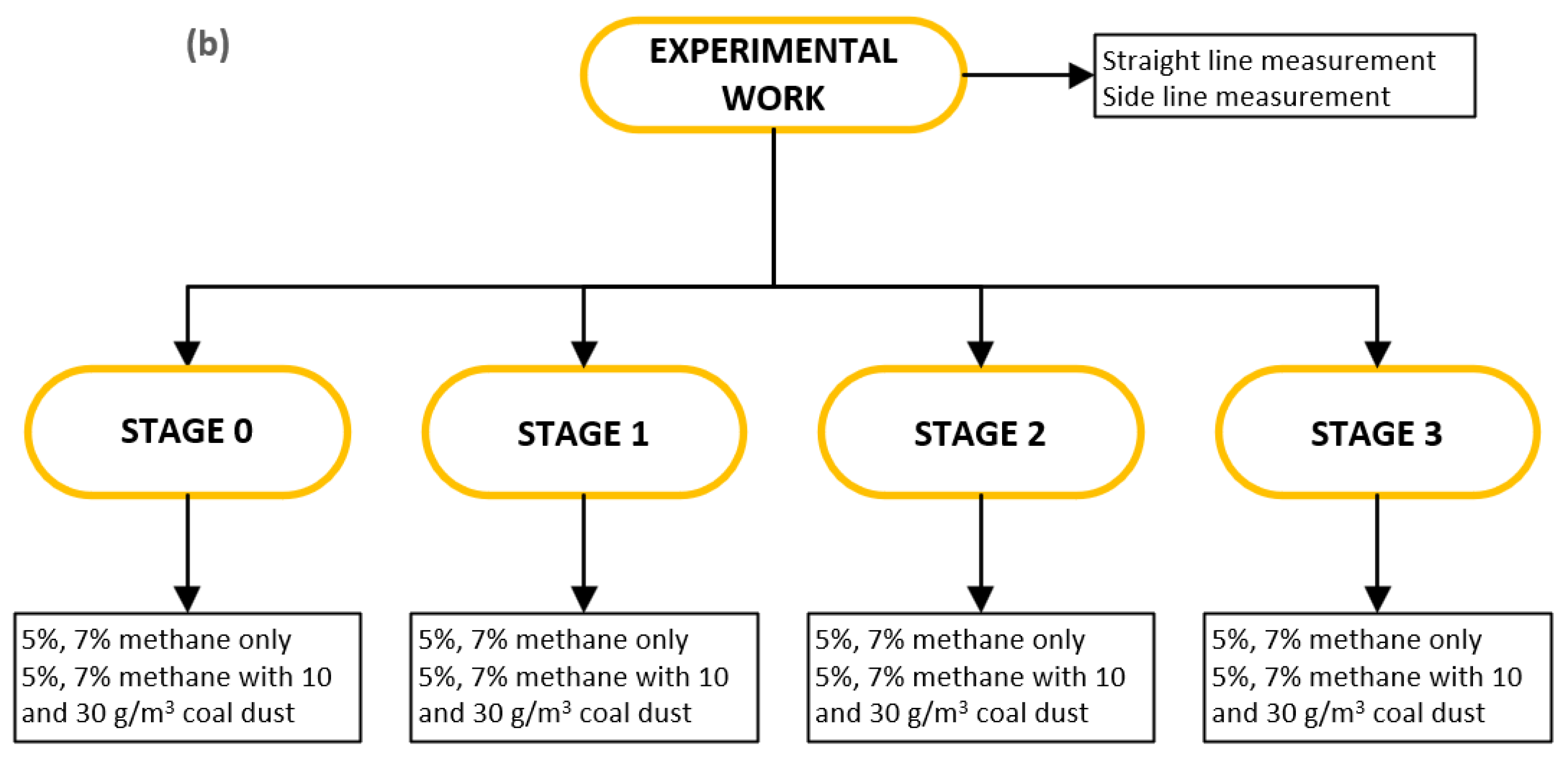

2. Methodology and Technique

2.1. Experimental Setup

2.2. Experimental Procedure

3. Results and Discussion

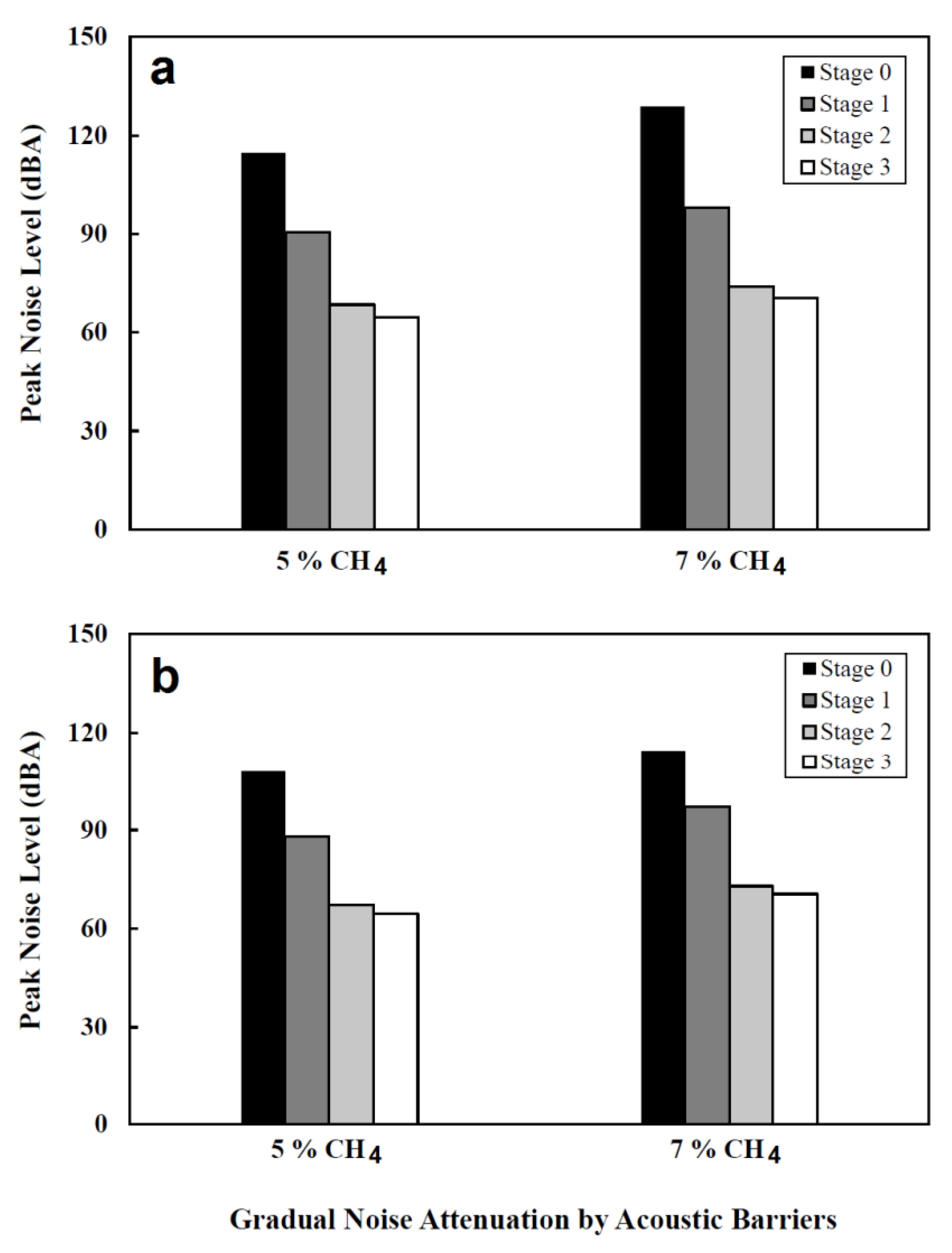

3.1. Attenuation of A-Weighted Noise Level

3.1.1. Variation in Methane Concentration

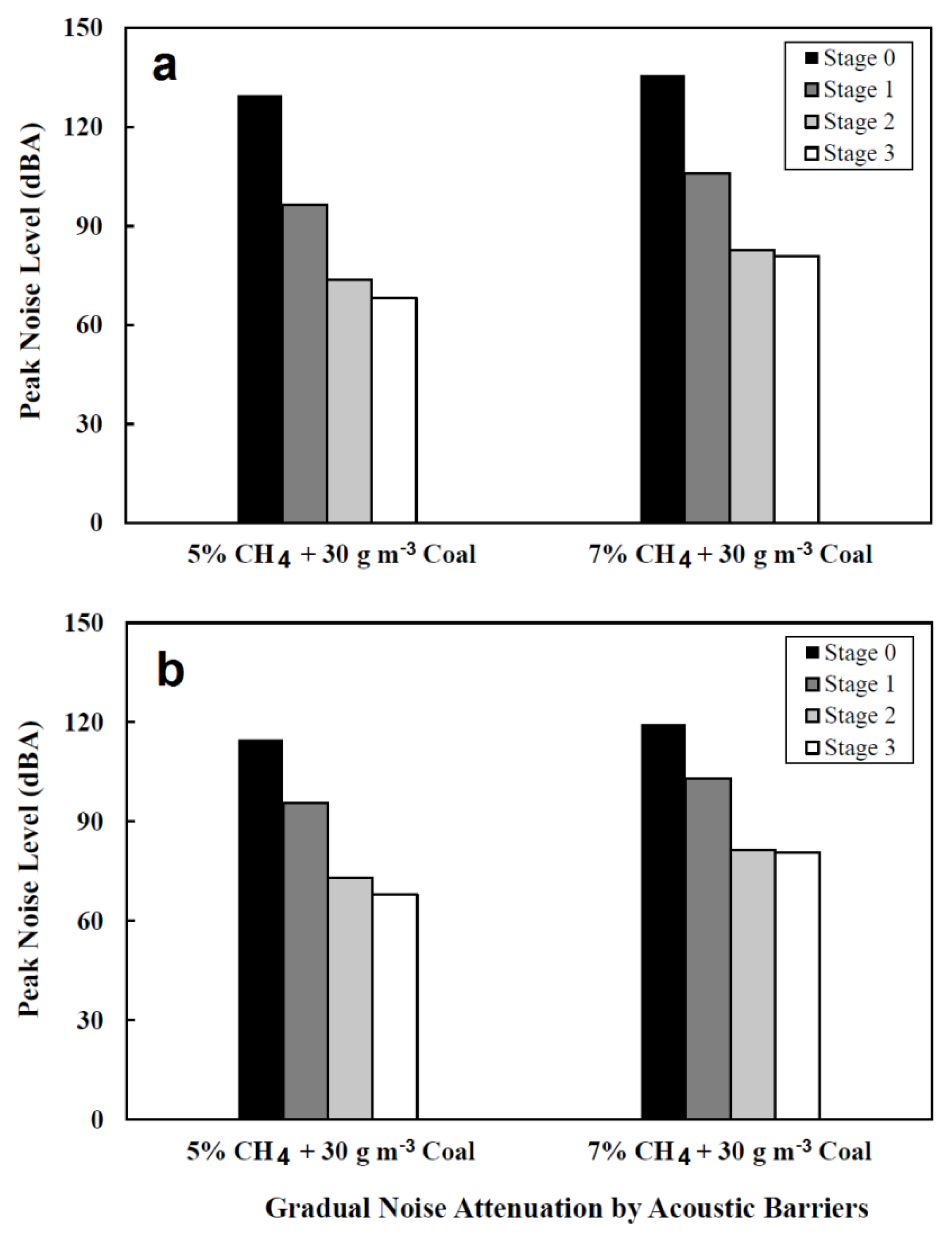

3.1.2. Variation in Methane Concentration with a Fixed Concentration of Coal Dust

3.1.3. Variation in Coal Dust Concentration with a Fixed Concentration of Methane

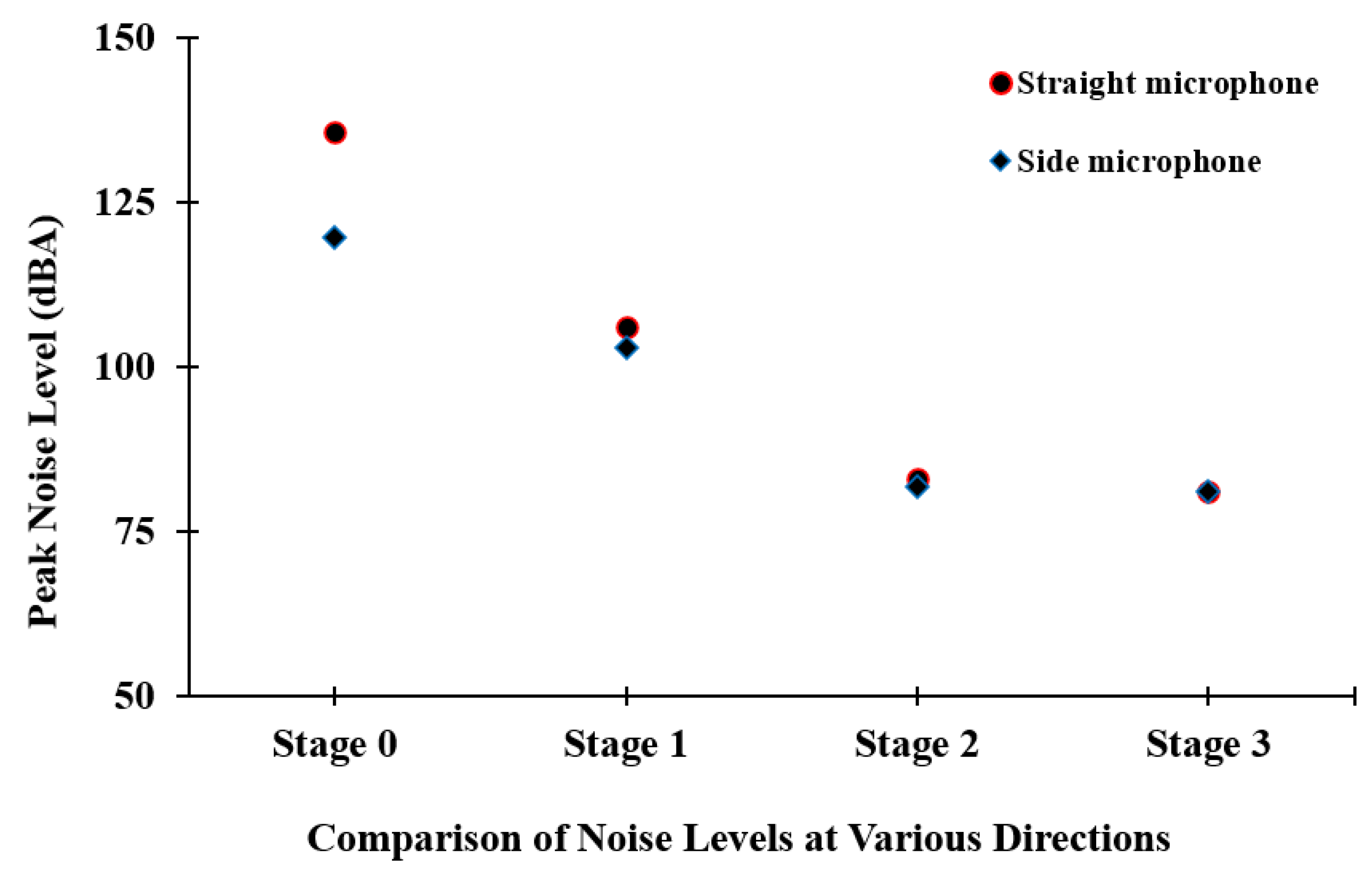

3.1.4. Examination of Noise Reduction in Various Directions

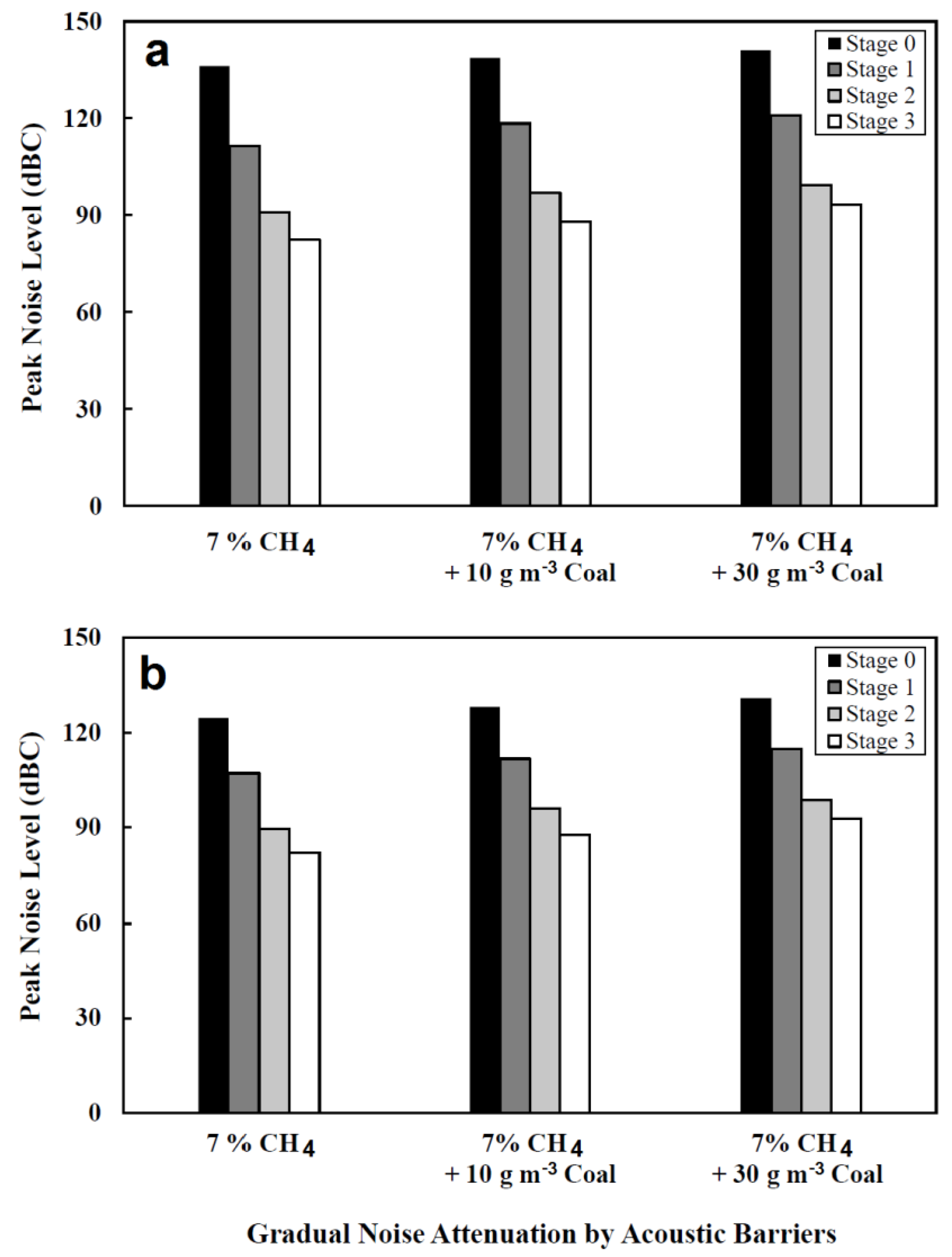

3.2. Attenuation of C-Weighted Noise Level

3.3. Attenuation of Z-Weighted Noise Level

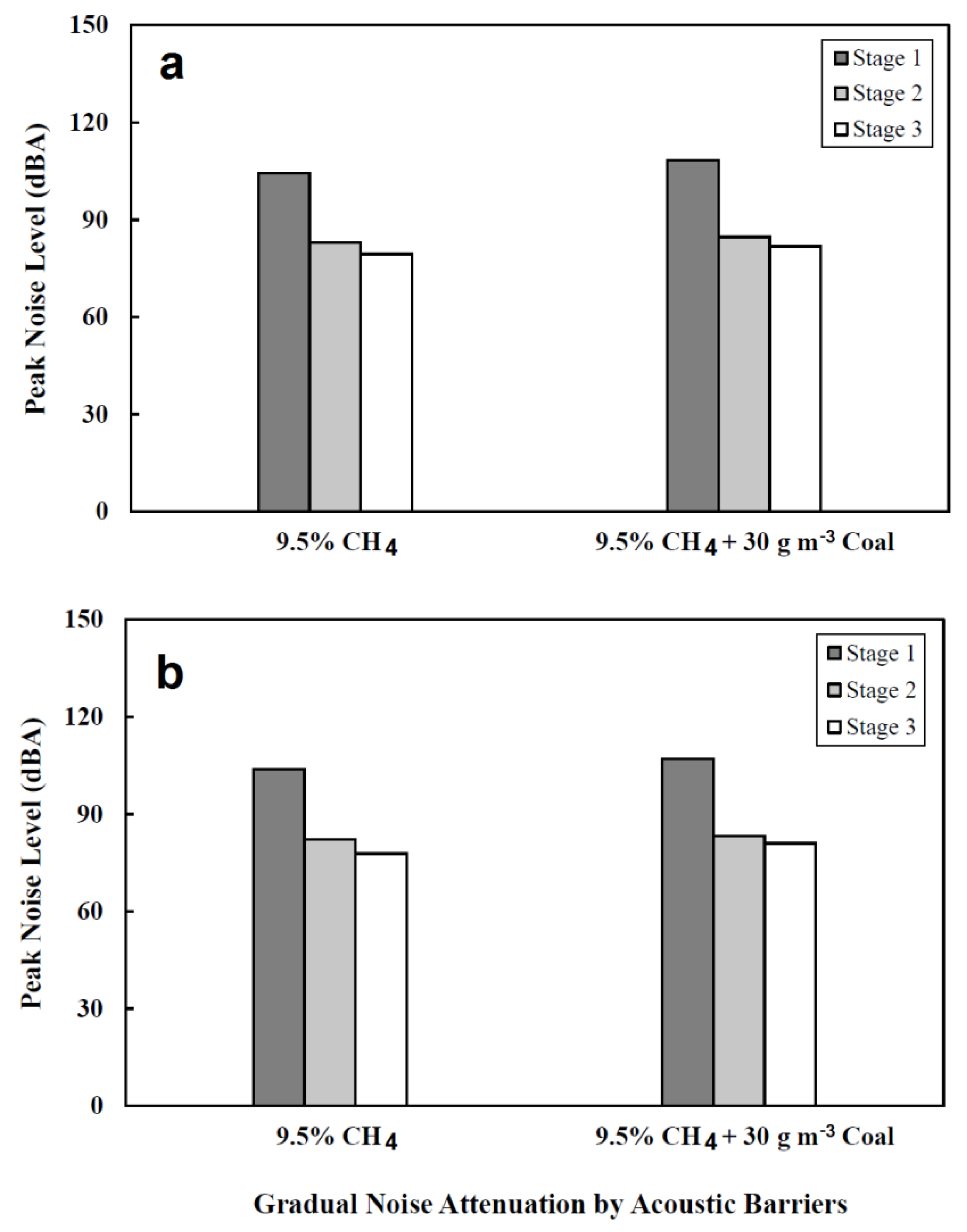

3.4. Noise Attenuation for the Stoichiometric Methane–Air Mixture Tests

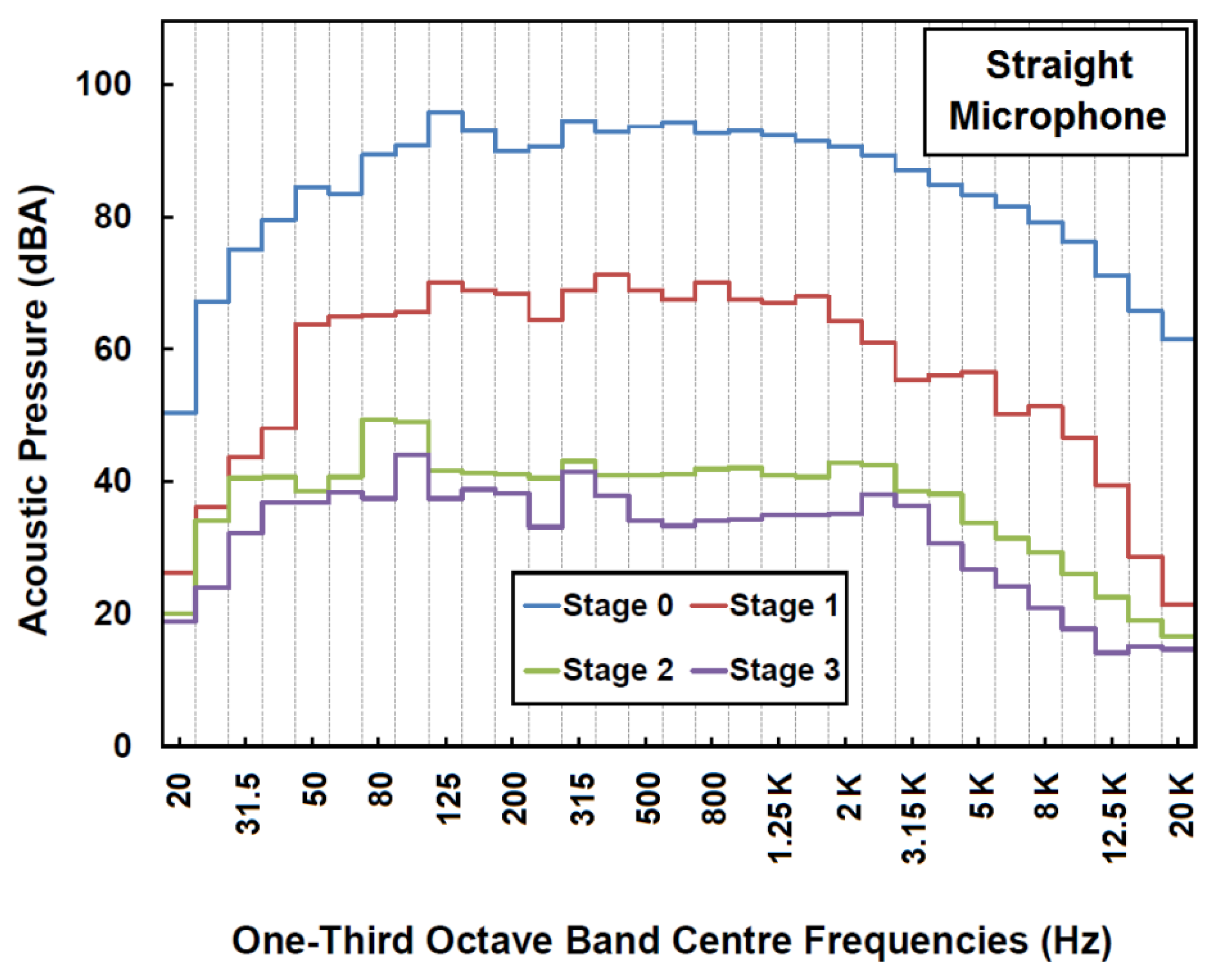

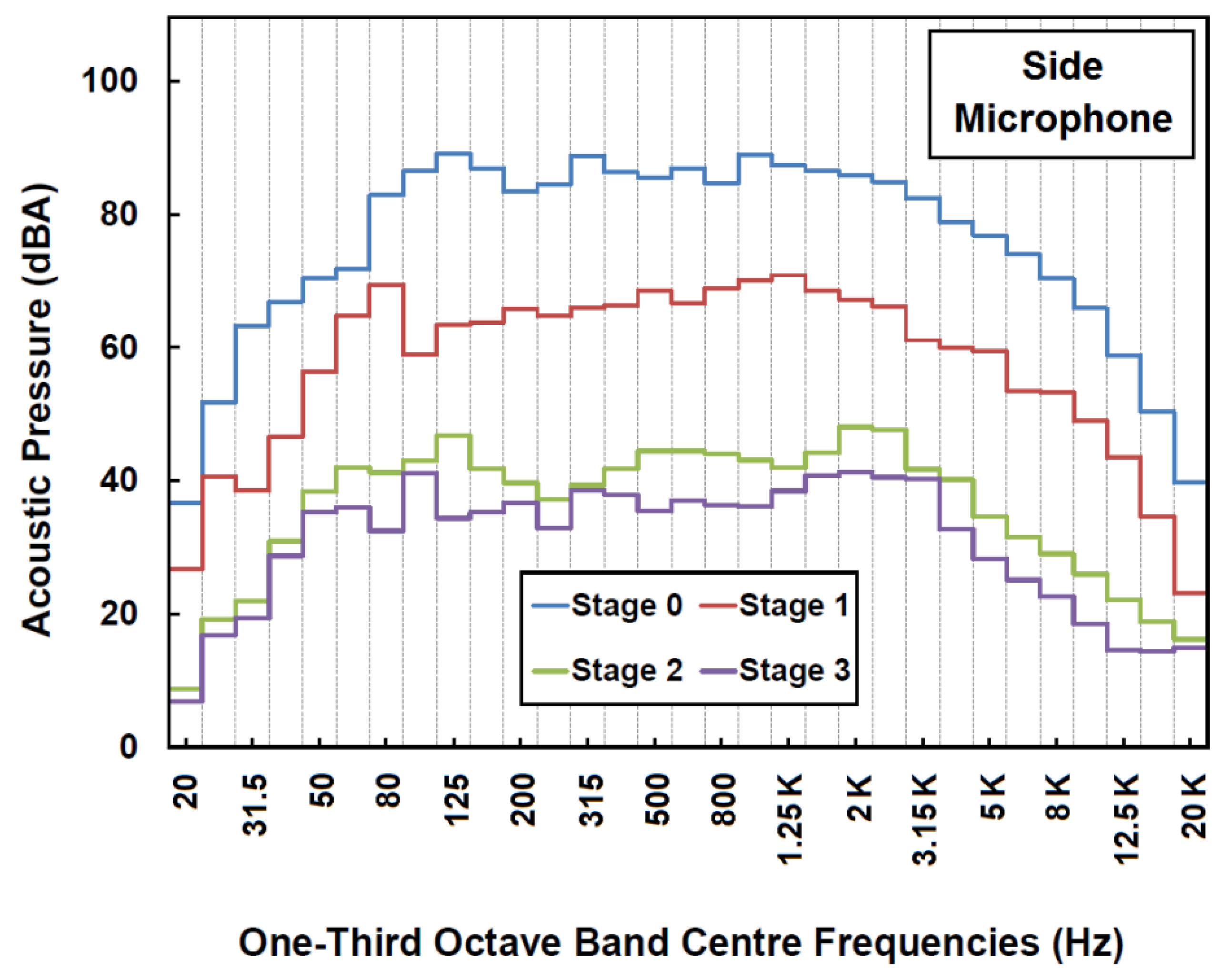

3.5. Suppression of Noise in Each One-Third Octave Band

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dhillon, B.S. Mine Safety: A Modern Approach; Springer Science & Business Media: London, UK, 2010. [Google Scholar]

- Dubaniewicz, T.H. From Scotia to Brookwood, fatal US underground coal mine explosions ignited in intake air courses. J. Loss Prev. Process Ind. 2009, 22, 52–58. [Google Scholar] [CrossRef]

- Richmond, J.K.; Price, G.; Sapko, M.; Kawenski, E. Historical Summary of Coal Mine Explosions in the United States, 1959–1981; US Department of the Interior, Bureau of Mines: Washington, DC, USA, 1983.

- Tu, J. Industrial Organization of the Chinese Coal Industry; Freeman Spogli Institute for International Studies: Stanford, CA, USA, 2011. [Google Scholar]

- Kundu, S.; Zanganeh, J.; Moghtaderi, B. A review on understanding explosions from methane–air mixture. J. Loss Prev. Process Ind. 2016, 40, 507–523. [Google Scholar] [CrossRef]

- Ajrash, M.J.; Zanganeh, J.; Moghtaderi, B. Methane-coal dust hybrid fuel explosion properties in a large scale cylindrical explosion chamber. J. Loss Prev. Process Ind. 2016, 40, 317–328. [Google Scholar] [CrossRef]

- Amyotte, P.R.; Mintz, K.J.; Pegg, M.J.; Sun, Y.-H.; Wilkie, K.I. Laboratory investigation of the dust explosibility characteristics of three Nova Scotia coals. J. Loss Prev. Process Ind. 1991, 4, 102–109. [Google Scholar] [CrossRef]

- Amyotte, P.R.; Mintz, K.J.; Pegg, M.J.; Sun, Y.H. The ignitability of coal dust-air and methane-coal dust-air mixtures. Fuel 1993, 72, 671–679. [Google Scholar] [CrossRef]

- Cashdollar, K.L. Coal dust explosibility. J. Loss Prev. Process Ind. 1996, 9, 65–76. [Google Scholar] [CrossRef]

- Cashdollar, K.L. Overview of dust explosibility characteristics. J. Loss Prev. Process Ind. 2000, 13, 183–199. [Google Scholar] [CrossRef]

- Dong, C.; Bi, M.; Zhou, Y. Effects of obstacles and deposited coal dust on characteristics of premixed methane–air explosions in a long closed pipe. Saf. Sci. 2012, 50, 1786–1791. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, J.; Chen, D. Flame propagation in hybrid mixture of coal dust and methane. J. Loss Prev. Process Ind. 2007, 20, 691–697. [Google Scholar] [CrossRef]

- Dastidar, A.G.; Amyotte, P.R.; Pegg, M.J. Factors influencing the suppression of coal dust explosions. Fuel 1997, 76, 663–670. [Google Scholar] [CrossRef]

- Garcia-Agreda, A.; Di Benedetto, A.; Russo, P.; Salzano, E.; Sanchirico, R. Dust/gas mixtures explosion regimes. Powder Technol. 2011, 205, 81–86. [Google Scholar] [CrossRef]

- Ajrash, M.J.; Zanganeh, J.; Moghtaderi, B. Effects of ignition energy on fire and explosion characteristics of dilute hybrid fuel in ventilation air methane. J. Loss Prev. Process Ind. 2016, 40, 207–216. [Google Scholar] [CrossRef]

- Ajrash, M.J.; Zanganeh, J.; Moghtaderi, B. Experimental investigation of the minimum auto-ignition temperature (MAIT) of the coal dust layer in a hot and humid environment. Fire Saf. J. 2016, 82, 12–22. [Google Scholar] [CrossRef]

- Oran, E.; Gamezo, V.; Zipf, R.K., Jr. Large-Scale Experiments and Absolute Detonability of Methane/Air Mixtures. Combust. Sci. Technol. 2015, 187, 324–341. [Google Scholar] [CrossRef]

- Liu, Q.; Bai, C.; Li, X.; Jiang, L.; Dai, W. Coal dust/air explosions in a large-scale tube. Fuel 2010, 89, 329–335. [Google Scholar] [CrossRef]

- Strahle, W.C. A review of combustion generated noise. Prog. Astronaut. Aeronaut 1975, 37, 229–248. [Google Scholar]

- O’Brien, W.D. Ultrasound–biophysics mechanisms. Prog. Biophys. Mol. Biol. 2007, 93, 212–255. [Google Scholar] [CrossRef]

- Leventhall, G. What is infrasound? Prog. Biophys. Mol. Biol. 2007, 93, 130–137. [Google Scholar] [CrossRef] [PubMed]

- Hansen, C.H.; Hansen, K.L. Noise Control from Concept to Application, 2nd ed.; Taylor and Francis Group: Abingdon, UK, 2022. [Google Scholar]

- Cirrus Research PLC. A Guide to Noise Measurement Terminology; Cirrus Research PLC: Hunmanby, UK, 2015; Available online: https://www.cirrusresearch.co.uk/library/documents/ebooks/noise-measurement-terminology-guide.pdf (accessed on 9 April 2024).

- Tao, Y.; Ren, M.; Zhang, H.; Peijs, T. Recent progress in acoustic materials and noise control strategies—A review. Appl. Mater. 2021, 24, 101141. [Google Scholar] [CrossRef]

- Nilsson, M.E. A-weighted sound pressure level as an indicator of short-term loudness or annoyance of road-traffic sound. J. Sound Vib. 2007, 302, 197–207. [Google Scholar] [CrossRef]

- Mershon, D.H.; King, L.E. Intensity and reverberation as factors in the auditory perception of egocentric distance. Percept. Psychophys. 1975, 18, 409–415. [Google Scholar] [CrossRef]

- Salam, G.C.M.A.; Chattopadhyay, G.C.N.; Jalal, M.; Rumi, U.; Eunus, H.Z.I. A Review on Jet Noise Reduction. J. Mod. Sci. Technol. 2013, 1, 19–29. [Google Scholar]

- Munjal, M. Automotive noise–the Indian scene in 2004. Proc. Acoust. 2004 2004, 1, 405–414. [Google Scholar]

- Thalheimer, E. Construction noise control program and mitigation strategy at the Central Artery/Tunnel Project. Noise Control Eng. J. 2000, 48, 157–165. [Google Scholar] [CrossRef]

- Pedersen, C.S. Human Hearing at Low Frequencies, with Focus on Noise Complaints; Acoustics, Department of Electronic Systems Aalborg University: Aalborg, Denmark, 2008. [Google Scholar]

- Forsyth, M. Buildings for Music: The Architect; the Musician, and the Listener from the Seventeenth Century to the Present Day; CUP Archive: Cambridge, UK, 1985. [Google Scholar]

- Billeter, P.; Egger, A.; Müller, R. Development and assessment of a new approach to determine structure-borne sound in rooms. In INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Denver, CO, USA, 28–30 August 2013; Institute of Noise Control Engineering: Wakefield, MA, USA, 2013; pp. 4329–4336. [Google Scholar]

- Li, X.; Liu, Q.; Pei, S.; Song, L.; Zhang, X. Structure-borne noise of railway composite bridge: Numerical simulation and experimental validation. J. Sound Vib. 2015, 353, 378–394. [Google Scholar] [CrossRef]

- Bengtsson, J.; Waye, K.P.; Kjellberg, A. Evaluations of effects due to low-frequency noise in a low demanding work situation. J. Sound Vib. 2004, 278, 83–99. [Google Scholar] [CrossRef]

- Zhang, H.; Xie, X.; Jiang, J.; Yamashita, M. Assessment on transient sound radiation of a vibrating steel bridge due to traffic loading. J. Sound Vib. 2015, 336, 132–149. [Google Scholar] [CrossRef]

- Sagartzazu, X.; Hervella-Nieto, L.; Pagalday, J. Review in sound absorbing materials. Arch. Comput. Methods Eng. 2008, 15, 311–342. [Google Scholar] [CrossRef]

- Verruijt, A. Theory and Problems of Poroelasticity; Delft University of Technology: Delft, The Netherlands, 2013. [Google Scholar]

- Serra, Q.; Ichchou, M.N.; Deü, J.F. Wave properties in poroelastic media using a Wave Finite Element Method. J. Sound Vib. 2015, 335, 125–146. [Google Scholar] [CrossRef]

- Amadasi, G.; Cerniglia, A.; Duperray, B. Experimantal Determination of Poro-elastic Properties of Materials Commonly Used for Noise and Vibration Control. In Proceedings of the 15th International Congress on Sound and Vibration, Daejeon, Republic of Korea, 10 July 2008; pp. 2457–2464. [Google Scholar]

- Narayanan, N.; Ramamurthy, K. Structure and properties of aerated concrete: A review. Cem. Concr. Compos. 2000, 22, 321–329. [Google Scholar] [CrossRef]

- Hamad, A.J. Materials; production, properties and application of aerated lightweight concrete: Review. Int. J. Mater. Sci. Eng. 2014, 2, 152–157. [Google Scholar] [CrossRef]

- Megasorber. Available online: https://megasorber.com/soundproofing-resources/soundproofing-barrier/ (accessed on 9 April 2024).

- Sorberbarrier. (Pyrotek Website). Available online: https://www.pyroteknc.com/products/sorber/sorberbarrier/ (accessed on 9 April 2024).

- Parikh, D.; Chen, Y.; Sun, L. Reducing automotive interior noise with natural fiber nonwoven floor covering systems. Text. Res. J. 2006, 76, 813–820. [Google Scholar] [CrossRef]

- Arenas, C.; Vilches, L.F.; Cifuentes, H.; Leiva, C.; Vale, J.; Fernández-Pereira, C. Development of Acoustic Barriers Mainly Composed of Co-Combustion Bottom Ash; World of Coal Ash (WOCA): Denver, CO, USA, 2011. [Google Scholar]

- Hertzberg, M.; Cashdollar, K.L. Introduction to Dust Explosions; Industrial Dust Explosions; ASTM International: West Conshohocken, PA, USA, 1987. [Google Scholar]

- Occupational Safety & Health Administration (OSHA). (United States Department of Labor Website). Available online: https://www.osha.gov/otm/section-3-health-hazards/chapter-5 (accessed on 2 April 2024).

- Vanderstraeten, B.; Tuerlinckx, D.; Berghmans, J.; Vliegen, S.; Van, E.; Smit, B. Experimental study of the pressure and temperature dependence on the upper flammability limit of methane/air mixtures. J. Hazard. Mater. 1997, 56, 237–246. [Google Scholar] [CrossRef]

- Gieras, M.; Klemens, R.; Rarata, G.; Wolański, P. Determination of explosion parameters of methane-air mixtures in the chamber of 40 dm3 at normal and elevated temperature. J. Loss Prev. Process Ind. 2006, 19, 263–270. [Google Scholar] [CrossRef]

| Stages | Peak Noise Level (dBA) | ||

|---|---|---|---|

| 7% CH4 | 7% CH4 and 10 g m−3 Coal Dust | 7% CH4 and 30 g m−3 Coal Dust | |

| Stage 0 | 129 | 131 | 136 |

| Stage 1 | 98 | 103 | 106 |

| Stage 2 | 74 | 79 | 83 |

| Stage 3 | 71 | 75 | 81 |

| Stages | Peak Noise Level (dBA) | ||

|---|---|---|---|

| 7% CH4 | 7% CH4 and 10 g m−3 Coal Dust | 7% CH4 and 30 g m−3 Coal Dust | |

| Stage 0 | 115 | 117 | 120 |

| Stage 1 | 97 | 102 | 103 |

| Stage 2 | 73 | 78 | 82 |

| Stage 3 | 70 | 75 | 81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zanganeh, J.; Kundu, S.; Moghtaderi, B. An Innovative Passive Noise Control Technique for Environmental Protection: An Experimental Study in Explosion Noise Attenuation. Sustainability 2024, 16, 3201. https://doi.org/10.3390/su16083201

Zanganeh J, Kundu S, Moghtaderi B. An Innovative Passive Noise Control Technique for Environmental Protection: An Experimental Study in Explosion Noise Attenuation. Sustainability. 2024; 16(8):3201. https://doi.org/10.3390/su16083201

Chicago/Turabian StyleZanganeh, Jafar, Sazal Kundu, and Behdad Moghtaderi. 2024. "An Innovative Passive Noise Control Technique for Environmental Protection: An Experimental Study in Explosion Noise Attenuation" Sustainability 16, no. 8: 3201. https://doi.org/10.3390/su16083201

APA StyleZanganeh, J., Kundu, S., & Moghtaderi, B. (2024). An Innovative Passive Noise Control Technique for Environmental Protection: An Experimental Study in Explosion Noise Attenuation. Sustainability, 16(8), 3201. https://doi.org/10.3390/su16083201