Abstract

In response to the ever-increasing pursuit of competitiveness among organizations in today’s global business landscape, the subject of supply chain management has become a vital domain encompassing a wide range of sectors and industries across the economy. The growing concern about sustainable development has prompted public and private supply chain players to incorporate the three pillars of sustainability, namely, economic, environmental, and social, into the design of their supply chain networks. This study reviews and examines the content of 102 relevant papers to discuss the mathematical models, modeling approaches, and solutions that have been explored in the existing literature on forward sustainable supply chain network design. This paper also investigates the sustainability elements and supply chain network peculiarities including design factors and decision levels. In this review, several limitations in the current literature on sustainable supply chain network design optimization models are highlighted. According to the analysis, it was found that a better understanding of the industry and its sustainability requirements and priorities is essential for designing sustainable supply chain networks that are tailored to the needs of a specific industry rather than achieving general sustainability objectives. In addition, integrating strategic, tactical, and operational decision levels in the design of supply chain networks is critical for evaluating their impact on each other in terms of sustainability. More sophisticated mathematical solution methods for dealing with real-life scenarios including nonlinearity and uncertainty sources are required. The paper concludes with new prospects of research to promote a better integration of sustainability into supply chain networks.

1. Introduction

With increasing industrialization and global development in production, consumption, and trading levels in recent decades, the need for effective supply chain management (SCM) has grown. SCM aims to improve the supply network’s competitive performance by integrating and coordinating internal processes within a firm and connecting them with the external processes of other players in the network such as suppliers, manufacturers, customers, and other entities [1]. The role of the supply chain in the globe is changing as a result of the dynamics of firm development and globalization [2]. The various trends in the economy, society, and environment caused by globalization, complicated trade flows, and, most importantly, sustainable development have a great impact on the configuration, design, and management of supply chain networks [3]. In light of that, many firms started adopting sustainable management practices due to the critical need for sustainability [4]. Supply chain network design (SCND) plays a significant role in supply chain performance. It is the most critical strategic decision in the SCM affecting the overall long-term viability of the chain [5]. In addition, it determines the nature of the supply chain, while considering sourcing, investment, and operational decisions [6]. SCND comprises identifying the locations, number, and capacities of facilities in the network, as well as the movement of material between the placed facilities [7]. It considers three decision levels: strategic, tactical, and operational. Strategic decisions are long-term decisions such as the number and location of production and warehousing facilities, transportation modes, and supplier selection [8]. In tactical decisions, the time frame considered is a quarter to a year. These decisions cover production planning, transportation planning, resource planning, production capacities, and pricing. Finally, operational decisions are made on a daily or weekly basis [9]. They consider inventory and production allocation, scheduling, routing considerations, and the coordination of product and material flow [10].

One of the key developments in SCM is the concept of sustainable development, which has spread throughout the scientific literature [11]. The notion of sustainable development was initially introduced in the Brundtland Report in 1987, and it addressed future issues such as population growth and the scarcity of sufficient resources. Sherafati et al. [12] have defined sustainable development as filling the demands of the present without jeopardizing future generations’ ability to satisfy their own needs. Current research is primarily concerned with evaluating SCM policies in terms of the triple bottom line of sustainability, which consists of economic considerations, environmental performance, and social responsibility [13]. The field of SCM has become more focused on changing supply chain strategy, due to the amplified social and political pressure, sensitivity around end-of-life goods, and transportation risks [14]. Global energy consumption, for example, is expected to rise significantly through 2030, with liquid fuels accounting for the majority of fuel demand in the transportation sector [15]. Thus, firms that confront cost, competitiveness, and environmental and social issues must reconfigure their supply chain architecture to be sustainable [16]. The issue of sustainable supply chain management (SSCM) has lately piqued the interest of practitioners and researchers due to considerable constraints and expectations imposed by many stakeholders such as customers, social activists, and non-governmental organizations [17]. Many firms are considering an acceptable degree of commitment to sustainable practices as a result of the requirement for sustainable supply chains. However, if businesses ignore environmental or social problems, their public image and, as a result, their economic performance may suffer. For example, several large companies have suffered damage to their public image and, as a result, have lost market share due to what the media and activists published about alleged social irresponsibility such as labor rights violations [18].

The incorporation of sustainability into SCND alters the configuration of the supply chain, thereby enhancing its performance. Traditional SCND approaches have focused on cost-based performance metrics, whereas recent regulations mandate stricter environmental codes of conduct. Hence, policymakers require organizations to broaden their set of objectives beyond economic metrics when designing or reconfiguring their supply chains [9]. Hence, sustainable SCND strives to establish the ideal supply chain configuration to optimize long-term economic profitability, environmental performance, and social factors such as job opportunities, safety, etc. [17]. The green supply chain network design (GSCND) is derived from sustainable SCND, focusing only on the supply chain’s environmental performance. It is a significant trend in most industrial operations that allows managers to address the negative effects of conventional supply chains on the environment [14]. In addition, it is used to incorporate environmental management principles with a prevention policy. Diabat and Govindan [19] have defined the GSCND as the collection of supply chain management policies, activities, and interactions established in response to environmental concerns in the design, purchase, manufacture, distribution, use, re-use, and disposal of the firm’s goods and services. Several sectors have emphasized the importance of sustainability in supply chain decisions. Food supply chain [20], pharmaceutical supply chain [21], cold supply chain [22], blood supply chain [23], biofuel supply chain [24], mining supply chain [14], and other supply chains strive to include the triple bottom line of sustainable considerations into their network design.

Generally, sustainable SCND comprises multiple conflicting objective functions, that require balancing [25]. It may involve maximizing the positive social impact, which includes social justice, the rights of stakeholders such as employees, consumers, and communities [17,26,27], and creating job opportunities [6,8,28]. It can also involve minimizing the negative environmental impact such as greenhouse gas (GHG) emissions [24,29,30], waste [31,32], and energy depletion [33,34]. Nevertheless, minimizing supply chain cost is the conventional objective considered in most network designs. Furthermore, recent sustainable SCND handles multiple levels in the network, different decision levels, multiple periods, multiple products, and several design factors. Thus, the optimization of sustainable SCND seeks the optimal combination of suppliers, facilities, transportation modes, and products.

In recent years, a few review papers have been published on sustainable SCND. Eskandarpour et al. [35] surveyed eighty-seven papers pertaining to this field of research between 1990 and 2014. The review covers mathematical models that address sustainability dimensions. Waltho et al. [36] presented a literature review on GSCND, concentrating on models and approaches that explicitly integrate carbon emissions and environmental legislation, between 2010 and 2017. Yadav et al. [37] evaluated the scientific contribution between 2005 and 2020, on the subject of agro-food supply chains, including network designs and performance measurements. Sidharath [38] explored the state of sustainable supply chain network models between 2010 and 2021, resulting in eighty-seven papers. The study also proposed a sustainable SCND framework that includes sustainability indicators and parameters. It is worth mentioning that the review conducted by [38] focused on the inclusion of sustainable development as one of the main factors impacting SCND. On the other hand, our paper mainly focuses on the approaches for the mathematical formulations and solution procedures to design a supply chain network.

This review aims to analyze the existing literature of sustainable SCND optimization. The study focuses on network design optimization, covering mathematical models, modeling approaches, and solution methods, as well as SCND characteristics such as design factors, and decision levels. This work specifically examines forward supply chains (FSCs) within the broader field of sustainable SCND. While acknowledging the significance of closed-loop supply chains (CLSCs) and their role in environmental efficiency [39], this study narrows its focus to FSCs. This concentration arises from a recognition of the unique operational challenges and sustainability issues inherent in FSCs. Moreover, as the field of sustainable SCND is expansive, with multiple intersecting sub-domains, a focused approach allows for a more in-depth and nuanced analysis of the optimization strategies, sustainability considerations, and practical applications specific to FSCs. The decision to focus on FSCs is further supported by the preliminary literature review findings, which indicated an extensive body of work specifically concerning FSCs. In addition to this, it was also noted that there is a great potential for a future comprehensive review dedicated to CLSCs, reflecting the substantial literature and the distinct considerations of these types of supply chains.

It is important to note that this comprehensive review extends beyond the scope of previous studies by Eskandarpour et al. [35], Waltho et al. [36], Yadav et al. [37], and Sidharath [38] by examining the range of sustainability dimensions and also critically analyzing the mathematical formulations and solution approaches tailored to various industry needs. While Eskandarpour et al. [35] conducted a review encompassing the period up to 2014, this study captures the significant developments of the subsequent seven years, a period marked by accelerated research activity in this domain. This work dives further into the optimization nuances and explores how the sustainability aspects are operationalized within mathematical models, what the research trends of this body of literature are, and what research gaps need to be addressed in future works. Moreover, while Sidharath [38] examined the state of sustainable supply chain network models in terms of the various approaches and methodologies followed in the literature, this review focuses primarily on approaches for mathematical formulations and solution procedures for designing a supply chain network. Furthermore, while Yadav et al. [37] focused on agro-food supply chains, this review spans multiple industries and categorizes them to highlight predominant ones and pinpoint those that warrant further scholarly attention. Additionally, unlike prior reviews such as the one by Waltho et al. [36], which predominantly focus on environmental aspects, this study provides a more balanced coverage across all sustainability dimensions, with a particular emphasis on the often-neglected social facets. The following research questions are designed to guide this review:

- What is the state of the art, academic productivity, and research tendencies of the published literature pertaining to sustainable SCND optimization methods?

- Which sustainability dimensions have been considered in the literature?

- Which design factors have been included in the optimization models of sustainable SCND, and to which applications/industries have they been applied?

- Which modeling approaches and solution methods have been explored in the literature?

- What are the research gaps that need to be addressed?

The remainder of this paper is structured as follows: Section 2 discusses the methodological approach adopted for this review. Section 3 presents the descriptive analysis and initial data statistics of the selected references for review. Section 4 focuses on the analysis of the reviewed literature, while Section 5 discusses the research findings. Finally, Section 6 concludes the review study and provides future research directions.

2. Methodology

The objective of this article is to provide a systematic literature review of the recent research activities pertaining to sustainable supply chain network design, with a focus on the modeling aspects and optimization approaches. This enables researchers to explore, evaluate, and interpret the existing body of literature, which allows them to identify research tendencies, compare the studies, and generate insights about the extant gaps and future research directions [37]. This work follows the four-step methodology devised by Mayring [40] and adopted by many researchers in the supply chain area reviews, such as [37,41,42], among others. These four steps are “material collection”, “descriptive analysis”, “category selection”, and “material evaluation”. The first step is related to material collection which gathers the literature from different sources, screens them based on inclusion and exclusion criteria, and selects the final list of articles for review. The initial descriptive analysis of the generated material is the focus of the second step. The third step involves category selection, which categorizes the selected studies based on different criteria to uncover the existing trends. Finally, the material evaluation step consists of a thorough examination of the generated data to identify the key issues, insights, peculiarities, gaps, and potential opportunities.

In the next subsections, the adopted search strategy and the different phases for relevant article selection to conduct this research are discussed in detail.

2.1. Search Strategy

The strategy of this search consists of selecting the search keywords, the covered period, and databases. Firstly, given the scope of this study and the aforementioned research questions, the search string is designed as follows: (“Optim*” OR “model*” OR “program*” OR “mathematical” OR “algorithm*” OR “decision” OR “simulat*”) AND (“green” OR “sustainab*”) AND ((“supply chain*” OR ”SCM”) AND ((“distribution” OR “network”) AND “design”)).

The search string is composed of three main blocks related with “AND” relationship operators to capture the studies belonging to the intersection of these three axes of research. The first block is related to modeling and optimization, the second block is related to sustainability and green aspects, and the third block belongs to SCND.

Secondly, the guidelines suggested by Popay et al. [43] are followed. These guidelines recommend searching for any extant review related to the investigated topic of research to ensure that the scope of the study has not been covered before. Considering the evolutionary state of the current field of research, and after conducting a preliminary search that revealed a growing publication trend and an increasing interest among researchers in this area, it was decided to undertake the search for a seven-year period from 2015 to 2022. The current research aims to extend the work of Eskandarpour et al. [35] through covering the period from 2015 to 2022. It also serves to evaluate the late research activities, and assess if the already pointed-out research gaps have been addressed by researchers, and if the suggested future research directions have been taken into consideration.

Finally, the Scopus database was selected to conduct the search as it is the largest multidisciplinary abstract and citation database that provides publications from peer-reviewed literature, in addition to its practical data export features and sufficient included details about the publications [44].

2.2. Article Selection

The search for the aforementioned combination of keywords was conducted using the option “Article title, Abstract, keywords” from the Scopus database. Journal articles written in the English language and published from January 2015 to December 2022 were included. Also, a large number of articles dealing with CLSCs and reverse logistics were excluded, focusing on the forward channels only. Although CLSCs are closely related to sustainability aspects, they were excluded due to the significantly large number of publications in this area of research and the peculiarities of this type of supply chain, which calls, in the authors’ view, for a separate review paper dedicated solely to them. Another exclusion criterion that was adopted in the selection process was based on the contribution of the studies, where articles with only minor contributions were excluded from the review. This criterion encompasses considerations such as the novelty and comprehensiveness of the approaches used for conducting the review, the extent to which the works advance the theoretical understanding or practical applications of sustainable SCND optimization, and the overall recognition within the scientific community.

Furthermore, back-tracking and forward-tracking were also used to check if any other relevant articles exist in the cited references or among those referring to the central sources [35]. This serves to ensure that no relevant publications are overlooked.

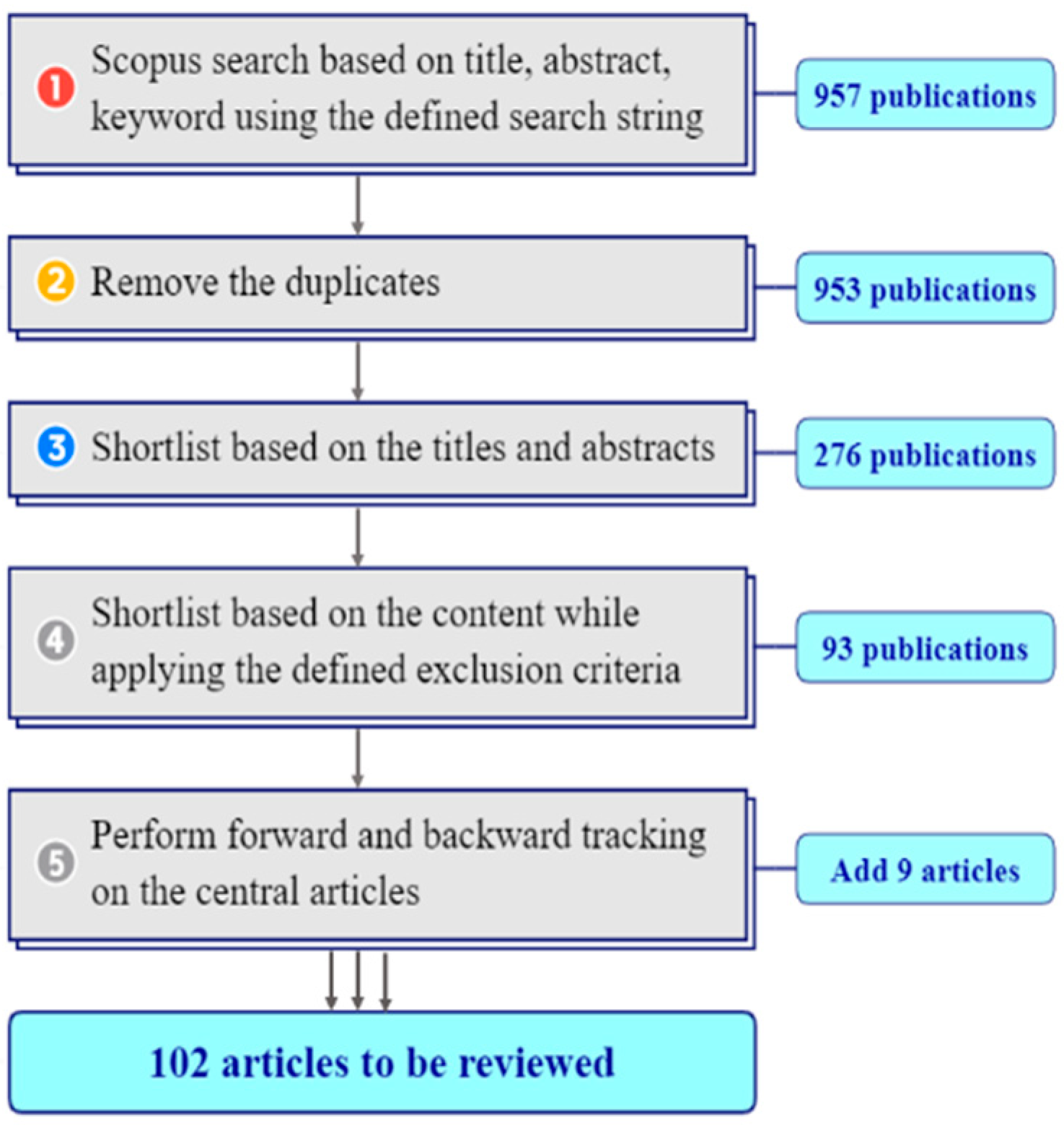

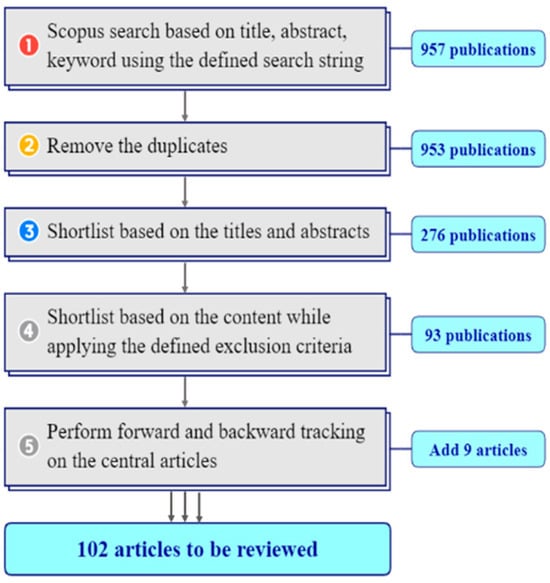

The initial search generated 957 articles that were reduced to 953 items after removing duplicates. The selection process of the relevant publications underwent several rounds of screening and filtering, as summarized in Figure 1. Initially, a joint examination of the titles and abstracts of the articles led to the shortlisting of 276 items that seemed more pertinent to the scope of this review. The next step considered screening these articles based on their content while taking into consideration the exclusion criteria. The current study focuses solely on journal papers and excludes studies that are insufficiently comprehensive in terms of proposed methodology and solutions. This round yielded 93 central studies. After conducting the backward and forward tracking based on them, 9 more items were added to yield a total of 102 articles to be reviewed.

Figure 1.

Article selection steps.

In summary, this methodology section delineates the systematic review protocol followed to explore advancements in sustainable SCND with an emphasis on optimization. The approach adhered to Mayring’s methodology [40] and was initiated with a strategic search for the literature from 2015 to 2022, postdating a similar review. A comprehensive screening refined the initial pool of 957 articles to 102 studies that align with the review’s stringent criteria, while deliberately excluding works on CLSCs from focused analysis. This selection paves the way for the descriptive analysis and initial data statistics discussed in the following section, where these chosen articles are further dissected to understand the current state of research and unveil directions and trends.

3. Descriptive Analysis and Initial Data Statistics

In this section, a descriptive analysis of the surveyed literature is presented, referring to the process of using descriptive data analytics to statistically summarize research trends and analyze them. According to Eskandarpour et al. [35], the activities in this area of study significantly grew, beginning in 2009, and have continued to rise since then. The findings of this review are in line with the previous research findings in [35]. The upward trend continued after 2014. It slightly declined during 2018, but very quickly recovered in 2019, and the number of publications continued to increase each year. In particular, the number of publications has surged during the last three years, with 2020, 2021, and 2022 contributing 54% (55 items) of the selected articles for review. Certain important factors contributed to the occurrence of this trend. Firstly, research has supported the surge and increase of academic research productivity that coincided with the arrival of the COVID-19 pandemic, particularly during the lockdown period [2]. Secondly, the arrival of COVID-19 brought about significant disruptions to global supply chains, which exposed their vulnerability and prompted researchers and practitioners to recognize the need for more resilient designs. Thus, the pandemic served as a wake-up call, highlighting the fragility of supply chains and inciting a reevaluation of their structures to enhance resilience. Thirdly, the emphasis on sustainability, decarbonization, and addressing climate change in recent years has added another layer of complexity to supply chain considerations and incited researchers to focus on integrating sustainability dimensions into SCND. These factors collectively contributed to the observed increasing trend in research about sustainable SCND in the past few years. This rapid growth reflects the growing interest among researchers and academicians in the mathematical formulation and solution procedure for sustainable SCND planning and optimization.

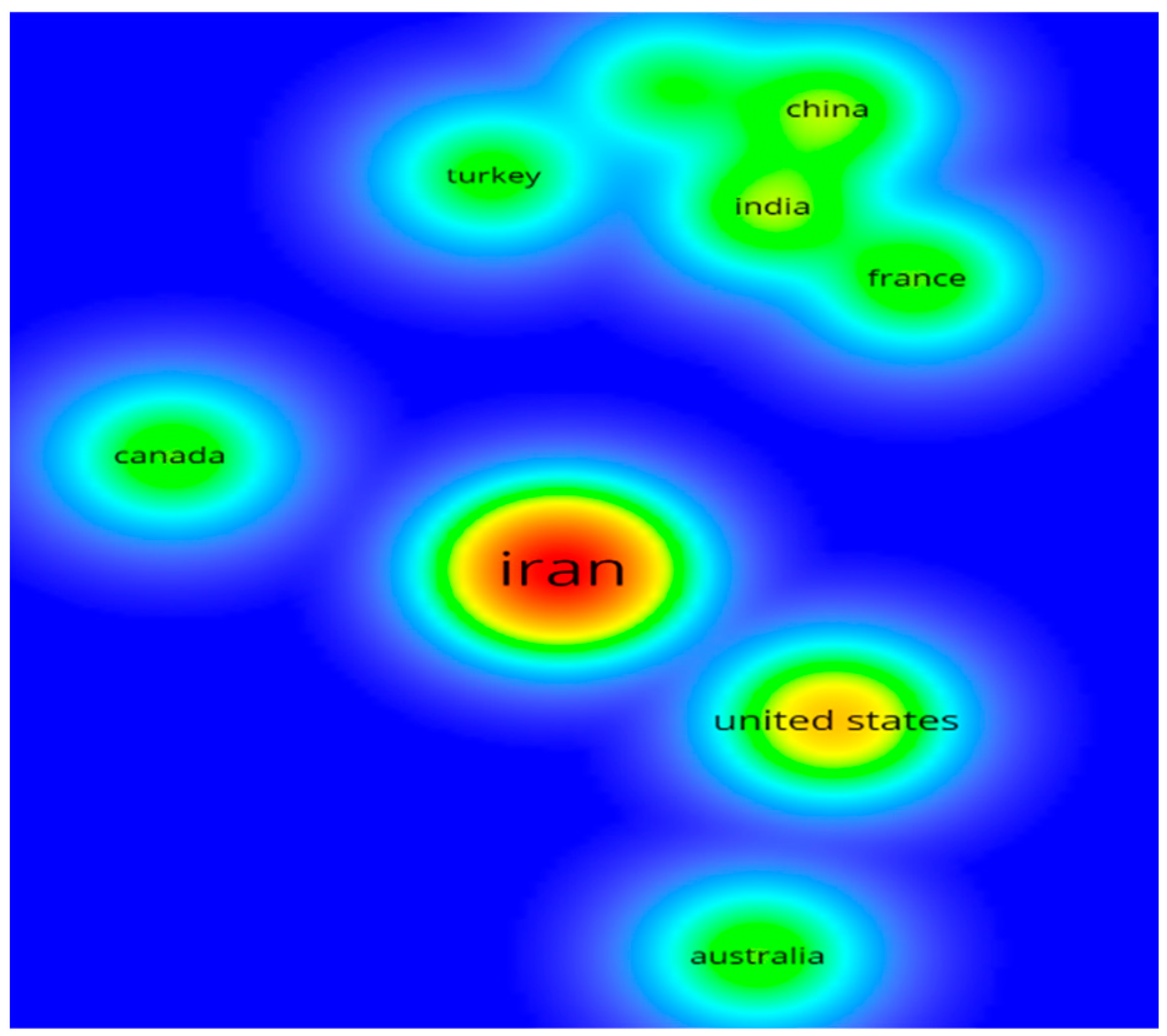

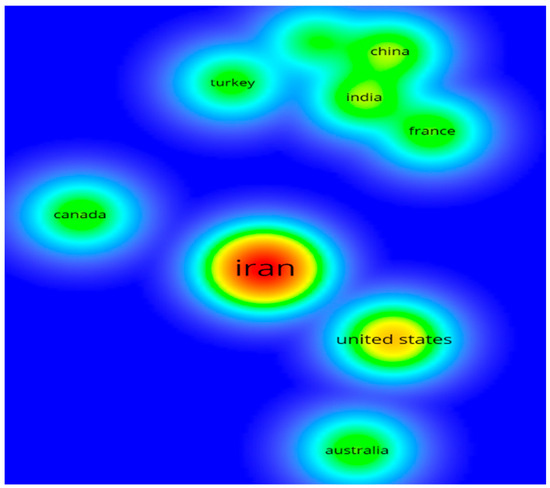

Furthermore, the countries where there was dominance in terms of sustainable SCND optimization research studies were investigated. Figure 2 presents a density visualization of the top 10 dominant countries in terms of number of articles produced. Iran appeared at the top of the list with 49 publications, followed by the United States with 16 publications, and then China and India with 9 publications each. Next, France, Australia, and Canada follow with eight articles each, and then Turkey, the United Kingdom, and Portugal with six, five, and four publications, respectively. In particular, the significant growth in terms of produced research in Iran was discussed by many researchers [14,21,45,46,47], who linked it to the substantial investments in science, research, and development throughout the past two decades. These government efforts dedicate a good portion of the country’s GDP to science and technology, aiming to train researchers and modernize research equipment [46,48,49,50].

Figure 2.

Density visualization of the top 10 productive countries in terms of the number of publications.

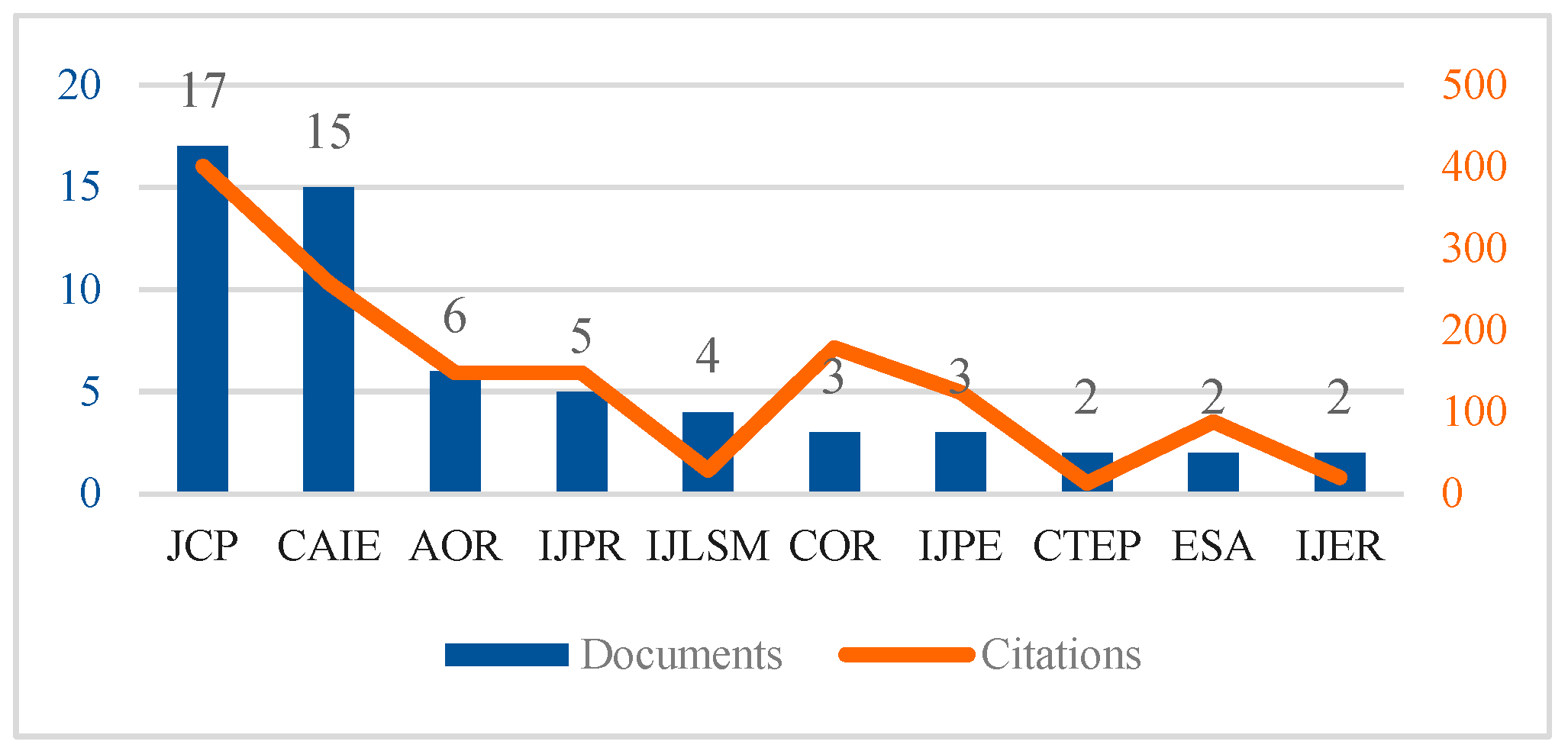

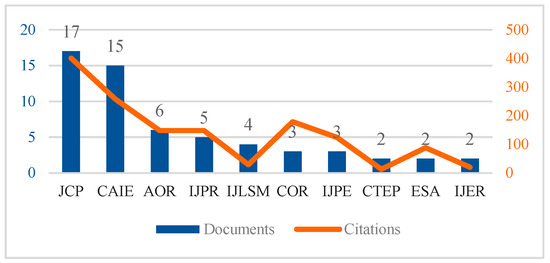

The selected articles for review appeared in a total of 47 journals. The graph of Figure 3 summarizes the top 10 journals in terms of the number of published studies and indicates the number of citations for each. These 10 journals contributed 60% of the selected references for this review. The Journal of Cleaner Production (JCP) occupies the first position; it includes 17 articles that represent about 17% of the total references. This is followed by the Computers and Industrial Engineering journal (CAIE) (15% contribution), Annals of Operations Research (AOR) (7% contribution), International Journal of Production Research (IJPR) (5% contribution), International Journal of Logistics Systems and Management (IJLSM) (4% contribution), Computers and Operations Research (COR) (3% contribution), International Journal of Production Economics (IJPE) (3% contribution), Clean Technologies and Environmental Policy (CTEP) (2% contribution), Expert Systems with Applications (ESA) (2% contribution), and International Journal of Energy Research (IJER) (2% contribution). The rest of the journals in the list include one publication each.

Figure 3.

Top 10 publishing journals in terms of the number of publications and citations.

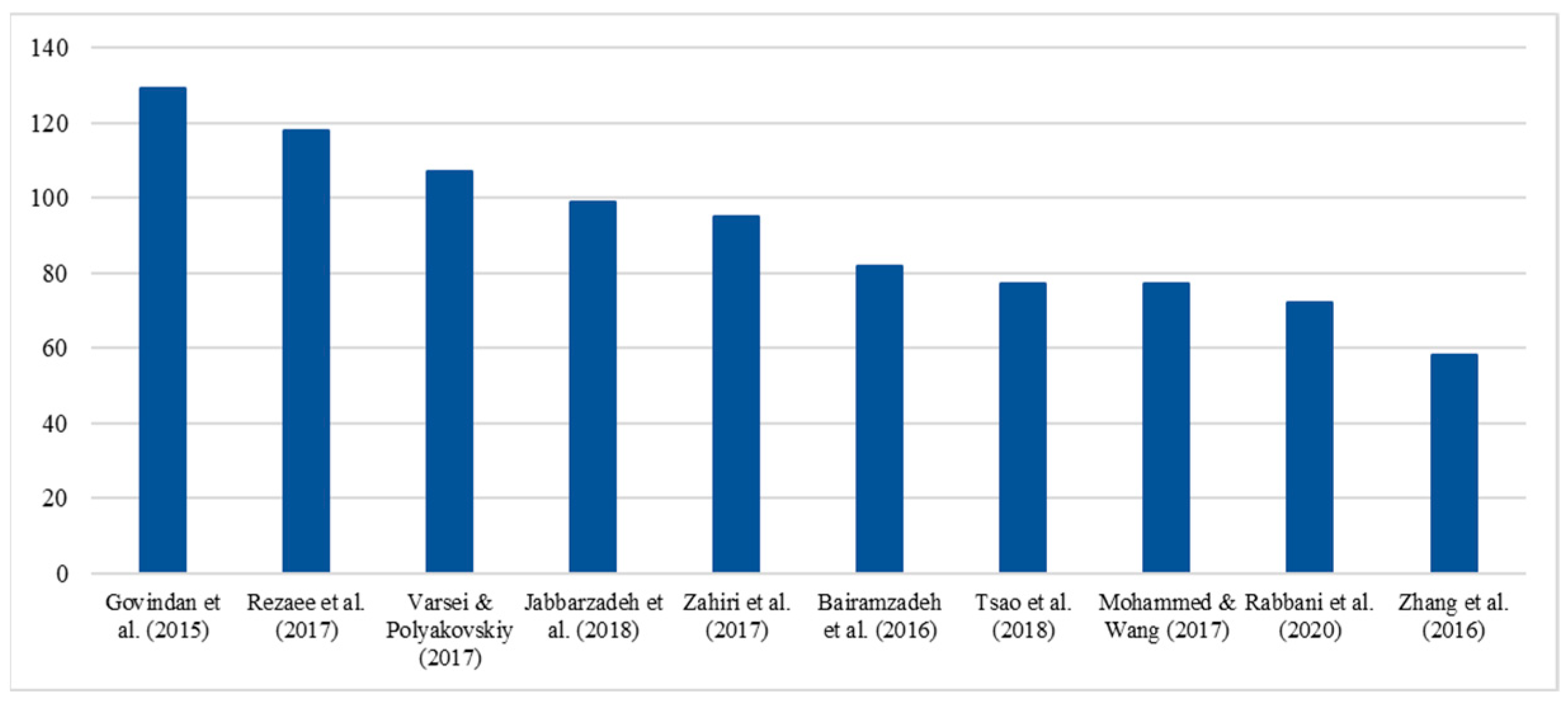

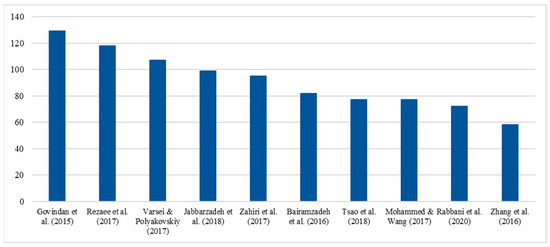

Citation analysis evaluates the frequency of citations and is then used to rank journals and experts in terms of their relevance to current trends in a certain area of research. As a result, citation analysis can offer information about article popularity over time. Strongly cited articles have a greater impact on scientific research than less cited articles [51]. In this context, Figure 4 illustrates the 10 most prominent papers in this field of study.

Figure 4.

The 10 most influential works (in terms of number of citations).

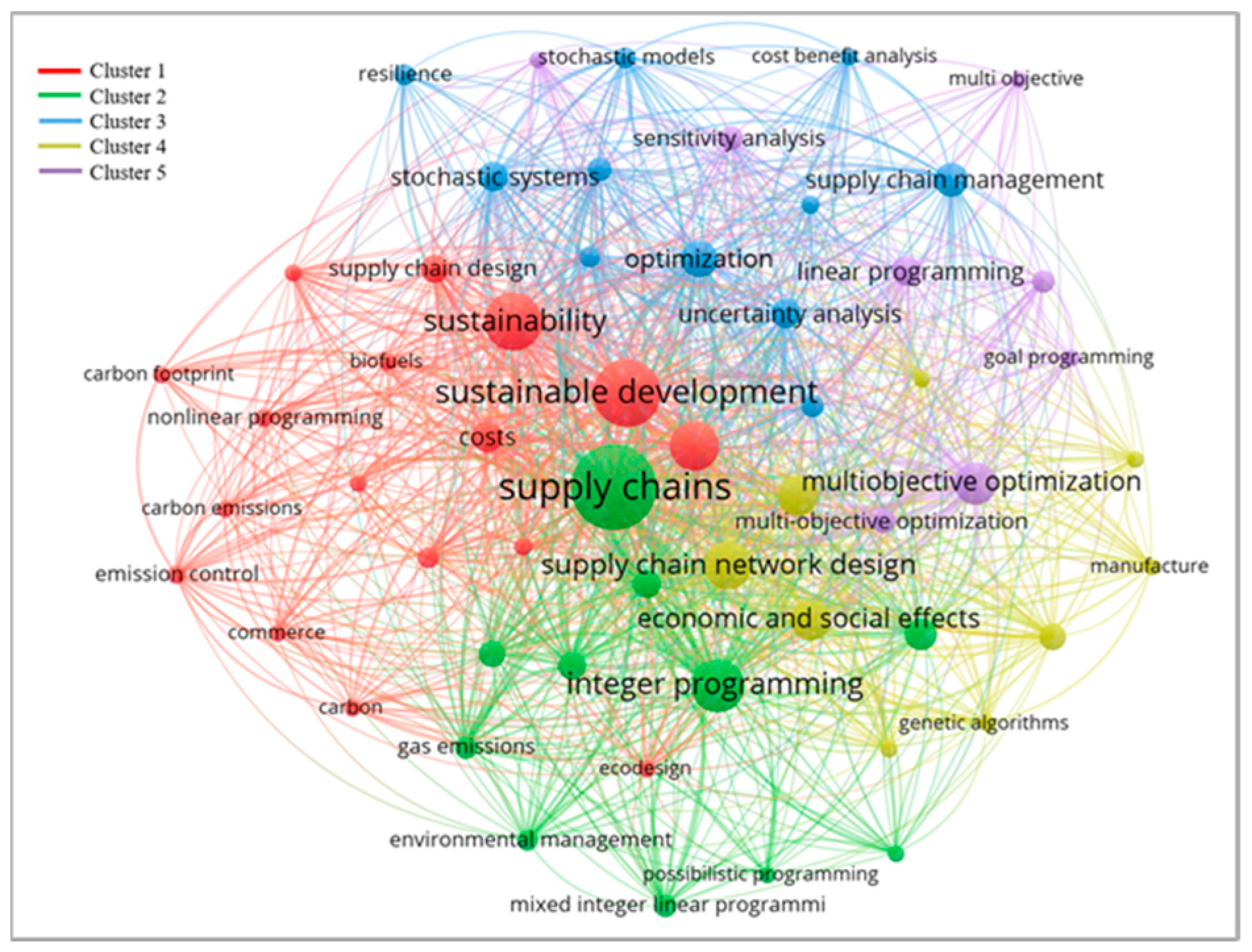

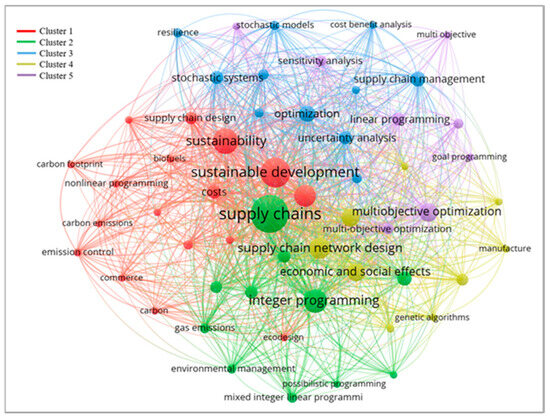

Furthermore, to analyze the authors’ keywords, a co-occurrence network [52] was established. A network node represents an entity such as an article, author, country, institution, keyword, or journal. The size of the node signifies the entity’s occurrence, while the link between the nodes represents the entity’s co-occurrence. The network of all keywords that co-occur at least five times is visualized using the VOS viewer in Figure 5 [53]. Five main clusters have been identified. The first main cluster (red) groups the keywords related to sustainability, which include sustainable supply chain, carbon emissions, costs, sustainable development, biofuels, and others. The second cluster (green) comprises keywords related to mainly green aspects, which include green supply chain, greenhouse gas, environmental impact, and environmental management. The third cluster (blue) groups the keywords linked to modeling techniques, that include mathematical programming and analyses, stochastics models, robust optimization, cost–benefit analysis, and uncertainty analysis. The fourth cluster (yellow) links keywords related to performance and solution methods, which cover decision-making, sustainability performance, economic and social efficiency, genetic algorithms, and particle swarm algorithms. The last cluster (purple) covers keywords related to multi-objective optimization, goal programming, and sensitivity analysis.

Figure 5.

Keyword co-occurrence network analysis conducted based on the 102 selected papers.

In conclusion, the descriptive analysis revealed a sustained growth in sustainable SCND optimization research, with a significant surge in publications in the past three years, demonstrating increased academic interest. The geographical analysis showed a convergence of studies emerging from Iran, followed by the United States, China, and India, highlighting the global span of research in this domain. Additionally, the literature is spread across numerous journals, with JCP and CAIE leading in publication volume. Finally, the visualization of keywords co-occurrences revealed five important clusters. These findings set the stage for an in-depth exploration of the themes and methods characterizing this growing body of work, which is discussed in the subsequent sections.

4. Results and Analysis

4.1. Article Classification

This subsection discusses the category selection phase of the adopted methodology. The surveyed literature is classified according to the criteria described below. Subsequently, various insights are generated based on this classification and are discussed in the next subsections.

Application/Industry: The first category employs the design of a sustainable supply chain network depending on the industry or application. This includes many industries such as food, medical devices, biofuel, electricity, coal, blood, manufacturing, and logistics, among others.

Design factor: The supply chain performance is impacted by the way its drivers are designed. The design factors include, but are not limited to, facility location, inventory, transportation, technologies, and sourcing. These are major design factors found in the reviewed literature, which are listed below.

- Facilities are the physical sites in the supply chain network, where goods are kept, assembled, or created. Decisions on the role, location, capacity, and flexibility of facilities have a substantial influence on the performance of the supply chain.

- The inventory includes all raw materials, work in process, and finished commodities within a supply chain.

- Transportation is the movement of inventory from one point in the supply chain to another. It can take many different modes and routes, each with its own set of performance characteristics.

- Technology has a significant influence on data and analysis about facilities, inventory, transportation, expenses, pricing, and consumers.

- Sourcing includes supplier selection, which is one of the major challenges that helps firms retain a strategically competitive position through operations and procurement management.

When considering the sustainability dimensions, designing these factors considers a distinct strategy owing to environmental, social, and economic considerations.

Decision level: The literature is classified based on the decision level involved in the network design. As mentioned earlier, there are three decision levels, namely, strategic, operational, and tactical. The decision level reflects the selected network design factor. For example, at the strategic level, the allocation, location, transportation modes, and sourcing are determined. The tactical decisions involve distribution capacity, inventory levels, and planning. Finally, short-term scheduling, product flow, and the routing of vehicles reflect the operational decisions.

Supply chain configuration: A variety of supply chain configurations is considered, such as single [54] or multiple periods [55], single [56] or multiple products [57], and the number of levels/echelons involved in the network design of the supply chain [7].

Sustainability dimension: The literature is also classified based on sustainability dimensions which cover economic, environmental, and social aspects [58], and the associated aspects involved in network design. Economic sustainability is a method of conducting economic activities in order to protect and develop long-term economic well-being [35]. In practice, it strives for a balance of economic growth, resource efficiency, and financial stability. Environmental sustainability is the ability to preserve and safeguard the natural environment throughout time, using proper practices and regulations that fulfill current requirements without jeopardizing future resource availability [59]. The focus of social sustainability is on the well-being of individuals and communities [60]. It is about encouraging equity, human rights, educational and healthcare access, and decent jobs.

4.2. Material Evaluation

This subsection analyzes the obtained literature and discusses the strengths and weaknesses of each category of research. The first part considers the sustainability dimensions, followed by the design factors, and the majority of this subsection discusses the mathematical modeling and solution approaches.

4.2.1. Analysis of Sustainability Dimensions

The investigation of sustainability in the context of SCND has grown progressively over the years. The studies analyzed in this paper recognize the multidimensional nature of sustainability and encapsulate its economic, environmental, and social aspects. In the reviewed literature, it is evident that each dimension has its own unique set of challenges and opportunities in this context.

Economic sustainability is the most frequently considered dimension (appearing in 101 studies), as it is central to the viability of any business venture. It broadly pertains to cost reduction and profitability enhancement across the supply chain network. Various factors such as facility location and production allocation often have significant economic implications and are thus consistently investigated in SCND research. Along these lines, studies like Rahimi et al. [6], Zahiri et al. [61], and Shaw et al. [62] have made valuable contributions by creating models to maximize profits, reduce costs, or strike a balance between the two. Secondly, the environmental dimension, appearing in 96 studies, has attracted increasing attention in recent years due to the growing awareness of climate change and other environmental issues. In the SCND context, environmental sustainability primarily involves the reduction of GHG emissions and waste, as well as the efficient use of resources. Several studies ([9,27,63,64]) have shown significant advancements in this area by introducing models to minimize carbon emissions and reduce environmental impact. Finally, social sustainability is the least studied dimension in the context of SCND, being explicitly mentioned in only 46 studies. In particular, the integration of the social dimension with the other two sustainability aspects has occurred in 45 studies. The social dimension involves aspects such as labor conditions, job creation, and social impact on regions. Although less prominent than the other two dimensions, social sustainability is of growing importance in today’s globally interconnected supply chains, where issues such as labor exploitation and social inequality have become increasingly visible [65]. Some of the pioneering efforts have targeted the integration of this dimension into SCND [6,61].

While the increased consideration of sustainability in SCND research is encouraging, the disparity in focus between the three dimensions suggests a need for more balanced and integrated approaches. Future studies should strive to consider all three dimensions of sustainability in their models, or at least explicitly acknowledge and discuss the reasons for focusing on specific dimensions over others. A more comprehensive understanding of sustainability is crucial for the development of truly sustainable SCND models and practices.

4.2.2. Integrating Application Area, Design Factors, and Decision Levels within SCND

With the rapid growth of sustainable SCND, understanding the interaction between its various aspects becomes crucial. There are several application areas, diverse design factors, and multiple decision levels that, when considered collectively, create a complex landscape of considerations, trade-offs, and synergies. Understanding the interplay between these aspects is not just an academic pursuit but a practical necessity for organizations. Nowadays, industries have distinct characteristics that warrant different SCND approaches, as they operate under varying economic, environmental, and social pressures that necessitate different sustainability objectives and approaches. This section uncovers the interplay between these elements and highlights their influence on incorporating sustainability dimensions into SCND.

- (a)

- Application Areas and Their Influence on Design Factors

The influence of application areas on SCND factors is significant and multifaceted. Different industries necessitate diverse approaches to SCND due to their unique characteristics, processes, and sustainability challenges [66]. In this subsection, the emphasis is placed on how these application areas imprint their unique characteristics onto SCND factors.

As a matter of fact, SCND primarily centers on production and inventory management within the manufacturing sector. High-volume manufacturing industries, such as automotive and electronics, face particular challenges related to production scale, efficiency, and waste minimization [67]. For example, in the automobile industry, production design factors such as production capacity and technology selection play a substantial role in shaping the supply chain network [68,69]. Similarly, as claimed by [70], inventory design factors significantly influence the sustainability performance of this type of supply chain. In the logistics sector, transportation and facility factors are paramount. Transportation logistics, with its massive carbon footprint, necessitates strategies to optimize routing, fleet mix, and mode selection to reduce emissions [71]. Facility factors, such as location, capacity, and layout, have significant implications on operational efficiency and environmental impact in warehousing and distribution centers [72].

In the food industry, the balance of production, inventory, transportation, and facility factors is key to ensuring both efficiency and sustainability. Production design factors like yield and waste in farming practices and inventory design factors like shelf-life and spoilage control are pivotal to reducing food waste and ensuring product quality [73]. Transportation factors, including the optimization of routing and temperature control, drastically reduce carbon emissions, ensure food safety, and increase customer satisfaction [74]. Similarly, facility factors, such as the location and capacity of warehouses and retail outlets, directly influence inventory levels, transportation needs, and the environmental footprint of the food supply chain [37,75].

Meanwhile, the service sector, including industries like hospitality and healthcare, displays unique SCND characteristics. In these sectors, the location of facilities, allocation of human resources, and service quality directly affect the sustainability performance of the supply chain network [76]. Unlike other sectors, service industries often demand direct interaction between the provider and the customer, resulting in a distinct set of design factors. In hospitality and healthcare, the location of facilities is not merely a logistical decision, but a strategic consideration, affecting operational efficiency, service accessibility, and local community impact [77]. Furthermore, human resource allocation is more than just meeting demand. It is also about creating an equitable and satisfactory work environment, which contributes to service quality and consistency [78].

- (b)

- Navigating Decision Levels for Sustainable SCND Outcomes

Embedding sustainability considerations into SCND mandates conscious decision-making at all levels [10]. Each of these decision levels presents its own unique set of challenges and opportunities, which requires meticulous navigation to achieve comprehensive sustainable outcomes. Furthermore, understanding the interconnected nature of decision levels within SCND provides important insights into achieving these outcomes. The strategic, tactical, and operational decisions interact in a complex manner with various SCND factors, forming a comprehensive system that influences sustainability performance. These interactions are pivotal in transforming the theoretical principles of sustainability into practical actions within the supply chain network [59].

Firstly, at the strategic level, decisions function as the foundation for integrating the organization’s sustainability principles into the supply chain network. High-impact decisions, such as technology selection, can greatly shape the overall sustainability profile of a supply chain [79]. For instance, within the manufacturing industry, a strategic commitment to more energy-efficient production machinery can lead to reduced energy consumption and related GHG emissions during the equipment’s operational lifespan [80]. Similarly, strategic decisions related to facility location and capacity can lead to significant impacts on the environmental and social outcomes of a supply chain. Such decisions are often influenced by a variety of factors, including, but not limited to, environmental regulations, socio-economic conditions, and the availability of sustainable resources. This, in turn shapes other design factors, like transportation and inventory, which contribute to molding the supply chain’s overall sustainability footprint [81]. Secondly, tactical decisions, generally regarded as mid-term planning activities, reflect the implementation of strategic sustainability goals into actionable plans. At this level, design factors such as production and inventory come to the fore. Tactical decisions related to eco-friendly production planning and green procurement practices serve as key levers in guiding the supply chain toward its sustainability goals [82]. These decisions significantly influence the sustainability performance of the supply chain by setting the stage for more sustainable operations and instilling a culture of sustainability within the organization [83]. In the field of transportation, tactical decisions concerning the selection and optimization of fleet mix or routing strategies directly influence carbon emissions and operational efficiency, which contribute to pushing the supply chain further along the sustainability trajectory [72]. Finally, at the operational level, decision-making often has immediate and tangible effects on the sustainability performance of the supply chain. These decisions typically influence daily operations and include actions such as implementing energy-efficient machine scheduling or waste-minimizing loading techniques. Such operational-level decisions can have a significant impact on design factors related to production and facilities, which contribute to improving resource efficiency and reducing waste. Similarly, in the transportation field, operational decisions such as green routing can optimize fuel usage, reduce emissions, and improve overall transportation efficiency [84].

It is also important to recognize that the decision levels are not isolated; they interact with one another and impact the overall supply chain sustainability. This implies that the strategic, tactical, and operational decision levels are interlinked across various design factors, forming a complex system that can significantly enhance or impede sustainability performance. For instance, a strategic decision to adopt a new sustainable technology would necessitate tactical and operational adjustments to fully realize its benefits. Therefore, decision levels within SCND should be viewed as interconnected layers, each influencing and being influenced by the others. Recognizing this complex interplay is crucial for organizations aiming to navigate toward more sustainable SCND outcomes [81].

In summary, the reviewed literature revealed a progressive incorporation of sustainability considerations within SCND, stressing the economic and environmental dimensions and acknowledging the less-explored social facet. It also articulated the need for industry-specific SCND approaches, shaped by strategic, tactical, and operational decisions to advance sustainability objectives. Building on this foundation, the following section presents the analytical models and computational strategies developed to navigate and optimize the complex interactions of these factors in the pursuit of sustainable SCND.

4.2.3. Mathematical Models

In this section, the major characteristics of the mathematical models for sustainable SCND and the solution procedures are reviewed. There is a great variety in sustainable SCND modeling approaches due to the different supply chain configurations, design factors, the number of objective functions incorporated in the model, and the nature of the inputs (deterministic or stochastic). The sustainable SCND optimization models take into account a wide range of decisions, including facility selection, location, and capacity, transportation mode and technology level selection, storage level, production quantities, and material flow, among others. In addition, the nature of the data (deterministic or stochastic) influences the structure of the optimization model, including the consideration of uncertainties included in some parameters, such as demand level and risk.

This section discusses the types of objective functions considered in the literature on sustainable SCND models, followed by the constraints that reflect the dimensions of sustainability. Afterward, the modeling techniques as well as the solution methods for solving the related optimization problems of the sustainable SCND models are presented.

It is important to note that, in reviewing the mathematical models applied in sustainable SCND, the authors’ intent was not to justify or critique each model in detail but rather to provide a comprehensive view of how these models are employed across different studies. A detailed evaluation of these models could provide a solid foundation for further theoretical development and practical application, and a compelling direction for future research.

- (a)

- Objective Functions

Sustainability aspects can be included in the objective function by concentrating on one dimension (single objective) or many dimensions simultaneously (multiple objectives). In some situations, multiple dimensions can be integrated into a single objective by turning non-homogeneous units into a single unit using conversion factors [85].

Single Objective: SCND may incorporate a single sustainability dimension in the objective function, while the constraints represent other dimensions. The related literature is presented according to the dimension of sustainability that is considered in the objective function. In addition, Table 1 summarizes the literature on sustainable SCND with a single objective. Given the results of Table 1, the following insights are drawn.

Economic dimension: The majority of the related literature considers the economic dimension as the objective function while representing the environmental [9,62,86,87], or environmental and social dimensions [88,89], in terms of constraints. The economic objectives mostly consider the cost aspect, such as minimizing the total supply chain cost, which may include capital [72], operational [31,90], production [85], distribution [91], and transportation costs [92].

The consideration of other economic objectives such as profit and market share rarely exists. For example, Lucía et al. [89] considered the maximization of the market value added as a measure of the accumulated economic performance.

The combination of social and environmental sustainability dimensions may occur in the economic objectives. For instance, Ren et al. [85] considered the cost of carbon emissions to be embedded into the objective function, while Costa et al. [16] focused on optimizing global profitability, including economic benefits and environmental credit.

Table 1.

Sustainable SCND models with a single objective and related sustainability dimensions.

Table 1.

Sustainable SCND models with a single objective and related sustainability dimensions.

| Article | Sustainability Dimension | ||||||

|---|---|---|---|---|---|---|---|

| Economic | Environmental | Social | |||||

| C | P | O | E | O | CSW | O | |

| [93] | ✓ | ||||||

| [74] | ✓ | ✓ | |||||

| [86] | ✓ | ✓ | |||||

| [94] | ✓ | ✓ | |||||

| [9,15,24,31,62,72,85,87,90,91,92,95,96,97] | ✓ | ✓ | |||||

| [88] | ✓ | ✓ | ✓ | ✓ | |||

| [89] | ✓ | ✓ | ✓ | ||||

| [16] | ✓ | ✓ | ✓ | ||||

| Total | 18 | 1 | 1 | 18 | 3 | 2 | 2 |

C: cost; P: profit; E: emissions; CSW: community safety and welfare; O: other.

Environmental dimension: It is worth mentioning that minimizing carbon or GHG emissions is widely considered in addressing the environmental burden of SCND. This is due to the fact that many researchers and industries have been motivated by the worldwide awareness of sustainability and environmental preservation to design a green and low-carbon supply chain network. Other researchers tackle the environmental design of a supply chain from different perspectives, such as the inclusion of renewable energy sources [94], water footprint and solid waste [88], and the production of biodiesel as a source of energy [16].

Social dimension: The social aspect is limitedly addressed in the surveyed literature. For example, Granillo-Macías [74] designed a food supply chain that involves economic and social factors. The objective function minimizes the cost of vehicle travel, the fixed cost for the use of vehicles, and the penalty that may be incurred for failing to meet breakfast delivery deadlines. Das et al. [88] considered the suppliers’ social risk in designing a sustainable supply chain network.

The inclusion of uncertainty sources is required for a real-life design of a supply chain network. According to Gao and You [96], uncertainties are prevalent in SCM and inherent in quantitative evaluations of SCND, and without properly managing them, both the optimality and feasibility of a SCND can be readily compromised. Quddus et al. [87] presented a two-stage stochastic mixed-integer linear programming (MILP) model to build and operate a sustainable multi-purpose pellet-processing facility under feedstock seasonality and uncertainty. Ren et al. [85] combined the life cycle assessment with SCM while considering the carbon price uncertainty in a pipe manufacturing industry by introducing a stochastic MILP model to design and plan the network. Similarly, Gao and You [96] incorporated stochastic programming to address the design and operational decisions under the uncertainty of a biofuel SCND. Das et al. [88] accounted for the uncertain environment of a multi-product and multi-echelon SCND through characterizing the demand and capacity as stochastic variables.

Multiple Objectives: Sustainable SCND optimization models with multiple objectives are widely adopted in the existing literature. In this review study, it is found that the majority of these models are bi-objective linear models, often focusing on economic and environmental objectives. Table 2 presents the literature on sustainable SCND models with two objectives. It is evident that the most common economic objective is cost reduction, while environmental objectives mainly focus on minimizing carbon and GHG emissions. This observation aligns with the findings presented in Table 1. Eskandarpour et al. [66] proposed a model to minimize logistics costs and carbon emissions in a SCND problem with multiple layers of facilities, technology levels, and transportation mode decisions. Mogale et al. [98] developed a bi-objective decision support model for a sustainable food grain supply chain that takes into account an entire network of procurement centers, state, and district warehouses, with fair pricing shops. Farazmand et al. [71] designed a green dynamic rail–road logistics network that takes into account both the financial and developmental aspects of the railway system. The aim is to minimize the total transportation cost across the multimodal network and the associated emissions from transportation activities. Gupta et al. [75] proposed a fuzzy model for joint storage facility site selection, the determination of appropriate storage conditions, and the transportation of agricultural produce between different sites while minimizing cost and food loss. Guo et al. [99] suggested a decomposition strategy for solving a large and multi-echelon supply chain to minimize the sum of procurement, production, transportation, and operational costs, as well as the sum of carbon emissions and water consumption.

Limited research demonstrates the consideration of profitability as an objective alongside environmental considerations [5,100,101,102,103,104,105,106,107]. For instance, the problem of electricity SCND using a smart grid and a bi-objective robust optimization method that maximizes profit and reduces GHG emissions has been addressed by Jabbarzadeh et al. [5]. Similarly, ecosystem network analysis was utilized to assess the resilience during the design of a sugar beet supply chain, that aims to maximize profit and minimize GHG emissions during transportation and production [107]. Furthermore, a robust possibilistic programming model for the design and planning of a pistachio supply chain in an uncertain environment, considering the maximization of profit and reduction of environmental effects, was proposed by [105].

Table 2.

Sustainable SCND models with multiple objectives and economic-environmental dimensions.

Table 2.

Sustainable SCND models with multiple objectives and economic-environmental dimensions.

| Article | Sustainability Dimension | |||||

|---|---|---|---|---|---|---|

| Economic | Environmental | |||||

| C | P | E | E/W | EI | O | |

| [7,14,20,54,56,57,66,69,98,108,109,110,111,112,113,114,115,116,117,118,119] | ✓ | ✓ | ||||

| [5,100,101,102,103,104,105,107] | ✓ | ✓ | ||||

| [34] | ✓ | ✓ | ||||

| [76] | ✓ | ✓ | ✓ | |||

| [75] | ✓ | ✓ | ||||

| [99] | ✓ | ✓ | ✓ | |||

| [106] | ✓ | ✓ | ||||

| [120] | ✓ | ✓ | ||||

| [22] | ✓ | ✓ | ||||

| Total | 29 | 9 | 32 | 2 | 4 | 2 |

C: cost; P: profit; E: emissions; E/W: energy/water consumption; EI: environmental impact; O: other.

Table 3 consolidates the sustainable SCND models with multiple objectives involving the three sustainability dimensions. Many of these optimization models are deterministic, with three objectives reflecting the aspects of sustainability. A multi-product and multi-period supply chain network with simultaneous pick-up and split delivery was designed by Abdi et al. [29] to reduce total cost and environmental pollution and increase customer satisfaction. Also, a multi-objective mathematical model was developed to design a natural gas supply chain network, with a focus on sustainable development goals [32]. In particular, the economic objective minimizes the supply chain’s total cost, while the environmental aspect is related to GHG emissions, electricity, gas and water consumption, and wastewater generation. Finally, the social objective maximizes the social impacts in terms of employment, balanced economic development, employee welfare, employee safety, customer cost risk, and operational environment risk. For example, a multi-objective model was proposed to configure a sustainable SCND, while maximizing resilience and responsiveness measures and minimizing total cost and environmental damages [121]. In addition, Jabbarzadeh et al. [122] considered the design of a sustainable supply network that performs resiliently with the inclusion of random disruptions, while maximizing environmental and social performances and minimizing the expected total cost.

It is worth noting that employment is the main indicator of social sustainability that is considered in the literature. Customer satisfaction is rarely addressed as a social indicator, which is perceived to be achieved by imposing penalties on violating time windows [123], reducing the number of expired products and their shortage [23], and meeting the demand [124]. Other social indicators include increasing customer service coverage [77], minimizing accidents [125], reducing traffic congestion [126], enhancing social responsibility [55], balancing driver’s workloads [63], and increasing dietary health [127].

Only a few studies have incorporated more than three objectives into their sustainable SCND optimization models. For instance, Fragoso and Figueira [128] developed a decision support system for sustainable SCND, taking into account a unique solution approach based on scalarizing functions. Their MILP model includes four objective functions, which are maximizing profit and revenue, minimizing cost, minimizing GHG emissions and water consumption, and maximizing employment and the number of suppliers and facilities. In another research, the added value of including environmental impact and social responsibility factors in SCND problems was demonstrated [125]. The model specifically targets four objectives: a cost-based objective, an environmental objective concentrating on carbon emission, exhaust emission, wastewater discharge, and solid waste discharge, and two social objectives (i.e., employment and accident rate). Fragoso et al. [33] investigated a regional supply chain network in the fishing industry and presented a multi-objective model with six objectives, four of which are economic, one environmental, and one social. Finally, a unique mathematical model for an integrated strategic-tactical SCND problem to quantify the concurrent effects of resilience and sustainability was proposed [129]. The model considers reducing economic indicators and environmental impacts as well as maximizing social responsibility and resilience level.

The inclusion of uncertainty has been addressed in a few studies in this area [6,8,28,55,61,123,130,131]. Some formulations have considered new social and environmental considerations in location-allocation supply chain models while using a novel robust approach to overcome the uncertainty of parameters [123]. Other studies provided an optimization strategy for uncertain conditions and the material quality effect based on a state task network formulation [130], or introduced a risk-averse multi-objective mathematical model for designing and planning a supply chain network under uncertainty by including conditional value at risk [6]. Finally, Zahiri et al. [61] presented an integrated resilient multi-objective optimization model for developing the supply chain network, while taking into account perishability, food waste valuation, and supply uncertainty.

In addition to the objective functions, sustainability dimensions could potentially be included in the mathematical constraints. Next, a list of constraints related to the sustainability dimensions found in the reviewed literature is provided.

Table 3.

Sustainable SCND models with multiple objectives and all sustainability dimensions.

Table 3.

Sustainable SCND models with multiple objectives and all sustainability dimensions.

| Article | Sustainability Dimension | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Economic | Environmental | Social | ||||||||

| C | P | E | E/W | EI | O | J | S | SI | O | |

| [29] | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| [32] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| [21,28,30,47,131,132,133,134] | ✓ | ✓ | ✓ | |||||||

| [128] | ✓ | ✓ | ✓ | ✓ | ||||||

| [33] | ✓ | ✓ | ✓ | ✓ | ||||||

| [77] | ✓ | ✓ | ✓ | |||||||

| [125] | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| [12,135,136,137] | ✓ | ✓ | ✓ | |||||||

| [126] | ✓ | ✓ | ✓ | |||||||

| [8,138,139] | ✓ | ✓ | ✓ | |||||||

| [27,61,140] | ✓ | ✓ | ✓ | |||||||

| [141] | ✓ | ✓ | ✓ | |||||||

| [121] | ✓ | ✓ | ✓ | |||||||

| [23,123] | ✓ | ✓ | ✓ | |||||||

| [142] | ✓ | ✓ | ✓ | |||||||

| [129] | ✓ | ✓ | ✓ | ✓ | ||||||

| [45] | ✓ | ✓ | ✓ | ✓ | ||||||

| [55] | ✓ | ✓ | ✓ | ✓ | ||||||

| [130] | ✓ | ✓ | ✓ | |||||||

| [17] | ✓ | ✓ | ✓ | ✓ | ||||||

| [122] | ✓ | ✓ | ✓ | |||||||

| [63] | ✓ | ✓ | ✓ | ✓ | ||||||

| [6] | ✓ | ✓ | ✓ | |||||||

| [127] | ✓ | ✓ | ✓ | |||||||

| [124] | ✓ | ✓ | ✓ | ✓ | ||||||

| [143] | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Total | 35 | 6 | 30 | 9 | 3 | 7 | 25 | 6 | 7 | 9 |

C: cost; P: profit; E: emissions; E/W: energy/water consumption; EI: environmental impact; J: job creation; S: satisfaction; SI: social impact; O: other.

- (b)

- Constraints

The sustainability considerations can be reflected not only in objective functions but also in the constraints, as provided by a few studies in the literature. Nevertheless, the economic dimension is considered in objective functions only. Therefore, the list of constraints considered in the surveyed literature that reflect the environmental and social dimensions is provided below.

Environmental Element:

- The fixed carbon emissions for operating plants and warehouses as well as the variable carbon emissions across the supply chain operations (transportation, handling, and manufacturing) must be within the maximum carbon footprint imposed on the supply chain network [88].

- The water footprint across the supply chain network must not exceed the maximum water footprint cap [88].

- The solid waste generated over the supply chain network should be below the maximum solid waste cap [88].

- The carbon emissions produced must not exceed the maximum carbon emissions from the transportation activities between supply chain echelons [9,89] or the production and shipping of manufactured products [56], or transportation and operation activities [86].

- The total GHG emissions from transportation activities and the emission of the consumed diesel fuel must be within the maximum permitted GHG emissions [15].

- Monitoring carbon emissions across the supply chain network through a carbon-trading mechanism that permits the selling and purchase of carbon credits [87,92].

Social Element:

- The procurement of materials must be carried out through a supplier that conforms to a minimum social sustainability index [88]. The social index is composed of indicators related to discrimination, human rights abuse, child labor, long working hours, and compensation.

- The average human development index for opening facilities must be within the average of all human development indices of all candidate facilities [89]. The human development index contains three issues of human development which are health, education, and economic welfare.

- The selection of a manufacturer is based on a social score that is obtained through the analytic hierarchy process (AHP) method, considering criteria of insurance, employment, dismissals, rest periods, safety, health, and the welfare status of employees [12].

In summary, this review has delineated the complexity of sustainable SCND through various models that integrate environmental, economic, and social dimensions. Studies typically strive to optimize across these dimensions, with common objectives including cost minimization, profit maximization, emission reduction, and the enhancement of social welfare. Certain works extend to multi-objective models that tackle specific industry challenges, like the design of resilient supply networks in the face of disruptions, while considering perishability, waste, and uncertainty. Key environmental constraints are applied to limit carbon footprints, solid waste, and GHG emissions, with mechanisms like carbon trading introduced to monitor and control emissions. Social sustainability is incorporated through adherence to standards and indexes that assess human rights, labor practices, and community impacts. With this framework of objectives and constraints in mind, the subsequent discussion focuses on the solution approaches. Therefore, the next section explores the various methodologies and techniques employed to solve the optimization problems presented in sustainable SCND.

4.2.4. Modeling Solution Approaches

The goal of this subsection is to identify the modeling techniques, solution approaches, and solvers utilized for solving sustainable SCND models. Due to the NP-hard nature of SCND optimization problems, a wide range of solution strategies may be applied to solve them [144]. Various modeling techniques are taken into account in the context of sustainable SCND. Modeling techniques are optimization models that represent the type of decision variables (integer, binary) and the problem’s linearity or nonlinearity. They include linear programming (LP), MILP, nonlinear programming (NLP), mixed-integer nonlinear programming (MINLP), stochastic programming, and more. Additionally, the reviewed literature consists of a variety of approaches for solving sustainable SCND optimization problems. These include exact solutions, heuristic/metaheuristic solutions, hybrid approaches, and other solution strategies.

In this section, the single-objective models are covered first, followed by multiple-objective models, and ultimately the tools needed to solve these optimization models.

- (a)

- Models with a Single Objective

The majority of single-objective models are formulated as MILP that are either deterministic models [74,86,90,91,92,93] or stochastic models [15,62,85,87,88], and are mostly solved using exact solution methods. Table 4 summarizes the solution methods for sustainable SCND with a single objective. Kabadurmus and Erdogan [92] introduced a MILP model for the multi-echelon, multi-product, and multimodal SCND problem with a constrained carbon cap-and-trade scheme and risk limit. The model was evaluated using a hypothetical but realistic case study. Ghelichi et al. [15] addressed the network design optimization of a multi-period and multi-product biodiesel supply chain through developing a two-stage stochastic programming model that considers uncertain fuel demand. A MILP formulation was introduced and tested in a case study in Iran. Das et al. [88] considered the demand and capacity uncertainties in the design of the sustainable supply chain network. The study used chance-constrained programming to transform the model into a deterministic MILP, which was then solved in order to find the optimum configuration of SCND. Ren et al. [85] incorporated the life cycle emissions and carbon price uncertainty into the design of a polyvinyl chloride supply chain and developed a stochastic MILP to cope with the existing uncertainties. A case study was conducted to establish a supply chain model with stochastic inputs and evaluate the effectiveness of the proposed model. A few of these MILP models are solved using other methods. For example, Quddus et al. [87] developed a hybrid decomposition approach that combines the sample average approximation with an improved progressive hedging algorithm to solve the proposed two-stage stochastic MILP model with supply uncertainty. Shaw et al. [62] employed the Benders decomposition method to solve the chance-constrained MILP model that handles various uncertainties related to suppliers’, plants’, warehouses’, and demands’ capacities. Granillo-Macías [74] solved the vehicle routing problem of a logistics network considering economic and social pillars of sustainability by employing the adaptive large neighborhood search algorithm (ALNS) that is assessed on instances with up to 100 customer nodes.

The MINLP representation of SCND is applied in different studies [89,94,95], where exact and heuristic solution methods are employed to tackle optimization problems. Lotfi et al. [94] studied sustainable SCND considering renewable energy and proposed a two-stage robust stochastic optimization for locating facilities and determining the type of used energy and the flow quantity among supply chain entities. Some other studies considered the network design problem to be expressed as MINLP that is first linearized and then solved. For instance, Alharbi et al. [95] designed a schedule for a sustainable container supply chain network and proposed a MINLP mathematical formulation to address the nonlinear objective function, which is first linearized and then solved using an iterative optimization method. Lucía et al. [89] developed a MINLP mathematical formulation to encounter the nonlinearity of some constraints related to economic sustainability and an optimization-based primal heuristic, based on weighted cost calculations, designed to solve the model.

Other modeling techniques involve extended goal programming (GP), which is applied in some cases to develop a macro-location model for a biodiesel-sustainable SCND [16].

Table 4.

Solution methods for sustainable SCND models with single objectives.

Table 4.

Solution methods for sustainable SCND models with single objectives.

| Solution Method | Articles |

|---|---|

| Stochastic programming | [15,85] |

| Constrained programming | [88] |

| Decomposition approach | [62,87] |

| Heuristics/Metaheuristics | [74,89,94,95] |

- (b)

- Models with Multiple Objectives

Several solution methods are deployed to solve the SCND optimization models with multiple objectives. In this subsection, each category of solution methods is discussed.

Different metaheuristics are employed, owing to the fact that these optimization models are complex and exact solution methods cannot provide the optimum configuration of a SCND in a reasonable timeframe. The non-dominated sorting genetic algorithm II (NSGA-II) to solve the optimization models was employed in [21,115,116,124]. For instance, the NSGA-II was developed to address the network design of a sustainable capacitated facility location problem that aims to minimize supply chain costs and environmental impacts [116]. Another solution method based on the particle swarm optimization (PSO) algorithm was adopted in [26,54,111]. PSO was used to solve a MILP model that minimizes cost and GHG emissions arising from location-allocation decisions of a green supply chain [111]. The simulated annealing (SA) metaheuristic was adopted as a solution method in [7,106]. The SA algorithm was used to tackle the non-convex nature of a mixed-integer bi-level programming model for their sustainable SCND [7]. It was also adopted in [106] as a multi-start SA algorithm, where the algorithm’s performance is measured by comparing its Pareto frontier to the exact Pareto frontier through studying a set of performance metrics.

Some studies integrated two or more algorithms to enhance the performance of the proposed solution methods. For instance, the NSGA-II and PSO algorithms were combined to solve MINLP optimization models that include facility location, transportation, and routing decisions [63,98]. The hybridization of NSGA-II and genetic algorithms (GA) was considered in some cases [30,77,100] while [69] combined GA, PSO, and evolutionary algorithms (EAs) to solve the stochastic programming model. Multiple metaheuristic algorithms including SA, PSO, and NSGA-II were utilized to solve a multi-objective stochastic programming model [141]. A multi-product vehicle routing problem with time windows was tackled by developing three swarm intelligence metaheuristics that were hybridized with the variable neighborhood search (VNS) algorithm [17]. For benchmarking purposes, these algorithms were compared to GA and VNS algorithms based on their Pareto frontier. A hybrid heuristic was developed by Hasani et al. [101], that incorporates ALNS and the improved strength Pareto EA algorithm 2 (SPEA2). Other researchers developed metaheuristic solutions including large neighborhood search (LNS) with multi-directional local search (LS) [66], hybrid firefly algorithm and SA [76], swarm intelligence and artificial bee colony (ABC) [120], multi-neighborhood descent traversal algorithm [125], SA and red deer algorithm (RDA), and hybrid GA-PSO [29].

The ɛ-constraint method is applied to multi-objective optimization models, where one objective function is prioritized and optimized, while other objective functions are incorporated in the constraints of the model [145]. In other words, the other objectives are bounded by the means of additional constraints given as ɛ in order to obtain the Pareto optimal set [146]. In addition to that, a substantial number of non-extremely efficient solutions that are helpful to decision-makers can be produced using the ɛ-constraint method [71]. The majority of the literature considers the economic objective as the main objective function of the model, while the environmental and social objectives as constraints. Attari and Torkayesh [14] converted a multi-objective MIP model that targets economic and environmental aspects into a single objective through representing the environmental criterion in the ɛ-constraint, and the resulting solutions were the Pareto optimal of the multi-objective problem. Similarly, Ghomi-Avili et al. [146] used the ɛ-constraint method to convert a bi-objective MINLP model into a single function. Also, Rahimi et al. [6] applied the same method to a multi-objective MINLP model to obtain the Pareto optimal solutions.

The augmented ɛ-constraint effectively searches the Pareto frontier and generates a uniform set of Pareto points in the design space. It is also an improved version of the conventional version of the ɛ-constraint described above. The method is utilized in models such as bi-objective MILP models [71,109], multi-objective MILP models [27,122,123,124,131,139,140], multi-objective NLP models [132], and multi-objective stochastic MILP models [8], which are then solved using exact solvers or metaheuristics.

Another approach to address problems with multiple objectives is through GP. This method searches for the best possible outcomes, which minimizes deviations from predefined goal values for one or more objectives [133]. A limited number of studies consider the use of GP [108,112,114,126,133,136]. For example, the method of GP was considered to develop a trade-off solution for three conflicting objectives of sustainability, using decision makers’ preferences to decide the ranking of the distinct goals [112]. In another study, GP was compared against the ɛ-constraint and LP-metrics methods in terms of obtaining the Pareto solutions of a linear programming model with four objectives [114]. The results demonstrated the effectiveness of the ɛ-constraint method over the other two methods.

Several fuzzy solution approaches are considered in multi-objective models. Sazvar et al. [129] constructed a robust fuzzy optimization approach to cope with uncertainties. Then, the multi-objective model was solved by applying multi-choice GP with a utility function approach. Tsao et al. [28] used an interactive method based on two-stage stochastic programming and fuzzy probabilistic multi-objective programming to overcome problems related to uncertainty. Zahiri et al. [61] provided a novel fuzzy possibilistic-stochastic programming approach and solved the model through a new Pareto-based lower bound method as well as an EA-based algorithm. Gholipour et al. [34] applied a fuzzy solution strategy on a bi-objective mathematical model by considering the fuzzy membership function. Balaman et al. [102] combined the fuzzy set theory and the ɛ-constraint method in order to address the uncertainties of economic and environmental sustainability aspects, while also capturing the trade-off between the two objectives.

Other methods are introduced and used to solve the multi-objective optimization models [12,23,32,33,108,121,128,130,142,143]. Sharefati et al. [12] utilized multi-criteria decision approaches to examine the three pillars of sustainability and identify certain indicators related to the social element. The work conditions indicator was specifically measured through a set of criteria, with a social score obtained for each criterion using the AHP technique, which influences the selection of a manufacturer. Another method, known as the technique for order preferences by similarity to ideal solution (TOPSIS), is used to calculate each region’s growth potential in terms of societal community development. The results of these methods are incorporated into the mathematical model. Heidari-Fathian and Pasandideh [23] developed an algorithm based on the Lagrangian relaxation approach to solve the MINLP model. Fragoso et al. [33] considered a multi-objective MIP model for a regional supply chain network in the fish processing industry. The model and decision-making process were examined using interactive decision maps to approximate and visualize the Pareto frontier in criteria space. Isaloo and Paydar [108] employed three exact solution approaches to solve a robust bi-objective SCND with environmental concerns. These methods included the weighted sum of objectives, weighted goal programming, and the LP-metric method. The weighted sum of objectives approach is one of the most common approaches used in multi-objective models, which is based on assigning a weight to each criterion and then minimizing the weighted total of all criteria [35]. Nayeri et al. [121] developed a new version of meta-goal programming, called the multi-choice meta-goal programming, associated with a utility function to solve the resulting multi-objective MIP model. Fragoso and Figueira [128] formulated and solved a multi-objective MIP model using the reference point method and a scalarizing function approach. Medina-Gonzalez et al. [130] offered an alternative technique based on a State Task Network formulation that can optimize under unknown conditions, take into account numerous selection criteria, and account for the material quality effect. The resulting collection of Pareto solutions were then evaluated using the Elimination and Choice Expressing Reality-IV approach, which identifies the ones with the best overall performance, when the parameters are unclear. Sabouhi et al. [142] provided a multi-period MILP model that uses the k-means clustering method to assess the sustainability performance of regions, and then solve the model using the Benders decomposition method. Table 5 summarizes the aforementioned solution methods for multi-objective models.

Table 5.

Solution methods for sustainable SCND models with multiple objectives.

- (c)

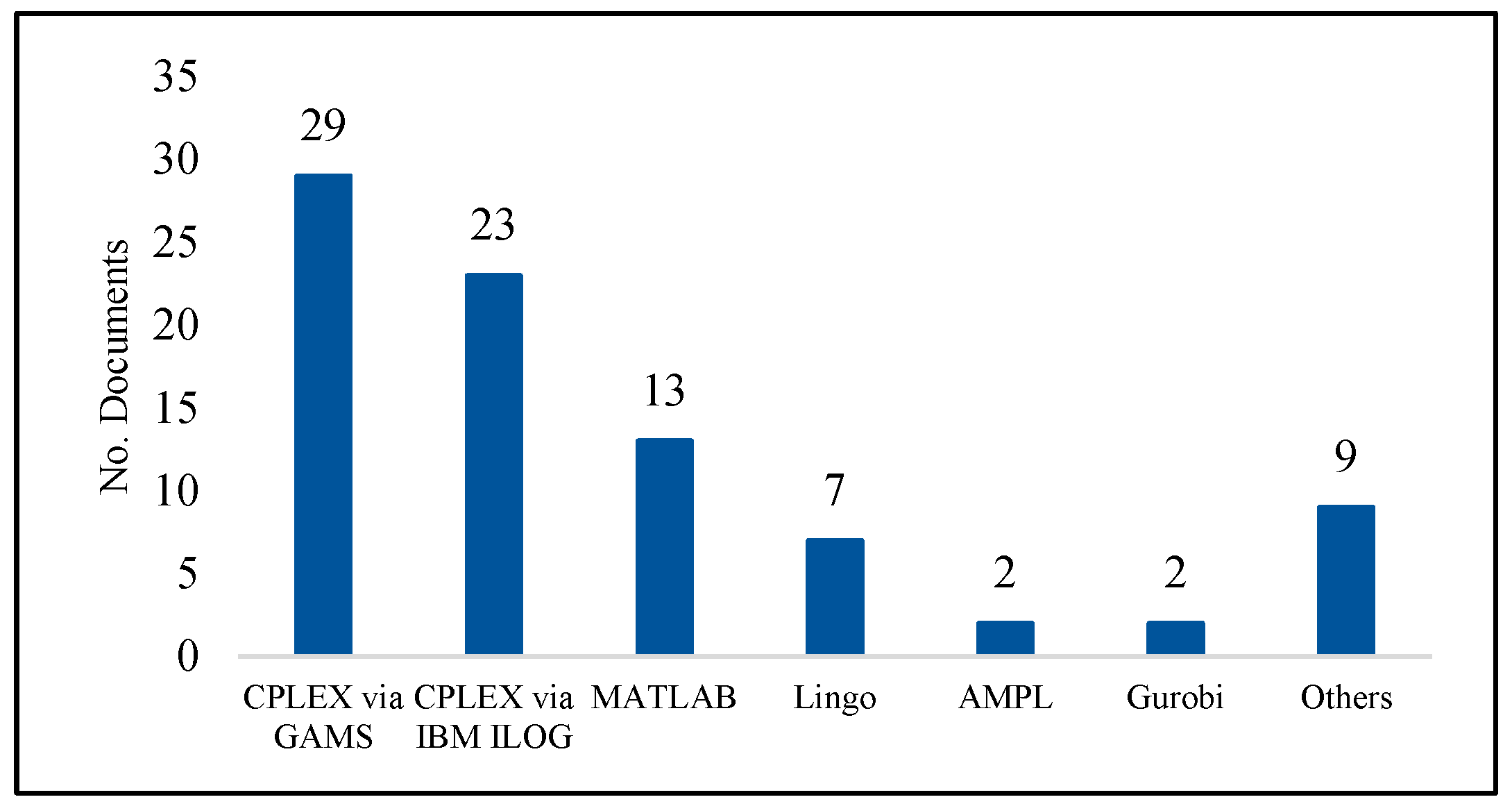

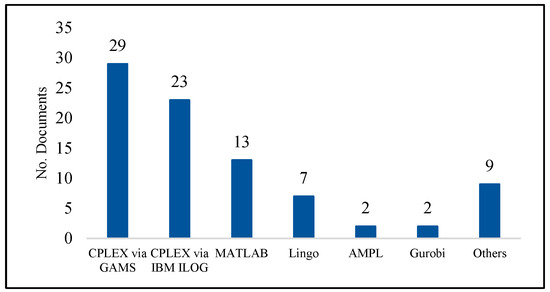

- Solvers