Unveiling Environmental Influences on Sustainable Fertilizer Production through Insect Farming

Abstract

1. Introduction

- The integration of the response surface methodology (RSM) and Internet of Things (IoT) technology to optimize black soldier fly larvae (BSFL) entomocomposting process (based on environmental factors) in the production of high-quality frass fertilizer.

- Implementation of a data-driven solution to discern important environmental variables that influence the nutrients generated in the BSFL composting process.

- Proposing a sustainable resilient framework for organic waste valorization and management through BSFL-driven recycling systems toward a circular economy.

2. Materials and Methods

2.1. Frass Fertilizer Production Experiments

2.2. Design of the Response Surface Methodology (RSM)

- y is the predicted response level;

- is the constant coefficient;

- is the coefficients of linear terms;

- is the interaction coefficients;

- is the coefficients of quadratic terms;

- , are the values of the experimental variables.

2.3. Model Fitting and Evaluation

- RSS is the sum of squares of residuals;

- TSS is the total sum of squares;

- n is the number of observations;

- k is the number of independent variables;

- SS is the sum of squares;

- DF is the degree of freedom.

3. Results

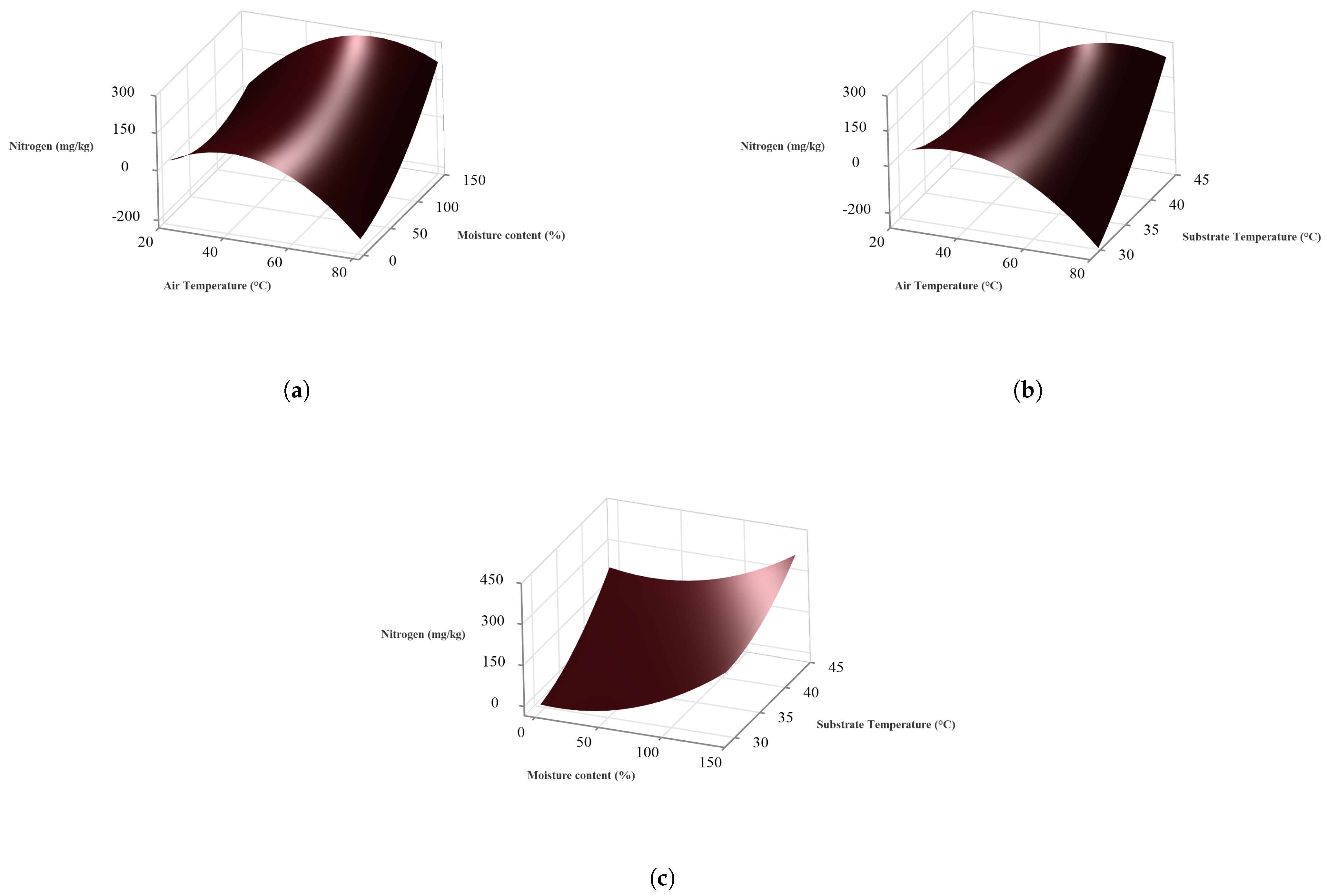

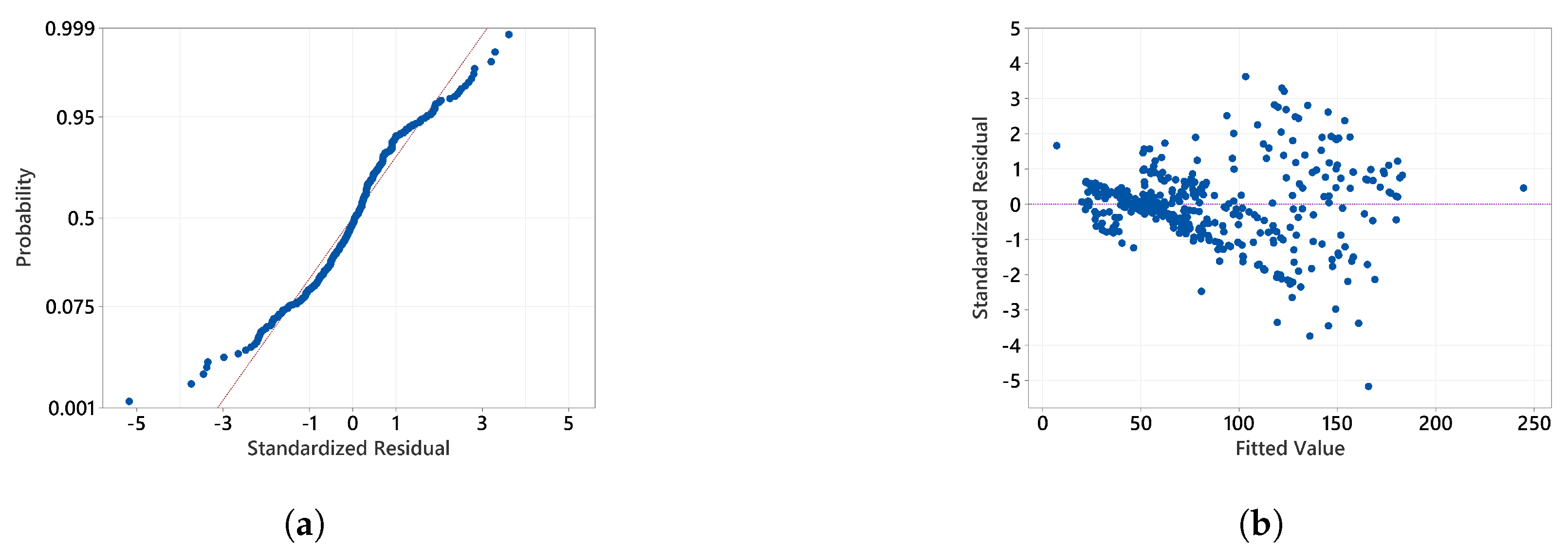

3.1. Nitrogen Accumulation in Frass Fertilizer

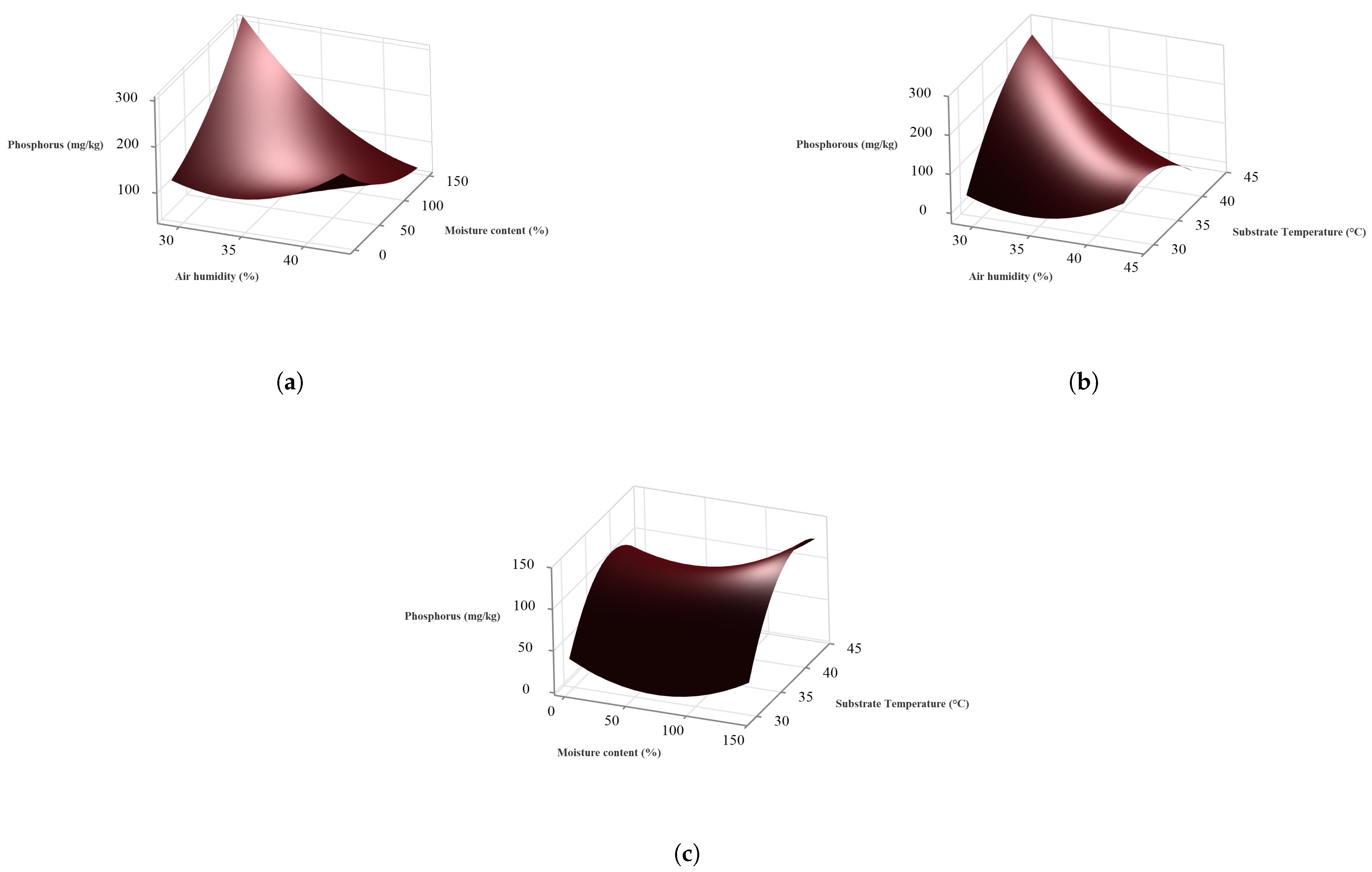

3.2. Phosphorus Accumulation in Frass Fertilizer

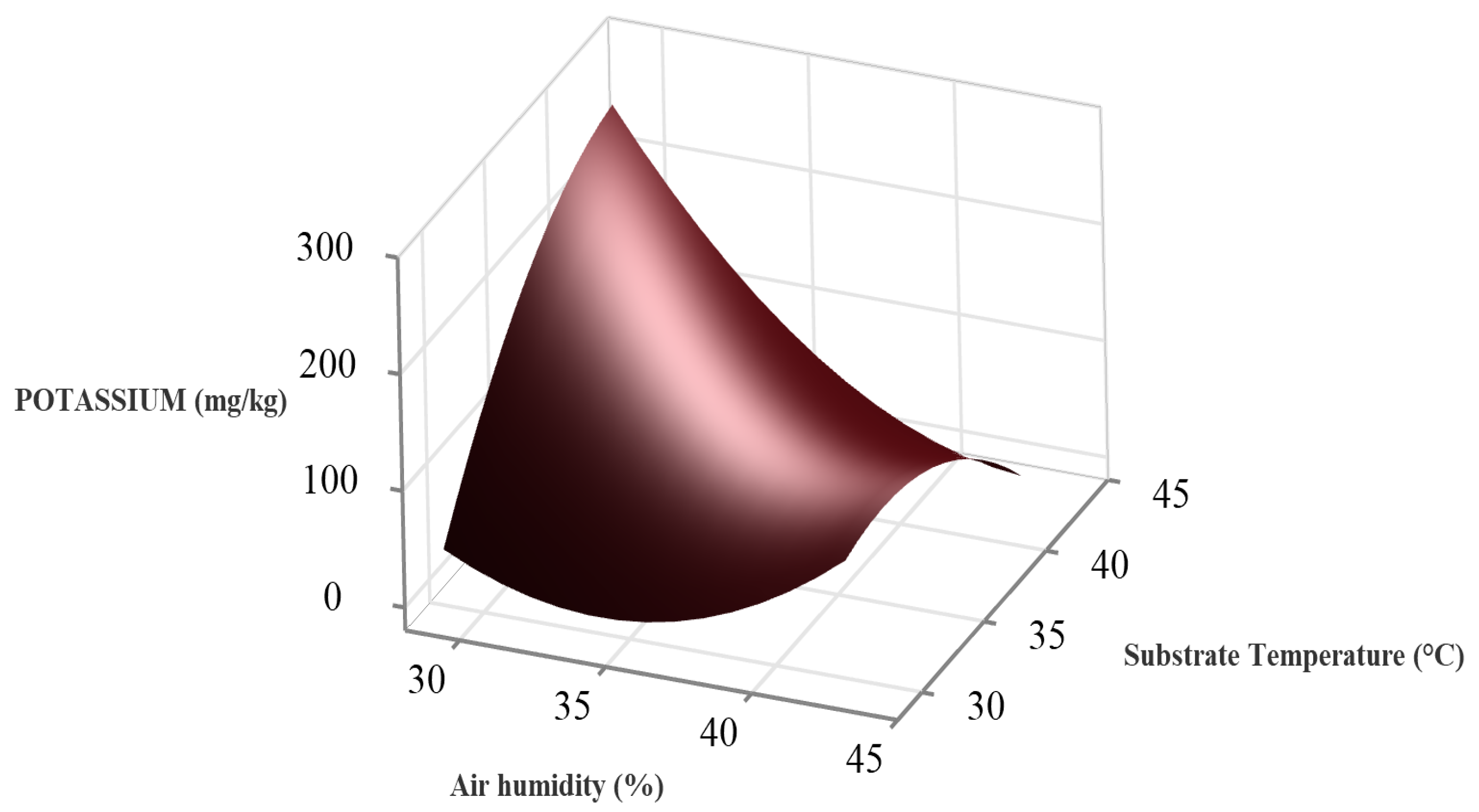

3.3. Potassium Accumulation in Frass Fertilizer

4. Discussion

4.1. Effect of Environmental Factors on Nitrogen Accumulation in Frass Fertilizer

4.2. Phosphorus and Potassium Accumulation in Frass Fertilizer as Influenced by Environmental Factors

4.3. Implications for Scaling of Frass Fertilizer Production Technologies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vlyssides, A.; Mai, S.; Barampouti, E. An integrated mathematical model for co-composting of agricultural solid wastes with industrial wastewater. Bioresour. Technol. 2009, 100, 4797–4806. [Google Scholar] [CrossRef] [PubMed]

- Pant, R.; Gupta, A.; Singh, A.; Srivastava, S.; Patrick, N. A Summary of the Role of Microorganisms in Waste Management. In Microbial Technology for Sustainable E-waste Management; Springer: Berlin/Heidelberg, Germany, 2023; pp. 337–352. [Google Scholar] [CrossRef]

- Oshins, C.; Michel, F.; Louis, P.; Richard, T.L.; Rynk, R. The composting process. In The Composting Handbook; Elsevier: Amsterdam, The Netherlands, 2022; pp. 51–101. [Google Scholar] [CrossRef]

- Azis, F.A.; Choo, M.; Suhaimi, H.; Abas, P.E. The Effect of Initial Carbon to Nitrogen Ratio on Kitchen Waste Composting Maturity. Sustainability 2023, 15, 6191. [Google Scholar] [CrossRef]

- Tumuhairwe, J.B.; Tenywa, J.S.; Otabbong, E.; Ledin, S. Comparison of four low-technology composting methods for market crop wastes. Waste Manag. 2009, 29, 2274–2281. [Google Scholar] [CrossRef] [PubMed]

- Beesigamukama, D.; Mochoge, B.; Korir, N.K.; Fiaboe, K.K.; Nakimbugwe, D.; Khamis, F.M.; Subramanian, S.; Wangu, M.M.; Dubois, T.; Ekesi, S.; et al. Low-cost technology for recycling agro-industrial waste into nutrient-rich organic fertilizer using black soldier fly. Waste Manag. 2021, 119, 183–194. [Google Scholar] [CrossRef] [PubMed]

- Beesigamukama, D.; Tanga, C.M.; Sevgan, S.; Ekesi, S.; Kelemu, S. Waste to value: Global perspective on the impact of entomocomposting on environmental health, greenhouse gas mitigation and soil bioremediation. Sci. Total Environ. 2023, 902, 166067. [Google Scholar] [CrossRef] [PubMed]

- Tanga, C.M.; Kababu, M.O. New insights into the emerging edible insect industry in Africa. Anim. Front. 2023, 13, 26–40. [Google Scholar] [CrossRef] [PubMed]

- Muinde, J.; Tanga, C.M.; Olukuru, J.; Odhiambo, C.; Tonnang, H.E.Z.; Senagi, K. Application of Machine Learning Techniques to Discern Optimal Rearing Conditions for Improved Black Soldier Fly Farming. Insects 2023, 14, 479. [Google Scholar] [CrossRef] [PubMed]

- Qomi, M.F.; Danaeefard, M.; Farhang, A.; Hosseini, P.; Arast, Y. Effect of Temperature on the Breeding Black Soldier Fly Larvae in Vitro for Basic Health-oriented Research. Arch. Hyg. Sci. 2021, 10, 67–74. [Google Scholar]

- Diener, S.; Zurbrügg, C.; Tockner, K. Conversion of organic material by black soldier fly larvae: Establishing optimal feeding rates. Waste Manag. Res. 2009, 27, 603–610. [Google Scholar] [CrossRef] [PubMed]

- Beesigamukama, D.; Mochoge, B.; Korir, N.K.; Fiaboe, K.K.; Nakimbugwe, D.; Khamis, F.M.; Subramanian, S.; Dubois, T.; Musyoka, M.W.; Ekesi, S.; et al. Exploring black soldier fly frass as novel fertilizer for improved growth, yield, and nitrogen use efficiency of maize under field conditions. Front. Plant Sci. 2020, 11, 574592. [Google Scholar] [CrossRef] [PubMed]

- Oonincx, D.G.; van Broekhoven, S.; van Huis, A.; van Loon, J.J. Correction: Feed conversion, survival and development, and composition of four insect species on diets composed of food by-products. PLoS ONE 2019, 14, e0222043. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, Ó.J.; Ospina, D.A.; Montoya, S. Compost supplementation with nutrients and microorganisms in composting process. Waste Manag. 2017, 69, 136–153. [Google Scholar] [CrossRef] [PubMed]

- Keener, H.; Ekinci, K.; Michel, F. Composting process optimization–using on/off controls. Compost Sci. Util. 2005, 13, 288–299. [Google Scholar] [CrossRef]

- Petric, I.; Mustafić, N. Dynamic modeling the composting process of the mixture of poultry manure and wheat straw. J. Environ. Manag. 2015, 161, 392–401. [Google Scholar] [CrossRef] [PubMed]

- Vasiliadou, I.A.; Chowdhury, A.K.M.M.B.; Akratos, C.S.; Tekerlekopoulou, A.G.; Pavlou, S.; Vayenas, D.V. Mathematical modeling of olive mill waste composting process. Waste Manag. 2015, 43, 61–71. [Google Scholar] [CrossRef] [PubMed]

- Courvoisier, P.; Clark, G. A numerical integrated model of composting processes using finite elements methods. In Proceedings of the XVII World Congress of the International Commission of Agricultural and Biosystems Engineering (CIGR), Québec City, QC, Canada, 6 July 2010; pp. 1–10. [Google Scholar]

- Bongochgetsakul, N.; Ishida, T. A new analytical approach to optimizing the design of large-scale composting systems. Bioresour. Technol. 2008, 99, 1630–1641. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.Y.; Chiu, S.L.; Lo, I.M. Effects of moisture content of food waste on residue separation, larval growth and larval survival in black soldier fly bioconversion. Waste Manag. 2017, 67, 315–323. [Google Scholar] [CrossRef] [PubMed]

- Yang-Jie, D.; Xiang, F.M.; Tao, X.H.; Jiang, C.L.; Zhang, T.Z.; Zhang, Z.J. A full-scale black soldier fly larvae (Hermetia illucens) bioconversion system for domestic biodegradable wastes to resource. Waste Manag. Res. 2023, 41, 143–154. [Google Scholar] [CrossRef] [PubMed]

- Stloukal, P.; Pekařová, S.; Kalendova, A.; Mattausch, H.; Laske, S.; Holzer, C.; Chitu, L.; Bodner, S.; Maier, G.; Slouf, M.; et al. Kinetics and mechanism of the biodegradation of PLA/clay nanocomposites during thermophilic phase of composting process. Waste Manag. 2015, 42, 31–40. [Google Scholar] [CrossRef] [PubMed]

- Oudart, D.; Robin, P.; Paillat, J.; Paul, E. Modelling nitrogen and carbon interactions in composting of animal manure in naturally aerated piles. Waste Manag. 2015, 46, 588–598. [Google Scholar] [CrossRef] [PubMed]

- Dickson, E.M.; Hastings, A.; Smith, J. Energy production from municipal solid waste in low to middle income countries: A case study of how to build a circular economy in Abuja, Nigeria. Front. Sustain. 2023, 4, 1173474. [Google Scholar] [CrossRef]

- Vishwakarma, A.; Kanaujia, K.; Hait, S. Global scenario of E-waste generation: Trends and future predictions. In Global E-Waste Management Strategies and Future Implications; Elsevier: Amsterdam, The Netherlands, 2023; pp. 13–30. [Google Scholar] [CrossRef]

- Haseli, G.; Torkayesh, A.E.; Hajiaghaei-Keshteli, M.; Venghaus, S. Sustainable resilient recycling partner selection for urban waste management: Consolidating perspectives of decision-makers and experts. Appl. Soft Comput. 2023, 137, 110120. [Google Scholar] [CrossRef]

- Waqas, M.; Hashim, S.; Humphries, U.W.; Ahmad, S.; Noor, R.; Shoaib, M.; Naseem, A.; Hlaing, P.T.; Lin, H.A. Composting processes for agricultural waste management: A comprehensive review. Processes 2023, 11, 731. [Google Scholar] [CrossRef]

- Zafaranlouei, N.; Ghoushchi, S.J.; Haseli, G. Assessment of sustainable waste management alternatives using the extensions of the base criterion method and combined compromise solution based on the fuzzy Z-numbers. Environ. Sci. Pollut. Res. 2023, 30, 62121–62136. [Google Scholar] [CrossRef] [PubMed]

- Synnefa. 2023. Available online: https://www.synnefa.io/farmshield (accessed on 1 December 2023).

- Perry, L.A.; Montgomery, D.C.; Fowler, J.W. Partition experimental designs for sequential processes: Part I—First-order models. Qual. Reliab. Eng. Int. 2001, 17, 429–438. [Google Scholar] [CrossRef]

- Bosque-Sendra, J.M.; Pescarolo, S.; Cuadros-Rodríguez, L.; García-Campaña, A.M.; Almansa-López, E.M. Optimizing analytical methods using sequential response surface methodology. Application to the pararosaniline determination of formaldehyde. Fresenius’ J. Anal. Chem. 2001, 369, 715–718. [Google Scholar] [CrossRef] [PubMed]

- Alin, A. Minitab. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 723–727. [Google Scholar] [CrossRef]

- Padmanabha, M.; Kobelski, A.; Hempel, A.J.; Streif, S. A comprehensive dynamic growth and development model of Hermetia illucens larvae. PLoS ONE 2020, 15, e0239084. [Google Scholar] [CrossRef] [PubMed]

- Vargas-García, M.; Suárez-Estrella, F.; López, M.; Moreno, J. Microbial population dynamics and enzyme activities in composting processes with different starting materials. Waste Manag. 2010, 30, 771–778. [Google Scholar] [CrossRef] [PubMed]

- Mathur, S.P. Composting processes. In Bioconversion of Waste Materials to Industrial Products; Springer: Boston, MA, USA, 1998; pp. 154–193. [Google Scholar] [CrossRef]

- MacDonald, N.W.; Zak, D.R.; Pregitzer, K.S. Temperature Effects on Kinetics of Microbial Respiration and Net Nitrogen and Sulfur Mineralization. Soil Sci. Soc. Am. J. 1995, 59, 233–240. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, Y.; Wang, D.; Ma, J.; Xue, K.; An, Z.; Luo, W.; Sheng, Y. Effects of Temperature and Humidity on Soil Gross Nitrogen Transformation in a Typical Shrub Ecosystem in Yanshan Mountain and Hilly Region. Life 2023, 13, 643. [Google Scholar] [CrossRef] [PubMed]

- Mosavian, S.N.; Eisvand, H.R.; Akbari, N.; Moshatati, A.; Ismaili, A. Do nitrogen and zinc application alleviate the adverse effect of heat stress on wheat (Triticum aestivum L.)? Not. Bot. Horti Agrobot. Cluj-Napoca 2021, 49, 12252. [Google Scholar] [CrossRef]

- Shumo, M.; Osuga, I.M.; Khamis, F.M.; Tanga, C.M.; Fiaboe, K.K.; Subramanian, S.; Ekesi, S.; van Huis, A.; Borgemeister, C. The nutritive value of black soldier fly larvae reared on common organic waste streams in Kenya. Sci. Rep. 2019, 9, 10110. [Google Scholar] [CrossRef]

- Singh, A.; Marathe, D.; Kumari, K. Black Soldier Fly Hermetia illucens (L.): Ideal environmental conditions and rearing strategies. Indian J. Entomol. 2022, 84, 743–753. [Google Scholar] [CrossRef]

- Mahmood, S.; Ali, A.; Zurbrügg, C.; Dortmans, B.; Asmara, D.R. Rearing performance of black soldier fly (Hermetia illucens) on municipal biowaste in the outdoor ambient weather conditions of Pakistan and Indonesia. Waste Manag. Res. 2023, 41, 644–652. [Google Scholar] [CrossRef] [PubMed]

- Alanna, N., S.; Cory, C., C. The effects of temperature on soil phosphorus availability and phosphatase enzyme activities: A cross-ecosystem study from the tropics to the Arctic. Biogeochemistry 2020, 151, 113–125. [Google Scholar] [CrossRef]

- Shah, P.N.; Ruan, X.; van Loon, J.J.; Dicke, M. Temperature-modulated host-pathogen interactions between Hermetia illucens L.(Diptera: Stratiomyidae) and Pseudomonas protegens Pf-5. J. Invertebr. Pathol. 2023, 198, 107934. [Google Scholar] [CrossRef] [PubMed]

- Eskander, S.; Saleh, H. Biodegradation: Process mechanism. Environ. Sci. Eng. 2017, 8, 1–31. [Google Scholar]

- Van Looveren, N.; Vandeweyer, D.; Van Campenhout, L. Impact of Heat Treatment on the Microbiological Quality of Frass Originating from Black Soldier Fly Larvae (Hermetia illucens). Insects 2022, 13, 22. [Google Scholar] [CrossRef] [PubMed]

- Van Peer, M.; Coudron, C.; Alvarez, C.; Kingston-Smith, J.A.A.; Van Miert, S. Literature Review to Define Knowledge Gaps on the Sustainable Production of Insects for Feed; European Union: Maastricht, The Netherlands, 2022. [Google Scholar]

- Mulu, D.; Yimer, F.; Opande, G. Characterizing quality of frass produced by black soldier fly (Hermetia illucens) larvae after treating water hyacinth and fruit wastes in various proportions. Biomass Convers. Biorefinery 2023, 13, 15185–15196. [Google Scholar] [CrossRef]

- Dinnes, D.L.; Karlen, D.L.; Jaynes, D.B.; Kaspar, T.C.; Hatfield, J.L.; Colvin, T.S.; Cambardella, C.A. Nitrogen management strategies to reduce nitrate leaching in tile-drained Midwestern soils. Agron. J. 2002, 94, 153–171. [Google Scholar] [CrossRef]

- Sanginga, N.; Woomer, P.L. Integrated Soil Fertility Management in Africa: Principles, Practices, and Developmental Process; CIAT: Palmira, Colombia, 2009. [Google Scholar]

- Gebbers, R.; Adamchuk, V.I. Precision agriculture and food security. Science 2010, 327, 828–831. [Google Scholar] [CrossRef]

- Katchali, M.; Senagi, K. Frass Fertilizer Production. Available online: https://dmmg.icipe.org/dataportal/dataset/unveiling-environmental-influences-on-sustainable-fertilizer-production-through-insect-farming (accessed on 1 January 2024).

| Variables | SI Units | Annotation | Lower Value | Upper Value |

|---|---|---|---|---|

| Air humidity | Percentage (%) | 29.1 | 41.9 | |

| Air temperature | Degree Celsius (°C) | 22 | 46.7 | |

| Moisture content | Percentage (%) | 27.0 | 148.4 | |

| Substrate temperature | Degree Celsius (°C) | 30 | 43 |

| Source | DF | SS | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Regression Model | 14 | 826,514 | 826,514 | 59,036.7 | 86.68 | 0.000 |

| Linear | 4 | 472,732 | 171,535 | 42,883.7 | 62.96 | 0.000 |

| Square | 4 | 178,450 | 74,321 | 18,580.4 | 27.28 | 0.000 |

| Interaction between factors | 6 | 175,332 | 175,332 | 29,221.9 | 42.90 | 0.000 |

| Residual Error | 365 | 248,607 | 248,607 | 681.1 | ||

| Lack-of-Fit | 338 | 248,607 | 248,607 | 735.5 | ||

| Pure Error | 27 | 0 | 0 | 0.0 | ||

| Total | 379 | 1,075,121 |

| Term | Estimated Coefficient | Standard Error of Coefficient | T-Statistic | p-Value | Remarks |

|---|---|---|---|---|---|

| Constant () | 121.021 | 5.336 | 22.680 | 0.000 | |

| 15.878 | 9.345 | 1.699 | 0.090 | Non-significant | |

| 39.474 | 10.944 | 3.607 | 0.000 | Significant | |

| 54.828 | 15.060 | 3.641 | 0.000 | Significant | |

| 85.977 | 10.569 | 8.135 | 0.000 | Significant | |

| −8.700 | 16.095 | −0.541 | 0.589 | Non-significant | |

| −121.940 | 14.898 | −8.185 | 0.000 | Significant | |

| 38.811 | 19.309 | 2.010 | 0.045 | Significant | |

| 23.092 | 8.814 | 2.620 | 0.009 | Significant | |

| −112.653 | 24.145 | −4.666 | 0.000 | Significant | |

| 85.410 | 24.480 | 3.489 | 0.001 | Significant | |

| 58.580 | 14.427 | 4.061 | 0.000 | Significant | |

| 92.589 | 37.313 | 2.481 | 0.014 | Significant | |

| 148.590 | 15.596 | 9.527 | 0.000 | Significant | |

| −84.313 | 17.982 | −4.689 | 0.000 | Significant |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Regression Model | 14 | 1,075,885 | 76,848.9 | 64.81 | 0.000 |

| Linear | 4 | 160,725 | 40,181.1 | 33.89 | 0.000 |

| Square | 4 | 117,409 | 29,352.2 | 24.76 | 0.000 |

| Interaction between factors | 6 | 53,672 | 8945.4 | 7.54 | 0.000 |

| Error | 519 | 615,361 | 1185.7 | ||

| Lack-of-Fit | 481 | 614,881 | 1278.3 | ||

| Pure Error | 38 | 481 | 12.6 | ||

| Total | 533 | 1,691,247 |

| Term | Estimated Coefficient | Standard Error of Coefficient | T-Statistic | p-Value | Remarks |

|---|---|---|---|---|---|

| Constant () | −881 | 4.51 | 20.21 | 0.000 | Significant |

| −46.3 | 9.15 | −5.41 | 0.000 | Significant | |

| −17.4 | 8.58 | −1.00 | 0.316 | Non-significant | |

| 120.7 | 8.76 | 4.49 | 0.000 | Significant | |

| 2.56 | 12.2 | 1.98 | 0.049 | Significant | |

| 1.03 | 20.1 | 2.44 | 0.015 | Significant | |

| 0.12 | 16.3 | 6.80 | 0.000 | Significant | |

| −0.65 | 8.82 | 2.89 | 0.004 | Significant | |

| 0.05 | 7.97 | −4.02 | 0.000 | Significant | |

| 0.51 | 27.9 | 3.82 | 0.000 | Significant | |

| −1.48 | 20.0 | −2.57 | 0.011 | Significant | |

| −0.1 | 14.4 | −4.93 | 0.000 | Significant | |

| −0.01 | 17.5 | −4.21 | 0.000 | Significant | |

| −0.34 | 22.9 | −1.00 | 0.316 | Non-significant | |

| 0.03 | 12.9 | −2.00 | 0.031 | Significant |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Regression Model | 14 | 961,065 | 68,647.5 | 63.41 | 0.000 |

| Linear | 4 | 114,174 | 28,543.4 | 26.37 | 0.000 |

| Square | 4 | 146,978 | 36,744.4 | 33.94 | 0.000 |

| Interaction between factors | 6 | 52,117 | 8686.2 | 8.02 | 0.000 |

| Error | 519 | 561,831 | 1082.5 | ||

| Lack-of-Fit | 481 | 561,350 | 1167.0 | ||

| Pure Error | 38 | 481 | 12.6 | ||

| Total | 533 | 1,522,896 |

| Term | Estimated Coefficient | Standard Error of Coefficient | T-Statistic | p-Value | Remarks |

|---|---|---|---|---|---|

| Constant () | −198 | 4.31 | 18.52 | 0.000 | |

| −76 | 8.74 | −5.08 | 0.000 | Significant | |

| −18.5 | 8.20 | −0.73 | 0.466 | Non-significant | |

| 119.2 | 11.7 | 1.49 | 0.137 | Non-significant | |

| 0.25 | 8.37 | 3.40 | 0.001 | Significant | |

| 1.32 | 19.2 | 3.28 | 0.001 | Significant | |

| 0.13 | 15.6 | 7.60 | 0.000 | Significant | |

| −0.68 | 8.43 | 4.42 | 0.000 | Significant | |

| 0.01 | 7.61 | −4.41 | 0.000 | Significant | |

| 0.54 | 26.7 | 4.29 | 0.000 | Significant | |

| −0.04 | 13.8 | −4.87 | 0.000 | Significant | |

| −1.4 | 19.1 | −1.03 | 0.302 | Non-significant | |

| −0.02 | 16.7 | −4.57 | 0.000 | Significant | |

| −0.36 | 21.9 | −1.61 | 0.109 | Non-significant | |

| 0.03 | 7.93 | 2.10 | 0.036 | Significant |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katchali, M.; Senagi, K.; Richard, E.; Beesigamukama, D.; Tanga, C.M.; Athanasiou, G.; Zahariadis, T.; Casciano, D.; Lazarou, A.; Tonnang, H.E.Z. Unveiling Environmental Influences on Sustainable Fertilizer Production through Insect Farming. Sustainability 2024, 16, 3746. https://doi.org/10.3390/su16093746

Katchali M, Senagi K, Richard E, Beesigamukama D, Tanga CM, Athanasiou G, Zahariadis T, Casciano D, Lazarou A, Tonnang HEZ. Unveiling Environmental Influences on Sustainable Fertilizer Production through Insect Farming. Sustainability. 2024; 16(9):3746. https://doi.org/10.3390/su16093746

Chicago/Turabian StyleKatchali, Malontema, Kennedy Senagi, Edward Richard, Dennis Beesigamukama, Chrysantus M. Tanga, Gina Athanasiou, Theodore Zahariadis, Domenica Casciano, Alexandre Lazarou, and Henri E. Z. Tonnang. 2024. "Unveiling Environmental Influences on Sustainable Fertilizer Production through Insect Farming" Sustainability 16, no. 9: 3746. https://doi.org/10.3390/su16093746

APA StyleKatchali, M., Senagi, K., Richard, E., Beesigamukama, D., Tanga, C. M., Athanasiou, G., Zahariadis, T., Casciano, D., Lazarou, A., & Tonnang, H. E. Z. (2024). Unveiling Environmental Influences on Sustainable Fertilizer Production through Insect Farming. Sustainability, 16(9), 3746. https://doi.org/10.3390/su16093746