The Influence of pH Environments on the Long-Term Durability of Coir Fiber-Reinforced Epoxy Resin Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

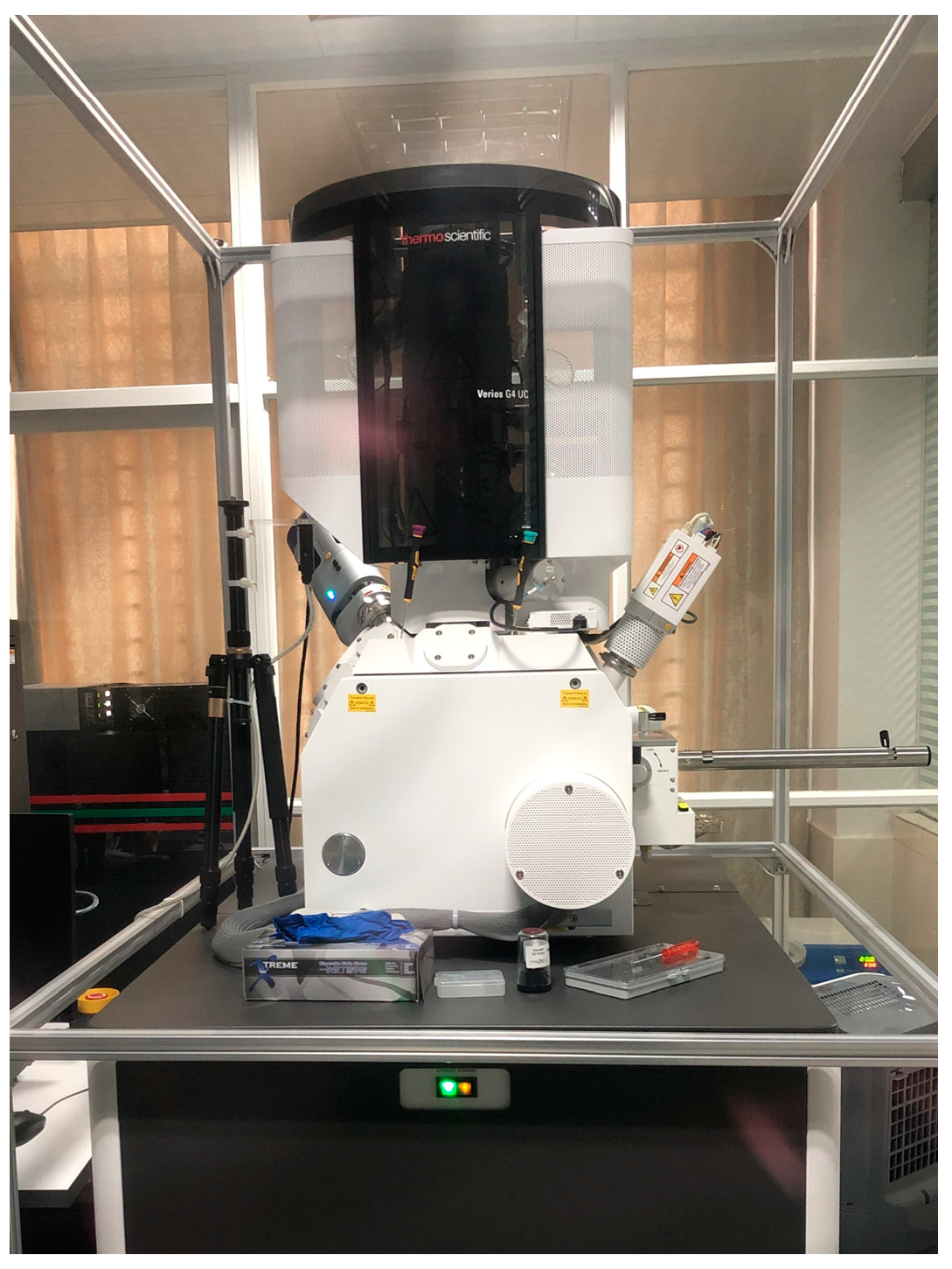

2.2. Principal Equipment and Instruments

2.3. Sample Preparation and Experimental Procedures

2.3.1. Pretreatment of the Coir Fibers

2.3.2. Preparation of CFRERCs

2.3.3. Experimental Design

2.4. Testing Methodology

2.4.1. Tensile Testing

2.4.2. FE-SEM Analysis

3. Results and Discussion

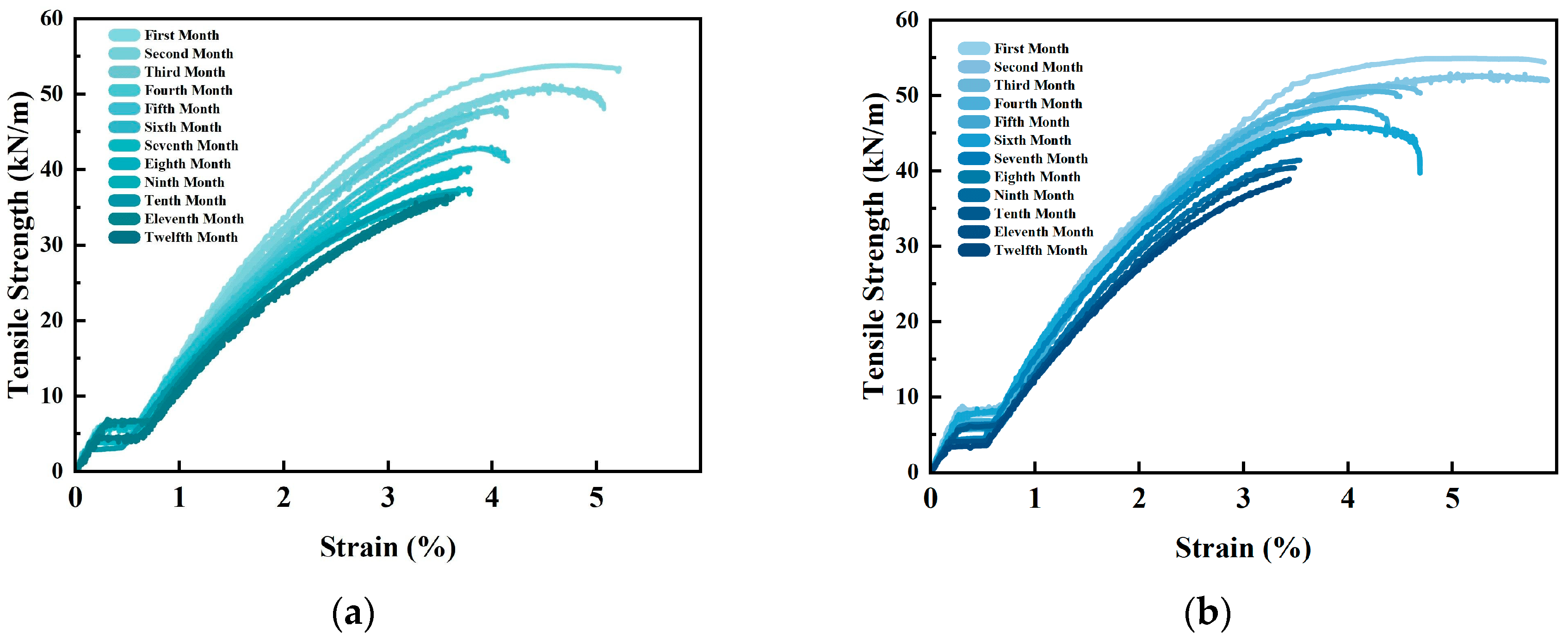

3.1. Durability Evaluation of CFRERCs

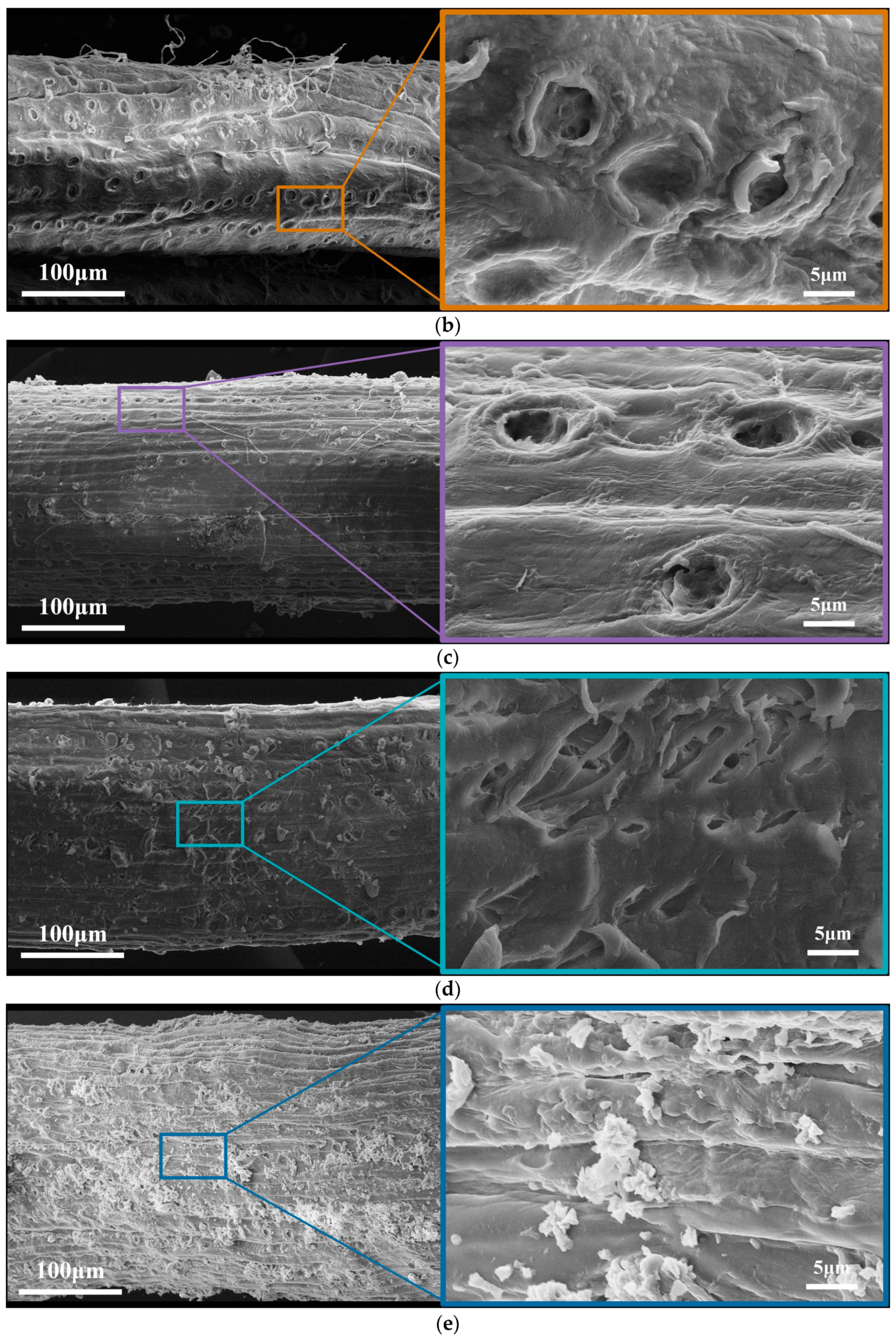

3.2. SEM Analysiss

4. Conclusions

- (1)

- The study reveals a consistent degradation of tensile strength in CFRERCs across all pH environments over a 12-month period. The greatest decline occurs in the alkaline environment (NaOH), with a 55.06% reduction, predominantly within the first 9 months. This is followed by a 44.87% decrease in the acidic environment (HCl), also mainly during the first 9 months. The pure water and seawater environments show more gradual reductions of 32.98% and 30.03%, respectively, with the seawater degradation continuing beyond 9 months. The initial rapid degradation in alkaline and acidic conditions is attributed to the breakdown of lignin and pectin, leaving corrosion-resistant cellulose, which moderates further strength loss. The seawater environment causes continuous degradation due to ongoing exposure to salts and microorganisms.

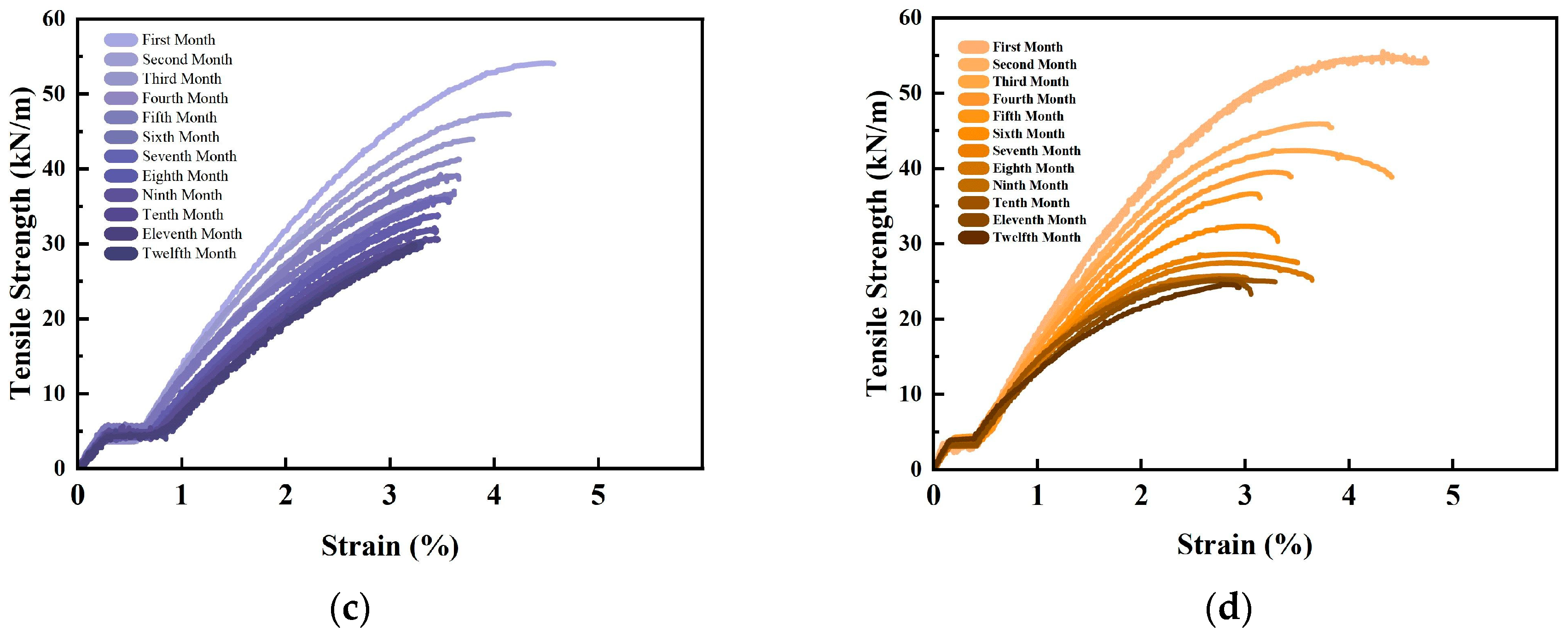

- (2)

- Distinct trends in tensile strain were observed across pH environments. The largest reduction of 36.45% occurs in the alkaline environment, followed by 25.56% in acidic conditions and 22.65% in seawater. The smallest reduction, 18.78%, is in pure water. Initially, tensile strain increases due to moisture-induced swelling. In seawater, the initial higher tensile strain is influenced by the protective effects of salts and microorganisms, but by the ninth month, tensile strain decreases more rapidly than in pure water. This accelerated reduction is due to seawater’s mildly alkaline nature, which increases the degradation rate compared to pure water.

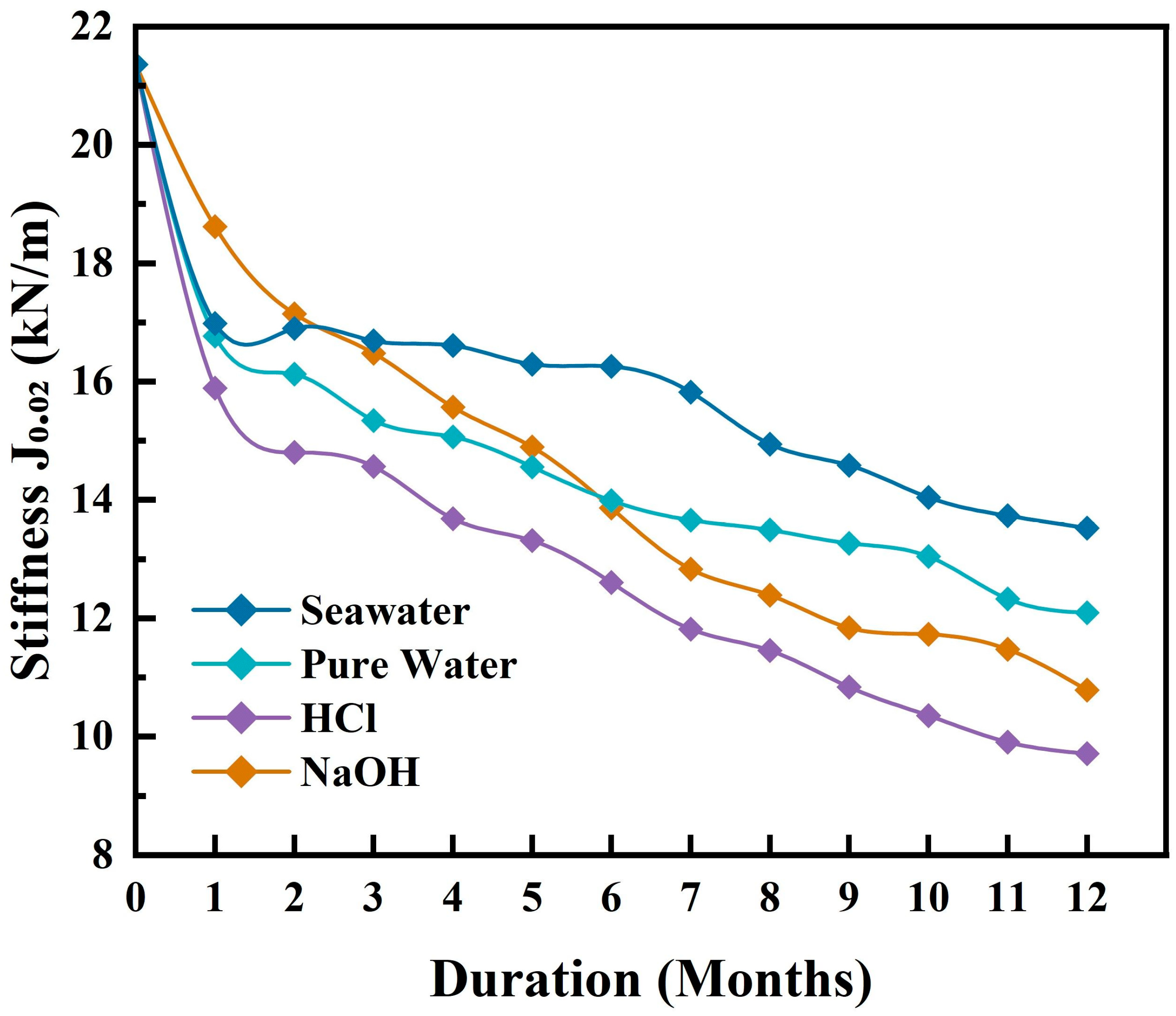

- (3)

- Long-term exposure to the acidic environment has the most significant impact on stiffness, with a 54.56% decrease. The alkaline environment follows with a 49.51% reduction, while pure water and seawater show smaller decreases of 43.39% and 36.72%, respectively.

- (4)

- FE-SEM analysis reveals the distinct effects of corrosive environments on the fibers’ structural integrity. Alkaline environments cause severe damage, including complete pectin erosion and extensive fiber surface roughening, leading to substantial reductions in mechanical strength. Acidic environments also erode pectin, but the slower degradation of lignin and cellulose results in less severe damage. In pure water, pectin undergoes deformation and partial hydrolysis, leading to swelling and softening that may weaken interface bonding without significantly damaging the fiber structure. Seawater exposure results in minimal corrosion, with salt deposits forming a protective layer that slows degradation, helping to maintain mechanical properties better than other environments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chatrabhuj; Meshram, K. Use of geosynthetic materials as soil reinforcement: An alternative eco-friendly construction material. Discov. Civ. Eng. 2024, 1, 41. [Google Scholar] [CrossRef]

- Dimitrievski, L.; Dimitrievski, D.; Dimitrievski, T.; Bogoevski, B.; Dimitrieska, V.; Nedelkovska, A. Several cases of application of geosynthetics in Macedonian engineering practice. ce/papers 2018, 2, 853–858. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, X.; Zhang, X. Laboratory Characterization of Geosynthetics-Reinforced Asphalt Mixture. Materials 2021, 14, 6424. [Google Scholar] [CrossRef]

- Cho, S.D.; Lee, D.Y. Performance Evaluation of Asphalt Pavement Reinforced with Glass Fiber Sheet Type of Geosynthetics. J. Korean Geosynth. Soc. 2011, 10, 1–8. [Google Scholar] [CrossRef]

- Liao, D.; Gu, T.; Yan, J.; Yu, Z.; Dou, J.; Liu, J.; Zhao, F.; Wang, J. Effect of thermal aging on the microscale mechanical response behavior of glass fiber/epoxy composites. J. Mater. Sci. 2024, 59, 15298–15314. [Google Scholar] [CrossRef]

- Luo, X.; Xu, J.-Y.; Li, W. Basalt fiber reinforced porous aggregates-geopolymer based cellular material. Funct. Mater. Lett. 2015, 8, 1550005. [Google Scholar] [CrossRef]

- Bi, M.; Qin, Q.; Deng, B.; Chen, D. Natural fibers as sustainable and renewable materials for green sample preparation. Trends Anal. Chem. 2024, 180, 117894. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Ilyas, R.A.; et al. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef] [PubMed]

- Lawer, A.K.; Ampadu, S.I.K.; Owusu-Nimo, F. The effect of randomly distributed natural fibers on some geotechnical characteristics of a lateritic soil. SN Appl. Sci. 2021, 3, 642. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Bak, M.; Alpár, T. A state-of-the-art review on coir fiber-reinforced biocomposites. RSC Adv. 2021, 11, 10548–10571. [Google Scholar] [CrossRef] [PubMed]

- Geethamma, V.G.; Kalaprasad, G.; Groeninckx, G.; Thomas, S. Dynamic mechanical behavior of short coir fiber reinforced natural rubber composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1499–1506. [Google Scholar] [CrossRef]

- Awad, E.H.; El-Nemr, K.F.; Atta, M.M.; Abdel-Hakim, A.; Sharaf, A. Electromagnetic interference shielding efficiency of irradiated wood-plastic composites based on graphene oxide nanoparticles. Radiat. Phys. Chem. 2023, 203, 110629. [Google Scholar] [CrossRef]

- Abdel-Hakim, A.; El Mogy, S.A.; Mourad, R.M. Impact of fiber coating with hydrophobic nanoparticles polymer on the physicomechanical properties of Pisum sativum L. fibers/ styrene butadiene rubber ecofriendly composites. Ind. Crops Prod. 2024, 209, 118054. [Google Scholar] [CrossRef]

- Girish, M.; Ramanatha Ayyar, T. Improvement of durability of coir geotextiles. In Proceedings of the Indian Geotextiles Conference, Bombay, India, 2000; Volume 1, pp. 309–310. [Google Scholar]

- Sen, T.; Reddy, H.J. Application of sisal, bamboo, coir and jute natural composites in structural upgradation. Int. J. Innov. Manag. Technol. 2011, 2, 186. [Google Scholar]

- Kumar, M.S.S.; Rajeshkumar, L.; Mavinkere, R.S.; Suchart, S. Mechanical behaviour analysis for banana/coir natural fiber hybrid epoxy composites through experimental modelling. J. Polym. Res. 2024, 31, 163. [Google Scholar] [CrossRef]

- Yahya, T.; Gokhan, D.; Seckin, K.; Abuzer, A. Mechanical, wear and thermal properties of natural fiber-reinforced epoxy composite: Cotton, sisal, coir and wool fibers. J. Mater. Sci. 2024, 59, 10844–10857. [Google Scholar] [CrossRef]

- Ru, S.; Renyan, Y.; Songmei, Y.; Can, Z. Effects of Physical and Mechanical Properties of Coir Fiber and Reinforced Epoxy Composites Treated with Acetic Anhydride and Alkali. J. Nat. Fibers 2023, 20, 2285819. [Google Scholar] [CrossRef]

- Jéssica, Z.S.; Andrade, J.J.d.O. Comparison between alternative chemical treatments on coir fibers for application in cementitious materials. J. Mater. Res. Technol. 2023, 25, 4634–4649. [Google Scholar] [CrossRef]

- Pan, Y.; Wang, Z.; Liu, Y. Study on the Influence of Pretreated Coir Fiber on the Properties of Cement-based Materials. China Concr. Cem. Prod. 2022, 5, 61–66. [Google Scholar] [CrossRef]

- Siddika, S.; Mansura, F.; Hasan, M.; Hassan, A. Effect of reinforcement and chemical treatment of fiber on the properties of jute-coir fiber reinforced hybrid polypropylene composites. Fibers Polym. 2014, 15, 1023–1028. [Google Scholar] [CrossRef]

- Abdullah, N.M.; Ahmad, I. Potential of using polyester reinforced coconut fiber composites derived from recycling polyethylene terephthalate (PET) waste. Fibers Polym. 2013, 14, 584–590. [Google Scholar] [CrossRef]

- Sumi, S.; Unnikrishnan, N.; Mathew, L. Experimental investigations on biological resistance of surface modified coir geotextiles. Int. J. Geosynth. Ground Eng. 2016, 2, 31. [Google Scholar] [CrossRef]

- Sayida, M.; Evangeline, S.; Vijayan, A.; Girish, M. Durability study of coir geotextile embedded in different types of subgrade soil. J. Nat. Fibers 2022, 19, 2288–2298. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Terrones, L.A.H.; D’Almeida, J.R.M. Mechanical performance of coir fiber/polyester composites. Polym. Test. 2008, 27, 591–595. [Google Scholar] [CrossRef]

- Harish, S.; Michael, D.P.; Bensely, A.; Lal, D.M.; Rajadurai, A. Mechanical property evaluation of natural fiber coir composite. Mater. Charact. 2009, 60, 44–49. [Google Scholar] [CrossRef]

- Rout, J.; Misra, M.; Mohanty, A.K.; Nayak, S.K.; Tripathy, S.S. SEM Observations of the Fractured Surfaces of Coir Composites. J. Reinf. Plast. Compos. 2003, 22, 1083–1100. [Google Scholar] [CrossRef]

- Code for Test and Measurement of Geosynthetics (SL 235-2012), Department of International Cooperation, Science and Technology. 2012. Available online: http://121.36.94.83:9008/jsp/yishenqing/appladd/biaozhunfile/detail.jsp?bzbh=SL%2B235-2012 (accessed on 1 May 2024).

- Bhaskar, A.B. Studies on Effective Use of Coir for Ground Improvement; University of Kerala: Trivandrum, India, 2011; Available online: http://hdl.handle.net/10603/62329 (accessed on 1 May 2024).

- Zhou, J.; Lucas, J.P. Hygrothermal effects of epoxy resin. Part I: The nature of water in epoxy. Polymer 1999, 40, 5505–5512. [Google Scholar] [CrossRef]

- Jojibabu, P.; Ram, G.D.J.; Deshpande, A.P.; Bakshi, S.R. Effect of carbon nano-filler addition on the degradation of epoxy adhesive joints subjected to hygrothermal aging. Polym. Degrad. Stab. 2017, 140, 84–94. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Studies on the durability of natural fibres and the effect of corroded fibres on the strength of mortar. Cem. Concr. Compos. 2005, 27, 575–582. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Thomas, S. Diffusion of water and artificial seawater through coir fiber reinforced natural rubber composites. Polym. Compos. 2005, 26, 136–143. [Google Scholar] [CrossRef]

- Sumi, S.; Unnikrishnan, N.; Mathew, L. Durability studies of surface-modified coir geotextiles. Geotext. Geomembr. 2018, 46, 699–706. [Google Scholar] [CrossRef]

- Ahad, N.A.; Mohamad Rosdi, M.H.H.; Yaacob, N.; Che Fauzi, N.H.N.; Zakaria, S. The effect of chemical treatments on tensile strength and absorption ability of epoxy/natural fibers composites. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 476, p. 012091. [Google Scholar] [CrossRef]

- Obada, D.O.; Dodoo-Arhin, D.; Jimoh, A.; Abdullahi, A.; Bansod, N.D.; Iorpenda, M.J.; Aquatar, M.O.; Sowunmi, A.R.; Abdulrahim, M.Y.; Abraham, C.Y.; et al. The effect of acid aging on the mechanical and tribological properties of coir–coconut husk-reinforced low-density polyethylene composites. Polym. Bull. 2021, 78, 3489–3508. [Google Scholar] [CrossRef]

- Gu, H. Tensile behaviours of the coir fibre and related composites after NaOH treatment. Mater. Des. 2009, 30, 3931–3934. [Google Scholar] [CrossRef]

- Mathura, N.; Cree, D. Characterization and mechanical property of Trinidad coir fibers. J. Appl. Polym. Sci. 2016, 133, 29. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Rokbi, M.; Osmani, H.; Imad, A.; Benseddiq, N. Effect of Chemical treatment on Flexure Properties of Natural Fiber-reinforced Polyester Composite. Procedia Eng. 2011, 10, 2092–2097. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; Elaya Perumal, A.; Arunsundaranayagam, D. Fiber surface treatment and its effect on mechanical and visco-elastic behaviour of banana/epoxy composite. Mater. Des. 2013, 47, 151–159. [Google Scholar] [CrossRef]

- Chollakup, R.; Smitthipong, W.; Kongtud, W.; Tantatherdtam, R. Polyethylene green composites reinforced with cellulose fibers (coir and palm fibers): Effect of fiber surface treatment and fiber content. J. Adhes. Sci. Technol. 2013, 27, 1290–1300. [Google Scholar] [CrossRef]

- Al-Khanbashi, A.; Al-Kaabi, K.; Hammami, A. Date palm fibers as polymeric matrix reinforcement: Fiber characterization. Polym. Compos. 2005, 26, 486–497. [Google Scholar] [CrossRef]

- Windyandari, A.; Kurdi, O.; Sulardjaka; Tauviqirrahman, M. Scanning Electron Microscopy Observation of Coir Fibre with Alkali and Drying Method Treatment. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1053, p. 012031. [Google Scholar] [CrossRef]

- Been Seok, Y.; Muhamad, M.; Mohamed, S.; Wee, F. Effect of Alkaline Treatment on Structural Characterisation, Thermal Degradation and Water Absorption Ability of Coir Fibre Polymer Composites. Sains Malays. 2019, 48, 653–659. [Google Scholar] [CrossRef]

- Rigolin, T.R.; Takahashi, M.C.; Kondo, D.L.; Bettini, S.H.P. Compatibilizer Acidity in Coir-Reinforced PLA Composites: Matrix Degradation and Composite Properties. J. Polym. Environ. 2019, 27, 1096–1104. [Google Scholar] [CrossRef]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Rahman, N.S.A.; Yhaya, M.F.; Azahari, B.; Ismail, W.R. Utilisation of natural cellulose fibres in wastewater treatment. Cellulose 2018, 25, 4887–4903. [Google Scholar] [CrossRef]

| Instrument Name | Model | Manufacturer | Application |

|---|---|---|---|

| Electric Blast Drying Oven | FX101-3 | Shanghai Shuli Instrument Co., Ltd. (Shanghai, China) | Drying samples |

| Microcomputer-Controlled Electronic Universal Testing Machine | WDW-100C | Shanghai Hualong Testing Instrument Co., Ltd. (Shanghai, China) | Tensile strength testing |

| Field Emission Scanning Electron Microscope (FE-SEM) | S-3000N | Hitachi, Ltd., (Tokyo, Japan) | Observing microstructural changes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Wang, J.; Peng, T. The Influence of pH Environments on the Long-Term Durability of Coir Fiber-Reinforced Epoxy Resin Composites. Sustainability 2025, 17, 364. https://doi.org/10.3390/su17010364

Li L, Wang J, Peng T. The Influence of pH Environments on the Long-Term Durability of Coir Fiber-Reinforced Epoxy Resin Composites. Sustainability. 2025; 17(1):364. https://doi.org/10.3390/su17010364

Chicago/Turabian StyleLi, Liangyong, Juntong Wang, and Tianxiang Peng. 2025. "The Influence of pH Environments on the Long-Term Durability of Coir Fiber-Reinforced Epoxy Resin Composites" Sustainability 17, no. 1: 364. https://doi.org/10.3390/su17010364

APA StyleLi, L., Wang, J., & Peng, T. (2025). The Influence of pH Environments on the Long-Term Durability of Coir Fiber-Reinforced Epoxy Resin Composites. Sustainability, 17(1), 364. https://doi.org/10.3390/su17010364