Abstract

This study conducts a life cycle assessment and exergoenvironmental evaluation of a double-effect vapor absorption chiller (DEAC) with a cooling capacity of 352 kW, employing three different energy sources: natural gas, biomethane, and green hydrogen. The main objectives of this paper are as follows: (i) provide an exergoenvironmental model for DEAC technologies, (ii) evaluation of a case-study where a DEAC is used to cover the cooling demand of a specific university building in the Northeast of Brazil, and (iii) evaluate the scenario where the DEAC is fed by green hydrogen (GH2) and compare it with conventional energy resources (natural gas and biomethane). In order to develop the exergoenvironmental model, two methodologies are essential: a thermodynamic analysis and a Life Cycle Assessment (LCA). The thermodynamic analysis was carried out using the Engineering Equation Solver (EES: 10.998) software. The LCA has been developed through the open-source software openLCA version 1.10.3, with the Ecoinvent 3.7.1 life cycle inventory database, whereas the chosen life cycle inventory assessment (LCIA) method was the ReCiPe Endpoint LCA method (Humanitarian, medium weighting–H, A). The main results indicate that green hydrogen provides a 99.84% reduction in environmental impacts compared to natural gas during the operational phase, while biomethane reduces these impacts by 54.21% relative to natural gas. In the context of life cycle assessment (LCA), green hydrogen decreases fossil resource depletion by 18% and climate change-related emissions by 33.16% compared to natural gas. This study contributes to enhancing the understanding of the environmental and exergoenvironmental impacts of a double-effect vapor absorption chiller by varying the fuel usage during the operational phase.

1. Introduction

The pursuit of sustainable and efficient solutions in the refrigeration sector is currently in the spotlight due to the need to reduce greenhouse gas emissions [1] associated with global warming and to promote the responsible use of natural resources. Technologies that utilize low-carbon fuels as an energy source and generate minimal environmental impacts present a challenge today [2]. In this regard, the ideal solution is to employ systems that enable greater integration with renewable energies and maximize the utilization of the energy consumed. The use of vapor absorption refrigeration systems has been increasing over the years due to their economic and environmental advantages stemming from the potential to utilize renewable energy sources for their operation [3].

Fossil fuels still dominate among global energy sources and are undoubtedly the primary contributors to greenhouse gas (GHG) emissions. Furthermore, global warming, coupled with the growth of economic and commercial activities, has led to a significant increase in the demand for electricity [4,5].

The effort by researchers to achieve carbon neutrality and net-zero emissions by 2050 requires a radical transformation, substituting fossil fuels with renewable energy sources [6]. Several studies in the field of vapor absorption refrigeration aim to reach these objectives. Hai et al. [7] conducted research on absorption refrigeration chillers that utilize solar collectors as a thermal source. Li et al. [8] analyzed the technical feasibility and energy efficiency of using biogas to power an absorption refrigeration chiller through direct combustion. Dadpour et al. [9] conducted a theoretical and experimental study on a cogeneration system consisting of an internal combustion engine and a double-effect chiller. Waste heat was used as the thermal source for the chiller. An energy, exergoeconomic, and environmental analysis was carried out; however, no life cycle assessment or more comprehensive exergoenvironmental analysis was performed. The studies conducted so far on vapor absorption refrigeration systems powered by direct or indirect combustion do not consider the comparative environmental impact of the various available energy sources, including both fossil fuels and low-carbon sources, such as green hydrogen, biomethane, and solar thermal energy.

The sustainability aspects of bioenergy systems can be evaluated using a wide range of advanced engineering frameworks [10]. Some methods presented in the literature for assessing the sustainability of energy systems include Life Cycle Assessment (LCA), exergoenvironmental study, and exergoeconomic analysis [11]. Life Cycle Assessment (LCA) is an internationally recognized and validated methodology for analyzing and quantifying the environmental impacts of energy systems [10]. It consists of a systematic and comprehensive approach designed to assess the environmental impacts of a product or process throughout its entire life cycle, from raw material extraction to end-of-life disposal [12].

The connection of exergy with other indicators has been studied by researchers Szargut et al. [13] and Tsatsaronis [14], who explored the possibility of combining exergy with other indicators. This approach also synthesizes information about energy and material flows and, when calculated based on exergy flows, can help identify opportunities for the integration of energy systems and efficiency improvements [15]. The environmental impacts derived from a Life Cycle Assessment (LCA) can also be evaluated based on exergy flows, forming the basis for the exergoenvironmental assessment methodology for energy systems [16].

Cavalcanti et al. [17] conducted an exergoenvironmental study of a cogeneration system using sugarcane bagasse for electricity generation, where the majority of environmental impacts were linked to exergy destruction in the furnace. Wang et al. [18] explored the use of natural gas and hydrogen in energy decarbonization, highlighting the challenges of liquefying these fuels due to high energy consumption and CO2 emissions.

Maciel et al. [19] investigated the environmental impacts associated with hydrogen production through electrolysis using renewable energy. They noted that hydropower stood out for exhibiting the highest ecological efficiency. However, it is important to highlight that the authors did not assess the feasibility of green hydrogen as a fuel. Kadam et al. [20] conducted a comparison of the thermoeconomic performance between vapor compression refrigeration cycles and absorption cycles, but they did not consider the use of low-carbon fuels in chiller operation. On the other hand, Souza et al. [21] proposed a cogeneration system at the Federal University of Paraíba (UFPB), utilizing organic Rankine cycles in combination with vapor absorption refrigeration. They highlighted significant improvements in mechanical power generation and exergoeconomic efficiency. However, an exergoenvironmental analysis of the system was not included.

The study by Marques et al. [22] conducted a Life Cycle Assessment (LCA) of a natural gas micro-trigeneration system, which produces electricity, cooling, and hot water. The system’s life cycle included all stages, from equipment production to final disposal. The LCA evaluation methods used in the study were Eco-indicator 99 and the ReCiPe method, the latter also being adopted in the present study. The software employed by Marques et al. [22] was SimaPro 9.0.0.49, with the Ecoinvent 3.5 database, while the present study used the open-source software OpenLCA 1.10.3 and the Ecoinvent 3.7.1 database.

The results indicate that the greatest environmental impacts are associated with the internal combustion engine and the biodiesel plant, mainly due to the material composition of these components and the use of natural gas as fuel.

Zun et al. [6] conducted a comparative study using three types of energy sources for a recreational single-effect vapor absorption refrigeration system. The system employed electric resistance heating, propane, and green hydrogen as energy sources for the chiller. In terms of carbon-neutral economics, 1 kg of hydrogen can potentially replace 3.28 kg of propane (costing approximately 3.60 to 4.30 USD). It is estimated that a reduction of 8–9 kg of CO2 can be achieved for each kg of hydrogen used. However, the study did not perform a more in-depth Life Cycle Assessment (LCA) and exergoenvironmental analysis.

As depicted in the above literature review, the scientific literature works present a significant gap in the investigation of exergoenvironmental evaluation of double-effect vapor absorption chillers that use low-carbon fuels. Studies in this area are necessary to contribute to the advancement of knowledge in energy conversion systems regarding efficiency enhancement and reduction of greenhouse gas emissions. Moreover, such systems have the potential to support the energy transition towards a carbon-neutral future scenario. The mentioned literature review, described in more detail through Table 1, highlights the fact that most studies do not provide an exergoenvironmental model of DEAC systems, and for that reason, it becomes difficult to evaluate the environmental impacts of internal energy fluxes and products of DEAC systems.

Table 1.

Literature review on studies considering the energy and environmental assessment of the absorption chiller technology.

Due to the scarcity of scientific studies analyzing the mentioned aspects, this work aims to fulfill such a research gap by providing the following contributions and innovative aspects to the scientific community:

- An exergoenvironmental assessment model for the assessment of DEAC systems, which will support researchers and engineers in the evaluation of such types of systems and in reproducing this type of study for other specific applications;

- Evaluation of a case study in which the analyzed DEAC system meets the annual cooling demand of a university building in northeastern Brazil;

- Introduction of GH2 as one of the DEAC fuel resources and its exergoenvironmental performance in comparison with conventional energy resources (NG and biomethane).

Therefore, the analysis will be conducted using three types of fuels during the system’s operational phase: natural gas, biomethane, and green hydrogen (GH2). A detailed Life Cycle Assessment (LCA) has been developed for the considered DEAC, utilizing the ReCiPe environmental impact assessment method and the Ecoinvent database. The LCA encompassed the life cycle of a DEAC system, from raw materials extraction to the disposal of the equipment, as well as the operation phase of the system, which demands electricity, water, the DEAC working fluid, and the considered energy resources, contributing to awareness of the environmental burdens associated with energy services.

2. Description of the DEAC

The DEAC is a type of refrigeration technology powered by low-grade heat sources, including industrial waste heat and renewable thermal energy, such as solar, geothermal, and biomass energy. It is distinguished by its low energy consumption, minimal moving parts, and stable operational performance. It is an effective low-carbon or zero-carbon energy utilization technology suitable for large-scale industrial waste heat recovery as well as small-scale distributed refrigeration [23,24].

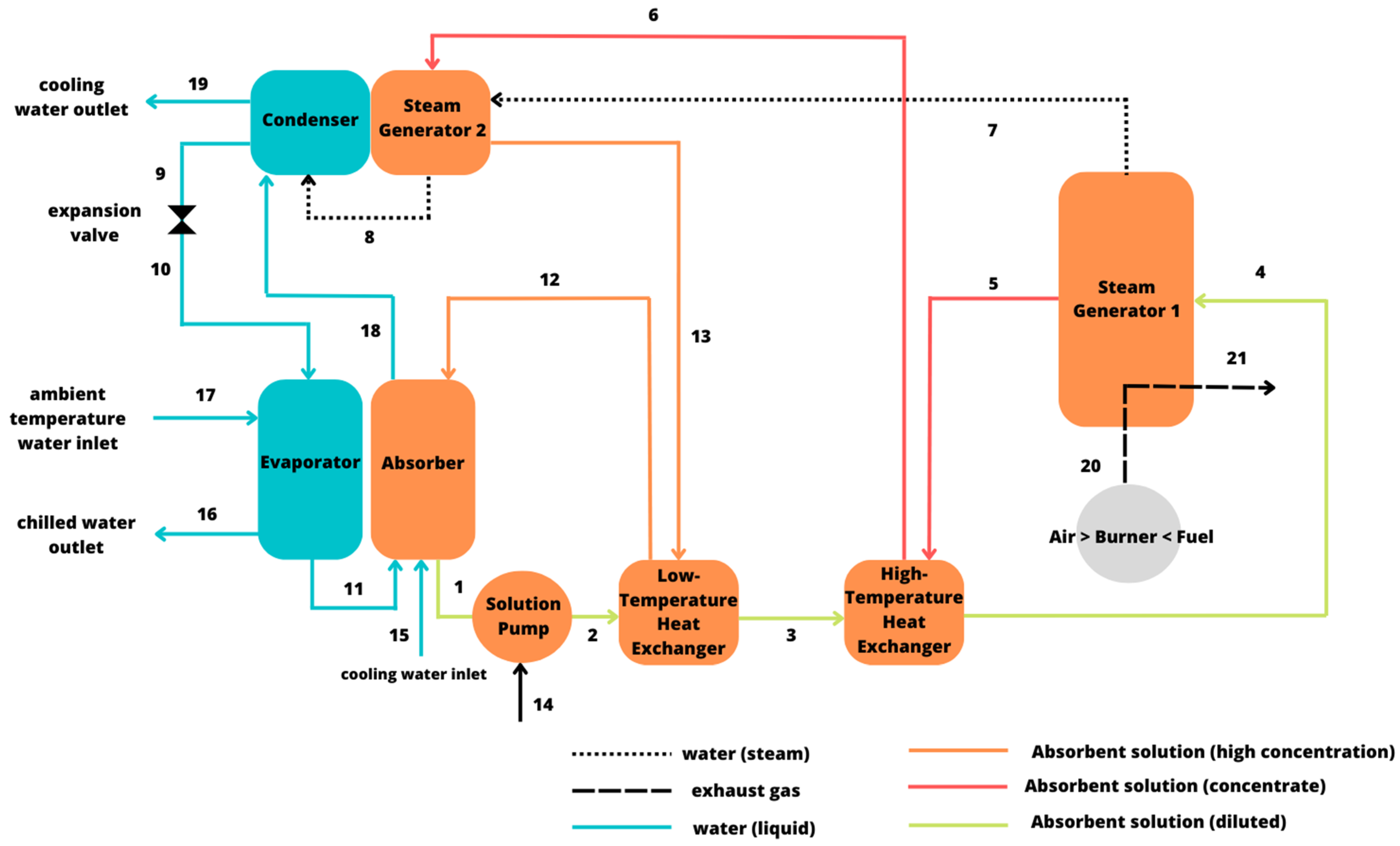

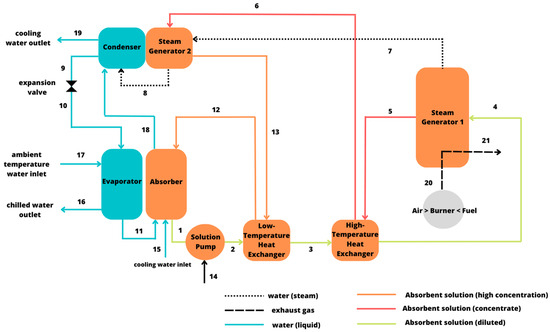

To better understand the system’s operation, it is essential to define the scope of this study. The DEAC, selected to meet the cooling demand of a university building, has a capacity of 352 kW and consists of the following components: steam generator 1, steam generator 2, two heat exchangers, an absorber, an evaporator, a condenser, an expansion valve, and a solution pump. Figure 1 illustrates the described system.

Figure 1.

Commercial double-effect vapor absorption refrigeration system (DEAC) with a capacity of 352 kW.

The DEAC operates as follows: at point 1 (Figure 1), a solution of water and lithium bromide with a high concentration of water exits the absorber. After passing through a pump (point 2), the solution’s pressure is increased, and it enters the low-temperature heat exchanger, where it is preheated. Exiting the low-temperature heat exchanger (point 3 in Figure 1), the solution passes through the high-temperature heat exchanger (points 3 and 4) and enters the steam generator 1. In this generator, the solution receives thermal energy from the direct combustion of a fuel (point 20), separating part of the water/lithium bromide solution. From steam generator 1, high-temperature water vapor (point 7) and a concentrated solution of water and lithium bromide (point 5) are produced.

The concentrated solution passes through the high-temperature heat exchanger and proceeds to steam generator 2 (point 6), where it receives high-temperature water vapor and the concentrated water/lithium bromide solution. From steam generator 2, the water vapor flows to the condenser (point 8), while the solution with a high concentration of lithium bromide is directed to the low-temperature heat exchanger (point 13). As the solution passes through the heat exchanger, it reaches the pressure and temperature necessary to return to the absorber (point 12).

The low-temperature water vapor enters the condenser (point 8), where it exchanges heat with the cooling water and condenses. At the condenser outlet (point 9), liquid water is observed, which then passes through an expansion valve (point 10), where pressure and temperature drop, allowing it to enter the evaporator. In the evaporator, the refrigerant fluid exchanges heat with the ambient-temperature water, cooling the external fluid to an average of 5 °C. Upon leaving the evaporator (point 11), the refrigerant fluid returns to the absorber, restarting the cycle.

Points 15, 18, and 19 refer to the system’s cooling fluid. Point 14 is the electrical energy input that powers the solution pump, while points 17 and 16 represent the entry of ambient-temperature water and the exit of chilled water, respectively.

3. Case Study

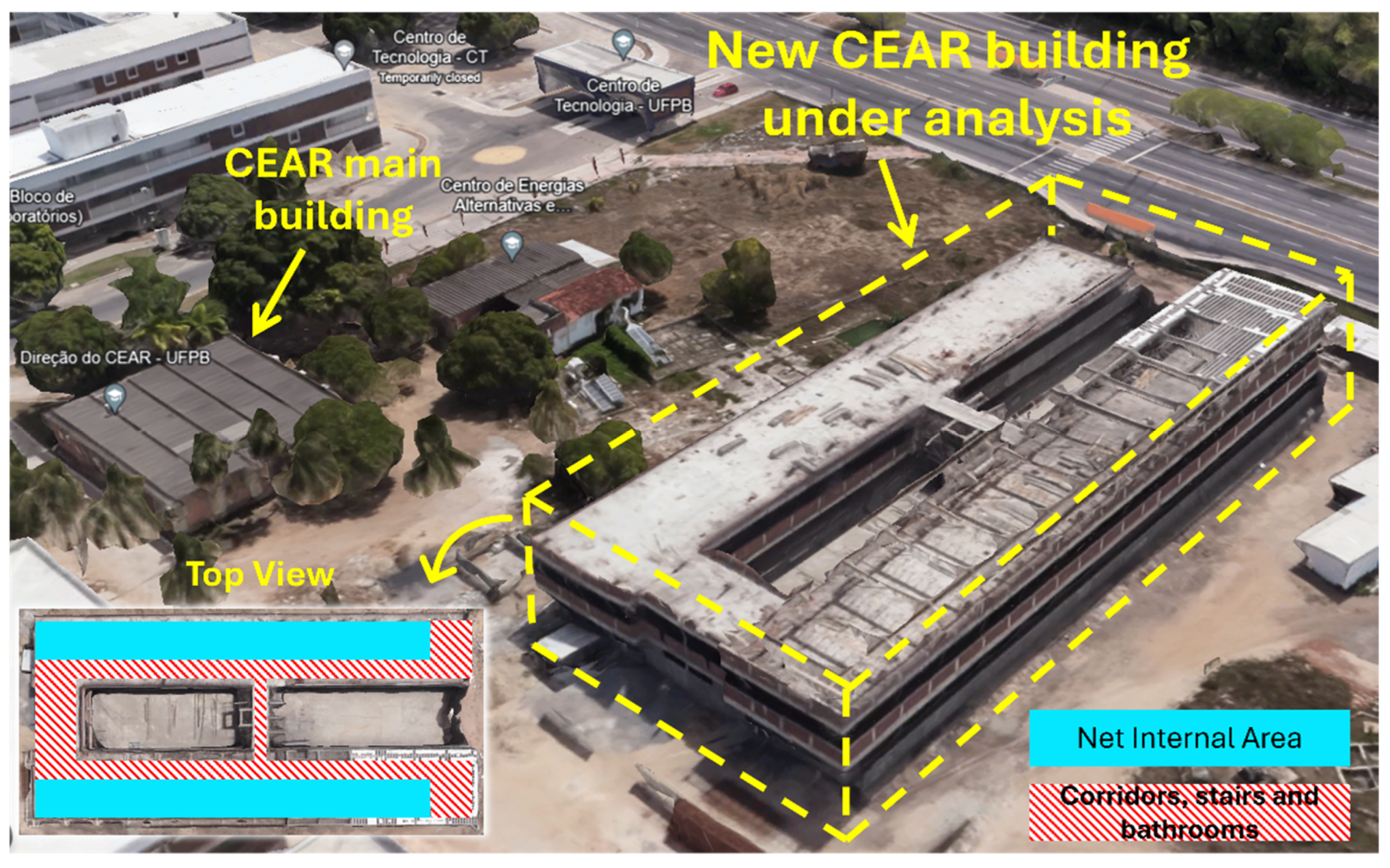

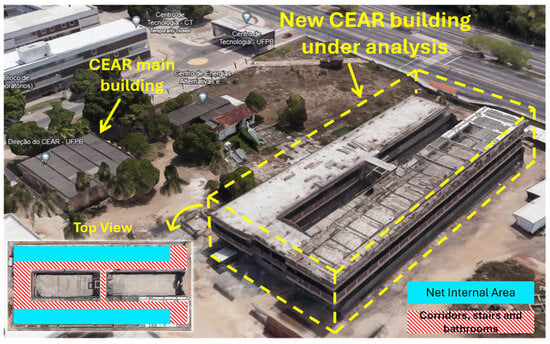

This section aims to present a case study of a building that can potentially benefit from the double-effect vapor absorption chiller (DEAC). It will estimate the monthly cooling demand of the building met by the DEAC system. The building is a newly constructed facility that will be part of the Center for Alternative and Renewable Energies (CEAR), hereafter referred to as the CEAR building (Figure 2) at the Federal University of Paraiba (UFPB) in João Pessoa, Northeast Brazil. The CEAR building, which is currently in the final stages of construction, consists of two blocks with a ground floor plus three additional floors each (Figure 3), which contains a variety of spaces, including the secretariat, coordination offices, auditoriums, professors’ offices, student rooms, laboratories, and classrooms.

Figure 2.

Facade of the CEAR-building located in the Center of Technology of the Federal University of Paraiba, Northeast of Brazil..

Figure 3.

Under-construction view of the CEAR building and the top view showing the net internal area (NIA) plus the area comprising corridors, stairs, and bathrooms.

Since the types of rooms in the CEAR building are quite heterogeneous, an average cooling load of 100 W/m2 [25] will be assumed, considering the net internal area (NIA) (Figure 2) of each floor. Each floor comprises approximately 1500 m2 of useful area, with about 600 m2 dedicated to corridors, stairs, and bathrooms. Therefore, the NIA of each floor is assumed to be 900 m2, which results in a total NIA of 3600 m2, considering the four floors, and hence, a total cooling load of 360 kW.

In the study conducted by Souza et al. [21], the authors estimated the monthly electricity consumption for electric chillers (Column A, Table 2) in a building called IES1, located near the CEAR building within the UFPB campus. As shown in Column A of Table 2, January had the highest electricity consumption for air conditioning, corresponding to the peak cooling demand of IES1. Therefore, the aforementioned cooling load of 360 kW, required to cool the entire NIA of the CEAR building, will be taken as the average hourly cooling demand for the ten working days in January. Column B of Table 2, which represents the ratio between the first value in Column A and all the other values in the same column, will then be used to calculate the average hourly cooling demand for the remaining months, from February to December (Column C, Table 2). Finally, Column D presents the total monthly cooling demand for the CEAR building.

Table 2.

Estimation of the average monthly cooling demand in the CEAR building, UFPB. Abbreviations: WD (number of working days for each month) [26]; A (monthly amount of electricity spent with air conditioning in the IES1, UFPB [21]; B (proportion between the first line of Column A and all lines of the same Column A); C (average hourly cooling demand); D (average monthly cooling demand).

4. Life Cycle Assessment

As noted in the literature, Life Cycle Assessment (LCA) is a crucial part of the exergoenvironmental analysis process, as it calculates environmental impact values using a quantitative method. LCA is an analytical technique under ISO 14040/14044 [27,28] guidelines that quantifies the environmental aspects of energy conversion systems throughout their lifecycle concerning material/energy resource consumption and resulting pollutant emissions [29,30]. In other words, LCA is an analytical tool that enables the assessment of potential environmental impacts at each stage of a product’s or service’s lifecycle, from raw material extraction to disposal [31].

Life Cycle Assessment (LCA) is a structured method that encompasses four main stages:

- Goal and Scope Definition: In this phase, the object of study is defined, and the system boundaries are established, determining what will be included and excluded from the analysis;

- Life Cycle Inventory (LCI): This stage involves compiling all data related to the inputs (materials, energy, etc.) and outputs (emissions, waste, etc.) associated with the object of study;

- Life Cycle Impact Assessment (LCIA): This stage uses the data collected in the previous step to evaluate the potential environmental impacts (such as on natural resources and ecosystems) and human health;

- Interpretation: The goal here is to analyze the results of the LCIA to identify the main contributors to significant environmental impacts and, based on this analysis, suggest possible improvements. This systemic approach allows for the identification, quantification, and mitigation of environmental impacts throughout the entire life cycle of a product or service, from raw material extraction to final disposal.

4.1. Scope Definition

The goal and scope definition phase should be carried out clearly, outlining the expected outcomes of the study [32]. This stage explains the rationale for conducting the LCA, with definitions of the study (product, system, or activity) and its lifecycle, as well as a description of the system boundaries (which may include raw material extraction, material processing, manufacturing, transportation, distribution, use, repair, maintenance, and disposal) [33].

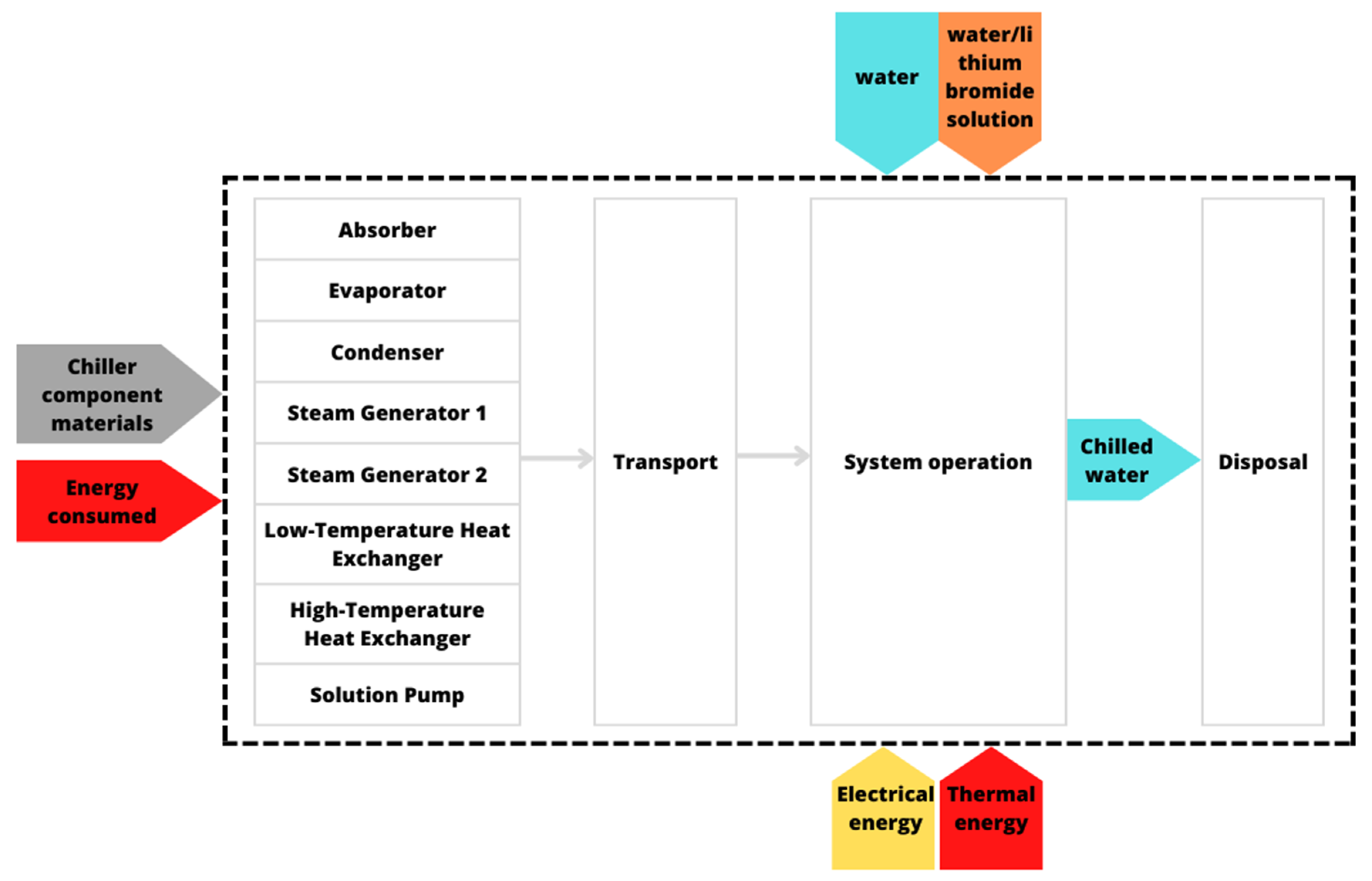

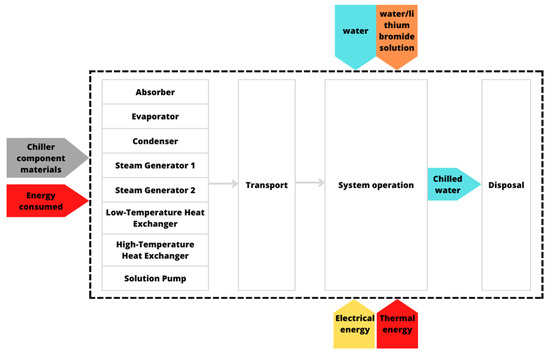

The scope of this study encompasses the stages of manufacturing, transportation, operation, and disposal of a vapor absorption chiller. In the manufacturing phase, the analysis will consider the materials and energy consumed in the production of all system components. Subsequently, the study will evaluate the impacts associated with the transportation of the chiller.

During the operation phase, three distinct scenarios will be analyzed: in Scenario 1, the chiller will operate using direct combustion of natural gas as the thermal source; in Scenario 2, the energy source will be biomethane; and in Scenario 3, the study will evaluate the environmental impacts of the chiller operating with green hydrogen (GH2).

In the final stage of the scope, the chiller will be disposed of in a landfill. Figure 4 illustrates the overall scope of the study, while Figure 5 presents the different thermal energy sources used in the chiller’s operation. A system lifespan of 20 years has been adopted [34].

Figure 4.

Illustration of the system boundaries for the LCA.

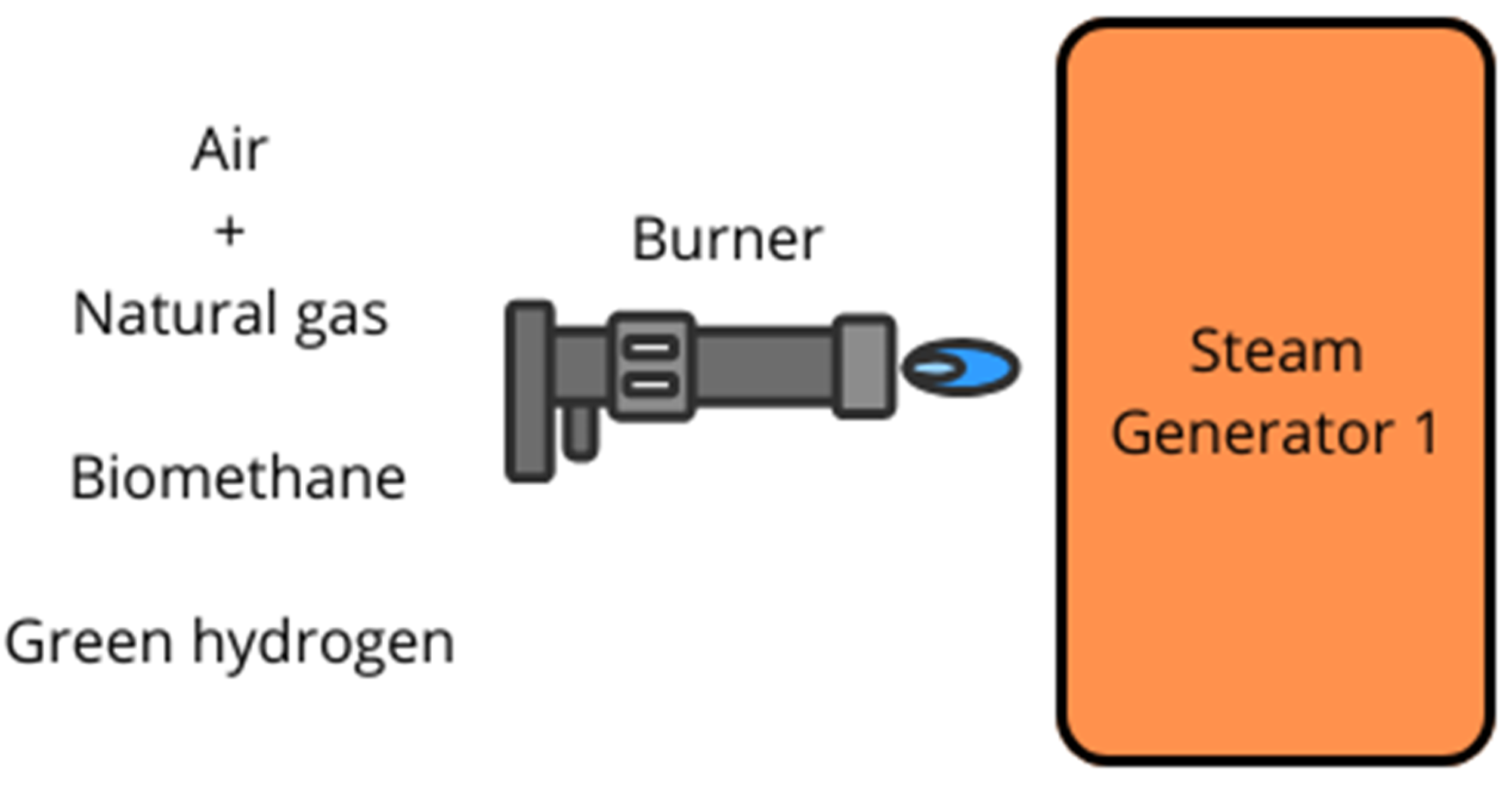

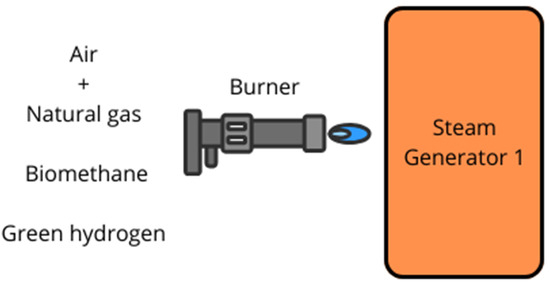

Figure 5.

Thermal energy sources considered for the absorption chiller operation.

4.2. Inventory Description

As previously mentioned, the Life Cycle Inventory (LCI) represents the stage of the LCA in which all inputs and outputs are associated with the object of study. In this study, inputs for the two main lifecycle phases of the system were considered: component manufacturing and system operation.

For the manufacturing phase, the consumption of raw materials and energy was evaluated, taking into account the mass of each component. In the operation phase, the analysis included thermal energy (from natural gas, biomethane, and green hydrogen), the water and lithium bromide solution, cooling water, and the electricity required for the system’s operation. Further details on the data for each component are presented in Table 3. Additionally, the transportation of the chiller from the manufacturer to the operational site and the disposal of the chiller were also considered in the simulation.

Table 3.

Input data for life cycle analysis.

According to LG [35], the absorption chiller has a total mass of 4200 kg. Steam generator 1 accounts for 900 kg, while the upper portion of the chiller, comprising steam generator 2 and the condenser, has a mass of 600 kg. The lower portion, consisting of the evaporator, absorber, solution pump, low-temperature heat exchanger, and high-temperature heat exchanger, totals 2700 kg. It is important to note that the mass related to attachments such as piping, sensors, and control panels is not included within the scope of this study. Therefore, for the purposes of the present analysis, a total mass of 3600 kg is considered.

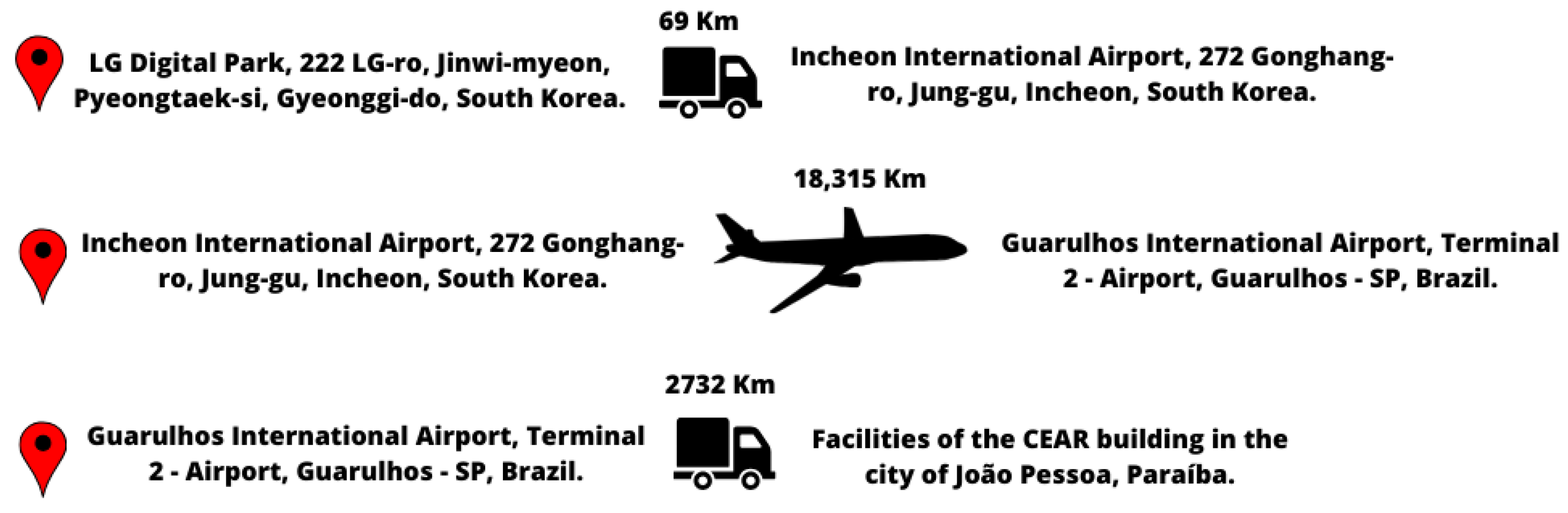

The chiller is manufactured in Gyeonggi-do Province, South Korea. This study does not include the transportation from the raw material extraction site to the manufacturer’s headquarters. Transportation from the factory to Incheon International Airport is carried out by truck, covering approximately 69 km. Subsequently, the transportation continues from Incheon to Guarulhos International Airport in containers via cargo plane, totaling a route of 18,315 km. Finally, from Guarulhos International Airport to the CEAR building facilities (as illustrated in Figure 6), located in the city of João Pessoa, the journey is again conducted by truck, covering about 2732 km.

Figure 6.

Schematic diagram of transportation routes.

4.3. System Operation

The operation stage of the system includes the cooling water, the electrical energy required to operate the pump, the water and lithium bromide solution, which are the working fluids, and the thermal energy necessary to operate steam generator 1. In this study, the operation of steam generator 1 is analyzed under three scenarios when it is powered by (i) the combustion gases of natural gas, (ii) the combustion gases of biomethane, and (iii) the combustion of green hydrogen.

The volumes of cooling water and chilled water, according to LG [35], are 0.028 m3 and 0.0168 m3, respectively. Therefore, the total volume is 0.0448 m3, with water losses not considered since the cycle is closed and potential losses over the chiller’s lifespan are negligible. The volume of the solution in the absorber is 0.019 m3, consisting of 55% lithium bromide (absorber fluid) and 45% water (refrigerant fluid).

The chiller has a cooling capacity of 352 kW and an estimated coefficient of performance (COP) of 1.51. Therefore, the thermal energy required to operate the chiller is calculated using Equation (1)

Within the scope of this study, it is considered that the system includes a solution pump (the only equipment that consumes electrical energy) with a power of 1.5 kW, which operates 24 h a day. Therefore, Equation (2) provides the electrical energy consumption. Table 4 describes the utilities required for the operation of the chiller.

Table 4.

Description of utilities required for chiller operation.

4.4. LCIA Method

In the context of Life Cycle Assessment (LCA), there are at least 64 methods for Life Cycle Impact Assessment (LCIA) [36]. A common classification in the literature is the division between midpoint approaches (intermediate stages of the cause–effect chain) and endpoint approaches (final stages of the cause–effect chain), which focus on different stages of this process. The interpretation of endpoint results does not require in-depth knowledge of environmental effects, which can facilitate more organized and informed decision-making [37]. The approach adopted in the present study is the ReCiPe method in its endpoint perspective.

The ReCiPe method in the endpoint approach comprises 17 categories distributed across three classes: human health, ecosystem quality, and resources. This methodology is one of the most advanced in Life Cycle Assessment (LCA), offering the largest set of impact categories. Additionally, ReCiPe combines the strengths of the midpoint-based Life Cycle Impact Assessment approach of the CML-IA method and the endpoint-based approach of the Eco-indicator 99 method [38].

As in other LCIA methods, the ReCiPe method presents uncertainties in the process of converting environmental flow inventories into environmental impacts [39]. Such uncertainties may arise for three reasons:

First, the quality and completeness of life cycle inventory data are essential for obtaining more accurate results. When information is missing, or the data used are imprecise, there may be an underestimation of environmental impacts, which compromises the analysis. Second, the coverage of substances analyzed varies between LCIA methods. In other words, not all methods consider the same number of substances for a given impact category, leading to different outcomes. Finally, even when substances are included in different methods, the characterization factors—which translate emissions into environmental impacts—may vary. This is due to different calculation methodologies and assumptions used by each method, resulting in some discrepancies in the final results.

5. Exergoenvironmental Assessment

According to Tsatsaronis et al. [40], exergoeconomics combines exergy flows with economic analysis in energy conversion processes. Exergoenvironmental assessment, on the other hand, employs the same exergy flows but focuses on environmental impacts. Therefore, the equations and balances used in exergoenvironmental assessment are similar to those employed in exergoeconomics.

As described by Meyer et al. [16], exergoenvironmental assessment consists of three main stages: (i) a detailed exergy analysis of the system, (ii) the quantification of environmental impacts, and (iii) the allocation of these environmental impacts to the exergy flows of the products of each component, followed by the calculation of exergoenvironmental variables and the exergoenvironmental assessment.

To perform the thermodynamic analysis of the DEAC system, the following simplifications were adopted:

- The solution pump was considered isentropic;

- Variations in kinetic and potential energies were negligible;

- In the condenser and evaporator, only the refrigerant circulates;

- The expansion valve was adiabatic;

- The refrigerant was assumed to be in saturation conditions at the outlets of the evaporator and condenser;

- The lithium bromide solution was in equilibrium at the exits of the absorber and steam generator;

- There was no heat transfer between the heat exchangers and the environment;

- Due to the low viscosity of the mixture and the laminar flow of the system, pressure drops due to friction in the heat exchangers, piping, and pumps were considered negligible.

The energetic and exergetic analysis of this system was conducted using the equations of the first and second laws of thermodynamics applied to each control volume of the system.

According to Alcântara et al. [3], the thermal energy of the combustion gases is obtained using the species conservation law, with reference to the amount of each hydrocarbon observed in the gas. The following equations represent the combustion reactions of natural gas and biomethane, respectively. It is assumed that the combustion is complete and occurs under standard conditions (25 + C and 1 atm).

Table 5 shows the composition of natural gas and biomethane used in this work. The composition of natural gas is provided by the PBGAS [41], and the composition of biomethane considered in this study follows the limits established by ANP [42]

Table 5.

Molar composition of natural gas and biomethane.

The green hydrogen used in this study is produced through the electrolysis of water using electricity generated from renewable energy sources. Almeida et al. [43] report that electrolysis is a very common process for the production of green hydrogen. With the help of an electric current, the water molecule (H2O) is dissociated into hydrogen gas (H2) and oxygen (O2). When the electricity required for this process comes exclusively from renewable sources, such as wind or solar energy, the product is referred to as green hydrogen.

Each kilogram of hydrogen contains approximately 2.4 times more energy than natural gas. Additionally, the only input required to release this energy is oxygen, and the only by-product is water. This means that, as an energy source, hydrogen produces zero greenhouse gas (GHG) emissions, as hydrogen combustion results in water, and thus, its burning does not contribute to GHG emissions, as illustrated by the hydrogen combustion reaction shown in the following equation. It is noteworthy that the energy released from hydrogen combustion is 242 kJ/mol or 121 kJ/g [5].

For the production of green hydrogen, according to Smolinka et al. [44], it was considered that producing 1 kg requires 54 kWh of electrical energy using the Polymer Electrolyte Membrane Electrolysis Cell (PEMEC) method.

The analysis of the environmental impact of the fuel is determined by the following equations:

where refers to the mass flow rate of the fuel (kg/s), is the specific mass of the fuel (kg/m3), is the exergy flow at the inlet of steam generator 1 and is the environmental impact per unit of exergy of the fuel.

The rate of environmental impact associated with the electricity powering the solution circulation pump (water and lithium bromide) is given by the following equation:

where is the environmental impact associated with electricity per unit of exergy and is the exergy flow associated with electricity.

The exergoenvironmental balance is determined by the following equation:

where is the environmental impact associated with the input flows to equipment k, is the environmental impact associated with the output flows of each equipment k, and is the result of applying the life cycle assessment (LCA) to each component of the system.

According to Marques et al. [32], the number of variables in the balance equations is generally greater than the number of flows, thus requiring the establishment of auxiliary equations. In most cases, the number of auxiliary equations is equal to the number of output flows minus one. The auxiliary equations are derived using the principles of the SPECO method (similar to those applied in exergoeconomic studies) to define the F (fuel) and P (product) of the system flows.

The equations derived from the F principle are developed for the exergy flows that supply exergy to the equipment. The decrease in exergy within the equipment constitutes part of the exergy of the fuel used by the equipment. Thus, the specific environmental impact of this flow remains constant between the inlet and the outlet.

The product equations are formulated for the exergy flows that increase between the inlet and the outlet, characterizing the equipment’s product. This increase is part of the exergy of the equipment’s product. Each unit of exergy is distributed to all exergy flows with the same average specific environmental impact of the product () [22].

Table 6 presents the exergoenvironmental balance for each piece of equipment in the DEAC under study.

Table 6.

Exergoenvironmental balance for each piece of equipment in the DEAC.

The exergoenvironmental variables are used to evaluate the environmental performance of each system component. The following equations are used to determine the average specific environmental impacts of the fuel and products for all system flows.

where and are the rates of environmental impact associated with the fuel and the product flows of the system components, respectively.

The expression that determines the rate of environmental impact related to the destruction of exergy is given by:

where is the environmental impact per unit of exergy associated with the fuel and is the exergy destroyed associated with the fuel for each component.

One way to calculate the environmental impact of equipment is by summing the environmental impact of the equipment (including all stages of the life cycle: manufacturing, transportation, installation, operation, maintenance, and disposal) as determined by the life cycle assessment (LCA) study, with the rate of environmental impact associated with exergy destruction. Therefore, the equation is written as follows:

Another exergoenvironmental parameter of interest for the study is the relative difference in specific environmental impacts, designated as and represented by the following expression:

The following equation shows how to determine another exergoenvironmental parameter called the exergoenvironmental factor (), which is used to compare the sources of environmental impact in a component. The value of this factor ranges from 1 to 0, with a value closer to 1 being better, as it indicates that the environmental impact due to exergy destruction is minimal.

6. Results and Discussion

The following subsections will present the results of the mass flow and exergy rate for the three fuels under study, the life cycle assessment of the chiller, and the results of the exergoenvironmental analysis.

6.1. Results of the Thermodynamic Analysis

Table 7 presents the mass flow rate (m), specific exergy, and exergy flow for each point in the DEAC system, considering natural gas, biomethane, and green hydrogen as fuels.

Table 7.

Exergy flows of the DEAC system.

Analyzing Table 7, it is observed that green hydrogen exhibits the highest exergy rate for a given amount of thermal energy required by the system under study. This is evidenced by flow 20 in the graph, which represents the entry of combustion gases into the steam generator 1.

Exergy rate is a measure of the quality or usefulness of an energy resource. For the same thermal energy demand, the exergy of different fuels can vary based on their ability to perform useful work.

Natural gas is primarily composed of methane (CH₄) and has a high exergy rate because methane has a high potential to release energy when burned. Its high energy density and combustion efficiency contribute to its elevated exergy rate.

Biomethane is essentially methane produced from biological processes, such as anaerobic digestion. Although its composition is similar to that of natural gas, the exergy rate of biomethane may be slightly lower due to potential impurities and variations in the quality of the produced fuel. However, in terms of pure exergy, biomethane is comparable to natural gas.

Green hydrogen, produced from the electrolysis of water using renewable energy, has a high exergy rate because, when burned, it produces only water while releasing a significant amount of energy per unit of mass. Although hydrogen has a lower volumetric energy density compared to hydrocarbons, its high exergy is evident due to its efficiency in energy conversion.

At point 11, the negative exergy value results from a comparison with the standard state, defined by an ambient temperature of 25 °C and an atmospheric pressure of 101.325 kPa. At the mentioned point, both pressure and temperature are below these reference values, resulting in negative exergy.

The exergy rate in the DEAC does not vary with the change of fuel because exergy is a property that depends on the thermodynamic conditions of the system (such as temperature, pressure, and the composition of the substances involved) and the environmental conditions. The change in fuel, which affects the heat source for the generator, alters the amount of thermal energy supplied but does not directly modify the thermodynamic properties of the system.

Regarding combustion engineering, it was assumed that combustion is complete and that there are no variations in the composition of the analyzed fuels. These assumptions have practical implications for operating conditions, such as reduced efficiency due to variations in the fuels’ calorific value, which directly impacts the amount of energy generated per cubic meter of gas burned. In the case of incomplete combustion, the consequences include the formation of by-products, as the fuel is not fully oxidized. For natural gas, this can result in the emission of carbon monoxide (CO), soot, and other unburned hydrocarbons, thereby increasing environmental pollution

6.2. Results of the Life Cycle Assessment

Table 8, Table 9 and Table 10 present the contribution of environmental impacts to the life cycle of the absorption refrigeration chiller under study using the Recipe (H/A) method. The analysis was conducted by substituting the fuel in the operation phase of the chiller while the stages of manufacturing, transportation, and disposal remained unchanged.

Table 8.

Relative contribution of the impact categories considered in ReCiPe 2016 (H/A) using natural gas as fuel (the following categories were omitted from the table: Ecosystems (freshwater ecotoxicity, terrestrial acidification, freshwater eutrophication, marine ecotoxicity, terrestrial ecotoxicity) and Human Health (ionizing radiation, ozone depletion, photochemical oxidant formation)).

Table 9.

Relative contribution of the impact categories considered in ReCiPe 2016 (H/A) using biomethane as fuel ( the following categories were omitted from the table: Ecosystems (freshwater ecotoxicity, terrestrial acidification; freshwater eutrophication, marine ecotoxicity, terrestrial ecotoxicity) and Human Health (ionizing radiation, ozone depletion, photochemical oxidant formation)).

Table 10.

Relative contribution of the impact categories considered in ReCiPe 2016 (H/A) using green hydrogen as fuel (the following categories were omitted from the table: Ecosystems (freshwater ecotoxicity, terrestrial acidification; freshwater eutrophication, marine ecotoxicity, terrestrial ecotoxicity) and Human Health (ionizing radiation, ozone depletion; photochemical oxidant formation)).

The ReCiPe method evaluates environmental impacts in three groups: Ecosystems, Human Health, and Resources. Impact categories with near-zero environmental relevance were excluded to maintain the most significant results and enable better interpretation. The excluded categories were Ecosystems (freshwater ecotoxicity, terrestrial acidification; freshwater eutrophication, marine ecotoxicity, terrestrial ecotoxicity) and Human Health (ionizing radiation, ozone depletion, photochemical oxidant formation).

Table 8 shows that the groups Ecosystems, Human Health, and Resources are affected, respectively, by 18.83%, 35.8%, and 45.4% of the total environmental impacts derived from the LCA results of the DEAC operating with natural gas as the energy resource.

Table 9 shows that the groups Ecosystems, Human Health, and Resources are affected, respectively, by 19.64%, 37.24%, and 43.12% of the total environmental impacts derived from the LCA results of the DEAC operating with biomethane as the energy resource.

Table 10 shows that the groups Ecosystems, Human Health, and Resources are affected, respectively, by 19.14%, 37.16%, and 43.7% of the total environmental impacts derived from the LCA results of the DEAC operating with green hydrogen as the energy resource.

The analysis of Table 8, Table 9 and Table 10 underscores the crucial importance of selecting cleaner and more sustainable energy sources for DEAC systems. While natural gas is widely used, it presents the greatest environmental impacts, particularly in terms of fossil fuel depletion and climate change. Biomethane, in turn, represents an advancement in sustainability by mitigating some of the impacts associated with natural gas. However, it is green hydrogen that stands out as the most promising option, offering the lowest environmental impacts across multiple categories.

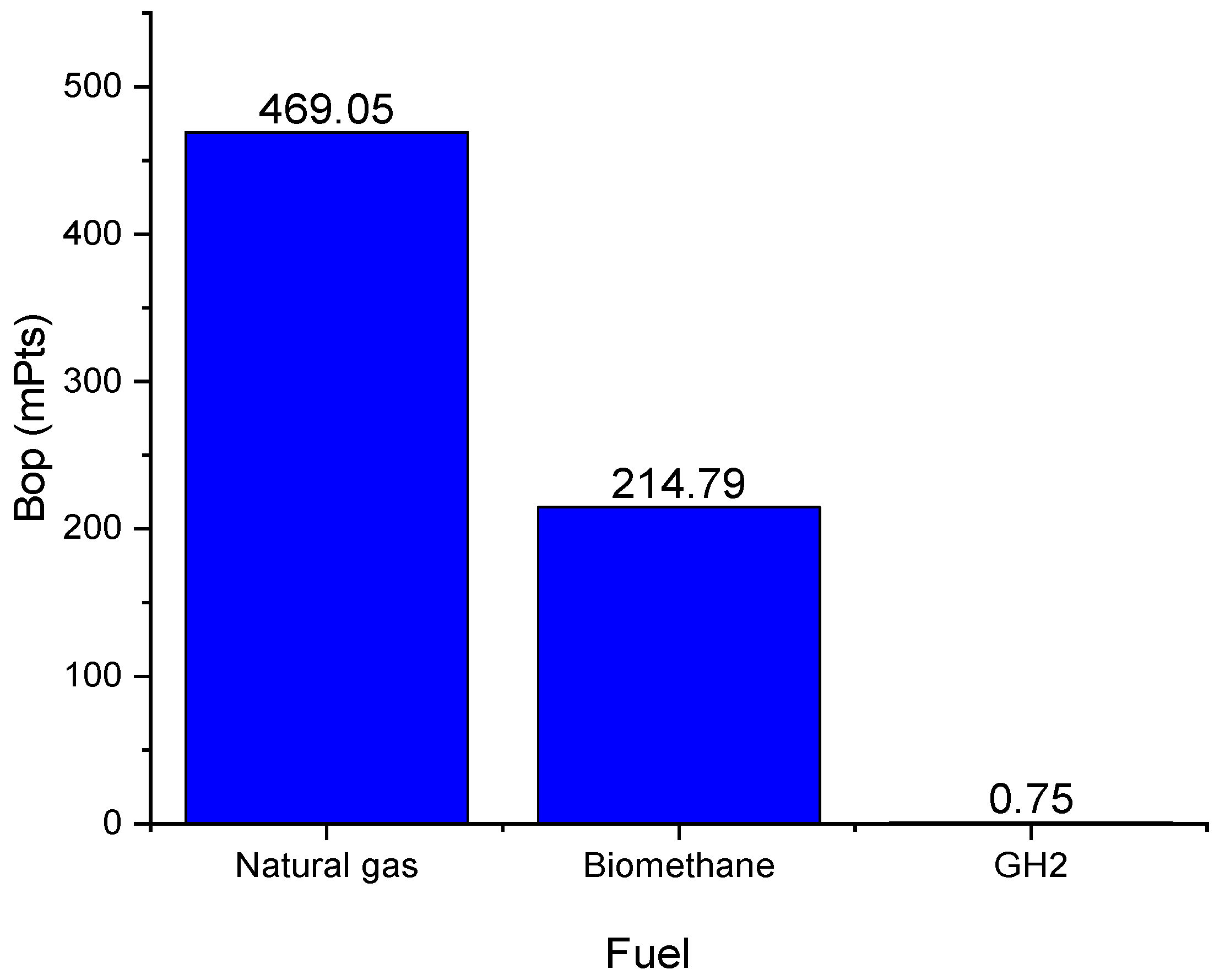

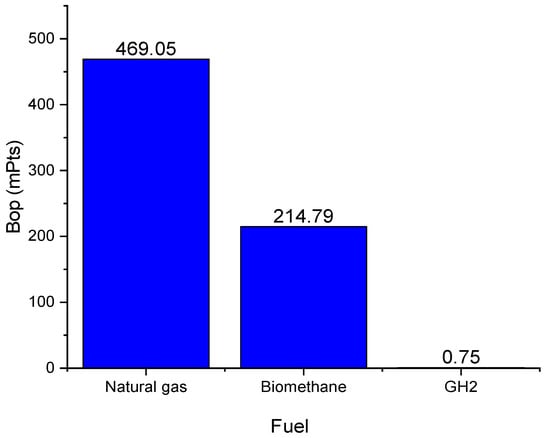

Figure 7 presents a comparative graph of the life cycle assessment of the operational phase, using the RECIPE Endpoint (H,A) method for the chiller, alternating between the three fuels: natural gas, biomethane, and green hydrogen (GH2).

Figure 7.

Lifecycle results of the chiller during the operational phase (Bop) comparing the use of three fuels: natural gas vs. biomethane vs. green hydrogen.

During the operational phase of the DEAC, where the highest consumption throughout the lifecycle is the thermal energy required for the operation of steam generator 1, green hydrogen achieves a 99.84% reduction in environmental impacts compared to natural gas.

Green hydrogen is produced using electricity generated from renewable sources, and when it is used for combustion, green hydrogen (GH2) emits water vapor as a by-product. This means that there are no greenhouse gas emissions or atmospheric pollutants during its use. Despite being the best choice from an environmental perspective, the technological pathway for the production of green hydrogen is economically burdensome. Appropriate regulation and private capital investment are essential to accelerate the development of this technology and reduce the costs associated with the installation, infrastructure, and operation of production systems. These measures can enhance both the technical and economic viability of green hydrogen in comparison to conventional alternatives, promoting its large-scale adoption and contributing to a more sustainable energy transition.

In Brazil, where the study was conducted, Law No. 14,948 was enacted on 2 August 2024 [45], establishing the legal framework for low-carbon hydrogen. This new legislation provides incentives for the production and commercialization of green hydrogen, encouraging an increase in private-sector investments. For example, Eletrobras is investing in hydrogen production through two commercial agreements, which will enable the future supply of this fuel. The CEAR building, the focus of the case study, already has a solar power plant and plans to utilize this infrastructure for green hydrogen production, further promoting sustainability.

Natural gas, although a relatively cleaner option compared to other fossil fuels, still results in CO2 and other pollutant emissions during combustion. This places it at a disadvantage compared to both green hydrogen and biomethane in terms of environmental impact reduction. Biomethane, being a renewable alternative derived from the decomposition of organic waste, represents an improvement over natural gas by reducing environmental impacts by 54.21% relative to natural gas. However, it may still produce emissions during combustion and is not as efficient as green hydrogen in terms of overall environmental impact reduction.

Biomethane exhibits chemical characteristics similar to those of natural gas, with the advantage of being directly injected into the existing network and distributed by the same companies that commercialize natural gas in Brazil. The expansion of biomethane usage not only leverages this infrastructure but also contributes to environmental sustainability, making the energy system more aligned with a low-emission future. In Brazil, the regulation of biomethane is governed by ANP Resolutions 886/2022 [42] and 906/2022 [46].

6.3. Results of the Exergoenvironmental Analysis

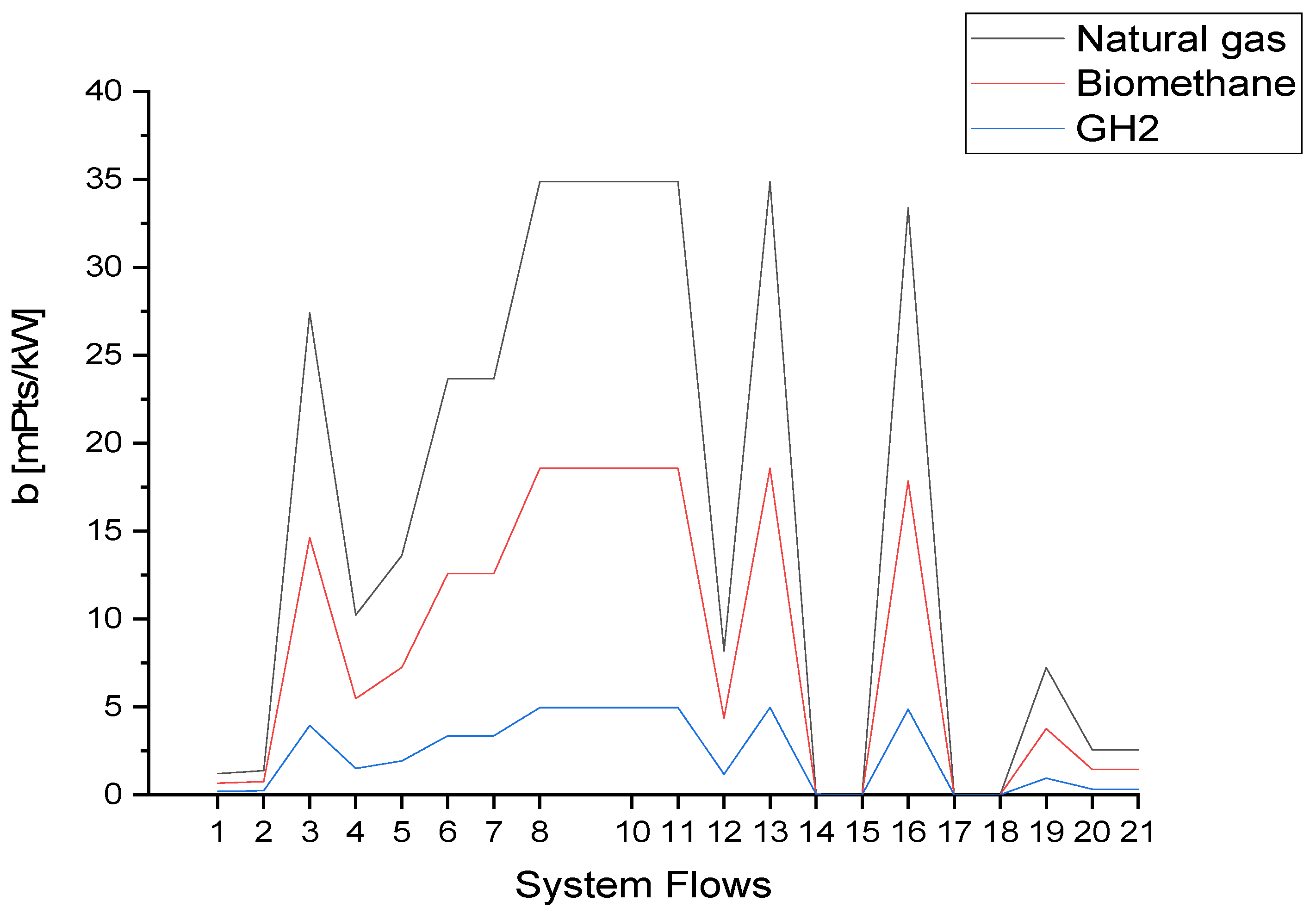

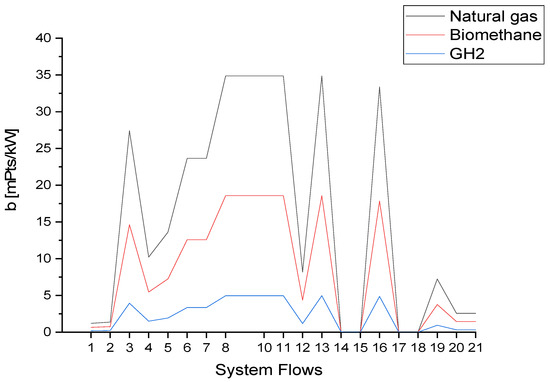

Figure 8 presents the comparative results for each system flow, highlighting the specific environmental impact of the three fuels analyzed. Biomethane exhibits lower specific impacts compared to natural gas, while green hydrogen demonstrates the lowest specific impacts overall.

Figure 8.

Comparative specific environmental impact (b) of natural gas vs. biomethane vs. green hydrogen.

Although the specific values differ for each fuel, the curves demonstrate the same behavior and compatibility. Peaks, valleys, and plateaus [22] occur in the same regions for all fuels.

Natural gas, represented by the blue line, exhibits significant peaks in certain system flows, particularly in flows 8, 10, 11, and 13. These peaks indicate a higher environmental impact compared to the other fuels, especially during periods of increased demand or intensive system operation.

Biomethane, indicated by the orange line, shows considerable variations in specific environmental impact, with peaks close to natural gas but generally below it. This suggests that, although biomethane has higher environmental impacts at certain times, it tends to be less harmful to the environment compared to natural gas.

Green Hydrogen (GH2), represented by the gray line, exhibits the lowest environmental impact values across nearly all system flows. This indicates that green hydrogen is the most environmentally friendly fuel option among the three, with minimal impacts compared to biomethane and natural gas.

The fluctuations observed in specific environmental impact across system flows may be indicative of variations in system efficiency or energy demand, directly influencing emissions and, consequently, the environmental impact.

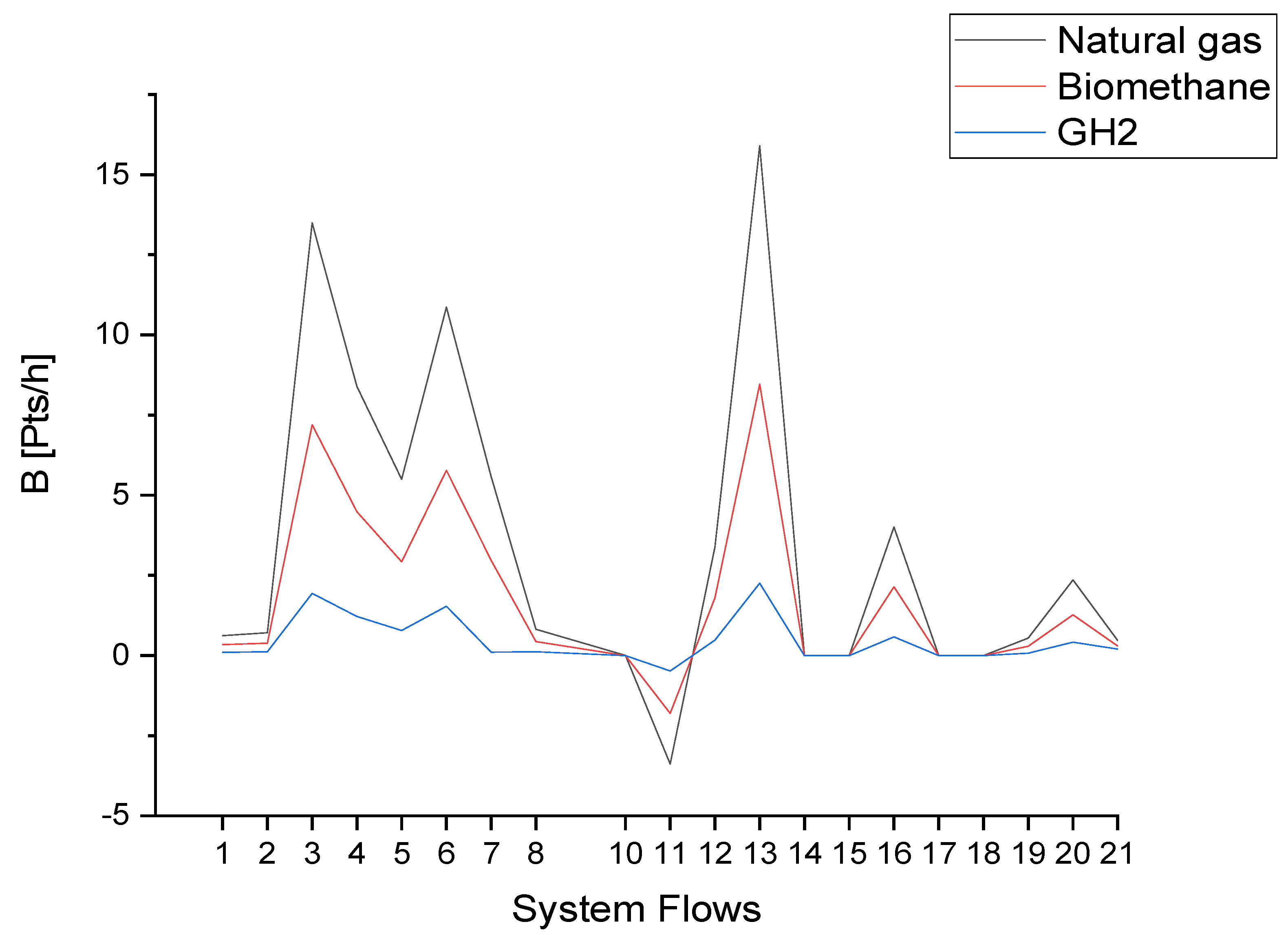

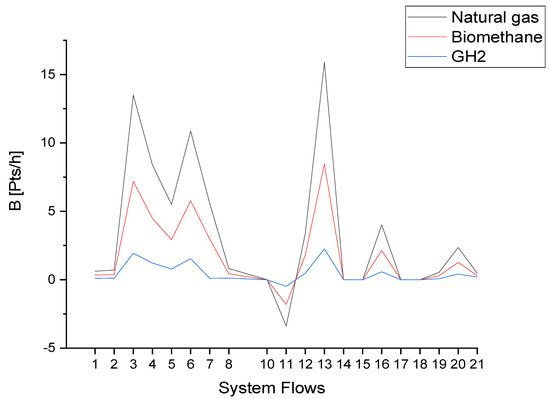

Figure 9 illustrates the environmental impact rates. It can be observed that points 13, 6, and 3 exhibit the highest environmental impact rates, with approximately 15,100 points/h, 14,500 points/h, and 11,000 points/h, respectively. Green hydrogen has the lowest impact rates, standing out as the cleanest fuel.

Figure 9.

Comparative environmental impact rate (B) of natural gas vs. biomethane vs. green hydrogen.

Due to the negative exergy value at point 11, the environmental impact rates also became negative at this point.

The points associated with the cooling fluid exhibit a zero impact rate, as it is considered that the fluid operates in a closed-loop system with no losses throughout its lifecycle.

The environmental impact rate of GH2 exhibits the lowest values, as the production of green hydrogen, obtained through the electrolysis of water using electricity from renewable sources such as solar and wind, represents a clean alternative with reduced environmental impact. This process splits water into hydrogen and oxygen without generating CO2 or pollutants. When green hydrogen is used as a fuel, its combustion results only in water, without releasing greenhouse gases, nitrogen oxides, or sulfur dioxides, in contrast to fossil fuels that contribute to global warming and air pollution.

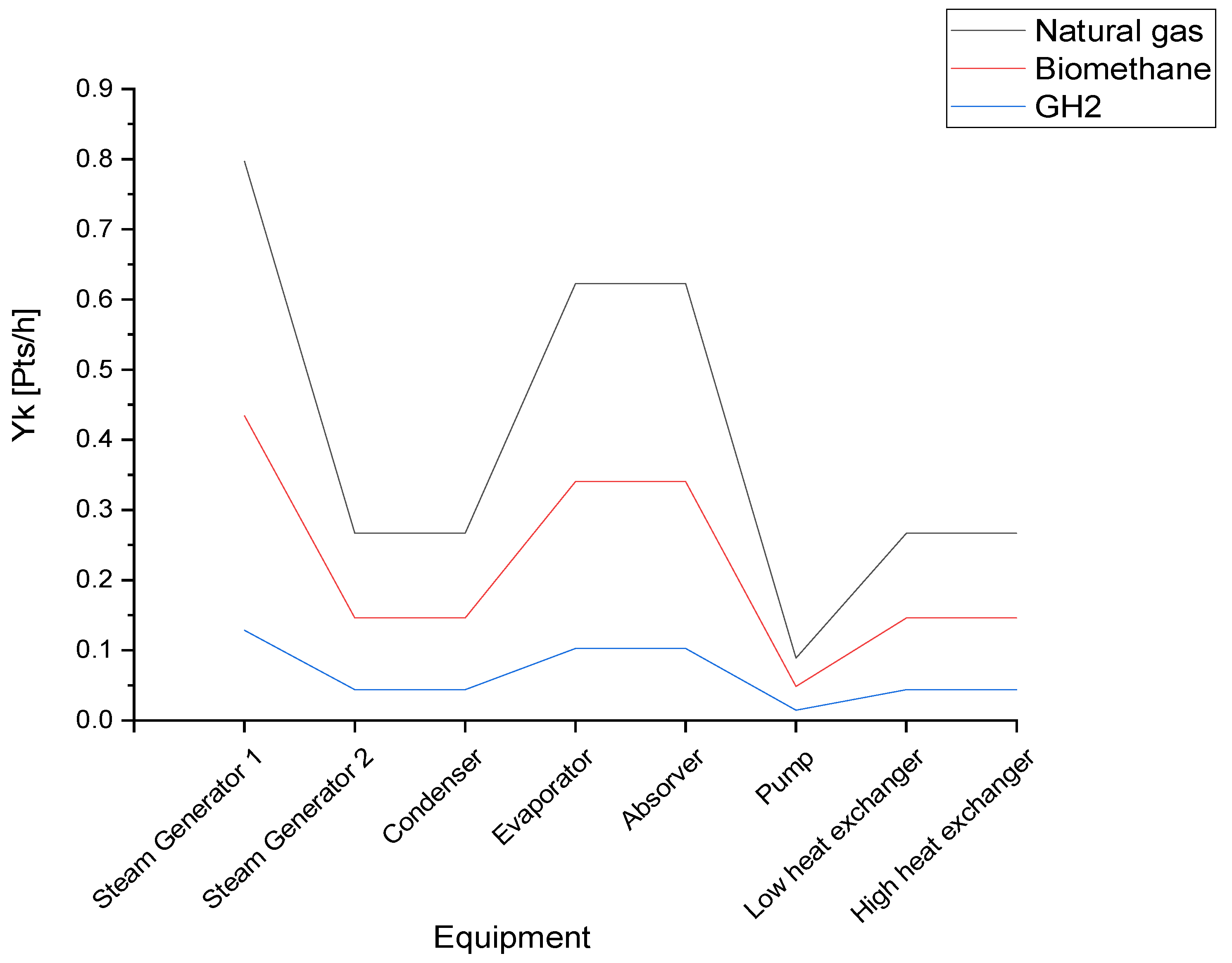

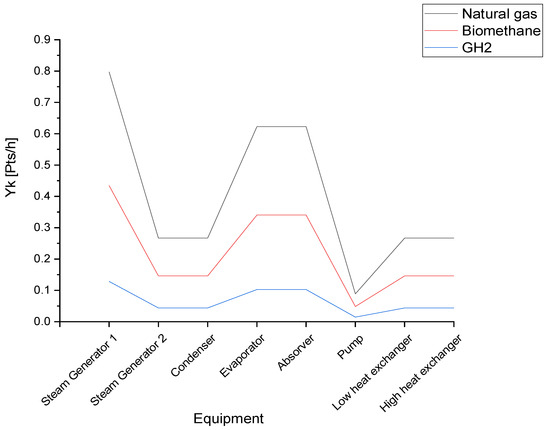

Figure 10 compares the relative environmental impacts considering the Life Cycle Assessment (LCA). Green hydrogen again has the lowest impact.

Figure 10.

Comparative environmental impact rate relative to LCA (Yk) of natural gas vs. biomethane vs. green hydrogen.

Steam generator 1 shows the highest relative environmental impact value, followed by the evaporator and absorber, across the three fuels analyzed. This can be explained by the exergy destruction in the combustion process, as well as the mass (Kg) and material used in the equipment, which affects the production, transportation, and disposal stages in the life cycle assessment. The steam generator 1 has a mass of 900 Kg, while the absorber and evaporator have a mass of 700 Kg. These latter two pieces of equipment are composed of 80% copper, which is characterized by highly energy-intensive extraction and production phases, resulting in significant environmental impacts, primarily due to electricity production from hard coal [47]

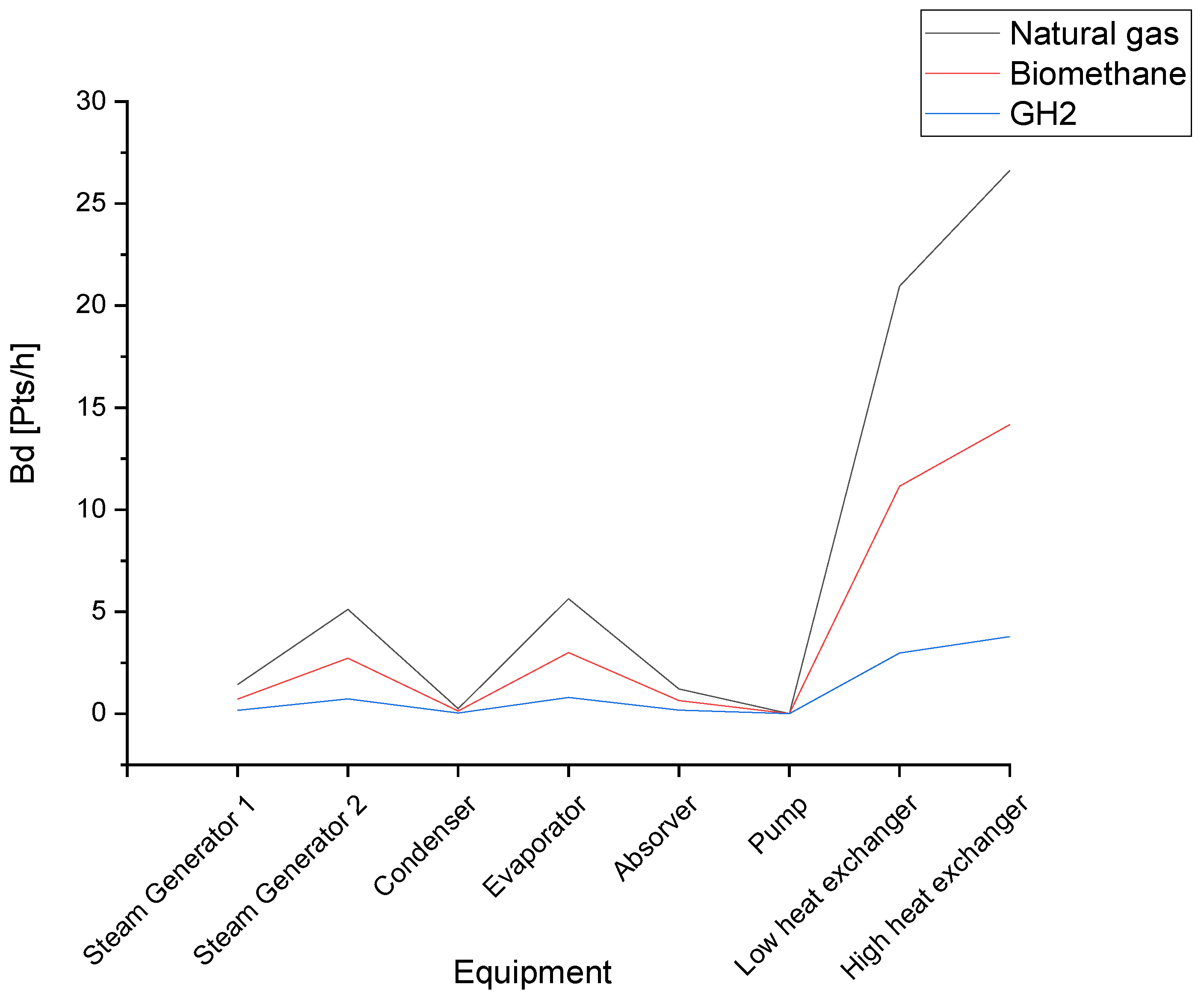

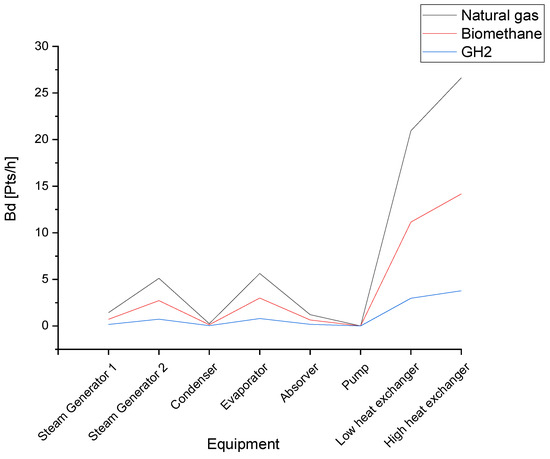

Figure 11 shows the exergy destruction associated with environmental impact. The highest values of exergy destruction are observed in the low- and high-temperature heat exchangers. This phenomenon indicates that these components exhibit high levels of specific environmental impact and exergy destruction, reflecting significant inefficiencies in the heat transfer process. The substantial exergy destruction in these heat exchangers can be attributed to large temperature gradients between the fluids, which generate thermal irreversibilities and, consequently, increase exergy losses.

Figure 11.

Comparative environmental impact rate associated with exergy destruction (Bd) of natural gas vs. biomethane vs. green hydrogen.

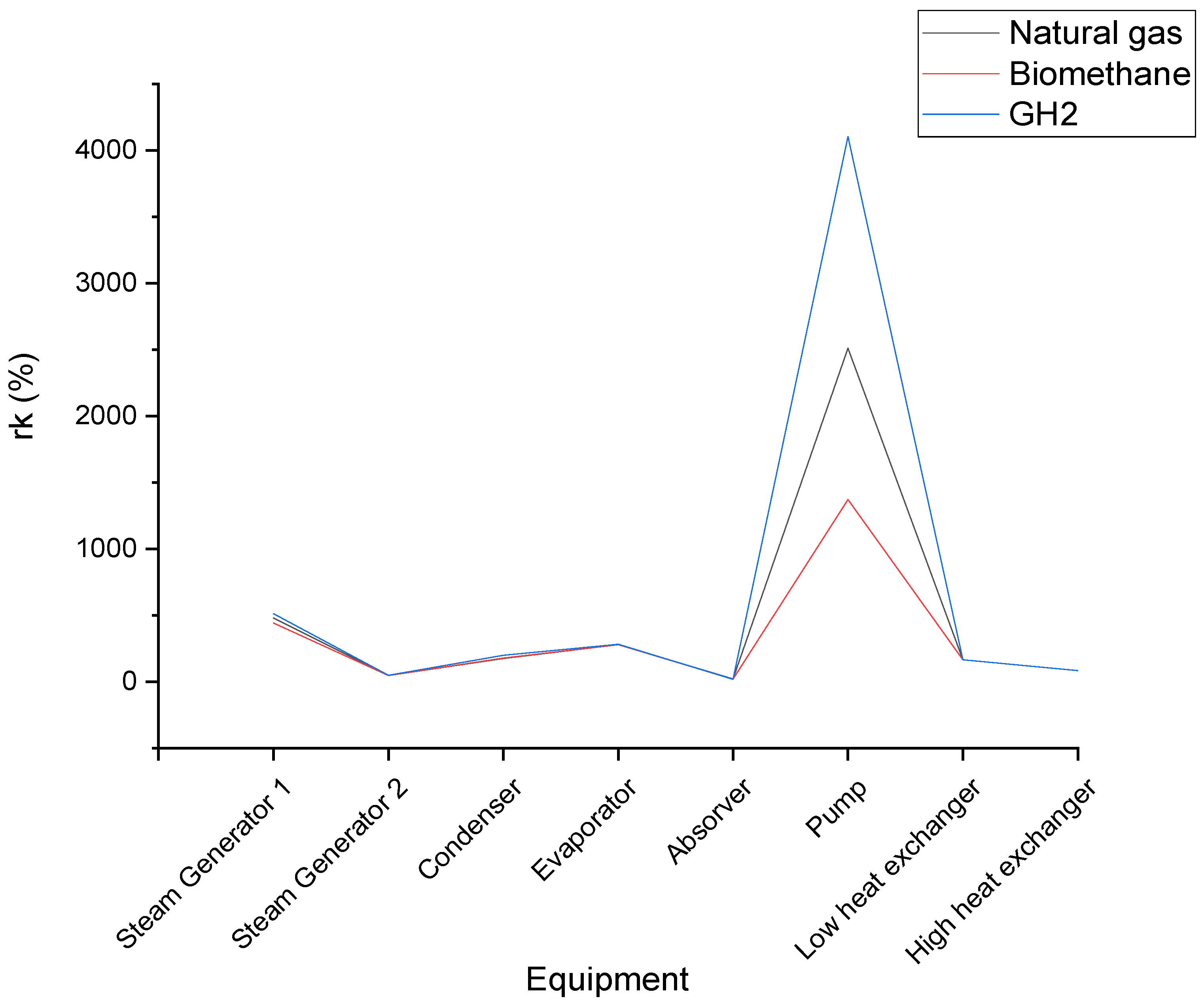

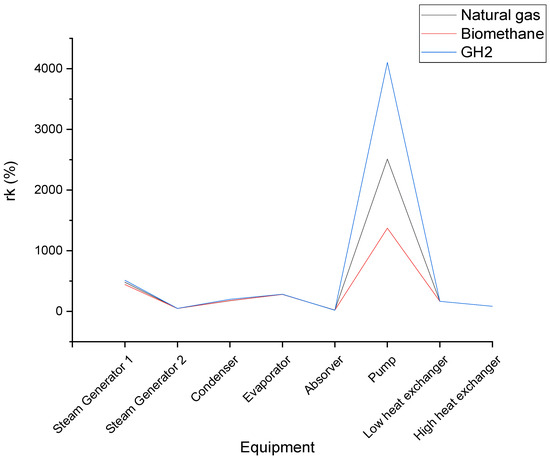

Figure 12 highlights the relative difference in environmental impact. The pump has a high rbk value, which is explained by the significant difference between the impacts of the product and the inputs. This occurs because, from point 1 to point 2, there is only an increase in pressure, while the temperature and concentration of the water-lithium bromide solution remain unchanged, resulting in no exergy gain. In other words, according to the SPECO method, the transition from point 1 to point 2 is inefficient. However, the environmental impact is minimal (Figure 10) compared to other components of the chiller.

Figure 12.

Comparative relative difference in the environmental impact (rk) of natural gas vs. biomethane vs. green hydrogen.

The relative difference between the environmental impacts of inputs and products (rbk) reflects the environmental quality of the equipment. Higher values indicate a greater need for optimization to reduce environmental impact [32]. Analyzing Figure 12 (excluding the pump), the equipment that requires the most optimization to improve environmental quality includes steam generator 1, the evaporator, and the low-temperature heat exchanger.

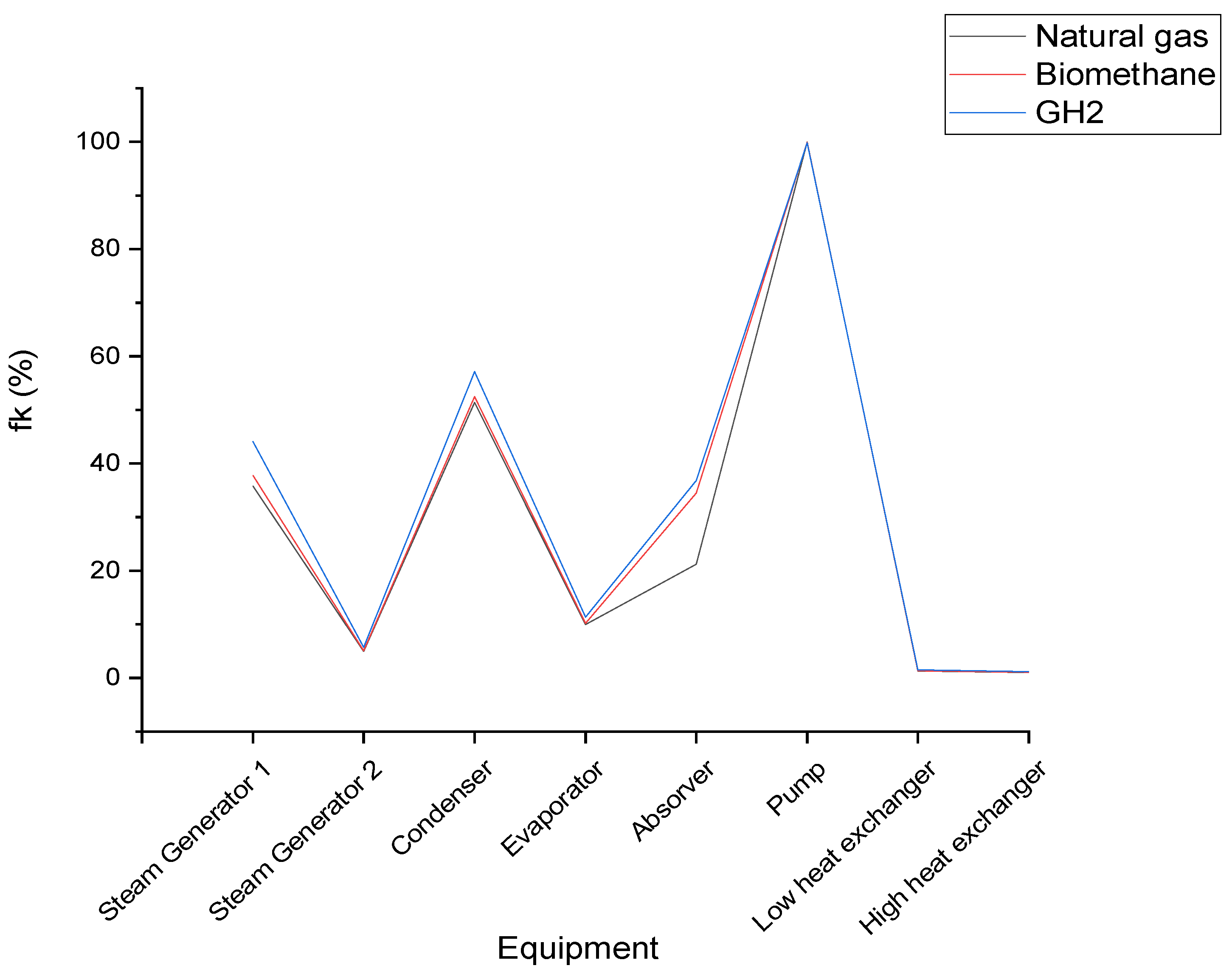

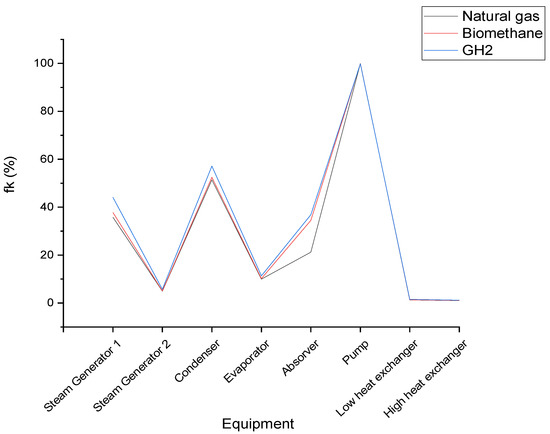

Figure 13 presents the comparative exergoenvironmental factor. The exergoenvironmental factor is related to the environmental impact due to exergy destruction. This value ranges from 0 to 100%, with higher values being preferable, as they indicate minimal impact from exergy destruction. Notably, if the value is closer to 100%, it suggests that the environmental impact associated with the component, Yk, is the most significant, and the study should focus on reducing this impact throughout the lifecycle. Conversely, if the value is close to 0, it indicates that the majority of the environmental degradation is due to exergy destruction within the equipment.

Figure 13.

Comparative exergoenvironmental factor (fk) of natural gas vs. biomethane vs. green hydrogen.

Analyzing Figure 13, it is observed that the equipment most in need of optimization includes the low-temperature heat exchanger, the high-temperature heat exchanger, and steam generator 2, followed by the evaporator.

The results presented provide a comprehensive and comparative view of the exergoenvironmental performance of the analyzed fuels. Green hydrogen emerges as the most advantageous option, offering the lowest environmental impact rates, the least exergy destruction, and notable stability in specific impacts. Biomethane, although less impactful than natural gas, still exhibits significant variations in environmental impacts. Therefore, the data support the superiority of green hydrogen as a more sustainable and efficient energy solution for DEAC systems, highlighting the need for investments in green hydrogen technologies to promote a cleaner and more responsible energy future [43].

7. Conclusions

The study analyzed the Life Cycle Assessment (LCA) and exergy-environmental evaluation of a double-effect absorption refrigeration system using three types of energy sources: natural gas, biomethane, and green hydrogen. The analysis aimed to compare the environmental and energetic performance of these fuels, providing a comprehensive perspective on their impacts and efficiency.

The search for sustainable and efficient solutions in the refrigeration sector has intensified due to the need to reduce greenhouse gas emissions and promote the responsible use of natural resources. Absorption refrigeration systems, capable of utilizing renewable energy sources, offer significant economic and environmental advantages.

Green hydrogen stands out for exhibiting the highest exergy rate for a specific amount of thermal energy required, surpassing both natural gas and biomethane. Compared to green hydrogen, natural gas has an exergy rate that is 31.10% lower, while biomethane has an exergy rate that is 33.96% lower.

The main results of the Life Cycle Assessment (LCA) of the fuels analyzed during the operational phase of the DEAC are as follows:

- Natural Gas: Exhibits significant environmental impacts, particularly in terms of fossil resource depletion (1403.71 mPts) and climate change (1425.00 mPts). These values represent 18% and 33.16% more environmental impacts when compared to GH2;

- Biomethane: Although still significant, it shows a reduction of 14,7% in impacts when compared to natural gas, with lower fossil resource depletion (1215.19 mPts);

- Green Hydrogen: Emerged as the cleanest option, with the lowest impacts in all evaluated categories, particularly in climate change (1222.47 mPts) and fossil resource depletion (1151.00 mPts).

During the operational phase of the DEAC, green hydrogen achieves a 99.84% reduction in environmental impacts compared to natural gas, primarily due to its production using renewable electricity and its emission of only water vapor during combustion. This substantial reduction in CO2 and other pollutants highlights the significant advantage of green hydrogen over natural gas and biomethane. While natural gas, although cleaner than other fossil fuels, still emits CO2 and pollutants, biomethane, a renewable fuel derived from organic waste, reduces environmental impacts by 54.21% relative to natural gas. However, biomethane is less effective than green hydrogen in the overall minimization of environmental impacts.

The change in fuel during the operational phase of the DEAC affected the magnitude of the exergoenvironmental results but did not alter the identification of the equipment requiring optimization in the system. Heat exchangers remain the primary contributors to exergy destruction, highlighting inefficiencies in the heat transfer process.

The relative environmental impact difference (Rbk) identified that the equipment requiring optimization to improve environmental quality includes steam generator 1, the evaporator, and the low-temperature heat exchanger. The exergoenvironmental factor (fbk) indicates that the equipment most in need of optimization includes the low-temperature heat exchanger, the high-temperature heat exchanger, and steam generator 2, followed by the evaporator.

In Brazil, the use of green hydrogen and biomethane as fuels is already regulated, which provides greater security for private sector investments. This paves the way for the expansion of cleaner energy sources, which can not only reduce dependence on fossil fuels but also stimulate technological advancement.

The Life Cycle Assessment (LCA) model and the exergoenvironmental model have proven to be suitable for this study. The results obtained can serve as a benchmark for decision-making aimed at reducing the environmental impacts associated with refrigeration production equipment.

This study provides a comprehensive analysis of the environmental impacts and energy efficiency of three different energy sources for a double-effect absorption refrigeration system. The results support the transition to green hydrogen as a viable and sustainable solution capable of minimizing environmental impacts and maximizing energy efficiency. Biomethane emerges as an intermediate alternative, offering advantages over natural gas but still falling short compared to green hydrogen.

Author Contributions

Conceptualization, J.L.d.M.N.; Data curation, R.J.D.S., J.B.d.C. and D.N.L.A.; Formal analysis, R.J.D.S., C.A.C.d.S., J.B.d.C. and D.N.L.A.; Investigation, J.L.d.M.N.; Methodology, J.L.d.M.N. and C.A.C.d.S.; Project administration, C.A.C.d.S.; Software, J.L.d.M.N.; Supervision, C.A.C.d.S.; Validation, C.A.C.d.S., J.B.d.C. and D.N.L.A.; Visualization, R.J.D.S., J.B.d.C. and D.N.L.A.; Writing—original draft, J.L.d.M.N.; Writing—review and editing, R.J.D.S. All authors have read and agreed to the published version of the manuscript.

Funding

The first author would like to acknowledge the Fundação de Apoio à Pesquisa do Estado da Paraíba (FAPESQ) for the financial support (through the doctoral scholarship) provided for the development of this work (Process number 88887.616915/2021-00).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhou, Y.; Xu, G.; Li, H.; Chen, Y.; Xu, X.; Li, M. Effect of greenhouse gas emissions on the life cycle of biomass energy production and conversion under different straw recycling modes. Environ. Res. 2023, 238, 117184. [Google Scholar] [CrossRef] [PubMed]

- Cavalcanti, E.J.C. Energy, exergy and exergoenvironmental analyses on gas-diesel fuel marine engine used for trigeneration system. Appl. Therm. Eng. 2021, 184, 116211. [Google Scholar] [CrossRef]

- Alcântara, S.C.S.; Villa, A.A.O.; da Costa, J.Â.P.; Cézar, K.L. Análise energética de um chiller de absorção integrado a uma unidade de cogeração a gás natural. Revista Principia—Divulgação Científica e Tecnológica do IFPB 2024. [Google Scholar] [CrossRef]

- Qazi, A.; Hussain, F.; Rahim, N.A.; Hardaker, G.; Alghazzawi, D.; Shaban, K.; Haruna, K. Towards Sustainable Energy: A Systematic Review of Renewable Energy Sources, Technologies, and Public Opinions. IEEE Access 2019, 7, 63837–63851. [Google Scholar] [CrossRef]

- de Lara, D.M.; Richter, M.F. Green Hydrogen: The Energy Source of the Future; Novos Cadernos NAEA: Brazil, 2023; Volume 26. [Google Scholar] [CrossRef]

- Zun, M.T.; Ahmad, M.S.; Fayaz, H.; Selvaraj, J.; Ahmed, W.; Wang, Y.; Ben Khedher, N.; Silitonga, A.; Elfasakhany, A.; Kalam, M.; et al. Towards techno-economics of green hydrogen as a primary combustion fuel for recreational vehicle vapor absorption refrigeration system. Sustain. Energy Technol. Assess. 2023, 56, 103007. [Google Scholar] [CrossRef]

- Hai, T.; Zoghi, M.; Habibi, H. Comparison between two LiBr–H2O absorption-compression chillers and a simple absorption chiller driven by various solar collectors: Exergy-economic performance and optimization. Energy 2023, 282, 128960. [Google Scholar] [CrossRef]

- Li, Y.; Wen, Z.; Li, J.; Cai, L.; Wang, H. Feasibility of utilizing by-product biogas in breweries after being decarbonized for refrigeration chiller and related primary energy efficiency analysis. Sustain. Energy Technol. Assess. 2019, 31, 390–400. [Google Scholar] [CrossRef]

- Dadpour, D.; Deymi-Dashtebayaz, M.; Hoseini-Modaghegh, A.; Abbaszadeh-Bajgiran, M.; Soltaniyan, S.; Tayyeban, E. Proposing a new method for waste heat recovery from the internal combustion engine for the double-effect direct-fired absorption chiller. Appl. Therm. Eng. 2022, 216, 119114. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Khounani, Z.; Hosseinzadeh-Bandbafha, H.; Gupta, V.K.; Amiri, H.; Lam, S.S.; Morosuk, T.; Tabatabaei, M. Exergoenvironmental analysis of bioenergy systems: A comprehensive review. Renew. Sustain. Energy Rev. 2021, 149, 111399. [Google Scholar] [CrossRef]

- Soltanian, S.; Aghbashlo, M.; Almasi, F.; Hosseinzadeh-Bandbafha, H.; Nizami, A.-S.; Ok, Y.S.; Lam, S.S.; Tabatabaei, M. A Critical Review of the Effects of Pretreatment Methods on the Exergetic Aspects of Lignocellulosic Biofuels; Elsevier Ltd.: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Omolayo, Y.; Feingold, B.J.; Neff, R.A.; Romeiko, X.X. Life Cycle Assessment of Food Loss and Waste in the Food Supply Chain; Elsevier B.V.: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy analysis of thermal, chemical, and metallurgical processes. Choice Rev. Online 1989, 26, 26–2722. [Google Scholar] [CrossRef]

- Tsatsaronis, G. Exergoeconomics and Exergoenvironmental Analysis. In Thermodynamics and the Destruction of Resources; Cambridge University Press: Cambridge, UK, 2011; pp. 377–401. [Google Scholar] [CrossRef]

- Carvalho, M.; Serra, L.M. Adaptation of the ascendency theory to industrial systems. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 546. [Google Scholar] [CrossRef]

- Meyer, L.; Tsatsaronis, G.; Buchgeister, J.; Schebek, L. Exergoenvironmental analysis for evaluation of the environmental impact of energy conversion systems. Energy 2009, 34, 75–89. [Google Scholar] [CrossRef]

- Cavalcanti, E.J.C.; Carvalho, M.; da Silva, D.R.S. Energy, exergy and exergoenvironmental analyses of a sugarcane bagasse power cogeneration system. Energy Convers. Manag. 2020, 222, 113232. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; He, L.; He, Y. Review on Absorption Refrigeration Technology and Its Potential in Energy-Saving and Carbon Emission Reduction in Natural Gas and Hydrogen Liquefaction. Energies 2024, 17, 3427. [Google Scholar] [CrossRef]

- Maciel, L.B.B.; Viola, L.; de Queiróz Lamas, W.; Silveira, J.L. Environmental studies of green hydrogen production by electrolytic process: A comparison of the use of electricity from solar PV, wind energy, and hydroelectric plants. Int. J. Hydrogen Energy 2023, 48, 36584–36604. [Google Scholar] [CrossRef]

- Kadam, S.T.; Kyriakides, A.-S.; Khan, M.S.; Shehabi, M.; Papadopoulos, A.I.; Hassan, I.; Rahman, M.A.; Seferlis, P. Thermo-economic and environmental assessment of hybrid vapor compression-absorption refrigeration systems for district cooling. Energy 2022, 243, 122991. [Google Scholar] [CrossRef]

- Souza, R.J.; Santos, C.A.C.D.; Ochoa, A.A.V.; Marques, A.S.; Neto, J.L.M.; Michima, P.S.A. Proposal and 3E (energy, exergy, and exergoeconomic) assessment of a cogeneration system using an organic Rankine cycle and an Absorption Refrigeration System in the Northeast Brazil: Thermodynamic investigation of a facility case study. Energy Convers. Manag. 2020, 217, 113002. [Google Scholar] [CrossRef]

- Marques, A.S.; Carvalho, M.; Ochoa, A.A.V.; Abrahão, R.; Santos, C.A.C. Life cycle assessment and comparative exergoenvironmental evaluation of a micro-trigeneration system. Energy 2021, 216, 119310. [Google Scholar] [CrossRef]

- Zhu, H.; Guo, B.; Geng, W.; Chi, J.; Guo, S. Simulation of an improved solar absorption refrigeration system with phase change materials. Energy Rep. 2022, 8, 3671–3679. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, S.; Wang, D.; Song, Q.; Zhou, S.; Wang, X.; Li, Y. Simulation Study on Solar Single/Double-Effect Switching LiBr-H2O Absorption Refrigeration System. Energies 2023, 16, 3220. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C.; Lowrie, F.; Tse, P. Embodied Carbon: The Inventory of Carbon and Energy (ICE); BSRIA: Bracknell, UK, 2011. [Google Scholar]

- Silva, H.C.N.; Dutra, J.C.C.; Costa, J.A.P.; Ochoa, A.A.V.; Santos, C.A.C.D.; Araújo, M.M.D. Modeling and simulation of cogeneration systems for buildings on a university campus in Northeast Brazil—A case study. Energy Convers. Manag. 2019, 186, 334–348. [Google Scholar] [CrossRef]

- ISO 14040; ABNT NBR ISO 14040 Second Edition Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 1 July 2024).

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidance. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 1 July 2024).

- Ayer, N.W.; Dias, G. Supplying renewable energy for Canadian cement production: Life cycle assessment of bioenergy from forest harvest residues using mobile fast pyrolysis units. J. Clean. Prod. 2018, 175, 237–250. [Google Scholar] [CrossRef]

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- De Souza, R.J.; Luiz, J.; Neto, M.; Santos, C.A.C.D.; Reini, M. Life Cycle Assessment Applied to an ORC System Operating under Two Modes: Evaluation of Two LCIA Methods. In Proceedings of the ECOS 2022 35th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Copenhagen, Denmark, 3–7 July 2022. [Google Scholar]

- Marques, A.S. Exergoeconomic and Environmental Assessment of a Micro-Cogeneration Unit Adriano da Silva Marques. Master’s Thesis, Federal University of Paraíba, João Pessoa, Brazil, 2018. [Google Scholar]

- Cavalcanti, E.J.C.; Carvalho, M.; Ochoa, A.A.V. Exergoeconomic and exergoenvironmental comparison of diesel-biodiesel blends in a direct injection engine at variable loads. Energy Convers. Manag. 2019, 183, 450–461. [Google Scholar] [CrossRef]

- Zhang, F.; Yan, Y.; Liao, G.; E, J. Energy, exergy, exergoeconomic and exergoenvironmental analysis on a novel parallel double-effect absorption power cycle driven by the geothermal resource. Energy Convers. Manag. 2022, 258, 115473. [Google Scholar] [CrossRef]

- LG. Catálogo de Chiller de Absorção. Available online: https://www.lg.com/br/business/download/airsolution/202004_Catalogo_ChillerAbsorcao[20210429_024814580].pdf (accessed on 9 April 2024).

- Damiani, M.; Sinkko, T.; Caldeira, C.; Tosches, D.; Robuchon, M.; Sala, S. Critical review of methods and models for biodiversity impact assessment and their applicability in the LCA context. Environ. Impact Assess. Rev. 2023, 101, 107134. [Google Scholar] [CrossRef]

- Bare, J.C.; Hofstetter, P.; Pennington, D.W.; de Haes, H.A.U. Midpoints versus endpoints: The sacrifices and benefits. Int. J. Life Cycle Assess. 2000, 5, 319. [Google Scholar] [CrossRef]

- Rashedi, A.; Khanam, T. Life cycle assessment of most widely adopted solar photovoltaic energy technologies by mid-point and end-point indicators of ReCiPe method. Environ. Sci. Pollut. Res. 2020, 27, 29075–29090. [Google Scholar] [CrossRef]

- Chen, X.; Matthews, H.S.; Griffin, W.M. Uncertainty caused by life cycle impact assessment methods: Case studies in process-based LCI databases. Resour. Conserv. Recycl. 2021, 172, 105678. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Winhold, M. Exergoeconomic analysis and evaluation of energy-conversion plants—I. A new general methodology. Energy 1985, 10, 69–80. [Google Scholar] [CrossRef]

- PBGAS—Paraíba Gas Company. What Is Natural Gas. 2024. Available online: https://pbgas.com.br/o-que-e-gas-natural (accessed on 20 February 2024).

- ANP—National Agency of Petroleum. Natural Gas and Biofuels. Resolution 886/2022. 2022. Available online: https://atosoficiais.com.br/anp/resolucao-n-886-2022-estabelece-a-especificacao-e-as-regras-para-aprovacao-do-controle-da-qualidade-do-biometano-oriundo-de-aterros-sanitarios-e-de-estacoes-de-tratamento-de-esgoto-destinado-ao-uso-veicular-e-as-instalacoes-residenciais-industriais-e-comerciais-a-ser-comercializado-no-territorio-nacional (accessed on 20 February 2024).

- de Almeida, A.S.; de Souza, J.G.; Madeiro, L.C.N.; da Costa, M.L.A.; Cunha, A.L.; Rodrigues, M.A.; dos Santos, A. Hydrogen, the fuel of the future. Divers. J. 2019, 4, 356–366. [Google Scholar] [CrossRef]

- Smolinka, T.; Wiebe, N.; Sterchele, P.; Palzer, A. Industrialization of Water Electrolysis in Germany: Opportunities and Challenges for Sustainable Hydrogen for Transport, Power, and Heat. 2018. Available online: https://www.now-gmbh.de/wp-content/uploads/2020/09/indwede-studie_v04.1.pdf (accessed on 8 October 2024).

- Brazil. Available online: https://www.planalto.gov.br/ccivil_03/_ato2023-2026/2024/lei/L14948.htm (accessed on 14 August 2024).

- ANP—National Agency of Petroleum. Natural Gas and Biofuels. Resolution 906/2022. 2022. Available online: https://atosoficiais.com.br/anp/resolucao-n-906-2022-estabelece-a-especificacao-e-as-regras-para-aprovacao-do-controle-da-qualidade-do-biometano-oriundo-de-aterros-sanitarios-e-de-estacoes-de-tratamento-de-esgoto-destinado-ao-uso-veicular-e-as-instalacoes-residenciais-industriais-e-comerciais-a-ser-comercializado-no-territorio-nacional (accessed on 20 February 2024).

- Dong, D.; van Oers, L.; Tukker, A.; van der Voet, E. Assessing the future environmental impacts of copper production in China: Implications of the energy transition. J. Clean. Prod. 2020, 274, 122825. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).