Abstract

This study examined the impact of supply chain collaboration (SCC) on supply chain innovation (SCI) and sustainability performance in the context of manufacturing firms in Jordan. The study also investigated the mediating role of SCI in the relationship between different types of SCC and sustainability performance. SCC was represented by three types namely, customer collaboration, supplier collaboration, and internal collaboration. Data were collected using a structured questionnaire that was distributed to employees from numerous management levels in firms located in Jordan as a developing country. A total of 314 valid responses were obtained between December 2024 and March 2025. The data were analyzed using partial least squares structural equation modeling with using the SmartPLS software package. The results of the study revealed that customer, supplier, and internal collaboration significantly enhanced SCI. These three forms of SCC also improved sustainability performance. SCI was found to directly influence sustainability performance, confirming its role as a driver of sustainable outcomes. Moreover, SCI mediated the relationship between internal collaboration and sustainability performance. However, no mediating effects were found between customer or supplier collaboration and sustainability performance. The findings contribute to the resource-based view and dynamic capabilities theory by highlighting collaboration and innovation as critical pathways for achieving sustainable performance. The study offers managerial insights for manufacturing firms in Jordan, emphasizing the importance of strengthening collaboration with customers and suppliers, while also fostering internal innovation to embed sustainability into organizational practices.

1. Introduction

Businesses today operate in fierce and hypercompetitive markets that are characterized by intense rivalry, uncertainty, and growing sophistication [1]. For many firms, responding to these challenges and introducing innovations is a difficult task [2]. Yunus [3] observed that organizations in win–win environments often face significant pressure, and not all are able to achieve optimal outcomes. This raises an important question: is innovation always advantageous [4]? The tendency to imitate competitors, often described as the “me-too” habit, can generate both notable successes and costly failures [1,5]. In this situation, innovation is no longer an option. Firms that desire long-term survival recognize the importance of sustainable business practices. It provides greater resilience than reliance on traditional business practices [6,7].

Supply chain collaboration is a powerful response to the challenges suppliers and retailers face. Mofokeng and Chinomona [8] emphasized that SCC strengthens relationships, reduces risks, and capitalizes on the advantages of partnership to enhance sustainability [9,10]. Collaboration may occur with the customers, suppliers and even in-team members. According to Akam et al. [11], it is very important for bringing together resources to improve both operational and sustainability performance. By exchanging information and resources, firms can develop integrated systems that support innovativeness and make them more competitive [12,13].

Collaboration has clear benefits in the real world. Collaborating firms can reduce costs and increase profits while enhancing sales forecast accuracy and improving logistics control [14,15,16]. According to Kumar et al. [17], partnerships can lead to shorter lead times, decreased bullwhip effects, improved skill development, greater flexibility, and increased customer satisfaction. The ability of a synchronized supply chain to produce value for end consumers is important for competitiveness [9,18]. Working relationship enhances replenishment plans, forecasts and techniques, which improves performance efficiencies and responsiveness [19].

Being innovative, or the ability to learn, adapt, and make things part of the culture [20], is very relevant for supply chain innovations (SCI) and performance [21]. SCC enables both upstream and downstream partners to access knowledge, encourages the creation of new knowledge, and shortens R&D cycles [22]. SCC drives SCI through these processes. The process of transforming an idea into a new and better product, service or process is known as SCI. According to Uddin and Akhter [23], SCI not only brings firms commercial competitiveness but also sustainability goals.

A collaboration that generates new solutions builds resilient supply chains. According to [24], SCCs foster spaces that allow people to work together flexibly and efficiently. Partnerships stimulate ideas that produce new technologies and processes. This means that these lower risks and increase flexibility while helping sustainability goals. These types of innovative ideas are beneficial for the economy, society, and the environment [18,25]. As per a recent study by Jum’a et al. [13], the world’s economy has drastically changed as a result of customer expectations being continuously raised.

As there is a growing interest in this relationship, there are still considerable gaps in research [23,26,27,28]. Although prior studies have explored how SCC and innovation influence sustainability in various global contexts, limited attention has been paid to how these dynamics unfold within developing economies such as Jordan, where manufacturing firms face distinct institutional, environmental, and resource constraints that challenge innovation and sustainability adoption [3,13]. The manufacturing sector in Jordan remains a vital yet under-researched domain for understanding how collaborative innovation can enhance resilience and sustainable performance amid supply disruptions, resource scarcity, and evolving regulatory frameworks [18,23]. Hence, examining the mediating role of supply chain innovation (SCI) in the relationship between SCC and sustainability performance in this local context is both timely and essential, as it provides insights into how Jordanian manufacturers can leverage collaborative capabilities to achieve long-term competitiveness and sustainability outcomes [10,29,30].

This research analyzes how SCC and SCI influences performance sustainability to help tackle existing gaps. The research seeks to answer the subsequent three core issues—Do end-users and supplier collaboration along with internal stakeholders affect SCI? How does collaboration affect sustainability performance? What is the role of SCI in the relationship between collaboration and sustainability outcomes?

The resource-based view and dynamic capabilities theory (DCT) guided this study. According to the resource-based view of the firm, SCC is an important resource that is not easily replicated by competitors. This is because SCC allows firms to pool together their capabilities, and combine resources such as expertise, technologies and information to enhance clever control [29]. The innovations that arise from these collaborations become strategic resources that improve efficiency and adaptability while supporting sustainability. From the DCT perspective, SCC enables firms to reconfigure and renew their capabilities in rapidly changing environments [30]. Collaborative innovation provides firms with the agility to respond to uncertainty, adopt new technologies, and embed sustainability into their strategies, thereby ensuring resilience and long-term performance.

The rest of this paper is organized as follows: The literature review on SCC, innovation, and sustainability will be introduced. The methodology will outline the research design and analysis methods. The results will present key findings. The discussion will interpret these findings, and the conclusion will summarize the main points, contributions, limitations, and future research directions.

2. Literature Review

2.1. Previous Studies

The relationship between SCC, innovation, and firm performance has been widely studied, but important gaps remain. Yunus [3] showed that collaboration with suppliers drives transformational change, while customer collaboration supports incremental improvements, both of which contribute to firm performance. Similarly, Solaimani and van der Veen [31] identified interaction, educational empowerment, and continuous learning as key drivers of SCI. They highlighted three capacities that enable this process: knowledge discovery, cooperation across levels, and both incremental and disruptive innovation. Yang and Lin [32] further emphasized that collaboration among supply chain participants strengthens green innovation performance, where leadership commitment and societal acknowledgment also play critical roles.

Singhry [33] investigated the mediating role of invention competence and found a positive relationship between supply chain efficiency and technology, although innovation capabilities negatively affected supply chain effectiveness. Hofman et al. [22] reported that public pressure enhances process eco-innovation through supplier collaboration, but market pressure failed to stimulate product eco-innovation. Afraz et al. [34] showed that SCI strengthens competitive advantage, with buyer–supplier relationships and resilience acting as mediators.

Uddin and Akhter [23] demonstrated that top management commitment and SCC positively influence environmental, social, and economic performance. Anh et al. [35] added that relational capital enables both incremental and radical innovations within collaborative contexts. Baig et al. [36] found that supplier collaboration supports radical and incremental innovation, which in turn improves market performance. Jimenez-Jimenez et al. [19] also showed that collaboration fosters technological innovation, boosting both incremental and radical product innovation. Nguyen et al. [37] emphasized the role of cognitive proximity in driving decision synchronization and incentive alignment, where synchronized decisions improve incremental innovation and information sharing enhances radical innovation.

Ocicka et al. [26] focused on green innovation, showing that firms collaborating with suppliers and customers are more likely to develop sustainable innovations. Uddin [15] confirmed that strategic commitment significantly shapes SCC, which then influences both operational and innovation performance. Billah et al. [38] highlighted the role of IoT in strengthening collaboration and sustainability performance, with supply chain dynamism moderating these effects.

More recently, Hariyadi et al. [16] examined sustainable SCC in Indonesia’s construction industry and identified six criteria—environmental commitment, business model innovations, green consumer partnerships, interpersonal relationships, responsible consumption, and long-term orientation—that are essential for managing construction and demolition waste. Zhang and Zhang [7] investigated the role of new quality productive forces and found that digitized labor processes improve green SCC, with supply chain digitalization amplifying these effects. Yu et al. [1] studied manufacturers and showed that digital strategy and capability enhanced collaborative innovation, which mediates the relationship between digital transformation and market performance.

Taken together, these studies confirm that collaboration with customers, suppliers, and internal partners is closely linked to innovation and performance outcomes. They also show the importance of leadership, strategy, technology, and environmental factors in shaping these dynamics. However, despite these contributions, a significant gap remains. Most prior studies have focused on either the direct impact of collaboration on innovation [19,36] or on the direct effect of collaboration on performance outcomes [23,37]. For example, Jimenez-Jimenez et al. [19] found that supply chain collaboration (SCC) fosters technological and product innovation, while Baig et al. [36] showed that collaborative relationships with suppliers and customers strengthen both incremental and radical innovation outcomes. Similarly, Uddin and Akhter [23] and Nguyen et al. [37] demonstrated that SCC positively affects operational and sustainability performance, emphasizing relational and knowledge-sharing mechanisms as performance drivers. However, these studies largely treat innovation and sustainability as independent outcomes of collaboration rather than exploring how innovation mediates the path toward sustainable performance.

Emerging literature has begun to highlight that collaborative innovation may act as a dynamic mechanism through which supply chain partners co-create value and embed sustainability into business operations [1,7,10,13,18]. For instance, Yu et al. [1] revealed that digital transformation enhances collaborative innovation, which subsequently improves market and sustainability outcomes, while Zhang and Zhang [7] noted that green collaboration enabled by digitalization fosters environmentally responsible supply chains. Similarly, Fontoura and Coelho [10] and Jum’a et al. [13] emphasized that collaboration-driven innovation enhances environmental, economic, and social performance by promoting eco-efficient processes and sustainable technologies. In addition, Tarigan et al. [18] underscored that internal and external integration supports supply chain agility and resilience, both of which are essential for achieving sustainable competitive advantage in turbulent markets.

Despite these advances, few studies have empirically tested the mediating role of SCI in linking SCC and sustainability performance, particularly within developing-country contexts where innovation resources and collaborative maturity are often constrained [15,16,26,27,34]. Therefore, this study addresses this critical gap by assessing how SCI can serve as a pivotal intermediary that connects collaborative efforts—across customers, suppliers, and internal functions—to long-term sustainability outcomes. This approach provides deeper insights into how firms, especially within the Jordanian manufacturing sector, can achieve competitive advantage by strategically aligning collaboration, innovation, and sustainability practices [13,23,30,34]. Table 1 shows the most relevant previous studies that highlight the significant associations between SCC, innovation and sustainability performance.

Table 1.

Summary of the most relevant studies.

2.2. Hypotheses Development and Conceptual Framework

2.2.1. Influence of SCC on SCI

SCC is defined as two or more members of a supply chain working together to build competitiveness through information sharing, joint decision-making, and profit sharing. This collaboration improves the profitability of serving end consumers compared to working individually [38,39]. In this study, SCC is examined through three dimensions: customer collaboration, supplier collaboration, and internal collaboration.

Customer collaboration facilitates the collection of customer insights and the exchange of knowledge, which encourages innovative activities and enhances production. Prior research has shown that customer collaboration helps firms strengthen their capabilities and supports both technical and organizational innovation [3,40]. Un and Asakawa [41] further explained that customer collaboration contributes more to product outcomes than to innovation inputs, as customers tend to focus primarily on the final results.

Supplier collaboration combines the efforts of suppliers and buyers to improve strategies in sourcing and procurement. Roscoe et al. [42] highlighted the role of supplier collaboration in advancing SCI. Firms with strong supplier relationships benefit particularly from incremental innovations. Collaboration with supply chain partners improves innovation outcomes [43,44], while cooperation with external partners enhances organizational knowledge and innovation capacity [3,4,45].

Internal collaboration refers to coordinated planning and incentive alignment across departments within a firm to support operational and logistical tasks [3,46]. Internal collaboration fosters innovation by creating new resources, enhancing capabilities, and transitioning from traditional work environments to more dynamic and knowledge-based systems [10,18,31]. It also improves communication and knowledge exchange, which are critical for organizational learning and innovation.

Based on this discussion, the following hypotheses are proposed:

H1.

Customer collaboration positively influences SCI.

H2.

Supplier collaboration positively influences SCI.

H3.

Internal collaboration positively influences SCI.

2.2.2. Influence of SCC on Sustainability Performance

Customer collaboration in supply chains involves close engagement with customers to understand their preferences, needs, and sustainability expectations [25]. Through co-designing products, sharing sustainability goals, and providing feedback on environmental impacts, firms can reduce waste, optimize resource use, and align products with consumer demand for environmentally responsible goods [47,48]. Such collaboration encourages innovation in sustainable practices and reduces environmental footprints [22]. Therefore, this study proposes:

H4.

Customer collaboration positively influences sustainability performance.

Supplier collaboration fosters robust and transparent relationships that guarantee the sustainable sourcing of raw materials and components [49]. Companies can improve energy efficiency, cut down on waste, and promote responsible sourcing by working with suppliers on sustainability goals [50,51]. By keeping an eye on and influencing suppliers’ social and environmental practices, effective collaboration with suppliers makes the supply chain more resilient and sustainable [18]. It also helps businesses lower their risks from problems and environmental issues. So, the next hypothesis is:

H5.

Supplier collaboration positively influences sustainability performance.

Internal collaboration encourages departments to cooperate within a company with a view to making the operations more sustainable [47]. Collaboration among various departments guarantees that sustainability targets are integrated into various aspects of the company, including production, purchase, R&D and strategic planning process [52]. Internal collaboration improves the efficiency of resource, energy and waste use while also developing a culture of sustainability in employees. [25,47]. This integrated technique promotes the environment and ensures the sustainability of the business in the long run [18]. Consequently, the subsequent hypothesis is posited.

H6.

Internal collaboration positively influences sustainability performance.

2.2.3. Influence of SCI on Sustainability Performance

SCI enhances the sustainability performance of manufacturing organizations through introduction of new technologies, processes and strategies that are friendly to the environment and socially responsible [13,30]. By investing in new logistics tools, optimizing resource use, and choosing more environmentally friendly materials, companies can reduce waste as well as carbon and energy footprints. Practicing data analytics is creating new ideas about production and circular economy that will help people make better choices [10,30]. These practices help businesses follow the rules, meet customer expectations, and make money in the long run by lowering costs and risks [53].

Innovation in the supply chain also helps the economy and society stay strong. Ethical sourcing and fair labor practices improve brand reputation and relationships with stakeholders [13,48]. At the economic level, digitalization, blockchain traceability, and AI forecasting improve agility and resilience [54]. These innovations increase transparency and efficiency, which are essential for competitiveness in sustainability-driven markets [13]. Therefore, the study postulates:

H7.

SCI positively influences sustainability performance.

2.2.4. Influence of SCI as a Mediator

Firms that prioritize innovation must not only introduce new technologies or processes but also embed innovation into collaborative supply chain practices [13,34]. Innovation in this sense is not a stand-alone activity; rather, it is shaped by how effectively firms engage customers, suppliers, and internal teams in coordinated efforts [34]. When collaboration occurs without innovation, its direct effects on sustainability may be limited, since firms lack the mechanisms to translate information sharing and joint decision-making into sustainable outcomes. SCI therefore acts as a crucial bridge, amplifying the benefits of collaboration and ensuring that partnerships lead to meaningful and measurable improvements in sustainability performance [55].

Customer collaboration can provide firms with valuable market intelligence, insights into changing preferences, and sustainability expectations [9,55]. However, without innovation, such insights may not result in improved products or processes. SCI allows companies to turn customer knowledge into environmentally friendly designs, energy-efficient manufacturing, and greener logistics solutions [9,34]. This development from customers’ knowledge to practical new ideas is the solution for reducing waste, carbon emissions and environmental footprints. This means that by working with customers, you can achieve long-term success [18].

Supplier collaboration also provides you with opportunities to adopt green practices in purchases and procurements [9]. But these partnerships will only produce systemic change through innovation. For instance, blockchain-based traceability, circular procurement systems, and supplier eco-certifications are all recent ways for supplier co-innovation to result in quantifiable sustainability impacts [56]. SCI also encourages suppliers to embrace new technologies that make things more efficient and open, highlighting the importance of collaboration in achieving social and environmental goals [57].

Internal collaboration helps people in different departments communicate, share resources, and make decisions more easily [9]. However, these internal synergies can only function through innovation [9,57]. New approaches such as consideration of big data analytics for forecasting demand, transitioning to renewable energy sources in operations or circular economy approaches are all examples of the ways that internal collaboration can result in performance gains at scale [10]. This highlights the intermediatory role of innovation that enables internal social collaboration beyond mere coordination to achieve meaningful improvements in sustainability related performance [13].

SCI is a capability which is very important for dynamic and uncertain. Organizations that can develop new ideas while collaborating will be able to adapt to evolving rules, disruptions and customer needs [55]. Without innovation, the benefits of collaboration might be small and may not result in long-term gains for sustainability solutions. Companies can gain a competitive edge by incorporating innovation into their collaborative supply chain practices. This can lead to less harm to the environment, better use of resources, and a greater sense of social responsibility [34,57].

Consequently, the following hypotheses are posited:

H8a.

SCI mediates the relationship between customer collaboration and sustainability performance.

H8b.

SCI mediates the relationship between supplier collaboration and sustainability performance.

H8c.

SCI mediates the relationship between internal collaboration and sustainability performance.

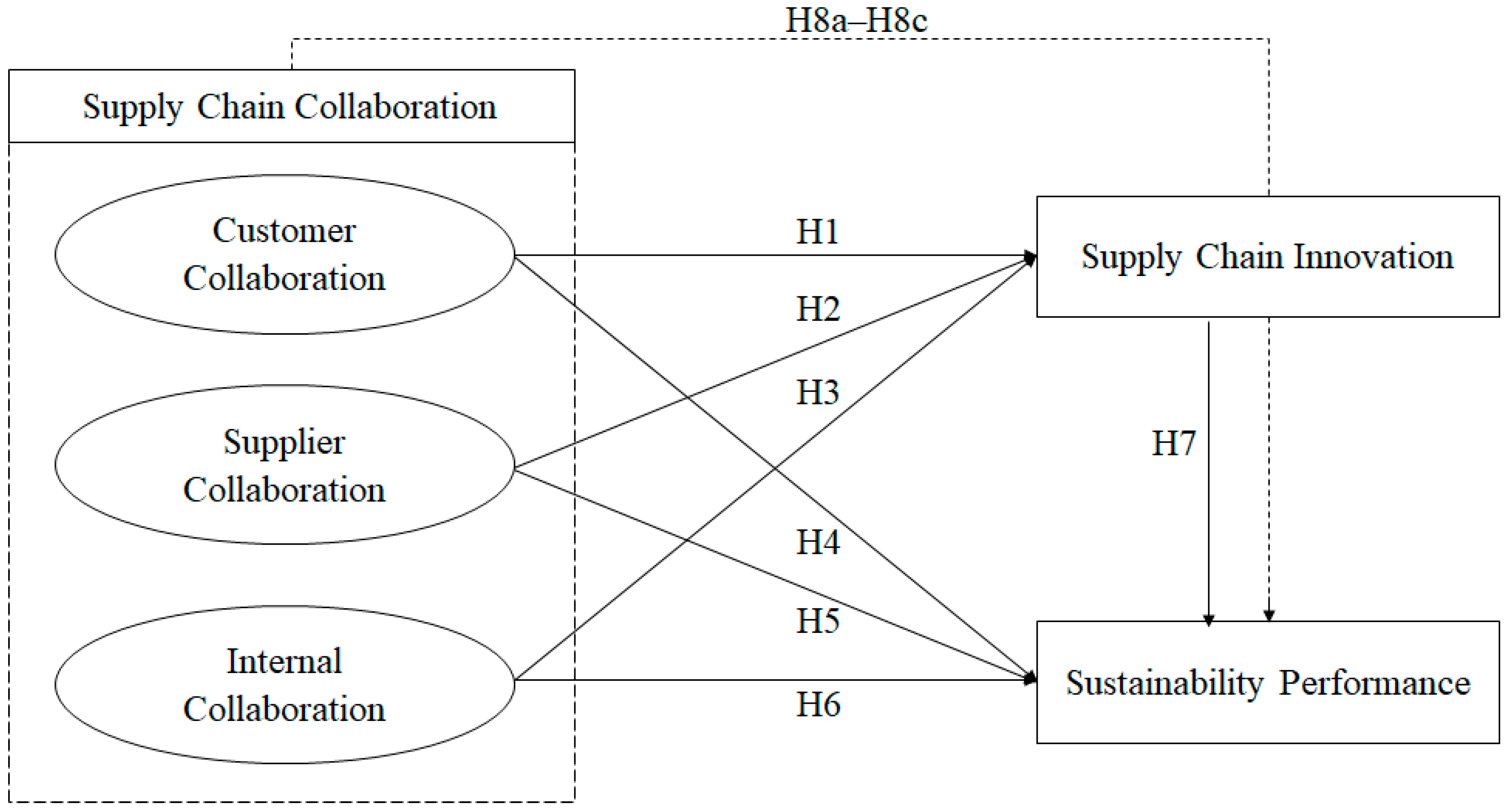

Based on the previous discussions, the conceptual model is developed as shown in Figure 1.

Figure 1.

Conceptual framework.

3. Methodology

3.1. Population and Sampling

The sampling procedures in this study involved defining the sampling frame, selecting appropriate sampling methods, determining the sample size, and implementing data collection procedures. The target population comprised employees from diverse organizations situated in Amman, Jordan. To get a range of points of view and get insights from decision-makers at different levels of the organization, respondents came from different management levels, such as operational, middle, and top management.

Because of limited time and resources, the study used a non-probability purposive sampling method. This method helped the researchers concentrate on people who were most likely to have useful information about how to work together in the supply chain, come up with new ideas, and improve sustainability. A structured questionnaire was used to gather data from participants through easy-to-use access channels. While probability sampling is typically favored for enhancing predictive accuracy, non-probability sampling has gained widespread acceptance in analogous research contexts and is regarded as appropriate for inferring population parameters when access to the entire population is impractical [58].

The sample covered a diverse range of sub-sectors within the Jordanian manufacturing industry, including chemical industries and cosmetics, packaging industry, plastic and rubber industries, leather industries and knitting, and food, catering and livestock industries, which collectively represent key pillars of Jordan’s manufacturing base [9,13]. The non-probability purposive sampling method was employed to ensure that respondents possessed sufficient knowledge and experience in supply chain collaboration, innovation, and sustainability practices [15,58]. Among the surveyed firms, the largest share of respondents originated from the plastic and rubber industries (28.4%), followed by food, catering and livestock industries (24.1%), chemical industries and cosmetics (20.3%), packaging industry (15.7%), and leather industries and knitting (11.5%), reflecting the actual distribution of active firms in the sectoral composition of Jordan’s manufacturing economy [18,23]. This approach enabled the inclusion of firms of varying sizes and operational capacities across these sectors, thereby capturing the structural and functional diversity of the Jordanian manufacturing sector. The sampling rationale was based on the accessibility and active participation of firms located primarily in Amman, which hosts the majority of industrial establishments and supply chain operations in Jordan [9,13].

The sample size was determined as per Hair et al.’s [59] guidelines, which stipulate that the sample is at least ten times bigger than the number of structural paths (arrows) pointing at a construct of the study model. The model used in this study involved 70 arrows, so at least 70 arrows had to participate. In order to enhance the robustness and reliability of results, the study deliberately opted for a much bigger sample. In order to achieve better estimates of parameters and make the results of the analysis (using SmartPLS software package) more valid, this choice was made.

Data was collected in a four-month period between December 2024 and March 2025. During this period, 314 valid surveys were obtained which is a sufficient sample for PLS-SEM. The large sample not only satisfied the statistical requirements but also facilitated applying the results to other organizations in Jordan.

To minimize the potential impact of common method bias (CMB) arising from self-reported data, several procedural and statistical remedies were implemented. Respondent anonymity was assured, and questionnaire items were carefully designed to reduce social desirability and acquiescence bias. In addition, Harman’s single-factor test was conducted, and the results showed that the first factor accounted for 32.6% of the total variance, which is below the 50% threshold, indicating that CMB was not a significant concern. Furthermore, “variance inflation factor” (VIF) values were examined, all of which were below the recommended cutoff of 3.3, confirming the absence of substantial common method bias in the dataset.

3.2. Measurement Items

We chose the measurement items from different previous studies. Items pertaining to customer collaboration, supplier collaboration, and internal collaboration were adopted from these studies [3,15,19,36]. Items pertaining to SCI were adopted from these studies [22,34,39]. Lastly, the sustainability performance items were adopted from these studies [23,29,60]. There were two sections in the questionnaire. The first section contained questions related to the demographics of the respondents. The second section contained the measurement items on which the participants were required to rate their level of agreement or disagreement on a five-point Likert scale (Appendix A).

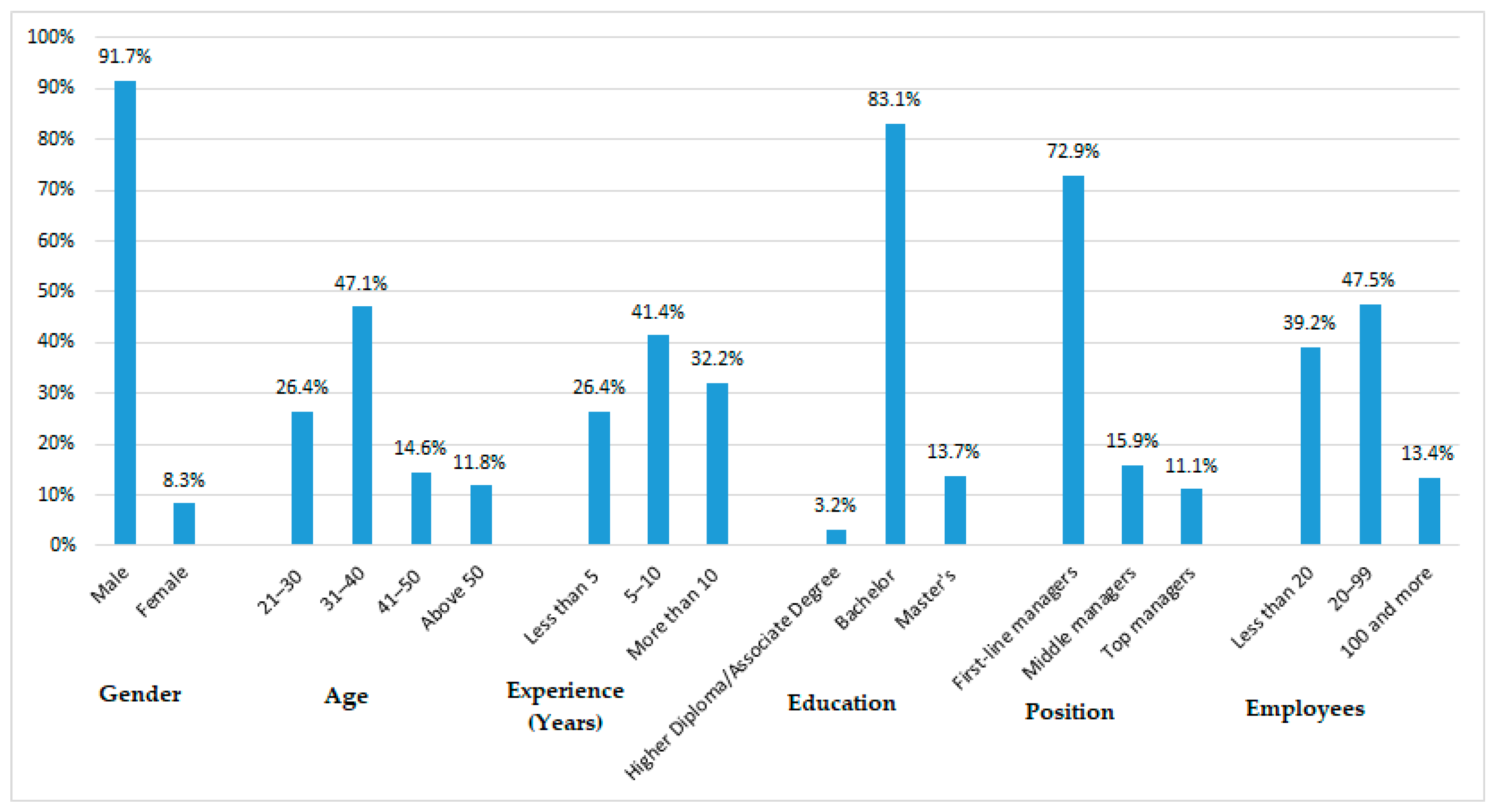

3.3. Profile of the Respondents

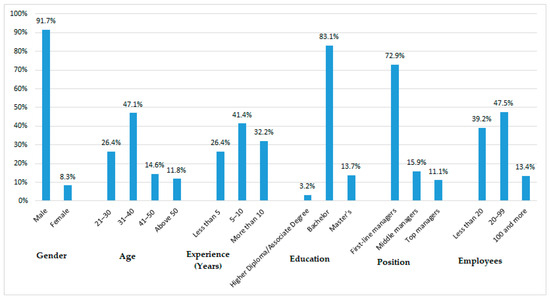

The participants’ demographics included gender, age, years of experience, education level, position and the number of employees. According to the results, there were 91.7% male and 8.3% female participants in this study. It is also observed that the highest number of respondents (47.1%) belonged to the age group “31–40 years”. 41.4% of the respondents had years of experience between 5 and 10 years. The majority of them had a bachelor’s degree (83.1%) and served as first-line managers (72.9%). Finally, the largest number of participants (47.5%) were from mid-level organizations having employees from 20 to 99 as shown in Figure 2.

Figure 2.

Profile of the respondents.

4. Findings

This chapter contained findings from the statistical data analysis, including descriptive statistics, collinearity statistics, measurement model analysis, structural model analysis and hypothesis testing. SPSS version 25 and SmartPLS version 3 were used to analyze the survey data.

4.1. Descriptive Analysis

Mean, standard deviation, skewness, kurtosis and standard error comprised the descriptive statistics of the study. The results showed that Internal Collaboration generated the highest mean (M = 4.2159, SD = 1.04438), followed by customer collaboration (M = 4.0552, SD = 0.85844). On the other hand, SCI generated the lowest mean score among the other latent variables (M = 3.8497, SD = 0.87453) as shown in Table 2.

Table 2.

Descriptive statistics (N = 314).

4.2. Multicollinearity Test

High correlations among the independent variables may raise severe issues concerning the estimated parameters. Moreover, the prediction based on the results may also be confined by the multicollinearity problem. The two most frequently used measures, tolerance and variance inflation factors (VIFs), were utilized in this study. The results showed that all the measures were within the acceptable range, e.g., tolerance values were higher than 0.10 and VIF values were lower than 5 [59] as shown in Table 3.

Table 3.

Collinearity statistics.

4.3. Structural Equation Modeling

Structural equation modeling was conducted using partial least squares (PLSs) in SmartPLS version 3 [61]. The analysis had been performed in two phases, including measurement model analysis and structural model analysis. Measurement model analysis deals with the reliability and validity of the constructs, where structural relationships or the hypotheses are tested using structural model analysis.

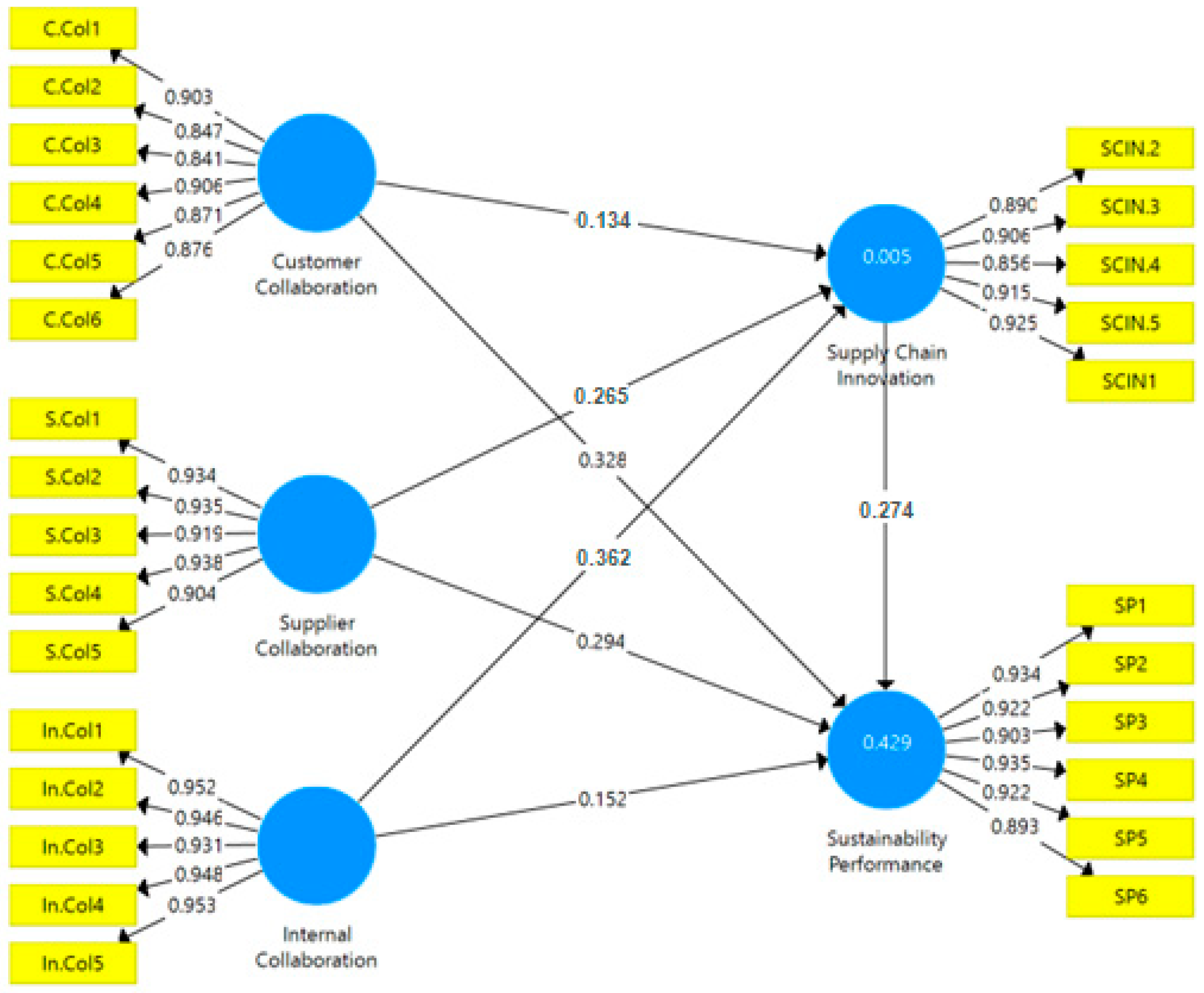

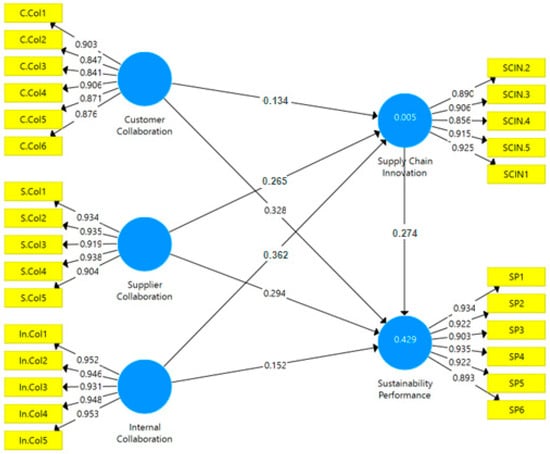

4.3.1. Measurement Model Analysis

Table 4 included a summary of the measurement model analysis including constructs, items, factor loadings, Cronbach’s alpha, composite reliability, and average variance extracted (AVE) as depicted in Figure 3. The reliability of the constructs was tested using Cronbach’s alpha and composite reliability, whose values crossed the recommended level (>0.70) and were thus acceptable. It was also observed that the constructs had convergent validity as the values of factor loading (>0.70) and AVE (>0.50) met the criteria [59].

Table 4.

Construct reliability and validity.

Figure 3.

Measurement model diagram.

Discriminant validity assessment was performed following the criteria of Fornell & Larcker [62], who suggested that the square root of AVE should be higher than the inter-construct correlations to ensure discriminant validity. The results showed that all the values of the square root of AVE were higher than inter-construct correlations, as demonstrated in Table 5.

Table 5.

Discriminant validity.

4.3.2. Structural Model Analysis

Results of the structural model analysis are shown in Table 6, including paths, beta, t statistics, p values and results. To assess the explanatory power of the model, the r square value was used where the results showed that 52.9% variation in sustainability performance was explained by the model. In addition to the R2 value (52.9%), the adjusted R2 and Q2 (predictive relevance) values were also calculated to further assess the model’s predictive ability. The adjusted R2 value was (52.4%), indicating a comparable level of explanatory power after accounting for the number of predictors, while the Q2 value was 0.317, confirming that the model possesses satisfactory predictive relevance. Together, these results demonstrate that the structural model exhibits strong predictive accuracy and robustness in explaining sustainability performance. The model fitness was assessed with the values of SRMR (0.037) and NFI (0.851) where SRMR was less than 0.09 and NFI was close to 0.90 and thus acceptable [63].

Table 6.

Results of the structural model.

The hypothesis testing results indicate that most of the proposed relationships were statistically supported based on the reported beta values, T-statistics, and p-values. Customer collaboration, supplier collaboration, and internal collaboration all showed significant positive effects on SCI, with internal collaboration emerging as the strongest predictor (β = 0.362, T = 4.804, p = 0.000). In addition, customer, supplier, and internal collaboration all had significant positive impacts on sustainability performance, with customer collaboration (β = 0.328, T = 4.514, p = 0.000) and supplier collaboration (β = 0.294, T = 4.524, p = 0.000) producing stronger effects compared to internal collaboration (β = 0.152, T = 2.557, p = 0.011). SCI also significantly contributed to sustainability performance (β = 0.274, T = 3.075, p = 0.001). However, the mediation analysis produced mixed outcomes. The mediating role of SCI was rejected in the cases of customer collaboration (β = 0.000, T = 0.030, p = 0.976) and supplier collaboration (β = 0.000, T = 0.042, p = 0.967), as both results were statistically insignificant. In contrast, SCI fully supported the mediating effect between internal collaboration and sustainability performance (β = 0.346, T = 4.158, p = 0.000), highlighting that innovation is a critical pathway through which internal collaboration drives sustainability outcomes.

5. Discussion

The results of Hypothesis H1 confirmed that customer collaboration has a positive influence on SCI, consistent with previous studies emphasizing customer engagement for product and process innovation through knowledge sharing and responsiveness to customer needs [3,40]. This finding suggests that Jordanian manufacturing firms benefit from customer input in developing innovative solutions, yet the extent of customer-driven innovation appears less intensive than in advanced economies. This may be attributed to institutional and cultural factors—such as limited technological readiness, conservative customer expectations, and less mature innovation ecosystems—that restrict co-creation opportunities. Consequently, while customer collaboration provides market insights, its translation into disruptive innovation remains constrained by contextual barriers.

The results of Hypothesis H2 demonstrated that SCI is significantly enhanced through supplier collaboration. This aligns with prior research that found close supplier–buyer relationships positively influence firms’ abilities to develop innovative sourcing and procurement practices [42,43]. However, the findings also indicate that supplier collaboration in Jordan tends to focus on operational efficiency and compliance rather than radical innovation. This may reflect the institutional emphasis on cost efficiency and resource optimization typical of developing economies, where suppliers often operate under capacity limitations and lack advanced R&D capabilities. Therefore, while supplier collaboration contributes to incremental innovation, systemic challenges may prevent it from fully supporting strategic innovation initiatives.

The results of Hypothesis H3 showed that internal collaboration has the strongest influence on SCI. This supports the findings of Tarigan et al. [18] and Solaimani and van der Veen [31], who emphasized that effective internal communication and planning foster a learning culture and facilitate knowledge transfer. In Jordan’s manufacturing sector, where hierarchical structures and centralized decision-making often dominate, internal collaboration becomes the most reliable and controllable driver of innovation. By promoting internal alignment, firms can leverage internal competencies to overcome institutional rigidity and transform traditional operations into innovation-oriented processes that enhance overall performance.

The results of Hypothesis H4 also confirmed the importance and positive effect of customer collaboration on sustainability performance. Consistent with Ahmed et al. [25] and Sudusinghe and Seuring [47], this finding reinforces that engaging customers in sustainability-oriented communication enables firms to better meet expectations for ethical and eco-friendly products. However, in the Jordanian context, customer collaboration often remains at the awareness level rather than deep sustainability co-development. Institutional pressures, such as weak regulatory enforcement and low consumer activism, may explain why customer collaboration directly improves sustainability outcomes but does not operate strongly through SCI.

Hypothesis H5 results showed that supplier collaboration has a significant positive effect on sustainability performance, supporting Jum’a et al. [50] and Tarigan et al. [18]. Yet, compared to similar studies in other developing economies, this collaboration appears more compliance-oriented—driven by external standards or donor requirements rather than proactive sustainability innovation. This suggests that suppliers in Jordan play a facilitating rather than transformative role in achieving sustainability, reflecting both resource constraints and the institutional focus on short-term cost advantages.

The results of Hypothesis H6 indicated that internal collaboration enhances sustainability performance, though to a lesser extent than customer and supplier collaboration. Similarly to the work of Shan et al. [52] and Sudusinghe and Seuring [47], cross-departmental coordination was found to integrate sustainability goals into operational processes. This outcome demonstrates that sustainability in Jordanian firms is still evolving from a compliance-based to a capability-based approach. Institutional limitations—such as fragmented organizational structures and limited incentives for sustainability innovation—may reduce the overall internal impact, but firms that foster integration across departments can still achieve measurable sustainability gains.

Furthermore, the results of Hypothesis H7 confirmed that SCI significantly enhances sustainability performance. This aligns with Jum’a et al. [13], Fontoura and Coelho [10], and Zhao et al. [54], who found that adopting digitalization, circular economy models, and advanced technologies improve environmental, social, and economic outcomes. However, compared with firms in more industrialized contexts, Jordanian manufacturers face cultural and financial barriers that limit the diffusion of such innovations. These contextual challenges emphasize the need for institutional support mechanisms—such as innovation grants, digital infrastructure, and collaborative R&D platforms—to fully harness SCI’s sustainability potential.

The rejection of Hypothesis H8a suggests that SCI does not mediate the relationship between customer collaboration and sustainability performance. One possible explanation is that customer collaboration in this context emphasizes product adaptation and responsiveness rather than innovation-driven sustainability initiatives [41]. Customers may provide feedback that enhances performance but does not necessarily drive innovation toward sustainability. Similarly, Hypothesis H8b was not supported, showing no mediating role of SCI between supplier collaboration and sustainability performance, contradicting prior works that highlighted supplier-driven innovation [22,42]. This divergence may stem from the institutional and cultural realities of Jordan’s supply base, where sustainability practices are often externally imposed rather than internally driven.

Finally, Hypothesis H8c confirmed that SCI mediates the relationship between internal collaboration and sustainability performance. Consistent with Afraz et al. [34] and Junaid et al. [55], this finding reveals that internal collaboration creates an environment conducive to learning and innovation, allowing sustainability objectives to be translated into tangible outcomes. Within Jordan’s context, this result highlights the unique importance of internal innovation mechanisms as firms rely more on internal resources than external networks to drive sustainability. Thus, innovation acts as a bridge through which internal synergies are transformed into sustained value creation, offering a distinctive theoretical contribution that emphasizes internal collaboration specificity in developing-country manufacturing sectors.

5.1. Managerial Implications

The study concludes by emphasizing the role of customer collaboration as a key enabler of innovation’ activities and enhancing sustainability performance. This implies that managers of Jordanian manufacturing companies need to engage customers in product design processes, feedback loops, and initiatives to reduce their company’s environmental impact. Companies should establish formal mechanisms for identifying the needs of customers, particularly for environmentally friendly products, and use this feedback for decision-making. Doing so enables manufacturers to not only generate new ideas faster, but they can also build trust with customers and make the market more competitive.

It was also found that collaboration with suppliers was extremely important for innovation performance and sustainability performance. Many Jordanian companies should establish long-term relationships with suppliers built on honesty, shared sustainability objectives and trust. Practical examples of actions to be implemented are provided, such as in situ training programs, supplier development programs or collaborative investments in green technologies. These types of partnerships will not only make purchasing more efficient but will also build the resilience of the supply chain and reduce environmental and social risks prevalent in the region.

Collaboration between companies was found to be very important for promoting sustainable, innovative development. Managers need higher levels of collaboration between functions like production, procurement, research and development, and sustainability. Cross-functional teams can help ensure that sustainability priorities are aligned with daily practice. This will help to ensure that practices such as resource conservation, waste reduction and innovation are embedded in the organizational culture. This will allow Jordanian companies to develop dynamic skills and attract creative and environmentally sound workers.

As per the study, supply chain innovation can enhance sustainability in supply chain management. In other words, it shows that managers should invest in technologies, processes, and systems. This means they need to digitize and automate. Also, they need to invest in the circular economy. In Jordan, manufacturers can boost efficiency, engine savings, and assess long-term impact by using these new ideas. Viewing innovation as a means of compliance will promote faster and lower-cost adaptation to stricter international sustainability standards.

Finally, the mediating effect of SCI was supported only in the relationship between internal collaboration and sustainability performance. This implies that while customer and supplier collaboration directly improve sustainability, internal collaboration requires innovation to translate into sustainable outcomes. Managers should therefore focus on fostering an internal culture that promotes experimentation, creativity, and the adoption of new technologies. Encouraging employees to contribute innovative ideas and supporting them with the necessary resources will help ensure that internal collaboration leads to measurable sustainability gains.

5.2. Theoretical Implications

The findings of this study provide several theoretical implications. First, they extend the resource-based view by showing that customer, supplier, and internal collaboration represent valuable resources that enhance innovation and sustainability performance. Second, the results enrich the dynamic capabilities theory by demonstrating how firms in dynamic environments such as Jordanian manufacturing can reconfigure their resources through collaboration and innovation to achieve sustainable outcomes. Third, the study highlights the mediating role of SCI, particularly in the relationship between internal collaboration and sustainability performance, which advances understanding of the mechanisms through which collaboration translates into long-term sustainability. Fourth, the study contributes to literature by integrating collaboration, innovation, and sustainability into a single framework, offering a comprehensive explanation of how firms can align operational strategies with sustainability goals. Finally, unlike previous studies conducted in developing-country manufacturing contexts, which often report a generalized mediating role of SCI across different collaboration dimensions [15,16,26,27,34], this study demonstrates that the mediating effect of SCI is specific to internal collaboration rather than universal. This finding suggests that in Jordan’s manufacturing sector, innovation outcomes depend more on intra-organizational coordination and knowledge integration than on external partnerships with customers or suppliers [18,31]. Such “internal collaboration specificity” contrasts with evidence from other developing economies, where supplier- or customer-driven innovation tends to dominate [19,36]. This highlights the contextual influence of organizational culture, resource structures, and institutional environments, which shape how collaborative innovation translates into sustainability outcomes [7,10,13]. Therefore, the study contributes theoretically by refining the understanding of how collaborative innovation mechanisms operate under resource-constrained and institutionally distinct settings typical of developing countries [23,30,34].

6. Conclusions

The main aim of this study was to examine the influence of SCC on SCI and sustainability performance in the context of manufacturing firms in Jordan. The study also investigated the mediating role of SCI in the relationship between different forms of collaboration and sustainability outcomes. To achieve this aim, data were collected through a structured questionnaire administered to employees from multiple management levels across organizations in Amman. Using SmartPLS software, the data were analyzed through partial least squares structural equation modeling.

The results showed that customer, supplier, and internal collaboration all had significant positive effects on SCI. These three forms of collaboration also positively influenced sustainability performance, with customer and supplier collaboration showing stronger effects compared to internal collaboration. SCI was found to directly enhance sustainability performance and to mediate the relationship between internal collaboration and sustainability performance. However, the mediating role of innovation was not supported in the cases of customer and supplier collaboration.

The managerial implications of these findings suggest that firms in Jordan should strengthen collaboration with customers and suppliers to improve innovation and sustainability outcomes, while also fostering internal collaboration to build a culture of innovation that supports sustainable practices. The theoretical implications highlight the importance of the resource-based view and dynamic capabilities theory in explaining how collaboration and innovation serve as pathways for achieving sustainability in dynamic environments.

This study has some limitations. The data were collected only from organizations in Amman, which may restrict the generalizability of the results to other regions in Jordan or different industries. The study also relied on cross-sectional data, which limits the ability to capture long-term causal effects. In addition, the use of self-reported survey responses may introduce bias. Another limitation of this study is the gender imbalance in the sample, with males accounting for 91.7% and females only 8.3%. This reflects the current composition of Jordan’s manufacturing workforce but may limit the generalizability of the findings.

Future studies should aim for a more gender-balanced sample to enhance representativeness. Moreover, future studies should expand the sample to include other cities and industries in Jordan to provide broader insights. Longitudinal research designs are recommended to examine how collaboration, innovation, and sustainability evolve over time. Future research could also incorporate objective performance data or case studies to complement survey findings and reduce potential bias. Finally, comparative studies across different countries could provide deeper insights into the role of cultural and institutional contexts in shaping the collaboration–innovation–sustainability nexus.

Author Contributions

Conceptualization, L.J.; methodology, L.J. and N.M.; software, D.A.; validation, N.M.; formal analysis, L.J.; investigation, L.J. and D.A.; resources, L.J.; data curation, N.M.; writing—original draft preparation, L.J.; writing—review and editing, D.A. and N.M.; visualization, N.M.; supervision, L.J.; project administration, L.J. and D.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethical review and approval were waived for this study by Institution Committee due to the German Jordanian University Regulations (English version-2025).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A. Constructs and Measurement Items

| Constructs | Measurement Items |

| Customer Collaboration |

|

| Supplier Collaboration |

|

| Internal Collaboration |

|

| Supply Chain Innovation |

|

| Sustainability Performance |

|

References

- Yu, Y.; Zeng, H.; Zhang, M. Digital transformation for supply chain collaborative innovation and market performance. Eur. J. Innov. Manag. 2025, 28, 2446–2468. [Google Scholar] [CrossRef]

- Handoyo, S.; Suharman, H.; Ghani, E.K.; Soedarsono, S. A business strategy, operational efficiency, ownership structure, and manufacturing performance: The moderating role of market uncertainty and competition intensity and its implication on open innovation. J. Open Innov. Technol. Mark. Complex. 2023, 9, 100039. [Google Scholar] [CrossRef]

- Yunus, E.N. Leveraging supply chain collaboration in pursuing radical innovation. Int. J. Innov. Sci. 2018, 10, 350–370. [Google Scholar] [CrossRef]

- Farida, I.; Setiawan, D. Business strategies and competitive advantage: The role of performance and innovation. J. Open Innov. Technol. Mark. Complex. 2022, 8, 163. [Google Scholar] [CrossRef]

- Chiu, J.; Chung, H.; Yang, Y.N. The impact of a conglomerate merger on its vendors and rivals–a case study of Google’s acquisition of Motorola. Technol. Anal. Strateg. Manag. 2016, 28, 176–189. [Google Scholar] [CrossRef]

- Ahmad, S.; Omar, R.; Quoquab, F. Family firms’ sustainable longevity: The role of family involvement in business and innovation capability. J. Fam. Bus. Manag. 2021, 11, 86–106. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y. Research on Collaborative Performance of Green Supply Chain Enabled by New Quality Productivity. Sustainability 2025, 17, 3793. [Google Scholar] [CrossRef]

- Mofokeng, T.M.; Chinomona, R. Supply chain partnership, supply chain collaboration and supply chain integration as the antecedents of supply chain performance. S. Afr. J. Bus. Manag. 2019, 50, 1–10. [Google Scholar] [CrossRef]

- Jum’a, L.; Bushnaq, M. Investigating the role of flexibility as a moderator between supply chain integration and firm performance: The case of manufacturing sector. J. Adv. Manag. Res. 2024, 21, 203–227. [Google Scholar] [CrossRef]

- Fontoura, P.; Coelho, A. How to boost green innovation and performance through collaboration in the supply chain: Insights into a more sustainable economy. J. Clean. Prod. 2022, 359, 132005. [Google Scholar] [CrossRef]

- Akam, M.J.; Sunday, E.G.; Etuk, I.U.; Ejikeme, O.B.; Arikpo, N.N. The role of integrated coordination in supply chain performance of firms in the manufacturing industry. Int. J. Integr. Supply Manag. 2023, 16, 26–51. [Google Scholar] [CrossRef]

- Tiwari, S. Supply chain integration and Industry 4.0: A systematic literature review. Benchmarking Int. J. 2021, 28, 990–1030. [Google Scholar] [CrossRef]

- Jum’a, L.; Zimon, D.; Ikram, M.; Madzík, P. Towards a sustainability paradigm; the nexus between lean green practices, sustainability-oriented innovation and Triple Bottom Line. Int. J. Prod. Econ. 2022, 245, 108393. [Google Scholar] [CrossRef]

- Liu, W.; Yan, X.; Si, C.; Xie, D.; Wang, J. Effect of buyer-supplier supply chain strategic collaboration on operating performance: Evidence from Chinese companies. Supply Chain. Manag. Int. J. 2020, 25, 823–839. [Google Scholar] [CrossRef]

- Uddin, M.B. The effect of strategic commitment and supply chain collaboration on operational and innovation performance. IIMB Manag. Rev. 2022, 34, 364–377. [Google Scholar] [CrossRef]

- Hariyadi, E.; Wong, W.K.; Negash, Y.T. Sustainable supply chain collaboration in construction and demolition waste management: Green innovation for sustainability performance. J. Mater. Cycles Waste Manag. 2025, 27, 3335–3351. [Google Scholar] [CrossRef]

- Kumar, G.; Banerjee, R.N.; Meena, P.L.; Ganguly, K.K. Joint planning and problem solving roles in supply chain collaboration. IIMB Manag. Rev. 2017, 29, 45–57. [Google Scholar] [CrossRef]

- Tarigan, Z.J.H.; Siagian, H.; Jie, F. Impact of internal integration, supply chain partnership, supply chain agility, and supply chain resilience on sustainable advantage. Sustainability 2021, 13, 5460. [Google Scholar] [CrossRef]

- Jimenez-Jimenez, D.; Martínez-Costa, M.; Sanchez Rodriguez, C. The mediating role of supply chain collaboration on the relationship between information technology and innovation. J. Knowl. Manag. 2019, 23, 548–567. [Google Scholar] [CrossRef]

- Galván, J.A.; Casman, E.; Fisher, E. What skills predict an intern’s ability to innovate new products? A quantitative study of innovation capability of Mexican college interns. Int. J. Interact. Des. Manuf. 2022, 16, 1301–1320. [Google Scholar] [CrossRef]

- Rhee, M.; Stephens, A.R. Innovation-orientated technology assimilation strategy and Korean SMES’enhancing innovation capability, competitive advantage and firm performance. Int. J. Innov. Manag. 2020, 24, 2050081. [Google Scholar] [CrossRef]

- Hofman, P.S.; Blome, C.; Schleper, M.C.; Subramanian, N. Supply chain collaboration and eco-innovations: An institutional perspective from China. Bus. Strategy Environ. 2020, 29, 2734–2754. [Google Scholar] [CrossRef]

- Uddin, M.B.; Akhter, B. Investigating the relationship between top management commitment, supply chain collaboration, and sustainable firm performance in the agro-processing supply chain. Oper. Manag. Res. 2022, 15, 1399–1417. [Google Scholar] [CrossRef]

- Wang, C.; Hu, Q. Knowledge sharing in supply chain networks: Effects of collaborative innovation activities and capability on innovation performance. Technovation 2020, 94, 102010. [Google Scholar] [CrossRef]

- Ahmed, W.; Ashraf, M.S.; Khan, S.A.; Kusi-Sarpong, S.; Arhin, F.K.; Kusi-Sarpong, H.; Najmi, A. Analyzing the impact of environmental collaboration among supply chain stakeholders on a firm’s sustainable performance. Oper. Manag. Res. 2020, 13, 4–21. [Google Scholar] [CrossRef]

- Ocicka, B.; Baraniecka, A.; Jefmański, B. Exploring supply chain collaboration for green innovations: Evidence from the high-tech industry in Poland. Energies 2022, 15, 1750. [Google Scholar] [CrossRef]

- Afum, E.; Issau, K.; Agyabeng-Mensah, Y.; Baah, C.; Dacosta, E.; Essandoh, E.; Agyenim Boateng, E. The missing links of sustainable supply chain management and green radical product innovation between sustainable entrepreneurship orientation and sustainability performance. J. Eng. Des. Technol. 2023, 21, 167–187. [Google Scholar] [CrossRef]

- Lin, J.; Fan, Y. Seeking sustainable performance through organizational resilience: Examining the role of supply chain integration and digital technology usage. Technol. Forecast. Soc. Change 2024, 198, 123026. [Google Scholar] [CrossRef]

- Jum’a, L.; Zimon, D.; Sroufe, R.; Tyan, J. Sustainable supply chain management’s impact on triple bottom line performance: Does the firm size matter? Corp. Soc. Responsib. Environ. Manag. 2024, 31, 4673–4693. [Google Scholar] [CrossRef]

- Jum’a, L.; Ikram, M.; Jabbour, C.J.C. Towards circular economy: A IoT enabled framework for circular supply chain integration. Comput. Ind. Eng. 2024, 192, 110194. [Google Scholar] [CrossRef]

- Solaimani, S.; van der Veen, J. Open supply chain innovation: An extended view on supply chain collaboration. Supply Chain. Manag. Int. J. 2021, 27, 597–610. [Google Scholar] [CrossRef]

- Yang, Z.; Lin, Y. The effects of supply chain collaboration on green innovation performance: An interpretive structural modeling analysis. Sustain. Prod. Consum. 2020, 23, 1–10. [Google Scholar] [CrossRef]

- Singhry, H.B. Effect of supply chain technology, supply chain collaboration and innovation capability on supply chain performance of manufacturing companies. J. Bus. Stud. Q. 2015, 7, 258. [Google Scholar]

- Afraz, M.F.; Bhatti, S.H.; Ferraris, A.; Couturier, J. The impact of supply chain innovation on competitive advantage in the construction industry: Evidence from a moderated multi-mediation model. Technol. Forecast. Soc. Change 2021, 162, 120370. [Google Scholar] [CrossRef]

- Anh, N.T.M.; Hui, L.; Khoa, V.D.; Mehmood, S. Relational capital and supply chain collaboration for radical and incremental innovation: An empirical study in China. Asia Pac. J. Mark. Logist. 2019, 31, 1076–1094. [Google Scholar]

- Baig, H.; Ahmed, W.; Najmi, A. Understanding influence of supply chain collaboration on innovation-based market performance. Int. J. Innov. Sci. 2021, 14, 376–395. [Google Scholar] [CrossRef]

- Nguyen, M.A.T.; Lei, H.; Vu, K.D.; Le, P.B. The role of cognitive proximity on supply chain collaboration for radical and incremental innovation: A study of a transition economy. J. Bus. Ind. Mark. 2019, 34, 591–604. [Google Scholar] [CrossRef]

- Billah, M.M.; Alam, S.S.; Masukujjaman, M.; Ali, M.H.; Makhbul, Z.K.M.; Salleh, M.F.M. Effects of Internet of Things, supply chain collaboration and ethical sensitivity on sustainable performance: Moderating effect of supply chain dynamism. J. Enterp. Inf. Manag. 2023, 36, 1270–1295. [Google Scholar] [CrossRef]

- Liao, S.H.; Hu, D.C.; Shih, Y.S. Supply chain collaboration and innovation capability: The moderated mediating role of quality management. Total Qual. Manag. Bus. Excell. 2021, 32, 298–316. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pujari, D.; Pontrandolfo, P. Green product innovation in manufacturing firms: A sustainability-oriented dynamic capability perspective. Bus. Strategy Environ. 2017, 26, 490–506. [Google Scholar] [CrossRef]

- Un, C.A.; Asakawa, K. Types of R&D collaborations and process innovation: The benefit of collaborating upstream in the knowledge chain. J. Prod. Innov. Manag. 2015, 32, 138–153. [Google Scholar]

- Roscoe, S.; Cousins, P.D.; Lamming, R.C. Developing eco-innovations: A three-stage typology of supply networks. J. Clean. Prod. 2016, 112, 1948–1959. [Google Scholar] [CrossRef]

- Hui, Z.; He-Cheng, W.; Min-Fei, Z. Partnership Management, Supply Chain Collaboration, and Firm Innovation Performance: An Empirical Examination. Int. J. Innov. Sci. 2015, 7, 127–138. [Google Scholar] [CrossRef]

- Iddris, F. Measurement of innovation capability in supply chain: An exploratory study. Int. J. Innov. Sci. 2016, 8, 331–349. [Google Scholar] [CrossRef]

- Pouwels, I.; Koster, F. Inter-organizational cooperation and organizational innovativeness. A comparative study. Int. J. Innov. Sci. 2017, 9, 184–204. [Google Scholar] [CrossRef]

- Yunus, E.N.; Tadisina, S.K. Drivers of supply chain integration and the role of organizational culture: Empirical evidence from Indonesia. Bus. Process Manag. J. 2016, 22, 89–115. [Google Scholar] [CrossRef]

- Sudusinghe, J.I.; Seuring, S. Supply chain collaboration and sustainability performance in circular economy: A systematic literature review. Int. J. Prod. Econ. 2022, 245, 108402. [Google Scholar] [CrossRef]

- Han, Z.; Huo, B. The impact of green supply chain integration on sustainable performance. Ind. Manag. Data Syst. 2020, 120, 657–674. [Google Scholar] [CrossRef]

- Brun, A.; Karaosman, H.; Barresi, T. Supply chain collaboration for transparency. Sustainability 2020, 12, 4429. [Google Scholar] [CrossRef]

- Jum’a, L.; Zimon, D.; Ikram, M. A relationship between supply chain practices, environmental sustainability and financial performance: Evidence from manufacturing companies in Jordan. Sustainability 2021, 13, 2152. [Google Scholar] [CrossRef]

- Jum’a, L.; Ikram, M.; Alkalha, Z.; Alaraj, M. Factors affecting managers’ intention to adopt green supply chain management practices: Evidence from manufacturing firms in Jordan. Environ. Sci. Pollut. Res. 2022, 29, 5605–5621. [Google Scholar] [CrossRef] [PubMed]

- Shan, H.; Li, Y.; Shi, J. Influence of supply chain collaborative innovation on sustainable development of supply chain: A Study on Chinese Enterprises. Sustainability 2020, 12, 2978. [Google Scholar] [CrossRef]

- Gupta, H.; Kusi-Sarpong, S.; Rezaei, J. Barriers and overcoming strategies to supply chain sustainability innovation. Resour. Conserv. Recycl. 2020, 161, 104819. [Google Scholar] [CrossRef]

- Zhao, N.; Hong, J.; Lau, K.H. Impact of supply chain digitalization on supply chain resilience and performance: A multi-mediation model. Int. J. Prod. Econ. 2023, 259, 108817. [Google Scholar] [CrossRef] [PubMed]

- Junaid, M.; Zhang, Q.; Syed, M.W. Effects of sustainable supply chain integration on green innovation and firm performance. Sustain. Prod. Consum. 2022, 30, 145–157. [Google Scholar] [CrossRef]

- Hadj, T.B. Effects of corporate social responsibility towards stakeholders and environmental management on responsible innovation and competitiveness. J. Clean. Prod. 2020, 250, 119490. [Google Scholar] [CrossRef]

- Khan, A.; Chen, C.C.; Suanpong, K.; Ruangkanjanases, A.; Kittikowit, S.; Chen, S.C. The impact of CSR on sustainable innovation ambidexterity: The mediating role of sustainable supply chain management and second-order social capital. Sustainability 2021, 13, 12160. [Google Scholar] [CrossRef]

- Malhotra, N.K. Marketing Research: An Applied Orientation, 6th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 8th ed.; Cengage: Boston, MA, USA, 2019. [Google Scholar]

- Zheng, G.W.; Siddik, A.B.; Masukujjaman, M.; Fatema, N. Factors affecting the sustainability performance of financial institutions in Bangladesh: The role of green finance. Sustainability 2021, 13, 10165. [Google Scholar] [CrossRef]

- Ringle, C.M.; Wende, S.; Becker, J.-M. SmartPLS 3, Version 3. [Computer software]. SmartPLS GmbH: Bönningstedt, Germany, 2015. Available online: http://www.smartpls.com (accessed on 1 May 2025).

- Fornell, C.; Larcker, D.F. Structural Equation Models with Unobservable Variables and Measurement Error: Algebra and Statistics. J. Mark. Res. 1981, 18, 382–388. [Google Scholar] [CrossRef]

- Byrne, B.M. Structural Equation Modeling with AMOS: Basic Concepts, Applications, and Programming, 2nd ed.; Routledge: Milton Park, UK, 2013. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).