Connecting with the Past: Filament Development and 3D Printing from Historical Wood Waste

Abstract

1. Introduction

1.1. Problem Statement

1.2. Literature Context

1.3. Research Gap

2. Research Aim

3. Materials and Methods

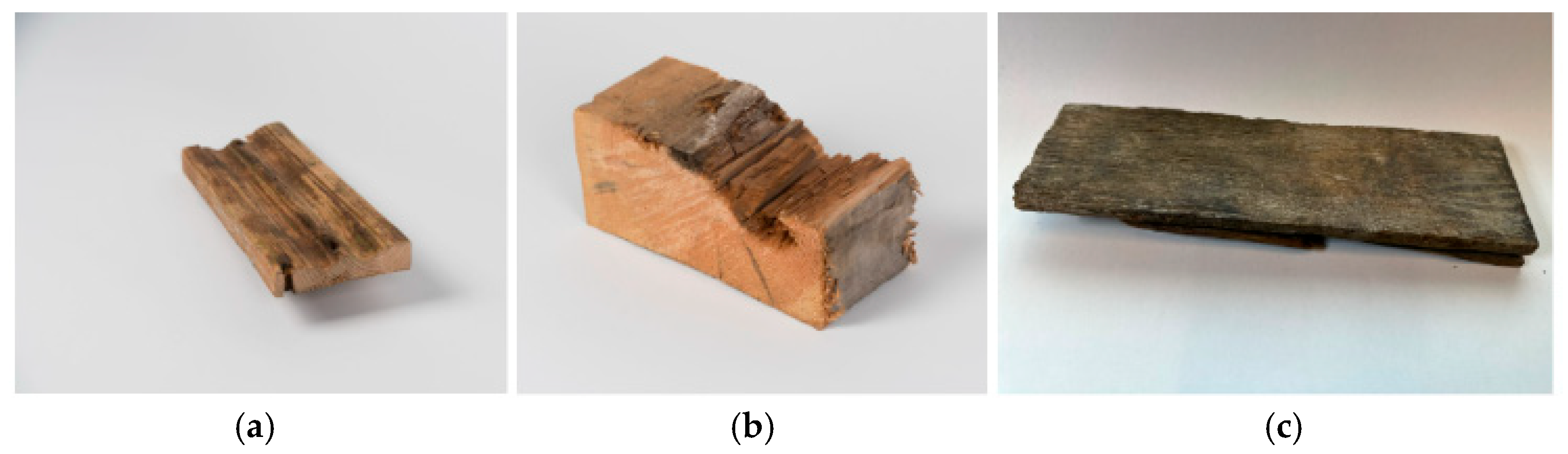

3.1. Object Selection

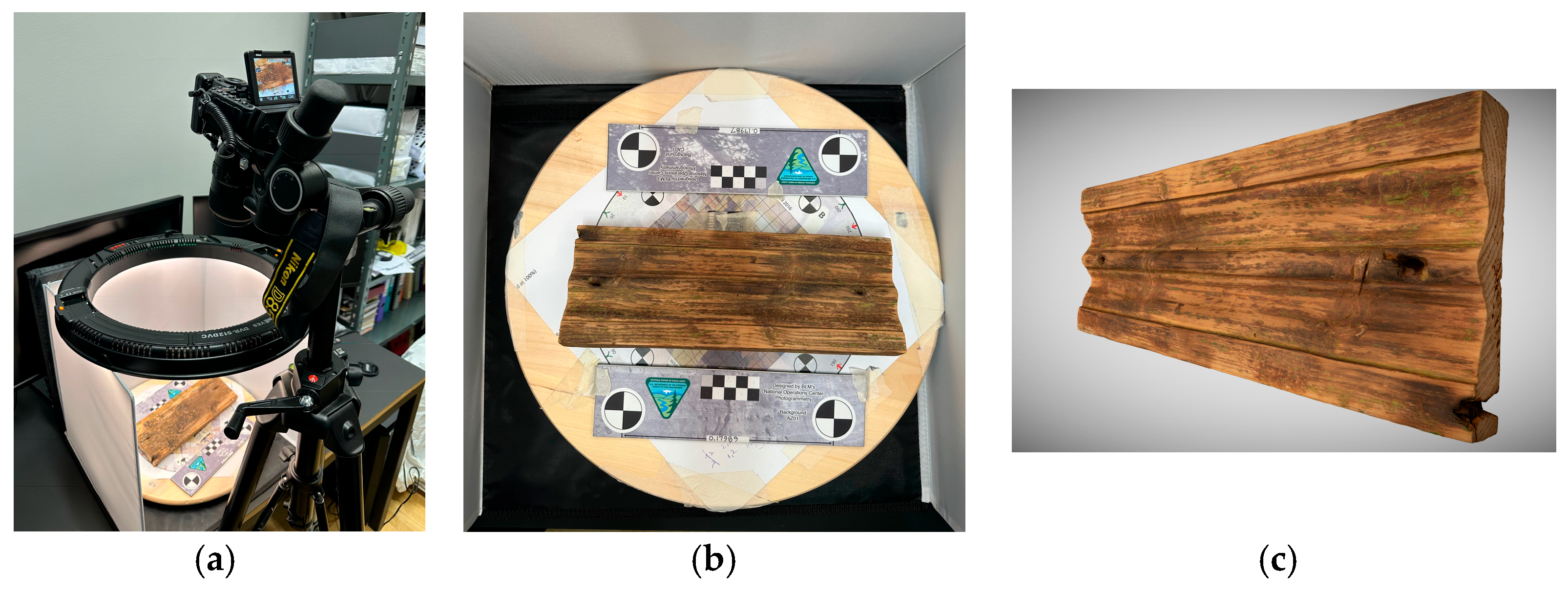

3.2. Three-Dimensional Modeling: Photogrammetry

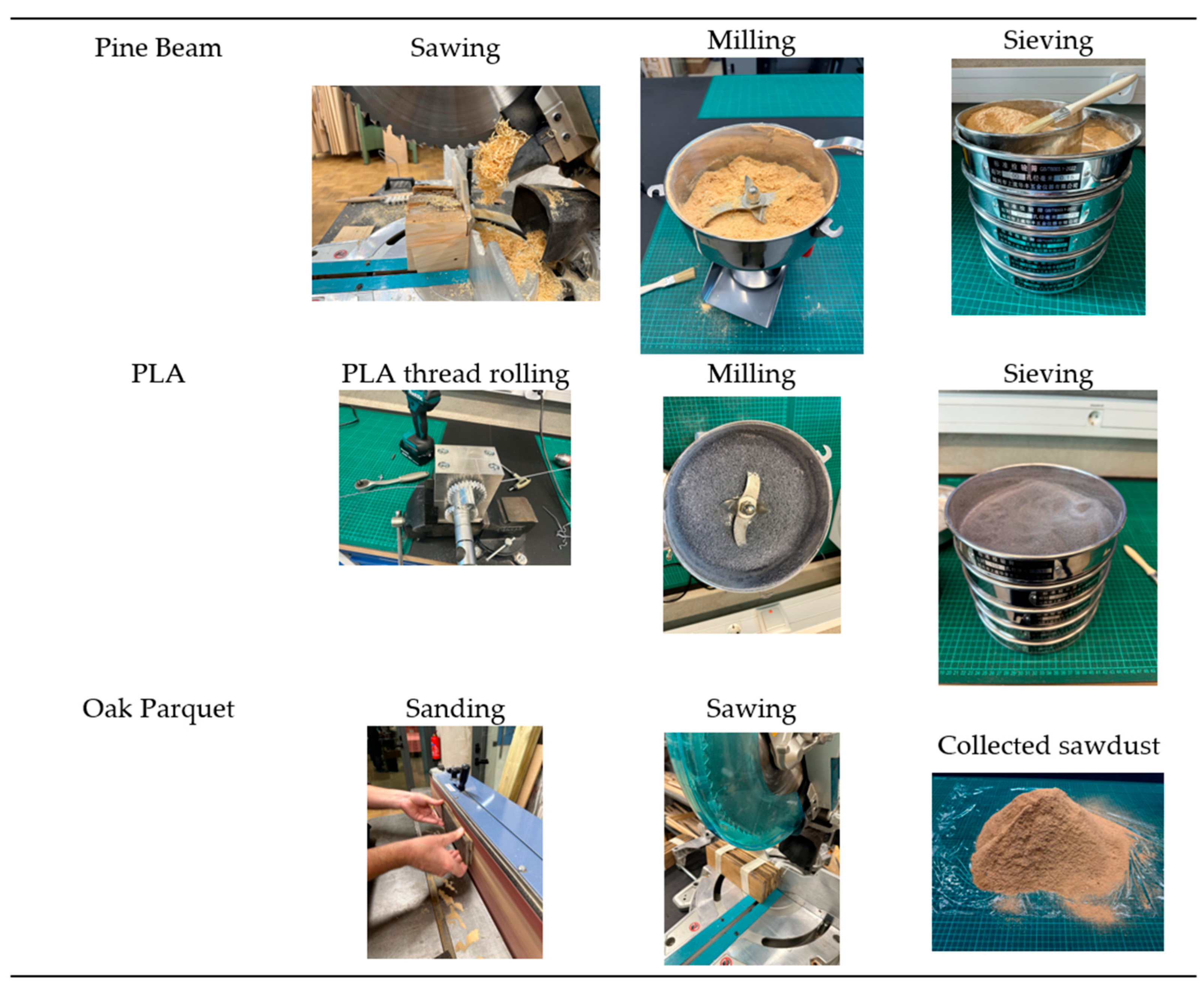

3.3. Sawdust and PLA Preparation

3.4. Determination of Printing Parameters

4. Results

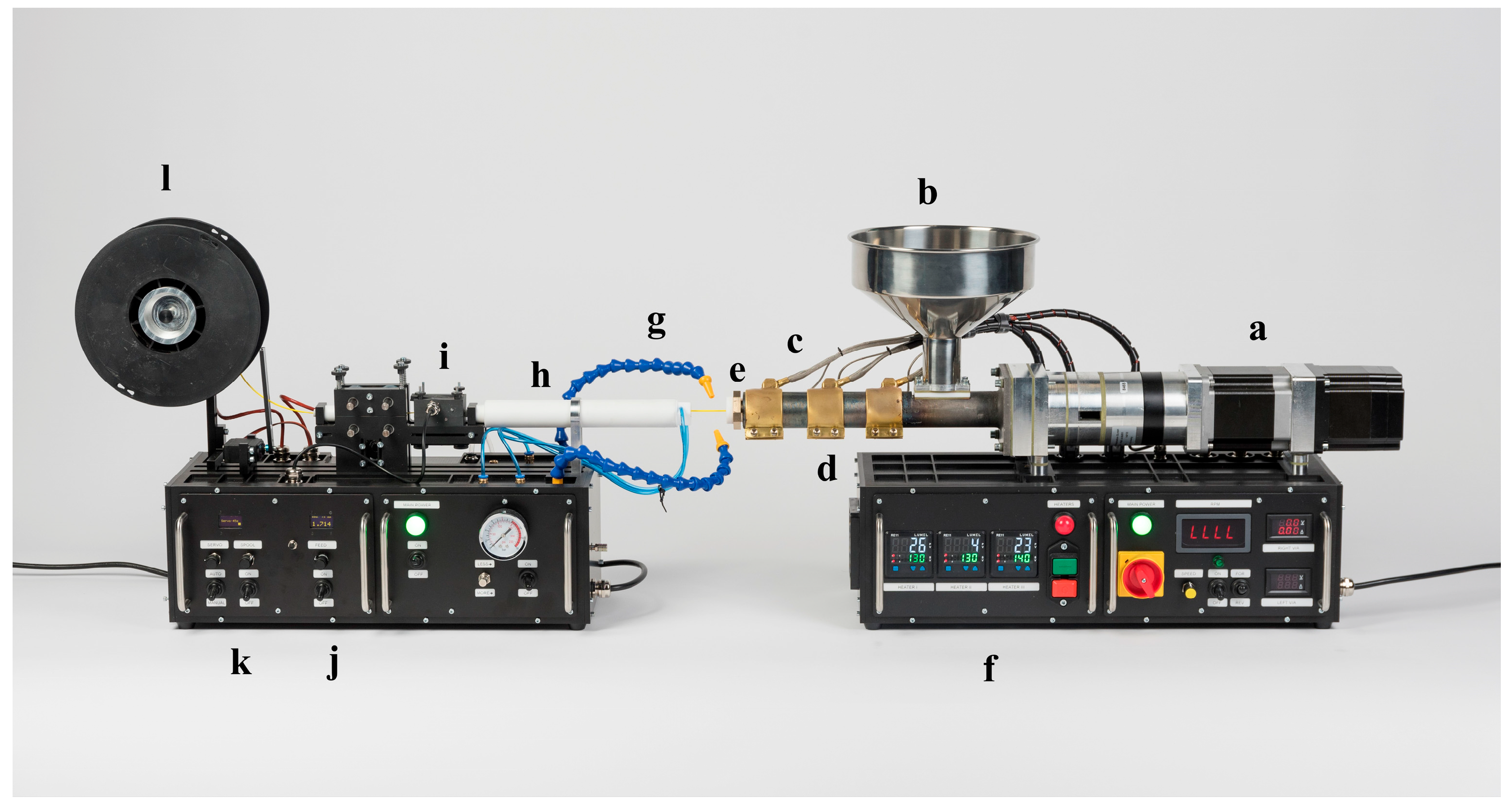

4.1. Filament Preparation

4.2. Filament Thread

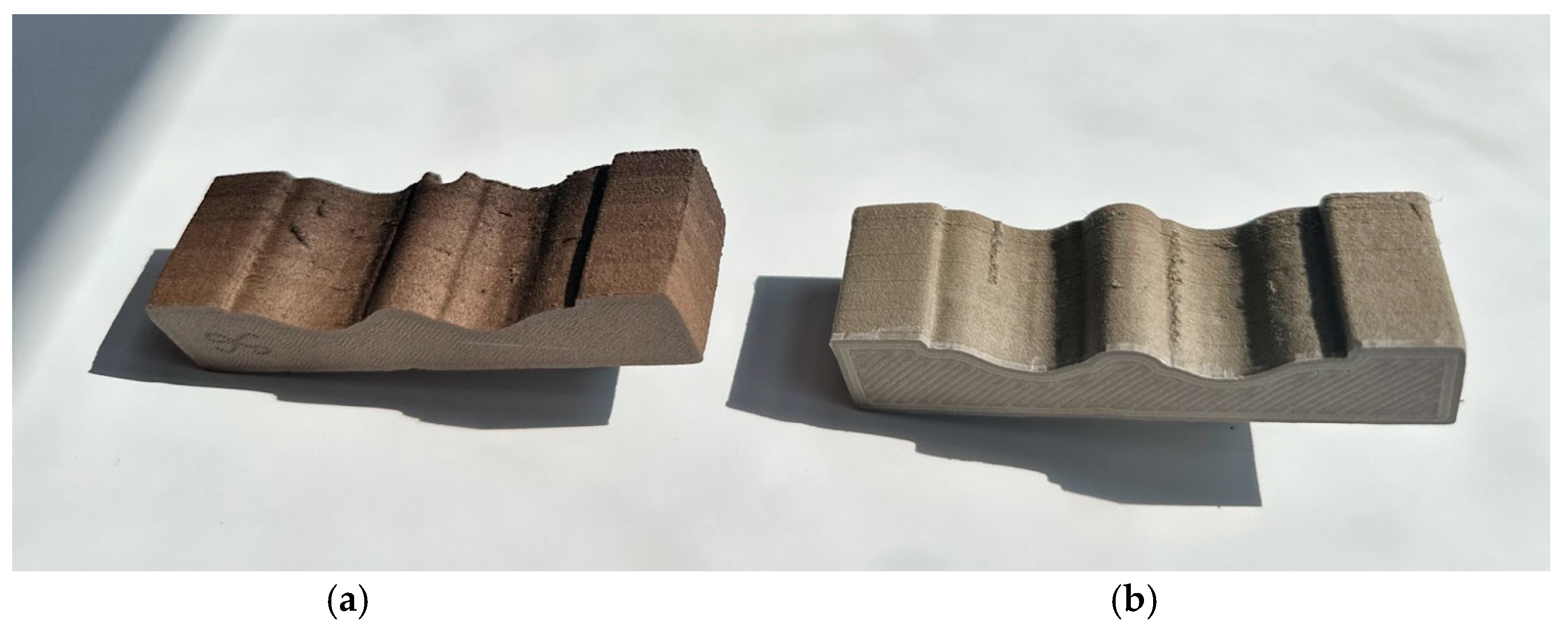

4.3. Three-Dimensional Printing with Wood-Based Filaments

4.4. Cost, Energy Consumption, and Environmental Impact

| Nr. | Process/Devices That Consume Electricity | Power [W] | Duration [h] | Electric Consumption [kWh] | CO2 Emission [kgCO2] | Remuneration of Personnel [€/hour] | Remuneration of Personnel [€] | Av. * Electricity Price During Process Conduction [s/kWh] | Consumed Electricity Cost [s/kWh] |

|---|---|---|---|---|---|---|---|---|---|

| Wood waste/PLA composite, total | - | 42 | 8 | 6 | - | 648 | - | 77 | |

| 1 | Cleaning of platband [52] | 1000 | 0.167 | 0.167 | 0.116 | 13.371 | 2.233 | 11.36 | 1.898 |

| 2 | Sandpaper cleaning | - | 0.500 | - | - | 13.371 | 6.686 | - | - |

| 3 | Photogrammetry | - | 4.500 | - | - | 50.000 * | 225 | - | - |

| 4 | Photo camera Nikon D850 battery [53] | 7 | 0.667 | 0.005 | 0.004 | - | - | 11.36 | 0.057 |

| 5 | LED ring light FalconEyes [54] | 32 | 0.667 | 0.022 | 0.016 | - | - | 11.36 | 0.250 |

| 6 | Desktop computer [55], monitor [56] | 850 + 28.8 | 4.000 | 3.516 | 2.427 | - | - | 11.36 | 39.942 |

| 7 | Machine sanding (oak) [57] | 2200 | 0.250 | 0.550 | 0.38 | 13.371 | 3.343 | 8.25 | 4.538 |

| 8 | Sawing [58], vacuum cleaner [59] | 1800 + 1000 | 0.333 | 0.933 | 0.644 | 13.371 | 4.450 | 8.25 | 7.698 |

| 9 | Wood sawdust milling | 1468 | 0.010 | 0.015 | 0.011 | - | - | 8.25 | 0.124 |

| 10 | Wood sawdust milling | - | 4.51 | - | - | 13.371 | 60.303 | - | - |

| 11 | Wood sawdust sieving | - | 3.00 | - | - | 13.371 | 40.120 | - | - |

| 12 | PLA thread rolling with cordless drill [60,61] | 270 | 0.333 | 0.09 | 0.063 | 13.371 | 4.453 | 9.20 | 0.828 |

| 13 | PLA milling | 1468 | 0.010 | 0.015 | 0.011 | - | - | 9.20 | 0.138 |

| 14 | PLA milling | - | 4.510 | - | - | 13.371 | 60.303 | - | - |

| 15 | PLA sieving | - | 3.00 | - | - | 13.371 | 40.113 | - | - |

| 16 | Weighing and mixing | 1.5 | 0.083 | 0.001 | 0.001 | 13.371 | 1.114 | 9.20 | 0.010 |

| 17 | Filament machine | 838.1 | 1.500 | 1.258 | 0.869 | 13.371 | 20.057 | 9.20 | 11.574 |

| 18 | Winding machine | 31 | 1.500 | 0.047 | 0.033 | 13.371 | 20.057 | 9.20 | 0.433 |

| 19 | 3D printing | 100 | 11.889 | 1.189 | 0.821 | 13.371 | 158.968 | 7.52 | 8.942 |

| Platband replica, new wood, total | - | 3 | 3 | 2 | - | 95 | - | 30 | |

| 20 | Blades’ production with profiling machine [62] | 1500 | 1.333 | 2.000 | 1.38 | 48.243 * | 64.165 | 12.65 | 25.300 |

| 21 | Blades’ template [63] | 400 | 0.333 | 0.134 | 0.093 | 48.243 * | 16.065 | 12.65 | 1.696 |

| 22 | Thicknessing of blank [64] | 5500 | 0.017 | 0.094 | 0.065 | 13.371 | 0.228 | 12.65 | 1.190 |

| 23 | Plaining of the blank [65] | 3000 | 0.001 | 0.003 | 0.003 | 13.371 | 0.014 | 12.65 | 0.038 |

| 24 | Sliding table saw [66] | 4000 | 0.017 | 0.068 | 0.047 | 13.371 | 0.228 | 12.65 | 0.861 |

| 25 | Table miller [67] | 5000 | 0.008 | 0.040 | 0.0028 | 13.371 | 0.107 | 12.65 | 0.506 |

| 26 | Machine operation | - | 1 | - | - | 13.371 | 13.371 | - | - |

5. Discussion and Conclusions

5.1. Key Findings and Interpretation

5.2. Comparison with Prior Work

5.3. Implications for Heritage Practices

5.4. Limitations

- Mechanical performance was not measured; thus, structural claims are out of scope. The results target visual and geometric fidelity rather than load-bearing service.

- Moisture content of sawdust/filament was controlled procedurally (drying steps) but not reported numerically; moisture–printability links remain to be modeled.

- Filament diameter control exhibited variability that affected feeding; no closed-loop diameter feedback was implemented.

- Process-level comparison excluded upstream material production and facility HVAC/lighting; it is not a full LCA and should be read as a bounded operational comparison [50].

- Health-related risks: Strong allergic reactions were observed during sawing, milling, and sieving, highlighting the need for improved safety measures and protective protocols in future work.

- Ethical/interpretive considerations (e.g., authenticity, reversibility, and labeling of replicas) are context-dependent and require curatorial oversight beyond the technical scope.

5.5. Future Work

- Diameter control: Implement closed-loop laser micrometry with feedback to winding speed for diameter tolerance.

- Higher wood content via pellets: The highest wood content achieved (50% old wood/50% PLA) in filament thread was not suitable for printing, due to easy cracking. Achieving higher wood waste content may be possible with pellet-based extrusion. The design and construction of a pellet machine is planned for future research.

- Natural binder exploration: Evaluate pine–resin derivatives as bio-binders or co-binders to improve interfacial adhesion and recyclability of all-biogenic composites, building on evidence of resin improving thermal/mechanical behavior in bioplastics and cementitious composites [73,74,75]; position this as a controlled experiment, not as a claim from the present data. Pine–resin has already been studied as a sustainable additive to improve the thermal properties of thermoplastic starch as well as mechanical, thermal and structural properties of bioplastic [70] and pumice–cement composites [72], pine resin biodegradability [73]. The pine–resin application instead of PLA as binder could allow for 3D-printed wood waste composite recycling as a whole substance. Historical decoration element replicas produced with pine–resin instead of PLA have more advantages on the cultural heritage sites.

- Outdoor performance: We conducted accelerated weathering and natural exposure for climate resistance, biodegradability, water absorption, occurrence of patina to validate facade applicability.

- Decision frameworks ana LCA boundary expansion: Extend assessment to cradle-to-gate (or gate-to-gate) scenarios, incorporate energy mix sensitivities, and codify heritage-specific decision criteria (significance, material identity, aesthetics, interventions).

5.6. Concluding Synthesis

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FDM | Fused deposition modeling |

| LCA | Life Cycle Assessment |

| PE | Polyethylene |

| PP | Polypropylene |

| EI | Environmental impact |

| PLA | Polylactic acid |

| FFF | Fused filament fabrication |

References

- Gineiko, A. Representative of Estonian Environmental Services AS. Phone Interview, 22 January 2024. [Google Scholar]

- European Commission. Waste Framework Directive. Energy, Climate Change, Environment. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en (accessed on 1 April 2025).

- What Is Additive Manufacturing. Built In. Available online: https://builtin.com/3d-printing/additive-manufacturing (accessed on 7 March 2024).

- Löschke, K.S.; Mai, J.; Proust, G.; Brambilla, A. Microtimber: The Development of a 3D Printed Composite Panel Made from Waste Wood and Recycled Plastics. In Digital Wood Design; Bianconi, F., Filippucci, M., Eds.; E-Publishing Inc.: Cham, Switzerland, 2019; pp. 827–848. [Google Scholar]

- Pringle, A.M.; Rudnicki, M.; Pearce, J.M. Wood Furniture Waste—Based Recycled 3-D Printing Filament. For. Prod. J. 2017, 68, 86–95. [Google Scholar] [CrossRef]

- Divakaran, N.; Das, J.P.; PV, A.K.; Mohanty, S.; Ramadoss, A.; Nayak, S.K. Comprehensive review on various additive manufacturing techniques and its implementation in electronic devices. J. Manuf. Syst. 2022, 62, 477–502. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef]

- Daian, G.; Ozarska, B. Wood waste management practices and strategies to increase sustainability standards in the Australian wooden furniture manufacturing sector. J. Clean. Prod. 2009, 17, 1594–1602. [Google Scholar] [CrossRef]

- Owoyemi, J.M.; Zakariya, H.O.; Elegbede, I.O. Sustainable wood waste management in Nigeria. Environ. Socio-Econ. Stud. 2016, 4, 1–9. [Google Scholar] [CrossRef]

- Hossain, U.; Poon, C.S. Comparative LCA of wood waste management strategies generated from building construction activities. J. Clean. Prod. 2017, 177, 387–397. [Google Scholar] [CrossRef]

- Zbieć, M.; Franc-Dąbrowska, J.; Drejerska, N. Wood Waste Management in Europe through the Lens of the Circular Bioeconomy. Energies 2022, 15, 4352. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M.; Guerra, F. 3D printing: State of the art and future perspectives. J. Cult. Heritage 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M. An application of integrated 3D technologies for replicas in cultural heritage. ISPRS Int. J. Geo-Information 2019, 8, 285. [Google Scholar] [CrossRef]

- Govedič, T.B.; Tomec, D.K.; Kuzman, M.K.; Oblak, L.; Glavonjic, B. Environmental assessment/evaluation of 3D printing and 3D printing with wood-PLA composites—Case study. Drv. Ind. 2024, 75, 49–58. [Google Scholar] [CrossRef]

- McKeown, P.; Jones, M.D. The Chemical Recycling of PLA: A Review. Sustain. Chem. 2020, 1, 1–22. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, S.M.; Shafiq, M.; Abbas, N. A review on PLA-based biodegradable materials for biomedical applications. Giant 2024, 18, 100261. [Google Scholar] [CrossRef]

- Kantaros, A.; Laskaris, N.; Piromalis, D.; Ganetsos, T. Manufacturing Zero-Waste COVID-19 Personal Protection Equipment: A Case Study of Utilizing 3D Printing While Employing Waste Material Recycling. Circ. Econ. Sustain. 2021, 1, 851–869. [Google Scholar] [CrossRef]

- Bhayana, M.; Singh, J.; Sharma, A.; Gupta, M. A review on optimized FDM 3D printed Wood/PLA bio composite material characteristics. Mater. Today Proc. 2023, 63, 311–318. [Google Scholar] [CrossRef]

- Bhagia, S.; Lowden, R.R.; Erdman, D., III; Rodriguez, M., Jr.; Haga, B.A.; Solano, I.R.M.; Gallego, N.C.; Pu, Y.; Muchero, W.; Kunc, V.; et al. Tensile properties of 3D-printed wood-filled PLA materials using poplar trees. Appl. Mater. Today 2020, 21, 100832. [Google Scholar] [CrossRef]

- Siddiqui, V.U.; Yusuf, J.; Sapuan, S.; Hasan, M.Z.; Bistari, M.M.M.; Mohammadsalih, Z.G. Mechanical Properties and Flammability Analysis of Wood Fiber Filled PLA Composites Using Additive Manufacturing. J. Nat. Fibers 2024, 21, 2409868. [Google Scholar] [CrossRef]

- Chien, Y.C.; Wu, J.H.; Shu, C.H.; Lo, J.T.; Yang, T.C. Closed-Loop Recycling of 3D-Printed Wood–PLA Composite Parts: Effects on Mechanical and Structural Properties via Fused Filament Fabrication. Polymers 2024, 16, 3002. [Google Scholar] [CrossRef]

- Ecker, J.V.; Haider, A.; Burzic, I.; Huber, A.; Eder, G.; Hild, S. Mechanical properties and water absorption behaviour of PLA and PLA/wood composites prepared by 3D printing and injection moulding. Rapid Prototyp. J. 2019, 25, 672–678. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. Fracture studies of 3D-printed PLA-wood composite. Procedia Struct. Integr. 2022, 37, 97–104. [Google Scholar] [CrossRef]

- Keerthana, M.; Reddy, V.D.; Nayak, B.R.P. Study and investigation on 3D printed wastewood and walnut filament with epoxy resin LY566 by using FDM. Int. J. Multidiscip. Res. 2024, 6, 1–9. [Google Scholar] [CrossRef]

- Maslej, M.; Wojnowska, M.; Peliński, K.; Słonina, M.; Smardzewski, J. Experimental Testing of Elastic Properties of LayWood Pyramidal Cores, BioResources. Available online: https://bioresources.cnr.ncsu.edu/resources/experimental-testing-of-elastic-properties-of-laywood-pyramidal-cores/ (accessed on 25 June 2025).

- Fico, D.; Rizzo, D.; Malinconico, F.; Corcione, C.E. A sustainable approach to recycling waste: Examples of the application of 3D printing to extend the life cycle of materials. Detritus 2024, 28, 60–69. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Palumbo, E.; Corcione, C.E. Development and characterization of sustainable PLA/Olive wood waste composites for rehabilitation applications using Fused Filament Fabrication (FFF). J. Build. Eng. 2022, 56, 104673. [Google Scholar] [CrossRef]

- Cengiz, Ö.; Aktepe, Ş. Evaluation of the Potentiality of Wood and Processing Dust as Sustainable Raw Materials for 3 Dimensional (3D) Printers. Eur. J. Sci. Technol. 2022, 38, 143–150. [Google Scholar] [CrossRef]

- Narlıoğlu, N.; Salan, T.; Alma, M.H. Properties of 3D-Printed Wood Sawdust-Reinforced PLA Composites. BioResources 2021, 16, 5467–5480. [Google Scholar] [CrossRef]

- Spohr, D.L.; Sánchez, F.A.L.; Marques, A.C. Estudo da viabilidade de fabricação de filamentos compósitos sustentáveis para impressão 3D a partir de uma matriz PLA reforçada com resíduos de fibras de madeira. Mix. Sustentável 2021, 7, 115–126. [Google Scholar] [CrossRef]

- Information Centre for Sustainable Renovation (ING). Available online: https://renoveeri.net/about-us (accessed on 12 December 2023).

- Veski, A. Carpenter’s and Furniture Maker’s Handbook; Estonian National Publishing House: Tallinn, Estonia, 1962; pp. 7–8. [Google Scholar]

- Private House Is Located on Lauliku 48, Nõmme District, Tallinn. The Same Original Wooden Door Platband Is Found on the Facade. According to the Estonian Construction Register, the First Information About This Building Is from 1923. (Building code 101005249). Available online: https://livekluster.ehr.ee/ui/ehr/v1/building/101005249 (accessed on 12 December 2023).

- Nõmme Self-Management Started to Be a Part of Tallinn City Since 1940. Source: Pöördeline 1940—Nõmme Museum. Available online: https://www.nommemuuseum.ee/artikkel/poordeline-1940/ (accessed on 23 January 2024).

- Gineiko, A. Supplementary Materials “Herne Street Residential Housing Construction Project with Construction Permission (2024)”; Zenodo: Geneva, Switzerland, 2025. [Google Scholar] [CrossRef]

- eSUN. eSUN PLA Pro Filament 3D Printer PLA Plus Filament PLA Pro. eSUN. Available online: https://www.esun3d.com/pla-pro-product/ (accessed on 24 April 2025).

- Olympus. BX53M Upright Microscope. Evident Scientific. Available online: https://evidentscientific.com/en/products/upright/bx53m (accessed on 23 September 2025).

- Smardzewski, J.; Wojciechowski, K.W.; Poźniak, A. Auxetic Lattice Truss Cores Fabricated by Laywood. BioResources 2018, 13, 8714–8727. [Google Scholar] [CrossRef]

- Molitch-Hou, M. An Interview with Wood Filament Inventor Kai Parthy, 3D Printing Industry. 14 February 2014. Available online: https://3dprintingindustry.com/news/journey-laywoo-d3-interview-wood-filament-inventor-kai-parthy-23357/ (accessed on 14 December 2023).

- Kliem, S.; Tahouni, Y.; Cheng, T.; Menges, A.; Bonten, C. Biobased Smart Materials for Processing via Fused Layer Modeling. AIP Conf. Proc. 2020, 2289, 020034. [Google Scholar] [CrossRef]

- Raise3D Pro2 3D Printer, Raise3D. Available online: https://www.raise3d.com/products/raise3d-pro2-3d-printer/ (accessed on 25 June 2025).

- 3Dfilamenten.nl, LayWoo-d3 Filament—1.75 mm—0.25kg. Available online: https://www.3dprima.com/filaments/special-filament-1-75mm/laywoo-d3-filament-1-75-mm-0-25kg_20285_1063 (accessed on 14 December 2023).

- Entris® II Essential Line Milligram Balance 220 g|1 mg|Sartorius. Available online: https://shop.sartorius.com/ww/p/entris-ii-essential-line-milligram-balance-220-g1-mg-external-adjustment/BCE223-1S#documentsTabHeader (accessed on 22 April 2025).

- Artillery Sidewinder SW-X2 3D Printer. Artillery3d. Available online: https://eu.artillery3d.com/products/artillery-sw-x2-fdm-3d-printer-larger-printed-size-300x300x400mm?shpxid=584d9c74-b3fa-4e6a-91bf-549e7864aaf2 (accessed on 22 April 2025).

- The Last Wood Bender: Kai Flexes His New Wood 3D Printing Filament, 3D Printing Industry. 2020. Available online: https://3dprintingindustry.com/news/the-last-wood-bender-kai-flexes-his-new-wood-3d-printing-filament-49540/ (accessed on 25 June 2025).

- Moon, K.J.; Yi, J.; Savage, V.; Bianchi, A. 3D printed pyrography: Using wood filament and dynamic control of nozzle temperature for embedding shades of color in objects. Addit. Manuf. 2024, 83, 104064. [Google Scholar] [CrossRef]

- Finnveden, G.; Potting, J. Life cycle assessment. In Encyclopedia of Toxicology, 3rd ed.; Wexler, P., Ed.; E-Publishing Inc.: Amsterdam, The Netherlands, 2014; pp. 74–77. [Google Scholar] [CrossRef]

- Mosomi, E.K.; Olanrewaju, O.A.; Adeosun, S.O. Pivotal role of polylactide in carbon emission reduction: A comprehensive review. Eng. Rep. 2024, 6, e12909. [Google Scholar] [CrossRef]

- Forfora, N.; Azuaje, I.; Kanipe, T.; Gonzalez, J.A.; Lendewig, M.; Urdaneta, I.; Venditti, R.; Gonzalez, R.; Argyropoulos, D. Argyropoulos, Are starch-based materials more eco-friendly than fossil-based? A critical assessment. Clean. Environ. Syst. 2024, 13, 100177. [Google Scholar] [CrossRef]

- Ghomi, E.R.; Khosravi, F.; Ardahaei, A.S.; Dai, Y.; Neisiany, R.E.; Foroughi, F.; Wu, M.; Das, O.; Ramakrishna, S. The life cycle assessment for polylactic acid (PLA) to make it a low-carbon material. Polymers 2021, 13, 1854. [Google Scholar] [CrossRef]

- Energy Meter 7-Mode 230VAC 16A White 3680W—Oomipood. Available online: https://www.oomipood.ee/en/product/GB350F_energiakulu_mootja_7_reziimi_230vac_16a_valge_3680w (accessed on 30 April 2025).

- Stanley Heat Gun: 2000W Heat Gun with Kitbox|STANLEY. Available online: https://cee.stanleytools.global/product/fme670k-qs/2000w-heat-gun-kitbox (accessed on 30 April 2025).

- Support Articles. Available online: https://www.nikonimgsupport.com/eu/BV_article?articleNo=000044904&configured=1&lang=en_GB (accessed on 30 April 2025).

- DVR-512DVC Bi-Color Dimmable LED Ring Light. Falcon Eyes. Available online: https://www.falconeyeshk.com/product-page/dvr-512dvc?srsltid=AfmBOorTJzwQ9hpo7Q_3z2BDI_VVo7zEGOXAGldjs08ebVhAFWkVPOVY (accessed on 9 May 2025).

- Computer Power Supply: EVGA Corporation, Brea, CA, USA, SuperNOVA 650W/750W/850W/1000W P5 Platinum Power Supply User Manual. EVGA (2021). Available online: https://www.evga.com/support/manuals/files/220-P5-1000-X1.pdf (accessed on 12 May 2025).

- Dell 27inch 4K UHD Computer Monitor—S2721QS|Dell Technologies, Round Rock, TX, USA. Dell. Available online: https://www.dell.com/en-us/shop/dell-27-4k-uhd-monitor-s2721qs/apd/210-axlg/monitors-monitor-accessories#techspecs_section (accessed on 12 May 2025).

- HV 80 OSZI|Bernardo Maschinen GmbH, Mudersbach, Germany. Available online: https://www.bernardo.at/en/shop/Edge-sanding-machine-with-oscillation-HV-80-OSZI--400-V~p86347 (accessed on 14 May 2025).

- LS1219L—Chopping and Miter Sa. Makita Corporation, Anjo, Japan. Available online: https://www.makita.ee/product/ls1219l.html (accessed on 14 May 2025).

- WD 2 Plus Wet and Dry Vacuum Cleaner. Alfred Kärcher GmbH & Co. KG, Winnenden, Germany. [Video]. Alfred Kärcher GmbH & Co. KG. Available online: https://www.kaercher.com/ee/home-garden/vee-ja-tolmuimejad/wd-2-plus-v-12-4-18-16280000.html (accessed on 14 May 2025).

- Makita. DDF083—Cordless Drill. Makita Corporation, Anjo, Japan. Available online: https://www.makita.ee/product/ddf083.html (accessed on 14 May 2025).

- Makita. BL1850B—18V LXT® Lithium-Ion 5.0Ah Battery. Makita Corporation, Anjo, Japan. Available online: https://www.makitatools.com/products/details/BL1850B (accessed on 14 May 2025).

- UT.MA SRL—Construction of Grinders and Sharpening Machines and Accessories for Sharpening Operations—Model P20 CNC. UT.MA SRL, Barberino Tavarnelle, Tuscany, Italy. Available online: https://www.utma.it/english/utma-profiling-machines-p20-cnc.html (accessed on 13 May 2025).

- Blade Template Produced with Contour Motion. Schneeberger, Rapperswil-Jona, Switzerland (2 April 2025). Schneeberger—Contour Motion. Available online: https://www.contourmotion.com/suppliers/schneeberger/ (accessed on 13 May 2025).

- Griggio. PSA 520 Thicknessing Machine User Manual. Griggio SpA, San Vendemiano, Italy. Available online: https://wtp.hoechsmann.com/en/lexikon/16464/psa_520 (accessed on 14 May 2025).

- Griggio. PF 310 Surface Planer User Manual. Griggio SpA, San Vendemiano, Italy. Available online: https://www.griggiomachinery.com/en/product/classic-machine/serie-pf/ (accessed on 14 May 2025).

- Altendorf Group. Altendorf WA 80—Altendorf Group. Altendorf GmbH & Co. KG, Minden, Germany. 2024. Available online: https://www.altendorfgroup.com/en/machines/altendorf-wa-80/ (accessed on 14 May 2025).

- Klipphausen, H.G.D. MINI-MAX T 45 CLASSIC—WOOD TEC PEDIA. SCM Group, Rimini, Italy. Available online: https://wtp.hoechsmann.com/en/lexikon/26959/mini-max_t_45_classic (accessed on 14 May 2025).

- Weighted Average Stock Exchange Prices over the Last 12 Months. Alexela. Available online: https://www.alexela.ee/en/viimase-12-kuu-kaalutud-keskmised-borsihinnad (accessed on 13 May 2025).

- Greenhouse Gas Emission Intensity of Electricity Generation in Europe. European Environment Agency’s Home Page. 2024. Available online: https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emission-intensity-of-1 (accessed on 12 May 2025).

- Ministry of Finance. Salary Survey of State Administrative and Administrative Institutions, State-Established Foundations and Public Institutions 2024. 2024. Available online: https://www.fin.ee/sites/default/files/documents/2024-09/Riigi%20ameti-%20ja%20hallatavate%20asutuste%2C%20riigi%20asutatud%20sihtasutuste%20ning%20avalik-%C3%B5iguslike%20asutuste%20palgauuring%202024.pdf (accessed on 12 May 2025).

- Aldas, M.; Ferri, J.M.; Lopez-Martinez, J.; Samper, M.D.; Arrieta, M.P. Effect of pine resin derivatives on the structural, thermal, and mechanical properties of Mater-Bi type bioplastic. Appl. Polym. Sci. 2019, 137, 48236. [Google Scholar] [CrossRef]

- Bicer, A.; Celik, N. Influence of pine resin on thermo-mechanical properties of pumice-cement composites. Cem. Concr. Compos. 2020, 112, 103668. [Google Scholar] [CrossRef]

- Jutila, L.; Layek, R.; Javanshour, F.; George, L.; Sarlin, E.; Kanerva, M. Effects of Pine Rosin on the Degradation of Mechanical Performance in Flax-Reinforced Polymeric Composites after Soil Burial at Low Temperatures. BioResources 2023, 18, 899–925. [Google Scholar] [CrossRef]

- Estonian Academy of Sciences. Winners of the Best Young Researchers in the “Science in Three Minutes” Competition Announced. Estonian Academy of Sciences. 2023. Available online: https://www.akadeemia.ee/selgusid-parimad-noorteadlased-kolme-minuti-loengutes-2/ (accessed on 17 September 2025). (In Estonian).

- Gineiko, A. 3D Printing Gives New Life to Historical Materials. Novaator. 2023. Available online: https://novaator.err.ee/1609602935/3d-printimine-annab-ajaloolistele-materjalidele-uue-elu (accessed on 17 September 2025). (In Estonian).

| Researcher | Study Focus | Material Composition | Wood Content Percentage | Production Method | Key Outcome |

|---|---|---|---|---|---|

| Keerthana et al., 2024 [24] | FDM * filaments from waste wood/walnut shell and epoxy resin | Waste wood, walnut shell, epoxy resin; percentage not specified | 80% waste wood + 20% walnut shell | No mention found | Tested tensile/flexural strength, thermal stability; supports sustainable manufacturing |

| Pringle et al., 2020 [5] | Furniture waste/PLA based filament for 3D printing | LDF-MDF-LDF scrubs, melamine-particleboard-paper, wood-based filler, PLA | 15–40% wood waste (30% the most suitable for printing) | Reducing the size of the components, mixing, filament extrusion, 3D printing | Homogeneously recycled wood furniture waste–based is suitable for filament production with diameter consistency of 1.65 ± 0.10 mm and 3D printing. |

| Maslej, et al., 2019 [25] | Elastic properties of Laywood filament pyramidal cores | Recycled wood dust + PLA | 30–40% recycled wood dust | Fused deposition modelling (FDM) | Determined elastic constants of the analytically manufactured cores. |

| Fico et al., 2024 [26] | FFF ** with PLA and various artisanal/agro-industrial wastes | PLA + olive wood, cocoa shell, ceramic, stone waste; percentage not specified | No online data available | Extrusion (type not specified) | Structural, morphological, thermal, mechanical analysis; supports circular economy; no quantitative data |

| Fico et al., 2022 [27] | PLA/olive wood waste filaments for FFF, life cycle assessment (LCA) | PLA + olive wood scraps | 10–20% wood waste | Extrusion (type not specified) | 10% LCA *** impact reduction at 20% wood; full characterization; environmental benefit |

| Cengiz and Aktepe et al. [28] | Wood/sawdust as sustainable 3D printing raw materials | PLA + wood powder (<850 μm); also cement, gypsum, etc. | 5–20% woof powder | PLA + 5% wood powder (<850 μm); also cement, gypsum, etc. | Increased deformation resistance; slight decrease in degradation temperature; conversion coefficient 0.4–0.65; sustainable |

| Narlıoğlu et al. 2021 [29] | PLA composites with pine sawdust for FDM | PLA + pine sawdust (177–250 μm) | 0/5/10/15/20% pine sawdust | Sieving, drying, twin-screw extrusion | Tensile strength decreases, flexural increases; melting temperature up to 155 °C; sawdust as value-added waste |

| Spohr et a. 2021 [30] | PLA filaments reinforced with wood waste from furniture machining | PLA + wood powder (≤300 μm) | 0/10/15/20% wood powder | Ball milling, drying, custom extruder (Felfil EVO), single pass | Hardness increases with wood content (except at 20%); increased fragility; melting point increases; more sustainable |

| Mass [kg] | Length [m] | Width [m] | Height [m] | |

|---|---|---|---|---|

| Platband | 0.200 | 0.265 | 0.0950 | 0.014 * |

| Oak parquet | 0.234 | 0.260 | 0.080 | 0.019 |

| Pine beam | 0.805 | 0.220 | 0.095 | 0.088 * |

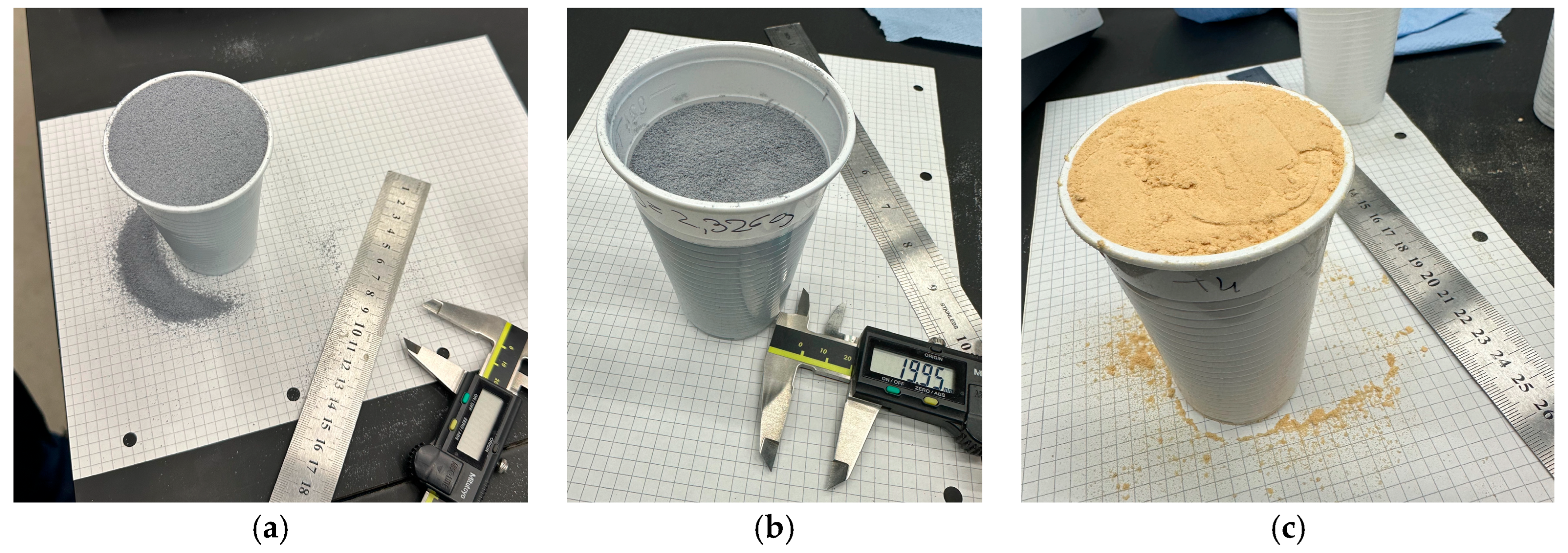

| Volume of Materials in Plastic Cup [m3] | Mass of Material in Normal Compression [kg] | Mass of Compressed Bulk Material [kg] | Compression Coefficient [-] | |

|---|---|---|---|---|

| PLA dust | 0.000231 | 0.122 | 0.165 | 0.740 |

| Pine beam sawdust | 0.000231 | 0.043 | 0.069 | 0.624 |

| Oak parquet sawdust | 0.000231 | 0.067 | 0.104 | 0.645 |

| 5% Wood/ 95% PLA | 10% Wood/ 90% PLA | 20% Wood/ 80% PLA | 30% Wood/ 70% PLA | 40% Wood/ 60% PLA | 50% Wood/ 50% PLA | |

|---|---|---|---|---|---|---|

| Pine beam sawdust [kg] | 0.004 | 0.007 | 0.014 | 0.021 | 0.028 | 0.035 |

| Oak parquet sawdust [kg] | 0.006 | 0.011 | 0.021 | 0.032 | 0.042 | 0.052 |

| PLA [kg] | 0.156 | 0.148 | 0.132 | 0.115 | 0.099 | 0.083 |

| Seria nr. Date | Composition | Servo [s] | Spool | Feed [RPM] | Heater I [°C] | Heater II [°C] | Heater III [°C] | Screw S. [RPM] |

|---|---|---|---|---|---|---|---|---|

| 1. 3 November 24 | 100% PLA | N/A | 6.3 | 10 | 140 | 90 | 90 | 5.6 |

| 2. 7 January 25 | 5% oak p./95% PLA | N/A | 6.2 | 6–7 | 120 | 90 | 110 | 5.6 |

| 3. 7 January 25 | 20% oak p./80% PLA | 56.5 | 7.5 | 13.85 | 140 | 90 | 105 | 5.6 |

| 4. 13 January 25 | 30% oak p./70%PLA | N/A | 8.5 | 12 | 140 | 90 | 105 | 9.2–10.5 |

| 5. 13 January 25 | 40% oak p./60% PLA | N/A | 8.5 | 12 | 140 | 90 | 105 | 9.2–10.5 |

| 6. 13 January 25 | 50% oak p./50% PLA | N/A | 8.5 | 12 | 140 | 90 | 105 | 9.2–10.5 |

| 7. 28 January 25 | 30% oak p./70% PLA | 92 | 8.7 | 10–14 | 140 | 90 | 105 | 9.2 |

| 8. 30 January 25 | 10% pine b./90% PLA | N/A | 8.7 | 10–14 | 140 | 90 | 105 | 9.2 |

| 9. 30 January 25 | 20% pine b./80% PLA | N/A | 8.7 | 10–14 | 140 | 90 | 105 | 9.2 |

| 10. 4 February 25 | 30% pine b./70% PLA | 33 | 8.9 | 15.5–16.5 | 140 | 90 | 105 | 9.2–10.5 |

| 11. 26 February 25 | 30% pine b./70% PLA | 33 | 8.9 | 20 | 140 | 90 | 105 | 8.1–12 |

| 12. 27 February 25 | 30% pine b./70% PLA | 33 | 12.5 | 23 | 140 | 90 | 105 | 9.2 |

| 13. 17 March 25 | 30% oak p./70% PLA | 33 | 12.5 | 23 | 140 | 90 | 105 | 9.2 |

| Code | Filament | Thread Ø [mm] | Nozzle Ø [mm] | Printing t [°C] | Printing Speed [mm/min] | Layer h [mm] | Pattern | Interior Fill [€] | Printing Bed [°C] | Cooling Layers | Duration [h] | Mass [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 3D Flex original | 1.6 | 1 | 210 | 400 | 0.2 | H | 50 | 0 | No | 3 | 0.013 |

| S2 | 3D Flex original | 1.6 | 1 | 240 | 400 | 0.2 | R | 50 | 0 | Every 20 | 5 | 0.026 |

| S3M | 3D Flex original | 1.662 | 0.4 | 220 | 2400 | 0.2 | R | 25 | 60 | Every 20 | 4 | 0.014 |

| S4 | meta5 | 1.75 | 0.4 | 220–260 | 2000 | 0.2 | H | 50 | 60 | All | 4 | 0.016 |

| S5 | Flex original | 1,75 | 0.4 | 220 | 2000 | 0.2 | H | 50 | 60 | All | 1.57 | 0.025 |

| S6 | 30% aok/70% PLA | 1.75 | 1 | 220–260 | 2000 | 0.2 | FHR | 50 | 60 | From 2 | 1.57 | 0.015 |

| S7 | 30% pine/70% PLA | 2.85 | 0.8 | 220–260 | 2400 | 0.2 | FHR | 50 | 60 | From 2 | 1.43 | 0.032 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gineiko, A. Connecting with the Past: Filament Development and 3D Printing from Historical Wood Waste. Sustainability 2025, 17, 9402. https://doi.org/10.3390/su17219402

Gineiko A. Connecting with the Past: Filament Development and 3D Printing from Historical Wood Waste. Sustainability. 2025; 17(21):9402. https://doi.org/10.3390/su17219402

Chicago/Turabian StyleGineiko, Aljona. 2025. "Connecting with the Past: Filament Development and 3D Printing from Historical Wood Waste" Sustainability 17, no. 21: 9402. https://doi.org/10.3390/su17219402

APA StyleGineiko, A. (2025). Connecting with the Past: Filament Development and 3D Printing from Historical Wood Waste. Sustainability, 17(21), 9402. https://doi.org/10.3390/su17219402