Design for Recycling: A Systematic Review of Approaches for Enhancing Product Recyclability

Abstract

1. Introduction

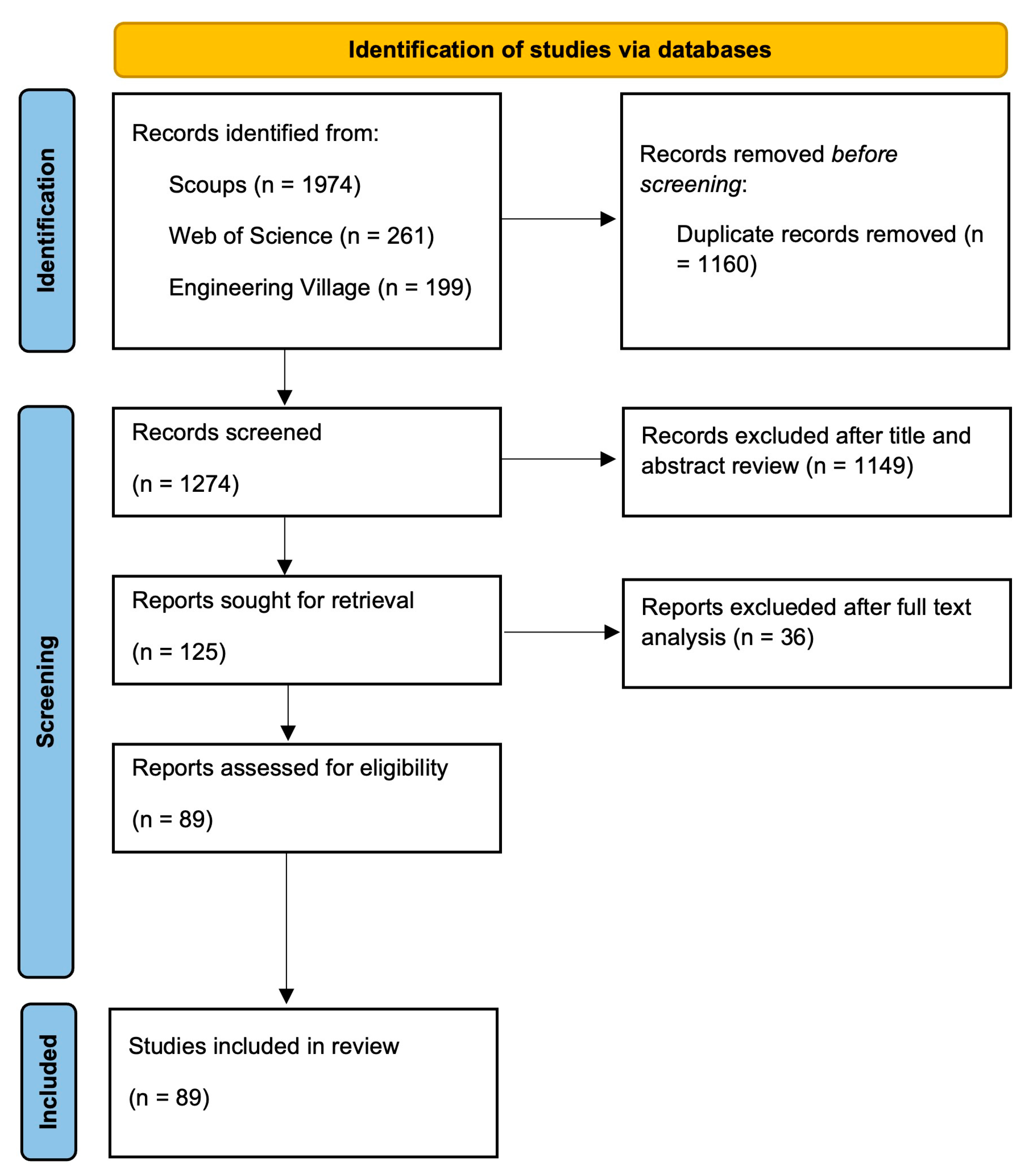

2. Methods

3. Results

3.1. Design for Recycling in Engineering

3.1.1. Definition of Recyclability

3.1.2. Definition of DfR

3.2. Identification of Optimal EOL Options

3.2.1. Recovery AND/OR Graph-Based Methods

3.2.2. MCDM-Based Methods

3.2.3. Empirical Information-Based Methods

3.2.4. Summary

3.3. Evaluation of Product’s Recyclability

3.3.1. Clarification of the Two “Evaluation” Methods

3.3.2. Design for Disassembly to Ease Recycling

3.3.3. Qualitative Recyclability Evaluation

3.3.4. Quantitative Recyclability Evaluation

3.3.5. Summary

3.4. Improvement of Product’s Recyclability

3.4.1. Approaches Applied in the Early Design Stage

- (1)

- Design Guidelines

- (2)

- Other Methods

3.4.2. Approaches Applied in the Later Design Stage

- (1)

- Modular Design

| References | Modular Drivers | Modular Methods | Case Study |

|---|---|---|---|

| Ma and Kremer (2015) [22] | Economic sustainability, environmental sustainability, social sustainability | Key components selection and three clustering algorithms | Coffee maker |

| Yan et al. (2012) [68] | Function, structure, material, manufacturability, component life, end-of-life options | DSM design structure matrix, a kernel-based fuzzy c-means (KFCM), GA | Reduction gear |

| Yang et al. (2011) [69] | Reuse, maintenance, recycling | Multi-objective optimization with risk constraint based on GGA | Refrigerator |

| Li et al. (2008) [67] | Disassembly, Reuse/recycle/disposal, material selection | Fuzzy connected graph, AHP, K ordered greedy clustering algorithm | Electrical alternator |

| Qian and Zhang (2009) [70] | Environmental aspects through the life cycle of the product | Fuzzy graph, fuzzy AHP, similarity analysis algorithm, independence analysis algorithm | Coffee maker |

| Ji et al. (2012) [71] | Facilitate life-cycle material efficiency | CCF graph and matrix, multi-attribute utility theory, leader-follower bilevel optimization model | Refrigerator |

| Yu et al. (2011) [72] | Function, structure, component lifetime, material compatibility, recyclability | Modular driving force, GGA | Refrigerator |

- (2)

- Other Methods

3.4.3. Approaches Beyond the Design Stage

- (1)

- Disassembly Analysis for EOL Products

- (2)

- Information Exchange for Design

3.4.4. Summary

4. Discussion

4.1. Limitations

4.2. Future Directions

4.2.1. DfR Knowledge Base

4.2.2. Recyclability Evaluation Indicators

4.2.3. Data-Driven Automated Design

4.3. Challenges

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DfR | Design for Recycling |

| DfX | Design for X |

| WEEE | Waste Electrical and Electronic Equipment |

| EOL | End-of-Life |

| DfE | Design for Environment |

| DfEOL | Design for End-of-Life |

| DfS | Design for Sustainability |

| AI | Artificial intelligence |

| DfD | Design for Disassembly |

| LCA | Life Cycle Assessment |

| MCDM | Multi Criteria Decision Making |

| TOPSIS | Technique for Order Preference by Similarity to Ideal Solution |

| CBR | Case-Based Reasoning |

| ELDA | End-of-Life Design Advisor |

| TBL | Triple Bottom Line |

| ORM | Object-Role Modeling |

| BOK | Body of Knowledge |

| QFD | Quality Function Deployment |

| CAD | Computer-Aided Design |

| IREDA | Integrated Recyclability and End-of-Life Design Algorithm |

| GA | Genetic Algorithm |

| GGA | Grouped Genetic Algorithm |

| SOM | Self-Organizing Maps |

| HOME | House of Modular Enhancement |

| CV | Configuration Value |

| PLM | Product Lifecycle Management |

| PDM | Product Data Management |

| IoT | Internet of Things |

| NLP | Natural Language Processing |

| LLM | Large Language Models |

| ML | Machine Learning |

| KG | Knowledge Graphs |

| HCI | Human Computer Interaction |

| XR | Extended Reality |

References

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; United Nations University (UNU): Tokyo, Japan; United Nations Institute for Training and Research (UNITAR)—Co-hosted SCYCLE Programme, International Telecommunication Union (ITU) & International Solid Waste Association (ISWA): Bonn, Germany, 2020. [Google Scholar]

- Ministry of Ecology and Environment of the People’s Republic of China. Review of the Regulations for the Administration of the Recovery and Disposal of Waste Electric and Electronic Products. Available online: https://english.mee.gov.cn/Resources/laws (accessed on 26 April 2024).

- Ministry of Justice, Japan. Act on Promotion of Recycling of Small Waste Electrical and Electronic Equipment (Act No. 57 of 2012). Available online: https://www.japaneselawtranslation.go.jp/en/laws/view/3209 (accessed on 26 April 2024).

- National Conference of State Legislatures. Electronic Waste Recycling. Available online: https://www.ncsl.org/environment-and-natural-resources/electronic-waste-recycling (accessed on 26 April 2024).

- Liu, Z.F.; Liu, X.P.; Wang, S.W.; Liu, G.F. Recycling Strategy and a Recyclability Assessment Model Based on an Artificial Neural Network. J. Mater. Process. Technol. 2002, 129, 500–506. [Google Scholar] [CrossRef]

- Van den Berg, M.R.; Bakker, C.A. A Product Design Framework for a Circular Economy. Prod. Lifetimes Environ. 2015, 365–379. Available online: https://resolver.tudelft.nl/uuid:307f8b21-f24b-4ce1-ae45-85bdf1d4f471 (accessed on 10 November 2024).

- Chiu, M.C.; Kremer, G.E.O. Investigation of the Applicability of Design for X Tools During Design Concept Evolution: A Literature Review. Int. J. Product Dev. 2011, 13, 132. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Sohlenius, G. Concurrent Engineering. CIRP Annals 1992, 41, 645–655. [Google Scholar] [CrossRef]

- Boothroyd, G.; Alting, L. Design for Assembly and Disassembly. CIRP Annals 1992, 41, 625–636. [Google Scholar] [CrossRef]

- Ferrão, P.; Amaral, J. Design for Recycling in the Automobile Industry: New Approaches and New Tools. J. Eng. Des. 2006, 17, 447–462. [Google Scholar] [CrossRef]

- Zussman, E.; Kriwet, A.; Seliger, G. Disassembly-Oriented Assessment Methodology to Support Design for Recycling. CIRP Annals 1994, 43, 9–14. [Google Scholar] [CrossRef]

- Tonnelier, P.; Millet, D.; Richir, S.; Lecoq, M. Is It Possible to Evaluate the Recovery Potential Earlier in the Design Process? Proposal of a Qualitative Evaluation Tool. J. Eng. Design 2005, 16, 297–309. [Google Scholar] [CrossRef]

- Xing, K.; Abhary, K.; Luong, L. IREDA: An Integrated Methodology for Product Recyclability and End-of-Life Design. J. Sustain. Prod. Des. 2003, 3, 149–171. [Google Scholar] [CrossRef]

- Sakundarini, N.; Taha, Z.; Abdul-Rashid, S.H.; Ghazilla, R.A.R. Incorporation of high recyclability material selection in computer aided design. Mater. Des. 2013, 56, 740–749. [Google Scholar] [CrossRef]

- Ishii, K. Product Modularity: A Key Concept in Life-Cycle Design. In Frontiers of Engineering: Reports on Leading-Edge Engineering from the 1996 NAE Symposium on Frontiers of Engineering; National Academies Press: Washington, DC, USA, 1997; p. 17. [Google Scholar]

- Erdos, G.; Kis, T.; Xirouchakis, P. Modelling and Evaluating Product End-of-Life Options. Int. J. Prod. Res. 2001, 39, 1203–1220. [Google Scholar] [CrossRef]

- González, B.; Adenso-Díaz, B. A Bill of Materials-Based Approach for End-of-Life Decision Making in Design for the Environment. Int. J. Prod. Res. 2005, 43, 2071–2099. [Google Scholar] [CrossRef]

- Teunter, R.H. Determining Optimal Disassembly and Recovery Strategies. Omega 2006, 34, 533–537. [Google Scholar] [CrossRef]

- Pnueli, Y.; Zussman, E. Evaluating the End-of-Life Value of a Product and Improving It by Redesign. Int. J. Prod. Res. 1997, 35, 921–942. [Google Scholar] [CrossRef]

- Feldmann, K.; Trautner, S.; Lohrmann, H.; Melzer, K. Computer-Based Product Structure Analysis for Technical Goods Regarding Optimal End-of-Life Strategies. Proc. Inst. Mech. Eng. Part B 2001, 215, 683–693. [Google Scholar] [CrossRef]

- Ma, J.; Okudan Kremer, G.E. A Fuzzy Logic-Based Approach to Determine Product Component End-of-Life Option from the Views of Sustainability and Designer’s Perception. J. Clean. Prod. 2015, 108, 289–300. [Google Scholar] [CrossRef]

- Ma, J.; Okudan Kremer, G.E.; Ray, C.D. A Comprehensive End-of-Life Strategy Decision Making Approach to Handle Uncertainty in the Product Design Stage. Res. Eng. Des. 2017, 29, 469–487. [Google Scholar] [CrossRef]

- Remery, M.; Mascle, C.; Agard, B. A New Method for Evaluating the Best Product End-of-Life Strategy During the Early Design Phase. J. Eng. Design 2012, 23, 419–441. [Google Scholar] [CrossRef]

- Chan, J.W.K. Product End-of-Life Options Selection: Grey Relational Analysis Approach. Int. J. Prod. Res. 2008, 46, 2889–2912. [Google Scholar] [CrossRef]

- Ishii, K.; Eubanks, C.F.; Di Marco, P. Design for Product Retirement and Material Life-Cycle. Mater. Des. 1994, 15, 225–233. [Google Scholar] [CrossRef]

- Lee, S.G.; Lye, S.W.; Khoo, M.K. A Multi-Objective Methodology for Evaluating Product End-of-Life Options and Disassembly. Int. J. Adv. Manuf. Technol. 2001, 18, 148–156. [Google Scholar] [CrossRef]

- Cheung, W.M.; Marsh, R.; Griffin, P.W.; Newnes, L.B.; Mileham, A.R.; Lanham, J.D. Towards Cleaner Production: A Roadmap for Predicting Product End-of-Life Costs at Early Design Concept. J. Clean. Prod. 2015, 87, 431–441. [Google Scholar] [CrossRef]

- Okumura, S.; Matsumoto, Y.; Hatanaka, Y.; Ogohara, K. Simultaneous Evaluation of Environmental Impact and Incurred Cost on Selection of End-of-Life Products Recovery Options. Int. J. Autom. Technol. 2016, 10, 699–707. [Google Scholar] [CrossRef]

- Lee, H.M.; Lu, W.F.; Song, B. A Framework for Assessing Product End-of-Life Performance: Reviewing the State of the Art and Proposing an Innovative Approach Using an End-of-Life Index. J. Clean. Prod. 2014, 66, 355–371. [Google Scholar] [CrossRef]

- Rao, R.V.; Padmanabhan, K.K. Selection of Best Product End-of-Life Scenario Using Digraph and Matrix Methods. J. Eng. Design 2008, 21, 455–472. [Google Scholar] [CrossRef]

- Shih, L.-H.; Chang, Y.-S.; Lin, Y.-T. Intelligent Evaluation Approach for Electronic Product Recycling via Case-Based Reasoning. Adv. Eng. Inform. 2006, 20, 137–145. [Google Scholar] [CrossRef]

- Rose, C.M.; Ishii, K. Product End-of-Life Strategy Categorization Design Tool. J. Electron. Manuf. 1999, 9, 41–51. [Google Scholar] [CrossRef]

- Rose, C.M.; Ishii, K.; Stevels, A. ELDA and EVCA: Tools for Building Product End-of-Life Strategy. J. Sustain. Prod. Des. 2001, 1, 181–195. [Google Scholar] [CrossRef]

- Ziout, A.; Azab, A.; Atwan, M. A Holistic Approach for Decision on Selection of End-of-Life Products Recovery Options. J. Clean. Prod. 2014, 65, 497–516. [Google Scholar] [CrossRef]

- Kroll, E.; Beardsley, B.; Parulian, A. A Methodology to Evaluate Ease of Disassembly for Product Recycling. IIE Trans. 1996, 28, 837–846. [Google Scholar] [CrossRef]

- Kroll, E. Application of Work-Measurement Analysis to Product Disassembly for Recycling. Concurrent Eng. 1996, 4, 149–158. [Google Scholar] [CrossRef]

- Kroll, E.; Hanft, T.A. Quantitative Evaluation of Product Disassembly for Recycling. Res. Eng. Design 1998, 10, 1–14. [Google Scholar] [CrossRef]

- Das, S.K.; Yedlarajiah, P.; Narendra, R. An Approach for Estimating the End-of-Life Product Disassembly Effort and Cost. Int. J. Prod. Res. 2000, 38, 657–673. [Google Scholar] [CrossRef]

- Harivardhini, S.; Murali Krishna, K.; Chakrabarti, A. An Integrated Framework for Supporting Decision Making During Early Design Stages on End-of-Life Disassembly. J. Clean. Prod. 2017, 168, 558–574. [Google Scholar] [CrossRef]

- Sabaghi, M.; Mascle, C.; Baptiste, P. Evaluation of Products at Design Phase for an Efficient Disassembly at End-of-Life. J. Clean. Prod. 2016, 116, 177–186. [Google Scholar] [CrossRef]

- Johnson, M.R.; Wang, M.H. Economical Evaluation of Disassembly Operations for Recycling, Remanufacturing, and Reuse. Int. J. Prod. Res. 1998, 36, 3227–3252. [Google Scholar] [CrossRef]

- Li, Z.; He, J.; Lai, X.; Huang, Y.; Zhou, T.; Vatankhah Barenji, A.; Wang, W.M. Evaluation of Product Recyclability at the Product Design Phase: A Time-Series Forecasting Methodology. Int. J. Comput. Integr. Manuf. 2018, 31, 457–468. [Google Scholar] [CrossRef]

- Umeda, Y.; Fukushige, S.; Mizuno, T.; Matsuyama, Y. Generating Design Alternatives for Increasing Recyclability of Products. CIRP Ann. 2013, 62, 135–138. [Google Scholar] [CrossRef]

- Favi, C.; Marconi, M.; Germani, M.; Mandolini, M. A Design for Disassembly Tool Oriented to Mechatronic Product De-Manufacturing and Recycling. Adv. Eng. Informat. 2019, 39, 62–79. [Google Scholar] [CrossRef]

- Kuo, T.C. Combination of Case-Based Reasoning and Analytical Hierarchy Process for Providing Intelligent Decision Support for Product Recycling Strategies. Expert Syst. Appl. 2010, 37, 5558–5563. [Google Scholar] [CrossRef]

- Nelen, D.; Manshoven, S.; Peeters, J.R.; Vanegas, P.; D’Haese, N.; Vrancken, K. A Multidimensional Indicator Set to Assess the Benefits of WEEE Material Recycling. J. Clean. Prod. 2014, 83, 305–316. [Google Scholar] [CrossRef]

- Knight, W.A.; Sodhi, M.S. Design for Bulk Recycling: Analysis of Materials Separation. CIRP Ann. 2000, 49, 83–86. [Google Scholar] [CrossRef]

- Aguiar, J.D.; de Oliveira, L.; da Silva, J.O.; Bond, D.; Scalice, R.K.; Becker, D. A Design Tool to Diagnose Product Recyclability During the Product Design Phase. J. Clean. Prod. 2017, 141, 219–229. [Google Scholar] [CrossRef]

- Papakostas, N.; Pintzos, G.; Triantafyllou, C. Computer-Aided Design Assessment of Products for End of Life Separation and Material Handling. CIRP Ann. 2015, 64, 185–188. [Google Scholar] [CrossRef]

- Chen, R.W.; Navin-Chandra, D.; Print, F.B. A Cost-Benefit Analysis Model of Product Design for Recyclability and Its Application. IEEE Trans. Compon. Packag. Manuf. Technol. Part A 1994, 17, 502–507. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.; Shrivastava, P.; Whitley, A.; Merchant, M.E. A web-based system for reverse manufacturing and product environmental impact assessment considering end-of-life dispositions. CIRP Annals 2004, 53, 5–8. [Google Scholar] [CrossRef]

- Alhaddi, H. Triple bottom line and sustainability: A literature review. Bus. Manag. Stud. 2015, 1, 6–10. [Google Scholar] [CrossRef]

- Kriwet, A.; Zussman, E.; Seliger, G. Systematic integration of design-for-recycling into product design. Int. J. Prod. Econ. 1995, 38, 15–22. [Google Scholar] [CrossRef]

- Telenko, C.; Seepersad, C.C. A methodology for identifying environmentally conscious guidelines for product design. J. Mech. Des. 2010, 132, 091009. [Google Scholar] [CrossRef]

- Telenko, C.; O’Rourke, J.M.; Seepersad, C.C.; Webber, M.E. A compilation of design for environment guidelines. J. Mech. Des. 2015, 138, 031102. [Google Scholar] [CrossRef]

- Mesa, J.A. Design for circularity and durability: An integrated approach from DFX guidelines. Res. Eng. Des. 2023, 34, 443–460. [Google Scholar] [CrossRef]

- Houe, R.; Grabot, B. Knowledge modeling for eco-design. Concurrent Eng. 2007, 15, 7–20. [Google Scholar] [CrossRef]

- Jalbout, S.E.; Keivanpour, S. Development of a body of knowledge for design for disassembly and recycling of high-tech products: A case study on lithium-ion batteries. J. Ind. Prod. Eng. 2023, 41, 19–39. [Google Scholar] [CrossRef]

- Wu, Y.; Ho, C.C. Integration of green quality function deployment and fuzzy theory: A case study on green mobile phone design. J. Clean. Prod. 2015, 108, 271–280. [Google Scholar] [CrossRef]

- Bereketli, I.; Genevois, M.E. An integrated QFDE approach for identifying improvement strategies in sustainable product development. J. Clean. Prod. 2013, 54, 188–198. [Google Scholar] [CrossRef]

- Gong, Q.; Zhang, H.; Jiang, Z.; Wang, H.; Wang, Y.; Hu, X. Nonempirical hybrid multi-attribute decision-making method for design for remanufacturing. Adv. Manuf. 2019, 7, 423–437. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, L.; Liu, Z.; Sutherland, J.W. Multi-criteria decision making and uncertainty analysis for materials selection in environmentally conscious design. Int. J. Adv. Manuf. Technol. 2010, 52, 421–432. [Google Scholar] [CrossRef]

- Wichniarek, R.; Grajewski, D.; Diakun, J.; Dostatni, E.; Karwasz, A. Automatization of the ecodesign process of small household appliances based on CAD 3D system. Teh. Vjesn. Tech. Gaz. 2018, 25, 18–25. [Google Scholar] [CrossRef]

- Brissaud, D.; Zwolinski, P. End-of-life-based negotiation throughout the design process. CIRP Ann. 2004, 53, 155–158. [Google Scholar] [CrossRef]

- Gu, P.; Hashemian, M.; Sosale, S.; Rivin, E. An integrated modular design methodology for life-cycle engineering. CIRP Ann. 1997, 46, 71–74. [Google Scholar] [CrossRef]

- Li, J.; Zhang, H.C.; Gonzalez, M.A.; Yu, S. A multi-objective fuzzy graph approach for modular formulation considering end-of-life issues. Int. J. Prod. Res. 2008, 46, 4011–4033. [Google Scholar] [CrossRef]

- Yan, J.; Feng, C.; Cheng, K. Sustainability-oriented product modular design using kernel-based fuzzy c-means clustering and genetic algorithm. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 1635–1647. [Google Scholar] [CrossRef]

- Yang, Q.; Yu, S.; Sekhari, A. A modular eco-design method for life cycle engineering based on redesign risk control. Int. J. Adv. Manuf. Technol. 2011, 56, 1215–1233. [Google Scholar] [CrossRef]

- Qian, X.; Zhang, H.C. Design for environment: An environmentally conscious analysis model for modular design. IEEE Trans. Electron. Packag. Manuf. 2009, 32, 164–175. [Google Scholar] [CrossRef]

- Ji, Y.; Jiao, R.J.; Chen, L.; Wu, C. Green modular design for material efficiency: A leader–follower joint optimization model. J. Clean. Prod. 2012, 41, 187–201. [Google Scholar] [CrossRef]

- Yu, S.; Yang, Q.; Tao, J.; Tian, X.; Yin, F. Product modular design incorporating life cycle issues—Group genetic algorithm (GGA) based method. J. Clean. Prod. 2011, 19, 1016–1032. [Google Scholar] [CrossRef]

- Umeda, Y.; Fukushige, S.; Tonoike, K.; Kondoh, S. Product modularity for life cycle design. CIRP Ann. 2008, 57, 13–16. [Google Scholar] [CrossRef]

- Sand, J.C.; Gu, P.; Watson, G. HOME: House of modular enhancement—A tool for modular product redesign. Concurrent Eng. 2002, 10, 153–164. [Google Scholar] [CrossRef]

- Smith, S.; Yen, C. Green product design through product modularization using atomic theory. Robotics Comput. Integr. Manuf. 2010, 26, 790–798. [Google Scholar] [CrossRef]

- Kimura, F.; Kato, S.; Hata, T.; Masuda, T. Product modularization for parts reuse in inverse manufacturing. CIRP Annals 2001, 50, 89–92. [Google Scholar] [CrossRef]

- Fukushige, S.; Tonoike, K.; Inoue, Y.; Umeda, Y. Scenario-based modularization and evaluation for product lifecycle design. In Proceedings of the ASME 2009 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, San Diego, CA, USA, 30 August–2 September 2009; American Society of Mechanical Engineers: New York, NY, USA, 2009. [Google Scholar] [CrossRef]

- Kim, S.; Moon, S.K. Eco-modular product architecture identification and assessment for product recovery. J. Intell. Manuf. 2016, 30, 383–403. [Google Scholar] [CrossRef]

- Viswanathan, S.; Allada, V. Configuration analysis to support product redesign for end-of-life disassembly. Int. J. Prod. Res. 2001, 39, 1733–1753. [Google Scholar] [CrossRef][Green Version]

- Kwak, M.J.; Hong, Y.S.; Cho, N.W. Eco-architecture analysis for end-of-life decision making. Int. J. Prod. Res. 2008, 47, 6233–6259. [Google Scholar] [CrossRef]

- Ko, Y. Modeling an innovative green design method for sustainable products. Sustainability 2020, 12, 3351. [Google Scholar] [CrossRef]

- Kuo, T.C. Enhancing disassembly and recycling planning using life-cycle analysis. Robot. Comput. Integr. Manuf. 2006, 22, 420–428. [Google Scholar] [CrossRef]

- Navin-Chandra, D. The recovery problem in product design. J. Eng. Des. 1994, 5, 65–86. [Google Scholar] [CrossRef]

- Dini, G.; Failli, F.; Santochi, M. A disassembly planning software system for the optimization of recycling processes. Prod. Plan. Control. 2001, 12, 2–12. [Google Scholar] [CrossRef]

- Movilla, N.A.; Zwolinski, P.; Dewulf, J.; Mathieux, F. A method for manual disassembly analysis to support the ecodesign of electronic displays. Resour. Conserv. Recycl. 2016, 114, 42–58. [Google Scholar] [CrossRef]

- Mangers, J.; Elahi, M.A.; Plapper, P. Digital twin of end-of-life process-chains for a circular economy adapted product design—A case study on PET bottles. J. Clean. Prod. 2023, 382, 135287. [Google Scholar] [CrossRef]

- Gaye, K.; Gardoni, M.; Coulibaly, A. An information system to support the recycling process of manufactured products. In Proceedings of the IDMME_P127, Proceedings of IDMME-Virtual Concept, Bordeaux, France, 20–22 October 2010; pp. 20–22. [Google Scholar]

- Pahl, G.; Beitz, W. Engineering Design, 3rd ed.; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Moghaddam, M.; Marion, T.; Holtta-Otto, K.; Fu, K.; Olechowski, A.; McComb, C. Special issue: Emerging technologies and methods for early-stage product design and development. J. Mech. Des. 2023, 145, 18–25. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Tseng, M.L.; Wong, W.P. Sustainable product design and development: A review of tools, applications, and research prospects. Resour. Conserv. Recycl. 2018, 132, 49–61. [Google Scholar] [CrossRef]

| Search by Keywords | Scopus | Web of Science | Engineering Village |

|---|---|---|---|

| (‘design for recycling OR ‘design for recyclability’ OR ‘recyclable design’ OR ‘recycling-oriented product design’) AND (‘product design’ OR ‘product development’) | 443 | 50 | 72 |

| (‘design for recycling’ OR ‘design for recyclability’ OR ‘recyclable design’ OR ‘recycling-oriented product design’) AND (‘circular economy’ OR ‘end-of-life’) | 478 | 84 | 60 |

| (‘design for recycling’ OR ‘design for recyclability’ OR ‘recyclable design’ OR ‘recycling-oriented product design’) AND (‘eco-design’ OR ‘sustainable design’ OR ‘design for environment’ OR ‘green design’ OR ‘environmentally conscious design’ OR ‘life cycle design’) | 343 | 52 | 20 |

| (‘design for recycling’ OR ‘design for recyclability’ OR ‘recyclable design’ OR ‘recycling-oriented product design’) AND (‘guideline’ OR ‘method’ OR ‘tool’ OR ‘application’ OR ‘evaluation’) | 710 | 75 | 47 |

| Total | 1974 | 261 | 199 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Gao, Q.; Li, W. Design for Recycling: A Systematic Review of Approaches for Enhancing Product Recyclability. Sustainability 2025, 17, 1790. https://doi.org/10.3390/su17051790

Wu X, Gao Q, Li W. Design for Recycling: A Systematic Review of Approaches for Enhancing Product Recyclability. Sustainability. 2025; 17(5):1790. https://doi.org/10.3390/su17051790

Chicago/Turabian StyleWu, Xiaoqing, Qi Gao, and Wenqi Li. 2025. "Design for Recycling: A Systematic Review of Approaches for Enhancing Product Recyclability" Sustainability 17, no. 5: 1790. https://doi.org/10.3390/su17051790

APA StyleWu, X., Gao, Q., & Li, W. (2025). Design for Recycling: A Systematic Review of Approaches for Enhancing Product Recyclability. Sustainability, 17(5), 1790. https://doi.org/10.3390/su17051790