Abstract

Upcycling is identified as a process of the transformation of waste materials to which it is possible to give a value of artistic or environmental quality. To date, the greatest use of upcycling can be found in the design, art and fashion sectors. As in other sectors, one of the biggest challenges in the construction industry in the future is the search for new ways to reuse discarded materials. In this sense, upcycling is a new technique for the recovery of removed waste but with a much lower use of energy and resources than the regeneration of recycled material. With respect to these issues, the aim of this paper is to present the results of a design experimentation aimed at defining methodologies and tools for the reuse of building components from the decommissioning or renovation processes of existing buildings, with an approach that integrates both the disassembling and the re-assembling of construction elements, in line with the sustainable development and climate neutrality goals that the European Union aims to achieve by 2050. The methodology used made use of a field experiment by means of the creation of a prototype that made it possible to evaluate the results of the study which, if on the one hand made it possible to define an appropriate procedure for upcycling, on the other hand highlighted how these procedures save energy and reduce the emission of CO2 in the environment. In this specific case, the experimentation gave the following results: energy savings 2038.92 kWh; CO2 reduction 641.80 kg compared to a similar intervention from scratch. Therefore, the definition of a replicable and scalable operational process for the upcycling activity applied to architecture allows, by means of the reuse of those building materials and construction elements that still have a useful life, and which can, therefore, be used in the field of architecture, for a profitable contribution to the development of sustainable procedures in the field of architecture and the circular economy.

1. Introduction

The construction sector is responsible for the production of more than a third of waste [1,2,3,4], and, at the same time today, there is little development of activities aimed at the reuse of waste products that come from the processes carried out in the construction field.

This criticality is currently not matched by an appropriate valorization of end-of-life products, an aspect that increasingly directs towards the incentive of procedures to strengthen the dynamics related to the recycling and reuse of waste so as to contribute to the achievement of the Sustainable Development Goals [5]. The reuse of waste that affects the world of architecture is substantially structured according to two different supply chains: a first, recycling, in which work is carried out for the recycling and subsequent transformation of waste as a “secondary raw material”; another which is aimed at the reuse of waste building materials with the aim of reuse both for the same functional purposes and for new uses and purposes [6]. Among the activities of waste reuse, there are several experiences that look at creative recycling, that is, the process of the transformation of waste materials to which it is possible to give a value of artistic or environmental quality. To date, the greatest use of upcycling is found in the design, art and fashion sectors. The term upcycling was used for the first time in 1994 by mechanical engineer Reiner Pilz in an article published in the October 23rd issue of the magazine Salvo, which dealt with the recovery of construction materials [7]. The article analyzed different operating methods to implement the system of the reuse of furniture elements or waste building materials. The concepts contained in the article were later taken up in 2002 by the American architect William McDonough and the German chemist Michael Braungart and published in their book Cradle to Cradle: Remaking the Way We Make Things [8] in which the theme of upcycling is proposed as a necessary procedure to activate and enhance circular economy systems based on life cycle analysis. Currently, about upcycling, there are numerous applications and studies conducted on the creative recycling of various materials used even outside the world of construction. It is possible to cite several authors who have investigated these issues while also expanding the fields of investigation, in particular, Rezaei Z. et al., who demonstrated how it is possible to obtain the construction of high-performance microbes and enzymes for advancement in the fields of synthetic biology and metabolic engineering [9]; Poblocki K. et al., who created a comprehensive overview for the use of a wide range of catalysts in the recycling of polymers and plastics, of general interest to the chemical community [10]; Hu Y. et al., who provided a summary of the general methodology and limitations of conventional plastics recycling by examining recent advances in hybrid chemical/biological recycling methods for various plastics, including polyethylene terephthalate, polyurethane, polyamide, polycarbonate, polyethylene, polypropylene, polystyrene and polyvinyl chloride [11]; Hassan M. et al., who addressed the creative recycling of recycled plastics and the use of waste biomass in sustainable composites in the 3D-printing integration gap [12]; Yang X. et. Al., who studied the recycling of textile industry’s waste polymeric garments and footwear (TCFs) as aggregates in cement to reduce plastic pollution [13]; Singh J. et al., who in their studies identified creative recycling activities by analyzing causal links between challenges and success factors, key system mechanisms and interventions [14].

In addition to plastics, wood has also been studied for upcycling: Vam Hees M. explored urban creative recycling in the context of the Dutch industry’s promising opportunities and good practices for upcycling [15]; Hossain UM et al. evaluated the technical feasibility and environmental sustainability of recycled wood aggregates and the alternative binder of the produced cement chipboard (CBP); they also compared the performance of the same elements made of virgin wood and with ordinary binder using experimental analyses and life cycle assessment (LCA) [16]; Wang L. et al. addressed the problem of reusing wood particles by adding PVA fibers in order to increase the mechanical strength of particleboard [17].

Similar to other sectors, one of the greatest challenges expected for the future in the construction world is precisely the search for new ways of recycling or reusing discarded materials [18]. The collection of data carried out on international research investigating issues of upcycling related to the world of construction was limited to sporadic cases [19,20,21,22], an aspect that highlighted how the various applications carried out are not yet structured with respect to a rigorous scientific approach and a consolidated methodological path. Therefore, the data research phase has been expanded towards the investigation of the best practices to be applied for the reuse of building elements in order to outline procedures and standardized with which to contribute to the implementation of suitable methods and tools for the reuse of building components. With respect to these considerations, a topic that has been widely studied and researched is design for disassembly which, although much investigated, often does not propose reuse solutions necessary for the definition of the entire circular process. Around the theme of disassembly, there are several contributions in the literature; for example, Srinivasa H. et al. explored a new methodology to perform design analysis for selected disassembly on a CAD model for defabrication evaluation [23]; Akanbi AL et al. defined the development of an analysis system to evaluate the end-of-life performance of buildings already in the design phase [24]. Dams B. et al., on the other hand, focused on the evaluation of the disassembly score of building components, analyzing windows and doors as adaptable and flexible elements thanks to modularity and with reversible connections and, therefore, more suitable for circularity [25].

In continuity with these issues, the aim of this paper is to present the results of a design experimentation aimed at defining methodologies and tools for the initiation of operational procedures necessary for reuse (reuse considers the use of a product according to a different functionality from the one for which it was designed) [26] of building components from building decommissioning processes, with a profitable design that integrates both the disassembling and re-assembling of construction elements, in line with the sustainable development and climate neutrality goals that the European Union intends to achieve by the first half of this century by means of the Circular Economy Action Plan 2020 [27,28].

The applied research study, carried out within the University of L’Aquila around the themes of the recycling and reuse of building materials, also involved a group of students of the fifth year of the Degree Course in Building Engineering–Architecture who created a simple architectural element in the laboratory by reusing discarded building materials. The research aimed to investigate how to define a replicable process of the systematization of upcycling activities applied to architecture by means of the reuse of those building materials and construction elements that, although still having a useful life, are often disposed of in landfills during renovation and building recovery interventions [29]. Considering that, in reality, a large portion of these materials have performance capabilities such that they can be reused for a different use and role, it was considered necessary to start this scientific research with the aim of encouraging more and more policies for the enhancement of materials and construction-site waste. To this end, a field experiment was carried out concerning the reuse of window frames and scraps of architectural façade cladding panels to create a “scenic space” for musical concerts. The experience has made it possible to define an organic design path to be followed in this type of activity and, at the same time, systematize the construction procedures necessary to allow suitable management of the construction phase of the artifacts within an upcycling activity applied to construction [30,31]. In this sense, upcycling is configured as a sustainable approach to the reuse of waste materials as it involves the use of much less energy and resources than the regeneration of the material to be transformed into secondary raw materials.

2. Materials and Methods

For the construction sector to be truly sustainable, the system must aim at the complete and total recovery of waste, closing the life cycle of buildings according to the criteria of the circular economy [32,33].

In the era of technological innovation, digital tools such as BIM supported by the dictates of the Minimum Environmental Criteria in procurement and in the reuse of construction materials certainly represent an excellent basis for the development of circular construction by subjecting each component to a recovery process, the ultimate principle of which is that waste ceases to be considered as such.

This is the concept of End of Waste (EoW) born in the EU with the Waste Framework Directive 2008/98/EC of 19 November 2008, subsequently amended by the new Directive (EU) 2018/851.

This Directive establishes that waste ceases to be waste when it is subjected to a recovery operation that may include recycling but also reuse [34,35,36], which meets specific criteria according to certain conditions (Article 184-ter of Legislative Decree 152/06) that indicate how the substance or object must be used for specific purposes based on a market and demand that meets technical requirements for those specific purposes (according to rules or regulations) and that does not result in overall negative impacts on the environment or human health.

The transfer of these principles to real conditions is not direct and easy to resolve. In particular, the procedures for the reuse of component elements, which allow them to fully activate circularity processes and with an environmental impact close to zero, are currently more complex than those of recycling as they involve the use of detailed selective demolitions and are essential to allow the recovery of the component elements to be reused. It is also necessary to initiate programs for the reuse of demolished construction elements, an aspect that necessarily implies the definition of standardized operating procedures, in order to increasingly facilitate the circularity of the process.

These criteria form the basis for the sustainability of the entire construction sector.

With respect to these indications, the process implemented in the case study in question arises from the need to give new life to waste construction elements often disposed of in landfills in large quantities and in a short time during the building renovation of existing buildings. The aim is to systematize upcycling procedures as it is believed that a “creative” approach to the issues of reuse can guarantee a profit on the part of those involved in the sector towards this operational practice. In this specific case, the research carried out has been applied on an experimental basis to the creation of a “scenic space” for musical concerts by reusing waste windows and doors. A methodological path was then defined, refined, rationalized and validated in the operational phase, capable of adequately scaling the operational phases. In this way, it was possible to develop and validate a procedural methodology that could be replicated in similar interventions.

The operating procedure sought was structured around the systematization of four operational phases considered basic to ensure the effective sustainability of the process and, at the same time, capable of satisfying the system of requirements required for the new element to be built. The particulars included were as follows:

- Analysis of materials with the ability to reuse, select, accept, characterize and catalog;

- Design of new elements;

- Construction of the artifact;

- Functionality check.

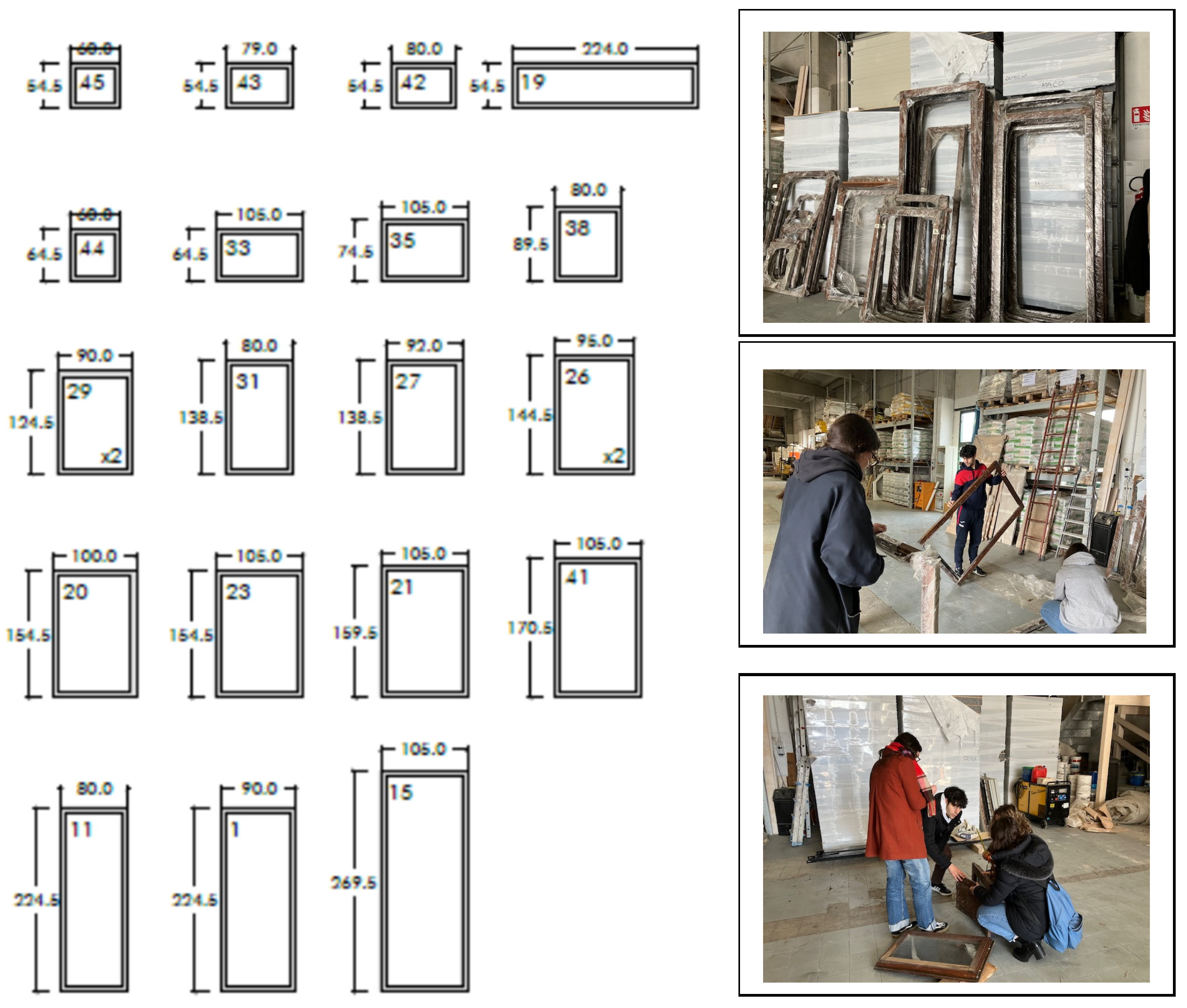

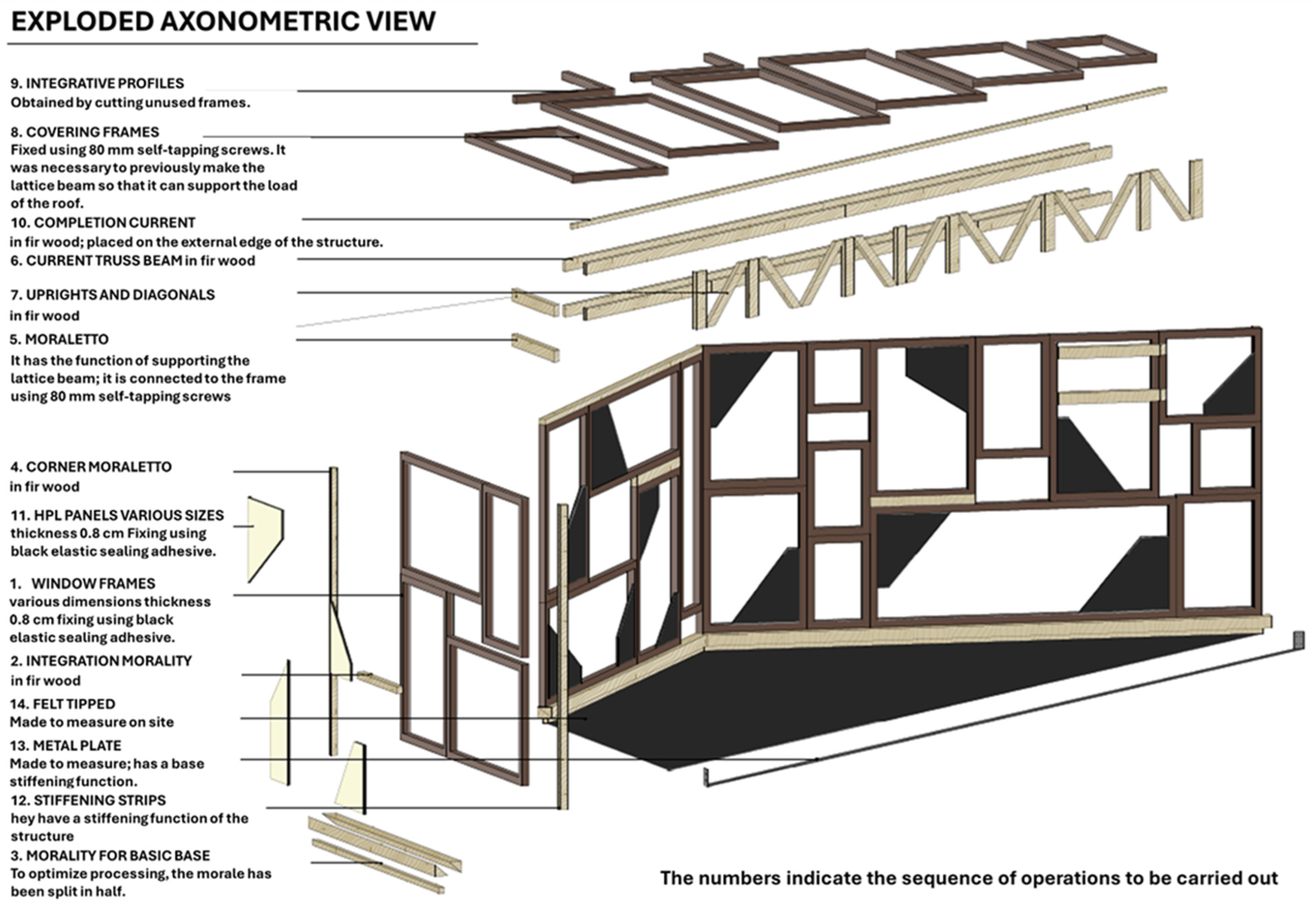

- Step 1. Material analysis with reuse, selection, acceptance, characterization and cataloging capabilities

The first phase must be organized with respect to the search and selection of waste building materials as it is essential to ensure that the elements to be reused are still able to ensure their own useful life path even with new roles. An assessment of the state of conservation must be carried out, which allows the selection of those considered suitable and those not up to par for reuse, which must, therefore, be discarded. The characteristics and specificities are then identified according to the new role that materials must assume within the new technological system. The elements considered suitable must be cataloged and grouped in an operational schedule in which the dimensions detected through direct measurements are reported, as in Figure 1.

Figure 1.

Step 1. Element evaluation, direct measurement and schedule of selected windows for reuse. In the specific case, considering that the selected component elements were all of the same material and had similar resistance characteristics, the abacus was drawn up only with respect to the geometric characteristics, without reporting physical characteristics and performance capacity, information that is essential to start the subsequent design phase.

In the case in question, the recycled materials for this experience were the wooden windows removed from a nineteenth-century building that had undergone an energy efficiency intervention. In addition, scraps of façade cladding panels, wooden roofing elements and plant engineering elements from other construction sites completed the set of components to be reused in the project.

- Step 2. Design of new elements

The second phase, the design phase, is necessarily subordinate to the availability of selected waste materials, which, in these cases, constitute a potential resource around which to frame the spatial setting and architectural language. The new element to be designed must, therefore, be sized according to the available elements, according to a “piece by piece” composition process of the elements to be reused. In these cases, intervention is carried out by means of a procedure that we could define as “reverse”, i.e., one that operates through a process of the recomposition of the available construction elements and which adapts the definition of the new system to this availability, without renouncing its functional vocation and its figurativeness.

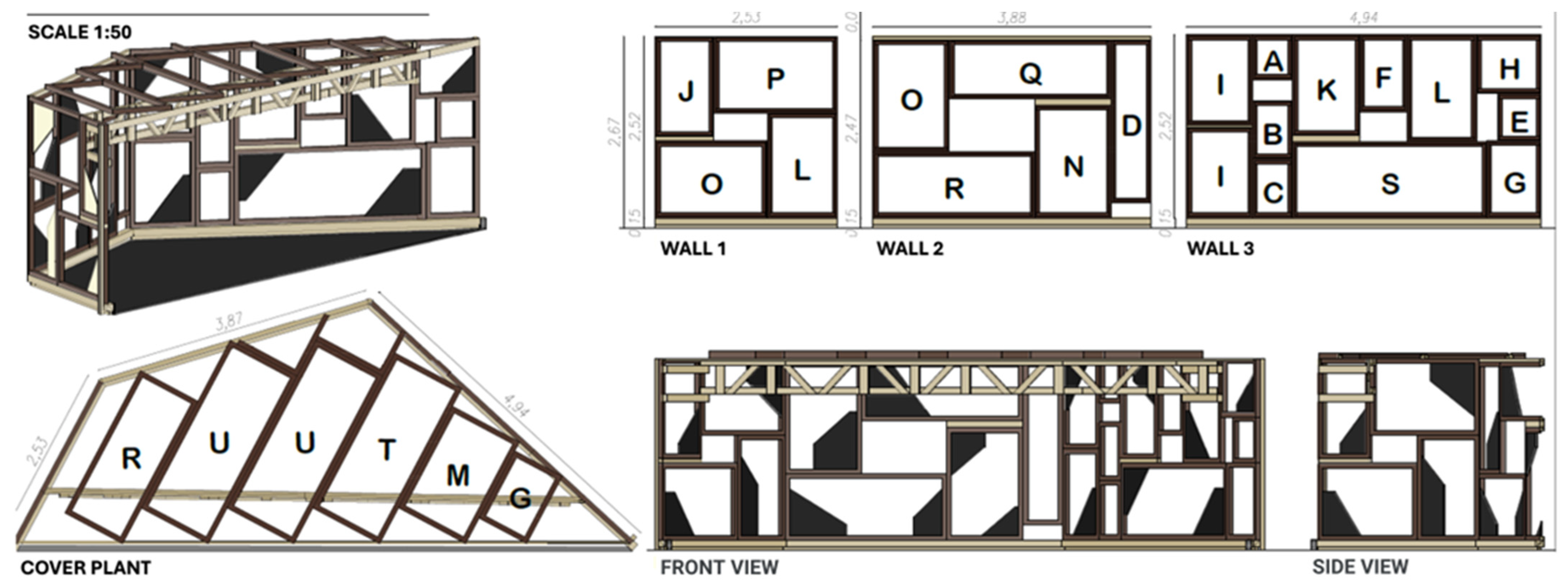

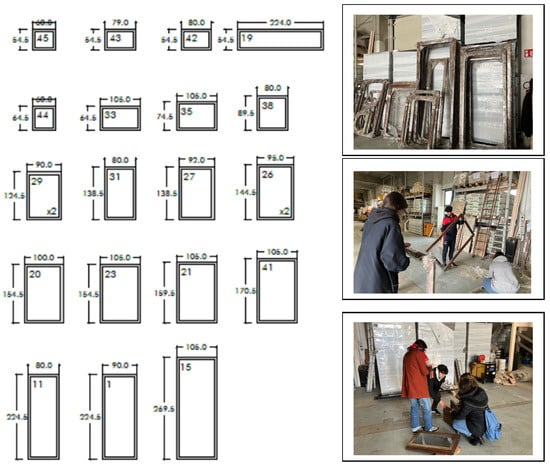

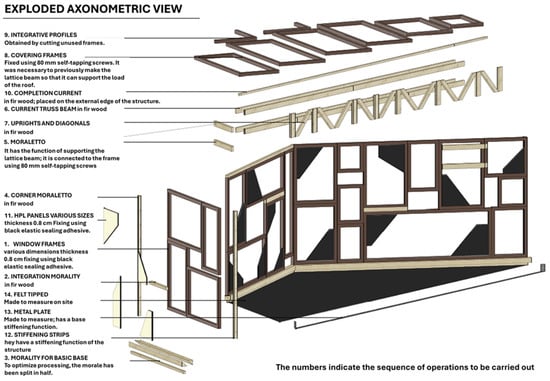

In the case study, the designed space was composed of three walls made by assembling several frames of the windows. The individual frames were then assembled to form 3 panels of similar height and different length, arranged in such a way as to meet both dimensional requirements and those relating to stability and strength. Considering that this design approach allows for multiple compliant solutions, it was decided to optimize the design choices through a BIM model that would allow us, through AI tools, to simulate different and consistent window arrangements. The procedure followed was to conduct an exhaustive analysis of the design alternatives based on the possible compatible solutions between the use of the individual frames deducible from the abacus and the panels to be made. The investigation was carried out within the Grasshopper platform by incorporating the Wallacei and Termite Nest plugins. The first, Wallacei, in using multi-objective genetic optimization algorithms, made it possible to group and manage the input data: No. of panels to be composed, size of the same, available frames present in the abacus; the second, Nest, for graphical analysis of the various design options generated. The multi-objective evolutionary solver generated several geometric variations related to the composition of the panels, compared to which the final choice of the 3 panels for the construction of the building was carried out. This procedure has made it possible to facilitate the selection of the elements to be recycled and also to optimize the figurative resolution with respect to the resources present. Once the configuration of the system was completed, the executive design was carried out, as shown in Figure 2, which also made it possible to define the roof, which was always resolved with the windows in the abacus. The construction details were subsequently completed by the definition of the correlations between the parts. In this circumstance, the methods of reusing the residual parts of the HPL slabs recovered from a construction site near the laboratory were also defined. With these waste elements, it was decided to integrate wooden frames to better define the spatial layout and to improve the overall acoustics of the stage space. With the drafting of the assembly diagrams, which are essential for the next phase, the design phase was concluded.

Figure 2.

Step 2. Final design. Plans and elevations of the composition of the panels that will form the walls of the stage space. The drafting of 3D views makes it possible to verify the ability of the individual designed elements, to correlate with each other and to verify the figurativeness of the designed object also from a spatial point of view. The drawings must then be used as assembly diagrams; for this reason, it is necessary to report the reference codes of the abacus on the component elements.

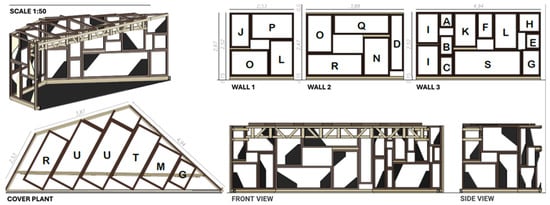

- Step 3. Construction of the artifact

The third phase, construction of the building, is configured as verification of the design phase. Considering that, in the case of upcycling, the construction procedures are postponed to dry assembly of the products to be made, this verification is carried out in the workshop. In this way, it will be possible to optimize the assembly phases of the component elements and, if necessary, also perform leak or resistance tests, depending on the performance required of the new product. If the scale of the intervention is such as making it difficult to assemble the planned element in the workshop, the construction of representative models of the entire system can be envisaged, leaving the entire assembly back to the construction site.

In the case study carried out, this activity was carried out in the laboratory, as shown in Figure 3. On the basis of what is reported in the executive drawings of the project, all of the windows belonging to the different panels to be made were distinguished and grouped; then, all of the parts were assembled with the help of self-tapping screws for wood. Once the individual panels were assembled, the stage space was assembled by processing trapezoidal wooden strips in the workshop with the necessary angles to fix the panels exactly. A truss beam, also made of waste planks from construction carpentry, was installed on the fourth side of the stage space to ensure the support of the roof panel.

Figure 3.

Step 3. Phases of assembly of the panels and assembly of the stage space in the laboratory. The assembly phase makes it possible to verify the coupling of the component elements and to define further assembly details necessary to complete the construction process of the product.

- Step 4. Functionality check

The verification of the functions is configured as a sort of testing of the work carried out, an operation that makes it possible to ascertain whether, with respect to the requirements, the structure can guarantee adequate performance levels. Therefore, the operational operations to be implemented in this phase will have to be established on a case-by-case basis, depending on what is expected to be achieved.

In this specific case, the verification of functionality essentially fell on the verification of the usability of the building. This verification was possible thanks to the availability of a group of musicians from the Conservatory A. Casella, who were planning to play in a square in the city of L’Aquila on a cultural event, to use our stage space. An initial graphic insertion check was, therefore, carried out (Figure 4). When the graphic verification gave a positive result, the stage space was dismantled in the laboratory and reassembled in the urban square where the event took place—Figure 5. This procedure confirmed that the module created using waste materials was suitable for its function and that this upcycling operation made it possible to reduce the environmental impact compared to a new construction of such a product.

Figure 4.

Step 4. Graphic verification of the insertion of the scenic space in the urban square: planimetric positioning and control rendering. The graphic insertion check is a fundamental step as it allows you to assess the compatibility of the element to be inserted in a particular place. When the upcycling operation is aimed at the creation of a functional construction element, this verification is equally necessary.

Figure 5.

Step 4. Functionality check. The stage space is reassembled in an urban square in the city of L’Aquila and used for a concert. This procedure is configured as a final step with respect to what is carried out in the workshop, an action that makes it possible to ascertain whether, with respect to the requirements, the product can guarantee adequate performance levels. In the case of modular construction elements, the verification of functionality can be substantiated in models representative of the entire system.

3. Results

The applied research activity carried out in this experience has made it possible to reflect, investigate and evaluate how to manage the design and construction process of an upcycling activity applied to the construction sector. In this specific case, work was carried out in the recovery with the reuse of functional construction elements with another role. This procedure makes it possible to significantly re-evaluate construction materials that are often considered landfill rubble because they are no longer suitable for their original role. The experimentation developed has shown that it is possible to activate creative reuse processes capable of significantly reducing the impacts when the elements that compose it are recycled with another role.

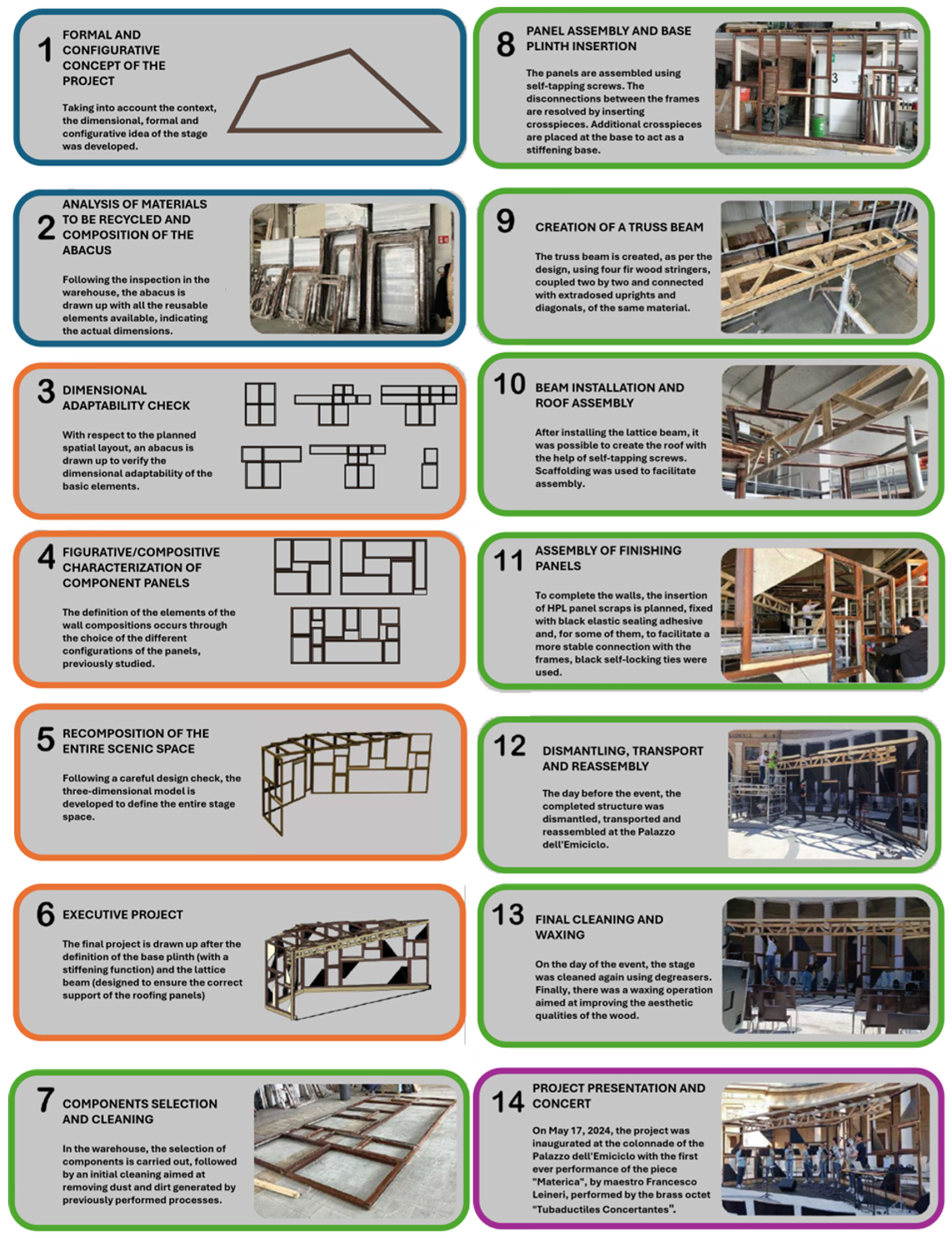

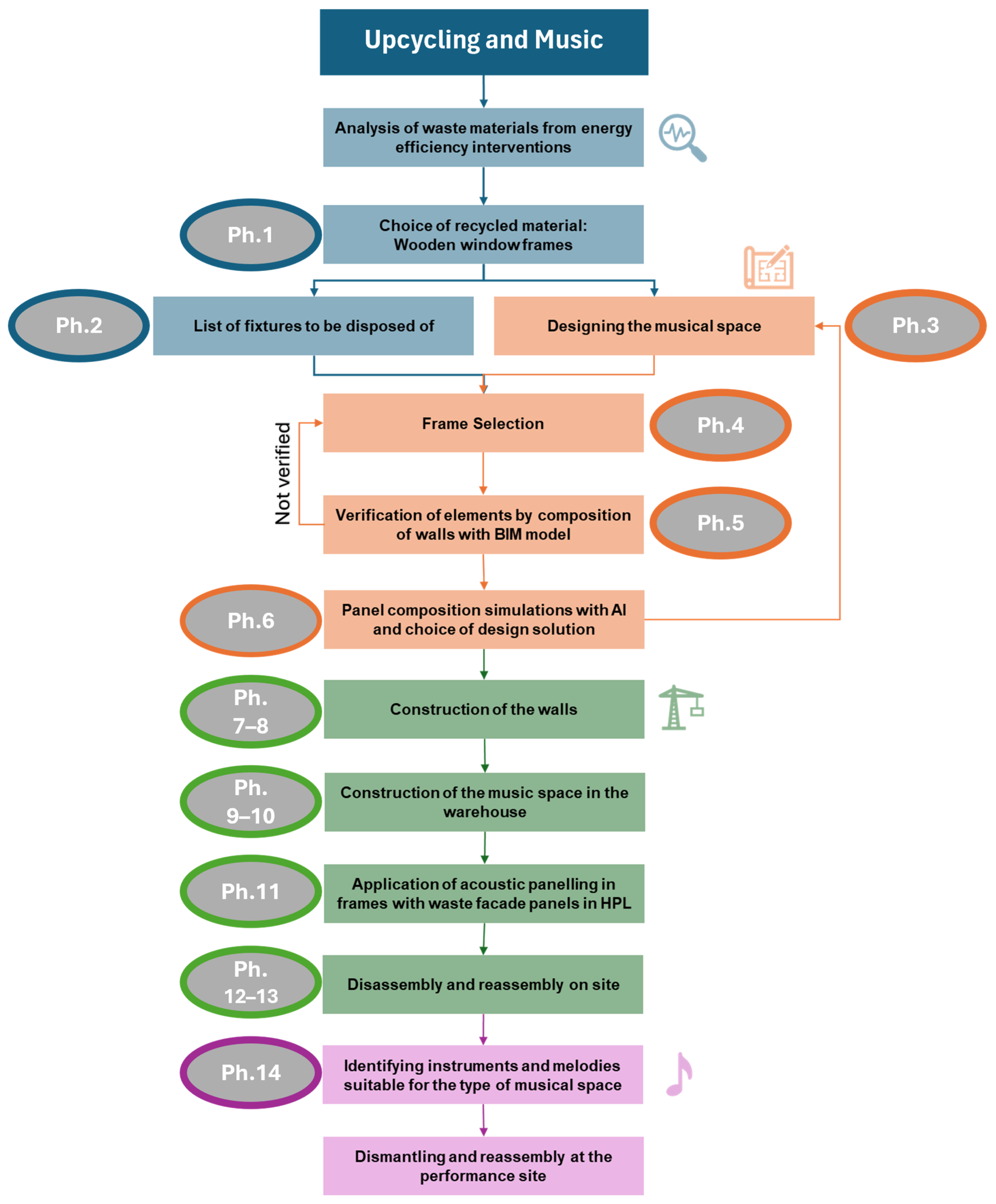

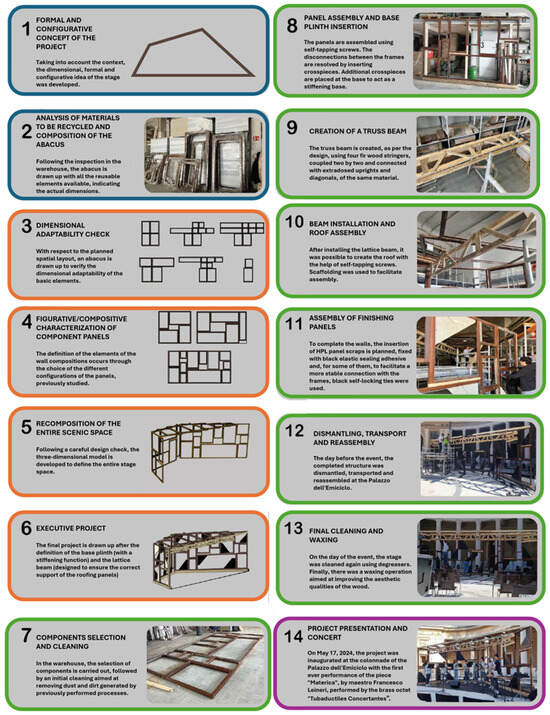

The operational procedure defined in this research, which can also be replicated for other experiences and summarized in the following diagram, is one of the results that this activity applied in the field has made possible to define and that, with this publication, is made available to those who want to try their hand at similar experiences. A selection and design procedure for the construction of new artifacts through the reuse of construction materials previously removed from buildings to be demolished or renovated instead of being disposed of in landfills is then reported.

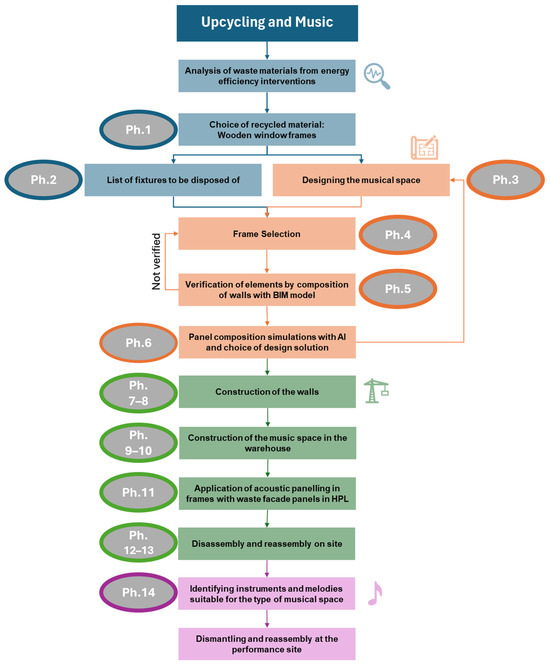

From the experience carried out in the field, the operating procedure followed was validated and synthesized, which then made it possible to define a methodological path to be applied in upcycling operations. In particular, the case study showed that to carry out a correct reuse of building materials, it is necessary to follow a preordained procedure that is structured with respect to a first phase aimed at defining the new compatible role to be attributed to the construction elements to be recycled. This operation takes place through an initial analysis of the materials to be recycled through the drafting of an abacus of the elements, a verification of dimensional adaptability, a figurative and compositional characterization of the new element to be built and the executive design. A second phase is instead recognizable in those construction activities that involve the selection and preparation of the component elements, their assembly and the verification of the final use, as shown in more detail in Figure 6.

Figure 6.

Summary of the upcycling process tested, reorganized through standard procedures according to the methodological scheme identified in the research.

From this application procedure, the operational process was then systematized and reworked in a methodological key in order to make it exportable in the upcycling operations of building materials. The following flowchart in Figure 7 shows the result of the defined operating methodology.

Figure 7.

Methodological scheme developed in applied research. This scheme is configured as a process of synthesis of the upcycling activity that allows it to be used in the various experiences of reuse of construction elements. It is an organic design path to be followed, capable of systematizing the construction procedures necessary to allow a suitable management of the construction phase of the artifacts within an upcycling activity applied to construction. In this sense, upcycling is configured as a sustainable approach to the reuse of waste materials as it involves the use of much less energy and resources than the regeneration of the material to be transformed into secondary raw materials.

The method illustrated makes it possible to obtain an exportable circular economy process which, in continuity with Design for Disassembly, allows waste to be minimized. It is well known that the increased use of waste materials leads to a reduction in the use of natural resources and a lower impact on the environment. The quantifiable advantage is due to the reduction in total annual greenhouse gas emissions. As stated by the European Environment Agency (EEA), industrial waste delivery and disposal processes are responsible for 9% of greenhouse gas emissions in Europe, and waste management alone accounts for more than 3.3%. It is also well established that reducing CO2 emissions in buildings does not only mean reducing energy requirements during operation but also reducing material emissions before they are even installed. In the case of wood, for example, landfill disposal is not recommended as it produces biogas pollution (methane 60% and carbon dioxide 40%), produced by the anaerobic degradation of organic matter, and contributes to the greenhouse effect. By way of example and to verify the appropriate validity of the process, it was verified, in terms of energy saved expressed in Kwh and reduction in CO2 emissions, how capable the upcycling operation illustrated in this study is.

In particular, the amount of energy saved, if a new product was to be built, would be equal to the sum of the energy required for the production of newly made wooden frames plus the energy expenditure for the disposal and recycling of old dismantled windows and doors not used for upcycling, or expressed as the following equation:

where EtR represents the share of energy saved expressed in Kwh, Ept the energy spent on the production of new frames and Esr the energy spent on the disposal and recycling of old windows and doors that have not been reused. With the same logic, the savings in terms of CO2 can be obtained as follows:

where CO2tR represents the share of total CO2 saved expressed in Kg; CO2pt is the amount of CO2 released into the environment to produce new frames, while CO2sr is the amount of carbon dioxide released into the environment for disposal and recycling. The estimate of energy consumption in kWh and CO2 emissions deriving from the production, use, recycling and final use of waste materials [36] of wooden windows and doors per unit area, i.e., in relation to 1.00 square meters, can be deduced from the following tables.

EtR = Ept + Esr

CO2tR = CO2pt + CO2sr

In particular, from Table 1, the unit value of Ept and CO2pt can be derived, respectively, equal to 29.4 kWh/sqm and 9.4 kgCO2/sqm:

Table 1.

Energy consumption and CO2 emissions for the production and transport of a newly built wooden chassis of surface 1 sqm (Kharazipour A. and Kües U.).

In Table 2, on the other hand, the unit value of Esr and CO2sr is equal to 17.3 kWh/sqm and 5.3 kgCO2/sqm, respectively.

Table 2.

Energy consumption and CO2 emissions for the disposal and recycling of an old wooden window with a surface area of 1 square meter not used for upcycling (Kharazipour A. and Kües U.).

Based on the values reported in Table 1 and Table 2, we can assume that the upcycling operation allows energy savings of 46.70 kWh/sqm (29.4 + 17.3) and a reduction in CO2 emissions of 14.70 kgCO2/sqm per unit of area if we consider that the total surface area of the reused windows and doors is equal to 43.66 square meters as shown in Table 3:

Table 3.

Area of the walls of the artifact.

It turns out that the total energy saved is equal to 2038.92 kWh, while the reduction in CO2 emissions is equal to 641.80 kg.

4. Discussion

With this research experience, it emerged that upcycling is a process of transforming unused or waste materials, an emerging practice in construction that aims to find sustainable, functional and aesthetically pleasing solutions for waste materials. The contribution of designers is essential to obtain advanced engineering solutions, even in design.

An important concept is to try to avoid the creation of waste already in the design phase of the intervention: through an accurate analysis, the designer of the building product could already indicate a subsequent function of waste materials.

This transversal area of the construction sector will offer important training and professional opportunities, creating interdisciplinary study paths oriented towards careers in sustainable innovation: upcycling in architecture can offer enormous professional and training opportunities as well as reduce the environmental impact by adopting innovative design with advanced engineering solutions.

In order to facilitate the application of this research, it would be necessary to encourage, already in the design phase, the drafting of the “building file” integrated by a “plan for the use and selective demolition of the components”, which should provide for the cataloging of the materials used and those that can be reused, the abacus of the elements and everything that in a given period of time will have to be replaced, recycled, disposed of or reused.

It is only through the detailed analysis of the intervention to be carried out, integrated by the procedures relating to maintenance interventions as well as the procedures of the recovery of materials and selective demolition that it is possible to design the circularity of the process. To achieve this goal, it will be very useful to use information models or digital technologies such as BIM and artificial intelligence, with which it will be easier to draw up an efficient plan aimed at managing procedures for the reuse or recycling of materials, after cataloging and estimating the quantities to be deconstructed with multi-criteria optimization through integrated platforms, which include in addition to the LCA also the cost analysis with LCC developed on the basis of the Design for Deconstruction or Design to Demolition project with the goal of 100% circularity through databases of reusable materials [37,38,39].

There is software on the market that aims at this process: product sheets, information specifications and information management plans are created; an open-source platform is implemented that plans waste production activities accompanied by an assessment of energy needs, elaborating, through LCA and LCC, an inventory of recyclable waste and a subsequent platform for its marketing [40].

In this case, the analysis was conducted a posteriori and with respect to the elements to be disposed of. Therefore, having identified the wooden frame as a suitable material for the construction of the musical space, different configurations of the panels were developed to optimize the size and quantity of the frames as much as possible.

Once the project and its work phases were conceived, an exploded view of the components in the upcycling process was also developed, which can then have an additional life even after their use. This allows for a wide range of materials and multiple continuous cycle configurations.

This approach to upcycling has a high level of flexibility as it allows it to be scaled to multiple construction solutions, i.e., it can be applied for the construction of building components at various scales. Functional construction elements can be created, capable of integrating the technological system of the envelope, as in the case of sunshade elements or substructures for green walls; elements for furnishing green spaces or urban spaces; small artifacts (Figure 8). All this clearly needs the definition of a predetermined and rigorous method in the application of upcycling in the architectural and artistic fields at different scales, with the aim of increasing the useful life of these elements. The research is, therefore, in continuity with those already widely investigated relating to disassembly procedures but which often do not address the procedures for reusing elements once disassembled. The topics developed in this study aim to identify an operational methodology that can be replicated and, therefore, be used in any recycling operation of building components for new compatible and sustainable uses. The results of this research will also allow the implementation of procedures related to the application of the circular economy in buildings that provide for the definition of control databases capable of recording the ways in which materials can be used, reused or recycled at the end of their useful life [41].

Figure 8.

Exploded view of assembled elements.

5. Conclusions

The recycling of materials today represents one of the greatest challenges for the future as it allows us to lighten the load of waste while saving precious energy [42,43,44]. Upcycling, the reuse of removed waste and materials, is a viable alternative to recycling. In fact, it is based on an even greener principle, using waste material with a different purpose from the original one: it is the art of reconverting a product by acting on the extension of its life cycle. All this allows you to save significant disposal costs as well as obtaining a huge benefit in terms of environmental sustainability by ensuring energy savings and a reduction in CO2 injection into the environment. Waste has become a precious resource, suitable for performing a different function than in the past [45,46]. The research aimed to investigate the definition of a replicable process of the systematization of upcycling activities in the case of the reuse of those materials and construction elements that, although still having their own useful life, during renovation and building recovery [47] or demolition interventions, are often disposed of in landfills.

The study highlighted several advantages:

- A method that can be exported in further cases of upcycling thanks to the use of waste products;

- The possibility of reducing energy consumption for disposal and the related CO2 emissions;

- The flexibility of the procedures since it allows the component elements to be reused several times also for other functional solutions.

Further procedures to encourage this operating procedure could be facilitated through the drafting of a project of the circularity of the intervention to be carried out, which, through the use of information models or digital technologies such as BIM and artificial intelligence, could be able to develop an efficient planning of the reuse or recycling of materials after cataloging and estimating the quantities to be deconstructed with optimization through integrated platforms, which include LCA and LCC-type cost analyses that could facilitate circularity processes also through the definition of databases of reusable materials.

Currently, however, there are some limitations in the application of the procedures for the reuse of construction materials, which are mainly attributable to the economic convenience of landfilling waste, compared to its recovery for reasoned reuse. All this is made even more complex because, even today, those process methods that direct towards the reuse of disused construction elements and that refer to implementation costs that are still not competitive are poorly structured. Experience has shown that through a rationally structured methodological path that is capable of considering functional and figurative needs in recycling on the same level as construction and operational ones, new paths can be opened for the reuse of building materials, and increasingly necessary activities that look positively at a reduction in environmental impacts and are among the sustainable interventions that are increasingly in demand today can emerge. In order to transfer these procedures to the world of production, it is necessary to involve the stakeholders of the sector to implement and encourage procedures of this kind so as to start the process of further validation and then to start a necessary regulatory update aimed at defining the fields of application, the administrative process and the procedures for the acceptance of reusable materials with the relative certificates of compatibility with upcycling.

Author Contributions

Conceptualization, methodology, validation, formal analysis, investigation and data curation, G.D.G. and E.L.; the drafting preparation of the original draft, E.L.; revision and modification, G.D.G.; supervision, G.D.G.; the authors have read and accepted the published version of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research has not received external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Acknowledgments

A special thanks goes to the students Elena Martini, Michelle Tarquini, Eva Patella and Andrea Recchia of the Degree Course in Building Engineering–Architecture of the University of L’Aquila for having contributed substantially to the design and construction of the “scenic space” that developed the figures of the project; to Mariangela De Vita for having taken care of the musical part of the show with the brass octet “Tubaductiles Concertantes” of the Conservatory A. Casella dell’Aquila, with the trombone class of Aldo Caterina and the coordination of Daniela Macchione. Thanks to the M° Giovanni IEIE, and to M° Francesco Leineri, for the world premiere of the piece “Materica”. We thank the trade associations ANCE Giovani, ANCE Giovani Abruzzo and ANCE Giovani L’Aquila for supporting the initiative together with the ESE-CPT Construction School of L’Aquila. We thank the construction company UNIREST srl of L’Aquila for the logistical support in the realization of the works and ZIACA 2 for the supply of the metal elements.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Delli, S.; Tondi, A. La Casa Riciclabile: I Rifiuti in Edilizia; EDICOM Edizioni: Monfalcone Gorizia, Italy, 1998. [Google Scholar]

- Antonini, E. La gestione dei residui dei processi di costruzione e demolizione. In Nuovi Scenari per gli Obiettivi di Sostenibilità in Edilizia; Lucarelli, M.T., Ed.; Falzea Editore: Reggio Calabria, Italy, 2005; pp. 179–183. [Google Scholar]

- Del Serrone, G.; Riccio, G.; Moretti, L. Cradle-to-cradle life cycle assessment of railway prestressed concrete sleepers: A state-of-the-art review and strategies for reducing environmental impacts. In Resources, Conservation and Recycling; Elsevier: Amsterdam, The Netherlands, 2025; Volume 214, p. 108020. ISSN 0921-3449. [Google Scholar] [CrossRef]

- Scalisi, F.; Sposito, C. Strategie e approcci green—Un contributo dall’off-site e dall’upcycling dei container marittimi dismessi|Green strategies and approaches—A contribution from the off-site and upcycling of discarded shipping containers. Agathón Int. J. Archit. Art Des. 2021, 10, 92–119. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Egbelakin, T.; Sher, W. Contributions of the circular economy to the UN sustainable development goals through sustainable construction. Resour. Conserv. Recycl. 2022, 178, 106023. [Google Scholar] [CrossRef]

- Todaro, B. Spolia nel progetto contemporaneo. In Il Reimpiego in Architettura: Recupero, Trasformazione e uso; Bernard, J.F., Bernardi, P., Esposito, D., Dillmann, P., Eds.; Ecole Rancaise de Rome: Roma, Italy, 2008. [Google Scholar]

- Thornton Kay, Salvo in Germany—Reiner Pilz, p14 Salvo NEWS No 99 11 October 1994. Available online: https://www.salvoweb.com/files/sn99sm24y94tk181119.pdf (accessed on 4 January 2025).

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002; p. 193. ISBN 0-86547-587-3. [Google Scholar]

- Rezaei, Z.; Dinani, A.S.; Moghimi, H. Cutting-edge developments in plastic biodegradation and upcycling via engineering approaches. Metab. Eng. Commun. 2024, 19, e00256. [Google Scholar] [CrossRef] [PubMed]

- Pobłocki, K.; Pawlak, M.; Drzeżdżon, J.; Jacewicz, D. Catalytic materials based on metals (ions) used in the upcycling of plastics and polymers into fuels and valuable chemicals as part of sustainable development. Mater. Sci. Eng. R Rep. 2024, 162, 100881. [Google Scholar] [CrossRef]

- Hu, Y.; Tian, Y.; Zou, C.; Moon, T.S. The current progress of tandem chemical and biological plastic upcycling. Biotechnol. Adv. 2024, 77, 108462. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.; Mohanty, A.K.; Misra, M. 3D printing in upcycling plastic and biomass waste to sustainable polymer blends and composites: A review. Mater. Des. 2024, 237, 112558. [Google Scholar] [CrossRef]

- Yang, X.; Liu, J.; Zhou, B.; Zhang, X. Upcycling of textile and footwear wastes for synergistical reinforcement of cement mortar. Compos. Commun. 2023, 41, 101646. [Google Scholar] [CrossRef]

- Singh, J.; Sung, K.; Cooper, T.; West, K.; Mont, O. Challenges and opportunities for scaling up upcycling businesses—The case of textile and wood upcycling businesses in the UK. Resour. Conserv. Recycl. 2019, 150, 104439. [Google Scholar] [CrossRef]

- van Hees, M.; Oskam, I.; Bocken, N. Motives, drivers and barriers to urban upcycling: Insights from furniture upcycling in the Netherlands. J. Clean. Prod. 2025, 486, 144485. [Google Scholar] [CrossRef]

- Hossain, U.; Wang, L.; Yu, I.K.; Tsang, D.C.; Poon, C.-S. Environmental and technical feasibility study of upcycling wood waste into cement-bonded particleboard. Constr. Build. Mater. 2018, 173, 474–480. [Google Scholar] [CrossRef]

- Wang, L.; Yu, I.K.; Tsang, D.C.; Yu, K.; Li, S.; Poon, C.S.; Dai, J.-G. Upcycling wood waste into fibre-reinforced magnesium phosphate cement particleboards. Constr. Build. Mater. 2018, 159, 54–63. [Google Scholar] [CrossRef]

- Passaro, A. Costruire e Dismettere. Nuove Strategie per il Riciclaggio in Edilizia; Arte Tipografia: Napoli, Italy, 1996. [Google Scholar]

- Bellicoso, A.; Manna, S.; Di Giovanni, G.; Angelucci, A. Urban mining and regeneration: Upcycling for the House of Culture in Rieti. In Transizione: Sfide e Opportunità per L’ambiente Costruito; Fatiguso, F., Fiorito, F., De Fino, M., Cantatore, E., Eds.; 2023; ISBN 979-12-81229-02-0. Available online: https://hdl.handle.net/11697/225894 (accessed on 2 February 2025).

- Pellizzari, A.; Genovesi, E. Neo Materiali 2.0 Nell’economia Circolare. Edizioni Ambiente, Milano, 2021. UpcycleHouse/Lendager Arkitekte. Available online: https://www.archdaily.com/458245/upcycle-house-lendagerarkitekter?ad_medium=widget&ad_name=recommendation (accessed on 15 January 2025).

- Rogora, A.; Lo Bartolo, D. Costruire Alternativo: Materiali e Tecniche Alternative per Un’architettura Sostenibile; Wolters Kluwer: Milano, Italy, 2013. [Google Scholar]

- Architectural Projects that Give New Life to Recycled Doors and Windows. Available online: https://www.archdaily.com/945506/10-architectural-projects-that-give-new-life-to-recycled-doors-and-windows (accessed on 15 January 2025).

- Srinivasan, H.; Figueroa, R.; Gadh, R. Selective disassembly for virtual prototyping as applied to de-manufacturing. Robot. Comput. Manuf. 1999, 15, 231–245. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Omoteso, K.; Bilal, M.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, J.M.; Owolabi, H.A. Disassembly and deconstruction analytics system (D-DAS) for construction in a circular economy. J. Clean. Prod. 2019, 223, 386–396. [Google Scholar] [CrossRef]

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Driesser, M.; Kretschmann, T.; Walker, P.; Emmitt, S. A circular construction evaluation framework to promote designing for disassembly and adaptability. J. Clean. Prod. 2021, 316, 128122. [Google Scholar] [CrossRef]

- British Standard 8887-2:2009; Design for Manufacture, Assembly, Disassembly and End-of Life Processing. British Standards Institution: London, UK, 2009.

- De la Varga Pastor, A. The Incorporation of the Circular Economy into State Waste Legislation as a Result of Directive (EU) 2018/851. Actualidad Juridica Ambiental, 176 ss., 2020. Available online: https://xreiss.efri.uniri.hr/article.php?id=1562 (accessed on 12 February 2025).

- Antoniazzi, S. Transition to Circular Economy and Management of Public Services of General Economic Interest. Central Eur. Public Adm. Rev. 2021, 19, 45–67. [Google Scholar] [CrossRef]

- Pauli, G. Upsizing: The Road to Zero Emissions, More Jobs, More Income and No Pollution; Greenleaf Publishing: Sheffield, UK, 1996. [Google Scholar]

- Iannou, K.; VeIshagh, A. Managing Sustainability in Product Design and Manufacturing; Manufacturing Department, University of Warwick: Coventry, UK, 2011. [Google Scholar]

- Gains, L.L.; Mintz, M.M. Energy Implications of Glass Container Recycling; Argonne National Laboratory: Lemont, IL, USA, 1994. [Google Scholar]

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Topology of Key Concepts and Terms; Faculty of Industrial Engineering, Delft University of Technology: Delft, The Netherlands, 2017. [Google Scholar]

- Gu, P.; Sosale, S. Product Modularization for Life Cycle Engineering; Department of Mechanical and Manufacturing Engineering, The University of Calgary: Calgary, AB, Canada, 1999. [Google Scholar]

- Broadbent, C. Steel’s recyclability: Demonstrating the benefits of recycling steel to achieve a circular economy. Int. J. Life Cycle Assess. 2016, 21, 1658–1665. [Google Scholar] [CrossRef]

- Aguilar-Jurado, M.Á.; Gil-Madrona, P.; Ortega-Dato, J.F.; Zamorano-García, D. Effects of an Educational Glass Recycling Program against Environmental Pollution in Spain. Int. J. Environ. Res. Public Health 2019, 16, 5108. [Google Scholar] [CrossRef]

- Kharazipour, A.; Kües, U. Recycling of Wood Composites and Solid Wood Products; Institute of Forest Botany, Georg-August-University: Göttingen, Germany, 2007. [Google Scholar]

- Delva, L.; Van Kets, K.; Kuzmanovic, M.; Demets, R.; Hubo, S.; Mys, N.; De Meester, S.; Ragaert, K. Mechanical Recycling of Polymers for Dummies; Centre for Polymer and Material Technologies, Departmentof Materials, Textiles and Chemical Engineering, Ghent University; Department of Green Chemistry and Technology, Ghent University: Ghent, Belgium, 2020. [Google Scholar]

- Recio, J.M.B.; Narváez, R.P.; Guerrero, P.J. Estimate of Energy Consumption and CO2 Emission Associated with Production, Use and Final Disposal of PVC, Aluminium and Wooden Windows; PVC-Ven-200501-2 Version 5; Deoartament de Projectes d’Enginerya, Universitat Politècnica de Catalunya, Environmental Modelling Laboratory, Report: Barcelona, Spain, 2005. [Google Scholar]

- The Circular Economy—A Powerful Force for Climate Mitigation; Transformative innovation for prosperous and low-carbon industry; Material Economics Sverige AB: Stockholm, Sweden, 2018; Available online: www.sitra.fi/en/publications/circular-economy-powerful-force-climate-mitigation/ (accessed on 15 January 2025).

- Ignatyev, I.A.; Thielemans, W.; Vander Beke, B. Recycling of Polymers: A Review. ChemSusChem 2014, 7, 1579–1593. Available online: www.acen.it (accessed on 9 February 2015). [CrossRef] [PubMed]

- Munaro, M.R.; Tavares, S.F. Materials passport’s review: Challenges and opportunities toward a circular economy building sector. Built Environ. Proj. Asset Manag. 2021, 11, 767–782. [Google Scholar] [CrossRef]

- Peters, J.R.; Dewulf, K. Design for End of Life: A Design Methodology for the Early Stages of an Innovation Process; Katholieke Universiteit Leuven, Centre for Industrial Management, Leuven, University College of West-Flanders, Industrial Design Centre, Kortrijk, Delft University of Technology, Design for Sustainability: Delft, The Netherlands, 2012. [Google Scholar]

- Idowu, S.O.; Capaldi, N.; Zu, L.; Gupta, A.D. Encyclopedia of Corporate Social Responsibility; Sherrat, A., Ed.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Available online: www.architetturaecosostenibile.it/materiali (accessed on 9 February 2015).

- Barbero, S. Systemic Design Guide for Policymaking: A Circular Europe on the Way; Allemandi: Torino, Italy, 2017. [Google Scholar]

- Hoornweg, D.; Bhada-Tata, P.; Kennedy, C. Waste production must peak this century. Nature 2013, 502, 615–617. [Google Scholar] [CrossRef] [PubMed]

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management; Urban development series; knowledge papers no. 15; World Bank: Washington, DC, USA, 2012. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).