Abstract

Coal mining, characterized by its complex operational environment and significant management challenges, is a prototypical high-risk industry with frequent accidents. Accurate identification of the key risk factors influencing coal mine safety is critical for reducing accident rates and enhancing operational safety. Comprehensive analyses of coal mine accident investigation reports provide invaluable insights into latent risk factors and the underlying mechanisms of accidents. In this study, we construct an integrated research framework that synthesizes large language models, association rule mining, and Bayesian networks to systematically analyze 700 coal mine accident investigation reports. First, a large language model is employed to extract risk factors, identifying multiple layers of risks, including 14 direct, 38 composite, and 75 specific factors. Next, the Apriori algorithm is applied to mine 281 strong association rules, which serve as the foundation for constructing a Bayesian network model comprising 127 nodes. Finally, sensitivity analysis and critical path analysis are conducted on the Bayesian network to reveal seven primary risk factors primarily related to on-site safety management, the execution of operational procedures, and insufficient safety supervision. The novelty of our framework lies in its efficient processing of unstructured text data via large language models, which significantly enhances the accuracy and comprehensiveness of risk factor identification compared to traditional methods. The findings provide robust theoretical and practical support for coal mine safety risk management and offer valuable insights for risk management practices in other high-risk industries. From a policy perspective, we recommend that the government strengthen legislation and supervision of coal mine safety with a particular focus on the enforcement of operational procedures and on-site safety management, promote comprehensive safety education and training to enhance frontline personnel’s awareness and emergency response capabilities, and leverage data-driven technologies to develop intelligent risk early-warning systems. These measures will improve the precision and efficiency of safety management and provide a scientific basis for accident prevention and control.

1. Introduction

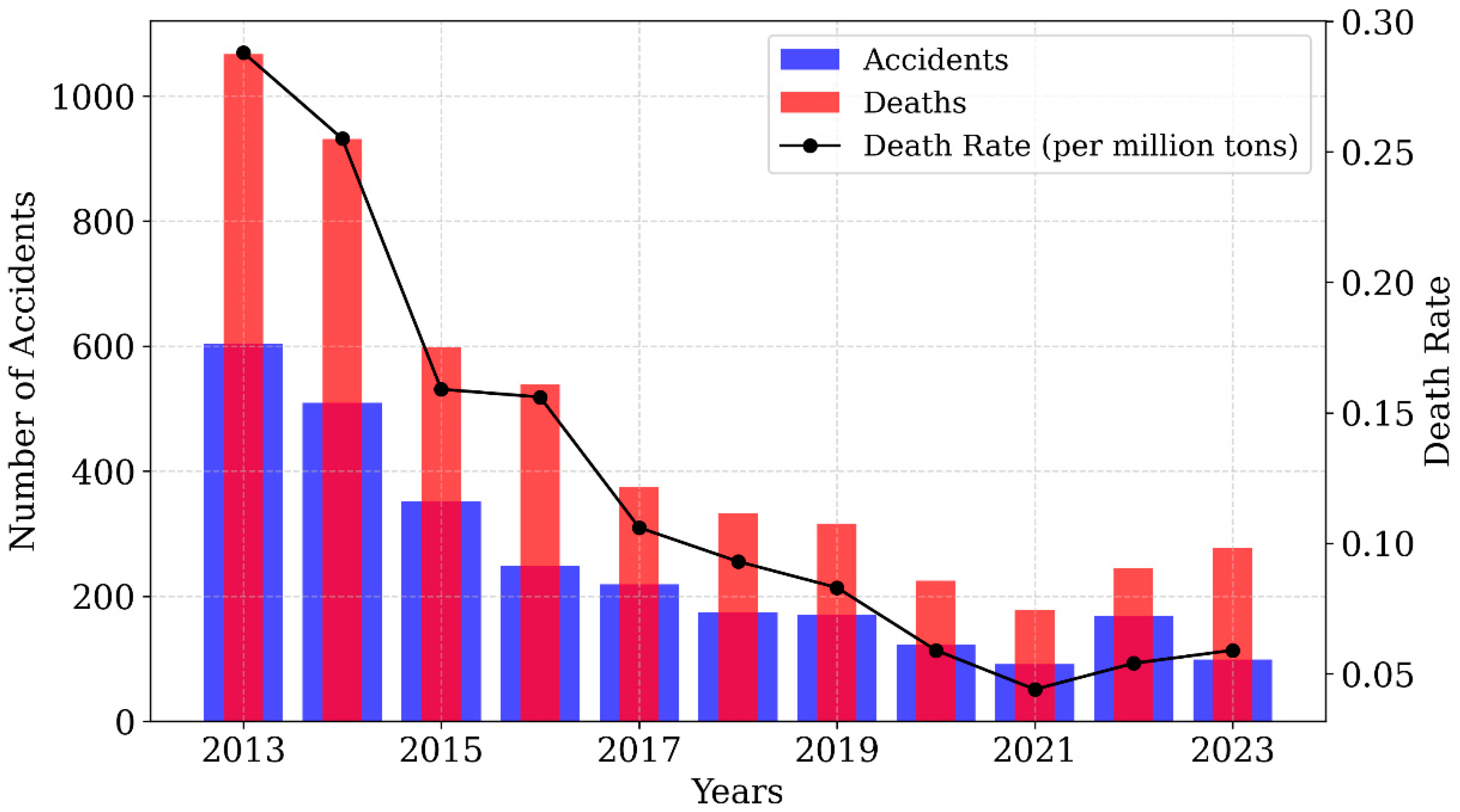

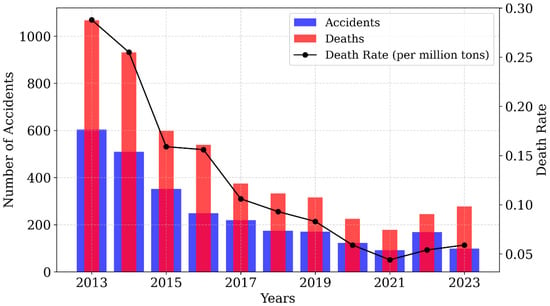

The occurrence of coal mine accidents not only results in human casualties and economic losses, but also generates a cascade of profound and long-lasting impacts, such as production suspensions, administrative penalties imposed on regulatory bodies, erosion of public trust in coal mining enterprises, and disruptions to coal supply chains. Given the severe and far-reaching consequences of such accidents, research focused on the prevention and mitigation of coal mine accidents holds substantial practical and societal value. Over the past several decades, the safety standards of coal mine production in China have significantly improved. As illustrated in Figure 1, between 2013 and 2023, three key indicators of safety performance—the frequency of coal mine accidents, the number of fatalities, and the death rate per million tons of coal—have all demonstrated a consistent downward trajectory. While the safety situation in Chinese coal mines has shown continuous improvement, the steady enhancement of safety standards faces persistent challenges, including increasing uncertainty in the external environment, inherent weaknesses in the safety infrastructure of mines, insufficient enforcement of corporate responsibility, and a shortage of skilled technical personnel. These issues constitute latent risks that may compromise the safety of coal mining operations. According to well-established accident causation theories [1,2,3,4], the occurrence of coal mine accidents is the result of the complex interaction of multiple risk factors. Effectively identifying and managing these latent risks in the coal mining process could lead to a significant reduction in the incidence of accidents.

Figure 1.

China’s coal mine safety production trends, 2013–2023.

Early research on coal mine accidents predominantly focused on the harm inflicted on miners, emphasizing the factors influencing both the likelihood of injury and its severity during such events. Key determinants identified in these studies include miners’ experience, the size of the coal mine, and the employed mining methods. These insights led to the development of protective measures aimed at enhancing miners’ safety in the workplace [5,6,7]. In addition, early research predominantly relied on accident statistics and case studies, utilizing quantitative methods and empirical observations to investigate accident causation [8]. While these approaches were innovative at the time, their effectiveness was limited by restricted data availability and relatively narrow methodological scope, hindering a comprehensive understanding of the complex causes of accidents. This limitation led subsequent scholars to recognize that a single-factor approach cannot fully account for the complexity of accidents, underscoring the need for a multidimensional analysis of the interactions between various contributing factors. Furthermore, early studies made significant contributions to the development of safety measures and the formulation of safety theories, providing invaluable theoretical foundations and practical insights that have been instrumental in shaping more refined risk assessment models and safety management systems in later research.

With the progressive improvement of coal mining environments, scholarly attention shifted toward the potential occupational health hazards associated with mining operations. Contemporary studies highlight that a wide range of factors—including occupational safety measures, the enforcement of safety regulations, risk control technologies, working conditions, and individual characteristics—have a significant impact on miners’ occupational health [9,10,11,12]. Currently, research on coal mine accidents primarily centers on accident prevention and risk control, with the overarching goal of minimizing their adverse impacts. A critical and effective research avenue involves the in-depth analysis of risk factors contributing to coal mine accidents, providing a robust scientific foundation for the formulation of preventive measures. Studies addressing coal mine accident risk factors can be broadly classified into three approaches: knowledge-driven, data-driven, and a fusion of knowledge and data-driven methodologies. In addition, risk factors are dynamic in nature, continuously evolving as mining environments, technological advancements, and safety management measures are progressively optimized [13]. By integrating historical accident data, researchers can trace the temporal evolution of risk factors, demonstrating that changes in production conditions, management levels, and external environments exert profound impacts on accident risk characteristics [14,15]. This dynamic evolution highlights the necessity of adopting adaptive risk management strategies to promptly identify and address emerging safety hazards [16]. Understanding the mechanisms behind these evolving risk factors not only aids in developing more proactive and targeted preventive measures but also lays a strong theoretical foundation and provides methodological support for future research employing knowledge-driven, data-driven, and hybrid approaches.

Knowledge-driven research primarily builds on the expertise of scholars and employs established theoretical frameworks to analyze critical risk factors associated with coal mine accidents. Among these frameworks, process safety management (PSM) is one of the most frequently applied. By integrating systematic risk assessment models such as HAZOP [17,18] and FTA [19], this approach effectively identifies and evaluates risk factors, thereby offering essential support for enhancing coal mine safety management systems [20,21,22,23]. For example, researchers have developed various risk factor analysis models [24,25,26,27,28,29,30] and have investigated the interaction mechanisms of coal mine accident risk factors within relevant theoretical frameworks [31,32,33,34,35]. These studies further assess the impact of these risk factors on accident outcomes, thereby providing a robust theoretical foundation for developing effective risk control strategies. Despite its contributions, the knowledge-driven approach exhibits certain limitations. It often focuses on specific types of coal mine accidents or examines risk factors in isolation, with minimal emphasis on the interrelationships and interactions among diverse factors. Such a narrow scope limits a comprehensive understanding of coal mine accident risks and undermines holistic risk management efforts [36,37,38].

Data-driven research on coal mine accident risk factors emphasizes the analysis of extensive coal mine accident datasets to identify and thoroughly investigate the key factors influencing such incidents. For instance, text mining techniques have been employed to extract risk factors from a vast number of coal mine accident investigation reports [39,40,41,42,43,44,45,46,47], while machine learning and deep learning models have been utilized to conduct advanced analyses of these identified factors [48,49,50,51,52,53]. This approach relies extensively on coal mine accident investigation reports, which systematically document the causes of accidents, providing a reliable data foundation for research in coal mine process safety management [54,55,56]. The adoption of advanced digital technologies in the coal mining sector has enabled real-time monitoring of production processes and the rapid detection of potential hazards, thereby offering critical support for preventing major accidents and safeguarding production facilities and personnel. The integration of digital technologies not only accelerates the response to safety hazards but also creates new opportunities for multi-source data integration and the optimization of risk management frameworks [57,58,59]. Historical data, including accident investigation reports, provide detailed insights into the causes and processes of accidents, forming a solid foundation for identifying the characteristics of risk factors and uncovering their evolutionary mechanisms. At the same time, real-time monitoring data capture dynamic changes in potential risks during production processes, enabling timely adjustments to safety management strategies.

By combining a deep analysis of risk factors’ characteristics and evolutionary mechanisms within historical data with the dynamic feedback provided by real-time monitoring, it becomes possible not only to validate analytical findings but also to optimize risk management strategies further. The seamless integration of historical and real-time data allows for a more precise understanding of the evolutionary trajectories of risk factors. Guided by process safety principles, this integration not only enhances the accuracy of analytical results but also provides systematic, scientifically grounded support for coal mine accident prevention and risk control [60]. Knowledge and data fusion-driven research on coal mine accident risk factors begins by leveraging the expertise of scholars to formulate research questions, followed by an in-depth analysis of coal mine accident data to investigate the root causes of these risks. Based on the findings, targeted risk mitigation strategies are developed, providing a robust foundation for effective risk management and accident prevention in coal mining operations [61,62,63,64,65]. This research approach not only builds on existing theoretical knowledge to refine the analysis of risk factors—such as categorizing risks by accident type [66,67] or location [68,69]—but also harnesses coal mine accident data to uncover novel insights and advance the understanding of underlying risk dynamics. The integration of knowledge and data is fundamental to conducting comprehensive and in-depth studies of coal mine accidents while establishing a foundation for dynamic process safety management. This fusion-driven research framework, guided by process safety principles, emphasizes systematization, prevention, and adaptability. By deeply integrating theoretical expertise with empirical data, it enables more precise identification and control of risk factors. Such an approach not only uncovers the underlying patterns and interactions among risk factors but also provides scientifically grounded and systematically informed decision-making support for coal mine safety management. As a result, it facilitates significant improvements in safety production levels while advancing the full implementation of process safety principles across the industry [70,71].

In summary, early research primarily relied on accident statistics and case studies to conduct quantitative investigations into the direct impacts of coal mine accidents on miner injuries and economic losses, identifying key risk factors such as miner experience, mine size, and mining methods. Although these methods were innovative at the time, their ability to reveal the complex causes and dynamic evolution of risk factors was limited by restricted data sources and a narrow methodological scope. With the continuous improvement of coal mining environments and technological advancements, the research focus has gradually shifted from isolated accident outcomes to the evolution of risk factors and their profound effects on miners’ occupational health. Accordingly, scholars have introduced knowledge-driven approaches based on theoretical frameworks, data-driven methods relying on big data analytics, and hybrid methodologies that integrate both strategies to explore the composition, interaction mechanisms, and evolution of accident risks from multiple dimensions. However, despite their distinct advantages, these approaches suffer from limitations—such as neglecting the interactions among multiple factors, incomplete information extraction, and an insufficient understanding of causal relationships—which prevent the establishment of a systematic, dynamic, and comprehensive risk assessment model. In light of these limitations and research gaps, there is an urgent need for a novel approach to overcome the shortcomings of existing methods. To address this gap, the present study proposes the use of advanced deep learning techniques and large language models to efficiently extract and analyze risk information from textual data while preserving semantic integrity. This approach aims to uncover the causal relationships among risk factors and track their dynamic evolution over time. Building on this foundation, this study seeks not only to construct a precise and efficient model for identifying and assessing coal mine accident risk factors but also to provide more scientific and systematic decision support for coal mine safety management and accident prevention.

From the perspective of risk factors, the key to effectively preventing and controlling coal mine accidents lies in the precise identification of the critical factors that contribute to their occurrence. Recent studies have widely employed text mining techniques for identifying coal mine accident risk factors, with the primary advantage being their ability to efficiently process large volumes of textual data, thereby significantly improving analysis efficiency [72,73]. However, one major drawback of text mining methods is that the process may disrupt the intrinsic semantic structure of the data, resulting in potential information loss [74,75]. Additionally, given the lack of in-depth understanding of the specific context within the coal mining industry, the risk factors identified solely through text mining often require further verification and refinement. The outcomes may not fully or accurately capture the real-world challenges encountered in coal mine production. As shown in Table 1, the main limitations and challenges of existing methods in handling risk factors are outlined in detail. To overcome the limitations inherent in existing methods for coal mine accident risk identification and to facilitate more precise analyses, this study proposes leveraging deep learning techniques using large language models [76,77,78]. Large language models are equipped with advanced natural language processing and understanding capabilities, enabling them to not only efficiently identify potential risk factors but also to uncover the causal relationships between these factors, while effectively preserving the semantic integrity of the data [79,80,81]. In the context of complex textual data, the efficiency of large language models further enhances the reliability and validity of the analysis results. By incorporating large language models, this study provides robust technical support for the development of a more accurate and practical coal mine accident risk factor analysis model. Furthermore, it offers a novel theoretical foundation and decision-making framework for coal mine safety management and accident prevention, thereby significantly enhancing the capacity to address the diverse safety challenges faced in coal mine production.

Table 1.

Comparison between this study and previous literature.

2. Materials and Methods

2.1. Dataset

To standardize the reporting and investigative processes for coal mine safety incidents, ensure the implementation of accountability measures for safety failures, and reduce the occurrence of production-related accidents, relevant government agencies have established comprehensive regulations governing the reporting and investigation of coal mine accidents, in accordance with applicable laws and regulations. As such, the formulation of each coal mine accident investigation report must follow a specified procedural framework to guarantee the authenticity, professionalism, objectivity, and authority of the findings. In comparison to other forms of accident-related data, investigation reports offer a more thorough and accurate representation of coal mine accidents. This rationale underpins the decision to select coal mine accident investigation reports as the primary source of data for this study. A total of 700 coal mine accident investigation reports were obtained from the official website of the National Mine Safety Administration, available at https://www.chinamine-safety.gov.cn/, and the respective provincial-level mine safety regulatory agencies. The 700 coal mine accident investigation reports used in this study encompass all accident levels and major types, providing a highly representative sample. These reports cover common safety hazards in coal mining, such as roof accidents, gas accidents, mechanical and electrical accidents, and transportation accidents, with accident levels ranging from particularly serious, serious, and major to general accidents. The reports are sourced from the National Mine Safety Administration and 25 provincial-level coal mine safety regulatory authorities, reflecting the safety conditions and management practices across different regions. However, given the greater number of coal mines and more frequent accidents in certain regions, regional imbalances may exist within the dataset. Nevertheless, these reports span a long period, offering valuable insights into coal mine safety issues over time. Through comprehensive analysis of these data, this study provides a scientific foundation for coal mine Safety Risk Assessments. Future research could expand the dataset further by incorporating coal mine accident data from additional regions and different mine types, thereby enhancing the generalizability of the conclusions.

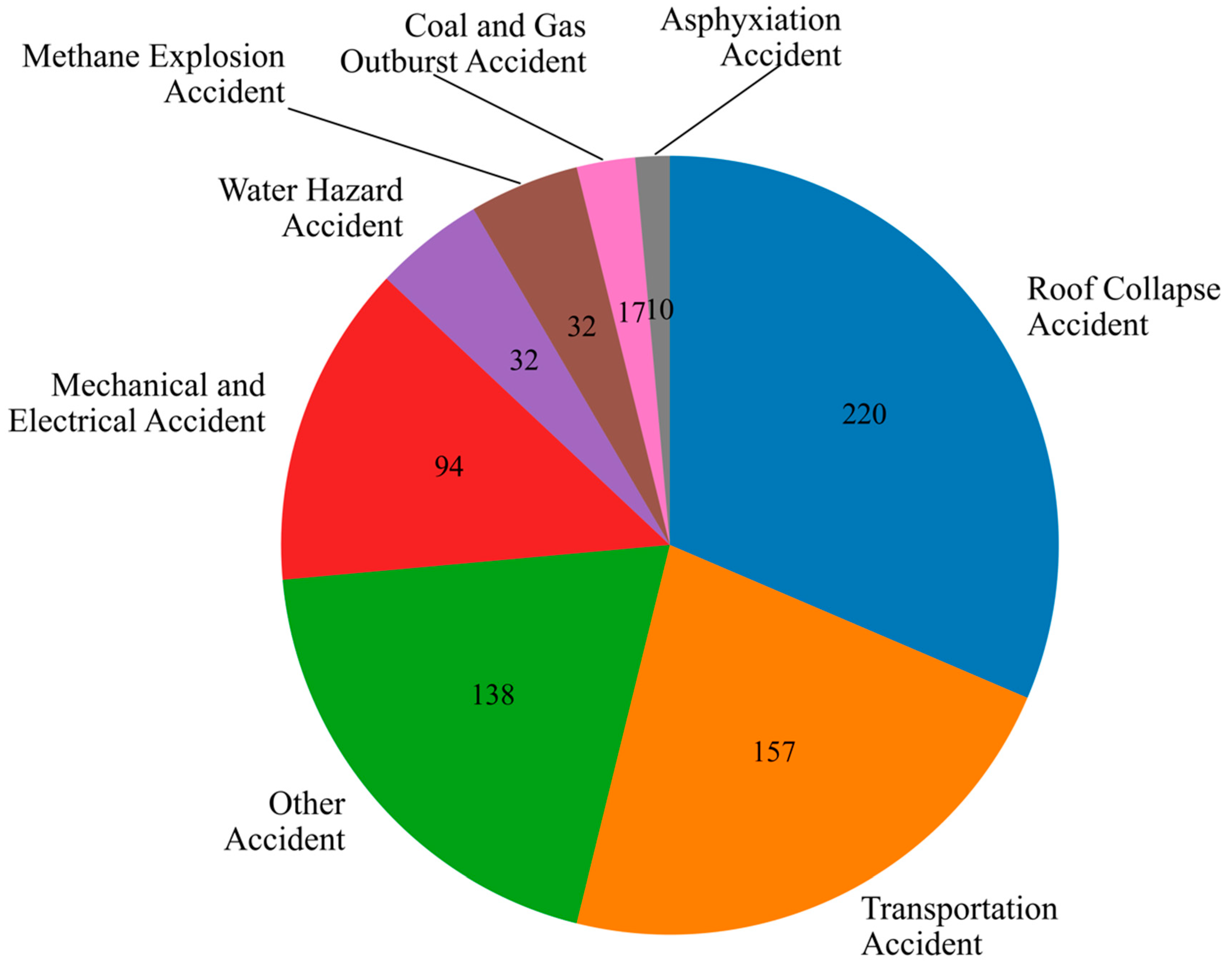

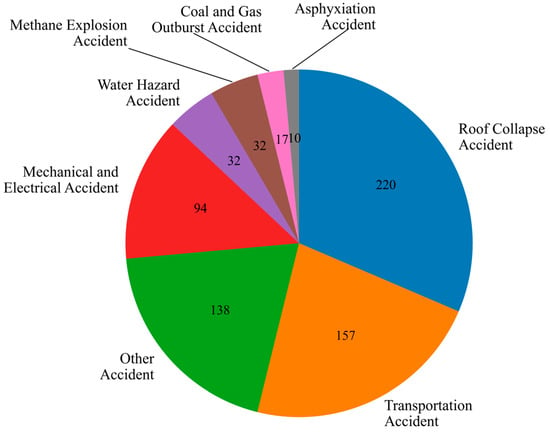

Coal mine accidents can be categorized into four levels based on the number of fatalities or direct economic losses incurred: particularly major accidents, major accidents, significant accidents, and general accidents. A particularly major accident refers to an incident resulting in 30 or more fatalities; a major accident involves fatalities ranging from 10 to 30; a significant accident is one that causes the deaths of 3 to 10 individuals; and a general accident is defined as an event resulting in fewer than 3 fatalities. Using this classification standard, an analysis of 700 coal mine accident investigation reports was conducted, revealing the distribution of accidents across these categories, as shown in Table 2. Furthermore, Figure 2 illustrates the distribution of coal mine accident types within the 700 reports.

Table 2.

Accident severity level statistics.

Figure 2.

Counts of coal mine accident types.

2.2. Identification of Coal Mine Accident Risk Factors

Identifying and extracting risk factors that contribute to coal mine accidents from accident investigation reports is a critical step in research focused on coal mine accidents based on risk factors. Text mining, as the primary method for identifying and extracting these risk factors, offers significant advantages in efficiently processing and automatically analyzing large-scale textual data. It effectively uncovers latent risk patterns and associations. This method is particularly suited for handling complex and content-rich accident investigation reports, significantly enhancing both the efficiency and coverage of the analysis [82]. However, the effectiveness of text mining is highly dependent on data quality and algorithm precision. Insufficient data preprocessing or the presence of ambiguity and unstructured content in the text can severely limit the accuracy of the analysis. Furthermore, text mining has inherent limitations in processing complex contexts and subtle semantic differences, necessitating continuous optimization of algorithms to meet specific analytical needs [83]. Given the unstructured nature of text data and the complexity of language, traditional text mining methods face challenges in accurately understanding text semantics. To address this issue, this study introduces Large Language Models (LLMs) to identify and extract coal mine accident risk factors. LLMs are a class of artificial intelligence models trained on vast amounts of data, designed to understand and generate natural language text. They are widely applied in various natural language processing (NLP) tasks, including text generation, machine translation, sentiment analysis, and question answering systems [84,85,86]. Leveraging their advanced natural language processing capabilities, this study applies LLMs to identify coal mine accident risk factors, ensuring the accuracy and consistency of the risk factor extraction process.

Cross-disciplinary studies have demonstrated that LLM-based approaches offer notable advantages in text semantic understanding tasks. For example, in the legal domain, Wei et al. (2023) compared a fine-tuned DistilBERT model with a non-fine-tuned counterpart in legal text classification and found that the fine-tuned model achieved substantially higher F1 scores at both the document and segment levels, while also outperforming traditional logistic regression models in identifying implicit associations within legal terminology and other complex semantic structures [87]. In the medical domain, Peng et al. (2023) showed that their proposed GatorTronGPT achieved an F1 score improvement of 3% to 10% over traditional models (e.g., BioGPT) in drug–disease relation extraction tasks and that a model trained on synthetic clinical text, GatorTronS, also surpassed baseline models (such as ClinicalBERT) in clinical concept extraction tasks [88]. Moreover, Li et al. (2023) employed CNN and BERT models to analyze construction accident narratives, demonstrating that deep learning models attained significantly higher accuracy in accident classification tasks than traditional methods combining TF-IDF with SVM, and observed that LLMs (such as GPT) can effectively predict accident types and visualize key semantic features through transfer learning [89]. Given that coal mine accident investigation reports exhibit considerable structural and linguistic similarities to the legal, medical, and construction accident reports mentioned above, these findings provide both theoretical and empirical evidence supporting the inference that LLM-based approaches could likewise offer significant advantages in semantic text understanding within the domain of coal mine accidents. Future work could build on this foundation by directly comparing the performance of LLM-based methods with traditional text mining approaches specifically in coal mine accident investigations. Large Language Models (LLMs) can be applied using several strategies, each tailored to specific objectives. The prompting strategy, for instance, involves providing explicit textual input to guide the model in generating relevant information or text. This approach is widely employed in tasks such as text generation, machine translation, and question answering systems. Its key advantage lies in its simplicity and flexibility. However, there is an inherent risk that the generated output may diverge from the intended target [90,91,92]. A second strategy, fine-tuning, involves adapting a pretrained LLM to a specific task or dataset to optimize its performance in a particular context. While this strategy effectively enhances task-specific performance, it requires a substantial volume of labeled data and may lead to overfitting [93,94,95]. Another approach, zero-shot learning, enables LLMs to handle new tasks without specific training on them, demonstrating the model’s remarkable generalization capabilities. This strategy offers high flexibility and convenience, as it eliminates the need for task-specific training; however, its effectiveness may be limited when dealing with complex tasks [96,97]. Lastly, few-shot learning involves providing the model with a small number of examples to facilitate quick adaptation to new tasks, making it particularly useful in data-scarce scenarios. While this strategy is effective in situations where sample sizes are limited, its success largely depends on the quality of the examples provided [98,99]. The diversity and flexibility inherent in these strategies underscore the broad applicability and significant potential of LLMs across various tasks. Given the length and complexity of coal mine accident investigation reports, this study will employ the prompting strategy to apply LLMs. By constructing logically coherent, clearly structured, and highly targeted prompt instructions, the model will be guided to effectively identify and extract risk factors associated with coal mine accidents.

2.3. Association Rule Mining

Association rule mining is a pivotal technique in data analysis, designed to uncover the underlying relationships between different attributes within a dataset [100,101]. Initially, it found applications in supermarket basket analysis [102,103,104], where it was used to identify latent patterns in consumer purchasing behavior. Association rules are typically expressed in the form of “if… then…”, consisting of an antecedent (condition) and a consequent (outcome). The core principle of association rule mining is to determine the likelihood that the consequent will occur given the presence of a specific antecedent within the dataset. In the process of association rule mining, two fundamental statistical measures are considered: support and confidence. Support indicates the frequency with which the association rule appears in the dataset, whereas confidence quantifies the reliability of the consequent occurring when the antecedent condition is met [105,106]. The mining process itself involves generating candidate itemsets, calculating the support of itemsets, constructing association rules, and evaluating the confidence of these rules. This technique has seen widespread application across various fields, including market basket analysis, recommender systems, and network traffic analysis [107,108,109].

Among the various association rule mining algorithms, the Apriori and FP-growth algorithms are the most widely adopted methods [110,111,112]. In recent years, there has been increasing scholarly interest in applying association rule mining techniques to the analysis of accident causation. By conducting in-depth mining of extensive accident datasets, this approach aims to uncover the latent factors and patterns that contribute to the occurrence of accidents. This method not only facilitates the identification of factors that are potentially associated with accidents under specific conditions but also offers new insights and strategies for accident prevention, management, and emergency response. This study utilizes the Apriori algorithm to investigate the hidden association rules between risk factors in coal mine accidents, with the goal of revealing the causal chains that lead to such incidents. The outcomes of this analysis provide a robust theoretical foundation for the development of Bayesian network models and for advancing risk assessment methodologies.

2.4. Bayesian Network

Bayesian networks, a type of probabilistic graphical model, represent the dependencies between random variables through a directed acyclic graph (DAG) structure [113,114,115]. Their flexibility and expressive power have made Bayesian networks indispensable in a wide range of disciplines, particularly for addressing complex systems and managing uncertainty [116,117,118]. In medical diagnostics, Bayesian networks synthesize patient symptoms, test results, and medical history, utilizing probabilistic inference to provide diagnostic support, thereby assisting healthcare providers in making more accurate and informed decisions [119,120,121]. In industrial and safety management, they are employed to assess potential safety risks, evaluate the likelihood of accidents, and identify their root causes, offering a scientific foundation for the development of more effective safety strategies and preventive measures [122,123]. In financial risk management, Bayesian networks model the interactions between market fluctuations, risk factors, and returns, providing a probabilistic framework for investment decision-making [124,125,126]. In natural language processing, they are widely applied in tasks such as semantic analysis, information retrieval, and text classification, helping to uncover latent information structures in textual data [127,128]. In the fields of ecology and environmental management, Bayesian networks are utilized to analyze the intricate relationships among various ecological factors and predict the potential impacts of environmental changes on ecosystems [129,130]. Beyond these, Bayesian networks also hold substantial promise in areas such as bioinformatics, cybersecurity, supply chain management, artificial intelligence, and machine learning [131,132,133]. This study applies the Bayesian network model to comprehensively examine the risk factors involved in coal mine accidents, explore their interdependencies, identify the critical pathways through which accidents occur, and uncover the underlying risk mechanisms. These insights provide both theoretical and practical guidance for the prevention and control of coal mine accidents.

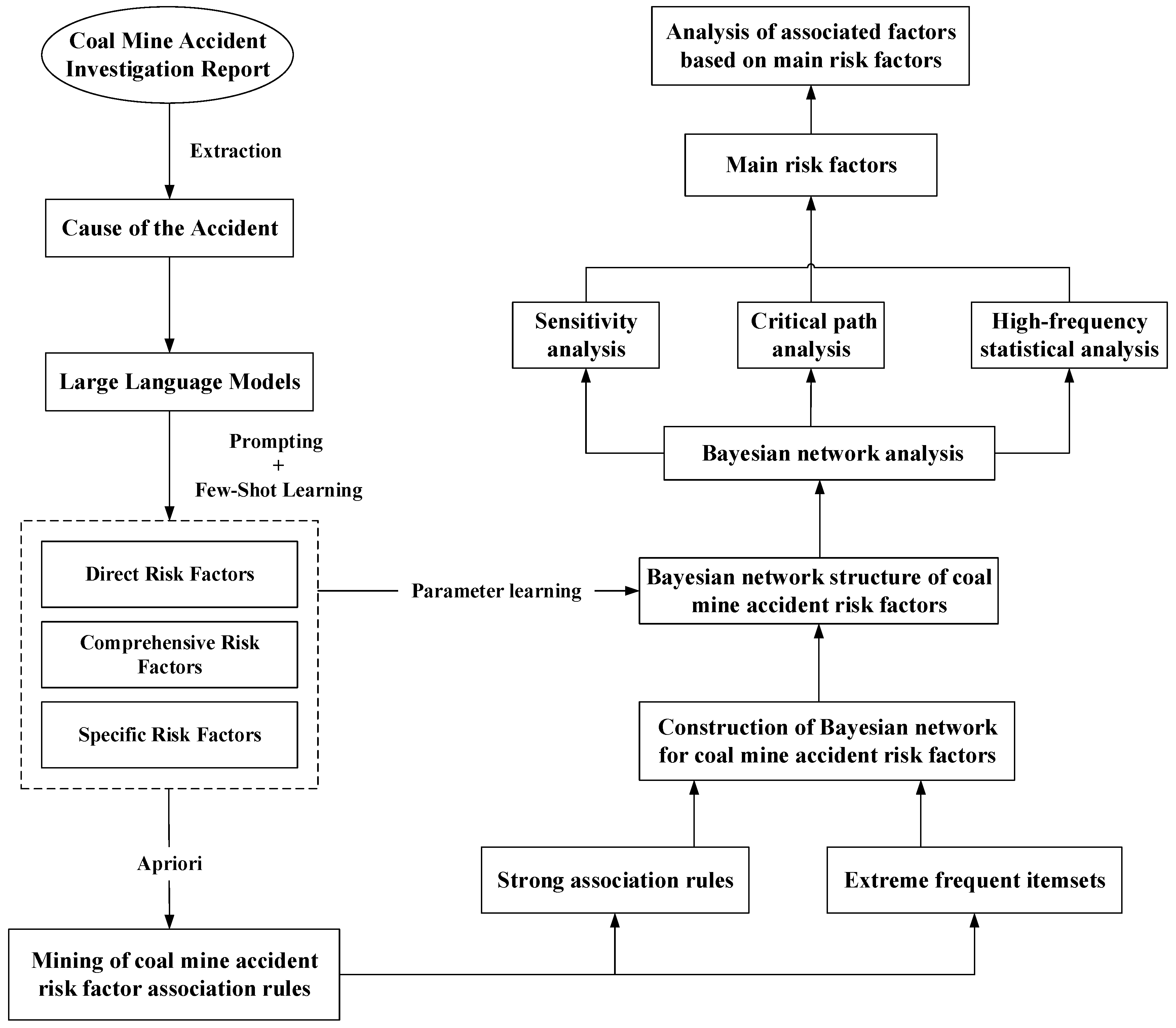

2.5. Research Framework

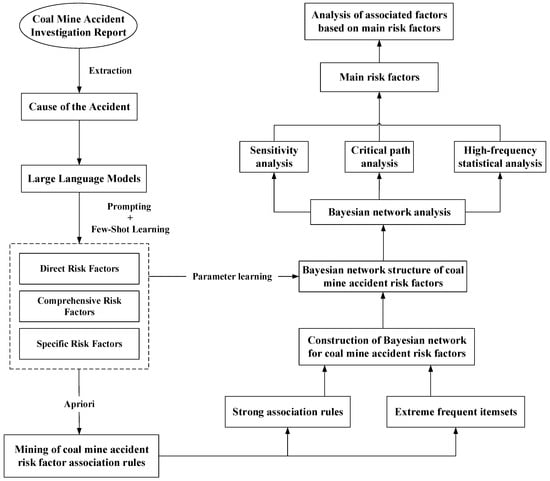

This study develops a comprehensive framework for identifying, analyzing, and modeling risk factors in coal mine accidents, comprising key components, including risk factor extraction, classification, association rule mining, and Bayesian network analysis. First, based on coal mine accident investigation reports, a large language model (LLM), combined with prompting and few-shot learning, is employed to process textual data, extracting direct risk factors from explicitly identified direct causes and deriving comprehensive and specific risk factors from indirectly stated causes. Subsequently, the Apriori algorithm is applied to the extracted risk factors for association rule mining, identifying strong association patterns among different risk factors. Extreme frequent itemsets (EFIs) are leveraged to identify and filter key highly associated risk factors. Based on the extracted strong association rules, a Bayesian network is constructed to more precisely characterize the dependency relationships among risk factors. The network’s conditional probability distribution is then optimized through parameter learning. Sensitivity analysis, critical path analysis, and high-frequency feature statistics are subsequently conducted to further identify the most influential risk factors and their interdependencies in accident occurrences. The proposed research framework systematically identifies coal mine accident risk factors and elucidates their interconnections. By integrating large language models with association rule mining, this framework efficiently extracts key risk factors from accident investigation reports and uncovers their underlying association patterns. Additionally, the Bayesian network modeling approach quantifies causal relationships among risk factors, establishing a scientific basis for risk prediction and decision-making. This framework advances the automation of accident risk analysis while providing more precise and data-driven risk assessments, thereby supporting more effective coal mine safety management and control strategies. The proposed research framework is illustrated in Figure 3.

Figure 3.

Research framework.

3. Results and Analysis

3.1. Identification Results of Risk Factors

This study employs large language models (LLMs) to extract risk factors from accident investigation reports, driven by the following three primary considerations:

- (1)

- Transfer Learning Advantages. LLMs are deep neural networks designed to process natural language and generate coherent text. Trained on vast text corpora (e.g., Wikipedia, books, news articles, and web pages), they have demonstrated outstanding performance across various natural language processing (NLP) tasks. The application of transfer learning allows these models to rapidly adapt to new tasks, such as risk factor identification, significantly enhancing both training efficiency and accuracy [134,135]. Through transfer learning, pretrained models are fine-tuned to meet specific task requirements, thus circumventing the complexities and resource demands of training from scratch. This approach not only optimizes model deployment speed and performance but also substantially boosts research and practical application efficiency.

- (2)

- Deep Semantic Understanding. LLMs, particularly those based on multi-layer Transformer architectures, are equipped to grasp and analyze the deep semantic structures and latent information embedded in the text [136,137]. This advanced capability enables these models to accurately extract risk factors that may not be immediately apparent from the complex structures of accident reports. Deep semantic understanding is particularly critical when processing large volumes of unstructured text data, providing robust technical support for the precise identification of risk factors.

- (3)

- Entity Relationship Extraction. LLMs (e.g., GPT and BERT), having been pretrained on extensive textual data, acquire sophisticated linguistic patterns and are fine-tuned for specific tasks such as entity relationship extraction. By leveraging attention mechanisms, these models focus on pivotal information within the text, using contextual understanding to identify and deconstruct complex relationships [138,139]. As a result, LLMs excel in extracting and interpreting entities and their interrelationships within intricate textual data. This capacity is particularly valuable for analyzing causal relationships, thereby enhancing our understanding of the interactions between risk factors in coal mine accidents.

Given the inherent capabilities of LLMs, utilizing them to extract risk factors from coal mine accident investigation reports presents a highly effective and justified approach. Drawing on their formidable transfer learning capacity, deep semantic comprehension, and efficient entity relationship extraction, LLMs are well suited to process and analyze complex accident reports, providing essential support for the precise identification and extraction of potential risk factors. To further optimize the efficiency of LLM deployment for text analysis, this study utilizes an API-based approach for model invocation.

3.1.1. Prompt Design

Prompting is a technique that involves meticulously crafting input text to guide a pretrained large language model (such as GPT-3) in generating the desired output [140,141]. This method has demonstrated remarkable efficacy and wide applicability across a variety of domains, including information extraction, text generation, and question answering systems [142,143]. When utilizing large language models to extract risk factors from coal mine accident investigation reports, the design of effective prompts is crucial. By strategically formulating input prompts to mirror human reasoning processes, the performance and efficiency of large language models in tasks involving logical reasoning, computational analysis, and decision support can be significantly enhanced, leading to clearer and more interpretable output.

First and foremost, the design of input prompts must be specific, unambiguous, and precise, as this is essential for enabling the model to accurately identify and extract key information, such as deficiencies in safety management and instances of employee misconduct. A well-crafted prompt not only enhances the relevance and accuracy of the model’s outputs but also bolsters its effectiveness in real-world applications. By optimizing the design of input prompts, the overall performance of the model can be significantly improved, making it more applicable and reliable in complex, dynamic environments. Moreover, adopting a chain-of-thought approach plays a crucial role in augmenting the efficacy of prompt design. Chain-of-thought, or causal reasoning, is a cognitive process that systematically links information points through logical sequences [144,145]. In the context of prompt design, utilizing this approach ensures that each step builds on the result of the previous one, thus forming a coherent and structured logical progression. This method enhances the systematicity and effectiveness of the prompt design, ensuring that each element of the prompt is functionally interconnected. Coal mine accident investigation reports typically encompass various sections, including the company profile, accident location, sequence of events, causes of the accident, and accountability. The risk factors influencing coal mine accidents are predominantly found in the section on accident causes, which are further categorized into direct and indirect causes. Direct causes refer to the specific events or actions that directly triggered the accident, while indirect causes are more concerned with the underlying risk factors that contributed to the occurrence. Given the distinct nature of how direct and indirect causes are described in accident reports, this study will develop separate prompts for extracting information related to direct causes and indirect causes, ensuring that each set of risk factors is addressed appropriately.

To ensure that the prompt design meets the highest standards and is practically viable, this study conducted rigorous validation across several state-of-the-art large language models, including Kimi, ChatGPT, and Tongyi Qianwen [146,147,148]. Identical prompts were applied across all models to systematically evaluate their performance in recognizing and extracting key information under different conditions. The results revealed a high level of consistency and strong effectiveness across all tested models, providing compelling evidence for the applicability and validity of the proposed prompt design. This outcome not only further affirms the reliability of the approach but also establishes a solid theoretical and practical foundation for its broader application in future contexts.

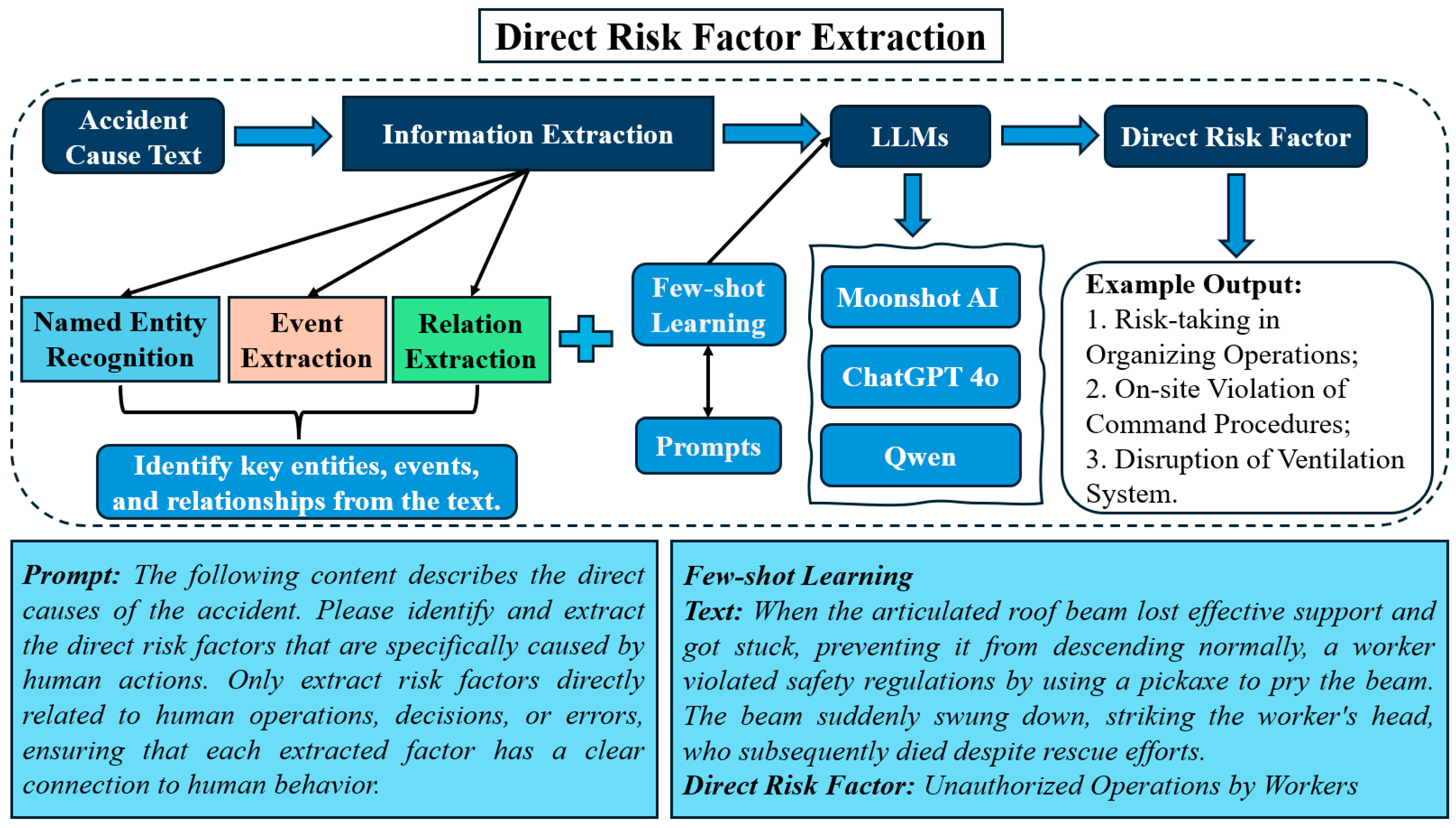

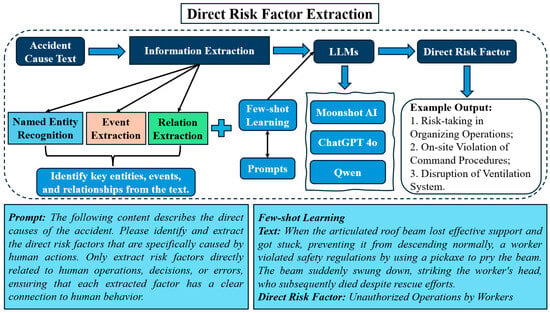

3.1.2. Direct Risk Factor Identification Results

This study utilizes large language models, with carefully crafted prompts, to extract direct risk factors from the direct causes of accidents. By conducting an in-depth analysis of coal mine accident reports and integrating the field’s systematic definitions of direct risk factors, we designed a specialized set of prompts for risk factor extraction. These prompts ensure that the model can accurately identify and extract critical factors. The direct causes encompass the triggering events leading to accidents, which include human behavior, equipment and technical failures, environmental changes, and managerial negligence. When designing text prompts to extract risk factors from the direct causes, particular emphasis is placed on various triggering events, especially human behavior-related factors such as violations of safety protocols or improper operations. To ensure the large language model accurately identifies and extracts risk factors from the direct causes—while avoiding erroneous inferences or excessive generalization—the prompts are exclusively focused on human behavior-related events. Other types of accident triggers are categorized under indirect causes. To further enhance the model’s recognition performance, this study integrates a few-shot learning approach. By providing specific examples of risk factor extraction (including accident text and corresponding annotations), the model is trained to enhance its accuracy. The prompts direct the model’s attention to specific tasks, thereby improving precision, while few-shot learning enables the model to effectively learn despite limited annotated data. The synergy of these two strategies not only strengthens the model’s reasoning capabilities but also enhances its adaptability in complex scenarios, significantly improving both its generalization ability and its practical application in real-world contexts. The process is illustrated in Figure 4, and the results of direct risk factor extraction are presented in Table 3.

Figure 4.

Direct risk factor extraction process.

Table 3.

Direct risk factors.

The extracted direct risk factors primarily encompass irregular operational behaviors, insufficient implementation of safety measures, deficiencies in on-site management, and violations of technical specifications. First, non-compliance with operational procedures by workers, unauthorized actions, and failure to implement essential safety precautions were identified as direct triggers of the accidents. These deviations from standard practices were pivotal in increasing the likelihood of incidents. Second, inadequate enforcement of safety measures, such as failing to reinforce supports as mandated or proceeding with excavation without addressing potential hazards, further amplified the operational risks. In terms of on-site management, the prevalence of unauthorized commands and illegal production practices resulted in a breakdown of safety oversight. Additionally, violations of technical standards, including insufficient support strength and disorganized ventilation systems, contributed to escalating the accident risks. Together, these factors represent the primary sources of direct risks in coal mine accidents, underscoring critical vulnerabilities in operational procedures and safety management.

3.1.3. Indirect Risk Factor Identification Results

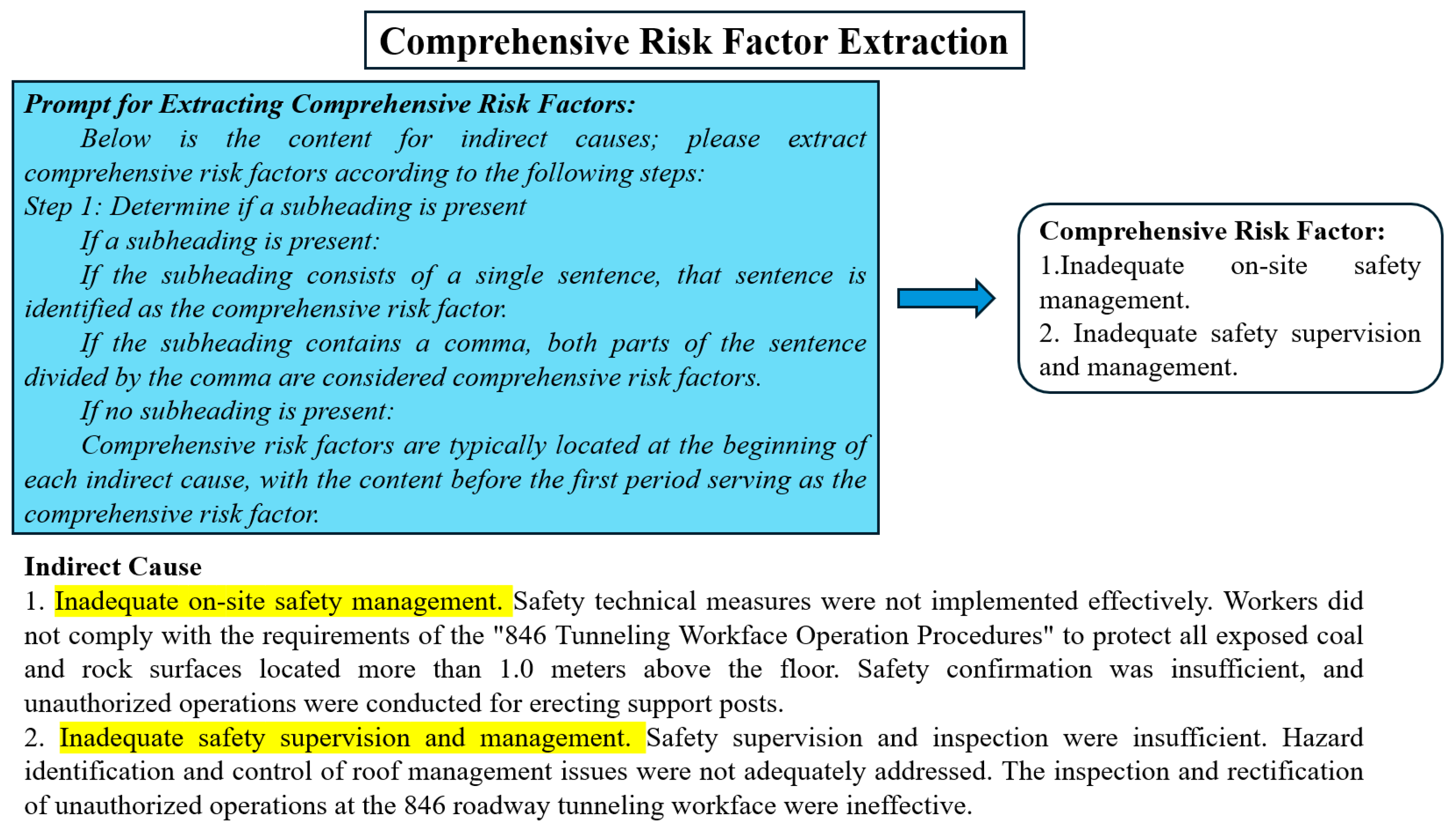

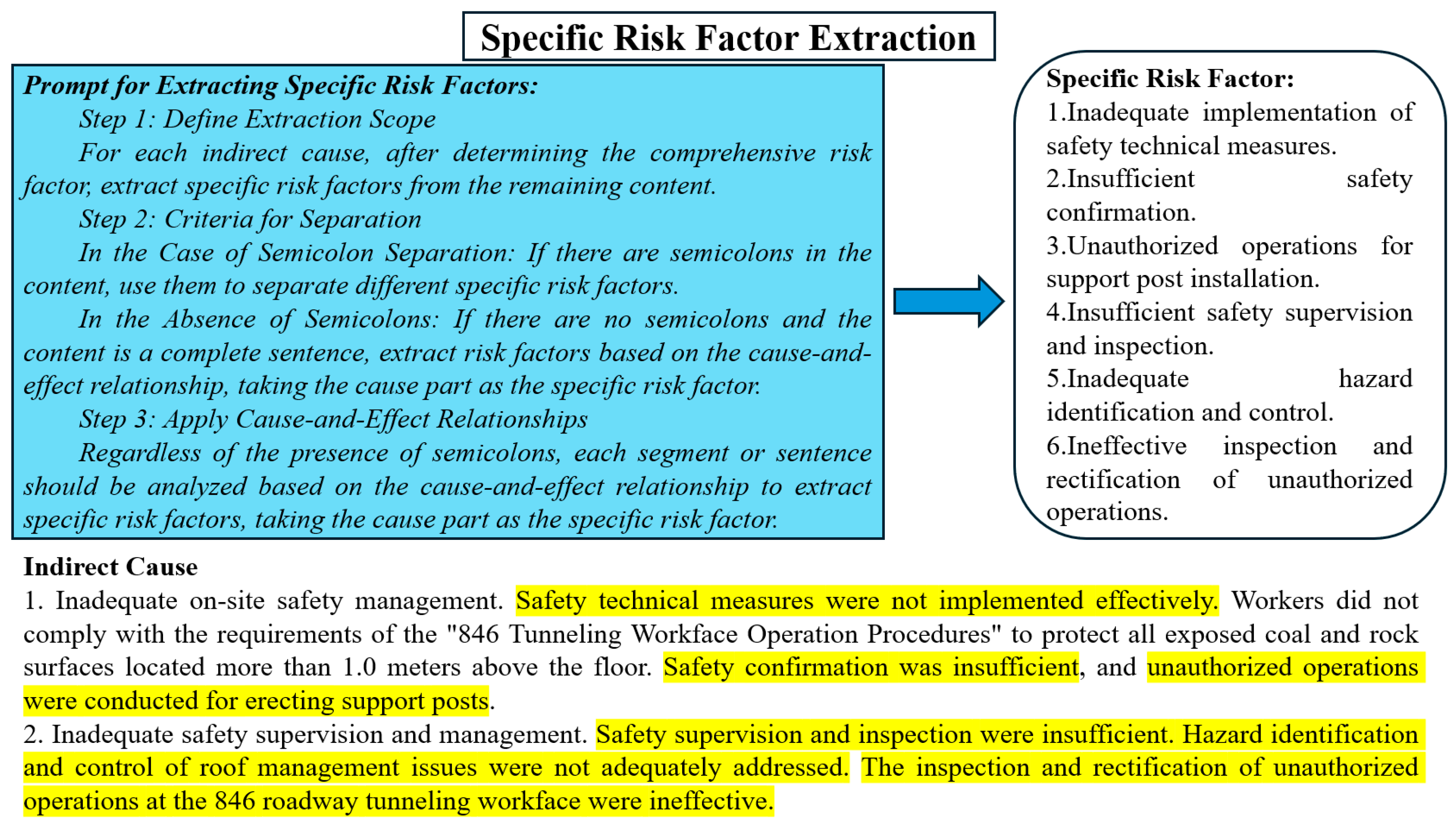

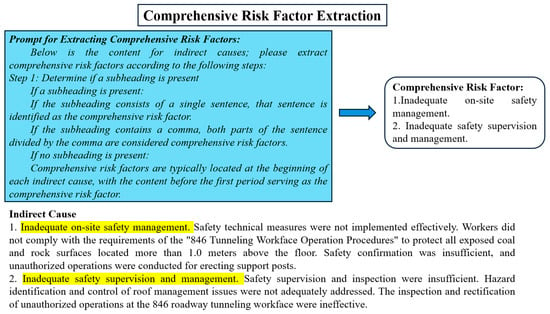

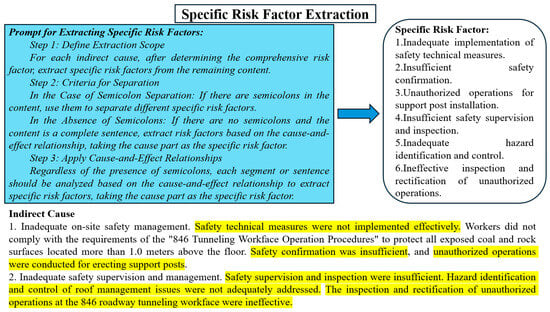

The identification and extraction of both composite and specific risk factors must be conducted from the indirect causes of coal mine accidents. The indirect causes section uncovers the deeper, underlying reasons for the triggering events of the accidents, such as deficiencies in site management, inadequate safety training, and the failure to effectively implement corporate responsibilities. These indirect causes are typically presented in a list format in coal mine accident investigation reports, with each cause being distinct and independent. When risk factors arise from the same indirect cause, a high degree of interrelationship exists among them. Each indirect cause typically encompasses one composite risk factor and several specific risk factors, with the latter representing concrete manifestations of the former. Therefore, when designing the text prompts for the identification and extraction of risk factors from the indirect causes, each cause should be addressed individually. The extraction process should follow a methodical approach, considering the hierarchical structure and causal relationships of the risk factors. The extraction procedures for both composite and specific risk factors are aligned with those for direct risk factors, employing a combined strategy of text prompts and few-shot learning. Figure 5 and Figure 6 present the text prompts used for extracting composite and specific risk factors, and the extraction results are displayed in Table 4 and Table 5, with the extracted risk factors highlighted in yellow.

Figure 5.

Comprehensive risk factor extraction process.

Figure 6.

Specific risk factor extraction process.

Table 4.

Comprehensive risk factors.

Table 5.

Specific risk factors.

Based on the extraction results, the composite risk factors predominantly span several critical areas, including management, technical operations, safety education and training, and safety supervision, along with the implementation of responsibilities. First, risks associated with management highlight significant deficiencies in the safety management systems and their enforcement within coal mining enterprises. These include violations of operational procedures and negligence in safety practices, underscoring the enterprise’s insufficient emphasis on safety management, which creates substantial gaps in the execution of safety protocols. Second, the risks within technical operations are primarily linked to inadequate operating procedures and neglect in equipment management. The lack of effective standards and controls not only amplifies safety hazards but also severely diminishes the enterprise’s capacity to anticipate and mitigate potential risks during production. Risks concerning safety education and training primarily stem from weak safety awareness among workers and insufficient training programs. This results in a lack of essential skills for risk identification and emergency response, thereby further increasing the likelihood of accidents. Finally, risks in safety supervision and the implementation of responsibilities expose deeper, systemic issues in the enterprise’s safety oversight, responsibility systems, and institutional enforcement. These include ineffective supervision and inadequately implemented accountability structures, reflecting the enterprise’s failure to fully discharge its safety obligations and resulting in lapses in safety management. These composite risk factors are deeply interrelated and represent fundamental weaknesses within the safety management systems of coal mining enterprises. They indicate that accidents are rarely attributable to a single cause but rather emerge as the inevitable result of multiple, interconnected factors. Thus, the accurate identification and effective management of these composite risks are not only essential for preventing accidents but also for enhancing the overall safety management system and ensuring production safety.

Based on the extraction results, the specific risk factors primarily encompass the following aspects. First, the inadequate implementation of safety management is a significant issue, evident in the failure to strictly adhere to on-site safety protocols, the delayed correction of unsafe practices, the neglect of safety inspection responsibilities, and disorganized on-site management. These issues expose critical deficiencies in the enforcement of safety management systems and the overall robustness of the management framework within coal mining enterprises. Second, the deficiency in safety education and training emerges as a pressing concern. This is particularly reflected in the weak safety awareness of workers, insufficient risk identification capabilities, and the superficial nature of training programs, which highlight the enterprise’s considerable shortcomings in enhancing employees’ safety knowledge. As a result, employees lack the necessary knowledge and emergency response skills to adequately address potential risks. Third, risks in technical operations primarily center around inadequate support measures, non-compliance with safety technical specifications, and violations of operational procedures. These issues point to significant weaknesses in the management of technical operations and the absence of effective safety standards, further exacerbating safety hazards during production. Fourth, the failure to enforce safety supervision and responsibility is evident in the lack of clarity around safety responsibilities, the formalized nature of safety inspections, and the inadequate performance of both higher-level companies and local regulatory bodies. These factors underscore structural deficiencies in the enforcement of safety production responsibilities and regulatory frameworks, rendering safety management systems largely ineffective. Lastly, deficiencies in emergency management and production organization are reflected in the failure to promptly identify and eliminate safety hazards, insufficient emergency response equipment, and poor coordination of production activities. These issues collectively heighten the potential for accidents, further amplifying the risks to safety.

In conclusion, the risk factors extracted in this study offer a profound reflection of the management deficiencies and safety vulnerabilities present at multiple levels within coal mining enterprises. These issues not only highlight gaps in day-to-day management but also emphasize the disjointedness and inefficiencies in the implementation of safety measures, which in turn increase the likelihood of accidents. To verify the accuracy and validity of the extracted risk factors, this study extracts risk factors using multiple large language models to verify consistency across models, thereby validating the effectiveness of the designed prompts in risk factor extraction. Simultaneously, the results are compared with manually extracted risk factors to provide additional assurance of the accuracy and effectiveness of the extraction process. These comparative analyses demonstrate the feasibility and reliability of the proposed extraction method in practice. A thorough analysis and effective response to these overarching risk factors are essential for enhancing the safety management standards of coal mining enterprises, ensuring operational safety, and mitigating the occurrence of accidents. Therefore, addressing these issues through targeted corrective actions is pivotal to achieving sustainable safety management and establishing a robust safety framework within coal mining enterprises.

3.2. Association Rule Mining Analysis

The occurrence of coal mine accidents is typically the result of the interaction of multiple risk factors. By identifying and mitigating the key risk factors and their propagation pathways, the frequency of such accidents can be significantly reduced. Accordingly, this study aims to identify and analyze critical risk factors based on those extracted by a large language model for coal mine accidents. The Apriori algorithm is employed to mine association rules from the Boolean dataset of coal mine accident risk factors, enabling the discovery of highly frequent itemsets and strong associations between risk factors. This analysis will provide a solid foundation for the identification and analysis of key risk factors, as well as for the construction of the Bayesian network topology.

When applying the Apriori algorithm for association rule mining, it is crucial to establish two key variables—support and confidence—whose threshold values directly influence the results of the mining process. The current academic literature on association rule mining reveals that there is no universally accepted standard for determining the minimum support and confidence thresholds. To strike a balance between minimizing the generation of irrelevant rules and ensuring the inclusion of significant associations, this study employs an iterative trial-and-error method to determine the optimal threshold combinations. After extensive testing and incorporating feedback from experts and coal mine management, the identified strong association rules were compared and analyzed against the operational rules and practices of coal mine production. Ultimately, the minimum support threshold was set at 0.5, the minimum confidence threshold at 0.4, the maximum number of antecedents was limited to 3, and the minimum lift threshold was set to 1. Through association rule mining, a set of highly frequent itemsets (see Table 6) and 281 strong association rules were derived (some of the results are shown in Table 7). The risk factors within the highly frequent itemsets indicate that these factors consistently appear in coal mine accidents and are key contributors to their occurrence. As seen in Table 6, the number of direct and comprehensive risk factors is relatively small, while specific risk factors are more numerous, underscoring the dominant role that specific risk factors play in triggering coal mine accidents. Furthermore, an analysis of the strong association rules shows that these rules are consistent with the established safety management protocols and procedures in coal mine operations, thus providing an accurate representation of the causal relationships between risk factors. For instance, the first association rule in Table 7 involves specific risk factors {S17, S5, S29, S14} and a comprehensive risk factor {C2}. These four specific risk factors all point to the inadequate management of on-site safety risks, while the comprehensive risk factor C2 represents “insufficient implementation of on-site safety measures”. This rule suggests that when on-site safety risks are not effectively addressed in a timely manner, they are strongly associated with the inadequate execution of safety measures, which, in turn, significantly heightens the likelihood of an accident occurring.

Table 6.

The extremely frequent itemset of risk factors.

Table 7.

Strong association rules (partial).

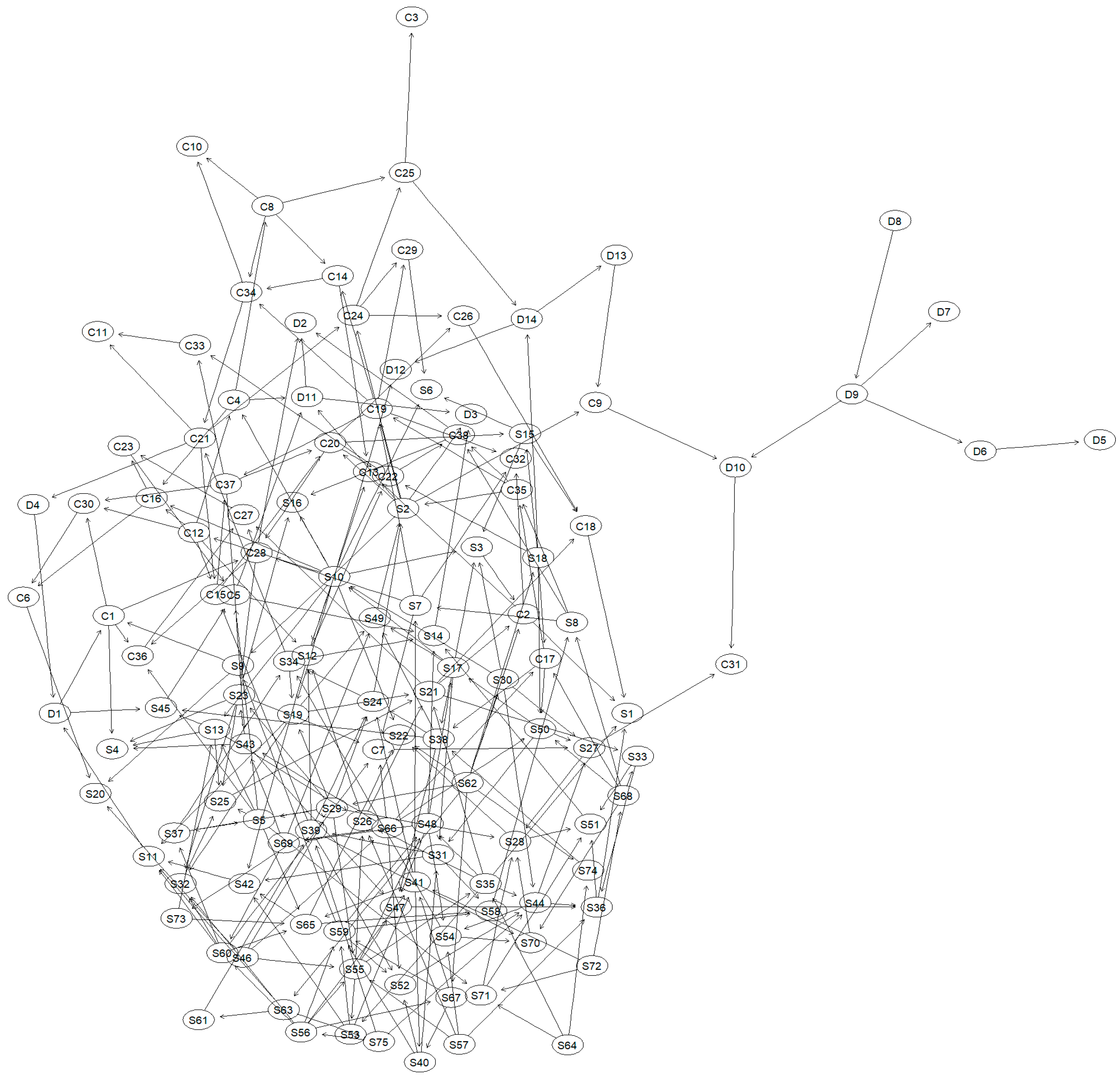

Based on the results of association rule mining on coal mine accident risk factors, a Bayesian network topology was constructed. In this network, the antecedents and consequents of strong association rules were used as nodes, while their relationships were represented by directed edges [149,150]. To ensure the structural validity of the Bayesian network, the network design strictly adhered to the directed acyclic graph (DAG) property, preventing the formation of directed cycles and ensuring the correct propagation of information and the effective computation of probabilities in Bayesian inference. This study employs a strong association rule-based approach as an initial structural learning method for the Bayesian network [151,152]. Its primary advantage lies in its ability to rapidly extract frequent dependencies among risk factors, thereby improving modeling efficiency and providing an intuitive initial network topology. However, since association rules identify correlations between variables based on co-occurrence frequency, they do not inherently imply causal relationships, which may introduce spurious associations. To address this issue, after the initial network construction, the structure was refined using causal constraints, theoretical analysis, and expert knowledge to enhance the reliability of causal inference [153]. Compared to score-based learning approaches, such as those using the Bayesian Information Criterion (BIC) and Akaike Information Criterion (AIC), the strong association rule-based approach offers greater computational efficiency and interpretability, making it particularly suitable for large-scale datasets and scenarios where expert knowledge is limited. However, score-based approaches optimize the network structure globally, ensuring the best model fit while mitigating the influence of spurious associations. Nonetheless, these methods entail high computational complexity, making them less efficient for large datasets. To achieve a balance between efficiency and accuracy, this study integrates the strengths of both approaches: strong association rules are first used to identify highly correlated variables, followed by causal constraint optimization to ensure that the final Bayesian network structure aligns with both data characteristics and the theoretical framework and practical standards of coal mine safety management.

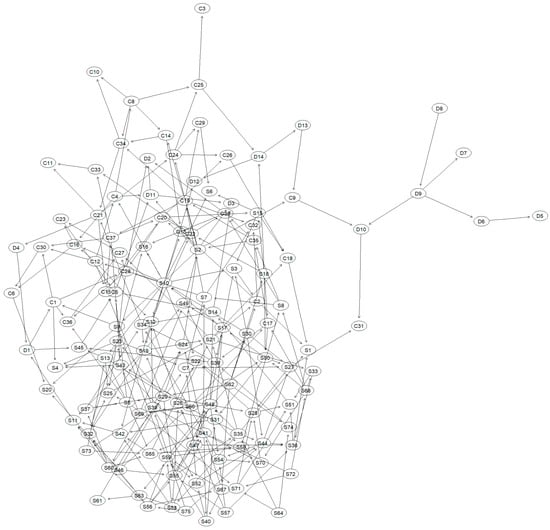

Following the initial construction of the Bayesian network topology, the causal relationships within the network were systematically evaluated and refined based on theoretical analysis and domain knowledge. This process ensured that the network structure was not only consistent with the results of data-driven association rule mining but also aligned with established theoretical frameworks and industry standards, thereby enhancing its accuracy and reliability. Specifically, association rule mining was employed to extract potential causal relationships, which were then subjected to structural validation and causal constraint refinement based on theoretical knowledge and industry standards in the field of coal mine safety. The evaluation criteria primarily included theoretical consistency, causality direction correctness, and the adequacy of empirical data support. The evaluation process focused on three key aspects: First, ensuring that the directionality of causal relationships adheres to established theoretical principles to prevent erroneous causal inference; second, identifying and eliminating spurious correlations, meaning that if an observed association between two variables is driven solely by a third confounding factor rather than a true causal relationship, the connection should be adjusted or removed; and third, improving the interpretability and practical applicability of the network, ensuring that the model not only captures meaningful probabilistic dependencies but also supports evidence-based decision-making in coal mine safety management. Ultimately, the optimized Bayesian network topology (as depicted in Figure 7) represents risk factors as nodes, with directed edges illustrating the probabilistic dependencies and causal relationships between these factors. This refined network structure reduces potential errors in causal inference, enhances the model’s stability and interpretability, and provides a robust scientific foundation for further analysis of key risk factors in coal mine accidents using Bayesian network methodology.

Figure 7.

Bayesian network topology structure.

3.3. Main Risk Factor Analysis of Coal Mine Accidents

The construction and analysis of the Bayesian network for coal mine accident risk factors aims to quantitatively identify the critical risk factors contributing to coal mine accidents, thereby facilitating the development of more targeted accident prevention strategies. In this study, the Bayesian network is constructed and analyzed using R, based on the previously established network topology. The parameter learning process is carried out through maximum likelihood estimation. The data used for parameter learning are derived from the risk factor identification results produced by the large language model. The results are processed with Python (v. 3.10.9.) and converted into the format required for parameter learning. The binary values (0/1) are mapped to “F/T,” where “0” represents the non-occurrence of a particular risk factor (F) and “1” represents its occurrence (T). This conversion prepares the data for Bayesian network parameter learning. Subsequent analyses include sensitivity analysis, critical path analysis, and frequency statistical methods to systematically identify and summarize the key risk factors influencing coal mine accidents.

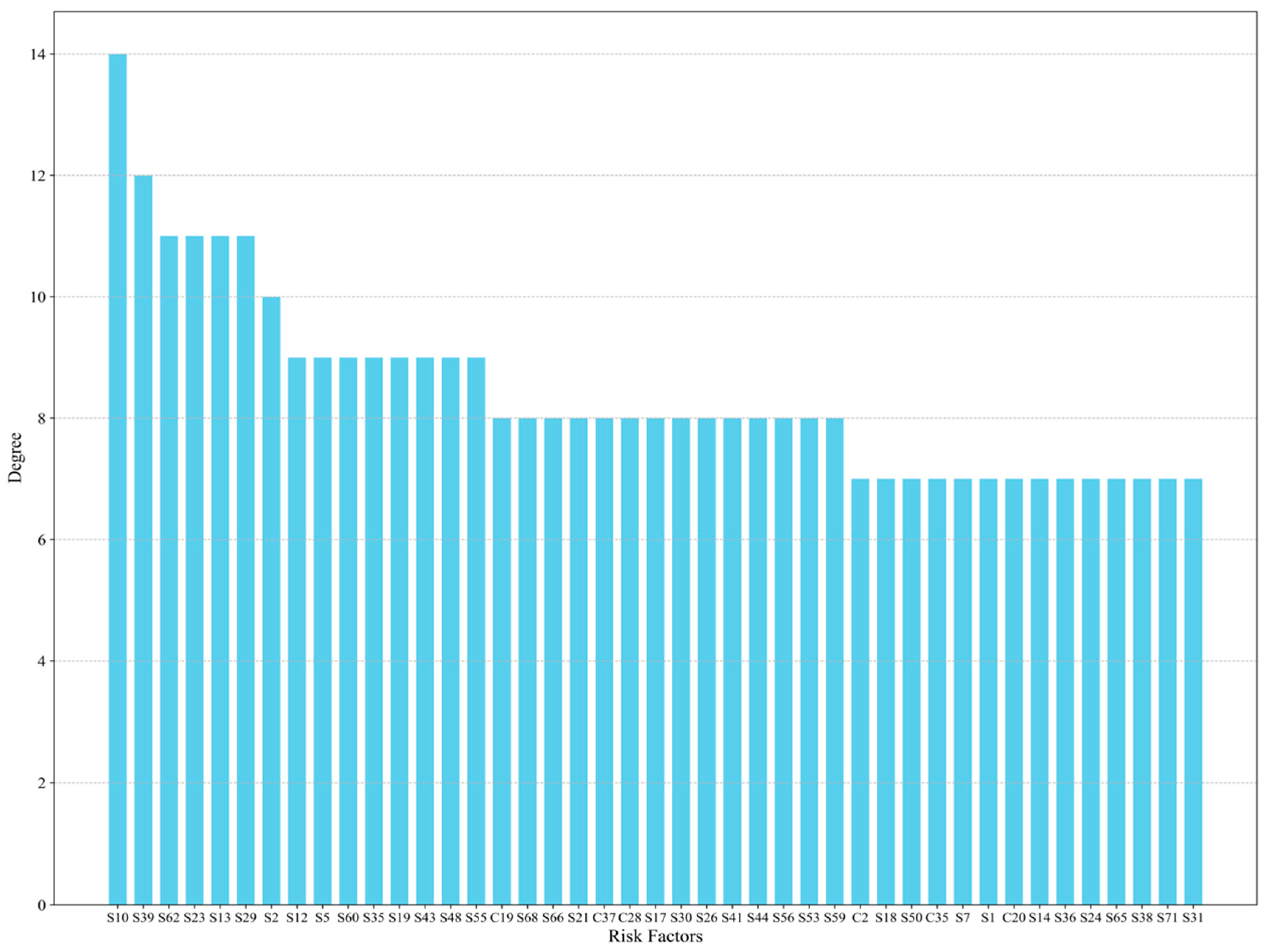

3.3.1. Sensitivity Analysis

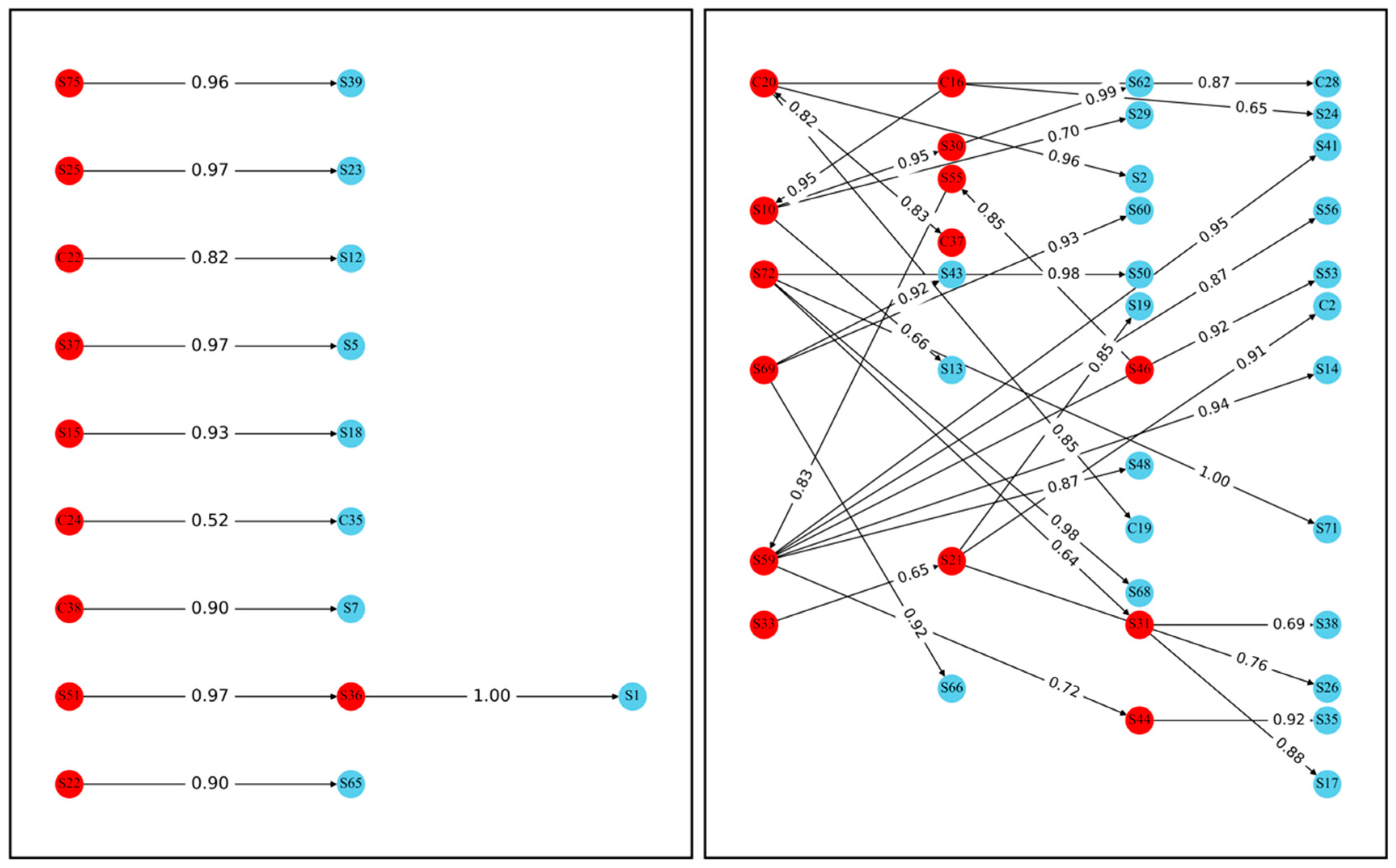

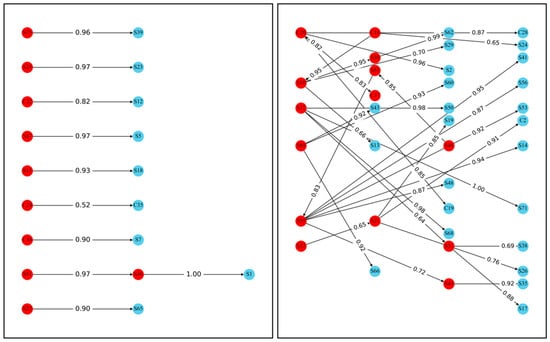

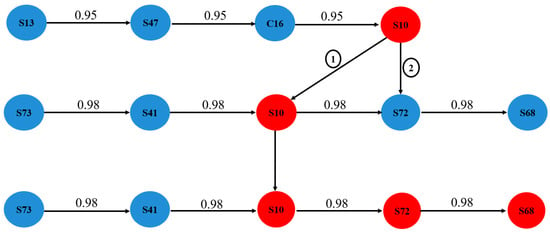

Sensitivity analysis is a vital tool in Bayesian networks, employed to quantify the influence of uncertain factors in input nodes on the target variable. In this study, R is utilized to conduct a sensitivity analysis of the nodes within the Bayesian network to identify the key risk factors. The application of sensitivity analysis to coal mine accident risk factors facilitates the identification of those factors that significantly affect the occurrence of coal mine accidents. The first step in sensitivity analysis is to define the target node. In this research, the average degree and the upper quartile of all nodes in the Bayesian network are computed to identify nodes with higher degrees, which are then regarded as important nodes. Through this process, 43 critical nodes were selected (see Figure 8), and these selected nodes are highlighted in red. Each of these 43 nodes is treated sequentially as the target node, with the remaining nodes acting as evidence nodes for sensitivity analysis. In each iteration, only the evidence node with the greatest influence on the target node is retained, and the sensitivity analysis threshold is set to 0.5. The results of the analysis are presented in Figure 9, where red nodes represent evidence nodes (those with the greatest impact on the target node), and blue nodes represent the target nodes.

Figure 8.

Node degree.

Figure 9.

Sensitivity analysis results.

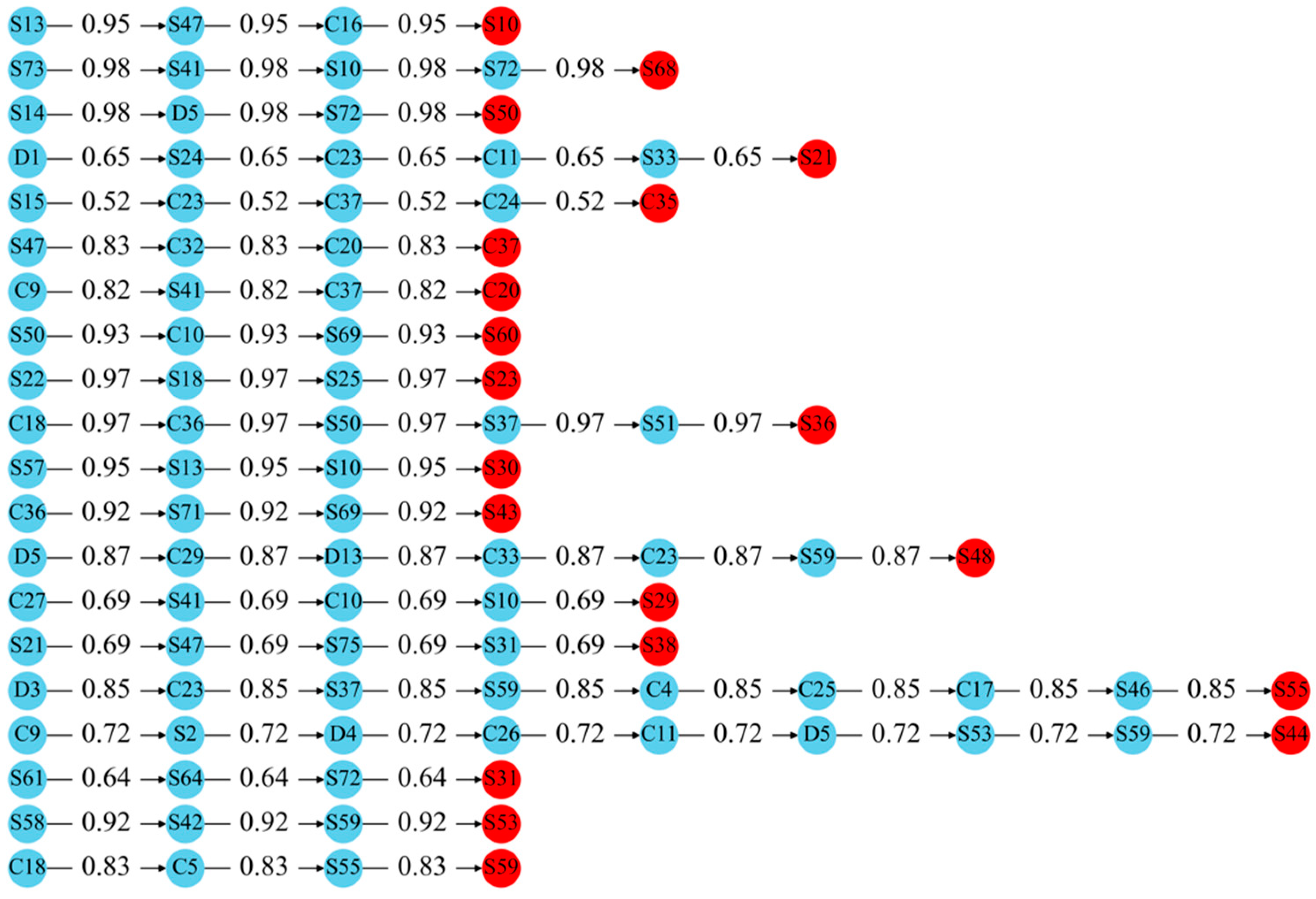

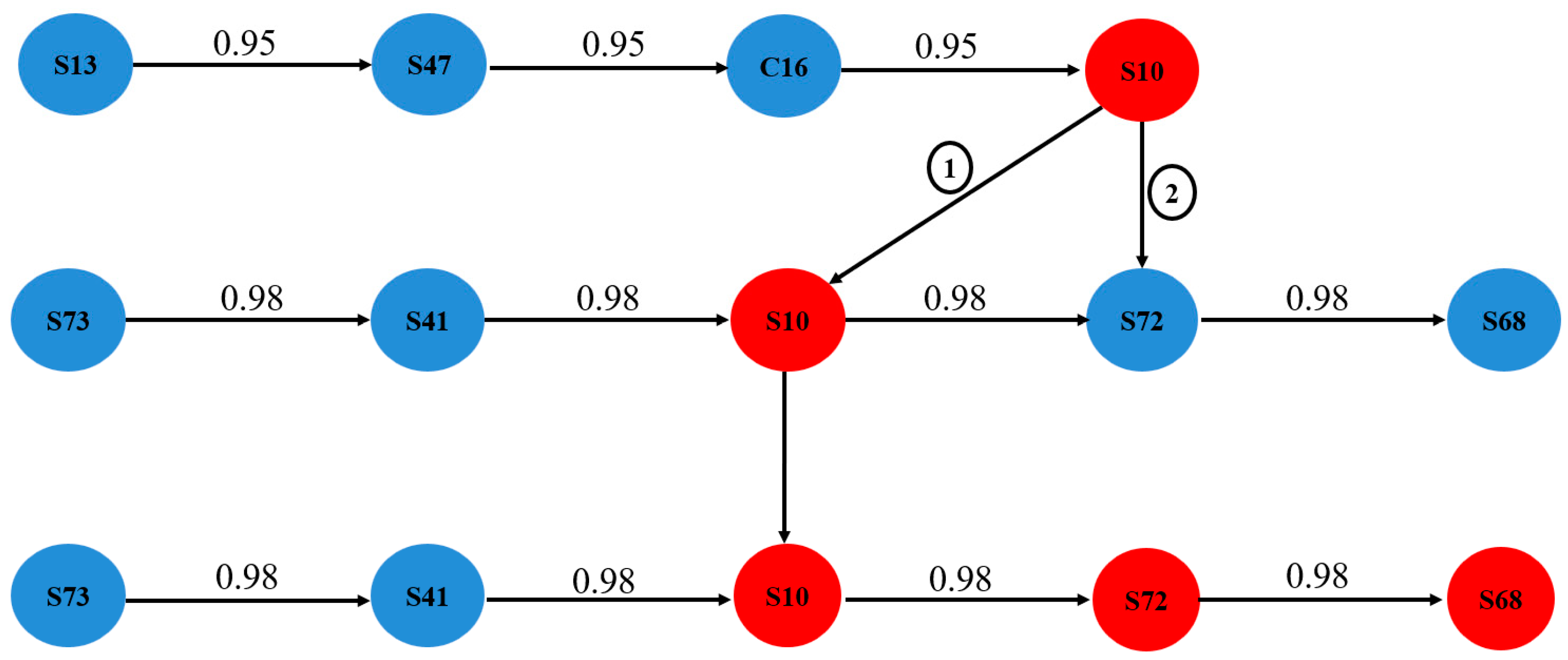

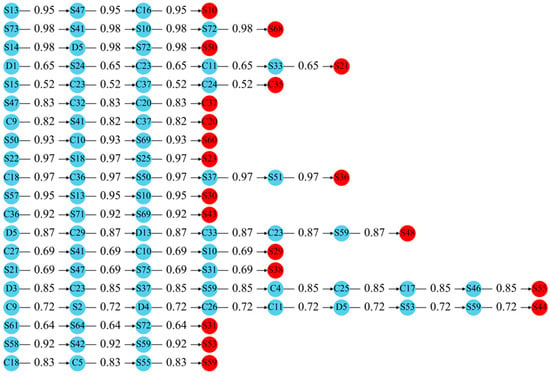

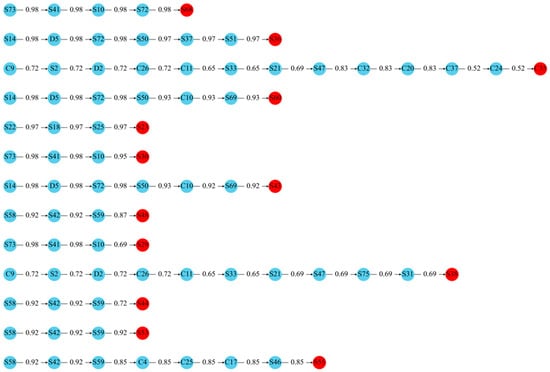

From the analysis, it is apparent that different evidence nodes exert significantly different influences on the target node. Further examination reveals that some nodes function both as target and evidence nodes, signifying that their influence within the network extends beyond merely being affected by other nodes; they also influence other nodes. Based on this observation, a sensitivity analysis chain is constructed. In this process, the most influential evidence node identified in the previous analysis is designated as the target node, and the search for the next most influential evidence node continues recursively until no further nodes meet the required conditions. The sensitivity analysis threshold remains at 0.5. To ensure the depth and robustness of the analysis, the number of nodes in the sensitivity chain must be at least four. The aim of sensitivity chain analysis is to progressively uncover the influence of the original target node within the network by identifying evidence nodes with the greatest impact on the target node. In this process, only the evidence node with the greatest influence on the target node is retained, which then becomes the new target node for subsequent recursive analysis. This iterative process results in multiple sensitivity chains, as shown in Figure 10, with the red nodes representing the initial target nodes. Upon reviewing the sensitivity chains, it becomes clear that although the initial target nodes vary across the chains, certain nodes appear in multiple chains. Furthermore, the sensitivity analysis results for these common nodes are not consistent. To ensure the optimality of the sensitivity analysis results for all nodes in the chain, the chains are merged. The merging process is depicted in Figure 11. Starting from the initial target node of each chain, the most influential preceding node is identified and treated as the new starting point. The search for the most influential preceding node continues until no more nodes meet the required criteria. Similarly, starting from the initial target node, the most influential succeeding node is identified across all chains, with the process continuing until no further qualifying nodes are found. The final sensitivity chain analysis results are shown in Figure 12, where red nodes represent the initial target nodes of each chain. Based on this analysis, 13 high-sensitivity risk factors were identified: S68, S36, C35, S60, S23, S30, S43, S48, S29, S38, S44, S53, and S55. The sensitivity analysis results illuminate the complexity of the mechanisms underlying coal mine accidents. These high-sensitivity risk factors have a substantial impact on the occurrence of coal mine accidents. To effectively reduce the frequency of such accidents, coal mine enterprises should prioritize managing and mitigating the safety risks associated with these high-sensitivity factors.

Figure 10.

Initial outcomes of sensitivity chain analysis.

Figure 11.

Process of sensitivity chain merging.

Figure 12.

Risk factor sensitivity analysis chains.

3.3.2. Critical Path Analysis

In this study, risk factors are categorized into three types: direct risk factors, comprehensive risk factors, and specific risk factors. Direct risk factors are those closely associated with human behavior and have the potential to directly trigger coal mine accidents. These factors include operational errors, violations, and inappropriate responses during emergencies. Typically, they are directly triggered by the decisions and actions of on-site personnel and have a direct causal relationship with the occurrence of accidents. Comprehensive risk factors, in contrast, are systemic or managerial issues that indirectly increase the likelihood of accidents by influencing the quality of corporate management, the implementation of safety protocols, and the enforcement of oversight mechanisms. These include gaps in management systems, inadequate training, insufficient supervision, and resource shortages. Although these factors may not directly initiate accidents, they significantly amplify the severity of other risk factors, thus exacerbating the risk. Specific risk factors refer to potential hazards that might lead to accidents under particular environmental or situational conditions, often linked to specific workflows or locations. These factors include hazards within the work environment, the risk of equipment or process failures under certain conditions, and time-dependent risks. While these factors may not directly cause accidents, they can significantly escalate the likelihood of an accident under the right conditions. Given the inherent characteristics of these three categories of risk factors, this study focuses on comprehensive risk factors as target nodes in key path analysis, based on causal relationships. While direct risk factors are closely tied to human behavior and often serve as direct triggers of accidents, their impact is typically short-term and immediate. As such, they are not well suited to reflect systemic issues and are therefore excluded from serving as key nodes in path analysis. Although specific risk factors can highlight hazards in particular environments or circumstances, they tend to be localized and condition-dependent, which limits their applicability across varying contexts. Consequently, they are also unsuitable as the primary target nodes for key path analysis. In contrast, comprehensive risk factors have more systemic characteristics and span multiple levels, such as management systems, oversight structures, and safety investments. These factors not only indirectly increase the likelihood of accidents by influencing other risk factors but also provide insight into the overall safety management capabilities of the organization, including the accumulation of long-term risks. Comprehensive risk factors thus offer a broader and more integrated perspective, which is critical for identifying underlying management problems and systemic risks within the organization. For these reasons, this study prioritizes comprehensive risk factors as the target nodes for key path analysis, in order to uncover the deeper managerial issues and systemic risks that underpin accident occurrences.

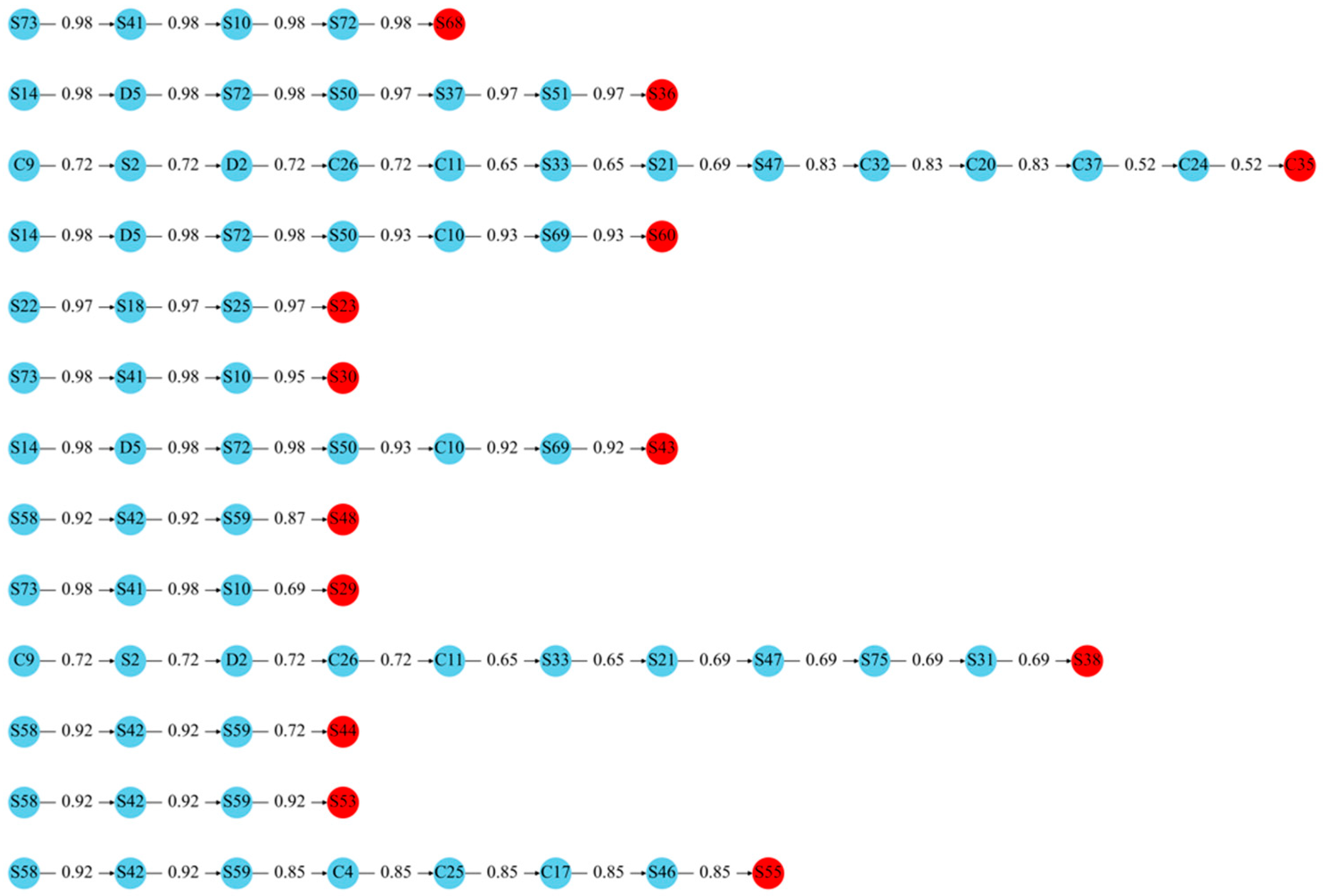

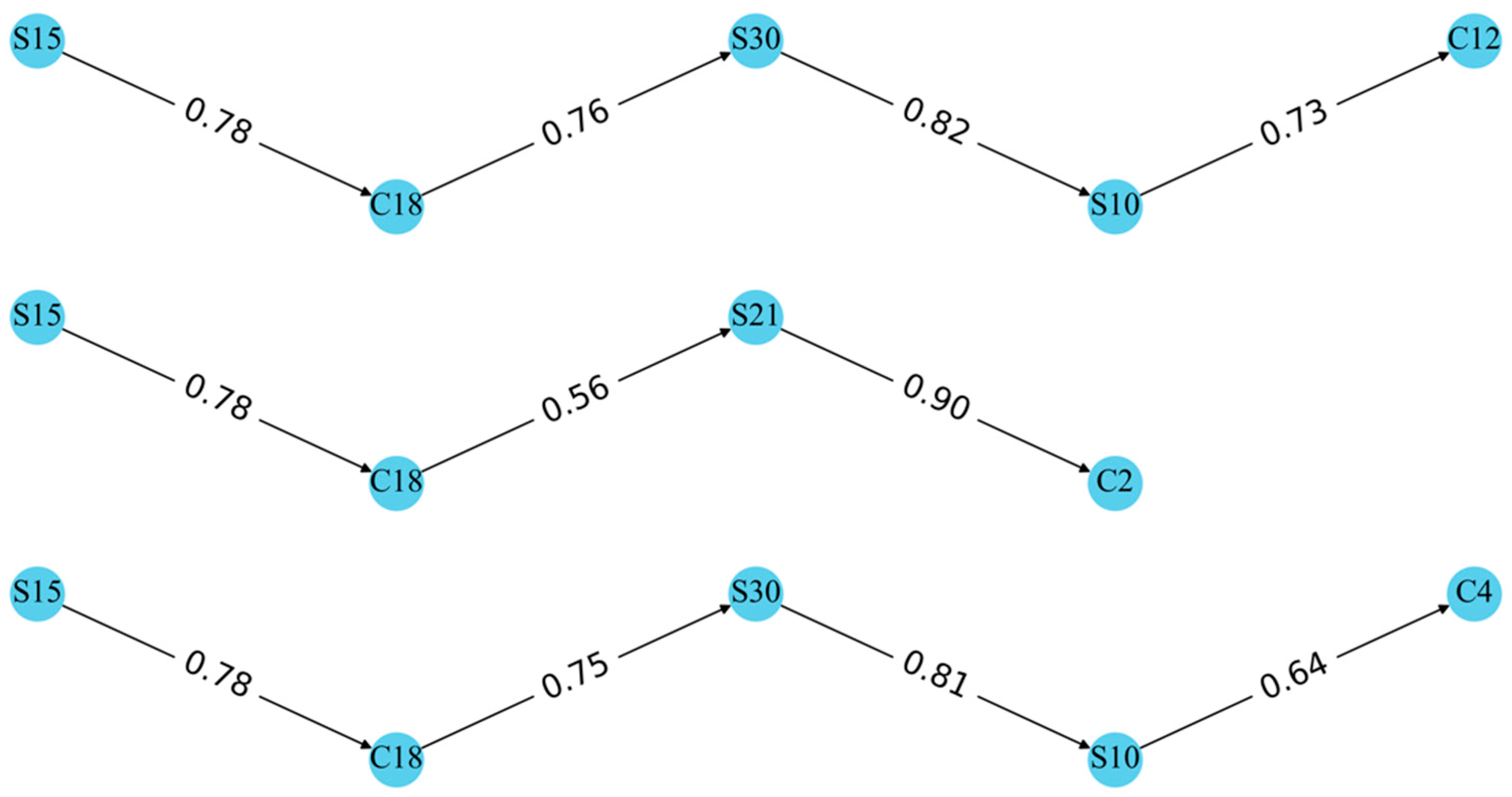

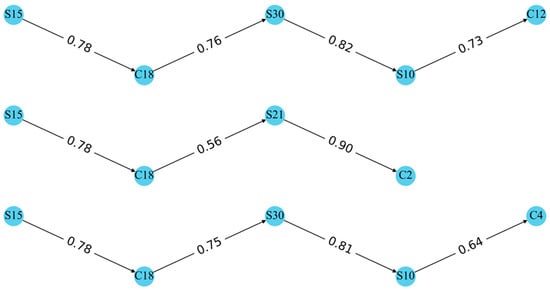

Using Bayesian network diagnostic inference methods for key path analysis, we first identify the parent node with the highest posterior probability from all comprehensive risk factor nodes, signifying that these factors significantly increase the likelihood of coal mine accidents. This parent node is then treated as the new evidence node, and forward and backward inference is carried out to sequentially identify the parent node with the highest posterior probability. These parent nodes represent the primary drivers triggering the previous set of nodes. This process is repeated until no additional nodes can be inferred, resulting in the key path, as shown in Figure 13. The nodes within this key path can be regarded as critical risk factors for coal mine accidents.

Figure 13.

Critical path analysis results.

As illustrated in Figure 13, regardless of the initial parent node chosen, nodes S15 and C18 consistently appear, underscoring a fundamental lack of risk awareness regarding safety production and poor management coordination within coal mining enterprises. Addressing these issues would effectively disrupt the primary path leading to accidents, thereby significantly reducing the likelihood of their occurrence. The key path analysis further reveals that inadequate oversight in the formulation and approval of procedural measures (S30) leads to unclear safety production responsibilities (S10), which in turn triggers insufficient safety supervision (C4) and lapses in on-site safety management (C12). Moreover, the failure to implement on-site safety measures (C2), weak safety culture (C14), and organizational deficiencies in production (S21) further exacerbate the likelihood of accidents. The key path analysis identifies the main risk factors influencing coal mine accidents as follows: C12, C2, C4, S10, S30, C18, S15, and S21.

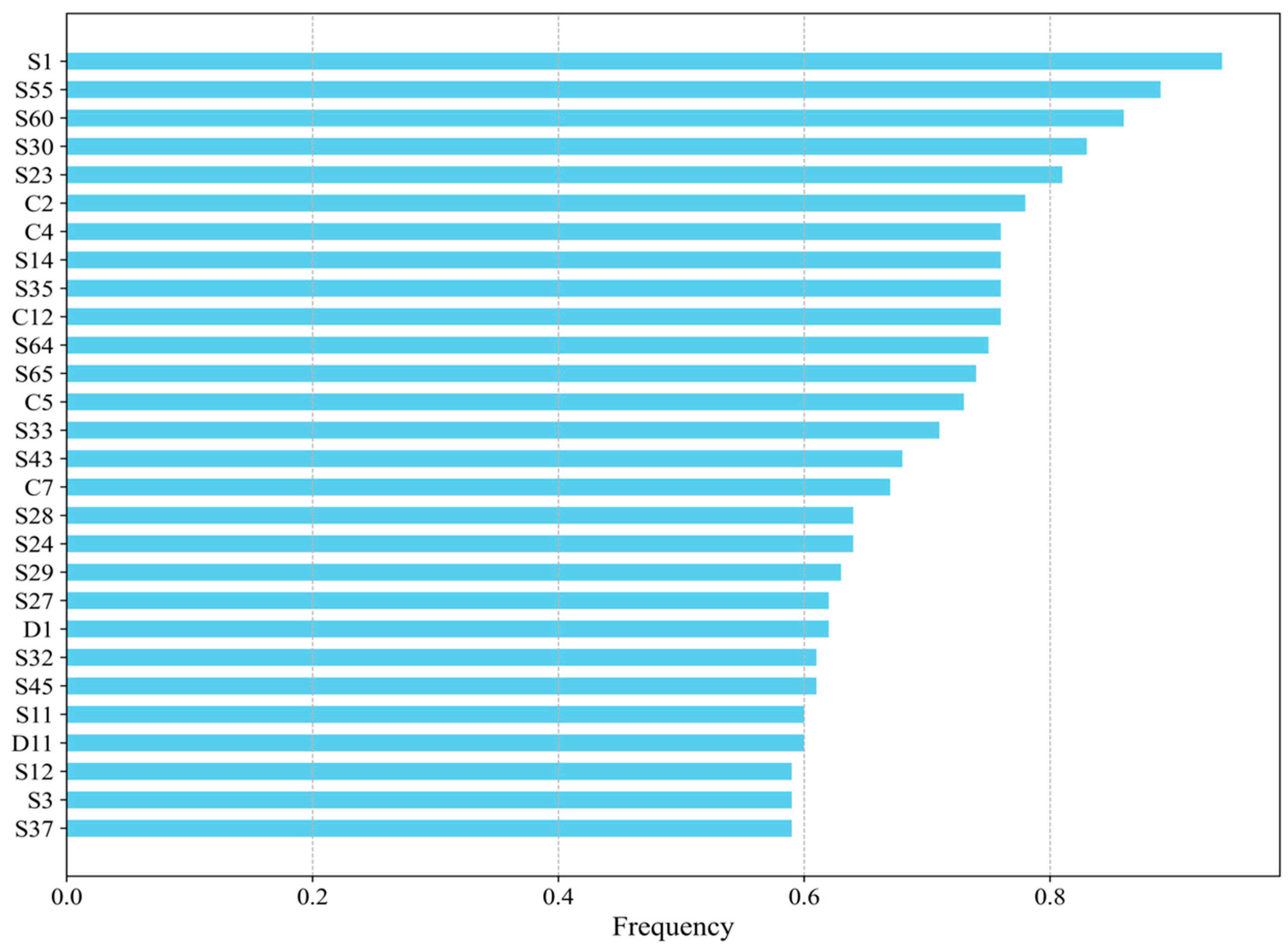

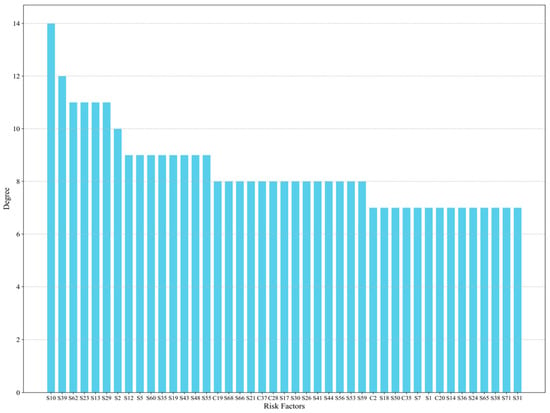

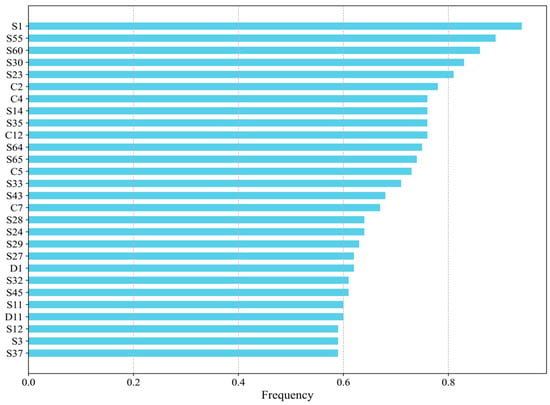

3.3.3. Frequency Statistical Analysis

A further analysis was conducted to assess the frequency of risk factors across all coal mine accident investigation reports (see Figure 14). From Figure 14, the top ten most frequent risk factors are as follows: S1, S5, S62, S39, S7, C2, S4, S14, S23, and S57. The higher the frequency of occurrence, the more likely it is that these risk factors are either overlooked in real-world operations or remain difficult to control within the existing management framework. High-frequency risk factors are often deeply embedded in various stages of the production process, having gone unrecognized and unaddressed over extended periods. This not only amplifies the cumulative effect of latent risks but also plays a significant role in triggering coal mine accidents.

Figure 14.

Frequency statistics of risk factors.

By synthesizing the findings from sensitivity analysis, key path analysis, and frequency statistics, the most critical risk factors contributing to coal mine accidents are identified and summarized in Table 8. Notably, issues such as violations of operational protocols by on-site personnel and inadequate enforcement of regulations are particularly concerning. These reflect significant deficiencies in workers’ safety awareness, operational competence, and risk identification abilities. The root cause of these problems lies in the failure of enterprises to provide effective safety training and technical support. Moreover, the lack of strict oversight in the formulation and approval of safety protocols has led to poor implementation of safety measures. As a result, workers are often unable to adopt appropriate safety precautions in the face of potential hazards, thus elevating the likelihood of accidents.

Table 8.

Bayesian network risk factor analysis results.

Furthermore, the absence of robust on-site management exacerbates the situation. The management has failed to fulfill its core responsibilities, particularly in overseeing and providing technical guidance to subordinate coal mines. This failure has resulted in unresolved safety hazards, thereby increasing the risk of rule violations. The inadequate implementation of safety measures at the operational level has further amplified the probability of accidents. Inadequate supervision and inspections have allowed risks to accumulate unchecked, ultimately creating the conditions for potentially catastrophic incidents.

3.3.4. Analysis of Risk Factors Associated with Main Risk Factors

The primary risk factors in coal mining enterprises’ safety production processes frequently occur and are often concealed, making early detection and control challenging. If these key risk factors are not addressed in a timely and effective manner, the risks will inevitably spread to surrounding nodes, triggering new safety hazards. This diffusion of risk not only heightens the probability of accidents but also complicates the identification and mitigation of safety risks.

For example, consider the major risk factor S23 (On-site workers violated work regulations). When the state of this node is set to T (true), the posterior probabilities of other nodes in the Bayesian network are computed. Among these, nodes S33, C7, S25, and S24 exhibit elevated posterior probabilities, indicating that when node S23 is not effectively controlled, the likelihood of related risk factors occurring significantly increases. Specifically, these factors include S33 (Violation of safety technical measures), C7 (Inadequate technical management), S25 (No safety management organization has been established), and S24 (Failure to follow the instructions of the on-site primary responsible person). A similar analysis of nodes S55, S60, S30, C2, C4, and C12 reveals associated risk factors with higher posterior probabilities, as shown in Table 9.

Table 9.

Associated factors of the main risk factors.

This demonstrates that when key risk factors remain uncontrolled, the probability of occurrence for linked risk factors rises significantly. In this context, implementing joint defense measures becomes a crucial strategy to prevent the further spread of risks within the accident network and to effectively reduce the likelihood of accidents.

4. Conclusions

This study employs large language models (LLMs) for an in-depth analysis of coal mine accident investigation reports, capitalizing on their advanced natural language processing (NLP) capabilities to effectively extract key risk factors impacting coal mine safety. Due to the lack of standardization in the formatting of these reports and the significant variation in their textual expressions, traditional text mining methods struggle to cope, which limits their applicability. To overcome these challenges, this study developed a specialized set of prompts designed for risk factor extraction, guiding the large language model to accurately identify risk factors within the reports. Ultimately, 14 direct risk factors, 38 integrated risk factors, and 75 specific risk factors were identified. Compared to traditional text mining techniques, such as word segmentation, keyword extraction, and semantic analysis, large language models demonstrate superior abilities in contextual understanding and semantic inference. These models are adept at handling complex, diverse linguistic structures, enabling them to process varied and non-standardized text with high accuracy. Furthermore, while traditional text mining methods rely on predefined rules or dictionaries that may fail to account for all potential risk factors, large language models offer greater flexibility in adapting to different expressions, ensuring a more comprehensive and precise extraction process. The NLP approach based on large language models not only preserves the integrity of the original information in the reports but also minimizes the loss of crucial details. Compared to traditional text mining methods, large language models (LLMs) exhibit significant advantages in deep semantic understanding. Traditional approaches, relying on predefined rules and keyword extraction, often fail to fully capture the complex contexts and implicit causal relationships within texts. In contrast, LLMs enable more precise analysis by accurately identifying semantic layers and subtle nuances in context. In this study, risk factors extracted by LLMs, such as “violation of work regulations by on-site workers” (S23), “failure to strictly implement pre-shift meeting arrangements” (S55), and “negligence in managing subordinate coal mines” (S60), demonstrate a level of detail and depth beyond the capabilities of traditional methods. These nuanced risk factors uncover issues that traditional methods typically overlook, rendering the findings more consistent with the actual challenges in coal mine safety management. Consequently, the recommendations proposed in this study are more actionable, providing a robust and reliable foundation for future risk assessments and safety decision-making.

After extracting risk factors from coal mine accident investigation reports, the next critical step is to assess their relationships with coal mine accidents. Given the large number of risk factors involved and their intricate interdependencies, traditional methods have limitations in effectively identifying causal relationships among them. Furthermore, overly complex network structures can impede the effective incorporation of expert knowledge, thereby diminishing both analytical accuracy and practical applicability. In contrast, Bayesian networks provide an efficient approach to handling multiple interrelated factors while simplifying complex analytical problems through graphical structures. They not only capture the intricate dependencies among risk factors but also integrate data-driven learning with expert knowledge, thereby improving the model’s robustness and predictive reliability. Moreover, Bayesian networks excel at modeling uncertainty, making them particularly suitable for analyzing unpredictable risks in coal mine accidents.

Therefore, this study employs Bayesian networks to analyze the risk factors associated with coal mine accidents, aiming to achieve a more comprehensive understanding of their underlying relationships and to generate valuable insights for coal mine safety management.