Prospects of Solar Energy in the Context of Greening Maritime Transport

Abstract

1. Introduction

2. Literature Review

- Section 3 describes research methodologies and data.

- Section 4 presents an analysis of alternative fuels used on marine vessels.

- Section 5 analyzes technologies that use solar energy in shipping and their technical and economic performance.

- Section 6 analyzes the challenges and trends in the use of solar energy for maritime transport.

- Section 7 discusses the obtained results and proposes future research directions for solar energy use in the maritime sector.

- Section 8 presents conclusions.

3. Description of Research Methodology and Data

- The level of GHG emissions to the environment.

- Energy efficiency.

- Features of production and transportation.

- Features of storage on board ship.

- Economic efficiency.

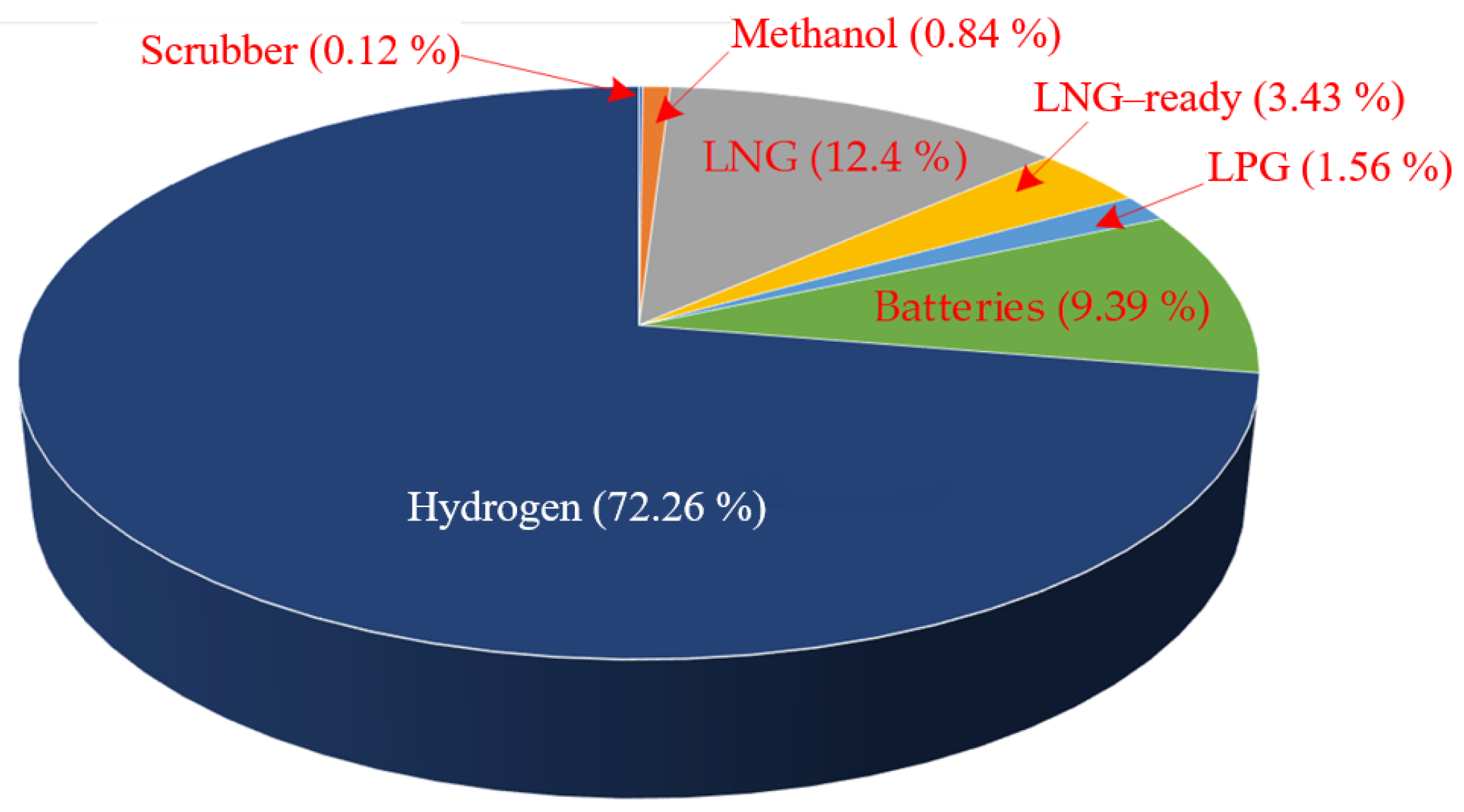

4. Analysis of Alternative Fuels Used on Marine Vessels

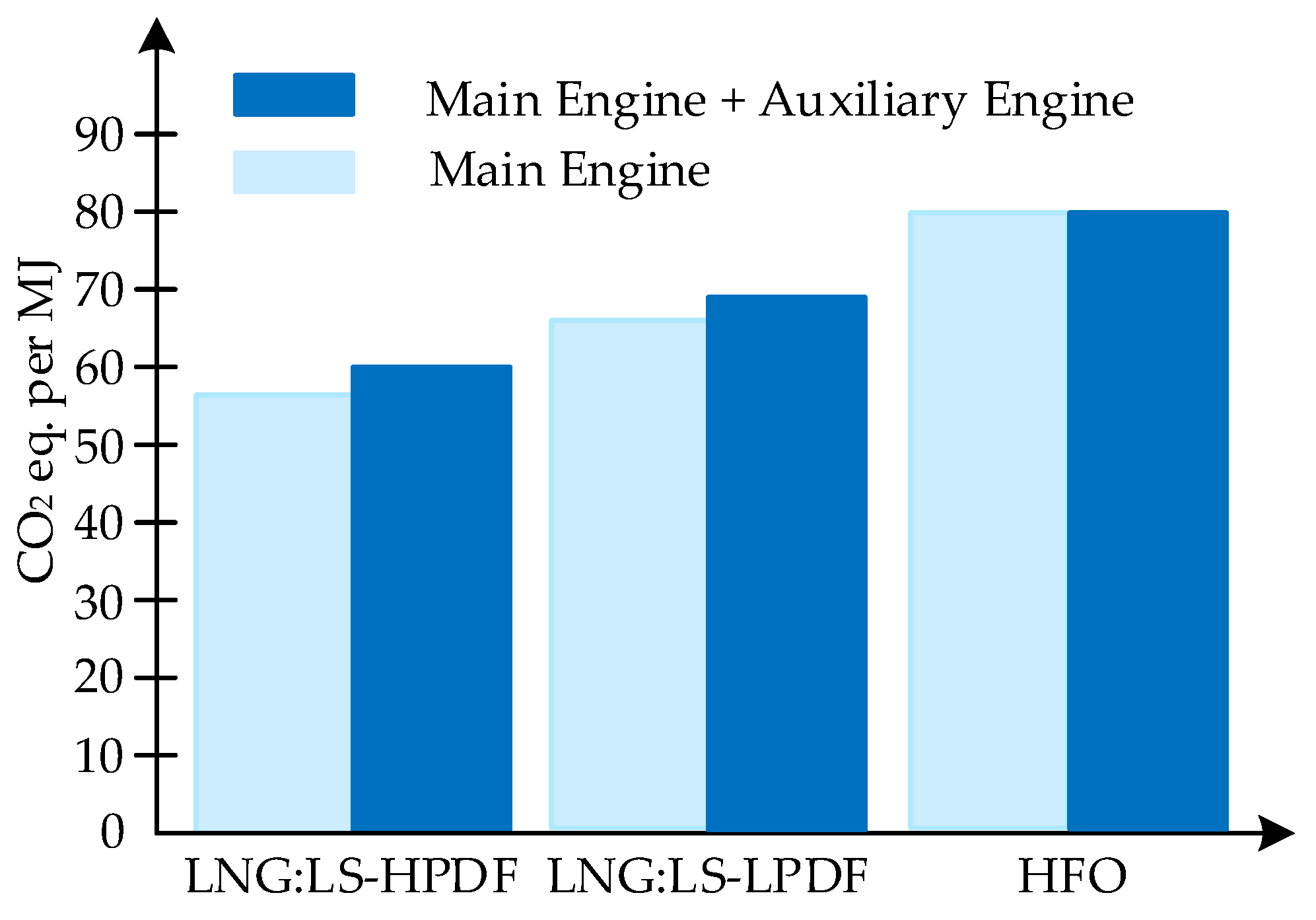

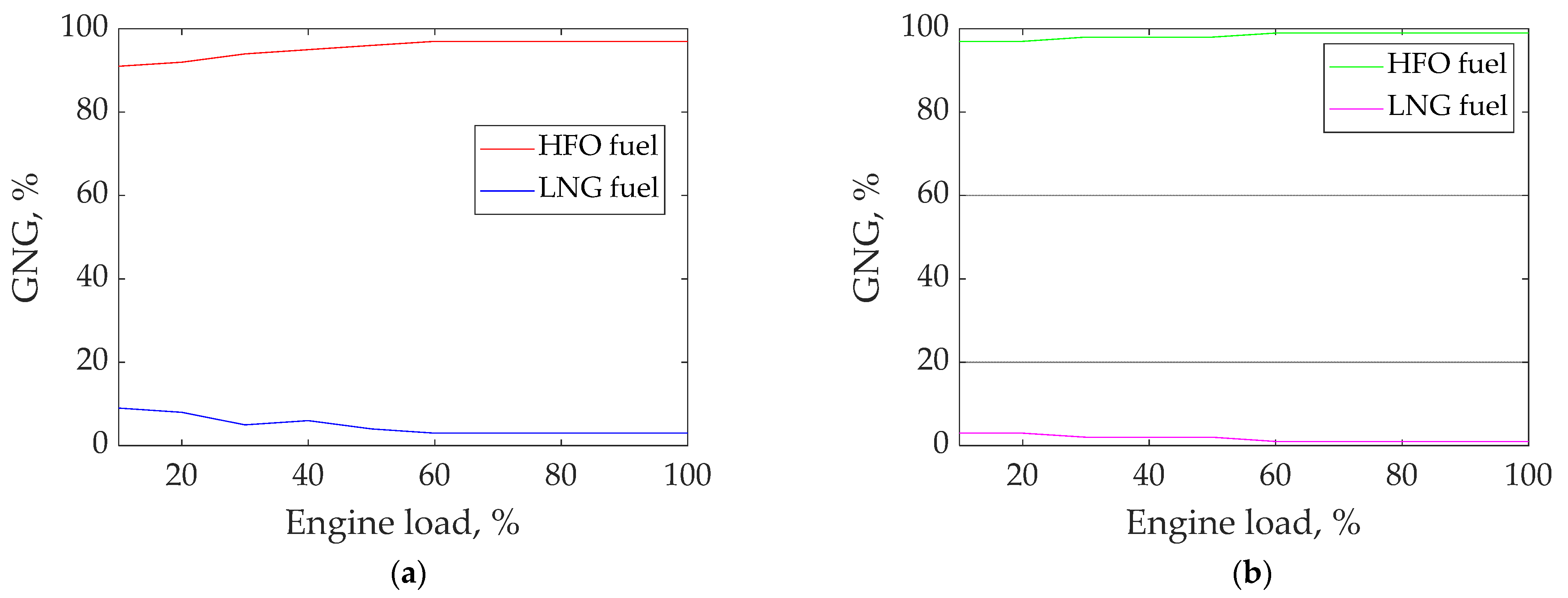

4.1. Liquefied Natural Gas

4.1.1. Environmental Impact of LNG-Powered Vessels

4.1.2. Features of LNG Production and Transportation

- In liquefaction processes, either a mixed or a pure refrigerant is employed. In MR technology, a specially selected blend of hydrocarbons is used to replicate the cooling curve of natural gas. In Cascade technology, several distinct pure refrigerants with cascading boiling points throughout the cycles are utilized. In EXP technology, nitrogen or methane is employed. Owing to the extremely low boiling points of these gases, the liquefaction of natural gas is accomplished in a single cycle. The ranking of the processes by the temperature difference between the refrigerant and natural gas is as follows: MR less Cascade; Cascade less EXP. A reduction in energy consumption is achieved by maintaining a smaller temperature difference. Such a smaller temperature difference can be attained by increasing the heat exchange surface area, which in turn requires greater capital investments. From the above, it follows that the optimization of the gas liquefaction process can be accomplished by balancing the refrigerant zones and the heat exchanger design [65].

- Two primary types of heat exchangers are employed in LNG production: (1) the plate-fin or brazed aluminum type (PFHE) and (2) the spiral-wound heat exchanger type (SWHE). The advantages of PFHE include low pressure drops, versatility in accommodating fluctuations in low-temperature differentials, and a greater number of competitive suppliers. In contrast, the drawbacks of PFHE encompass the necessity for meticulous design and a pronounced susceptibility to physical damage, both of which are inherent to the aluminum construction of PFHE [63]. Among the advantages of SWHE are its higher reliability and ease of operation. However, its disadvantages include a higher cost, limited flexibility with respect to the feed gas composition, and less favorable mass and dimensional characteristics. Moreover, SWHE units are produced by only a few companies. Additionally, SWHE offers a higher maximum capacity (a single PFHE is rated at 1.5 million tons per year, whereas one SWHE can reach up to 4 million tons per year). The benefits and drawbacks of these heat exchanger types ultimately determine their application in various installations. For instance, Cascade and EXP installations employ PFHE, while SWHE is used in large-scale MR installations [65,66].

- Five types of drives and two types of compressors should be considered when analyzing the equipment used in liquefaction processes. The drive and compressor are adapted to the specific technology of the liquefaction process [64].

4.1.3. Features of LNG Storage on Marine Vessels

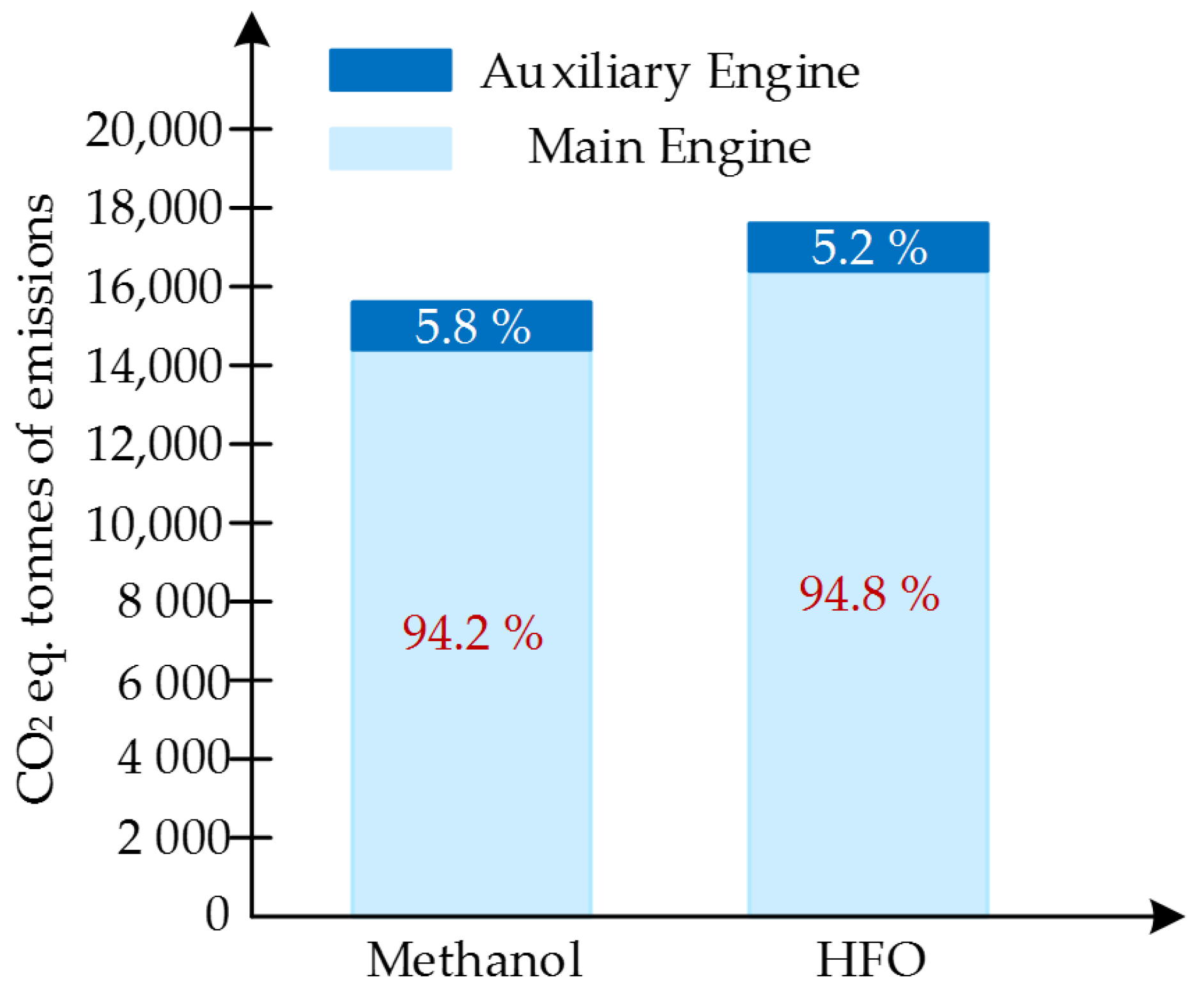

4.2. Methanol

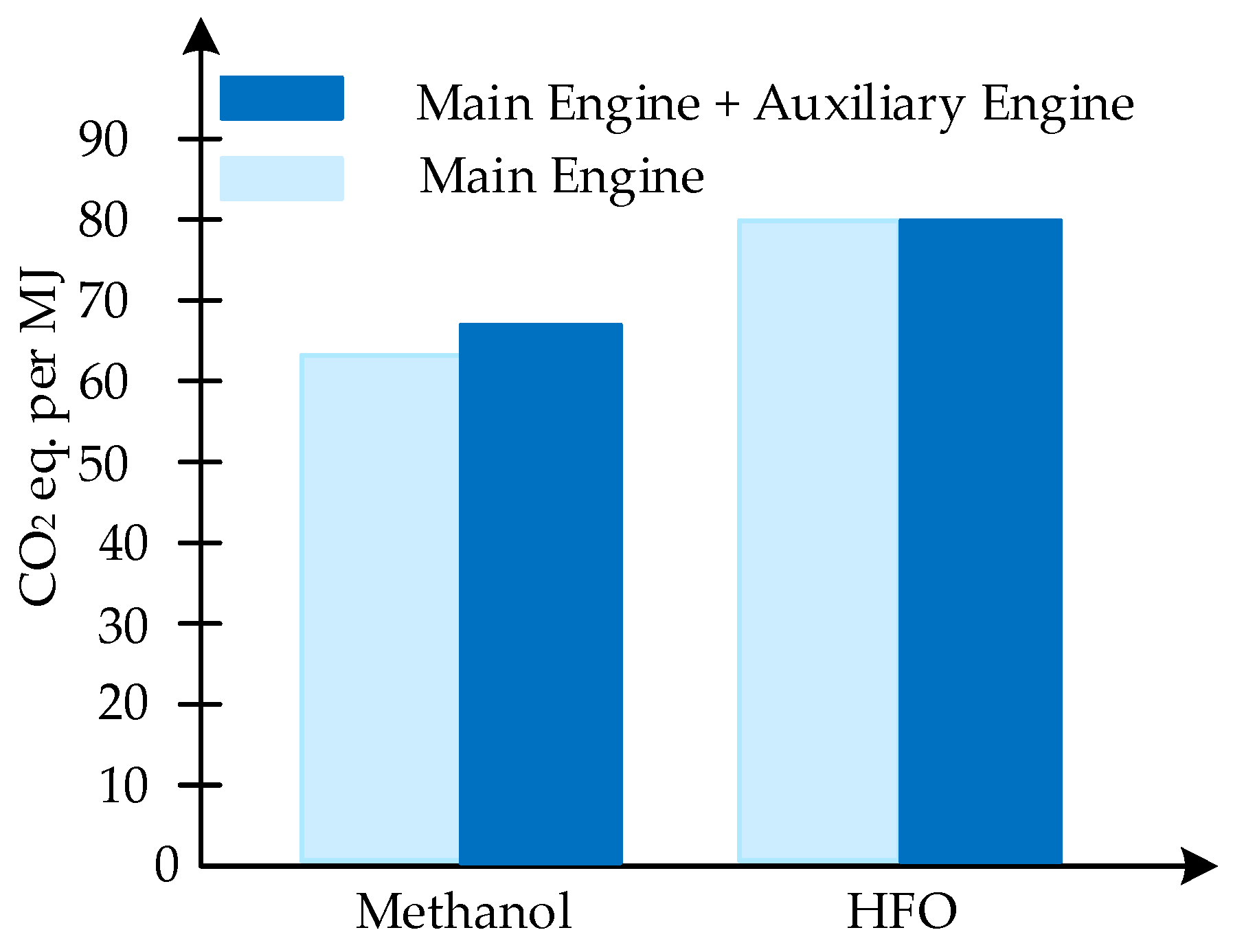

4.2.1. Environmental Impact of Methanol-Powered Marine Engines

4.2.2. Methanol Production and Transportation Features

4.2.3. Methanol Storage Features on Marine Vessels

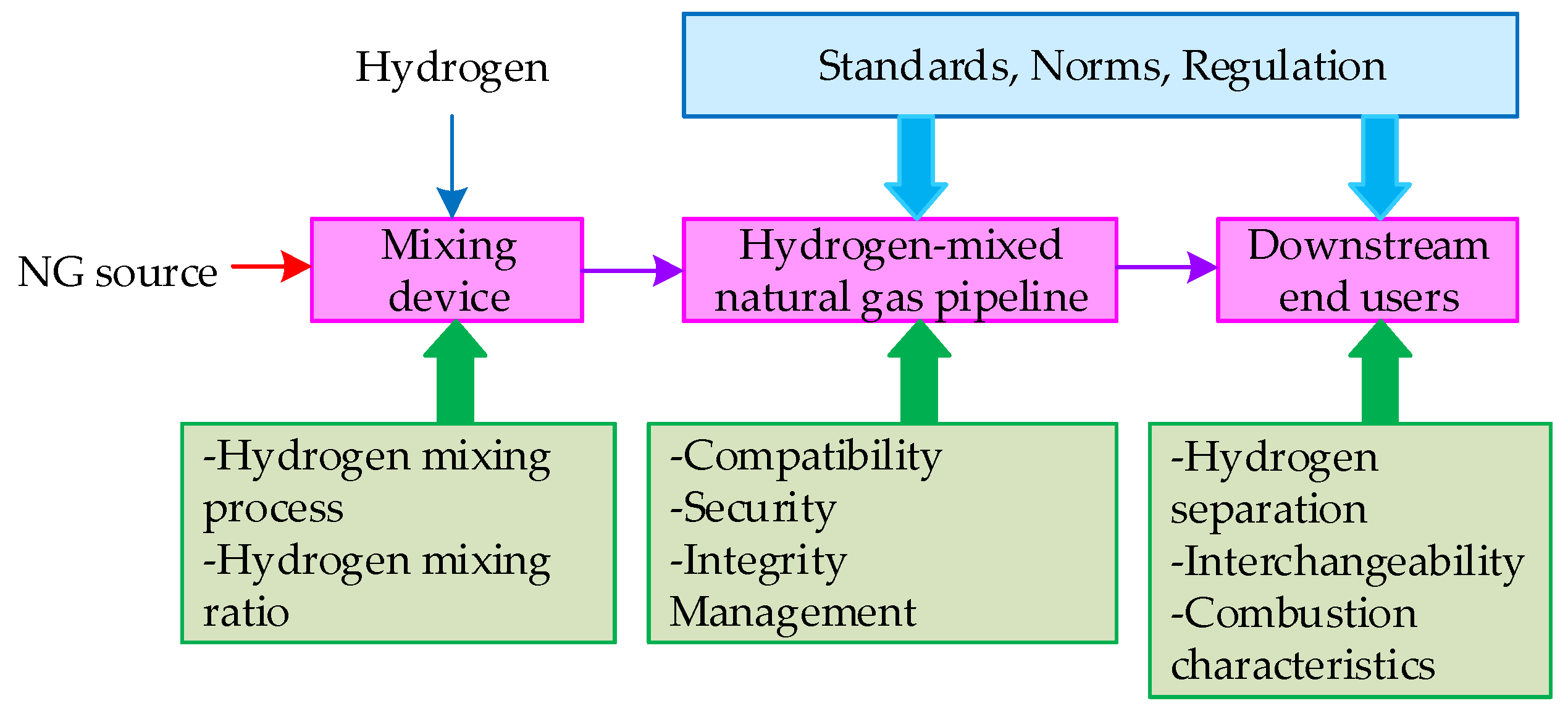

4.3. Hydrogen

4.3.1. Parameters of Hydrogen as Fuel for Marine Vessel Engines

4.3.2. Features of Hydrogen Production and Transportation

4.3.3. Features of Hydrogen Storage on Marine Vessels

Hydrogen Usage Onboard

Reactor Development

Hazards of Using Hydrogen Onboard

4.4. Ammonia

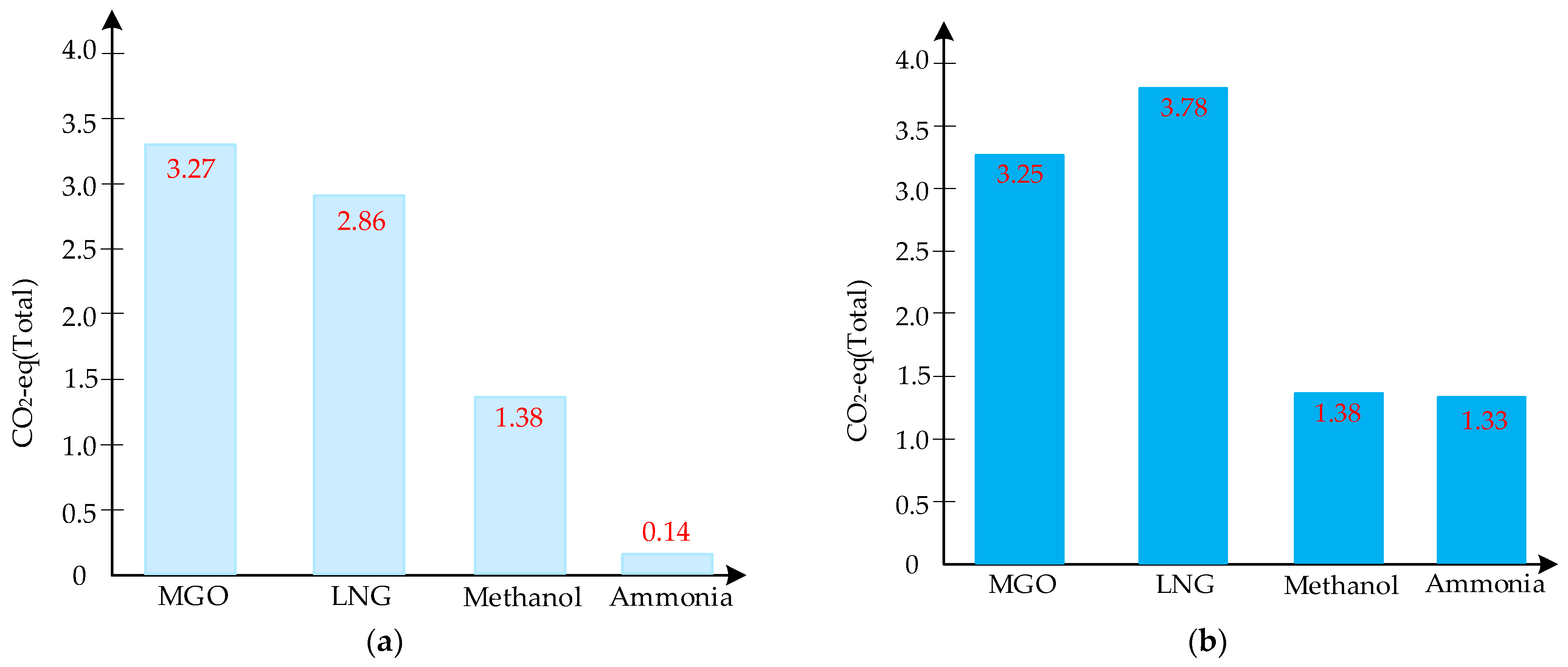

4.4.1. Environmental Impact of Ammonia-Powered Marine Engines

4.4.2. Features of Ammonia Production and Transportation

4.4.3. Features of Ammonia Storage on Marine Vessels

4.5. Biofuel

4.5.1. Environmental Impact of Marine Engines Running on Biofuel

4.5.2. Features of Biofuel Manufacturing and Transportation

- Carbohydrate crops.

- Oil crops.

- Lignocellulosic biomass.

- Woody biomass.

- Algal biomass, as well as residues from their production and processing.

4.5.3. Features of Biofuel Storage on Marine Vessels

4.6. The Techno-Economic Analysis of Alternative Fuels for Marine Vessels

4.6.1. Analysis of Technologies

- PEMFCs—Proton Exchange Membrane Fuel Cells.

- AFCs—Alkaline Fuel Cells.

- PAFCs—Phosphoric Acid Fuel Cells.

- MCFCs—Molten Carbonate Fuel Cells.

- SOFCs—Solid Oxide Fuel Cells.

4.6.2. Economic Performance Analysis

5. Innovative Approaches and Challenges of Using Solar Energy in Shipping

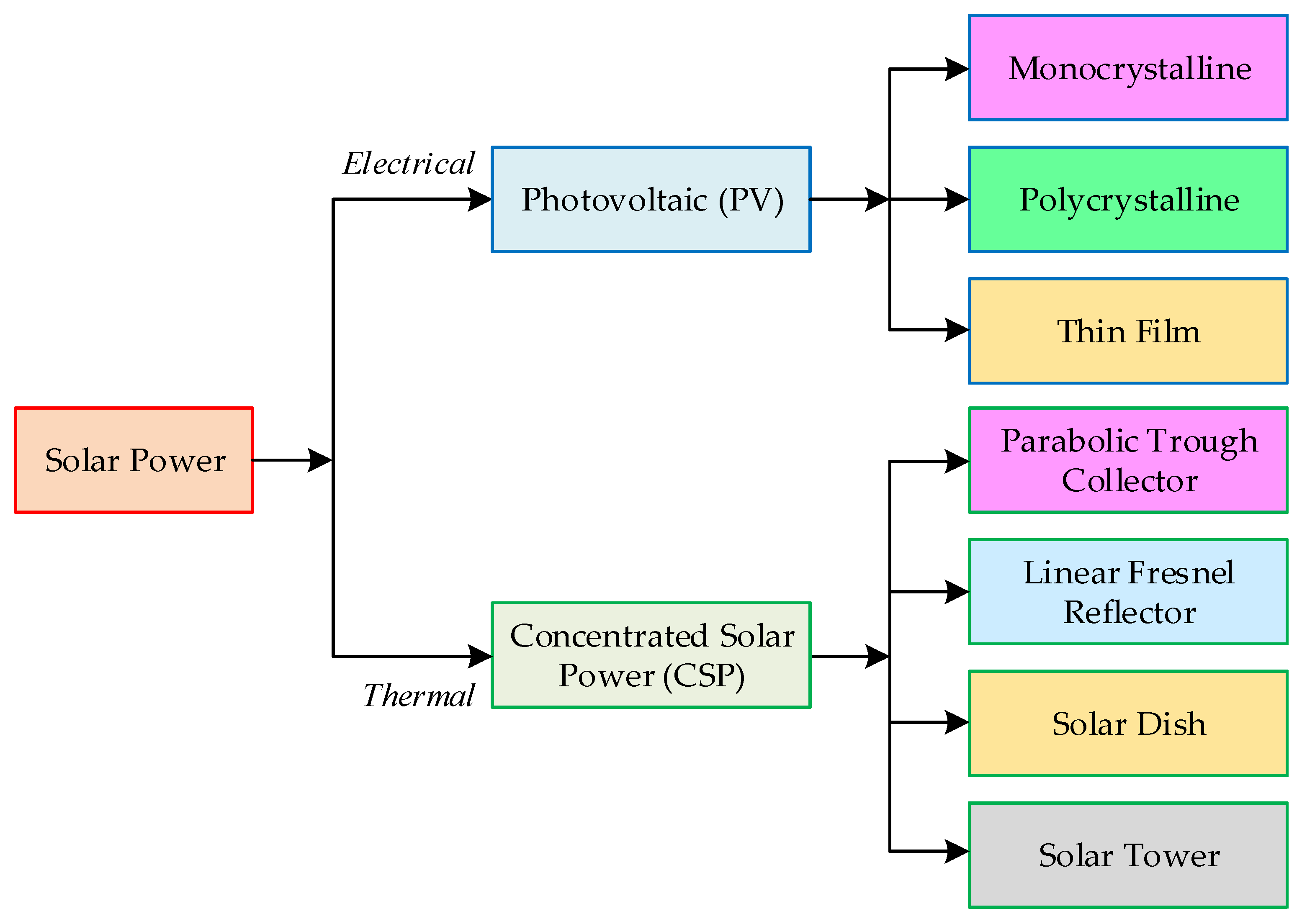

5.1. Components of Solar-Powered Marine Vessels

5.1.1. PV Array

5.1.2. DC–DC Converter as a Power Stabilizer

5.1.3. PV MPPT

5.1.4. Electric Motor

5.1.5. Battery Management System

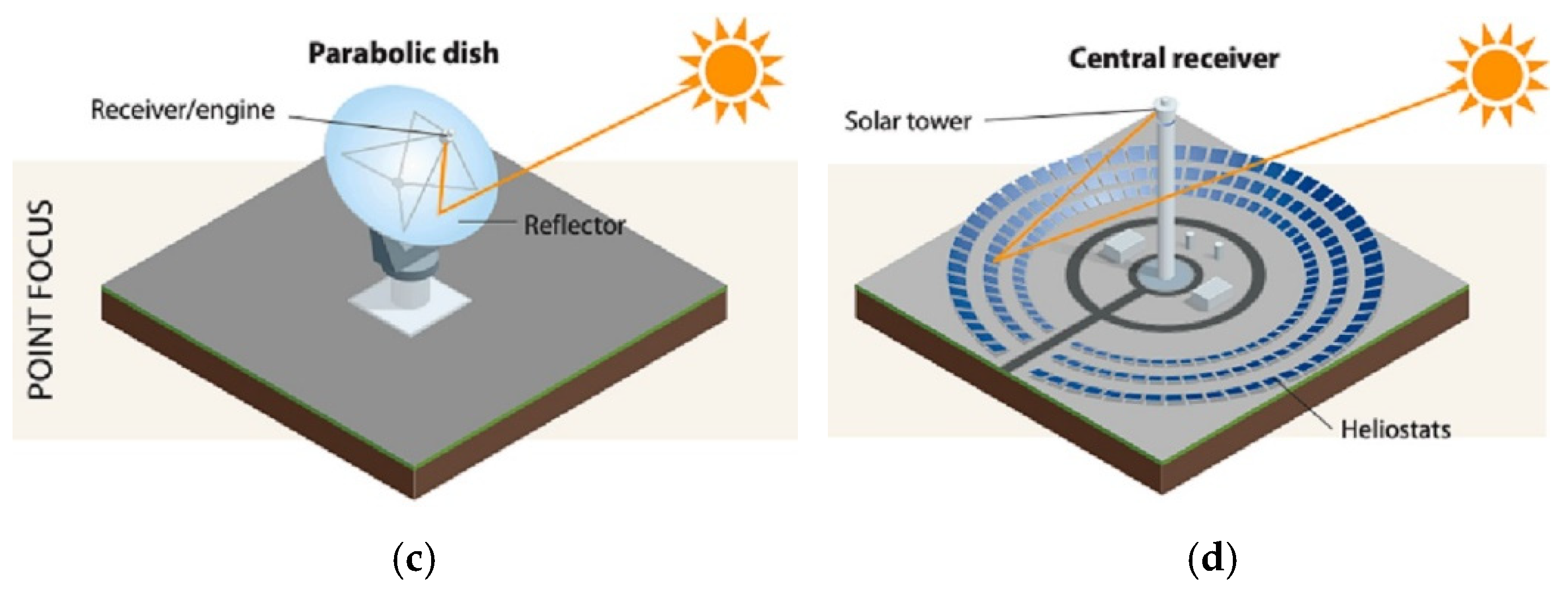

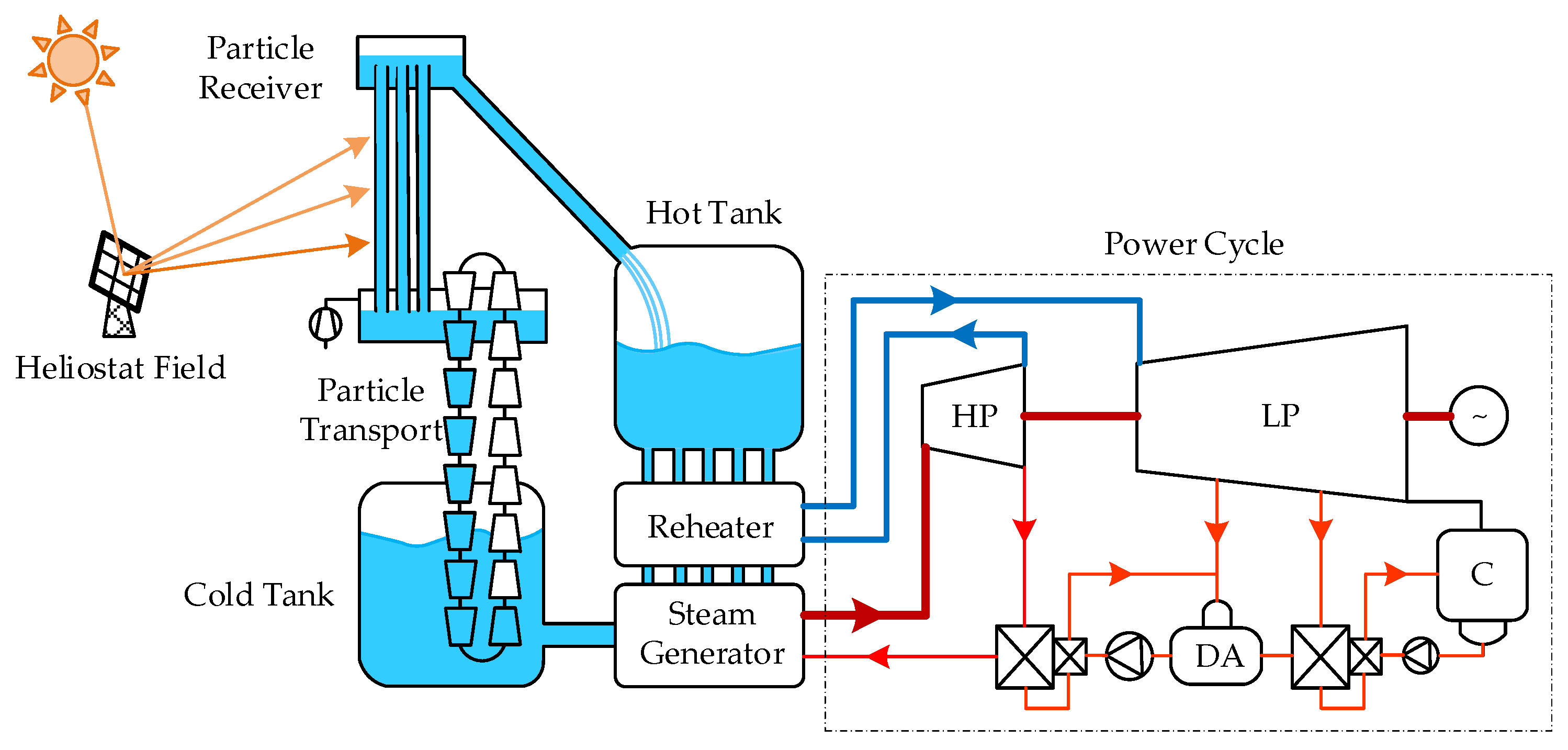

5.2. The Application of Concentrated Solar Energy Systems on Marine Vessels

5.3. Contrasting PV and CSP

5.4. Techno-Economic Analysis of the Use of Battery Storage Systems for Powering Marine Vessel Engines

6. Emerging Trends in Solar Energy for Maritime Transport

6.1. Analysis of the Limitations for the Use of Solar Energy on Marine Vessels

6.2. Trends in the Development of Solar Energy for Marine Transportation

7. Discussion

- Hydrogen is a highly flammable fuel.

- Risks of hydrogen leaks through joints and cracks in any pipelines or storage system.

- Hydrogen disperses easily in the air.

- In high concentrations, hydrogen can displace oxygen in the air, leading to asphyxiation.

- The necessity to avoid explosion risks [85].

- The necessity of appropriate materials capable of withstanding low temperatures to prevent brittleness.

- The necessity to prevent liquid hydrogen spills to avoid asphyxiation and explosion.

8. Conclusions

- The adaptation of concentrated solar power (CSP) systems for marine applications.

- The development of materials and designs for solar panels is specifically intended for the marine environment.

- The development of methods for evaluating the long-term economic benefits of using solar energy on ships.

- The improvement of regulatory frameworks and international standards for the application of solar energy on ships.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Type of Fuel | Calorific Value (MJ/kg) | Onboard Storage Requirements | Utilization Efficiency | Byproduct of Utilization | Availability of Commercial Utilization Technologies | |

|---|---|---|---|---|---|---|

| FC (Electrical Efficiency) | ICE (Internal Combustion Engine) | |||||

| Liquefied Natural Gas (LNG) | 50–55 | 163° (under pressure or without pressure) | 45–60% (SOFC) 35–45% (PEMFC) | 35–40% | CO2, H2O, NOx (ICE) | ICE: Yes, widely available for commercial use; FC: Underdeveloped, no commercial maritime use |

| Hydrogen | 120–140 | 350–700 bar (gaseous), −252.8 °C (liquefied), material-based storage | 50–60% (PEFMC/SOFC) | 30–35% | H2O, NOx (ICE) | ICE: Yes, available for commercial use; FC: Yes, available for commercial use |

| Ammonia | 22.5 | 21 °C below 8.8 bar or 33 °C at atmospheric pressure | 30–60% (SOFC) 15–30% (AFC) | 35–40% | H2O, N2, NOx (ICE) | ICE: Underdeveloped; FC: Underdeveloped, no commercial maritime use |

| Methanol | 22.7 | Liquid at ambient temperature | 30–50% (SOFC) 20–30% (DFMC) | 40% | CO2, H2O, CO (ICE), NOx (ICE) | ICE: Yes, widely available for commercial use; FC: Underdeveloped, no commercial maritime use |

| Biodiesel | 38–46 | Liquid at ambient temperature | 10–30% (AFC) | 10–30% (AFC), Varies | CO2, H2O, CO (ICE), NOx (ICE) | ICE: Yes, widely available for commercial use; FC: Underdeveloped, no commercial maritime use |

| Electricity | - | High energy density battery systems such as NMC, LFP, NCA, and solid-state batteries | - | - | - | Currently available only for small shore-based vessels |

| Fuel | Material for Fuel Production | Fuel Production Costs/Import Price, USD/MJ | Fossil Fuel Price, USD/MJ | Total Price |

|---|---|---|---|---|

| LNG | Natural gas | 0.0022–0.0092 | 0.014 | 0.16–0.66 |

| LBG | Biomass | 0.0081–0.032 | 0.57–2.29 | |

| Biodiesel | Soybean, palm oil, rapeseed | 0.013–0.027 | 0.92–1.93 | |

| Methanol | Biomass | 0.021–0.037 | 1.50–2.64 | |

| Methanol | Natural gas | 0.006–0.022 | 0.43–1.57 | |

| Hydrogen SMR | Wind power, water | 0.0063–0.035 | 0.45–2.5 | |

| Hydrogen electrolysis | Wind power, water | 0.025–0.08 | 1.78–5.71 | |

| Hydrogen electrolysis | Nuclear energy, water | 0.019–0.045 | 1.36–3.21 | |

| Ammonia | Natural gas | 0.0093–0.036 | 0.66–2.57 | |

| Ammonia | Wind power | 0.021–0.037 | 1.50–2.64 |

| Component | Capital Investments for Vessel Modernization, USD/kW | Capital Expenditures for Construction of New Vessels (Four-Stroke Engine/Two-Stroke Engine), USD/kW | Life Cycle |

|---|---|---|---|

| Propulsion system | |||

| ICE diesel, biodiesel | - | 240/460 | 30 years |

| ICE, methanol | 328 | 265/505 | 30 years |

| ICE, ammonia | - | 370/600 | 30 years |

| ICE, LNG, LBG, hydrogen | 900 | 387/850 | 30 years |

| Fuel cell, SOFC | - | 4000–9000 | 7–12 years |

| Fuel cell, PEMFC | - | 730–2860 | 7–12 years |

| Electrical and generator, LNG, LBG, hydrogen | - | 400 | 30 years |

| Electric motor | - | 250 | 30 years |

| Fuel storage system | |||

| Gas supply system + tank, LNG, LBG, USD/kg | 270–420 | 270–420 | 30 years |

| Gas supply system + high-pressure tank (700 bar), Hydrogen, USD/kg | - | 576–868 | 30 years |

| Criteria | PV | CSP |

|---|---|---|

| Storage and intermittency | It generates electricity immediately, making storage difficult, and batteries are economically unfeasible for large installations. Intermittency is the main drawback of PV. | Overcoming interruptions and maintaining supply at night, TES (Thermal Energy Storage) is an attractive feature of CSP, making it dispatchable and increasing CSP’s penetration in energy sectors. |

| Efficiency | Maximum efficiency 10–28%, with productivity decreasing over time. | Average efficiency 41%, efficiency increases with temperature. |

| Capacity factor | 10–35% | With TES 29–33%, without TES 28–29%. |

| Equipment | Direct current must be converted to alternating current using inverters. | Output is alternating current combined with feeding cycles; therefore, an inverter is not needed. |

| Solar Irradiance | Uses Global Horizontal Irradiance (GHI) and can operate in diffuse light. | CSP uses only Direct Normal Irradiance (DNI), which varies from 65 to 85% of total GHI. |

| Control System | Advantages | Disadvantages |

|---|---|---|

| FOC | 1. Lower torque pulsation coefficient on the motor shaft. 2. Better speed control quality at speeds higher than the rated value. | 1. Less energy efficiency. 2. Worse torque control quality. |

| DTC | 1. Better energy efficiency. 2. Better torque control quality. | 1. Higher torque pulsation coefficient on the motor shaft. 2. Lower speed control quality at speeds greater than the rated value. |

| Filtration Type | Advantages | Disadvantages |

|---|---|---|

| Frequency domain | 1. Higher filtering accuracy | 1. More time of unstable operation of the compensator. 2. More complex algorithm for obtaining the desired signals of phase currents of the stator phase currents of the induction motor. |

| Time domain | 1. Less time of unstable operation of compensator. 2. Simpler algorithm to obtain the desired signals of induction motor stator phase currents. | 1. Less accurate filtering. |

| Battery Type | Advantages |

|---|---|

| Gel battery | 1. No maintenance required. 2. No leaks. 3. Can be submerged in water. 4. Spill-proof. 5. Eliminated gas emission. 6. Can be safely used near sensitive electronics and in public areas. |

| Pure lead thin film | 1. Can withstand higher charge power. 2. Charges quickly. 3. 400 cycles of charge and discharge. |

| Lithium-manganese | 1. Can withstand higher charge power. 2. Charges quickly. 3. 400 cycles of charge and discharge. |

| With absorbed glass mat | 1. Good starting power. 2. Deep cycle capability. |

References

- Li, B.; Elmi, Z.; Manske, A.; Jacobs, E.; Lau, Y.Y.; Chen, Q.; Dulebenets, M.A. Berth allocation and scheduling at marine container terminals: A state-of-the-art review of solution approaches and relevant scheduling attributes. J. Comput. Des. Eng. 2023, 10, 1707–1735. [Google Scholar] [CrossRef]

- UNCTAD. Review of Maritime Transport 2022; United Nations Conference on Trade and Development: Bridgetown, Barbados, 2022; Available online: https://unctad.org/rmt2022 (accessed on 15 July 2024).

- Fratila, A.; Gavril, I.A.; Nita, S.C.; Hrebenciuc, A. The importance of maritime transport for economic growth in the European union: A panel data analysis. Sustainability 2021, 13, 7961. [Google Scholar] [CrossRef]

- Elmi, Z.; Li, B.; Liang, B.; Lau, Y.Y.; Borowska-Stefańska, M.; Wiśniewski, S.; Dulebenets, M.A. An epsilon-constraint-based exact multi-objective optimization approach for the ship schedule recovery problem in liner shipping. Comput. Ind. Eng. 2023, 183, 109472. [Google Scholar] [CrossRef]

- Issa, M.; Ilinca, A.; Martini, F. Ship energy efficiency and maritime sector initiatives to reduce carbon emissions. Energies 2022, 15, 7910. [Google Scholar] [CrossRef]

- Hoang, A.T.; Foley, A.M.; Nižetić, S.; Huang, Z.; Ong, H.C.; Ölçer, A.I.; Nguyen, X.P. Energy-related approach for reduction of CO2 emissions: A critical strategy on the port-to-ship pathway. J. Clean. Prod. 2022, 355, 131772. [Google Scholar] [CrossRef]

- Xing, H.; Spence, S.; Chen, H. A comprehensive review on countermeasures for CO2 emissions from ships. Renew. Sustain. Energy Rev. 2020, 134, 110222. [Google Scholar] [CrossRef]

- Jones, M.W.; Peters, G.P.; Gasser, T.; Andrew, R.M.; Schwingshackl, C.; Gütschow, J.; Houghton, R.A.; Friedlingstein, P.; Pongratz, J.; Le Quéré, C. National contributions to climate change due to historical emissions of carbon dioxide, methane, and nitrous oxide since 1850. Sci. Data 2023, 10, 155. [Google Scholar] [CrossRef]

- Nunes, L.J. The rising threat of atmospheric CO2: A review on the causes, impacts, and mitigation strategies. Environments 2023, 10, 66. [Google Scholar] [CrossRef]

- Chataut, G.; Bhatta, B.; Joshi, D.; Subedi, K.; Kafle, K. Greenhouse gases emission from agricultural soil: A review. J. Agric. Food Res. 2023, 11, 100533. [Google Scholar] [CrossRef]

- Dervash, M.A.; Yousuf, A.; Ozturk, M.; Bhat, R.A. Global warming: Impacts of temperature escalation. In Phytosequestration: Strategies for Mitigation of Aerial Carbon Dioxide and Aquatic Nutrient Pollution; Springer International Publishing: Cham, Switzerland, 2023; pp. 27–36. [Google Scholar] [CrossRef]

- Mariappan, S.; David Raj, A.; Kumar, S.; Chatterjee, U. Global warming impacts on the environment in the last century. In Ecol. Footpr. Clim. Change: Adapt. Approaches Sustain; Springer International Publishing: Cham, Switzerland, 2023; pp. 63–93. [Google Scholar] [CrossRef]

- Singh, E.A.; Shindikar, M.R. A comprehensive review on climate change and its effects. Int. J. Environ. Clim. Change 2023, 13, 924–931. [Google Scholar] [CrossRef]

- Jain, A.K. Global Carbon Budget 2022. Earth Syst. Sci. Data 2022, 14, 4811–4900. [Google Scholar] [CrossRef]

- Issa Zadeh, S.B.; López Gutiérrez, J.S.; Esteban, M.D.; Fernández-Sánchez, G.; Garay-Rondero, C.L. Scope of the literature on efforts to reduce the carbon footprint of seaports. Sustainability 2023, 15, 8558. [Google Scholar] [CrossRef]

- Cardoso, M.; Santos, T.; Tessarolo, L.G.A.; Aprigliano, V.; Rodrigues da Silva, A.N.; da Silva, M.A.V. Exploring the Resilience of Public Transport Trips in the Face of Urban Violence from a Gender Perspective. Sustainability 2023, 15, 16960. [Google Scholar] [CrossRef]

- Jiwa, M.Z.; Kim, Y.T.; Mustaffa, Z.; Kim, S.; Kim, D.K. A Simplified Approach for Predicting Bend Radius in HDPE Pipelines during Offshore Installation. J. Mar. Sci. Eng. 2023, 11, 2032. [Google Scholar] [CrossRef]

- Ding, C.; Zhu, J.; Qin, W.; Tao, X.; Fan, F.; Li, R.; Li, C. A Hydrogen Farm Strategy for Scalable Solar Hydrogen Production with Particulate Photocatalysts. Angew. Chem. Int. Ed. 2020, 59, 9653–9658. [Google Scholar] [CrossRef]

- Tay, Z.Y.; Konovessis, D. Sustainable energy propulsion system for sea transport to achieve United Nations sustainable development goals: A review. Discov. Sustain. 2023, 4, 20. [Google Scholar] [CrossRef]

- Munim, Z.H.; Chowdhury, M.M.H.; Tusher, H.M.; Notteboom, T. Towards a prioritization of alternative energy sources for sustainable shipping. Mar. Policy 2023, 152, 105579. [Google Scholar] [CrossRef]

- Parhamfar, M.; Sadeghkhani, I.; Adeli, A.M. Towards the application of renewable energy technologies in green ports: Technical and economic perspectives. IET Renew. Power Gener. 2023, 17, 3120–3132. [Google Scholar] [CrossRef]

- Sagin, S.V.; Kuropyatnyk, O.A. Using exhaust gas bypass for achieving the environmental performance of marine diesel engines. Austrian J. Tech. Nat. Sci. 2021, 7–8, 36–43. [Google Scholar] [CrossRef]

- Shi, J.; Zhu, Y.; Feng, Y.; Yang, J.; Xia, C. A prompt decarbonization pathway for shipping: Green hydrogen, ammonia, and methanol production and utilization in marine engines. Atmosphere 2023, 14, 584. [Google Scholar] [CrossRef]

- Bilgili, L. A systematic review on the acceptance of alternative marine fuels. Renew. Sustain. Energy Rev. 2023, 182, 113367. [Google Scholar] [CrossRef]

- Popek, M. Alternative Fuels–Prospects for the Shipping Industry. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2024, 18, 25–33. [Google Scholar] [CrossRef]

- Melnyk, O.; Onishchenko, O.; Onyshchenko, S. Renewable energy concept development and application in shipping industry. Lex Portus 2023, 9, 15. [Google Scholar] [CrossRef]

- McLaughlin, H.; Littlefield, A.A.; Menefee, M.; Kinzer, A.; Hull, T.; Sovacool, B.K.; Bazilian, M.D.; Kim, J.; Griffiths, S. Carbon capture utilization and storage in review: Sociotechnical implications for a carbon reliant world. Renew. Sustain. Energy Rev. 2023, 177, 113215. [Google Scholar] [CrossRef]

- Memon, S.U.R.; Manzoor, R.; Fatima, A.; Javed, F.; Zainab, A.; Ali, L.; Ullah, U.; Saleem, A.; Ullah, Q. A Comprehensive Review of Carbon Capture, Utilization, and Storage (CCUS): Technological Advances, Environmental Impact, and Economic Feasibility. Sch. Acad. J. Biosci. 2024, 7, 184–204. [Google Scholar] [CrossRef]

- Petrychenko, O.; Kulakov, M.; Prytula, D. The evolution of ship’s saving energy policy in the world. In Proceedings of the International Conference on Science and Technology «Navigation, Shipping and Technology», Odesa, Ukraine, 18–19 November 2021; pp. 39–46. Available online: http://onma.edu.ua/wp-content/uploads/2021/12/ISCT-NST-novyjSformuloj.pdf (accessed on 20 September 2024).

- Sagin, S.; Kuropyatnyk, O.; Sagin, A.; Tkachenko, I.; Fomin, O.; Píštěk, V.; Kučera, P. Ensuring the Environmental Friendliness of Drillships during Their Operation in Special Ecological Regions of Northern Europe. J. Mar. Sci. Eng. 2022, 10, 1331. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, S.; Feng, Y.; Hu, Z.; Yuan, L. Influences of Solar Energy on the Energy Efficiency Design Index for New Building Ships. Int. J. Hydrogen Energy 2017, 42, 19389–19394. [Google Scholar] [CrossRef]

- Budashko, V.V.; Kozminykh, M.A.; Mazur, O.M.; Onyshchenko, O.A.; Bucaros, A.Y. Energy-Efficient Cooling Systems for Special Equipment of Maritime and Land Military Complexes. In Proceedings of the XI International Scientific and Practical Conference “Modern Approaches to High-Efficiency Use of Transport Means”, Izmail, Ukraine, 3–4 December 2020. [Google Scholar]

- Karatuğ, Ç.; Durmuşoğlu, Y. Design of a Solar Photovoltaic System for a Ro-Ro Ship and Estimation of Performance Analysis: A Case Study. Sol. Energy 2020, 207, 1259–1268. [Google Scholar] [CrossRef]

- Glykas, A.; Papaioannou, G.; Perissakis, S. Application and cost–benefit analysis of solar hybrid power installation on merchant marine vessels. Ocean Eng. 2010, 37, 592–602. [Google Scholar] [CrossRef]

- Bezyk, Y.; Górka, M.; Sówka, I.; Nęcki, J.; Strąpoć, D. Temporal dynamics and controlling factors of CO2 and CH4 variability in the urban atmosphere of Wroclaw, Poland. Sci. Total Environ. 2023, 893, 164771. [Google Scholar] [CrossRef]

- Ha, S.; Jeong, B.; Jang, H.; Park, C.; Ku, B. A framework for determining the life cycle GHG emissions of fossil marine fuels in countries reliant on imported energy through maritime transportation: A case study of South Korea. Sci. Total Environ. 2023, 897, 165366. [Google Scholar] [CrossRef] [PubMed]

- Bilgili, L.; Ölçer, A.I. IMO 2023 strategy-Where are we and what’s next? Mar. Policy 2024, 160, 105953. [Google Scholar] [CrossRef]

- Animah, I.; Shafiee, M. Application of risk analysis in the liquefied natural gas (LNG) sector: An overview. J. Loss Prev. Process Ind. 2020, 63, 103980. [Google Scholar] [CrossRef]

- Kaiser, S.; Siems, F.; Mostert, C.; Bringezu, S. Environmental and Economic Performance of CO2-Based Methanol Production Using Long-Distance Transport for H2 in Combination with CO2 Point Sources: A Case Study for Germany. Energies 2022, 15, 2507. [Google Scholar] [CrossRef]

- Biswal, T.; Shadangi, K.P.; Sarangi, P.K.; Srivastava, R.K. Conversion of Carbon Dioxide to Methanol: A Comprehensive Review. Chemosphere 2022, 298, 134299. [Google Scholar] [CrossRef]

- Meesattham, S.; Kim-Lohsoontorn, P. Low-Temperature Alcohol-Assisted Methanol Synthesis from CO2 and H2: The Effect of Alcohol Type. Int. J. Hydrogen Energy 2022, 47, 22691–22703. [Google Scholar] [CrossRef]

- Vedachalam, S.; Baquerizo, N.; Dalai, A.K. Review on impacts of low sulfur regulations on marine fuels and compliance options. Fuel 2022, 310, 122243. [Google Scholar] [CrossRef]

- Lindstad, E.; Lagemann, B.; Rialland, A.; Gamlem, G.M.; Valland, A. Reduction of maritime GHG emissions and the potential role of E-fuels. Transp. Res. Part D Transp. Environ. 2021, 101, 103075. [Google Scholar] [CrossRef]

- Herdzik, J. Decarbonization of Marine Fuels—The Future of Shipping. Energies 2021, 14, 4311. [Google Scholar] [CrossRef]

- Abbas, A.J.; Hassani, H.; Burby, M.; John, I.J. An investigation into the volumetric flow rate requirement of hydrogen transportation in existing natural gas pipelines and its safety implications. Gases 2021, 1, 156–179. [Google Scholar] [CrossRef]

- Thawko, A.; Eyal, A.; Tartakovsky, L. Experimental comparison of performance and emissions of a direct-injection engine fed with alternative gaseous fuels. Energy Convers. Manag. 2022, 251, 114988. [Google Scholar] [CrossRef]

- Ahmadi, P.; Torabi, S.H.; Afsaneh, H.; Sadegheih, Y.; Ganjehsarabi, H.; Ashjaee, M. The effects of driving patterns and PEM fuel cell degradation on the lifecycle assessment of hydrogen fuel cell vehicles. Int. J. Hydrogen Energy 2020, 45, 3595–3608. [Google Scholar] [CrossRef]

- Machaj, K.; Kupecki, J.; Malecha, Z.; Morawski, A.W.; Skrzypkiewicz, M.; Stanclik, M.; Chorowski, M. Ammonia as a potential marine fuel: A review. Energy Strategy Rev. 2022, 44, 100926. [Google Scholar] [CrossRef]

- Huang, J.; Fan, H.; Xu, X.; Liu, Z. Life cycle greenhouse gas emission assessment for using alternative marine fuels: A very large crude carrier (VLCC) case study. J. MArine Sci. Eng. 2022, 10, 1969. [Google Scholar] [CrossRef]

- Drazdauskas, M.; Lebedevas, S. Optimization of Combustion Cycle Energy Efficiency and Exhaust Gas Emissions of Marine Dual-Fuel Engine by Intensifying Ammonia Injection. J. Mar. Sci. Eng. 2024, 12, 309. [Google Scholar] [CrossRef]

- Wang, H.; Daoutidis, P.; Zhang, Q. Ammonia-based green corridors for sustainable maritime transportation. Digit. Chem. Eng. 2023, 6, 100082. [Google Scholar] [CrossRef]

- Chavando, A.; Silva, V.; Cardoso, J.; Eusebio, D. Advancements and challenges of ammonia as a sustainable fuel for the maritime industry. Energies 2024, 17, 3183. [Google Scholar] [CrossRef]

- Stathatou, P.M.; Bergeron, S.; Fee, C.; Jeffrey, P.; Triantafyllou, M.; Gershenfeld, N. Towards decarbonization of shipping: Direct emissions & life cycle impacts from a biofuel trial aboard an ocean-going dry bulk vessel. Sustain. Energy Fuels 2022, 6, 1687–1697. [Google Scholar] [CrossRef]

- Khan, M.I.; Gutiérrez-Alvarez, R.; Asfand, F.; Bicer, Y.; Sgouridis, S.; Al-Ghamdi, S.G.; Jouhara, H.; Asif, M.; Kurniawan, T.A.; Abid, M.; et al. The economics of concentrating solar power (CSP): Assessing cost competitiveness and deployment potential. Renew. Sustain. Energy Rev. 2024, 200, 114551. [Google Scholar] [CrossRef]

- International Maritime Organization. Fourth IMO GHG Study 2020: Executive summary; International Maritime Organization: London, UK, 2020. [Google Scholar]

- Peng, Y.; Li, X.; Wang, W.; Wei, Z.; Bing, X.; Song, X. A method for determining the allocation strategy of on-shore power supply from a green container terminal perspective. Ocean. Coast. Manag. 2019, 167, 158–175. [Google Scholar] [CrossRef]

- Sagin, S.V.; Sagin, S.S.; Madey, V. Analysis of methods of managing the environmental safety of the navigation passage of ships of maritime transport. Technol. Audit Prod. Reserves 2023, 4, 33–42. [Google Scholar] [CrossRef]

- Bilgili, L. Life cycle comparison of marine fuels for IMO 2020 Sulphur Cap. Sci. Total Environ. 2021, 774, 145719. [Google Scholar] [CrossRef] [PubMed]

- Çelikaslan, Z.; Kılıç, A. Safety Precautions for The Use of LNG as Marine Fuel. J. Marit. Transp. Logist. 2023, 4, 11–22. [Google Scholar] [CrossRef]

- Kuittinen, N.; Koponen, P.; Vesala, H.; Lehtoranta, K. Methane slip and other emissions from newbuild LNG engine under real-world operation of a state-of-the art cruise ship. Atmos. Environ. X 2024, 23, 100285. [Google Scholar] [CrossRef]

- Poberezhnyi, R.V.; Sagin, S.V. Ensuring environmental performance of diesel engines of river and sea transport vessels. Ship Power Plants: Sci. Tech. Collect. 2020, 41, 5–9. [Google Scholar] [CrossRef]

- Lehtoranta, K.; Kuittinen, N.; Vesala, H.; Koponen, P. Methane Emissions from a State-of-the-Art LNG-Powered Vessel. Atmosphere 2023, 14, 825. [Google Scholar] [CrossRef]

- Zhang, J.; Meerman, H.; Benders, R.; Faaij, A. Comprehensive review of current natural gas liquefaction processes on technical and economic performance. Appl. Therm. Eng. 2020, 166, 114736. [Google Scholar] [CrossRef]

- Gao, L.; Wang, J.; Binama, M.; Li, Q.; Cai, W. The design and optimization of natural gas liquefaction processes: A review. Energies 2022, 15, 7895. [Google Scholar] [CrossRef]

- Xu, J.; Lin, W.; Chen, X.; Zhang, H. Review of unconventional natural gas liquefaction processes. Front. Energy Res. 2020, 10, 915893. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, B.; Liang, R.; Wang, R.; Sun, Y. Environmental impact of the natural gas liquefaction process: An example from China. Appl. Sci. 2020, 10, 1701. [Google Scholar] [CrossRef]

- Junsang, P.; Jaturanonda, C.; Wuttipornpun, T.; Watcharejyothin, M. Liquefied natural gas logistics management through optimal road-rail intermodal logistics planning considering community safety: A case study in Thailand. Int. J. Knowl. Syst. Sci. (IJKSS) 2023, 14, 1–25. [Google Scholar] [CrossRef]

- Milioulis, K.; Bolbot, V.; Theotokatos, G. Model-based safety analysis and design enhancement of a marine LNG fuel feeding system. J. Mar. Sci. Eng. 2021, 9, 69. [Google Scholar] [CrossRef]

- Kim, S.K.; Park, S.I.; Paik, J.K. Collision-accidental limit states-based safety studies for a LNG-fuelled containership. Ocean Eng. 2022, 257, 111571. [Google Scholar] [CrossRef]

- Goolak, S.; Petrychenko, O.; Burmaka, I.; Vynohradova, A. The use of LNG as an alternative marine fuel: Conceptual requirements and safety measures. In Proceedings of the 28th International Scientific Conference Transport Means, Kaunas, Lithuania, 2–4 October 2024; pp. 965–970. [Google Scholar] [CrossRef]

- Parris, D.; Spinthiropoulos, K.; Ragazou, K.; Giovou, A.; Tsanaktsidis, C. Methanol, a Plugin Marine Fuel for Green House Gas Reduction—A Review. Energies 2024, 17, 605. [Google Scholar] [CrossRef]

- Arnaiz del Pozo, C.; Cloete, S.; Jiménez Álvaro, Á. Techno-Economic Assessment of Long-Term Methanol Production from Natural Gas and Renewables. Energy Convers. Manag. 2022, 266, 115785. [Google Scholar] [CrossRef]

- Guil-López, R.; Mota, N.; Llorente, J.; Millán, E.; Pawelec, B.; Fierro, J.L.G.; Navarro, R.M. Methanol Synthesis from CO2: A Review of the Latest Developments in Heterogeneous Catalysis. Materials 2019, 12, 3902. [Google Scholar] [CrossRef]

- Simon Araya, S.; Liso, V.; Cui, X.; Li, N.; Zhu, J.; Sahlin, S.L.; Jensen, S.H.; Nielsen, M.P.; Kar, S.K. A Review of The Methanol Economy: The Fuel Cell Route. Energy 2020, 13, 596. [Google Scholar] [CrossRef]

- Zincir, B.; Deniz, C.; Tunér, M. Investigation of Environmental, Operational and Economic Performance of Methanol Partially Premixed Combustion at Slow Speed Operation of a Marine Engine. J. Clean. Prod. 2019, 235, 1006–1019. [Google Scholar] [CrossRef]

- Ammar, N.R. An Environmental and Economic Analysis of Methanol Fuel for a Cellular Container Ship. Transp. Res. D Transp. Environ. 2019, 69, 66–76. [Google Scholar] [CrossRef]

- Tadros, M.; Ventura, M.; Soares, C.G. Review of Current Regulations, Available Technologies, and Future Trends in the Green Shipping Industry. Ocean Eng. 2023, 280, 114670. [Google Scholar] [CrossRef]

- Tian, Z.; Wang, Y.; Zhen, X.; Liu, Z. The Effect of Methanol Production and Application in Internal Combustion Engines on Emissions in the Context of Carbon Neutrality: A Review. Fuel 2022, 320, 123902. [Google Scholar] [CrossRef]

- Xing, H.; Stuart, C.; Spence, S.; Chen, H. Alternative Fuel Options for Low Carbon Maritime Transportation: Pathways to 2050. J. Clean. Prod. 2021, 297, 126651. [Google Scholar] [CrossRef]

- Musyoka, S.K.; Khalil, A.S.; Ookawara, S.A.; Elwardany, A.E. Effect of C4 alcohol and ester as fuel additives on diesel engine operating characteristics. Fuel 2023, 341, 127656. [Google Scholar] [CrossRef]

- Svanberg, M.; Ellis, J.; Lundgren, J.; Landalv, I. Renewable Methanol as a Fuel for the Shipping Industry. Renew. Sustain. Energy Rev. 2018, 94, 1217–1228. [Google Scholar] [CrossRef]

- Ellis, J.; Tanneberger, K. Study on the use of ethyl and methyl alcohol as alternative fuels in shipping. Eur. Marit. Saf. Agency 2015, 46, 1–38. [Google Scholar]

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- Cheng, W.; Cheng, Y.F. A techno-economic study of the strategy for hydrogen transport by pipelines in Canada. J. Pipeline Sci. Eng. 2023, 3, 100112. [Google Scholar] [CrossRef]

- Zhang, C.; Shao, Y.; Shen, W.; Li, H.; Nan, Z.; Dong, M.; Bian, J.; Cao, X. Key technologies of pure hydrogen and hydrogen-mixed natural gas pipeline transportation. Acs Omega 2023, 8, 19212–19222. [Google Scholar] [CrossRef]

- Teoh, Y.H.; How, H.G.; Le, T.D.; Nguyen, H.T.; Loo, D.L.; Rashid, T.; Sher, F. A review on production and implementation of hydrogen as a green fuel in internal combustion engines. Fuel 2023, 333, 126525. [Google Scholar] [CrossRef]

- Li, J.; Zhang, L.; Li, R.; Yang, X.; Zhang, T. High-pressure gaseous hydrogen storage vessels: Current status and prospects. Energy Storage Sci. Technol. 2021, 10, 1835. [Google Scholar] [CrossRef]

- Mallouppas, G.; Yfantis, E.A. Decarbonization in shipping industry: A review of research, technology development, and innovation proposals. J. Mar. Sci. Eng. 2021, 9, 415. [Google Scholar] [CrossRef]

- ISO 8178-7:2015 Standard; Reciprocating internal combustion engines — Exhaust emission measurement — Part 7: Engine family determination. International Organization for Standardization (ISO): Geneva, Switzerland, 2015.

- Bunse, M.J. Sustainable Supply Chains for Maritme Biofuels 2021. Available online: https://platformduurzamebiobrandstoffen.nl/wp-content/uploads/2021/04/2021_PDB_Bunse_Sustainable-supply-chains-for-maritime-biofuels.pdf (accessed on 10 November 2024).

- Wang, Y.; Wright, L.A. A comparative review of alternative fuels for the maritime sector: Economic, technology, and policy challenges for clean energy implementation. World 2021, 2, 456–481. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Zhen, L. Berth and quay cranes allocation problem with on-shore power supply assignment in container terminals. Comput. Ind. Eng. 2024, 188, 109910. [Google Scholar] [CrossRef]

- Elkafas, A.G.; Rivarolo, M.; Gadducci, E.; Magistri, L.; Massardo, A.F. Fuel cell systems for maritime: A review of research development, commercial products, applications, and perspectives. Processes 2022, 11, 97. [Google Scholar] [CrossRef]

- Kryshtopa, S.; Górski, K.; Longwic, R.; Smigins, R.; Kryshtopa, L. Increasing parameters of diesel engines by their transformation for methanol conversion products. Energies 2021, 14, 1710. [Google Scholar] [CrossRef]

- Gadducci, E.; Lamberti, T.; Rivarolo, M.; Magistri, L. Experimental campaign and assessment of a complete 240-kW Proton Exchange Membrane Fuel Cell power system for maritime applications. Int. J. Hydrogen Energy 2022, 47, 22545–22558. [Google Scholar] [CrossRef]

- Halder, P.; Babaie, M.; Salek, F.; Shah, K.; Stevanovic, S.; Bodisco, T.A.; Zare, A. Performance, emissions and economic analyses of hydrogen fuel cell vehicles. Renew. Sustain. Energy Rev. 2024, 199, 114543. [Google Scholar] [CrossRef]

- Khurshid, H.; Mohammed, B.S.; Al-Yacoubya, A.M.; Liew, M.S.; Zawawi, N.A.W.A. Analysis of hybrid offshore renewable energy sources for power generation: A literature review of hybrid solar, wind, and waves energy systems. Dev. Built Environ. 2024, 19, 100497. [Google Scholar] [CrossRef]

- Manneh, O.; Islam, M.S.; Danso, Y. Application of Renewable Energy Technologies in Marine Vessels; State of the Art Review. Ph.D. Dissertation, Departmental of Technical and Vocational Education (TVE), Islamic University of Technology (IUT), Board Bazar, Gazipur, Bangladesh, 2022. Available online: http://103.82.172.44:8080/xmlui/handle/123456789/1815 (accessed on 12 December 2024).

- Adham, M.I. Analysis and Optimal Planning of Nuclear-Renewable Hybrid Energy Systems for Ships. Ph.D. Dissertation, University of Ontario Institute of Technology, Oshawa, ON, Canada, 2021. Available online: https://library-archives.canada.ca/eng/services/services-libraries/theses/Pages/item.aspx?idNumber=1344012581 (accessed on 12 December 2024).

- Sharma, K.; Syal, P. A Review on Solar Powered Boat Design. Int. Res. J. Adv. Sci. Hub 2021, 3, 1–10. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, Z.; Lin, J. Multi-energy complementary power systems based on solar energy: A review. Renew. Sustain. Energy Rev. 2024, 188, 114464. [Google Scholar] [CrossRef]

- Nyanya, M.N.; Vu, H.B.; Schönborn, A.; Ölçer, A.I. Wind and solar assisted ship propulsion optimisation and its application to a bulk carrier. Sustain. Energy Technol. Assess. 2021, 47, 101397. [Google Scholar] [CrossRef]

- Bonthagorla, P.K.; Mikkili, S. Optimal PV array configuration for extracting maximum power under partial shading conditions by mitigating mismatching power losses. CSEE J. Power Energy Syst. 2020, 8, 499–510. [Google Scholar] [CrossRef]

- Minak, G. Solar Energy-Powered Boats: State of the Art and Perspectives. J. Mar. Sci. Eng. 2023, 11, 1519. [Google Scholar] [CrossRef]

- Tercan, Ş.H.; Eid, B.; Heidenreich, M.; Kogler, K.; Akyürek, Ö. Financial and technical analyses of solar boats as a means of sustainable transportation. Sustain. Prod. Consum. 2021, 25, 404–412. [Google Scholar] [CrossRef]

- Murshed, N.; Tushar, M.S.K.; Chowdhury, S. Power Performance Analysis of PV Module with DC to DC Buck Converter. Adv. J. Grad. Res. 2020, 8, 27–39. [Google Scholar] [CrossRef]

- Waseem, M.; Ahmad, M.; Parveen, A.; Suhaib, M. Battery technologies and functionality of battery management system for EVs: Current status, key challenges, and future prospectives. J. Power Sources 2023, 580, 233349. [Google Scholar] [CrossRef]

- Lawan, M.; Aboushady, A.; Ahmed, K.H. Photovoltaic MPPT techniques comparative review. In Proceedings of the 2020 9th International Conference on Renewable Energy Research and Application (ICRERA), Glasgow, UK, 27–30 September 2020; IEEE: New York, NY, USA, 2020; pp. 344–351. [Google Scholar] [CrossRef]

- Prastiko, D.H.; Supardi, A. Pengendali dan Monitoring Kecepatan Putar Motor Induksi 3 Fasa Berbasis Programmable Logic Controller dan Expansion dengan Human Machine Interface. Emit. J. Tek. Elektro 2022, 22, 168–176. [Google Scholar] [CrossRef]

- Sharma, S.K.; Sharma, G.; Gaur, A.; Arya, A.; Mirsafi, F.S.; Abolhassani, R.; Rubahn, H.-G.; Yu, J.-S.; Mishra, Y.K. Progress in electrode and electrolyte materials: Path to all-solid-state Li-ion batteries. Energy Adv. 2022, 1, 457–510. [Google Scholar] [CrossRef]

- Benlahbib, B.; Dahbi, A.; Fares, B.; Lakhdari, A.; Bouarroudj, N.; Mekhilef, S.; Abdelkrim, T. An experimental investigation design of a bidirectional DC-DC buck-boost converter for PV battery charger system. Int. J. Power Electron. Drive Syst. (IJPEDS) 2023, 14, 2362–2371. [Google Scholar] [CrossRef]

- Andriani, D.; Bicer, Y. A review of hydrogen production from onboard ammonia decomposition: Maritime applications of concentrated solar energy and boil-off gas recovery. Fuel 2023, 352, 128900. [Google Scholar] [CrossRef]

- Benghanem, M.; Haddad, S.; Alzahrani, A.; Mellit, A.; Almohamadi, H.; Khushaim, M.; Aida, M.S. Evaluation of the performance of polycrystalline and monocrystalline PV technologies in a hot and arid region: An experimental analysis. Sustainability 2023, 15, 14831. [Google Scholar] [CrossRef]

- Zubeer, S.A.; Ali, O.M. Performance analysis and electrical production of photovoltaic modules using active cooling system and reflectors. Ain Shams Eng. J. 2021, 12, 2009–2016. [Google Scholar] [CrossRef]

- Emmanuel, B.; Yuan, Y.; Gaudence, N.; Zhou, J. A review on the influence of the components on the performance of PVT modules. Sol. Energy 2021, 226, 365–388. [Google Scholar] [CrossRef]

- Rasul, M.J.; Kim, J. Comprehensive review and comparison on battery technologies as electric-powered source in marine applications. J. Energy Storage 2024, 88, 111509. [Google Scholar] [CrossRef]

- Dotto, A.; Satta, F.; Campora, U. Energy, environmental and economic investigations of cruise ships powered by alternative fuels. Energy Convers. Manag. 2023, 285, 117011. [Google Scholar] [CrossRef]

- Greenp Pingkuo, L.; Jiahao, W. Study on the diffusion of CCUS technology under carbon trading mechanism: Based on the perspective of tripartite evolutionary game among thermal power enterprises, government and public. J. Clean. Prod. 2024, 438, 140730. [Google Scholar] [CrossRef]

- Chettri, M.; Kundu, S.; Diyali, N.; Biswas, B. Using Solar Energy in Methanol Production: Efficiency, Environmental Impact and Economical Performance. Ref. Modul. Chem. Mol. Sci. Chem. Eng. 2024. [Google Scholar] [CrossRef]

- Melnyk, O.; Onyshchenko, S.; Onishchenko, O.; Lohinov, O.; Ocheretna, V. Integral Approach to Vulnerability Assessment of Ship’s Critical Equipment and Systems. Trans. Marit. Sci. 2023, 12. [Google Scholar] [CrossRef]

- Abraham, E.J.; Linke, P.; Al-Rawashdeh, M.; Rousseau, J.; Burton, G.; Al-Mohannadi, D.M. Large-scale shipping of low-carbon fuels and carbon dioxide towards decarbonized energy systems: Perspectives and challenges. Int. J. Hydrogen Energy 2024, 63, 217–230. [Google Scholar] [CrossRef]

- Bondarenko, I.; Lukoševičius, V.; Neduzha, L. Novel ‘Closed’-System Approach for Monitoring the Technical Condition of Railway Tracks. Sustainability 2024, 16, 3180. [Google Scholar] [CrossRef]

- Harahap, F.; Nurdiawati, A.; Conti, D.; Leduc, S.; Urban, F. Renewable marine fuel production for decarbonised maritime shipping: Pathways, policy measures and transition dynamics. J. Clean. Prod. 2023, 415, 137906. [Google Scholar] [CrossRef]

- Ampah, J.D.; Yusuf, A.A.; Afrane, S.; Jin, C.; Liu, H. Reviewing two decades of cleaner alternative marine fuels: Towards IMO’s decarbonization of the maritime transport sector. J. Clean. Prod. 2021, 320, 128871. [Google Scholar] [CrossRef]

- Daniel, H.; Trovão, J.P.F.; Williams, D. Shore power as a first step toward shipping decarbonization and related policy impact on a dry bulk cargo carrier. eTransportation 2022, 11, 100150. [Google Scholar] [CrossRef]

- Kalikatzarakis, M.; Geertsma, R.D.; Boonen, E.J.; Visser, K.; Negenborn, R.R. Ship energy management for hybrid propulsion and power supply with shore charging. Control Eng. Pract. 2018, 76, 133–154. [Google Scholar] [CrossRef]

- Yu, J.; Voß, S.; Tang, G. Strategy development for retrofitting ships for implementing shore side electricity. Transp. Res. Part D Transp. Environ. 2019, 74, 201–213. [Google Scholar] [CrossRef]

- Sciberras, E.A.; Zahawi, B.; Atkinson, D.J. Reducing shipboard emissions—Assessment of the role of electrical technologies. Transp. Res. Part D Transp. Environ. 2017, 51, 227–239. [Google Scholar] [CrossRef]

- Riabov, I.; Goolak, S.; Kondratieva, L.; Overianova, L. Increasing the energy efficiency of the multi-motor traction electric drive of an electric locomotive for railway quarry transport. Eng. Sci. Technol. Int. J. 2023, 42, 101416. [Google Scholar] [CrossRef]

- Riabov, I.; Goolak, S.; Neduzha, L. An Estimation of the Energy Savings of a Mainline Diesel Locomotive Equipped with an Energy Storage Device. Vehicles 2024, 6, 611–631. [Google Scholar] [CrossRef]

- Goolak, S.; Liubarskyi, B.; Riabov, I.; Lukoševičius, V.; Keršys, A.; Kilikevičius, S. Analysis of the Efficiency of Traction Drive Control Systems of Electric Locomotives with Asynchronous Traction Motors. Energies 2023, 16, 3689. [Google Scholar] [CrossRef]

- Goolak, S.; Liubarskyi, B.; Riabov, I.; Chepurna, N.; Pohosov, O. Simulation of a direct torque control system in the presence of winding asymmetry in induction motor. Eng. Res. Express 2023, 5, 025070–025086. [Google Scholar] [CrossRef]

- Goolak, S. Methodological Guidelines for Choosing a Method of Compensation of Higher Harmonic Current Components in Traction Drive Systems of Electric Rolling Stock. In Proceedings of the proceedings of the 27th International Scientific Conference Transport Means, Palanga, Lithuania, 4–6 October 2023; pp. 685–690. [Google Scholar] [CrossRef]

- Goolak, S. Improving the Efficiency of Electric Rolling Stock Operation Through the Use of Adaptive Filtering Methods for High Harmonic Current Components in Traction Drive Systems. Probl. Energeticii Reg. 2023, 4, 1–13. [Google Scholar] [CrossRef]

- Goolak, S. To the Choice of Filter Approximation in the Synthesis of the Reactive Power Compensator Control System. In Proceedings of the 28th International Scientific Conference Transport Means, Kaunas, Lithuania, 2–4 October 2024; pp. 192–197. [Google Scholar] [CrossRef]

| Fuel Type | LNG | HFO | |

|---|---|---|---|

| Main engine type | Low-speed high-pressure dual-fuel engines (LS-HPDF) | Low-speed low-pressure dual-fuel engines (LS-LPDF) | Low-speed diesel cycle engines (LSD) |

| Engine model: | 6G50ME-GI | 6X-52DF | 6G50ME |

| Average main engine load at sea and operating days | 72.5%/250 days | ||

| Engine thermal efficiency (%) at 72.5% MCR | 55.30 | 50.20 | 53.9 |

| SFC (g/kWh) at 72.5% MCR (Primary/Pilot Fuel) | 126.85/3.9 | 141.75/1.95 | 147.24/ - |

| Lower heating value (LHV), MJ/kg | 49.2 | 49.2 | 40.2 |

| Emission factor (GHG t/t of Fuel) | |||

| CO2 | 2.75 | 2.75 | 3.144 |

| CH4 | 0.001449 | 0.017086 | 0.00006 |

| N2O | 0.000217 | 0.000137 | 0.00016 |

| Fuel Type | LNG | HFO |

|---|---|---|

| Type of auxiliary engine | Medium-speed high-pressure dual-fuel engines (MS-LPDF) | Medium-speed diesel cycle engines (MSD) |

| SFOC (g/kWh) | 152 | 195 |

| Emission factor (GHG t/t of Fuel) | ||

| CO2 | 2.75 | 3.144 |

| CH4 | 0.036 | 0.00006 |

| N2O | 0.000131 | 0.00025 |

| Load (%) | LS-HPDF | LS-LPDF | ||

|---|---|---|---|---|

| SFOS | SPOS | SFOS | SPOS | |

| 10 | 141.4 | 12.5 | 156.8 | 4.7 |

| 20 | 137.1 | 10.1 | 152.6 | 4.1 |

| 30 | 133.8 | 8.0 | 149.1 | 3.5 |

| 40 | 131.4 | 6.3 | 146.3 | 2.9 |

| 50 | 129.8 | 5.0 | 144.1 | 2.5 |

| 60 | 129.2 | 4.1 | 142.6 | 2.1 |

| 70 | 129.4 | 3.5 | 141.7 | 1.8 |

| 80 | 130.6 | 3.3 | 141.5 | 1.6 |

| 90 | 132.7 | 3.5 | 142.0 | 1.5 |

| 100 | 135.6 | 4.1 | 143.1 | 1.4 |

| Indicator | Cascade | MR | EXP |

|---|---|---|---|

| Application | LS Onshore | LS Onshore, SS, and Offshore | SS Onshore and Offshore |

| Energy efficiency | H | M to H | L |

| Equipment quantity | H | L to M | L |

| Heat transfer surface area | M | H | L |

| Operational simplicity | L | L to M | H |

| Ease of startup and adjustment | M | L | H |

| Feed gas composition adaptability | H | M | H |

| Vessel motion sensitivity | H | M to H | L |

| Space requirements | H | M | L |

| Hydrocarbon refrigerant storage | H | M to H | None |

| Capital expenditure | H | L to M | L |

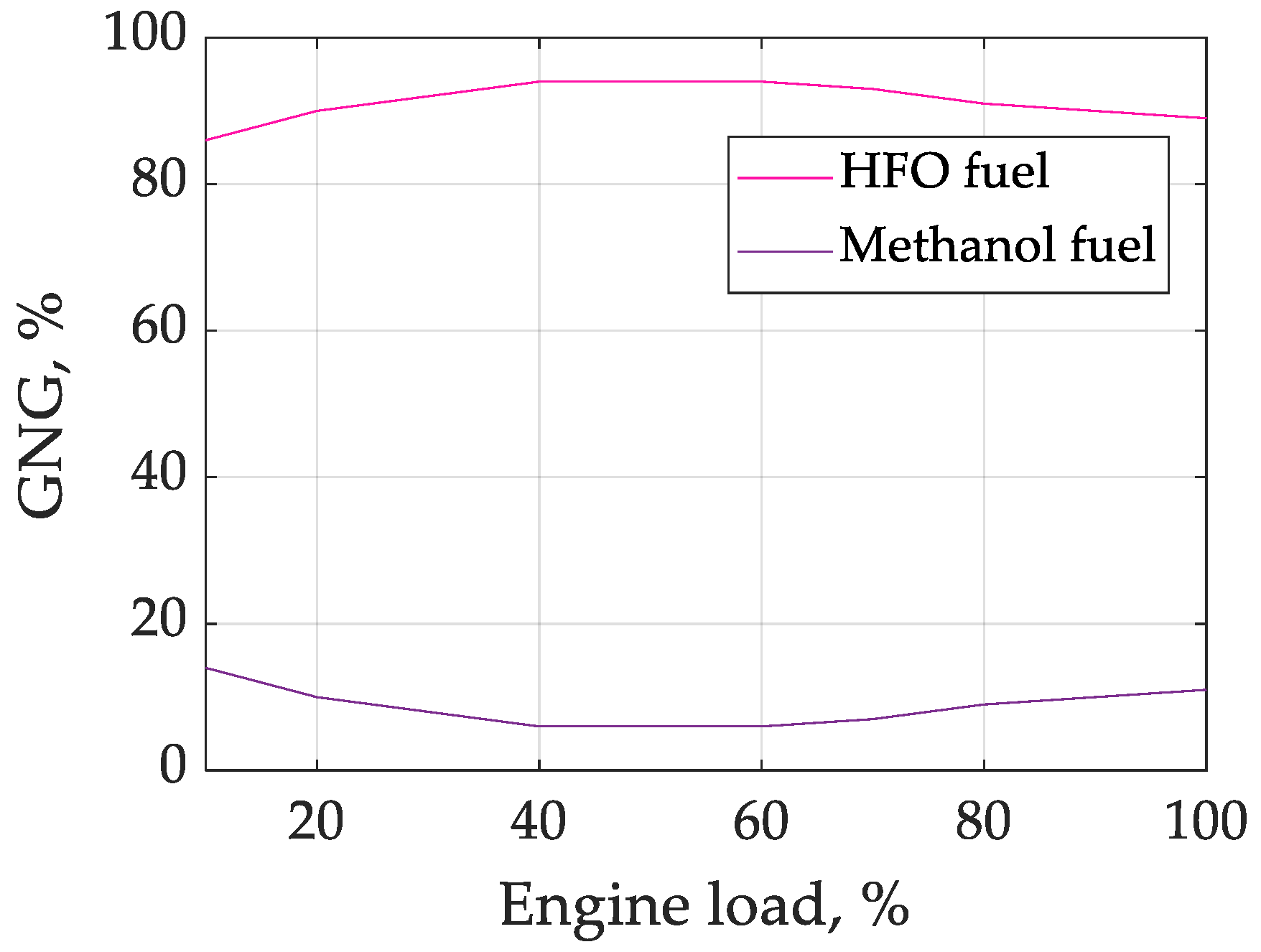

| Fuel Type | Methanol | HFO |

|---|---|---|

| Main Engine Type | LSD | LSD |

| Engine manufacturer model | 6G50ME-LGIM | 6G50ME |

| Thermal efficiency (%) at 72.5% MCR | 53.9 | 53.9 |

| SFC (g/kWh) at 72.5% of MCR (methanol/HFO) | 307.5/13.1 | 147.24/- |

| Lower heating value (LHV), MJ/kg | 19.9 | 40.2 |

| Emission Factor (GNG t/ton of fuel) | ||

| CO2 | 1.375 | 3.144 |

| CH4 | 0.000006 | 0.00006 |

| N2O | 0.00016 | 0.00016 |

| Fuel Type | Methanol | HFO |

|---|---|---|

| Auxiliary engine type | MSD | MSD |

| SFOC (g/kWh) | 370 | 195 |

| Emission factor (GHG t/t fuel) | ||

| CO2 | 1.375 | 3.144 |

| CH4 | 0.00006 | 0.00006 |

| N2O | 0.00025 | 0.00025 |

| Engine Load (%) | HFO | Methanol |

|---|---|---|

| 10 | 141.4 | 45.9 |

| 20 | 137.1 | 33.3 |

| 30 | 133.8 | 25.1 |

| 40 | 131.4 | 20.8 |

| 50 | 129.8 | 19.7 |

| 60 | 129.2 | 21.3 |

| 70 | 129.4 | 24.8 |

| 80 | 130.6 | 29.9 |

| 90 | 132.7 | 35.8 |

| 100 | 135.6 | 41.9 |

| Parameter | Units | Hydrogen | Methane |

|---|---|---|---|

| Gas density at standard conditions (ISO) | kg/m3 | 0.0905 | 0.716 |

| Relative gas density (air = 1) | relative units | 0.07 | 0.554 |

| Relative density, liquid (water = 1) | relative units | 0.071 | 0.44–0.48 |

| Lower heating value | MJ/kg | 119.96 | 50 |

| Critical temperature | °C | −240 | −82.45 |

| Boiling point | °C | −253 | −161.48 |

| Melting point | °C | −259 | −187.6 |

| Combustibility range | % (v/v) | 4–77 | 5–14 |

| Maximum combustion velocity | m/s | 2.91 | 0.37 |

| Autoignition temperature | °C | 585 | 537 |

| UN number | 1954 | 1971 | |

| Additional information | Burns with an invisible flame, extremely flammable gas | Asphyxiating |

| Technology | Energy Consumption (kWh/kg(H2)) | Operating Temperature (°C) | Hydrogen Pressure (MPa) | Stack Lifetime (hours) | Deployment Scale (kW) |

|---|---|---|---|---|---|

| Alkaline | 53.4 | 80 | 0.7 | 90,000 | >100,000 |

| PEM | 54.6 | 80 | 0.5 | 50,000 | >100,000 |

| SOFC | 36.14 | >800 | 0.1 | 23,000 | 7.5 |

| Membraneless | 54.34 | <50 | 0/1 | - | ~10 |

| Engine Type | Fuel | CO2 | CH4 | CO2-eq (CH4) | N2O | CO2-eq (N2O) | CO2-eq (Total) |

|---|---|---|---|---|---|---|---|

| Two-stroke slow-speed main engine (ME) with diesel cycle | MGO | 3.21 | 6.53 × 10−5 | 1.83 × 10−3 | 2.22 × 10−4 | 5.88 × 10−2 | 3.27 |

| LNG | 2.75 | 1.64 × 10−3 | 4.58 × 10−2 | 2.45 × 10−4 | 6.51 × 10−2 | 2.86 | |

| Methanol | 1.38 | 3.34 × 10−5 | 9.35 × 10−4 | 1.00 × 10−5 | 2.65 × 10−3 | 1.38 | |

| Ammonia | 0 | 0 | 0 | 5.42 × 10−4 | 1.44 × 10−1 | 0.14 | |

| Four-stroke medium-speed auxiliary engine with Otto cycle | MGO | 3.21 | 5.35 × 10−5 | 1.50 × 10−3 | 1.60 × 10−4 | 4.25 × 10−2 | 3.25 |

| LNG | 2.75 | 3.54 × 10−2 | 9.92 × 10−1 | 1.29 × 10−4 | 3.41 × 10−2 | 3.78 | |

| Methanol | 1.38 | 2.53 × 10−5 | 7.09 × 10−4 | 7.59 × 10−6 | 2.01 × 10−3 | 1.38 | |

| Ammonia | 0 | 0 | 0 | 5.02 × 10−3 | 1.33 | 1.33 |

| Fuel Property | Ammonia | Diesel |

|---|---|---|

| Liquid density, kg/m3 | 602.8 | 832 |

| Heat of combustion, MJ/kg | 18.8 | 42.7 |

| Octane number | 110 | 30 |

| Cetane number | 5–7 | 40–55 |

| Ignition temperature, °C | 651 | 254–285 |

| Laminar flame speed, m/s | 0.07–0.14 | 0.87 |

| Stoichiometric air-to-fuel ratio | 6.06 | 14.5 |

| Heat of vaporization, kJ/kg | 1370 | 232 |

| Operating Mode | Mode 1 | Mode 2 | Mode 3 | Mode 4 | Mode 5 |

|---|---|---|---|---|---|

| Weighting Factor | 0.05 | 0.05 | 0.25 | 0.50 | 0.15 |

| Engine Conditions Using Biofuel Mixture | |||||

| Engine Load (%) | 20 | 32 and 37 | 41 | 61 and 63 | 90 |

| Engine Speed, rpm | 37 | 55 and 66 | 63 | 79 | 90 |

| Power (kWh) | 1986 | 3178 and 3675 | 4072 | 6058 and 6257 | 8939 |

| Fuel Consumption (kg·h−1) | 280 | 561 and 825 | 736 | 1179 and 1215 | 1780 |

| Specific Fuel Consumption (g·kWh−1·h−1) | 141 | 177 and 224 | 181 | 195 and 194 | 199 |

| Engine Conditions Using LSMGO | |||||

| Engine Load (%) | 23 | 37 | 44 | 67 | 90 |

| Engine Speed, rpm | 36 | 55 | 63 | 79 | 87 |

| Power (kWh) | 2284 | 3675 | 4370 | 6654 | 8939 |

| Fuel Consumption (kg·h−1) | 304 | 587 | 762 | 1245 | 1703 |

| Specific Fuel Consumption (g·kWh−1·h−1) | 133 | 160 | 174 | 187 | 191 |

| Renewable Carrier | Production Technology |

|---|---|

| LBG/LNG | Anaerobic digestion |

| Gasification and cat. reaction (Sabatier process) | |

| Ethanol | Fermentation from sugars |

| Fermentation from lignocellulosic waste | |

| Methanol | Anaerobic production of methane and dehydration |

| Gasification from solid biomass | |

| DME (dimethyl ether) | Gasification |

| Dehydration of bio-methanol | |

| SVO (straight vegetable oil) | Extraction from plants |

| FAME (fatty acid methyl esters) | Transesterification of vegetable oils |

| HVO (hydrotreated vegetable oil) | Hydrogenation of vegetable oils |

| Renewable diesel | FT, HTL, pyrolysis, HVO |

| Lignin diesel oil | Solvolysis |

| Fuel | LHV (MJ/kg) | HHV (MJ/kg) | Energy Density (MJ/L) |

|---|---|---|---|

| HFO | 39 | 42 | 39 |

| ULS MDO (Ultra-Low Sufhur Marine Diesel Oil) | 43 | 46 | 36 |

| Petrol | 43 | 47 | 32 |

| LBG | 48 | 55 | 21 |

| Biomethanol | 20 | 23 | 16 |

| Bioethanol | 27 | 30 | 21 |

| SVO | 37 | 40 | 34 |

| FAME | 38 | 40 | 34 |

| HVO | 43 | 47 | 33 |

| FT diesel (Fischer–Tropsch diesel fuel) | 44 | – | 34 |

| UPO (Upgraded Pyrolysis Oil) | 43 | 47 | 36 |

| Lignin oil | 33 | 35 | – |

| HTL biocrude (Hydrothermal Liquefaction Biocrude) | 34–38 | – | – |

| Component | Capital Investments for the Construction of New Ships (Four-Stroke Engine/Two-Stroke Engine), USD/kW | Life Cycle |

|---|---|---|

| Propulsion system | ||

| Electric motor | 400 | 30 years |

| Fuel storage system | ||

| Battery, NMC, USD/kWh | 400–1000 and expected to fall to 124 in 2030 | 8–11 years |

| Battery, LPF, USD/kWh | 210–1000 and expected to fall to 70 in 2030 | 7–13 years |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrychenko, O.; Levinskyi, M.; Goolak, S.; Lukoševičius, V. Prospects of Solar Energy in the Context of Greening Maritime Transport. Sustainability 2025, 17, 2141. https://doi.org/10.3390/su17052141

Petrychenko O, Levinskyi M, Goolak S, Lukoševičius V. Prospects of Solar Energy in the Context of Greening Maritime Transport. Sustainability. 2025; 17(5):2141. https://doi.org/10.3390/su17052141

Chicago/Turabian StylePetrychenko, Olga, Maksym Levinskyi, Sergey Goolak, and Vaidas Lukoševičius. 2025. "Prospects of Solar Energy in the Context of Greening Maritime Transport" Sustainability 17, no. 5: 2141. https://doi.org/10.3390/su17052141

APA StylePetrychenko, O., Levinskyi, M., Goolak, S., & Lukoševičius, V. (2025). Prospects of Solar Energy in the Context of Greening Maritime Transport. Sustainability, 17(5), 2141. https://doi.org/10.3390/su17052141