Construction and Application of Enterprise Electric Carbon Model: A Study Based on Key Enterprises in Qinghai Province

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Data Acquisition and Preprocessing

3.2. Settings of the Electric Carbon Model

4. Results and Evaluations

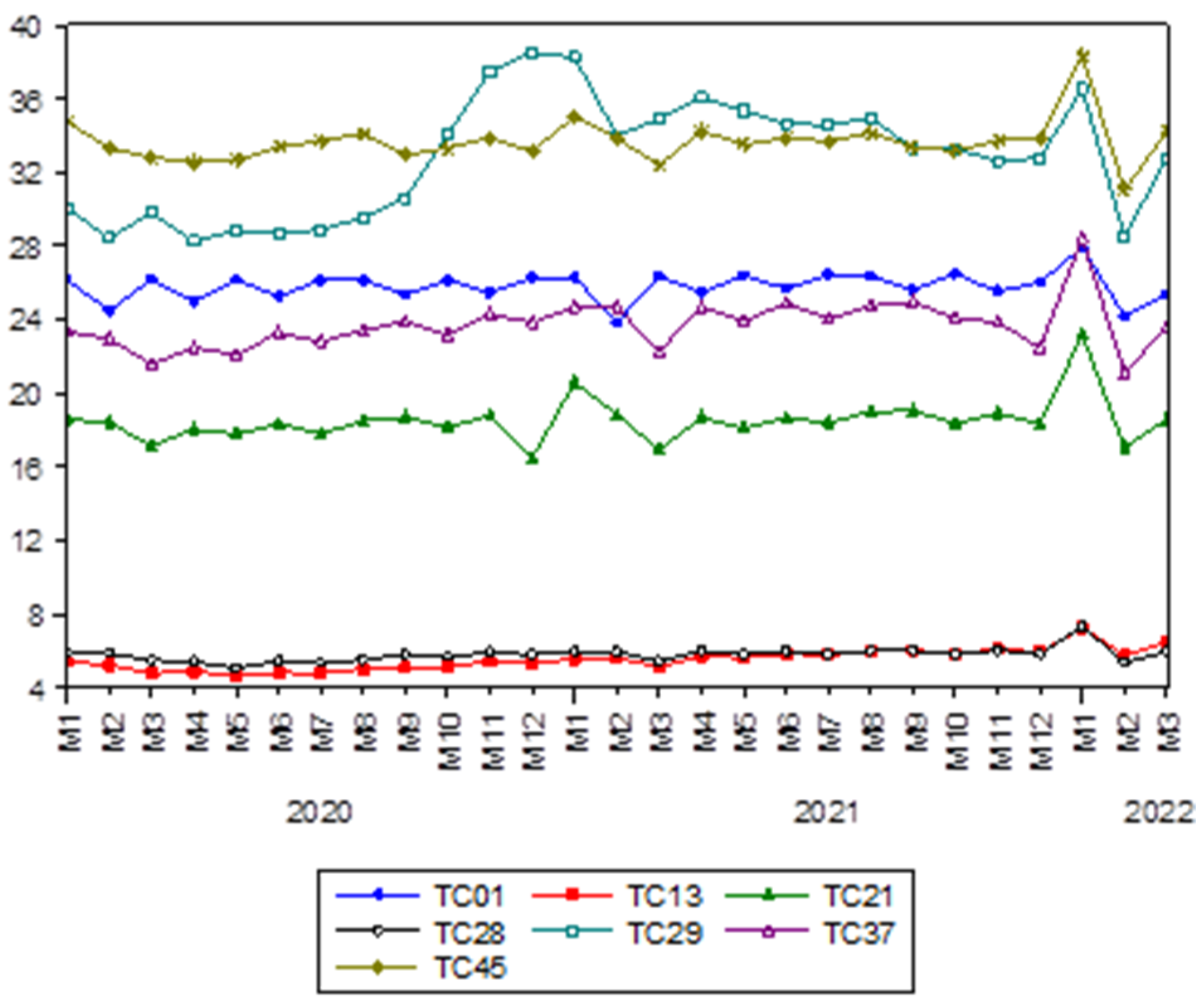

4.1. Carbon Emission Measurement Results of Sample Enterprises in the Electrolytic Aluminum Industry

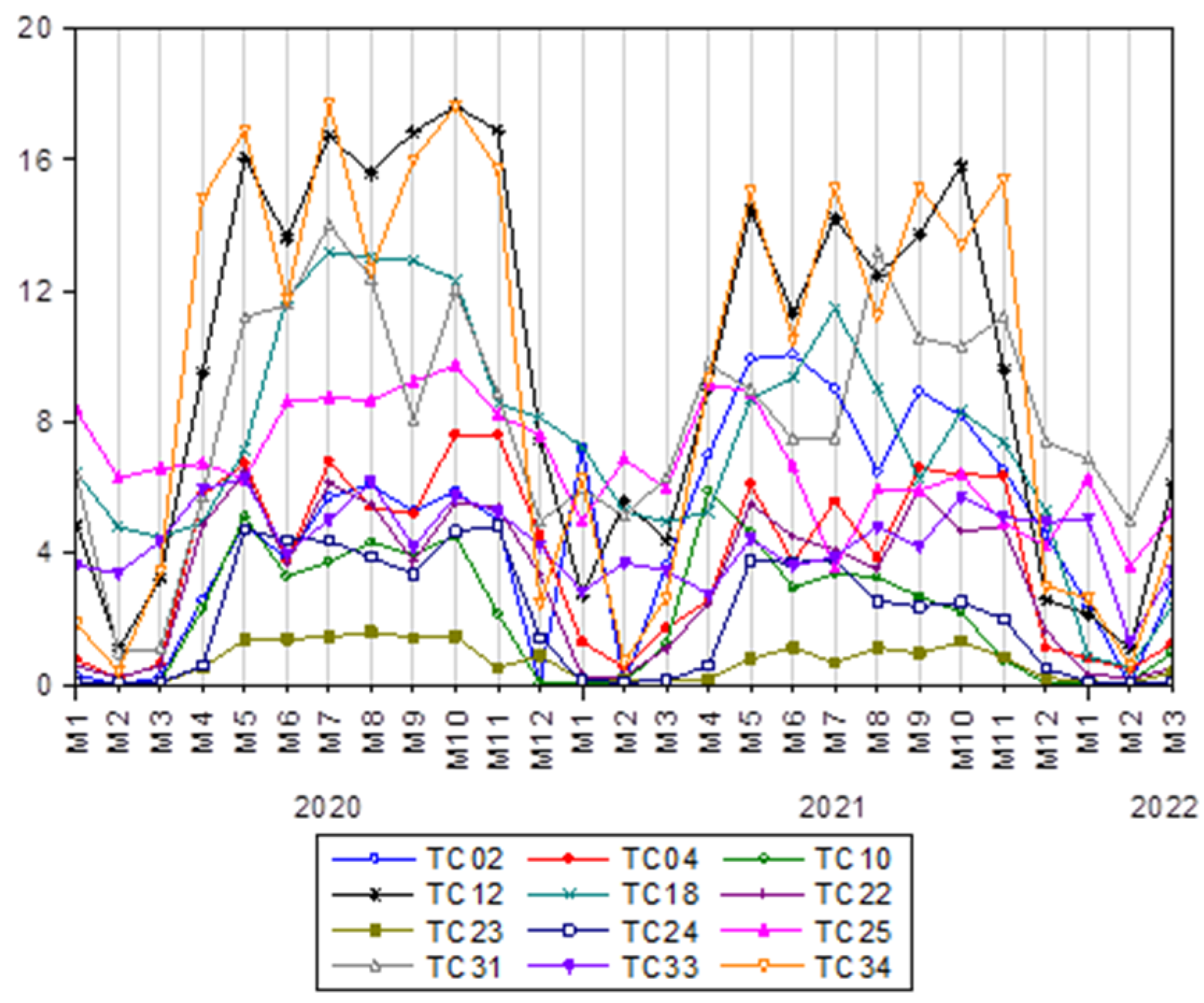

4.2. Carbon Emission Measurement Results of Sample Enterprises in the Cement Industry

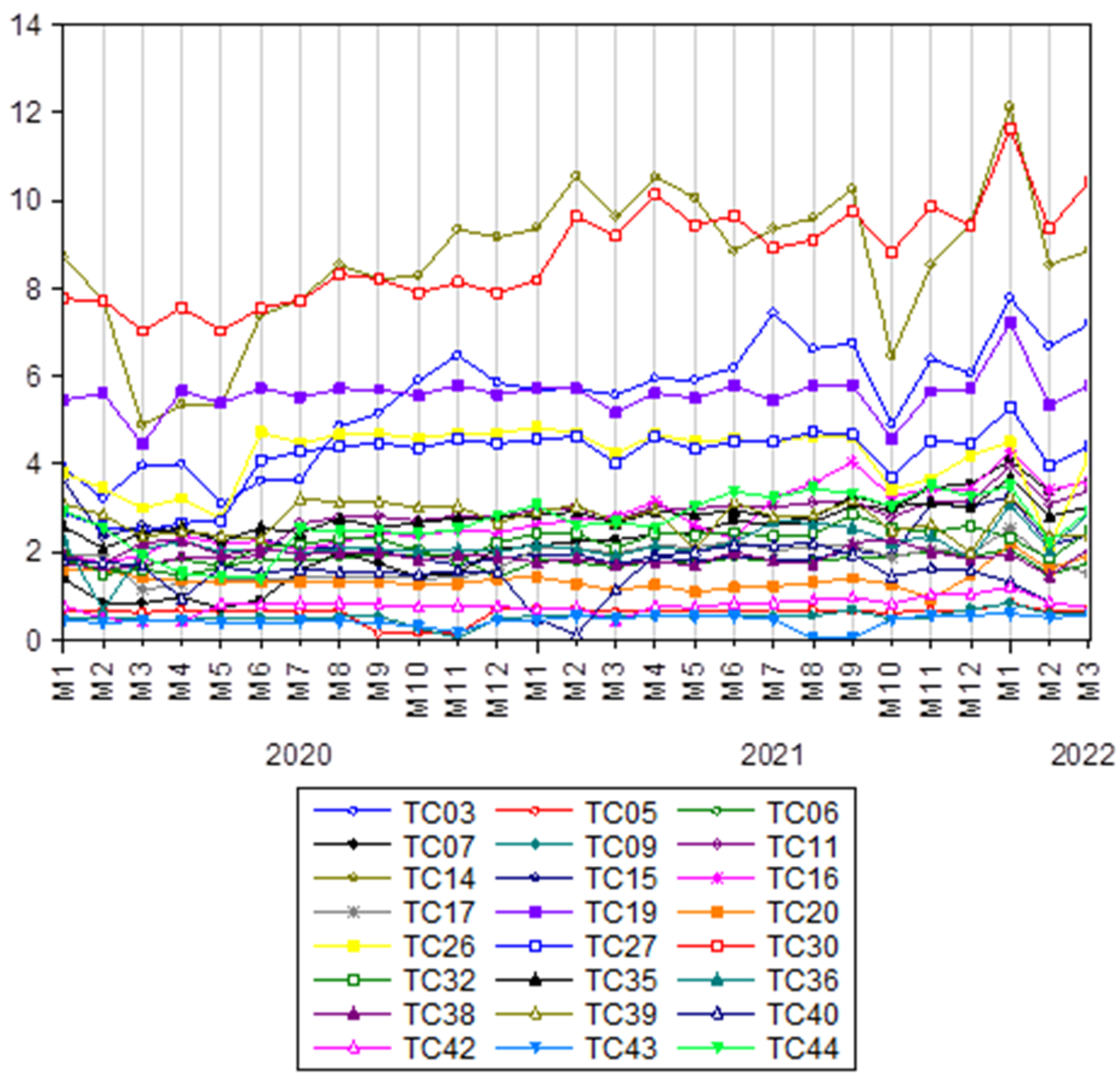

4.3. Carbon Emission Measurement Results of Sample Enterprises in the Ferroalloy Industry

5. Conclusions and Policy Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shi, J.; Tang, H.; Zhou, Q.; Han, L.; Hao, R. High frequency measurement of carbon emissions based on power big data: A case study of Chinese Qinghai province. Sci. Total Environ. 2023, 902, 166075. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ji, H.; Wang, S.; Wang, H.; Shi, J. Research on Carbon Emissions Estimation in Key Industries Based on the Electricity–Energy–Carbon Model: A Case Study of Henan Province. Energies 2024, 17, 2933. [Google Scholar] [CrossRef]

- IPCC. Guidelines for National Greenhouse Gas Inventories; Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2006; Volume 2, Chapter 6. [Google Scholar]

- Shi, J.; Zhou, Q.; Han, L.; Si, Y. High-Frequency Multi-Dimensional Monitoring of Carbon Emissions in Qinghai Province; Research Report; Carbon Economy and Econometrics Research Center, Beijing University of Posts and Telecommunications: Beijing, China, 2021. [Google Scholar]

- Zhang, M. Carbon Emissions Measurement of Sub-industries in China’s Manufacturing Sector—Also on the Existence of EKC in Manufacturing. Soft Sci. 2015, 29, 113–116. [Google Scholar] [CrossRef]

- Shen, L.; Gao, T.; Zhao, J.; Wang, L.; Wang, L.; Liu, L.; Chen, F.; Xue, J. Factory-level measurements on CO2 emission factors of cement production in China. Renew. Sustain. Energy Rev. 2014, 34, 337–349. [Google Scholar] [CrossRef]

- UNFCCC. The United States: United Nations Framework Convention on Climate Change; United Nations General Assembly: New York, NY, USA, 2006. [Google Scholar]

- Guo, J.; Liu, C.; Sun, P. Carbon Emissions of China’s Industrial Sectors: Influencing Factors and Emission Reduction Potentials. Resour. Sci. 2011, 33, 1630–1640. [Google Scholar]

- Sinden, G. The contribution of PAS 2050 to the evolution of international greenhouse gas emission standards. Int. J. Life Cycle Assess. 2009, 14, 195–203. [Google Scholar] [CrossRef]

- Shan, Y.; Guan, D.; Liu, J.; Mi, Z.; Liu, Z.; Liu, J.; Schroeder, H.; Cai, B.; Chen, Y.; Shao, S.; et al. Methodology and applications of city level CO2 emission accounts in China. J. Clean. Prod. 2017, 161, 1215–1225. [Google Scholar] [CrossRef]

- Ma, X.; Wang, C.; Dong, B.; Gu, G.; Chen, R.; Li, Y.; Zou, H.; Zhang, W.; Li, Q. Carbon emissions from energy consumption in China: Its measurement and driving factors. Sci. Total Environ. 2019, 648, 1411–1420. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Lai, X.; Tian, C. Focusing on the Development Trends of Low-Carbon Standards—The UK PAS 2050 Carbon Footprint Standard. Environ. Prot. 2010, 2010, 74–76. [Google Scholar] [CrossRef]

- ISO 14064-1:2018; Greenhouse Gases—Part 1: Specification with Guidance at the Organization Level for Quantification and Reporting of Greenhouse Gas Emissions and Removals. International Organization for Standardization (ISO): Geneva, Switzerland, 2018.

- Hao, R. Study on the Spatiotemporal Patterns and Spatial Effects of Carbon Emission Efficiency in the Beijing-Tianjin-Hebei Region Based on Nighttime Light Data. Master’s Thesis, Beijing Normal University, Beijing, China, 2023. [Google Scholar]

- Yu, S.; Wei, Y.M.; Guo, H.; Ding, L. Carbon emission coefficient measurement of the coal-to-power energy chain in China. Appl. Energy 2014, 114, 290–300. [Google Scholar] [CrossRef]

- Bryant, R.A.; Bundy, M.F.; Zong, R. Comparing Methods for Determining Carbon Dioxide Emissions from Stationary Sources. In Proceedings of the 38th Stationary Source Sampling and Analysis for Air Pollutants Conference, Point Clear, AL, USA, 2–7 March 2014. [Google Scholar]

- Whittaker, C.; McManus, M.C.; Hammond, G.P. Greenhouse gas reporting for biofuels: A comparison between the RED, RTFO and PAS2050 methodologies. Energy Policy 2011, 39, 5950–5960. [Google Scholar] [CrossRef]

- Schaefer, F.; Blanke, M. Opportunities and Challenges of Carbon Footprint, Climate or CO2 Labelling for Horticultural Products. Erwerbs-Obstbau 2014, 56, 73–80. [Google Scholar] [CrossRef]

| Enterprise Code 1 | Emission Scale 2 | Monthly Total Emission Range (10,000 tons) | Average Monthly Carbon Emission Intensity (tons/ton) | Remarks |

|---|---|---|---|---|

| 13 | Small | 5–7 | 9.73 | Enterprises in the table are generally arranged by their average monthly total emissions, from smallest to largest. |

| 28 | 5–7 | 6.83 | ||

| 21 | Medium | 15–30 | 7.48 | |

| 37 | 15–30 | 6.75 | ||

| 1 | 15–30 | 7.71 | ||

| 29 | Large | 30–40 | 6.7 | |

| 45 | 30–40 | 7.16 |

| Enterprise Code | Emission Scale | Monthly Average Total Emission (tons) | Carbon Emission Intensity (tons/ton) | Remarks |

|---|---|---|---|---|

| 23 | Small | 0–3 | 0.69 | Enterprises in the table are generally arranged by their average monthly total emissions, from smallest to largest. |

| 24 | 0–3 | 0.8 | ||

| 10 | 0–3 | 0.76 | ||

| 22 | Medium | 3–6 | 0.92 | |

| 4 | 3–6 | 0.69 | ||

| 33 | 3–6 | 0.78 | ||

| 2 | 3–6 | 0.81 | ||

| 25 | Large | 6–10 | 0.99 | |

| 18 | 6–10 | 0.74 | ||

| 31 | 6–10 | 0.85 | ||

| 34 | 6–10 | 0.74 | ||

| 12 | 6–10 | 0.76 |

| Enterprise Code | Emission Scale | Monthly Average Total Emission (tons) | Carbon Emission Intensity (tons/ton) | Remarks |

|---|---|---|---|---|

| 43 | Small | 0–2 | 6.61 | Enterprises in the table are generally arranged by their average monthly total emissions, from smallest to largest. |

| 9 | 0–2 | 6.71 | ||

| 5 | 0–2 | 9.08 | ||

| 42 | 0–2 | 53.04 | ||

| 20 | 0–2 | 7.71 | ||

| 40 | 0–2 | 4.09 | ||

| 17 | 0–2 | 6.96 | ||

| 6 | 0–2 | 6.54 | ||

| 38 | 0–2 | 6.48 | ||

| 36 | Medium | 2–5 | 6.3 | |

| 32 | 2–5 | 7.13 | ||

| 7 | 2–5 | 6.52 | ||

| 15 | 2–5 | 6.66 | ||

| 44 | 2–5 | 6.37 | ||

| 11 | 2–5 | 6.18 | ||

| 39 | 2–5 | 7.26 | ||

| 16 | 2–5 | 4.48 | ||

| 35 | 2–5 | 6.96 | ||

| 27 | 2–5 | 3.8 | ||

| 26 | 2–5 | 6.2 | ||

| 3 | Large | 5–10 | 7.93 | |

| 19 | 5–10 | 6.3 | ||

| 14 | 5–10 | 6.51 | ||

| 30 | 5–10 | 6.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Pan, Q.; Shi, J.; Ji, H. Construction and Application of Enterprise Electric Carbon Model: A Study Based on Key Enterprises in Qinghai Province. Sustainability 2025, 17, 2243. https://doi.org/10.3390/su17052243

Li Z, Pan Q, Shi J, Ji H. Construction and Application of Enterprise Electric Carbon Model: A Study Based on Key Enterprises in Qinghai Province. Sustainability. 2025; 17(5):2243. https://doi.org/10.3390/su17052243

Chicago/Turabian StyleLi, Zengwei, Qifang Pan, Junyi Shi, and Haoyang Ji. 2025. "Construction and Application of Enterprise Electric Carbon Model: A Study Based on Key Enterprises in Qinghai Province" Sustainability 17, no. 5: 2243. https://doi.org/10.3390/su17052243

APA StyleLi, Z., Pan, Q., Shi, J., & Ji, H. (2025). Construction and Application of Enterprise Electric Carbon Model: A Study Based on Key Enterprises in Qinghai Province. Sustainability, 17(5), 2243. https://doi.org/10.3390/su17052243