Innovative Blade and Tine Push Weeder for Enhancing Weeding Efficiency of Small Farmers

Abstract

:1. Introduction

Related Works

2. Materials and Methods

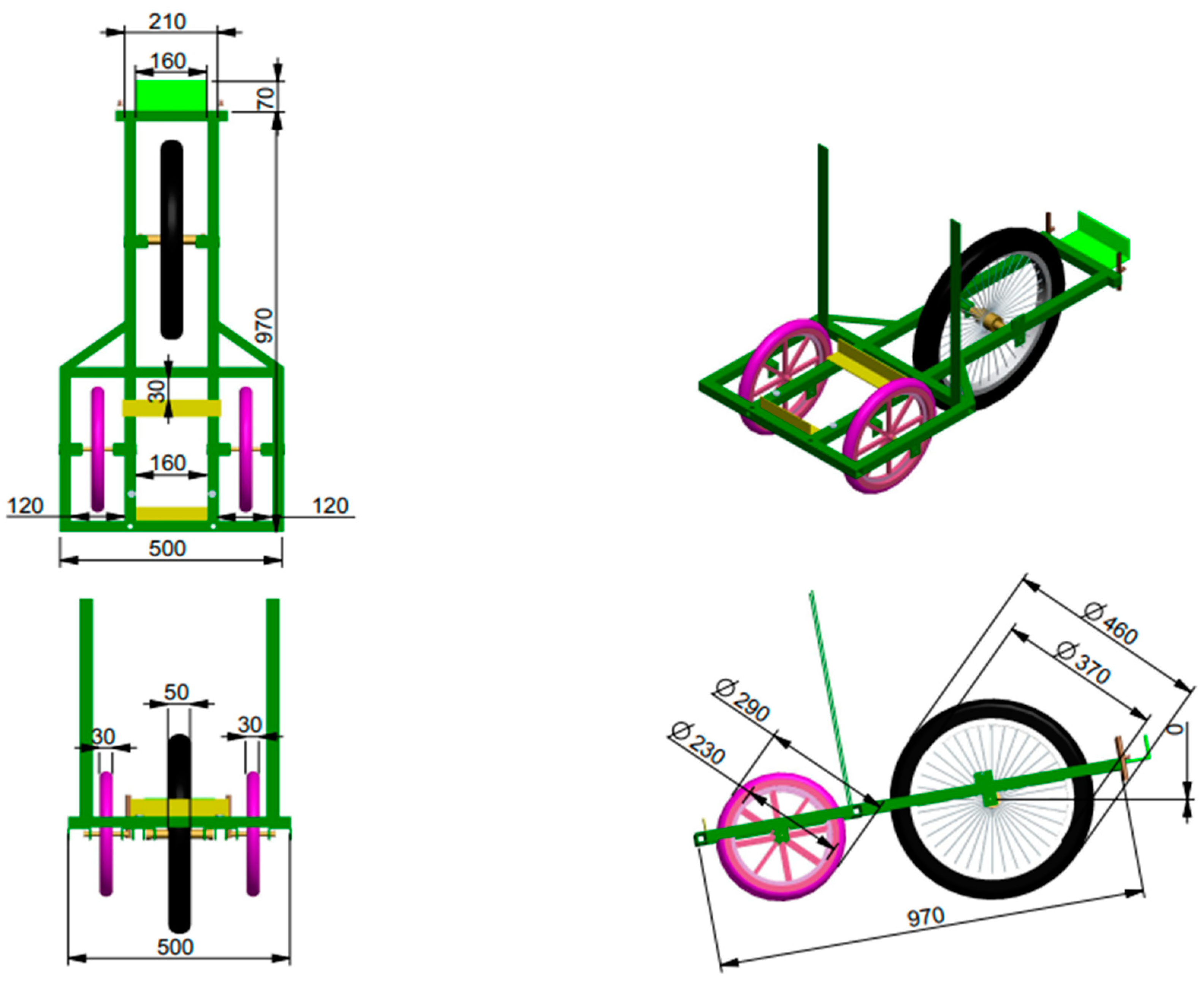

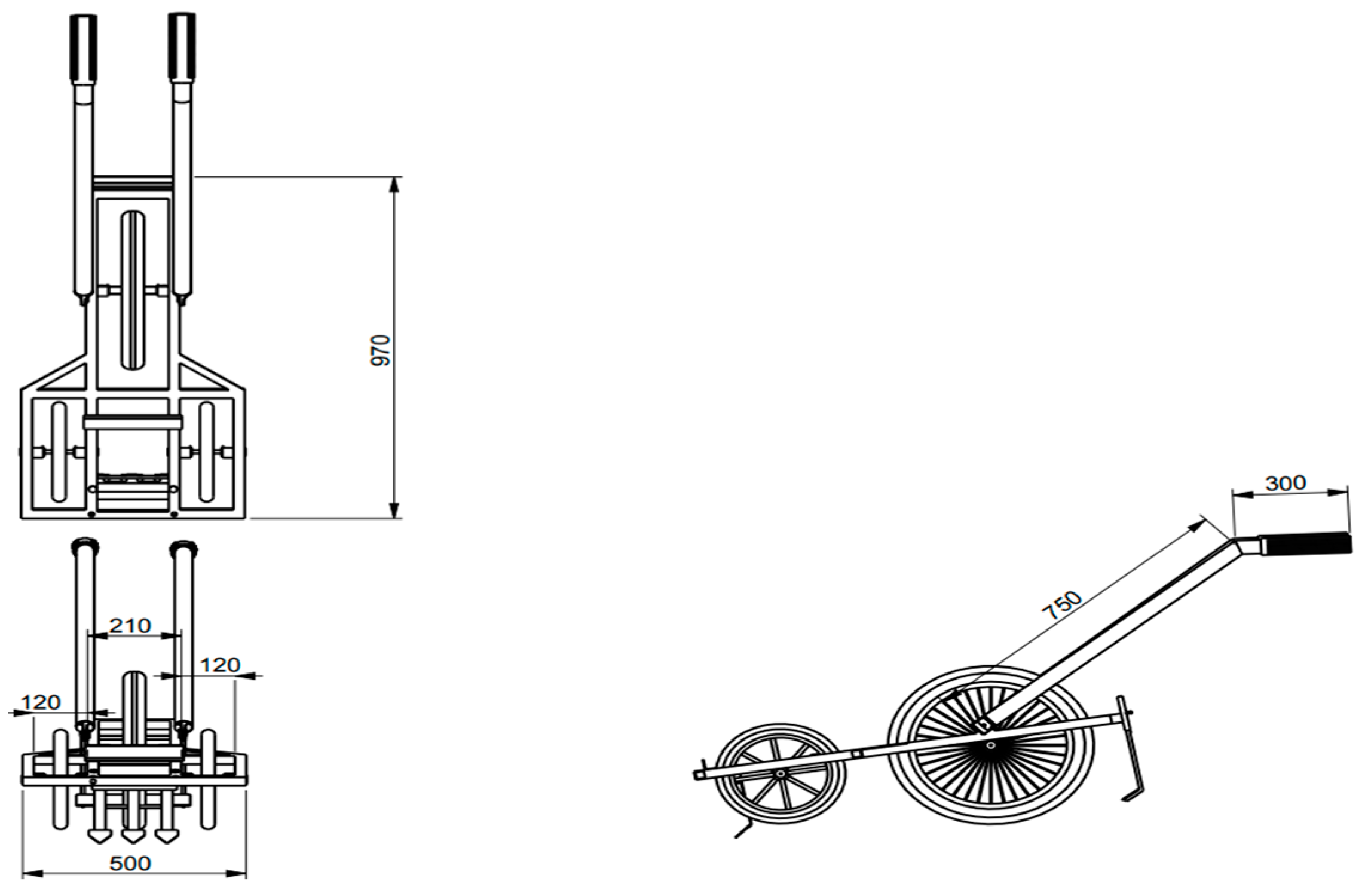

2.1. Main Frame Design

Main Frame Specifications

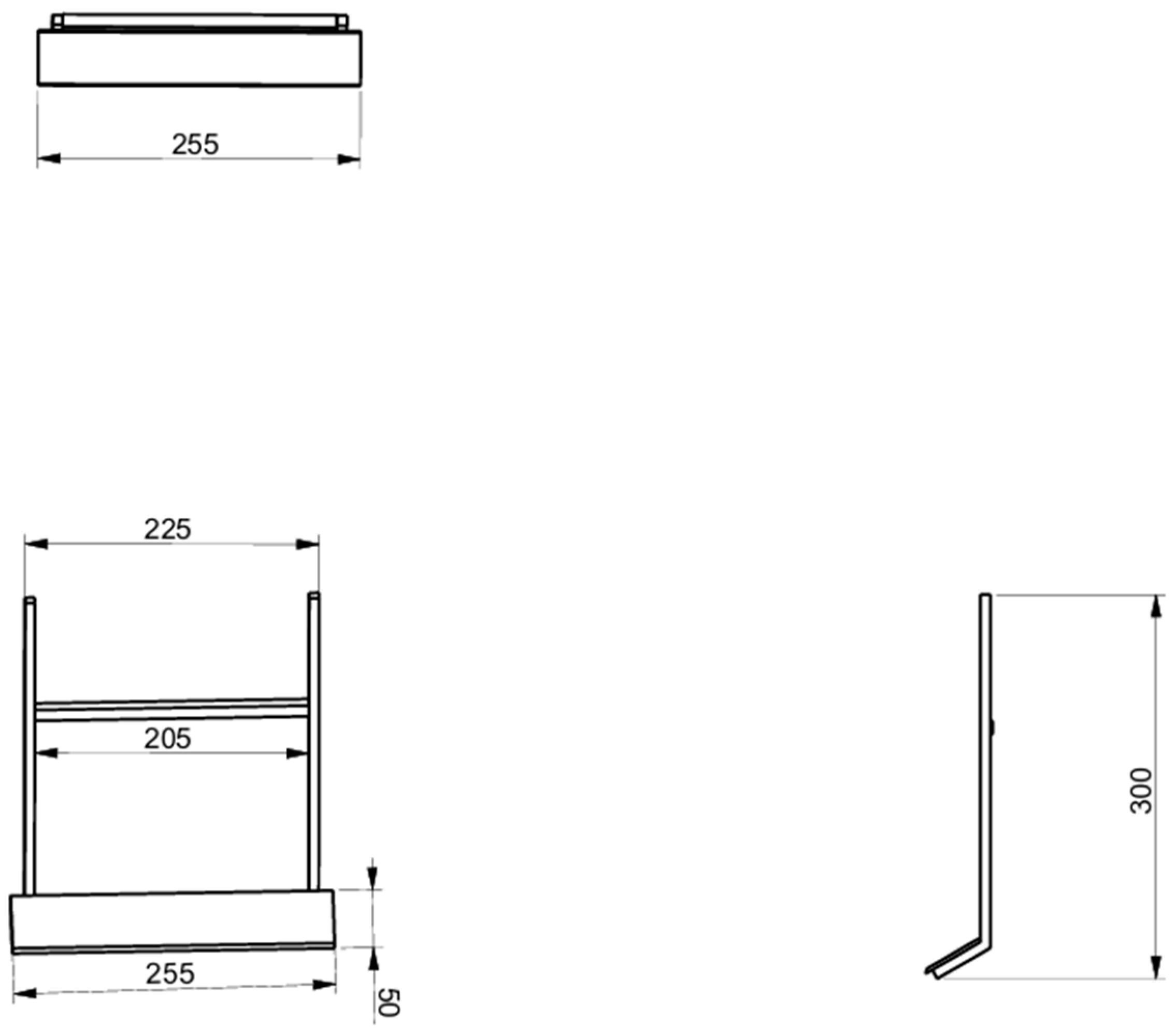

2.2. Handle

Specifications of Handle

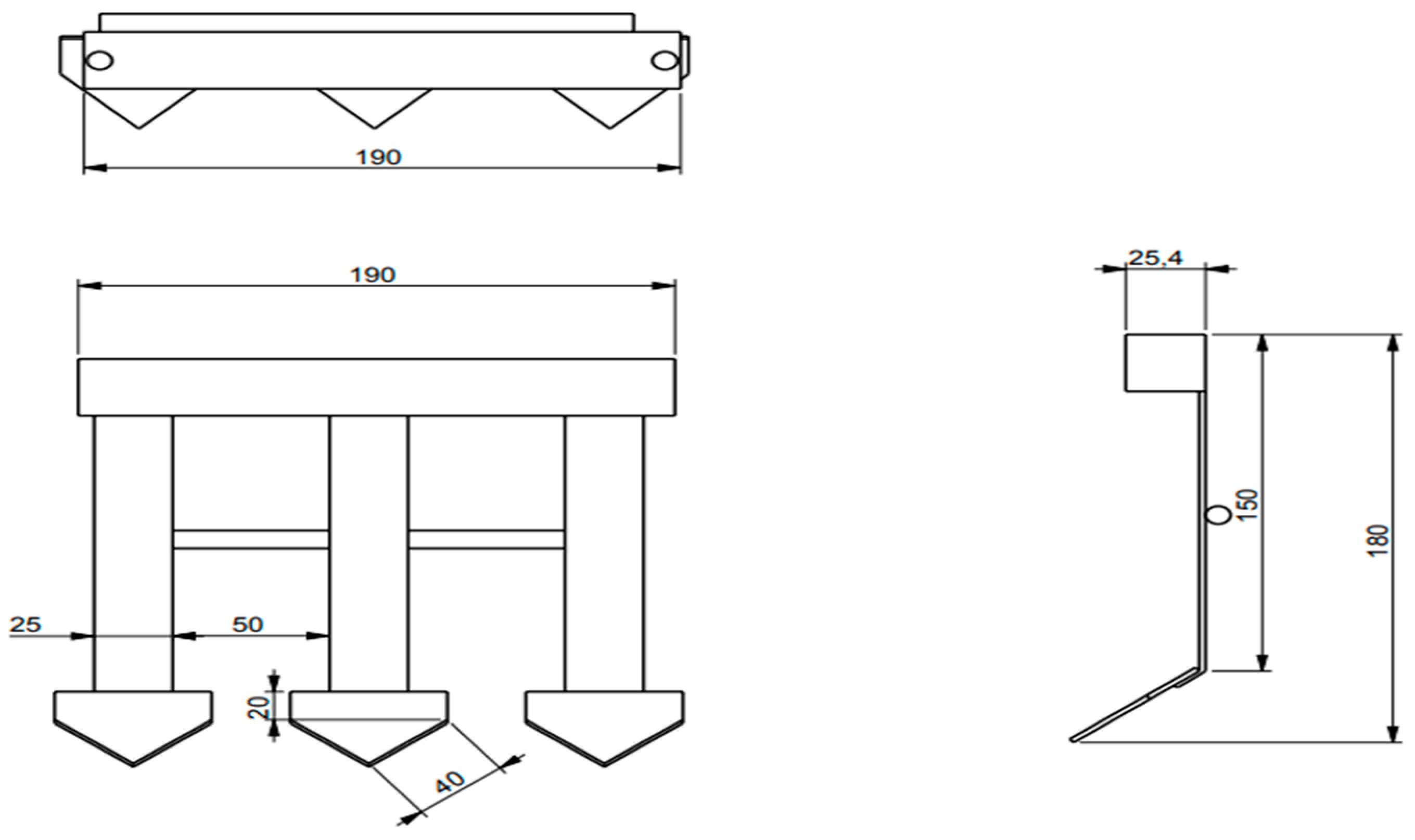

2.3. Design of Weeder Blades

2.3.1. Straight Blade

Specifications of Straight Blade Weeder

2.3.2. Tine Blade

Specifications of Tine Blade

2.4. Clamp

2.5. Adjustment and Working of Blade and Tine-Type Push Weeder

Working Mechanism

2.6. Machine Parameters

2.6.1. Experimental Procedure

2.6.2. Experimental Design

Layout of Experimental Plot

2.6.3. Field Preparation

2.6.4. Physical Properties of Soil

Moisture Content

- MC (db) = Moisture content dry basis (%);

- Ww = Weight of undried soil (g);

- Wd = Weight of oven-dried soil (g).

Bulk Density

2.6.5. Effective Field Capacity

2.6.6. Theoretical Field Capacity

2.6.7. Weeding Efficiency

- = Total number of unwanted plants per unit area before weeding;

- = Sum of unwanted plants per unit area after weeding.

2.6.8. Plant Damage

- PD = Plant damage, %;

- n1 = Sum of plants after weeding;

- n2 = Sum of plants before weeding.

2.6.9. Performance Index of Developed Weeder

- PI = Performance index;

- FC = Weeder field capacity, ha h−1;

- PD = Plant damage, %;

- WE = Weeding efficiency %;

- p = Power, hp.

2.6.10. Actual Weeding Depth of Cut

2.6.11. Actual Weeding Width of Cut

2.6.12. Draft Measurement

2.6.13. Economic Evaluation of Blade and Tine Push Weeder

Fixed Cost

- Depreciation

- Interest

- Shelter, Insurance, and Taxes

Operating Cost

- Repair and Maintenance

- Wages of Operator

Total Cost of Weeding per Ha

3. Results and Discussion

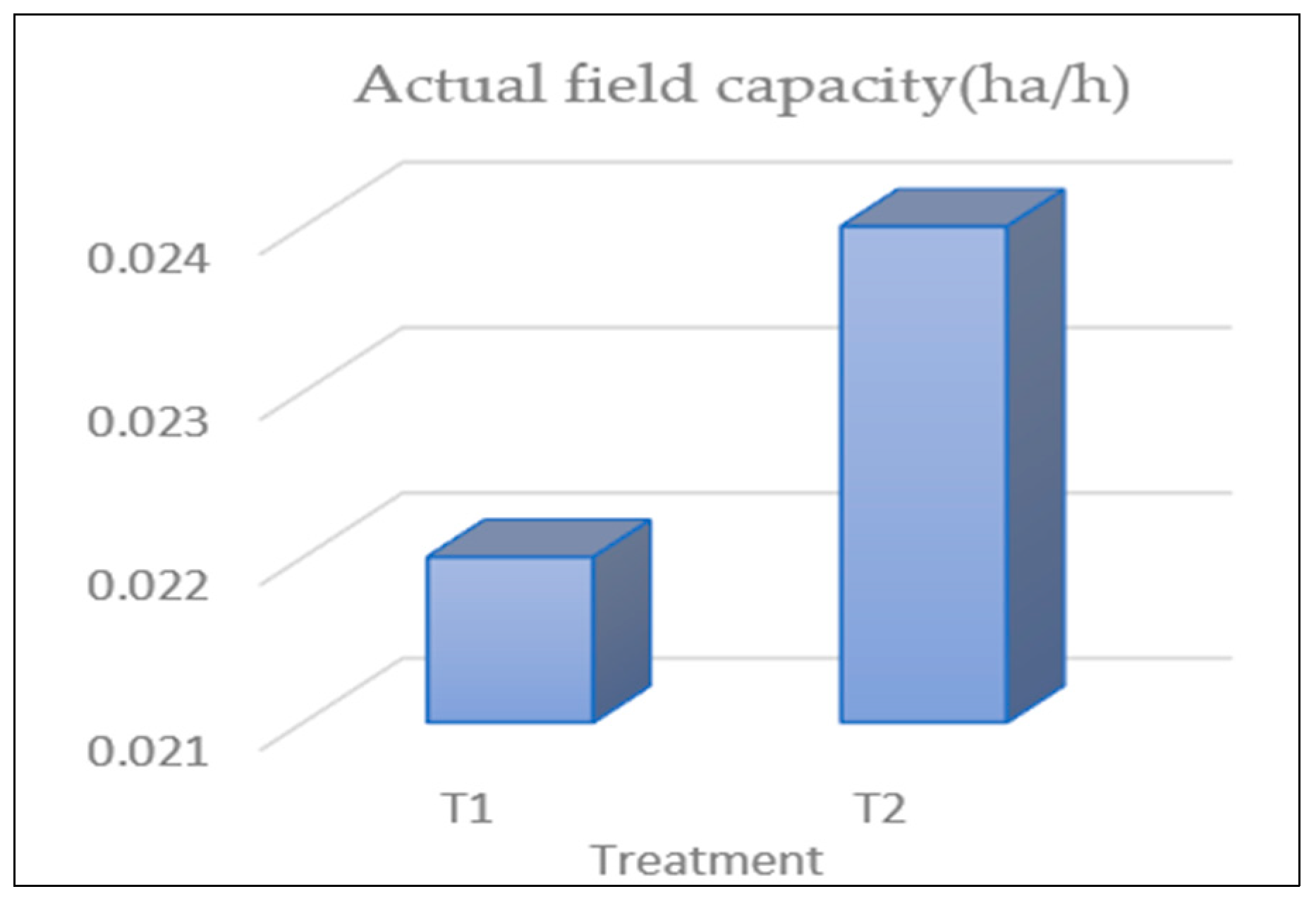

3.1. Actual Field Capacity of the Blade and Tine-Type Push Weeder

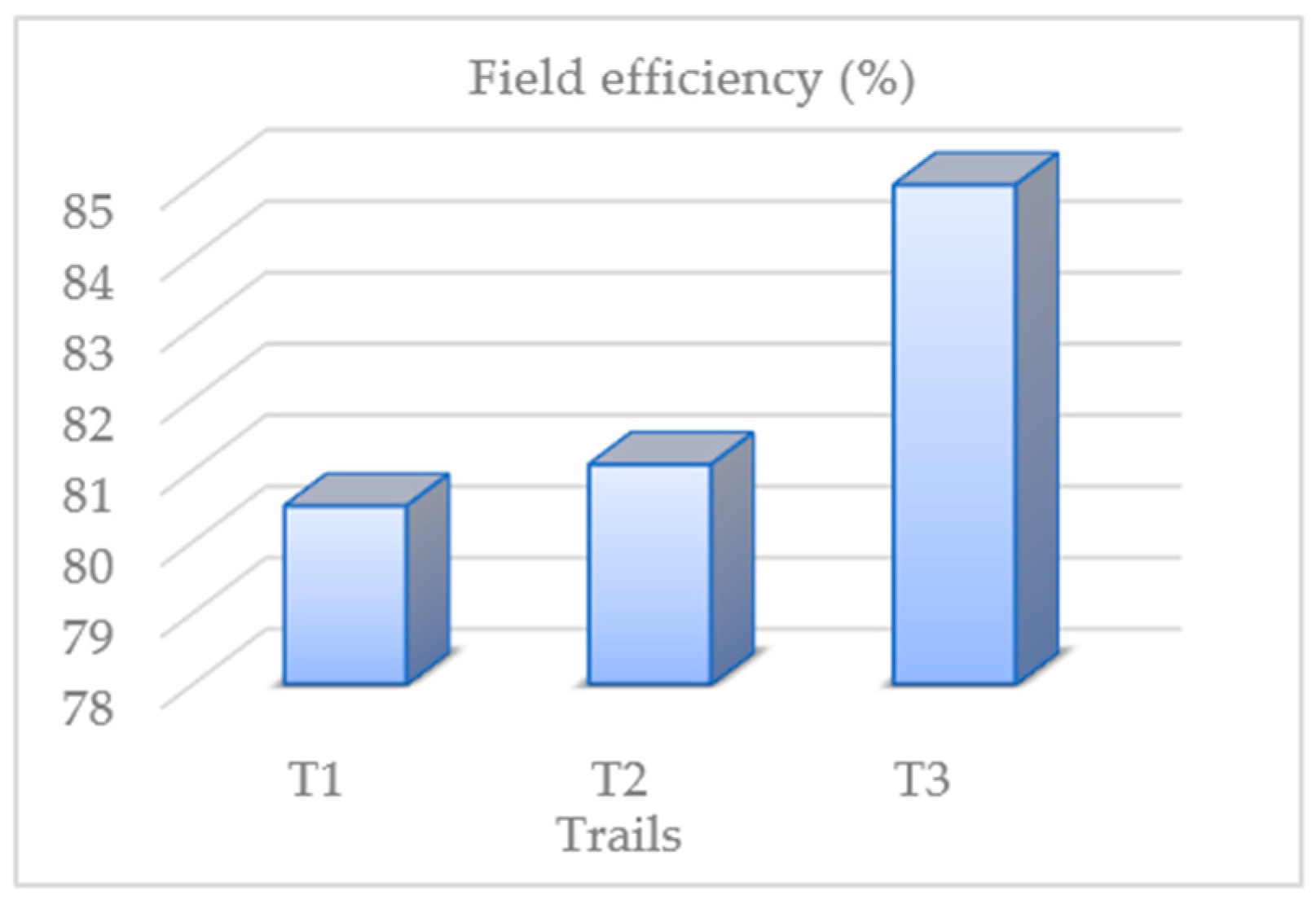

3.2. Field Efficiency of Push-Type Manual Weeder

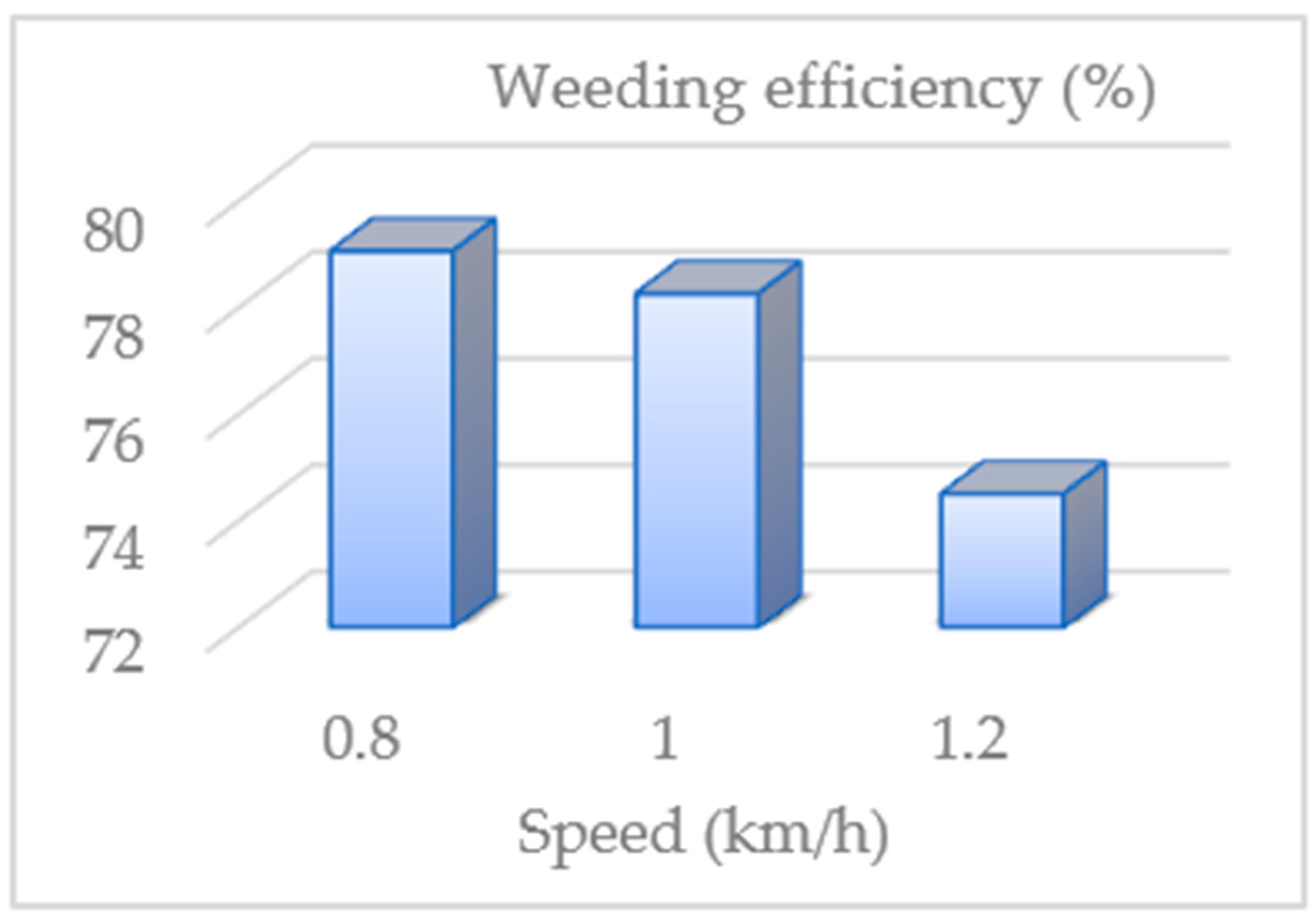

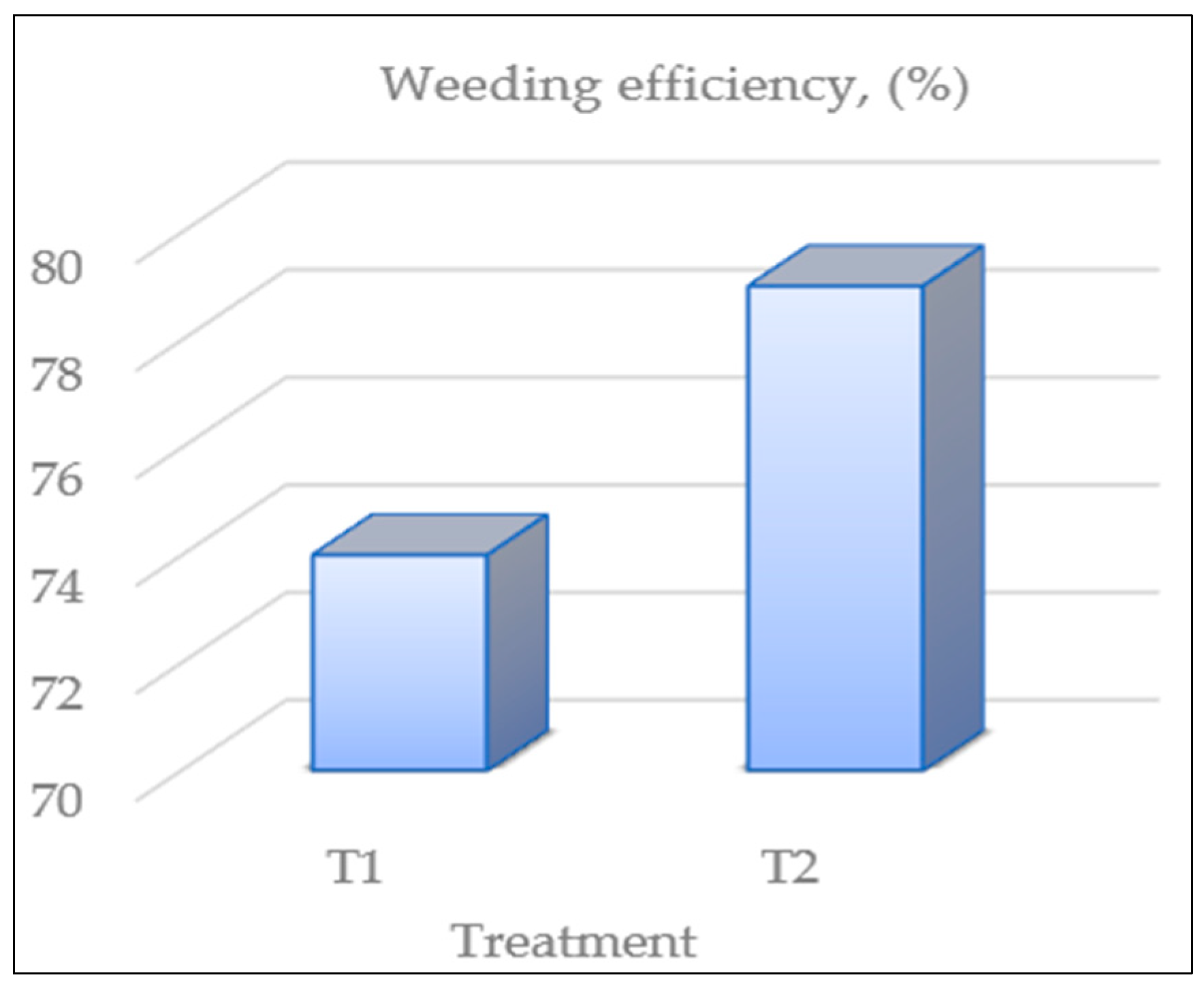

3.3. Weeding Efficiency of the Blade and Tine-Type Push Weeder

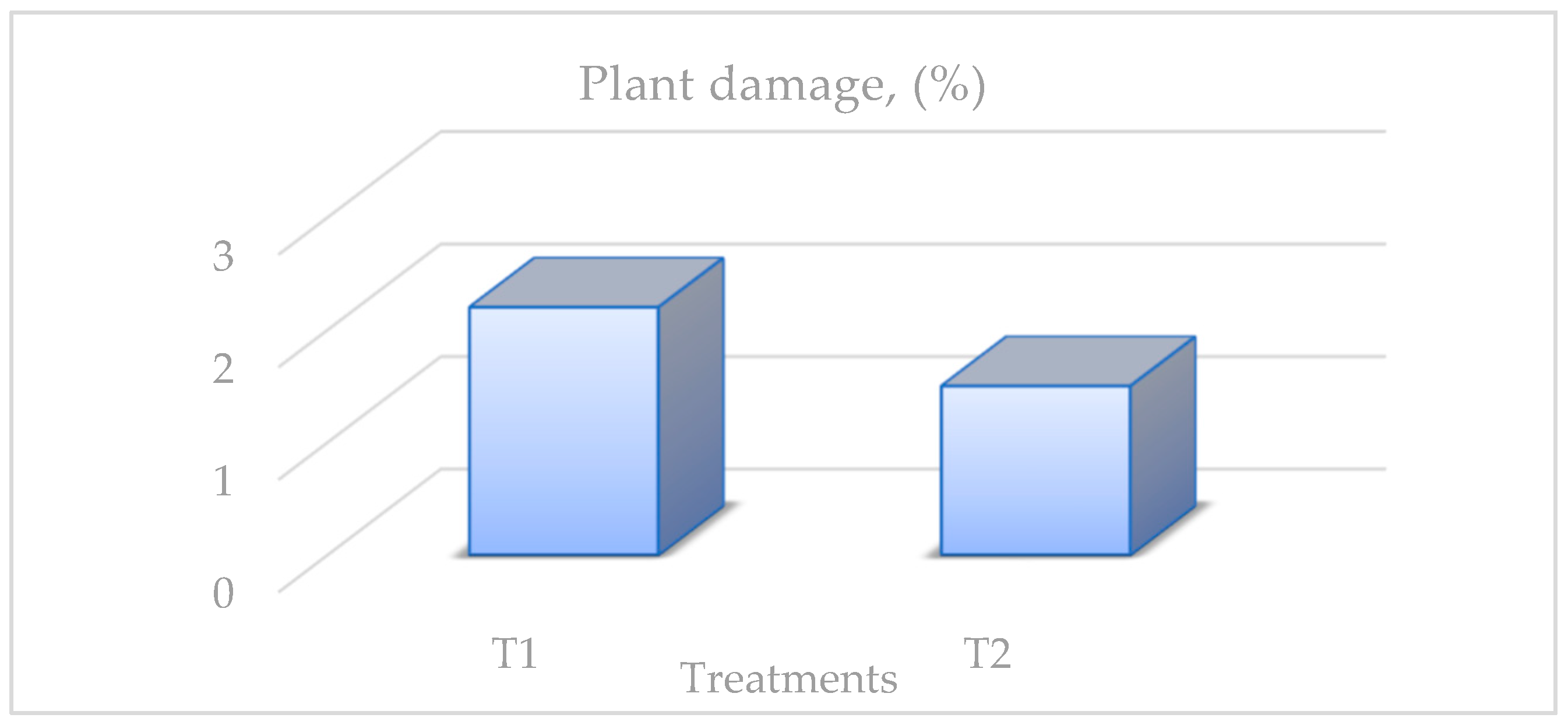

3.4. Effect of Developed Weeder Working Parameters on Plant Damage in Green Pea

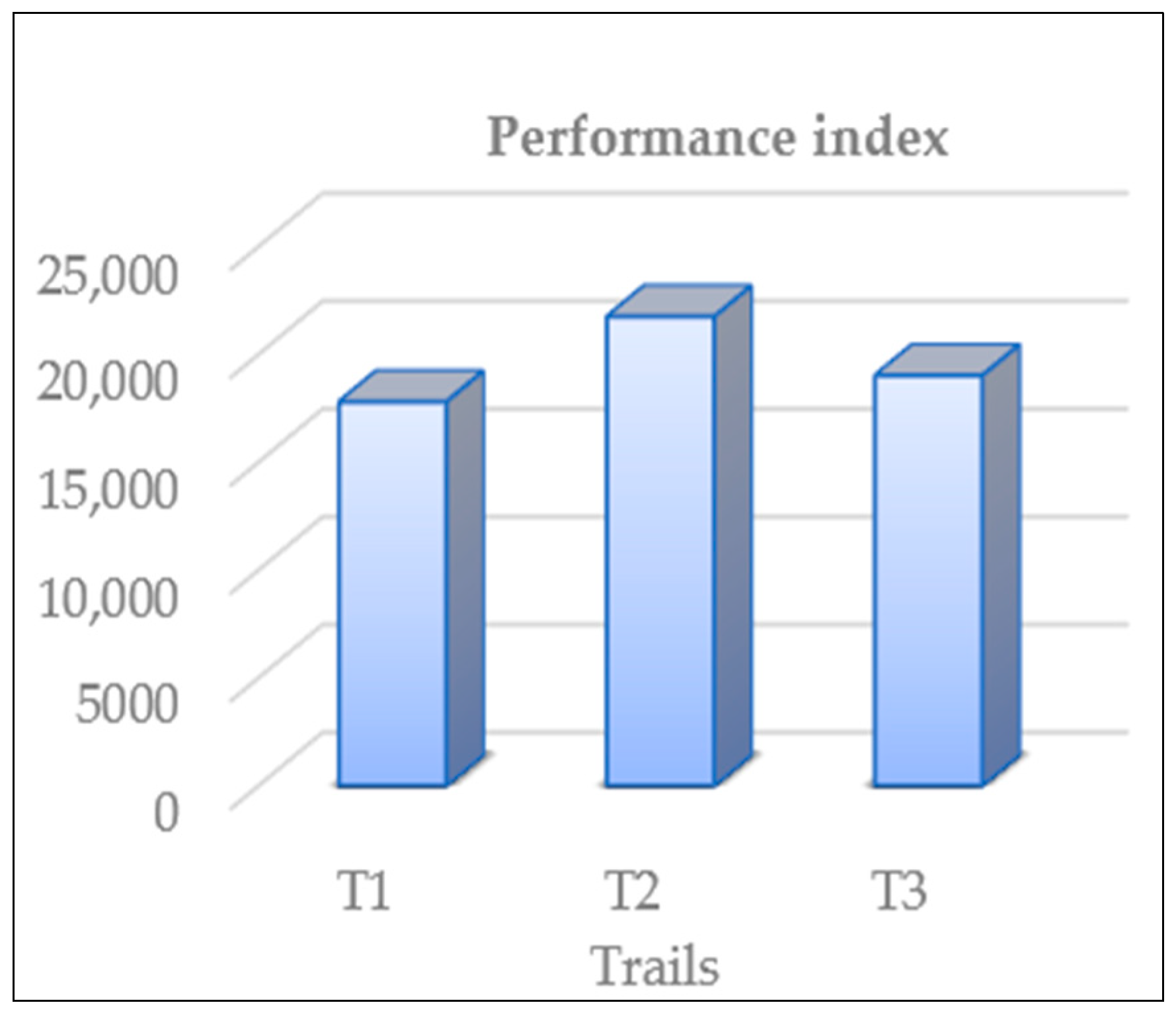

3.5. Effect of Developed Weeder Working Parameters on the Performance Index

3.6. Draft

3.7. Calculation of Cost of Operation of Blade and Tine Push Weeder

- Economic Analysis:

- Estimated lifespan of the weeder = 10 years.

- The annual usage of the weeder is determined using the following assumption:Working hour (h) = 300 h/year;Salvage value (S) = 10 percent of initial cost;Rate of interest = 10 percent per annum;Repair and maintenance = 5 percent of initial cost;Labor required = 01;Shelter, insurance, and tax cost = 2 percent of capital cost.

- A. Fixed Cost

- B. Variable Cost

- ⮚

- Average effective field capacity for green pea weeding = 0.020 ha/h;

- ⮚

- Cost of operation of weeder for green pea crop = = INR 2108/ha.

3.8. Comparative Study Between Blade and Tine Push Weeder with Wheel Hoe

3.8.1. Comparison of Blade and Tine Push Weeder’s Actual Field Capacity with Wheel Hoe’s Actual Field Capacity

3.8.2. Comparison of Blade and Tine Push Weeder’s Field Efficiency with Wheel Hoe’s Field Efficiency

3.8.3. Comparison of Blade and Tine Push Weeder’s Weeding Efficiency with Wheel Hoe’s Weeding Efficiency

3.8.4. Comparison of Blade and Tine Push Weeder’s Plant Damage with Wheel Hoe’s Plant Damage

3.9. Comprehensive Comparison of Current Weed Control Technologies

3.10. Limitations of the Proposed Weeder

- ⮚

- Inadequate efficiency in denser weeds.

- ⮚

- Labor-intensive for heavy fields.

- ⮚

- Limited adaptability for diverse soils.

- ⮚

- Not ideal for every crop.

- ⮚

- Not added autonomous method.

- ⮚

- Long-term durability and wearability.

- ⮚

- Limited customization for different weed species.

4. Conclusions

- In the current paper, the blade and tine-type push weeder for agriculture was developed to perform interrow mechanical weed control in >60 cm row-spaced crops. A conventional weeder was modified and equipped with blades, tines, a long handle, and a three-wheeled frame. Theoretical and actual calculations were completed based on the existing equations, and AutoCAD drawings of weeders were presented.

- The developed blade and tine push weeder has a faster speed and weeding efficacy than traditional weeders like wheel hoes, sickles, chris, powers, shovels, hand forks, etc. Its advantages, such as eliminating the need for prolonged sitting and bending postures, contribute to reduced fatigue and increased efficiency. In contrast, the developed weeder with two blades is more efficient than a single-working-element weeder.

- This translates into increasing efficiency, which is reasonably available to small and marginal farmers. Additionally, the low-cost maintenance and user-friendly fabrication make it accessible for various operators, including women, thereby improving the overall agricultural yield.

- ⮚

- Incorporating adjustable seating features for improved operator comfort.

- ⮚

- Adjust the BLDC motor for self-propelled weeding.

- ⮚

- Conduct comprehensive testing of the weeder across various crops to ensure its versatility and effectiveness.

- ⮚

- Consider the implementation of lugged wheels for increased traction and improved performance in diverse soil conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Michaliszyn-Gabryś, B.; Bronder, J.; Krupanek, J. Social Life Cycle Assessment of Laser Weed Control System: A Case Study. Sustainability 2024, 16, 2590. [Google Scholar] [CrossRef]

- Press Information Bureau, Government of India. Empowering Rural India: NABARD Survey on Rural Financial Inclusion; Press Information Bureau, Government of India: New Delhi, India, 2024. Available online: https://pib.gov.in/PressNoteDetails.aspx?NoteId=153270&ModuleId=3®=3&lang=1 (accessed on 10 February 2025).

- ICAR’s “Vision-2030” Unveiled by Agriculture Minister|ICAR. Icar.gov.in. Available online: https://icar.gov.in/node/1646 (accessed on 8 January 2025).

- Hajjar, M.J.; Ahmed, N.; Alhudaib, K.A.; Ullah, H. Integrated Insect Pest Management Techniques for Rice. Sustainability 2023, 15, 4499. [Google Scholar] [CrossRef]

- Nath, C.P.; Singh, R.G.; Choudhary, V.K.; Datta, D.; Nandan, R.; Singh, S.S. Challenges and Alternatives of Herbicide-Based Weed Management. Agronomy 2024, 14, 126. [Google Scholar] [CrossRef]

- Rao, V.S. Principles of Weed Science; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar] [CrossRef]

- Opasatian, I.; Ahamed, T. Driveway Detection for Weed Management in Cassava Plantation Fields in Thailand Using Ground Imagery Datasets and Deep Learning Models. AgriEngineering 2024, 6, 3408–3426. [Google Scholar] [CrossRef]

- Massenssini, A.M.; Bonduki, V.H.A.; Melo, C.A.D.; Tótola, M.R.; Ferreira, F.A.; Costa, M.D. Soil Microorganisms and Their Role in the Interactions between Weeds and Crops. Planta Daninha 2014, 32, 873–884. [Google Scholar] [CrossRef]

- Farooq, M.; Flower, K.C.; Jabran, K.; Wahid, A.; Siddique, K.H. Crop Yield and Weed Management in Rainfed Conservation Agriculture. Soil Tillage Res. 2011, 117, 172–183. [Google Scholar] [CrossRef]

- Ramesh, D.; Chandrasekaran, M.; Soundararajan, R.P.; Subramanian, P.P.; Palled, V.; Kumar, D.P. Solar-Powered Plant Protection Equipment: Perspective and Prospects. Energies 2022, 15, 7379. [Google Scholar] [CrossRef]

- Gharde, Y.; Singh, P.K.; Dubey, R.P.; Gupta, P.K. Assessment of Yield and Economic Losses in Agriculture Due to Weeds in India. Crop Prot. 2018, 107, 12–18. [Google Scholar] [CrossRef]

- Varanasi, A.; Prasad, P.V.; Jugulam, M. Impact of Climate Change Factors on Weeds and Herbicide Efficacy. Adv. Agron. 2016, 135, 107–146. [Google Scholar] [CrossRef]

- Roslim, M.H.M.; Juraimi, A.S.; Che’Ya, N.N.; Sulaiman, N.; Manaf, M.N.H.A.; Ramli, Z.; Motmainna, M. Using Remote Sensing and an Unmanned Aerial System for Weed Management in Agricultural Crops: A Review. Agronomy 2021, 11, 1809. [Google Scholar] [CrossRef]

- Ghersa, C.M.; Benech-Arnold, R.L.; Satorre, E.H.; Martínez-Ghersa, M.A. Advances in Weed Management Strategies. Field Crops Res. 2000, 67, 95–104. [Google Scholar] [CrossRef]

- Rajković, M.; Malidža, G.; Tomaš Simin, M.; Milić, D.; Glavaš-Trbić, D.; Meseldžija, M.; Vrbničanin, S. Sustainable Organic Corn Production with the Use of Flame Weeding as the Most Sustainable Economical Solution. Sustainability 2021, 13, 572. [Google Scholar] [CrossRef]

- Binni, I.M.; Rabiu, A.L.; Kabir, M.H.; Jibril, A. A Survey on Performance Evaluation of Different Types of Weeders. Int. J. Appl. Eng. Technol. 2016, 6, 8–13. [Google Scholar]

- Jia, W.; Tai, K.; Wang, X.; Dong, X.; Ou, M. Design and Simulation of Intra-Row Obstacle Avoidance Shovel-Type Weeding Machine in Orchard. Agriculture 2024, 14, 1124. [Google Scholar] [CrossRef]

- Matsuda, Y.; Kakutani, K.; Toyoda, H. Unattended Electric Weeder (UEW): A Novel Approach to Control Floor Weeds in Orchard Nurseries. Agronomy 2023, 13, 1954. [Google Scholar] [CrossRef]

- Singh, G. Weed Management in Peas (Pisum sativum L.)—A Review. Agric. Rev. 2003, 24, 217–222. [Google Scholar]

- Nag, P.K.; Gite, L.P. Farm Mechanization: Nature of Development. In Human-Centered Agriculture: Ergonomics and Human Factors Applied; Nag, P.K., Gite, L.P., Eds.; Springer: Singapore, 2020; pp. 149–171. [Google Scholar] [CrossRef]

- Gianessi, L.P.; Reigner, N.P. The Value of Herbicides in U.S. Crop Production. Weed Technol. 2007, 21, 559–566. [Google Scholar] [CrossRef]

- Dhananivetha, M.; Amnullah, M.M.; Murali Arthanari, P.; Mariappan, S. Weed Management in Onion: A Review. Agric. Rev. 2017, 38, 76–80. [Google Scholar] [CrossRef]

- Kumar, N.; Kumar, S.; Nayak, M.; Ramya, V. Performance Evaluation of Weeders. Int. J. Sci. Environ. Technol. 2014, 3, 2160–2165. [Google Scholar]

- Ye, S.; Zhang, X.; Wang, Q.; Li, X.; Hu, F.; Song, H.; Zheng, D. Design and Experiment of a High-Clearance Mid-Tillage Weeder for Dryland Farming. Agriculture 2024, 14, 435. [Google Scholar] [CrossRef]

- Fang, H.; Xu, G.; Xue, X.; Niu, M.; Qiao, L. Study of Mechanical-Chemical Synergistic Weeding on Characterization of Weed–Soil Complex and Weed Control Efficacy. Sustainability 2023, 15, 665. [Google Scholar] [CrossRef]

- Zawada, M.; Legutko, S.; Gościańska-Łowińska, J.; Szymczyk, S.; Nijak, M.; Wojciechowski, J.; Zwierzyński, M. Mechanical Weed Control Systems: Methods and Effectiveness. Sustainability 2023, 15, 15206. [Google Scholar] [CrossRef]

- Sampurno, R.M.; Liu, Z.; Abeyrathna, R.M.R.D.; Ahamed, T. Intrarow Uncut Weed Detection Using You-Only-Look-Once Instance Segmentation for Orchard Plantations. Sensors 2024, 24, 893. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, G.; Yao, J.; Huang, D.; Tan, H.; Jia, H.; Zou, Z. An Improved U-Net Model Based on Multi-Scale Input and Attention Mechanism: Application for Recognition of Chinese Cabbage and Weed. Sustainability 2023, 15, 5764. [Google Scholar] [CrossRef]

- Singh, S.P.; Singh, M.K.; Solanki, R.C. Design and Development of Four-Wheel Weeder for Wide-Row Crops. Indian J. Agric. Sci. 2016, 86, 42–49. [Google Scholar] [CrossRef]

- Saleh, A.; Suleiman, M.L. Design, Construct and Evaluation of a Single Row Hand-Pushed Mechanical Weed Control Machine. J. Appl. Sci. Environ. Manag. 2021, 25, 401–406. [Google Scholar] [CrossRef]

- Jena, P.P.; Mohanty, S.K.; Mishra, J.N. Development of Ergonomically Designed Weeder for Increasing Productivity. J. Agric. Technol. 2016, 3, 59. [Google Scholar]

- Nkakini, S.; Husseni, A. Development and Evaluation of Wheeled Long-Handle Weeder. West Indian J. Eng. 2015, 37, 37. [Google Scholar]

- Manjunatha, K.; Sushilendra, S.S.; Vijayakumar, P. Development and Evaluation of Manually Operated Sprocket Weeder. Int. J. Agric. Eng. 2014, 26, 64–72. [Google Scholar]

- Gite, L.P.; Yadav, B.G. Optimum Handle Height for a Push-Pull Type Manually-Operated Dryland Weeder. Ergonomics 1990, 33, 1487–1494. [Google Scholar] [CrossRef]

- Choudary, R.B.; Sekhar, V.C.; Ajayaram, B.; Rao, G.N. Fabrication and Field Evaluation of a Wheel Weeder. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1070, p. 012134. [Google Scholar] [CrossRef]

- Kachhot, A.R.; Dulawat, M.S.; Makavana, J.M.; Dobariya, U.D.; Vadher, A.L. Development of Solar Operated Walking Type Power Weeder. Agric. Sci. Green Energy 2021, 2, 30–41. [Google Scholar] [CrossRef]

- Singh, S.; Dave, A.K.; Padhee, D.; Kulhariya, S.K.; Yadav, N.K. Performance Evaluation of Manually Operated Weeder. J. Pharmacogn. Phytochem. 2020, 9, 1370–1374. [Google Scholar]

- Singh, M.U. Performance Evaluation of Some Manually Operated Weeders Used in Jhum Cultivation in Hill Regions of Arunachal Pradesh. Indian J. Hill Farming 2017, 30, 2. [Google Scholar]

- Yadav, R.; Pund, S. Development and Ergonomic Evaluation of Manual Weeder. Int. J. Agric. Eng. 2007, 9, 1–9. [Google Scholar]

- Babu, D.A.; Ramana, C.; Kumar, A.A. Performance Evaluation of a Prototype Weeder with Various Blades and Orientations. Int. J. Agric. Eng. 2024, 26, 4. [Google Scholar]

- Sharma, D.N.; Mukesh, S. Farm Machinery Design Principles and Problems; Jain Brothers: New Delhi, India, 2013. [Google Scholar]

- Michael, A.M.; Ojha, T.P. Principles of Agricultural Engineering: Farm Power, Farm Machinery, and Farm Buildings, 15th ed.; Jain Brothers: New Delhi, India, 2021; Volume 1. [Google Scholar]

- Balachand, C.H. Design, Development and Evaluation of Animal Drawn Weeder Suitable for Non-Descript Bullocks of Chhattisgarh Region. M.Tech. Thesis, Indira Gandhi Krishi Vishwavidyalaya, Raipur, India, 2006. [Google Scholar]

- Javadi, A.; Hajahamad, A. Effect of new combined implement for reducing secondary tillage operation. Int. J. Agric. Biol. 2006, 8, 724–727. [Google Scholar]

- Kushwaha, D.K.; Thomas, E.V.; Maiti, B.; Ghosh, B.C.; De, B. Assessment and Optimization of Bulk Density and Angle of Repose of Tea Leaves for Metering Device Using Desirability Function. Int. J. Sci. Eng. Technol. 2015, 4, 36–39. [Google Scholar]

- Jain, S.C.; Grace Philip, G. Farm Machinery an Approach; Standard Publishers Distributors: New Delhi, India, 2003. [Google Scholar]

- Sahay, J. Elements of Agricultural Engineering; Standard Publishers Distributors: New Delhi, India, 2006. [Google Scholar]

- Tajuddin, A. Design, Development and Testing of Engine Operated Weeder. Agric. Eng. Today 2006, 30, 25–29. [Google Scholar]

- Srinivas, I.; Adake, R.; Reddy, B.; Korwar, G.; Thyagaraj, C.; Dange, A.; Veeraprasad, G.; Reddy, C. Comparative Performance of Different Power Weeders in Rainfed Sweet Sorghum Crop. Indian J. Dryland Agric. Res. Dev. 2010, 25, 63–67. Available online: http://drylandagri.org.in/Journals/2010%20Vol.%2025-num-2-8.pdf (accessed on 8 January 2025).

- Devojee, B.; Meena, S.; Sharma, A.; Agarwal, C. Performance Evaluation of Weeder by Number of Blades per Flange in maize Crop. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 2389–2397. [Google Scholar] [CrossRef]

- Mehra, N.; Gautam, A.K.; Pathak, U.; Shrivastava, A.K. Development of Mathematical Model for Repair and Maintenance of Farm Tractors. J. Multidiscip. Adv. Res. 2017, 6, 93–98. [Google Scholar]

- Kamboj, P.; Khurana, R.; Dixit, A. Farm Machinery Services Provided by Selected Cooperative Societies. Agric. Eng. Int. 2012, 14, 123. [Google Scholar]

- IS: 9164-1979; Bureau of Indian Standards. Guide for Estimating Cost of Farm Machinery Operation. Bureau of Indian Standards: New Delhi, India, 1982.

- Sundaram, P.K.; Rahman, A.; Singh, A.K.; Sarkar, B. A Novel Method for Manual Weeding in Row Crops. Indian J. Agric. Sci. 2021, 91, 946–948. [Google Scholar] [CrossRef]

- Shekhar, S.; Chandra, S.; Roy, D.K. Performance Evaluation of Different Weeding Tools in Maize. Indian J. Weed Sci. 2010, 42, 95–97. [Google Scholar]

| Title of Paper | Review of Literature | Limitations | Method Adopted for This Research |

|---|---|---|---|

| Performance evaluation of weeders [24] | This study evaluated the field performance of four weeders. The field capacity of kauri (W1), twine wheel hoe (W2), push–pull-type cycle weeder (W3), and push–pull-type cycle weeder (W4) was 0.002, 0.010, 0.020, and 0.035 ha/h, respectively. | This study explains the lower performance of existing weeders. | Performance and evaluation |

| Design and development of four-wheel weeder for wide-row crops [29] | The author developed four wheels and ‘Swinging handles’ for the wide row-to-row spaced crops based on anthropometric data of men and women workers. The weight of the weeder was kept lower than 10 kg, the lowest field capacity was 0.0206 ha/h, and the weeding efficiency was higher than 95%. The push force needs 6.34 N per cm cutting width. | This weeder requires more pushing force. | Design |

| Design, construct and evaluation of a single-row hand-pushed mechanical weed control machine [30] | This research focuses on designing, building, and performing a hand-pushed weed control machine. The components include mild steel (3 mm, 5 mm), 30 mm circular (hollow) pipes, a 10 mm diameter steel rod, and a 40 cm pneumatic tire. | These weeders are unable to provide uniform depth of cut and lateral stability due to a single wheel. | Frame design and selection of materials |

| Development of ergonomically designed weeder for increasing productivity [31] | This research explains that the weeding angle is based on the functional design and geometry of the weeder and usually lies between 30° and 45°. Based on anthropometric data, the authors suggest ergonomic handle design dimensions: the recommended handle grip diameter is 30 to 35 mm, the crossbar handle length is 450 mm, and the handle height is between 0.93 and 1.03 m. | This weeder, similar to a wheel hoe, may still cause operator strain, require manual effort, and be less effective in compact soils and varying field conditions. | Handle design |

| Development and evaluation of wheeled long-handle weeder [32] | The authors designed and tested a push-type wheel with an adjustable long-handle weeder. Obtained field capacity, efficiency, weeding index, and performance index were 0.050 ha/h, 87.5%, 86.5%, and 1108.48, respectively. High efficiency of 91.7% was obtained at a speed of 0.04 m/s and at 0.4 m depth of cut. | This weeder also has a single wheel and single blade, which may face stability issues and reduced cutting efficiency. | Weeder blade design |

| Development and evaluation of manually operated sprocket weeder [33] | The parts of this weeder were the handlebar, front axle, sprocket, wheel hub, fork, galvanized iron pipe, and a V-shaped blade made from hardened steel, which was attached to the fork with the help of an adjustable U-clamp. The wedding efficiency, field capacity, and time savings of the weeder were 94.5%, 0.032 ha/h, and 84%. The cost of operation was INR 375/ha, with a saving of 79.16% compared to the traditional method. | Single arrow blade means less efficiency and not ergonomic friendly. | Development and performance |

| Optimum handle height for a push-pull type manually-operated dryland weeder [34] | This study suggests a handle height of 100 cm based on the available anthropometric data of Indian workers for the push–pull-type manually operated dryland weeder. | Handle design | |

| Fabrication and field evaluation of a wheel weeder [35] | In this research, we developed a wheel weeder with conventional weeding tools, viz. trench hoe, spade, and wheel weeder. It operates up to a depth of 22 to 35 mm with a field capacity of 0.0038 ha/h. | Less field efficiency. | Field evaluation |

| Development of Solar operated walking type power weeder [36] | The weeder developed by these authors was a sweep-type blade attached behind the main frame, and the BLDC motor (750 w, 48 v) was used for the drive. The performance of the weeder was evaluated at three different forward speeds of 1.0–1.5 (S1), 1.5–2.0 (S2), and 2.0–2.5 (S3) km/h, respectively. Field capacities of S1, S2, and S3 were 0.042, 0.059, and 0.075 ha/h. The weeding and field efficiency for S1, S2, and S3 were found to be 90.94, 84.69, and 83.50% and 79.21, 83.97, and 85.68%, respectively. | In continuous operation due to solar dependency; bulky structure and higher initial costs. | Design |

| Performance evaluation of manually operated weeder [37] | The weeder can work up to 3.0–4.0 cm depth of operation with actual field capacity of 0.031 ha/h, theoretical field capacity of 0.0428 ha/h, field efficiency of 65.54%, plant damage of 2.166, weeding efficiency of 88.15%, performance index of 12622.1, and draft requirement of 193 N (0.079 hp) for 25 cm width of operation. | Bulky structure and not ergonomic friendly. | Performance evaluation |

| Performance evaluation of some manually operated weeders used in jhum cultivation in hill regions of Arunachal Pradesh [38] | This study evaluated the field performance of four different types of manually operated weeders, namely, wheel hoe with tines (W1), wheel hoe with sweep blade (W2), peg-type dry-land weeder (W3), and straight blade hand hoe (W4). The average adequate field capacity of 0.0185 (W1), 0.022 (W2), 0.016 (W3), and 0.017 ha/h (W4), respectively. The maximum weeding efficiency of 79.72% (W1) followed by 78.19% (W2), 75.71% (W3), and 72.50% (W4). Percentage plant damage was highest under 2.5% (W4) followed by 1.5% (W1), 1% (W2), and 0% (W3), respectively. | This study expresses less performance of manual weeders. | Performance evaluation and weeder blade design |

| Development and ergonomic evaluation of manual weeder [39] | This study evaluated the field performance of four different types of manually operated weeders, namely, wheel hoe with tines (W1), wheel hoe with sweep blade (W2), peg-type dry-land weeder (W3), and straight blade hand hoe (W4). The average adequate field capacity of 0.0185 (W1), 0.022 (W2), 0.016 (W3), and 0.017 ha/h (W4), respectively. The maximum weeding efficiency of 79.72% (W1) was followed by 78.19% (W2), 75.71% (W3), and 72.50% (W4). Percentage plant damage was highest under 2.5% (W4) followed by 1.5% (W1), 1% (W2), and 0% (W3), respectively. | Balancing issues due to single-wheeled weeder. | Performance evaluation and blade design |

| Performance evaluation of weeders [40] | This work compares the field performance of different weeder namely khurpi (W1), push type cycle weeder (W2) and power weeder (W3). The highest field efficiency was obtained for 91.5% (W1) followed by 85.4% (W2) and 71.25% (W3). The field capacity of 0.065 (W3), 0.025 (W1) and 0.035 ha/h (W2), respectively | This study expresses less performance of push type cycle weeder (W2), and power weeder (W3) | Performance evaluation |

| S. No | Particular | Values |

|---|---|---|

| 1 | Length, mm | 970 |

| 2 | Width, mm | 500 |

| 3 | Height, mm | 1040 |

| 4 | Weight, kg | 30 |

| Replication | Independent Variable (A) | Dependent Variables (B) | Trail Code |

|---|---|---|---|

| R1 R2 R3 | 1. Forward speeds (T): T1 = 0.8 km/h, T2 = 1 km/h, T3 = 1.2 km/h |

| R1 * T1 * B R2 * T1 * B R3 * T1 * B R1 * T2 * B R2 * T2 * B R3 * T2 * B R1 * T3 * B R2 * T3 * B R3 * T3 * B |

| S. No | Particulars | (T1) | (T2) | (T3) |

|---|---|---|---|---|

| 1 | Weeding time (h/ha) | 41.67 | 33.34 | 29.41 |

| 2 | Draft (kgf) | 1.8 | 2.0 | 2.4 |

| 3 | Power (hp) | 0.007 | 0.007 | 0.009 |

| S. No | Particular | T1 | T2 | T3 |

|---|---|---|---|---|

| 1 | Weed population (weed m−2) | 102 | 86 | 92 |

| 2 | Height of weed (cm) | 10–15 | 10–15 | 10–15 |

| S. No | Particular | Values |

|---|---|---|

| 1 | Name of crop | Green pea |

| 2 | Row-to-row spacing | 60 cm |

| 3 | Crop stage | 15 to 20 cm height from field (vegetative stage) |

| Particular | Trail 1 | Trail 2 | Trail 3 |

|---|---|---|---|

| Width of cut, (cm) | 27–29 | 27–29 | 27–29 |

| Depth of cut, (cm) | 3–5 | 3–5 | 3–5 |

| Treat No | Field Capacity (ha/h) | Plant Damage (%) | Weeding Efficiency (%) | Power (hp) | Performance Index |

|---|---|---|---|---|---|

| T1 | 0.0161 | 1.51 | 79.06 | 0.007 | 17,797 |

| T2 | 0.020 | 2.73 | 78.26 | 0.007 | 21,749 |

| T3 | 0.024 | 4.28 | 74.5 | 0.009 | 19,016 |

| Particular | T1 | T2 |

|---|---|---|

| Actual field capacity (ha/h) | 0.022 | 0.024 |

| Field efficiency (%) | 73.66 | 85 |

| Weeding efficiency (%) | 74.0 | 79 |

| Plant damage (%) | 2.20 | 1.5 |

| Method of Weeding | Adopted Technology | Price | Complication | Number of Operators | Efficiency | Impact on Environment | Availability |

|---|---|---|---|---|---|---|---|

| Robots | Autonomous robots with sensors and cameras for weed detection and removal | High | High (requires programming, maintenance) | High (requires specialized knowledge) | High (precise weed control) | Medium (potential herbicide use) | Low (expensive, requires infrastructure) |

| Precision Sprayers | GPS and sensors for targeted herbicide application | Medium-High | Medium | Medium (operator needed for setup) | High (precise herbicide use) | High (minimized chemical use | Medium (requires advanced tech) |

| Laser method | Lasers to destroy weeds without chemicals | High | High (requires setup and maintenance | Low (automated) | Medium (effective but expensive) | Medium (energy use) | Low (not feasible for small farms) |

| Power weeder | Tines or blades for mechanical weed removal | Medium | Medium | Medium (operator needed) | High (mechanical removal) | Medium (reduced chemical use) | Medium (costly, not universally adaptable) |

| Blade and Tine Push Weeder (Proposed) | Manual push mechanism with blade and tine system | Low | Low (simple operation) | Low (ergonomically designed to reduce fatigue) | High (effective weed control) | Low (no herbicide use, minimal soil disturbance) | High (affordable, practical for smallholder farms) |

| S. No | Particular | Values |

|---|---|---|

| 1 | Actual field capacity, ha/h | 0.020 |

| 2 | Theoretical field capacity, ha/h | 0.025 |

| 3 | Field efficiency, % | 85 |

| 4 | Width of cut, cm | 25–27 |

| 5 | Depth of cut, cm | 3–5 |

| 6 | Draft of weeder, kgf | 2.2 |

| 7 | Weeding efficiency, % | 78 |

| 8 | Plant damage, % | 2.7 |

| 9 | Performance index | 21,749 |

| 10 | Cost of operation, INR/ha | 2108 |

| 11 | Cost of machine, INR | 7500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Praveen, K.; Belagalla, N.; Dharavat, N.; Corrie, L.; D, G. Innovative Blade and Tine Push Weeder for Enhancing Weeding Efficiency of Small Farmers. Sustainability 2025, 17, 2639. https://doi.org/10.3390/su17062639

Praveen K, Belagalla N, Dharavat N, Corrie L, D G. Innovative Blade and Tine Push Weeder for Enhancing Weeding Efficiency of Small Farmers. Sustainability. 2025; 17(6):2639. https://doi.org/10.3390/su17062639

Chicago/Turabian StylePraveen, Kalluri, Ningaraj Belagalla, Nagaraju Dharavat, Leander Corrie, and Gireesha D. 2025. "Innovative Blade and Tine Push Weeder for Enhancing Weeding Efficiency of Small Farmers" Sustainability 17, no. 6: 2639. https://doi.org/10.3390/su17062639

APA StylePraveen, K., Belagalla, N., Dharavat, N., Corrie, L., & D, G. (2025). Innovative Blade and Tine Push Weeder for Enhancing Weeding Efficiency of Small Farmers. Sustainability, 17(6), 2639. https://doi.org/10.3390/su17062639