Application of a Filler in the Form of Micronized Chalcedonite to Biodegradable Materials Based on Thermoplastic Starch as an Element of the Sustainable Development of Polymeric Materials

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Domínguez-Solera, E.; Gadaleta, G.; Ferrero-Aguar, P.; Navarro-Calderón, Á.; Escrig-Rondán, C. The Biodegradability of Plastic Products for Agricultural Application: European Regulations and Technical Criteria. Clean Technol. 2025, 7, 11. [Google Scholar] [CrossRef]

- Plastics Europe. The Circular Economy for Plastics—A European Analysis; Plastics Europe: Brussels, Belgium, 2024. [Google Scholar]

- Folino, A.; Pangallo, D.; Calabrò, P.S. Assessing Bioplastics Biodegradability by Standard and Research Methods: Current Trends and Open Issues. J. Environ. Chem. Eng. 2023, 11, 109424. [Google Scholar] [CrossRef]

- Fabijański, M.; Gołofit, T. Influence of Processing Parameters on Mechanical Properties and Degree of Crystallization of Polylactide. Materials 2024, 17, 3584. [Google Scholar] [CrossRef] [PubMed]

- Fazeli, M.; Islam, S.; Baniasadi, H.; Abidnejad, R.; Schlapp-Hackl, I.; Hummel, M.; Lipponen, J. Exploring the potential of regenerated Ioncell fiber composites: A sustainable alternative for high-strength applications. Green Chem. 2024, 26, 6822–6835. [Google Scholar] [CrossRef]

- Saavedra-Rojas, F.A.; Bhandari, S.; Lopez-Anido, R.A. Environmental Durability of Bio-Based and Synthetic Thermoplastic Composites in Large-Format Additive Manufacturing. Polymers 2024, 16, 787. [Google Scholar] [CrossRef]

- Rydz, J.; Sikorska, W.; Musioł, M. Biosynthesis and Biodegradation— Eco-Concept for Polymer Materials. Int. J. Mol. Sci. 2024, 25, 2674. [Google Scholar] [CrossRef]

- Gilani, I.E.; Sayadi, S.; Zouari, N.; Al-Ghouti, M.A. Plastic waste impact and biotechnology: Exploring polymer degradation, microbial role, and sustainable development implications. Bioresour. Technol. Rep. 2023, 24, 101606. [Google Scholar] [CrossRef]

- Bao, Q.; Wong, W.; Liu, S.; Tao, X. Accelerated Degradation of Poly(lactide acid)/Poly(hydroxybutyrate) (PLA/PHB) Yarns/Fabrics by UV and O2 Exposure in South China Seawater. Polymers 2022, 14, 1216. [Google Scholar] [CrossRef]

- Airinei, D.N.; Modrogan, C.; Orbuleț, O.D.; Dǎncilǎ, A.M.; Boşomoiu, M.; Matei, C. Biodegradable Thermoplastic Materials with Application in the Manufacture of Bags Without Synthetic Polymers. Polymers 2025, 17, 356. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biodegradable compatibilized polymer blends for packaging applications: A literature review. J. Appl. Polim. Nauka. 2018, 135, 45726. [Google Scholar] [CrossRef]

- Müllera, K.; Bugnicourt, E.; Latorre, M.; Jorda, M.; Echegoyen Sanz, Y.; Lagaron, J.; Miesbauera, O.; Bianchin, A.; Hankin, S.; Bölz, U. Review on the Processing and Properties of Polymer Nanocomposites and Nanocoatings and Their Applications in the Packaging, Automotive and Solar Energy Fields. Nanomaterials 2017, 7, 74. [Google Scholar] [CrossRef] [PubMed]

- Naziemiec, Z.; Saramak, D. Effective methods of chalcedonite processing. Min. Sci. 2021, 28, 7–18. [Google Scholar] [CrossRef]

- Surowiak, A.; Gawenda, T.; Stempkowska, A.; Niedoba, T.; Nad, A. The Influence of Selected Properties of Particles in the Jigging Process of Aggregates on an Example of Chalcedonite. Minerals 2020, 10, 600. [Google Scholar] [CrossRef]

- Naziemiec, Z.; Pichniarczyk, P.; Saramak, D. Current issues of processing and industrial utilization of chalcedonite. Inż. Miner. 2017, 1, 89–96. [Google Scholar]

- Fabijański, M. Mechanical Properties of Polylactide Filled with Micronized Chalcedonite. J. Compos. Sci. 2022, 6, 387. [Google Scholar] [CrossRef]

- Adewumi, F.D.; Lajide, L.; Adewole, E.; Johnson, J.A. Synthesis and Characterization of Native and Modified Bitter Yam Starch Grafted with Acrylonitrile. Polímeros 2022, 32, e2022041. [Google Scholar] [CrossRef]

- Ojogbo, E.; Ogunsona, E.O.; Mekonnen, T.H. Chemical and Physical Modifications of Starch for Renewable Polymeric Materials. Mater. Today Sustain. 2020, 7–8, 100028. [Google Scholar] [CrossRef]

- Garbarski, J.; Fabijański, M. Strength of the thermoplastic starch/polylactide mixture. Przem. Chem. 2024, 103, 381. [Google Scholar] [CrossRef]

- Jia, X.; Wen, Q.; Sun, Y.; Chen, Y.; Gao, D.; Ru, Y.; Chen, N. Preparation and Performance of PBAT/PLA/CaCO3 Composites via Solid-State Shear Milling Technology. Polymers 2024, 16, 2942. [Google Scholar] [CrossRef]

- Rana, L.; Kouka, S.; Gajdosova, V.; Strachota, B.; Konefał, M.; Pokorny, V.; Pavlova, E.; Stary, Z.; Lukes, J.; Patocka, M.; et al. Thermoplastic Starch with Maltodextrin: Preparation, Morphology, Rheology, and Mechanical Properties. Materials 2024, 17, 5474. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, L.; McClements, D.J.; Yang, T.; Zhang, Z.; Ren, F.; Miao, M.; Tian, Y.; Jin, Z. Starch-Based Biodegradable Packaging Materials: A Review of Their Preparation, Characterization and Diverse Applications in the Food Industry. Trends Food Sci. Technol. 2021, 114, 70–82. [Google Scholar] [CrossRef]

- Mohammadi Nafchi, A.; Moradpour, M.; Saeidi, M.; Alias, A.K. Thermoplastic Starches: Properties, Challenges, and Prospects. Starch-Stärke 2013, 65, 61–72. [Google Scholar] [CrossRef]

- Garcia, M.A.V.T.; Garcia, C.F.; Faraco, A.A.G. Pharmaceutical and Biomedical Applications of Native and Modified Starch: A Review. Starch-Stärke 2020, 72, 1900270. [Google Scholar] [CrossRef]

- Żołek-Tryznowska, Z.; Piłczyńska, K.; Murawski, T.; Jeznach, A.; Niczyporuk, K. Study on the Printability of Starch-Based Films Using Ink-Jet Printing. Materials 2024, 17, 455. [Google Scholar] [CrossRef]

- Żołek-Tryznowska, Z.; Kałuża, A. The Influence of Starch Origin on the Properties of Starch Films: Packaging Performance. Materials 2021, 14, 1146. [Google Scholar] [CrossRef]

- Lepak-Kuc, S.K.; Kądziela, A.A.; Staniszewska, M.; Janczak, D.; Jakubowska, M.; Bednarczyk, E.; Murawski, T.T.; Piłczyńska, K.; Żołek-Tryznowska, Z. Sustainable, cytocompatible and flexible electronics on potato starch-based films. Sci. Rep. 2024, 14, 1. [Google Scholar] [CrossRef]

- Surendren, A.; Mohanty, A.K.; Liu, Q.; Misra, M. Green Chemistry CRITICAL REVIEW A review of biodegradable thermoplastic starches, their blends and composites: Recent developments and opportunities for single-use plastic packaging alternatives. Green Chem. 2022, 22, 8606–8636. [Google Scholar] [CrossRef]

- Fabijański, M.; Garbarski, J. Physical properties of the mixture polylactide/thermoplastic starch. Przem. Chem. 2023, 102, 954. [Google Scholar] [CrossRef]

- Fabijański, M.; Garbarski, J. Mechanical properties of thermoplastic starch filled with calcium carbonate. Przem. Chem. 2023, 102, 829. [Google Scholar] [CrossRef]

- Khan, B.; Khan Bilal Niazi, M.; Samin, G.; Jahan, Z. Thermoplastic starch: A possible biodegradable food packaging material—A review. Food Process Eng. 2017, 40, e12447. [Google Scholar] [CrossRef]

- Adamus, J.; Spychaj, T.; Zdanowicz, M.; Jędrzejewski, R. Thermoplastic starch with deep eutectic solvents and montmorillonite as a base for composite materials. Ind. Crop. Prod. 2018, 123, 278–284. [Google Scholar] [CrossRef]

- Fabra, M.J.; Martínez-Sanz, M.; Gómez-Mascaraque, L.; Gavara, R.; López-Rubio, A. Structural and physicochemical characterization of thermoplastic corn starch films containing microalgae. Carbohydr. Polym. 2018, 186, 184. [Google Scholar] [CrossRef] [PubMed]

- Stepczyńska, M.; Rytlewski, P.; Moraczewski, K.; Pawłowska, A.; Karasiewicz, T. Novel Biocomposite of Starch and Flax Fiber Modified with Tannic Acid with Biocidal Properties. Polymers 2024, 16, 1108. [Google Scholar] [CrossRef]

- Pichaiyut, S.; Nakason, C.; Wisunthorn, S. Biodegradability and Thermal Properties of Novel Natural Rubber/Linear Low Density Polyethylene/Thermoplastic Starch Ternary Blends. J. Polym. Environ. 2018, 26, 2855. [Google Scholar] [CrossRef]

- Kotwa, A.; Ramiączek, P.; Bąk-Patyna, P.; Kowalik, R. Parameters of Concrete Modified with Micronized Chalcedonite. Materials 2023, 16, 3602. [Google Scholar] [CrossRef]

- Jaworska, B.; Sokołowska, J.; Łukowski, P.; Jaworski, J. Waste mineral powders as components of polymer—Cement composites. Arch. Civ. Eng. 2015, 61, 199–210. [Google Scholar] [CrossRef]

- Spychał, E.; Vyšvařil, M. Physico-Mechanical Properties and Hydration Processes of Cement Pastes Modified with Pumice, Trass and Waste Chalcedonite Powder. Materials 2024, 17, 236. [Google Scholar] [CrossRef]

- Wieczorek, M.; Pichniarczyk, P. Properties of cement with the low Portland clinker and the different content of silica fly ash as well granulated blast furnace slag. Cem. Lim. Concr. 2022, 4, 285–299. [Google Scholar] [CrossRef]

- Spychał, E.; Kotwa, A. Assessment of the possibility of using chalcedonite powder as a component of mortars. Struct. Environm. 2022, 4, 119–125. [Google Scholar] [CrossRef]

- Michel, M.M. Characteristics of chalcedonite from Teofilów deposit for possible use in technology of water and wastewater treatment. Gospod. Surowc. Min. 2011, 1, 49–68. [Google Scholar]

- Fabijański, M. Study on mechanical properties of phosphogypsum-filled polylactide. Przem. Chem. 2016, 95, 2227–2229. [Google Scholar] [CrossRef]

- Data Sheet. Available online: https://oferta.grupaazoty.com/upload/1/files/2022/envifill/m/envifill%20MB%20173.pdf (accessed on 10 February 2025).

- Data Sheet. Available online: https://crusil.pl/wp-content/uploads/2024/02/Karta-produktu-Crusil-Maczka-chalcedonitowa-M10.pdf (accessed on 10 February 2025).

- ISO 527-2; Plastics—Determination of Tensile properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- ISO 527-1; Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- ISO 868; Plastics—Determination of Water Absorption. ISO: Geneva, Switzerland, 2008.

- ISO 179-1; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. ISO: Geneva, Switzerland, 2010.

- PN-EN ISO 62; Plastics—Determination of Water Absorption. ISO: Geneva, Switzerland, 2008.

| Properties | Standard | i.u. | Value |

|---|---|---|---|

| Density | ISO 1183 | g/cm3 | 1.25 |

| MFR (190 °C/2.16 kg) | ISO 1133 | g/10 min | 30 |

| Tensile strength | ISO 527-1,-2 | MPa | 50 |

| Elongation at break | ISO 527-1-2 | % | 10 |

| Young’s modulus | ISO 527-1,-2 | MPa | 2600 |

| Bending stress | ISO 178 | MPa | 70 |

| Ball indentation hardness | ISO 2039-1 | MPa | 115 |

| Vicat softening point | ISO 306 | °C | 60 |

| Chemical Composition % wt. | |

|---|---|

| SiO2 | >97 |

| Al2O3 | <2.2 |

| Fe2O2 | <0.2 |

| CaO | <0.1 |

| MgO | <0.1 |

| K2O | <0.3 |

| Na2O | <0.1 |

| TiO2 | <0.1 |

| Specific density | 2.60 g/cm3 |

| Bulk density | 0.45–0.55 g/cm3 |

| Shaken density | 0.60–0.65 g/cm3 |

| Loss on ignition LOI (1 h 950 °C) | 1.37% |

| Normal fire resistance PN-EN 993-12sP | 173 (1730 °C) |

| Granulation D-90 | ≤10 μm |

| Granulation D-50 | ≤3 μm |

| Optical propertiesL/a/b | 84.16/0.95/4.57 |

| Envifill MB173, % wt. | Crusil M10, % wt. |

|---|---|

| 100 | 0 |

| 95 | 5 |

| 90 | 10 |

| 85 | 15 |

| Injection Parameters | Values | |

|---|---|---|

| Injection: | ||

| Speed | 30% | |

| Pressure | 120 bar | |

| Processing temperature | zone 1 | 190 °C |

| zone 2 | 190 °C | |

| zone 3 | 170 °C | |

| zone 4 | 170 °C | |

| zone 5 | 80 °C | |

| Pressure: | ||

| Time | 10 s | |

| Holding pressure | 30 bar | |

| Closing force: | ||

| Average | 880 N | |

| Closing the mold: | ||

| Pressure | 170 bar | |

| Speed | 40% | |

| Mold protection time | 10 s | |

| Cycle time | 120 s | |

| Against pressure | 5 bar | |

| Mold opening: | ||

| Against pressure | 10 bar | |

| Cooling time | 15 s | |

| Temperature | 30 °C | |

| Filler Content, % wt. | 0 | 5 | 10 | 15 |

|---|---|---|---|---|

| Average value | 24.34 | 24.99 | 25.71 | 26.19 |

| Standard deviation | 0.006 | 0.037 | 0.066 | 0.268 |

| Measurement uncertainty, 95%, k = 2 | ±0.002 | ±0.012 | ±0.021 | ±0.085 |

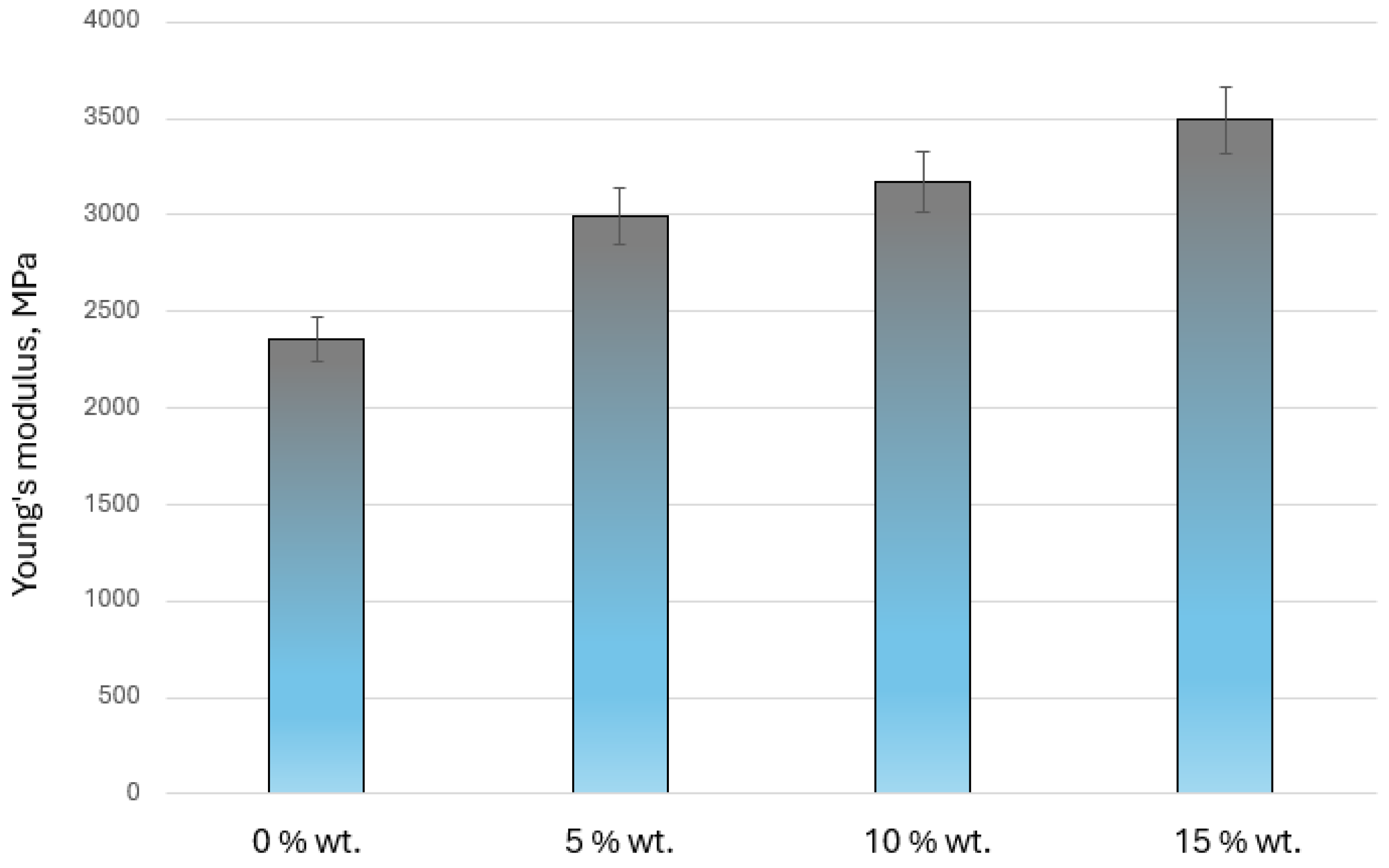

| Filler Content, % wt. | Elongation at Maximum Stress ε, % | Maximum Stress σ, MPa | Young’s Modulus E, MPa |

|---|---|---|---|

| 0 | 8.87 ± 0.44 | 56.80 ± 2.84 | 2353.87 ± 117.70 |

| 5 | 6.11 ± 0.30 | 52.07 ± 2.60 | 2995.13 ± 149.75 |

| 10 | 5.44 ± 0.27 | 49.20 ± 2.46 | 3169.49 ± 158.47 |

| 15 | 4.14 ± 0.21 | 41.30 ± 2.06 | 3492.77 ± 174.63 |

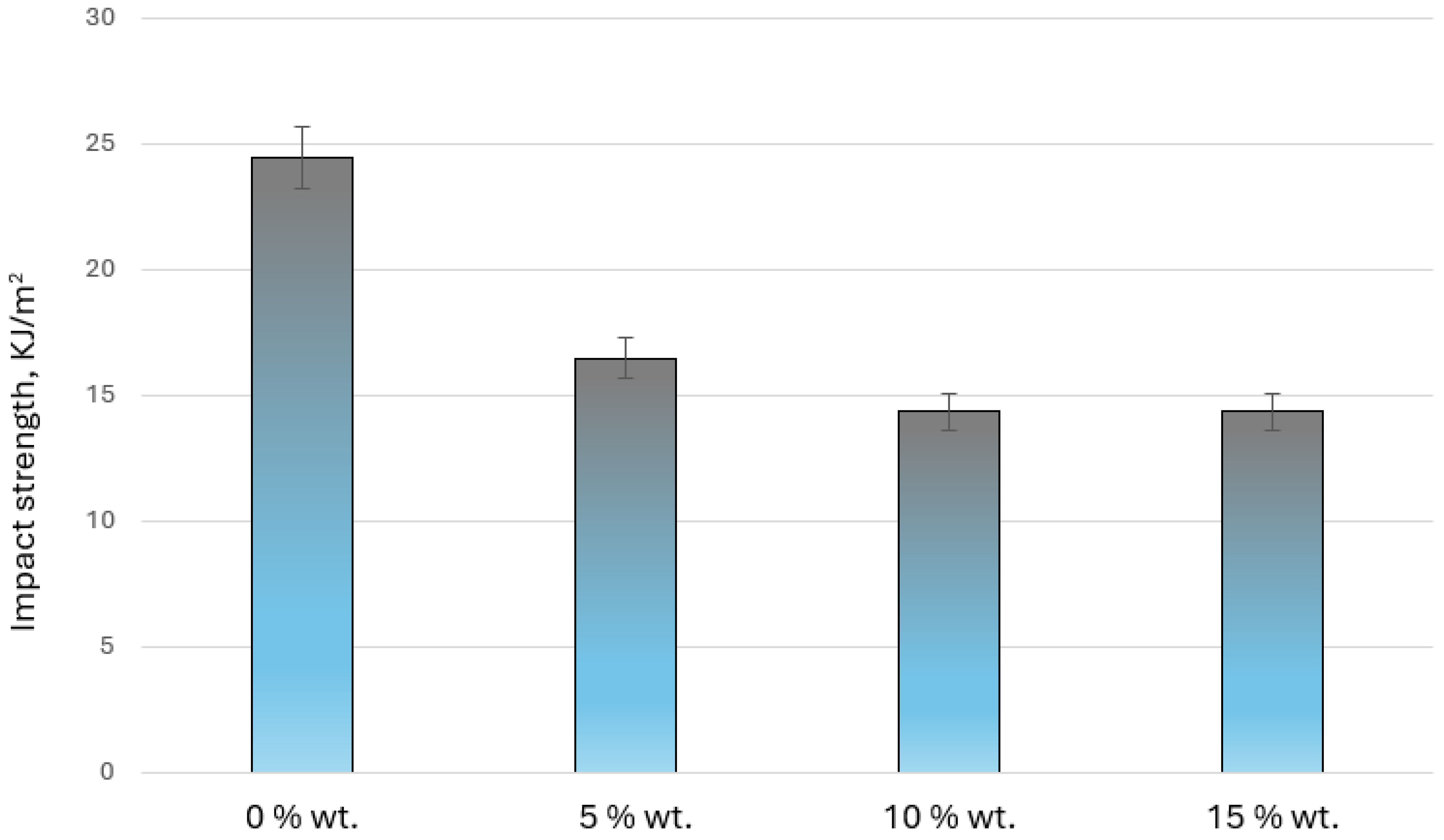

| Filler Content, % wt. | 0 | 5 | 10 | 15 |

|---|---|---|---|---|

| Average value, kJ/m2 | 24.50 | 16.50 | 14.38 | 14.38 |

| Standard deviation | 4.378 | 2.622 | 3.187 | 3.449 |

| Measurement uncertainty, 95%, k = 2 | ±1.384 | ±0.829 | ±1.008 | ±1.091 |

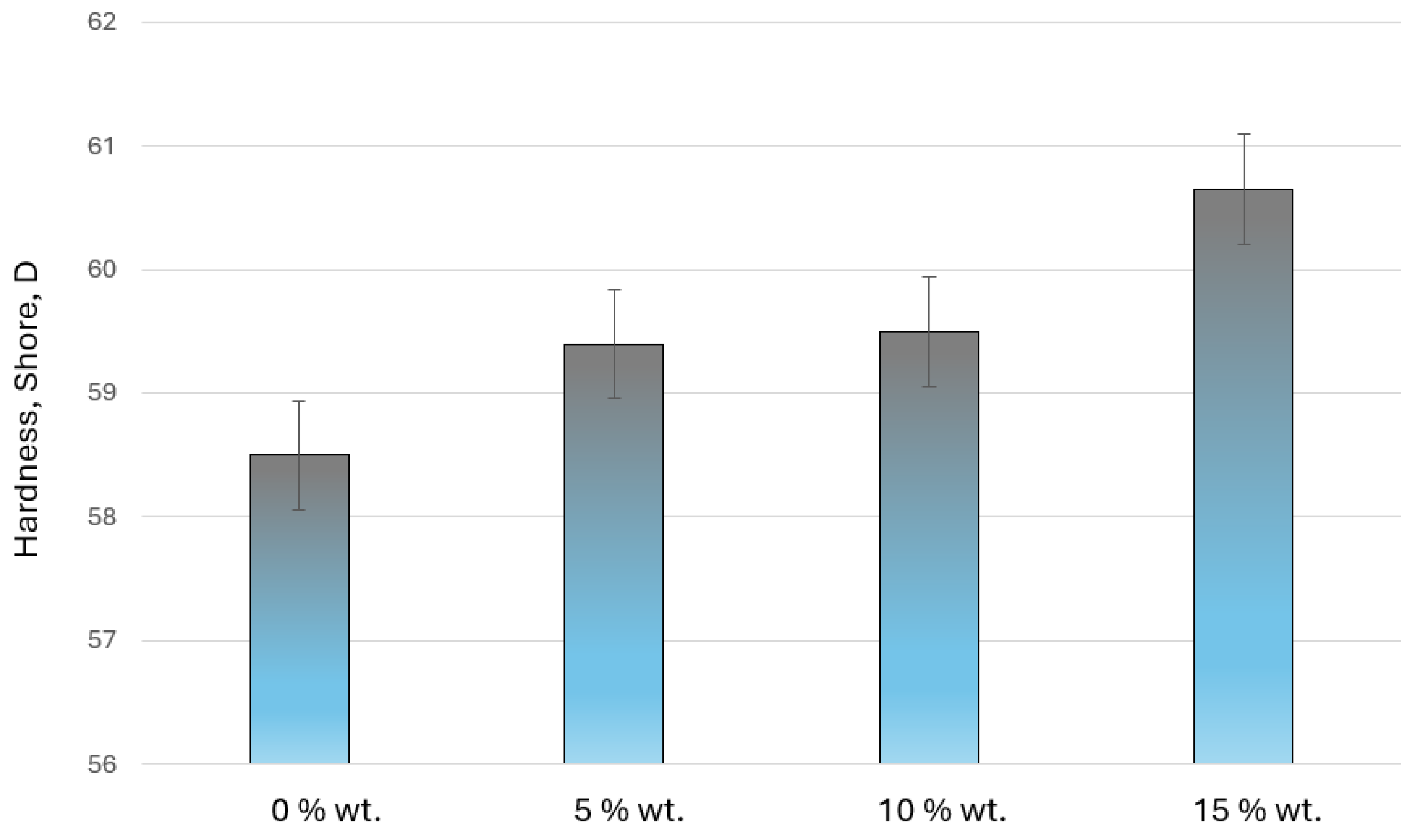

| Filler Content, % wt. | 0 | 5 | 10 | 15 |

|---|---|---|---|---|

| Average value, Shore “D” degree | 58.50 | 59.40 | 59.50 | 60.65 |

| Standard deviation | 1.130 | 1.350 | 1.202 | 0.474 |

| Measurement uncertainty, 95%, k = 2 | ±0.357 | ±0.427 | ±0.380 | ±0.150 |

| Filler Content, % wt. | Weight of Samples Before Immersion in Water, g | Sample Weight After 7 Days of Immersion in Water, g | Difference in Mass, g |

|---|---|---|---|

| 0 | 10.56 | 10.60 | 0.04 |

| 5 | 10.82 | 10.87 | 0.05 |

| 10 | 11.17 | 11.22 | 0.05 |

| 15 | 11.36 | 11.43 | 0.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garbarski, J.; Fabijański, M. Application of a Filler in the Form of Micronized Chalcedonite to Biodegradable Materials Based on Thermoplastic Starch as an Element of the Sustainable Development of Polymeric Materials. Sustainability 2025, 17, 2731. https://doi.org/10.3390/su17062731

Garbarski J, Fabijański M. Application of a Filler in the Form of Micronized Chalcedonite to Biodegradable Materials Based on Thermoplastic Starch as an Element of the Sustainable Development of Polymeric Materials. Sustainability. 2025; 17(6):2731. https://doi.org/10.3390/su17062731

Chicago/Turabian StyleGarbarski, Jacek, and Mariusz Fabijański. 2025. "Application of a Filler in the Form of Micronized Chalcedonite to Biodegradable Materials Based on Thermoplastic Starch as an Element of the Sustainable Development of Polymeric Materials" Sustainability 17, no. 6: 2731. https://doi.org/10.3390/su17062731

APA StyleGarbarski, J., & Fabijański, M. (2025). Application of a Filler in the Form of Micronized Chalcedonite to Biodegradable Materials Based on Thermoplastic Starch as an Element of the Sustainable Development of Polymeric Materials. Sustainability, 17(6), 2731. https://doi.org/10.3390/su17062731