Study on Carbon Emission Accounting Method System and Its Application in the Iron and Steel Industry

Abstract

1. Introduction

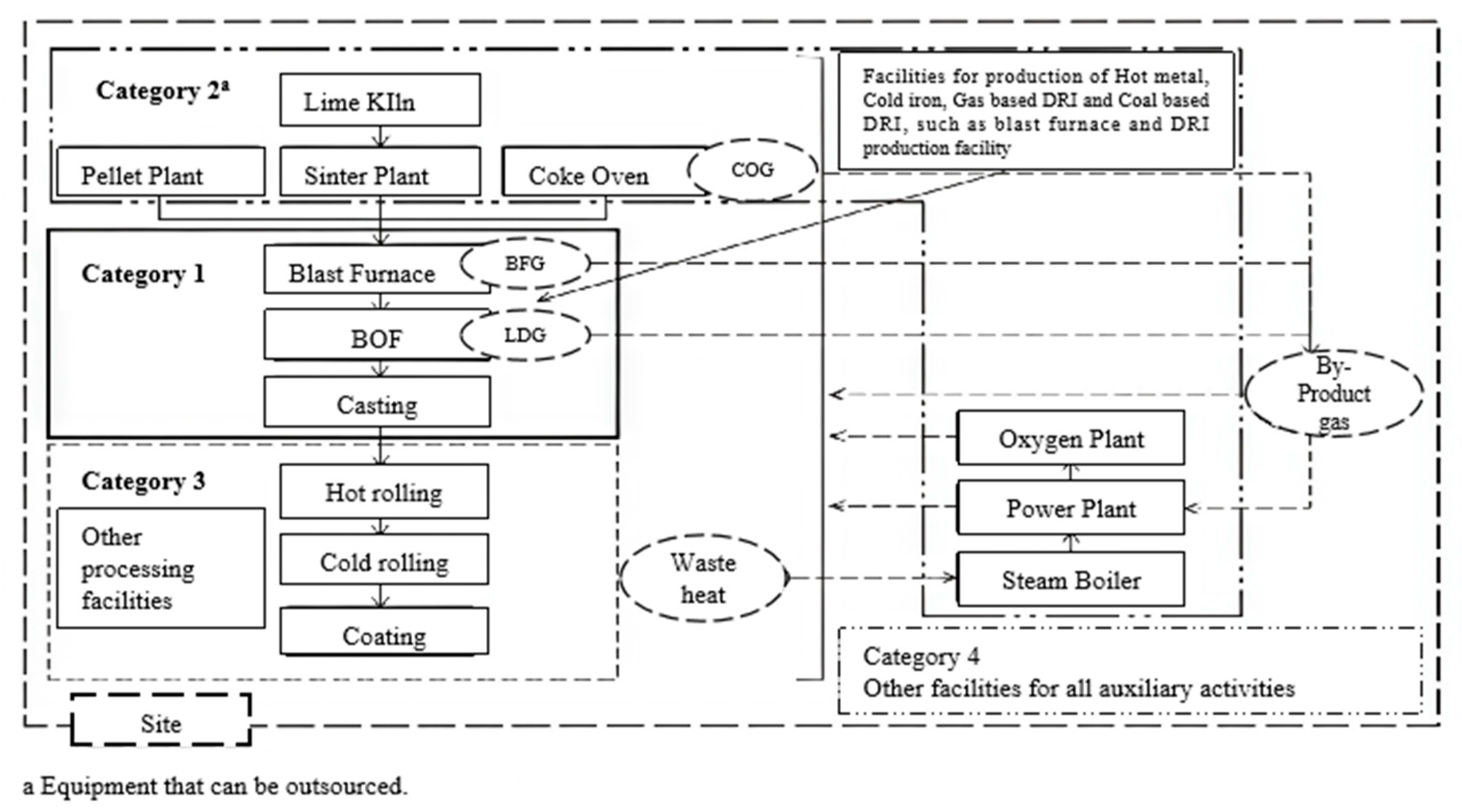

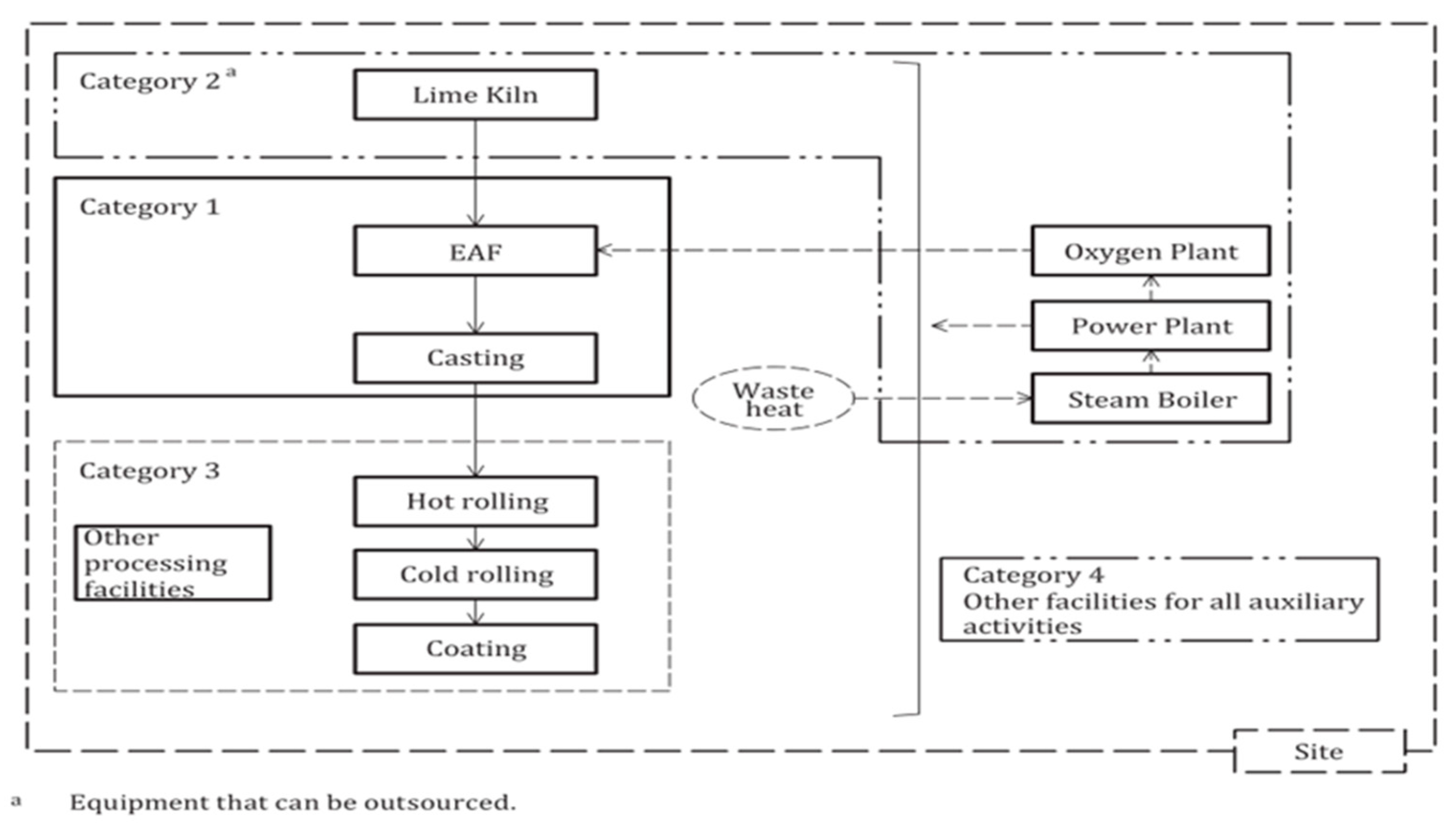

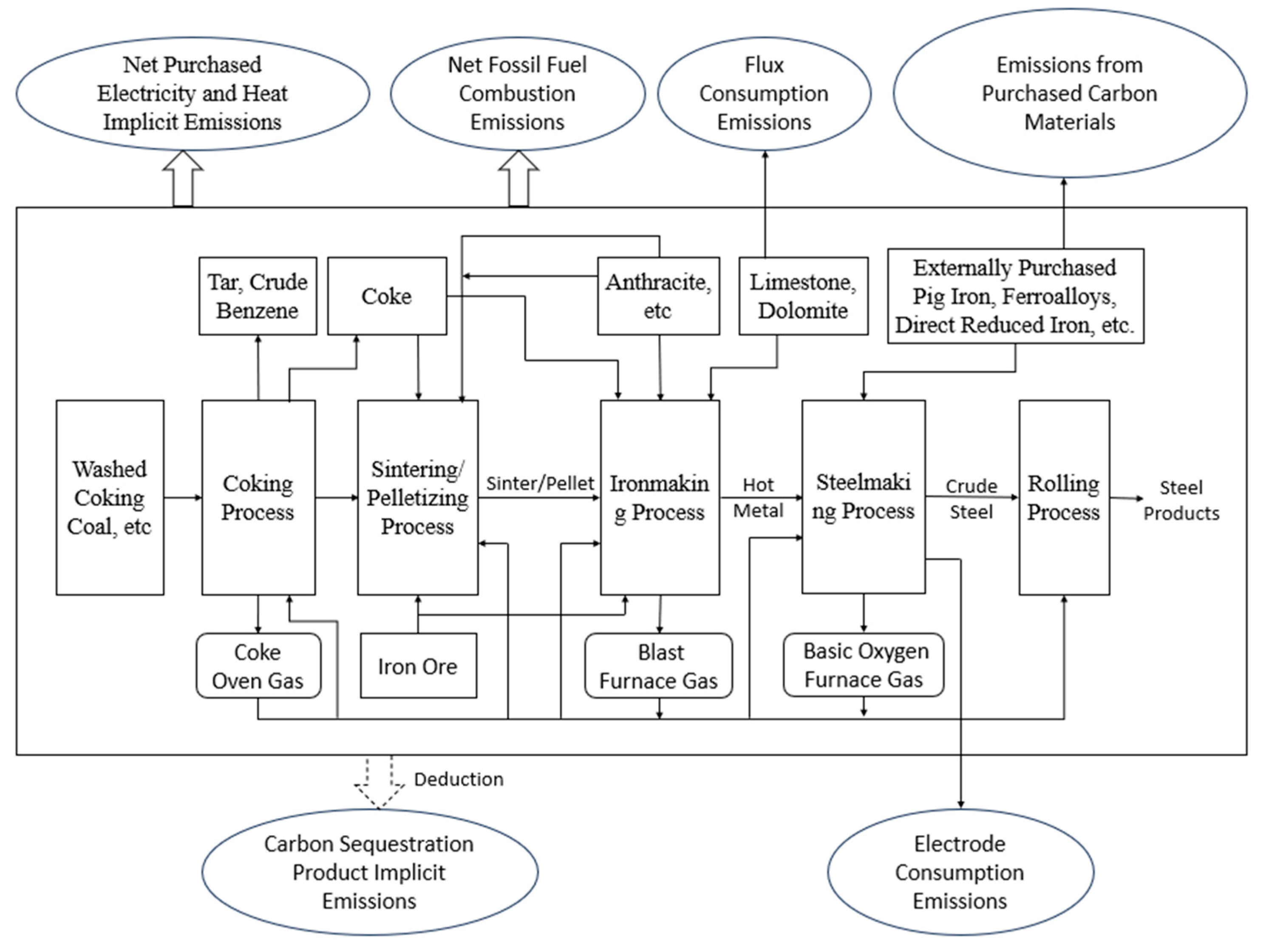

2. Classification of Carbon Emission Accounting System

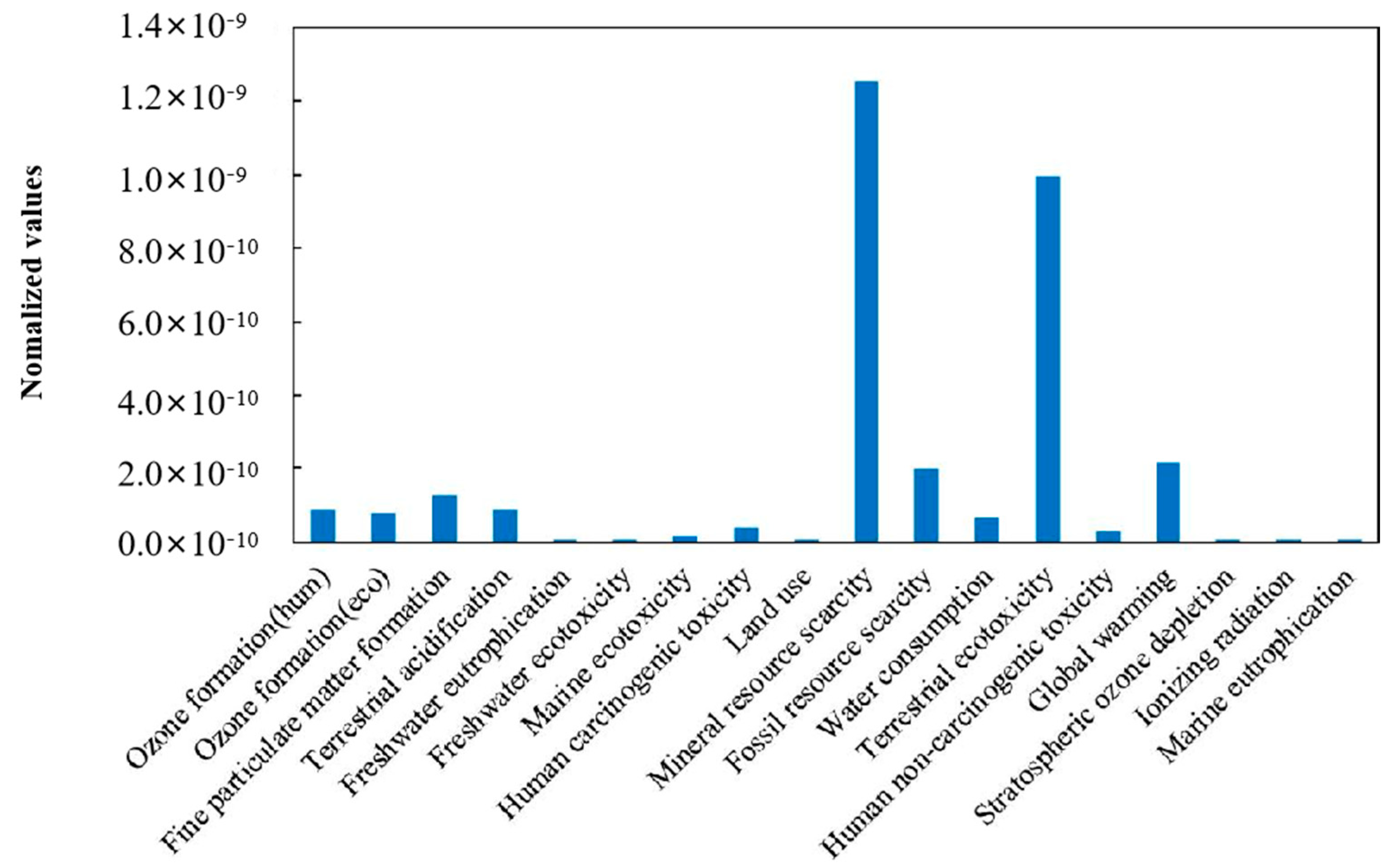

2.1. LCA

| LCA Method | Advantages | Disadvantages | Application Scenario | References | |

|---|---|---|---|---|---|

| Midpoint method | CML2001 |

|

| Applicable for in-depth analysis of specific environmental issues. | [40,41,42] |

| Middle point (H) of ReCiPe |

|

| Applicable to contexts necessitating a holistic assessment of the environmental impacts associated with products or processes. | [43,44,45] | |

| IPCC GWP100a |

|

| Applicable for evaluating the contribution of greenhouse gas emissions from products or activities to global warming. | [24,46,47] | |

| End-point method | IMPACT2002+ |

|

| Applicable for assessing the overarching impacts of products or activities on human health and ecosystem quality from a macroscopic perspective. | [48,49,50] |

| ReCiPe end method |

|

| Applicable for evaluating the environmental impacts of products or processes across multiple dimensions. | [51,52,53,54] | |

2.2. IOA

3. Analysis on the Application of Carbon Emission Accounting System

3.1. International General Method

3.1.1. IPCC National Greenhouse Gas Inventory

- Emission factor method

- ECO2, Non-energy = CO2 emissions to be reported in the IPPU department, in tons;BOF = The amount of crude steel of the alkaline oxygen converter, produced in tons;EAF = Crude steel quantity of electric arc furnace produced, in tons;OHF = The amount of crude steel produced, in tons;IP = Output of pig iron not converted into steel, in tons;DRI = The quantity of direct reducing iron produced by the state, in tons;SI = The amount of molten slag produced by the state, in tons;P = The amount of pellets produced by the state, in tons;EFx = Emission factor, measured in x per ton of CO2/production.

- 2.

- Mass balance method

- 3.

- Actual measurement method

3.1.2. International Iron and Steel Association

- Draw a boundary

- 2.

- Calculation method

3.1.3. ISO 14404 Calculation Method of Carbon Dioxide Emission Intensity in Iron and Steel Production

3.2. Regional Accounting Method

3.2.1. EU “Carbon Tariff”

3.2.2. Guidelines for Accounting Methods and Reporting of Greenhouse Gas Emissions from China

3.3. Comparative Analysis and Summary

3.3.1. Boundary Contrast

3.3.2. Data Collection and Uncertainty

3.3.3. Summary

4. Conclusions and Outlook

Funding

Conflicts of Interest

References

- Yu, W.; Luo, J. Impact on Carbon Intensity of Carbon Emission Trading—Evidence from a Pilot Program in 281 Cities in China. Int. J. Environ. Res. Public Health 2022, 19, 12483. [Google Scholar] [CrossRef] [PubMed]

- Feng, K.; Shao, S. Better Understanding Insurance Mechanism in Dealing with Climate Change Risk, with Special Reference to China. Int. J. Environ. Res. Public Health 2021, 18, 2996. [Google Scholar] [CrossRef]

- Reddy, M.S.; Ponnamma, D.; Sadasivuni, K.K.; Kumar, B.; Abdullah, A.M. Carbon dioxide adsorption based on porous materials. RSC Adv. 2021, 11, 12658–12681. [Google Scholar] [CrossRef]

- Lv, Y.; Niu, D.; Liu, X.; Li, Y. Corrosion Damage and Life Prediction of Concrete Structure in a 41-Year-Old Steelworks. Materials 2022, 15, 5893. [Google Scholar] [CrossRef]

- Sun, W.; Dong, H. Measurement of provincial carbon emission efficiency and analysis of influencing factors in China. Environ. Sci. Pollut. Res. Int. 2022, 30, 38292–38305. [Google Scholar] [CrossRef]

- Nataliya, T.; Kevin, T.; Matthew, M.; Steven, R.; David, K.; Conor, H.; Maral, B.; Peter, F.; Courtney, L.; Cristian, R.; et al. Global database of cement production assets and upstream suppliers. Sci. Data 2023, 10, 696. [Google Scholar]

- Zhang, K.; Jiang, L.; Jin, Y.; Liu, W. The Carbon Emission Characteristics and Reduction Potential in Developing Areas: Case Study from Anhui Province, China. Int. J. Environ. Res. Public Health 2022, 19, 16424. [Google Scholar] [CrossRef]

- Dong, Z.; Yao, S. Digital finance reduces urban carbon footprint pressure in 277 Chinese cities. Sci. Rep. 2024, 14, 16526. [Google Scholar] [CrossRef]

- Freire, F.D.; da Silva, N.O.; de Oliveira, V.R. Economic growth and greenhouse gases in Brazilian States: Is the environmental Kuznets curve applicable hypothesis? Environ. Sci. Pollut. Res. Int. 2023, 30, 44928–44942. [Google Scholar] [CrossRef]

- Talwar, N.; Holden, N.M. The limitations of bioeconomy LCA studies for understanding the transition to sustainable bioeconomy. Int. J. Life Cycle Assess. 2022, 27, 680–703. [Google Scholar] [CrossRef]

- Luo, Y.; Su, R. Environmental Impact of Waste Treatment and Synchronous Hydrogen Production: Based on Life Cycle Assessment Method. Toxics 2024, 12, 652. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Pan, X.; Jin, C.; Li, Y.; Xu, Q.; Zhang, D.; Li, H. Life Cycle Assessment-Based Carbon Footprint Accounting Model and Analysis for Integrated Energy Stations in China. Int. J. Environ. Res. Public Health 2022, 19, 16451. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Yang, D.; Huang, A. LEAP-Based Greenhouse Gases Emissions Peak and Low Carbon Pathways in China’s Tourist Industry. Int. J. Environ. Res. Public Health 2021, 18, 1218. [Google Scholar] [CrossRef] [PubMed]

- Lathan, R.; Hitchman, L.; Walshaw, J.; Ravindhran, B.; Carradice, D.; Smith, G.; Chetter, I.; Yiasemidou, M. Telemedicine for sustainable postoperative follow-up: A prospective pilot study evaluating the hybrid life-cycle assessment approach to carbon footprint analysis. Front. Surg. 2024, 11, 1300625. [Google Scholar] [CrossRef]

- Li, S.; Deng, H.; Zhang, K. The Impact of Economy on Carbon Emissions: An Empirical Study Based on the Synergistic Effect of Gender Factors. Int. J. Environ. Res. Public Health 2019, 16, 3723. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, M.; Luan, Y.; Cui, W.; Lin, X. Spatial Evolutionary Characteristics and Influencing Factors of Urban Industrial Carbon Emission in China. Int. J. Environ. Res. Public Health 2022, 19, 11227. [Google Scholar] [CrossRef]

- Yang, P.; Liang, X.; Drohan, P.J. Using Kaya and LMDI models to analyze carbon emissions from the energy consumption in China. Environ. Sci. Pollut. Res. Int. 2020, 27, 26495–26501. [Google Scholar] [CrossRef]

- Chen, X.; Mao, J.; Yu, G. Analysis of iron composite flow in China. Environ. Sci. Pollut. Res. Int. 2022, 29, 65613–65624. [Google Scholar] [CrossRef]

- Yu, Y.; You, K.; Cai, W.; Feng, W.; Li, R.; Liu, Q.; Chen, L.; Liu, Y. City-level building operation and end-use carbon emissions dataset from China for 2015–2020. Sci. Data 2024, 11, 138. [Google Scholar] [CrossRef]

- ISO 14404; Calculation Method of Carbon Dioxide Emission Intensity from Iron and Steel Production. International Organization for Standardization: Geneva, Switzerland, 2013.

- Roibás, L.; Loiseau, E.; Hospido, A. Determination of the carbon footprint of all Galician production and consumption activities: Lessons learnt and guidelines for policymakers. J. Environ. Manag. 2017, 198, 289–299. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Li, K.; Ward, H.; Lin, H.X.; Tukker, A. Traded Plastic, Traded Impacts? Designing Counterfactual Scenarios to Assess Environmental Impacts of Global Plastic Waste Trade. Environ. Sci. Technol. 2024, 58, 8631–8642. [Google Scholar] [CrossRef] [PubMed]

- Gómez, P.; Elduque, D.; Pina, C.; Javierre, C. Influence of the Composition on the Environmental Impact of Soft Ferrites. Materials 2018, 11, 1789. [Google Scholar] [CrossRef] [PubMed]

- Alyaseri, I.; Zhou, J. Towards better environmental performance of wastewater sludge treatment using endpoint approach in LCA methodology. Heliyon 2017, 3, e00268. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Ma, X.; Shen, X.; Zhai, Y.; Zhang, T.; Ji, C.; Hong, J. Life cycle assessment of electrolytic manganese metal production. J. Clean. Prod. 2020, 253, 119951. [Google Scholar] [CrossRef]

- Deng, L.; Adams, T.A., II. Comparison of steel manufacturing off-gas utilization methods via life cycle analysis. J. Clean. Prod. 2020, 277, 123568. [Google Scholar] [CrossRef]

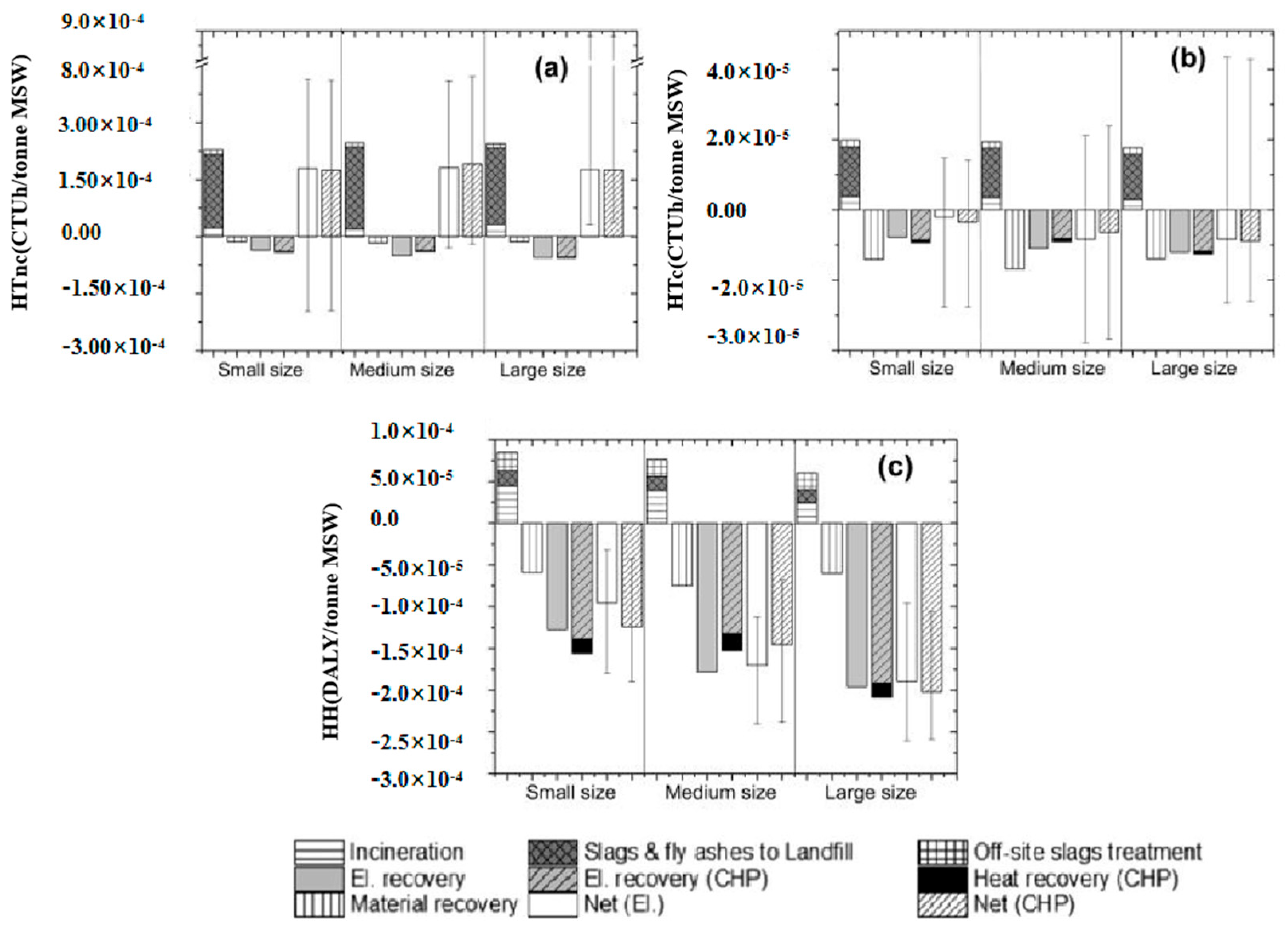

- Di Maria, F.; Mastrantonio, M.; Uccelli, R. The life cycle approach for assessing the impact of municipal solid waste incineration on the environment and on human health. Sci. Total Environ. 2021, 776, 145785. [Google Scholar] [CrossRef]

- Yuan, Y.; Li, T.; Zhai, Q. Life Cycle Impact Assessment of Garbage-Classification Based Municipal Solid Waste Management Systems: A Comparative Case Study in China. Int. J. Environ. Res. Public Health 2020, 17, 5310. [Google Scholar] [CrossRef]

- Leon-Medina, J.X.; Camacho, J.; Gutierrez-Osorio, C.; Salomón, J.E.; Rueda, B.; Vargas, W.; Sofrony, J.; Restrepo-Calle, F.; Pedraza, C.; Tibaduiza, D. Temperature Prediction Using Multivariate Time Series Deep Learning in the Lining of an Electric Arc Furnace for Ferronickel Production. Sensors 2021, 21, 6894. [Google Scholar] [CrossRef]

- Acquaye, A.; Feng, K.; Oppon, E.; Salhi, S.; Ibn-Mohammed, T.; Genovese, A.; Hubacek, K. Measuring the environmental sustainability performance of global supply chains: A multi-regional input-output analysis for carbon, sulphur oxide and water footprints. J. Environ. Manag. 2017, 187, 571–585. [Google Scholar] [CrossRef]

- He, Y.T.; Zhang, Y.C.; Huang, W.; Wang, R.N.; He, L.X.; Li, B.; Zhang, Y.L. Impact of digital economic development and environmental pollution on residents’ health: An empirical analysis based on 279 prefecture-level cities in China. BMC Public Health 2023, 23, 959. [Google Scholar] [CrossRef]

- Tang, L.; Xue, X.; Jia, M.; Jing, H.; Wang, T.; Zhen, R.; Huang, M.; Tian, J.; Guo, J.; Li, L.; et al. Iron and steel industry emissions and contribution to the air quality in China. Atmos. Environ. 2020, 237, 117668. [Google Scholar] [CrossRef]

- Fang, H.; Gao, J.; Tong, Y.; Liu, Q.; Cheng, S.; Li, G.; Yue, T. Advances in the sources, chemical behaviour, and whole process distribution of Hg, As, and Pb in the iron and steel smelting industry. J. Hazard. Mater. 2024, 480, 135912. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.; Zhang, Z.; Zhang, F. Coupling coordination development of energy-economy-carbon emissions in China under the background of “double carbon”. PLoS ONE 2022, 17, e0277828. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Y.; Cheng, Z.; Zhang, H. The Effect of Manufacturing Agglomeration on Haze Pollution in China. Int. J. Environ. Res. Public Health 2018, 15, 2490. [Google Scholar] [CrossRef]

- Xiao-qi, W.-j.L.J.-l.C.S.-y.J.J.W. Air Pollutant Emission Inventory from Iron and Steel Industry in the Beijing-Tianjin-Hebei Region and Its Impact on PM 2. 5. Environ. Sci. Technol. 2018, 39, 1445–1454. [Google Scholar] [CrossRef]

- Akrivou, C.; Łȩkawska-Andrinopoulou, L.; Tsimiklis, G.; Amditis, A. Industrial symbiosis platforms for synergy identification and their most important data points: A systematic review. Open Res. Eur. 2021, 1, 101. [Google Scholar] [CrossRef]

- Liu, S.; Li, P.; Wang, J.; Liu, P. Toward industry 5.0: Challenges and enablers of intelligent manufacturing technology implementation under the perspective of sustainability. Heliyon 2024, 10, e35162. [Google Scholar] [CrossRef]

- Tong, L.; Liu, X.; Liu, X.; Yuan, Z.; Zhang, Q. Life cycle assessment of water reuse systems in an industrial park. J. Environ. Manag. 2013, 129, 471–478. [Google Scholar] [CrossRef]

- Foroughi, F.; Rezvani Ghomi, E.; Morshedi Dehaghi, F.; Borayek, R.; Ramakrishna, S. A Review on the Life Cycle Assessment of Cellulose: From Properties to the Potential of Making It a Low Carbon Material. Materials 2021, 14, 714. [Google Scholar] [CrossRef]

- Daniyan, I.; Mpofu, K.; Ramatsetse, B.; Gupta, M. Review of life cycle models for enhancing machine tools sustainability: Lessons, trends and future directions. Heliyon 2021, 7, e06790. [Google Scholar] [CrossRef]

- Wang, A.; Fang, Y.; Zhou, Y.; Wang, C.; Dong, B.; Chen, C. Green Protective Geopolymer Coatings: Interface Characterization, Modification and Life-Cycle Analysis. Materials 2022, 15, 3767. [Google Scholar] [CrossRef] [PubMed]

- Paletto, A.; Bernardi, S.; Pieratti, E.; Teston, F.; Romagnoli, M. Assessment of environmental impact of biomass power plants to increase the social acceptance of renewable energy technologies. Heliyon 2019, 5, e02070. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Sun, J.; Ma, J.; Xu, F.; Qiu, L. Environmental Assessment of a Hybrid Solar-Biomass Energy Supplying System: A Case Study. Int. J. Environ. Res. Public Health 2019, 16, 2222. [Google Scholar] [CrossRef]

- Li, Y.; Lan, S.; Ryberg, M.; Pérez-Ramírez, J.; Wang, X. A quantitative roadmap for China towards carbon neutrality in 2060 using methanol and ammonia as energy carriers. iScience 2021, 24, 102513. [Google Scholar] [CrossRef]

- Presciutti, A.; Gebennini, E.; Liberti, F.; Nanni, F.; Bragaglia, M. Comparative Life Cycle Assessment of SLS and mFFF Additive Manufacturing Techniques for the Production of a Metal Specimen. Materials 2023, 17, 78. [Google Scholar] [CrossRef]

- An, J.; Zou, Z.; Chen, G.; Sun, Y.; Liu, R.; Zheng, L. An IoT-Based Life Cycle Assessment Platform of Wind Turbines. Sensors 2021, 21, 1233. [Google Scholar] [CrossRef]

- Mostashari-Rad, F.; Ghasemi-Mobtaker, H.; Taki, M.; Ghahderijani, M.; Saber, Z.; Chau, K.W.; Nabavi-Pelesaraei, A. Data supporting midpoint-weighting life cycle assessment and energy forms of cumulative exergy demand for horticultural crops. Data Brief 2020, 33, 106490. [Google Scholar] [CrossRef]

- Benoit, S.; Chamberland, J.; Doyen, A.; Margni, M.; Bouchard, C.; Pouliot, Y. Integrating Pressure-Driven Membrane Separation Processes to Improve Eco-Efficiency in Cheese Manufacture: A Preliminary Case Study. Membranes 2020, 10, 287. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Mei, L.; Xu, X.; Yin, H.; Feng, X.; Chen, J. Carbon Reduction of the Three-Year Air Pollution Control Plan under the LEAP Model Using a GREAT Tool in Panzhihua, China. Int. J. Environ. Res. Public Health 2022, 19, 14482. [Google Scholar] [CrossRef]

- To, W.M.; Lai, T.M.; Lo, W.C.; Lam, K.H.; Chung, W.L. The growth pattern and fuel life cycle analysis of the electricity consumption of Hong Kong. Environ. Pollut. 2012, 165, 1–10. [Google Scholar] [CrossRef]

- Gallagher, C.L.; Holloway, T. Integrating Air Quality and Public Health Benefits in U.S. Decarbonization Strategies. Front. Public Health 2020, 8, 563358. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.W.; Peters, G.P.; Gasser, T.; Andrew, R.M.; Schwingshackl, C.; Gütschow, J.; Houghton, R.A.; Friedlingstein, P.; Pongratz, J.; Le Quéré, C. National contributions to climate change due to historical emissions of carbon dioxide, methane, and nitrous oxide since 1850. Sci. Data 2023, 10, 155. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Yin, X.; Wu, C. Comparative Evaluation of Biomass Power Generation Systems in China Using Hybrid Life Cycle Inventory Analysis. Sci. World J. 2014, 2014, 735431. [Google Scholar] [CrossRef]

- Shang, M.; Luo, J. The Tapio Decoupling Principle and Key Strategies for Changing Factors of Chinese Urban Carbon Footprint Based on Cloud Computing. Int. J. Environ. Res. Public Health 2021, 18, 2101. [Google Scholar] [CrossRef]

- Chen, S.; Chen, B.; Feng, K.; Liu, Z.; Fromer, N.; Tan, X.; Alsaedi, A.; Hayat, T.; Weisz, H.; Schellnhuber, H.J.; et al. Physical and virtual carbon metabolism of global cities. Nat. Commun. 2020, 11, 182. [Google Scholar] [CrossRef]

- Gao, Z.; Geng, Y.; Wu, R.; Zhang, X.; Pan, H.; Jiang, H. China’s CO2 emissions embodied in fixed capital formation and its spatial distribution. Environ. Sci. Pollut. Res. Int. 2020, 27, 19970–19990. [Google Scholar] [CrossRef]

- Mangır, N.; Şahin, Ü.A. An environmentally extended global multi-regional input–output analysis of consumption-based and embodied import-based carbon emissions of Turkey. Environ. Sci. Pollut. Res. 2022, 29, 54813–54826. [Google Scholar] [CrossRef]

- Long, Y.; Yoshida, Y.; Liu, Q.; Zhang, H.; Wang, S.; Fang, K. Comparison of city-level carbon footprint evaluation by applying single- and multi-regional input-output tables. J. Environ. Manag. 2020, 260, 110108. [Google Scholar] [CrossRef]

- Chen, Q.; Gao, Y.; Pan, C.; Xu, D.; Cai, K.; Guan, D.; He, Q.; Li, S.; Liu, W.; Meng, B.; et al. An interprovincial input–output database distinguishing firm ownership in China from 1997 to 2017. Sci. Data 2023, 10, 293. [Google Scholar] [CrossRef]

- Wang, T.; Chen, Y.; Zeng, L. Spatial-Temporal Evolution Analysis of Carbon Emissions Embodied in Inter-Provincial Trade in China. Int. J. Environ. Res. Public Health 2022, 19, 6794. [Google Scholar] [CrossRef]

- Han, J.; Tan, Z.; Chen, M.; Zhao, L.; Yang, L.; Chen, S. Carbon Footprint Research Based on Input–Output Model—A Global Scientometric Visualization Analysis. Int. J. Environ. Res. Public Health 2022, 19, 11343. [Google Scholar] [CrossRef] [PubMed]

- Wood, R.; Moran, D.D.; Rodrigues, J.F.D.; Stadler, K. Variation in trends of consumption based carbon accounts. Sci. Data 2019, 6, 99. [Google Scholar] [CrossRef] [PubMed]

- Arto, I.; Rueda-Cantuche, J.M.; Peters, G.P. Comparing the gtap-mrio and wiod databases for carbon footprint analysis. Econ. Syst. Res. 2014, 26, 327–353. [Google Scholar] [CrossRef]

- Lee, C.-H.; Ma, H.-W. Improving the integrated hybrid LCA in the upstream scope 3 emissions inventory analysis. Int. J. Life Cycle Assess. 2013, 18, 17–23. [Google Scholar] [CrossRef]

- Buetre, B.L.; Ahmadi-Esfahani, F.Z. Updating an input–output table for use in policy analysis. Aust. J. Agric. Resour. Econ. 2000, 44, 573–603. [Google Scholar] [CrossRef][Green Version]

- Li, L.; Lei, Y.; Pan, D. Study of CO2 emissions in China’s iron and steel industry based on economic input–output life cycle assessment. Nat. Hazards 2016, 81, 957–970. [Google Scholar] [CrossRef]

- Yang, W.; Min, Z.; Yang, M.; Yan, J. Exploration of the Implementation of Carbon Neutralization in the Field of Natural Resources under the Background of Sustainable Development—An Overview. Int. J. Environ. Res. Public Health 2022, 19, 14109. [Google Scholar] [CrossRef]

- Liao, S.; Wang, D.; Xia, C.; Tang, J. China’s provincial process CO2 emissions from cement production during 1993–2019. Sci. Data 2022, 9, 165. [Google Scholar] [CrossRef]

- Du, M.; Zhou, Q.; Zhang, Y.; Li, F. Towards sustainable development in China: How do green technology innovation and resource misallocation affect carbon emission performance? Front. Psychol. 2022, 13, 929125. [Google Scholar] [CrossRef]

- ISO 14404-2:2024; Calculation Method of Carbon Dioxide Emission Intensity from Iron and Steel Production. Part 2: Steel plant with Electric Arc Furnace (EAF). ISO: Geneva, Switzerland, 2024.

- Blowers, P.; Lownsbury, J.M. Carbon dioxide emission implications if hydrofluorocarbons are regulated: A refrigeration case study. Environ. Sci. Technol. 2010, 44, 1526–1529. [Google Scholar] [CrossRef]

- Zhao, A.; Song, X.; Li, J.; Yuan, Q.; Pei, Y.; Li, R.; Hitch, M. Effects of Carbon Tax on Urban Carbon Emission Reduction: Evidence in China Environmental Governance. Int. J. Environ. Res. Public Health 2023, 20, 2289. [Google Scholar] [CrossRef] [PubMed]

- Song, X.C.; Du, S.; Deng, C.N.; Xie, M.H.; Shen, P.; Zhao, C.; Chen, C.; Liu, X.Y. Life Cycle Carbon Emission Accounting and Emission Reduction Potential Assessment of Steel Industry. Environ. Sci. 2023, 44, 6630–6642. [Google Scholar]

- Böhringer, C.; Schneider, J.; Asane-Otoo, E. Trade in Carbon and Carbon Tariffs. Environ. Resour. Econ. 2021, 78, 669–708. [Google Scholar] [CrossRef]

- Kono, D.Y. Tariffs and Carbon Emissions. Int. Interact. 2017, 43, 895–919. [Google Scholar] [CrossRef]

- Rahmatmand, B.; Tahmasebi, A.; Lomas, H.; Honeyands, T.; Koshy, P.; Hockings, K.; Jayasekara, A. A technical review on coke rate and quality in low-carbon blast furnace ironmaking. Fuel 2023, 336, 127077. [Google Scholar] [CrossRef]

- The National Development and Reform Commission (NDRC). Guidelines for Accounting Methods and Reporting of Greenhouse Gas Emissions from Iron and Steel Production Enterprises (Pilot); Document No. 2526 [2013] of Climate Office; The National Development and Reform Commission (NDRC): Beijing, China, 2013. [Google Scholar]

- Banerjee, S.; Aamir Khan, M.; Iftikhar ul Husnain, M. Searching appropriate system boundary for accounting India’s emission inventory for the responsibility to reduce carbon emissions. J. Environ. Manag. 2021, 295, 112907. [Google Scholar] [CrossRef]

- Chu, Y.; Pan, Y.; Zhan, H.; Cheng, W.; Huang, L.; Wu, Z.; Shao, L. Systems Accounting for Carbon Emissions by Hydropower Plant. Sustainability 2022, 14, 6939. [Google Scholar] [CrossRef]

- Pan, W.; Li, K.; Teng, Y. Rethinking system boundaries of the life cycle carbon emissions of buildings. Renew. Sustain. Energy Rev. 2018, 90, 379–390. [Google Scholar] [CrossRef]

- Jursová, S.; Burchart-Korol, D.; Pustějovská, P.; Korol, J.; Blaut, A. Greenhouse Gas Emission Assessment from Electricity Production in the Czech Republic. Environments 2018, 5, 17. [Google Scholar] [CrossRef]

- Tan, W.; Xi, B. Toward Carbon Emission Reduction in Steel Production by Substituting Pulverized Coal and Coke with Biochar. ACS EST Eng. 2024, 4, 1253–1255. [Google Scholar] [CrossRef]

- Cammarata, M.; Timpanaro, G.; Incardona, S.; La Via, G.; Scuderi, A. The Quantification of Carbon Footprints in the Agri-Food Sector and Future Trends for Carbon Sequestration: A Systematic Literature Review. Sustainability 2023, 15, 15611. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, P.; Yao, M.; Xue, M.; Miao, J.; Liu, B.; Wang, F. Multi-scope electricity-related carbon emissions accounting: A case study of Shanghai. J. Clean. Prod. 2020, 252, 119789. [Google Scholar] [CrossRef]

- Ding, Y.; Yin, J.; Jiang, H.; Xia, R.; Zhang, B.; Luo, X.; Wei, D. A dual-core system dynamics approach for carbon emission spillover effects analysis and cross-regional policy simulation. J. Environ. Manag. 2023, 348, 119374. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Wu, R.; Wang, S. How technological progress affects the carbon emission efficiency? Evidence from national panel quantile regression. J. Clean. Prod. 2021, 307, 127133. [Google Scholar] [CrossRef]

- Xiong, L.; Wang, M.; Mao, J.; Huang, B. A Review of Building Carbon Emission Accounting Methods under Low-Carbon Building Background. Buildings 2024, 14, 777. [Google Scholar] [CrossRef]

- Li, Y.; Yang, X.; Du, E.; Liu, Y.; Zhang, S.; Yang, C.; Zhang, N.; Liu, C. A review on carbon emission accounting approaches for the electricity power industry. Appl. Energy 2024, 359, 122681. [Google Scholar] [CrossRef]

- Zhang, C.; Guo, S.; Tan, L.; Randhir, T.O. A carbon emission costing method based on carbon value flow analysis. J. Clean. Prod. 2020, 252, 119808. [Google Scholar] [CrossRef]

- He, H.; Zhou, S.; Zhang, L.; Zhao, W.; Xiao, X. Dynamic Accounting Model and Method for Carbon Emissions on the Power Grid Side. Energies 2023, 16, 5016. [Google Scholar] [CrossRef]

- Ogle, S.M.; Buendia, L.; Butterbach-Bahl, K.; Breidt, F.J.; Hartman, M.; Yagi, K.; Nayamuth, R.; Spencer, S.; Wirth, T.; Smith, P. Advancing national greenhouse gas inventories for agriculture in developing countries: Improving activity data, emission factors and software technology. Environ. Res. Lett. 2013, 8, 015030. [Google Scholar] [CrossRef]

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Martínez-Blanco, J.; Inaba, A.; Finkbeiner, M. Scoping organizational LCA—Challenges and solutions. Int. J. Life Cycle Assess. 2015, 20, 829–841. [Google Scholar] [CrossRef]

- Ji, L.; Liang, S.; Qu, S.; Zhang, Y.; Xu, M.; Jia, X.; Jia, Y.; Niu, D.; Yuan, J.; Hou, Y. Greenhouse gas emission factors of purchased electricity from interconnected grids. Appl. Energy 2016, 184, 751–758. [Google Scholar] [CrossRef]

- Mansner, R. Leagile Category Management: Utilizing Lean and Agile Methods in Category Management. Master’s Thesis, LUT University, Lappeenranta, Finland, 2019. [Google Scholar]

- Wu, B.; Qiu, W.; Huang, W.; Meng, G.; Huang, J.; Xu, S. A multi-source information fusion approach in tunnel collapse risk analysis based on improved Dempster–Shafer evidence theory. Sci. Rep. 2022, 12, 3626. [Google Scholar] [CrossRef] [PubMed]

- Lacagnina, C.; David, R.; Nikiforova, A.; Kuusniemi, M.-E.; Cappiello, C.; Biehlmaier, O.; Wright, L.; Schubert, C.; Bertino, A.; Thiemann, H. Towards a Data Quality Framework for Eosc Authorship Community; EOSC Association: Brussels, Belgium, 2022. [Google Scholar]

- Song, J.; Gao, Q.; Hu, X.; Lei, J. The impact of digital transformation of infrastructure on carbon emissions: Based on a “local-neighborhood” perspective. PLoS ONE 2024, 19, e0307399. [Google Scholar] [CrossRef]

- Bianchini, S.; Damioli, G.; Ghisetti, C. The environmental effects of the “twin” green and digital transition in European regions. Environ. Resour. Econ. 2022, 84, 41–42. [Google Scholar] [CrossRef]

- Tian, B.; Pan, C.; Xing, Y.; Gu, Y. Analysis of production decision-making evolution of steel enterprises under carbon border adjustment mechanism. Heliyon 2024, 10, e33382. [Google Scholar] [CrossRef]

- Tang, M.; Kumar, P.; Chen, H.; Shrivastava, A. Deep Multimodal Learning for the Diagnosis of Autism Spectrum Disorder. J. Imaging 2020, 6, 47. [Google Scholar] [CrossRef]

- ISO 14064; Greenhouse Gases. International Organization for Standardization: Geneva, Switzerland, 2018.

- Teng, Y.; Li, C.Z.; Shen, G.Q.P.; Yang, Q.; Peng, Z. The impact of life cycle assessment database selection on embodied carbon estimation of buildings. Build. Environ. 2023, 243, 110648. [Google Scholar] [CrossRef]

- Anderson, J.; Rode, D.; Zhai, H.; Fischbeck, P. Future U.S. Energy Policy: Two Paths Diverge in a Wood—Does It Matter Which Is Taken? Environ. Sci. Technol. 2020, 54, 12807–12809. [Google Scholar] [CrossRef]

- Gamarra, A.R.; Lechón, Y.; Banacloche, S.; Corona, B.; de Andrés, J.M. A comparison and methodological proposal for hybrid approaches to quantify environmental impacts: A case study for renewable energies. Sci. Total Environ. 2023, 867, 161502. [Google Scholar] [CrossRef]

- Lakner, Z.; Popp, J.; Oláh, J.; Zéman, Z.; Molnár, V. Possibilities and limits of modelling of long-range economic consequences of air pollution—A case study. Heliyon 2024, 10, e26483. [Google Scholar] [CrossRef]

- Lu, L.; Yang, S.; Li, Q. The interaction of digital economy, artificial intelligence and sports industry development --based on China PVAR analysis of provincial panel data. Heliyon 2024, 10, e25688. [Google Scholar] [CrossRef] [PubMed]

- Day, M.; Pouliot, G.; Hunt, S.; Baker, K.R.; Beardsley, M.; Frost, G.; Mobley, D.; Simon, H.; Henderson, B.B.; Yelverton, T.; et al. Reflecting on progress since the 2005 NARSTO emissions inventory report. J. Air Waste Manag. Assoc. 2019, 69, 1023–1048. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, L.; Zheng, Y.; Tian, F. Cooperation, hotspots and prospects for tourism environmental impact assessments. Heliyon 2023, 9, e17109. [Google Scholar] [CrossRef] [PubMed]

- Lei, Q.; Yu, H.; Lin, Z. Understanding China’s CO2 emission drivers: Insights from random forest analysis and remote sensing data. Heliyon 2024, 10, e29086. [Google Scholar] [CrossRef]

| Intermediate Consumption | Final Demand | Import Inf | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Consumption Export Outflow and Investment | |||||||||||

| T (Tokyo) | T | O | |||||||||

| 1 | … | n | |||||||||

| Intermediate Input | T | 1 | |||||||||

| … | |||||||||||

| n | |||||||||||

| Added Value | |||||||||||

| Gross Input | |||||||||||

| Input | Output | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Intermediate Use | Final Use | Total | |||||||||||||||||

| Province 1 | … | Province m | Province 1 | … | Province m | Exports | Output | ||||||||||||

| Sector | … | Sector n | Sector | … | Sector n | Category | … | Category | Category | … | Category | ||||||||

| 1 | 1 | 1 | k | 1 | k | ||||||||||||||

| Intermediate | Province 1 | Sector 1 | … | … | … | ||||||||||||||

| input | |||||||||||||||||||

| ⋮ | ⋮ | ⋮ | … | ⋮ | ⋮ | ⋮ | ⋮ | … | ⋮ | ⋮ | ⋮ | ⋮ | |||||||

| Sector n | … | … | … | … | |||||||||||||||

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | |||||||||||||||

| Sector 1 | … | … | … | ||||||||||||||||

| Province m | ⋮ | ⋮ | ⋮ | … | ⋮ | ⋮ | … | ⋮ | ⋮ | … | ⋮ | ⋮ | |||||||

| Sector n | … | … | … | ||||||||||||||||

| Imports | … | … | … | … | … | … | |||||||||||||

| Value-added | … | … | … | ||||||||||||||||

| Total input | … | … | … | ||||||||||||||||

| Direct carbon emissions | … | … | … | ||||||||||||||||

| Carbon Emission Accounting System | ||

|---|---|---|

| Method | LCA | IOA |

| Scope of application | Suitable for accounting at the micro-level, such as individual products. In steel production, it is suitable to analyze the carbon footprint of individual products or production links. | Applicable to macro-level computations, such as those conducted at the national or corporate sector scale. In steel production, it is suitable to analyze the carbon emissions of the whole industry. |

| Advantages |

|

|

| Disadvantages |

|

|

| Improvement direction |

|

|

| Calculation error | Due to the subjectivity of boundary setting and truncation error, it may lead to uncertainty in evaluation results. | It has good system integrity at the macro level, but due to the differences in departmental mergers and the annual summary characteristics of data, the accounting results at the micro level are not accurate enough. |

| Data dependency | A large amount of high-precision data is needed to support its detailed life cycle analysis. Data is usually mainly based on physical units, which requires high data quality. | Relying on the input–output table, its data update cycle is long, and it is difficult to quickly reflect the impact of technological changes on the environment. Data is usually dominated by monetary units, which makes it difficult to accurately reflect physical flow. |

| Method | Method Characteristics | Data Needed to Calculate Emissions from Fossil Fuel Combustion | Data Required for Calculation of Industrial Process Emissions |

|---|---|---|---|

| Emission coefficient method | This approach is relatively simple, user-friendly, and imposes low demands on data quality, albeit with a higher degree of uncertainty in the calculated results. |

|

|

| Mass balance method | While more complex and demanding in terms of data and technical expertise, this method yields comparatively more accurate computational outcomes. |

|

|

| Actual measurement method | The method, though labor-intensive and costly, with many data points that are challenging to ascertain, offers a heightened degree of precision in its computational outcomes. |

|

|

| Serial Number | Accounting Method | Release Time | Main Purpose | Scope of Application | Compute Principle | Accounting Type | Accounting Boundary | Let out Divisor |

|---|---|---|---|---|---|---|---|---|

| 1 | IPCC accounting methods 1 | 2006 | Report on national greenhouse gas emissions and removals. | Guidelines for national and regional greenhouse gas inventories. | Input–output | Emission factor method |

| Default value |

| 2 | International iron and steel association | 2016 | Investigate the carbon footprint throughout the steel life cycle and unearth the potential for carbon reduction. | Accounting and reporting of gas emissions of iron and steel enterprises. | Life cycle | Carbon balance method | Carbon emissions from all production processes:

| Default value |

| 3 | International Organization for Standards (ISO) | 2013 | Investigate the carbon footprint throughout the steel life cycle and unearth the potential for carbon reduction. | Accounting and reporting of gas emissions of iron and steel enterprises. | Life cycle | Emission factor method | Carbon emissions from all production processes:

| Default value |

| 4 | Guidelines for the Preparation of Provincial Greenhouse Gas Inventories | 2011 | Preparation of provincial greenhouse gas inventories. | Accounting and reporting of gas emissions of iron and steel enterprises in each province. | Input–output | Emission factor method |

| Default value or measured value |

| 5 | Guidelines for Accounting Methods and Reporting on Greenhouse Gas Emissions of Chinese Steel Production Enterprises | 2013 | Establish the enterprise greenhouse gas emission reporting system, improve the steel industry greenhouse gas emission statistical accounting system, and other related work references. | Accounting and reporting of greenhouse gas emissions of Chinese steel production enterprises. | Input–output | Emission factor method |

| Default value or measured value |

| 6 | Requirements of the greenhouse gas emission accounting and reporting—Part 5: Iron and steel production enterprise | 2015 | It can be used as a reference for the development of carbon emission trading, the establishment of an enterprise greenhouse gas emission reporting system, and the improvement of the greenhouse gas emission statistical accounting system in the steel industry. | Accounting and reporting greenhouse gas emissions of Chinese steel production enterprises. | Input–output | Emission factor method |

| Default value or measured value |

| 7 | Tianjin accounting method | 2013 | For the use of carbon emission trading and carbon verification in the steel industry in Tianjin City. | Accounting and reporting of carbon emissions of steel production enterprises in Tianjin. | Input–output | Emission factor method |

| Default value or measured value |

| 8 | Shanghai accounting method | 2012 | For the use of carbon emission trading and carbon verification in the steel industry in Shanghai. | Carbon dioxide emission accounting and reporting for major emitters in the Steel Industry in Shanghai. | Input–output | Emission factor method (in which some process emissions use the balance method) |

| Default value or measured value |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, L.; Cheng, S.; Tong, Y.; Zhang, Y.; Zhu, F.; Tian, Y.; Yue, T. Study on Carbon Emission Accounting Method System and Its Application in the Iron and Steel Industry. Sustainability 2025, 17, 3829. https://doi.org/10.3390/su17093829

Ren L, Cheng S, Tong Y, Zhang Y, Zhu F, Tian Y, Yue T. Study on Carbon Emission Accounting Method System and Its Application in the Iron and Steel Industry. Sustainability. 2025; 17(9):3829. https://doi.org/10.3390/su17093829

Chicago/Turabian StyleRen, Le, Sihong Cheng, Yali Tong, Yifeng Zhang, Fan Zhu, Yi Tian, and Tao Yue. 2025. "Study on Carbon Emission Accounting Method System and Its Application in the Iron and Steel Industry" Sustainability 17, no. 9: 3829. https://doi.org/10.3390/su17093829

APA StyleRen, L., Cheng, S., Tong, Y., Zhang, Y., Zhu, F., Tian, Y., & Yue, T. (2025). Study on Carbon Emission Accounting Method System and Its Application in the Iron and Steel Industry. Sustainability, 17(9), 3829. https://doi.org/10.3390/su17093829