Abstract

China produces and consumes most of coal in the world. This situation is expected to continue within a certain period in the future. Currently, Chinese coal industry is confronted with several serious problems relating to land resource, water resource, environmental, and ecological sustainability. Coal resource exploitation causes the permanent fracture and movement of strata structure, which have caused the fracture and collapse of overlying strata and further led to the subsidence of ground surface as well as the seepage of water in aquifers around the coal seam, which has resulted not only in the loss of land and water resources, but also in serious threats and accidents to underground mining. On the other hand, mining and mineral-processing wastes are one of the world’s long plagued concerns among solid wastes. Coal gangue, as the major waste with a huge amount of discharge, has not only occupied the land, but has also contaminated the ambient land resources and hydrological environment, and further led to ecological system destruction and degradation. What is more, in China there are large amounts of coal—located under railways, buildings, and water bodies—which are unavailable with traditional mining methods. These problems are obviously threaten the concept of green sustainable development. This paper introduces a novel developed solid dense stowing mining method, which is able to significantly reduce or event eliminate the corresponding damages caused by underground mining behavior and realize green and sustainable development. The novelty of this research work is realizing the automation and synchronization of mining and material stowing with an appropriate compaction ratio for adequate support of goaf roof. It can improve the stability of rock strata and the safety and efficiency of underground mining. We also studied and designed a perfect stowing material by using coal gangue and fly ash with appropriate proportions under different particle size gradations. By implementation of the above-mentioned methods in China, the solid dense stowing rate of mined seam areas have reached more than 95% and the overburden strata movements have been reduced to extremely low level which had nearly no damages to above buildings. The solid dense stowing mining method has also realized the reuse and recycling of coal mine solid wastes. Meanwhile, considerable previously unavailable coal resources under buildings, railways, and water bodies have been made available for exploration, which could extend the life of coal mines and increase the sustainability for coal industry and the environment. Ultimately, this method is a reliable way to realize green and sustainable mining. The strata structure protection, the surface subsidence prevention, and coal mine solid waste disposal have been realized at the same time.

1. Introduction

Coal occupies the absolute majority of primary energy supply in China. It takes about 71.7% and 67% of domestic primary energy production and consumption. About 75% of industrial fuels, 85% of chemical raw materials, and 90% of civil fuels depend on coal production. For a long period in future, coal resource is still expected to supply most of China’s energy consumption. Currently, Chinese coal industry occupies more than one-third of global coal production with annual production up to about 3.5–4 billion tons, in which at least 2.5 billion tons coming from underground mining. However, together with the high-intensity exploitation of coal resource, a series of problems concerning environment, ecological, and geological destructions and damage have inevitably occurred [1,2,3,4,5,6].

In addition to the common concerns of air pollution and greenhouse gas emission which are caused by coal combustion, the underground coal mining process causes more serious and permanent destruction, including land resource subsidence and occupation, water resource loss and pollution, air pollution, as well as ecological damage and degradation [1,2,4,7,8,9,10,11].

In China, about 95% of coal production is fulfilled by underground mining with long-wall working faces and corresponding goaf roof collapse management. This kind of mining method has led to structural destruction of overlying strata and further caused surface subsidence. Meanwhile, coal mining and power production have generated huge amounts of solid waste, like gangue and fly ash, which are discharged in dumps on land surface, which have occupied a large area of land resources. Now in China there are more than 4.3 × 105 hm2 mining subsidence area, in which farmland, buildings, and infrastructure are seriously damaged. The annual increase of mining subsidence area is about 5 × 104 hm2, related to coal resource exploitation is about 0.2 hm2 subsidence per 104 t coal yield. Gangue dumps in total piled about 4.5 billion tons of coal mine solid waste in China, with an annual increasing around 0.95 billion tons. At present, there are about 1500 coal mine dumps located in China, which have occupied 8 × 104 hm2 of land [1,3,5,12]. Gangue dumps still contain a certain amount of coal, which could spontaneously combust when oxygen reacts with the pyrite inside the piled gangue. Annually, there are about 140 coal mine dump fires that release huge amounts of hazardous pollutants and greenhouse gases into the atmosphere. Underground coal mining causes strata movement and damage, which has further led to releasing of coal bed gas and strata water. Water and gas are the main origin of coal mine accident; meanwhile, loss of underground water could cause destruction of surface vegetation and ecological environment, especially in west arid and semi-arid area of China. According to statistic data, in China the average coal mine water drainage is about 2 t per ton of coal production, and this value in north China has reached about 10 t, the maximum could be up to 47 t. North China is lack of natural water resource, coal mine drainage has occupied about 19% of karst water in north China, but only 30% of the coal mine drainage has been utilized [5,13,14]. Due to high intensity of coal resource exploitation as well as the irregular distribution of coal resource in China, lots of domestic coal mine enterprises are facing a serious problem of coal resource depletion, especially the coal mines on east part of China, most coal resources are located under cover occupied by buildings, railways, and water bodies, which are unavailable for exploitation. For example, the coal mine base Xuzhou, after continuous mining of 130 years, there are still more than 80% of coal resources remain being cover occupied under urban area. However, most of the coal mines around Xuzhou city have become resource depletion [15,16,17,18].

Coal mine gangue is a collective name, gangue is mixture of waste rocks which are generated during the construction of coal mines, coal excavation and coal processing. Actually the use of gangue as a foundation cushion for dams and buildings or as backfill and stabilization material in underground coal mining for controlling the strata movement can be an effective way to the reuse and recycle coal mine solid waste. A lot of studies and applications of gangue have been conducted in many countries such as China, Germany, etc. However, waste backfilling is no longer utilized in Germany, since several specific conditions of German hard coal mines—such as the technology, infra-structure, and costs—have made the stowing process no longer economically viable.

For efficient use of geological coal resources, as well as coordination development between coal mining and environment protection, land resource conservation, sustainable development of coal mine areas, and realization of “green mining”, a novel method of working-face goaf area roof management is needed [1,2,3,4,5,16,17,18,19,20]. Existing roof management methods are caving, simple backfilling, pillar supporting, slow caving, etc. Among them, caving and slow caving methods could not control the goaf roof; pillar supporting method results in massive wasting of coal resource; and traditional simple backfilling methods could only control the subsidence with satisfactory effects, but it has low efficiency and high costs, since the operation is non-mechanized [19,20,21,22,23,24,25,26]. Thus, for development of a fully mechanized, goaf roof well-controlled stowing technologies and stowing material are necessary, which could have significant positive influence on the sustainable development of Chinese coal industry.

Mining with goaf simple backfilling has been utilized in a few countries with small scale since several decades. Usually they were implemented in metal mines. Research and application of backfilling technologies in metallic and non-metallic mines has made considerable progress, including dry material backfilling, water-sand backfilling, pneumatic backfilling, paste cemented backfilling, full tailings backfilling, etc. [2,6,8,9]. Actually, these methods were developed based on the conditions of metal mines, which are inappropriate for coal mining working faces, since in metal-deposit mines, ore seams are mined with room and pillar methods. After mining, the rooms provided sufficient space and accesses for huge equipment. Meanwhile, strata control requirements in metallic mines are not so rigorous like in coal mines, since coal resources distribute in sedimentary strata, and are excavated normally via longwall collapsing method, which hardly provides adequate space and access for backfilling equipment as with metal-deposit mines [24,27,28,29,30].

Since the 1960s water-sand backfilling technology has been implemented in European countries for coal mining under buildings [2]. In the 1970s, Fushun and Xinwen coal mines in China also used this method in pilot mining processes under buildings, and found that with sand-water backfilling, the surface subsidence coefficient could be controlled within a certain range of 0.12–0.16; with high quality sand (soil content in sand lower than 20%; compaction rate 5%–6%), surface subsidence rate could be limited to be only 0.06. Sand-water backfilling could achieve high quality of subsidence control. However, this method could not be commonly utilized, since there were not enough sand resources for backfilling at a large scale and the cost was too high [5,30,31,32].

In Germany, two backfilling methods have been primary utilized over the last 30 years, they are pneumatic backfilling and hydraulic backfilling. The operational experience in coal mine Friedrich-Heinrich in Germany had shown that the backfilling rate could only achieve 0.7. Meanwhile the implementation of facilities, operation, and maintenance of material transport infrastructure had become a big challenge because of the limitations of operating space in goaf, thus these methods are no longer utilized in German underground coal mines [2,8,24,29].

Coal mine gangue has also be utilized as common backfilling material. Relevant pilot applications were implemented in 1970s, in Chinese coal mine areas like Huainan, Beijing, Beipiao, and Zhonglianshan. Commonly used backfilling methods at that time included gangue self-slide backfilling, paste material backfilling, gangue pneumatic backfilling, and manpower gangue backfilling. Among which the gangue self-slide backfilling could only be used for steep-inclined coal seam; pneumatic backfilling and paste backfilling needed high quality and fine processing of gangue materials and the facilities were too complex to be installed and equipped in goaf with relative narrow space; the results of simple mechanized gangue backfilling methods at that time indicated that, with raw gangue from roadway and coal processing, the surface subsidence cofficient could only be controlled in a range of 0.4–0.5. Hence, the traditional methods were theoretically or practically inappropriate to achieve satisfactory effect of strata movement control. Due to the lack of the corresponding strata control theory as well as the limitation of mechanical equipment, traditional gangue backfilling methods had also great limitations on efficiency of coal production, which also led to high occupation of manpower. The above-mentioned problems limited the utilization of traditional backfilling methods to a large extent.

Since the 1980s, gangue cementation backfilling method has been developed and utilized, which could build self-sustaining backfilling medium body and provide excellent support strength. However, this method consumes a huge amount of cement, up to 240 kg per backfilling m3, which has greatly limited its utilization. The underground transportation of cementation material through extremely long distances was also difficult. In the 1990s, paste backfilling and full gangue cementation methods were developed. In paste backfilling material, the concentration of aggregate material (gangue, sand) can be 50%, and the cementing agent (cement or speed coagulation material) concentration is about 20% [2,8,9,10,11]. Recently, paste cement backfilling technology has been developed with pilot facility applied in Chinese coal mines, which has achieved control of goaf roof caving and surface subsidence [2,5,30,31,32,33]. Cementing material could build backfilling medium body rapidly after working face advance within 12–24 h and prevent the strata above the goaf space from movement and fracture. However, the problems which were caused by material long distance transport and equipment complexity were still unresolved. The cementation backfilling process was especially difficult to implement simultaneously with working face advancement, since the working face facilities needed to be held to wait for the solidification of cementation material, which had significantly reduced the working efficiency of coal production. Meanwhile, relevant research has also shown that the cemented backfilling body contained coal, clay minerals, mudstone, and pyrite. These materials could interact with moisture, oxygen, and water in coal mines, further causing volume expansion and potentially leading to disintegration of the backfilling medium body. Hence relevant attempts and studies had pointed out that non-cemented gangue aggregates, together with fine filler materials, could have adequate mechanical strength and stiffness for a more appropriate solution of coal mine goaf stowing material.

Generally, effective and successful mining goaf stowing requires effective material transportation into goaf and immediate compaction behind the advance of the coal excavation working face. For implementation of goaf solid material dense backfilling, three critical technical developments are necessary, they are: (1) continuous stowing material supply into goaf; (2) specific roof support technology for insuring the stability of goaf roof strata while also keeping enough working space in goaf for stowing operations; (3) a power supply for compaction of stowing material in goaf to achieve sufficient support strength.

Our research team has combined both coal mine mechanized mining and fully automated dense stowing technologies and developed a fully mechanized dense stowing mining technology that has made great progress in offering surface subsidence minimization, mining waste disposal and recycling, as well as high efficiency of coal production.

2. Materials and Methods

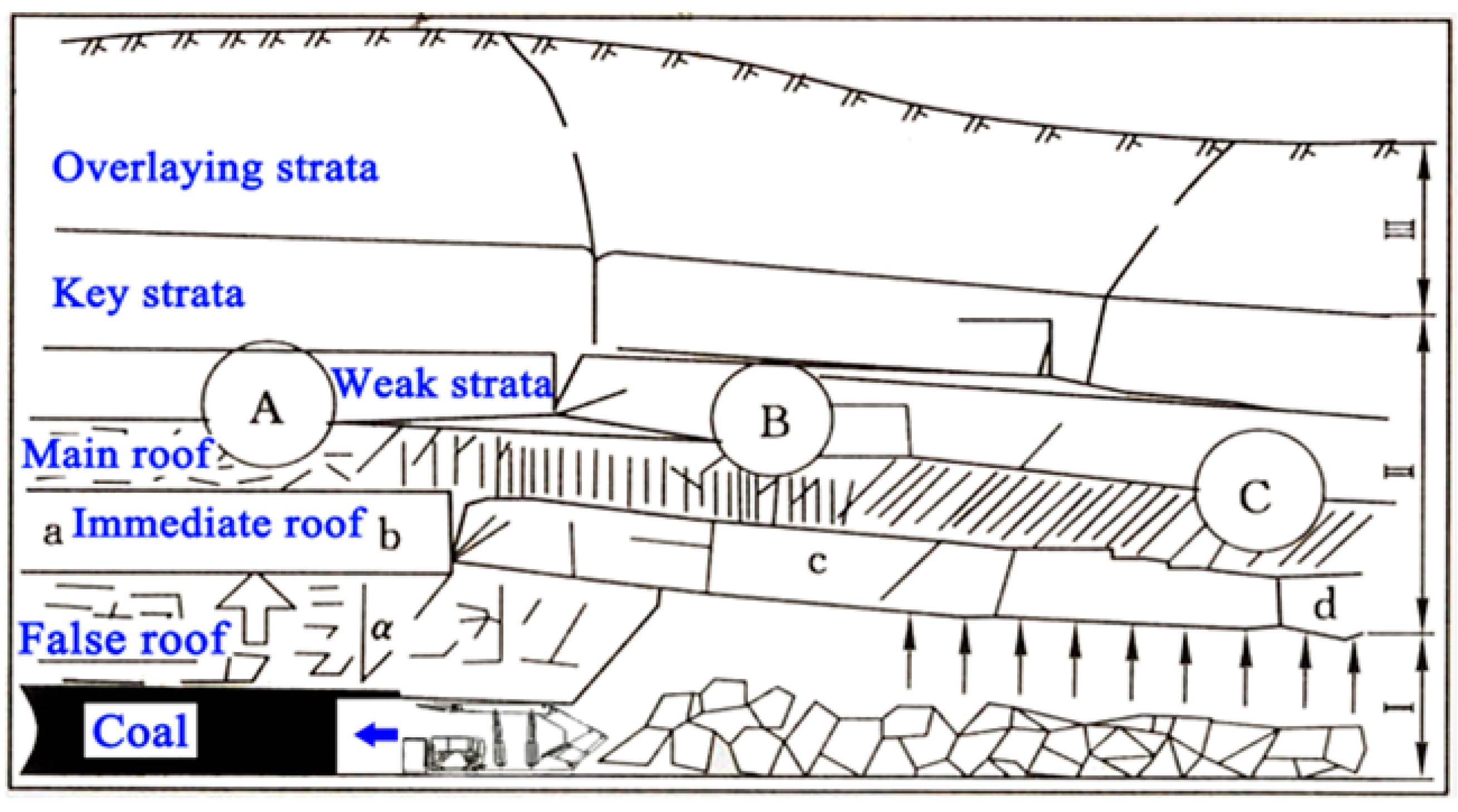

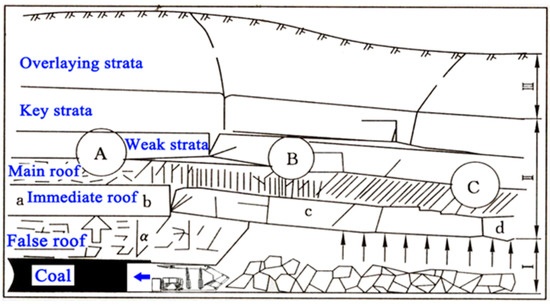

An underground coal mine longwall working face is generally between 200 and 400 m long and the full thickness of the coal seams are excavated by a coal mining machine like a shearer or plow. After the coal seam has been excavated, the roof rock behind the hydraulic supporters becomes unsupported and loose via the following processes [27,28,29,30]: (1) strata pressure load concentrates on the goaf roof and floor due to the absence of coal seam; (2) loosening of the immediate roof and floor strata as the goaf area converges; (3) cracking occurs, especially in the immediate roof strata; (4) stress relief in the main roof strata occurs above the face area; (5) release of gas quantities from neighboring seams and porous enclosing rock happens during stress relief in the seam, floor, and roof areas; (6) collapsing of the roof strata happens, further transmitting to the upper strata; (7) strata stresses increase around the edge of the working face. Based on extended observation, the overburden failure above a longwall collapsing working face can be divided into three areas according to the strata slippage and damage. They are the collapsing area, fracture area, and bending subsidence area, which are shown in Figure 1.

Figure 1.

(A) Coal seam support area (a~b); (B) Overburden separation area (b~c); (C) Re-densing area (c~d); (I) Collapsing area, (II) Fracture area; (III) Bending subsidence area; (α) Support effect angle.

As shown in Figure 1, overburden characters of the area (I), (II), and (III) are:

- (I)

- In the collapsing area, roof strata collapse and pile up occur irregularly, the loosening coefficient is relatively large and could reach 1.1~1.3. However, after re-densing process (in area C), the bulk coefficient could be reduced to about 1.03.

- (II)

- In the fracture area, after damaging the strata, the broken rocks still remain in regular arrangement. Hence the bulk coefficient is much smaller than collapsing area, since only fractures are built through the strata.

- (III)

- The bending subsidence area covers from the top of fracture area to the ground surface. In this area the strata move continuously and monolithically. In the vertical section, from upper to the bottom of this area, the subsidence differences are very small. Fracture development is rare.

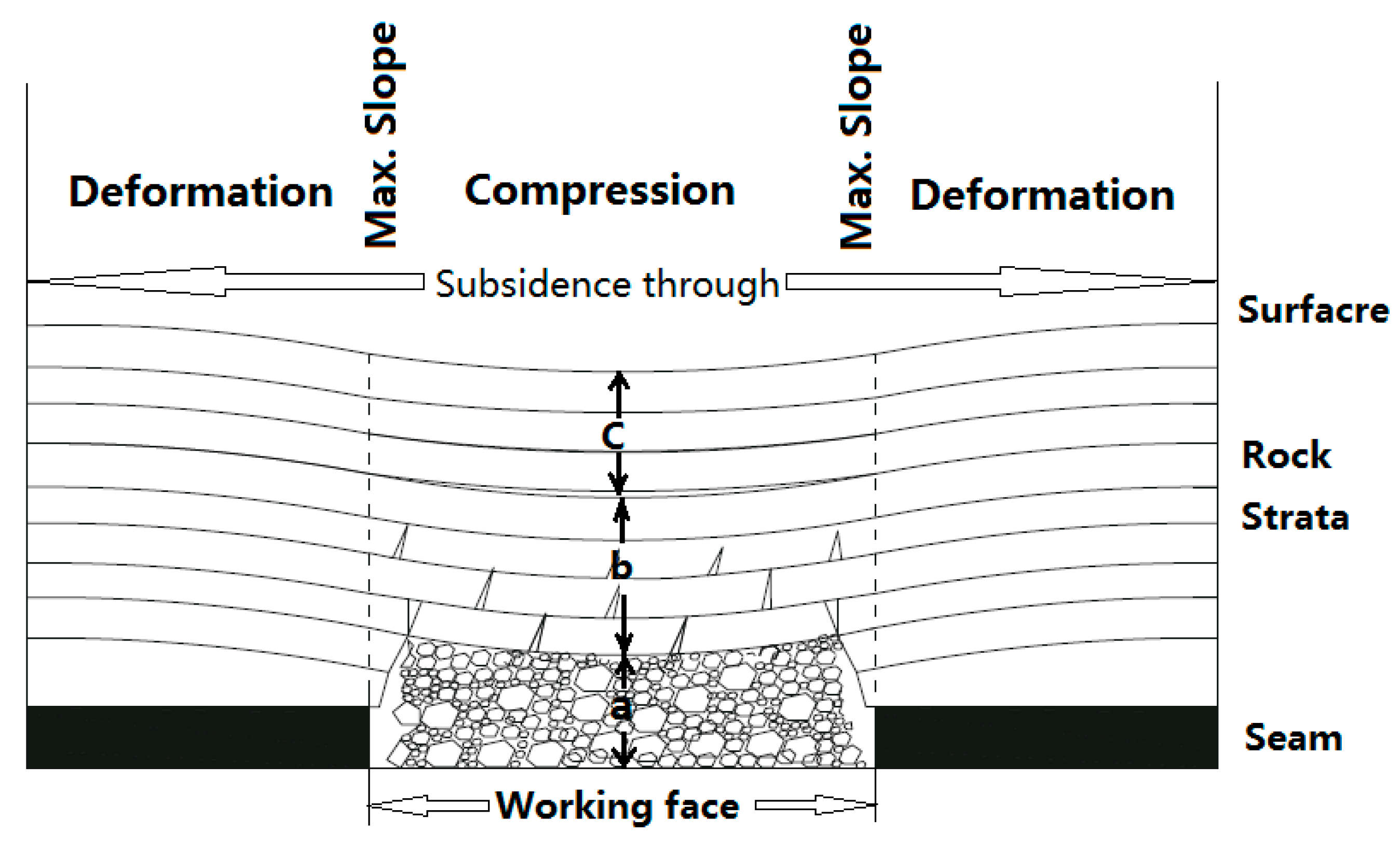

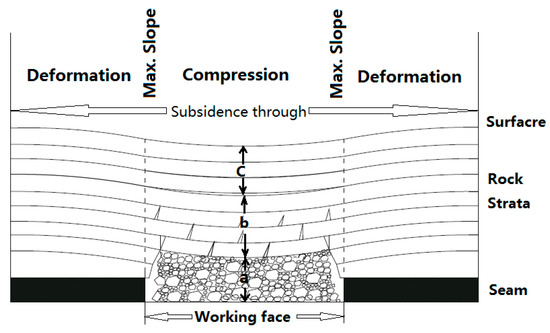

Finally, the strata movement leads to subsidence of ground surface, which is shown in Figure 2 as follows.

Figure 2.

Principle of coal mine subsidence, (a) Collapsing area; (b) Fracture area; (c) Bending subsidence area; (γ) Fracture angle.

Areas (I) and (II) are ‘water-transmit areas’, which means if the overburdened aquifers are located within the ‘water-transmit’ area, then the strata water could flow through the fractures into the goaf and coal mining area.

The strata movement and fracture theory illustrate that, in order to minimize the mining subsidence on the ground surface, as well as to avoid mining water hazards, immediate and effective stowing of goaf space before the occurrence of fracture and strata movement is the best method.

2.1. Fully Mechanized Solid Dense Stowing Method and System

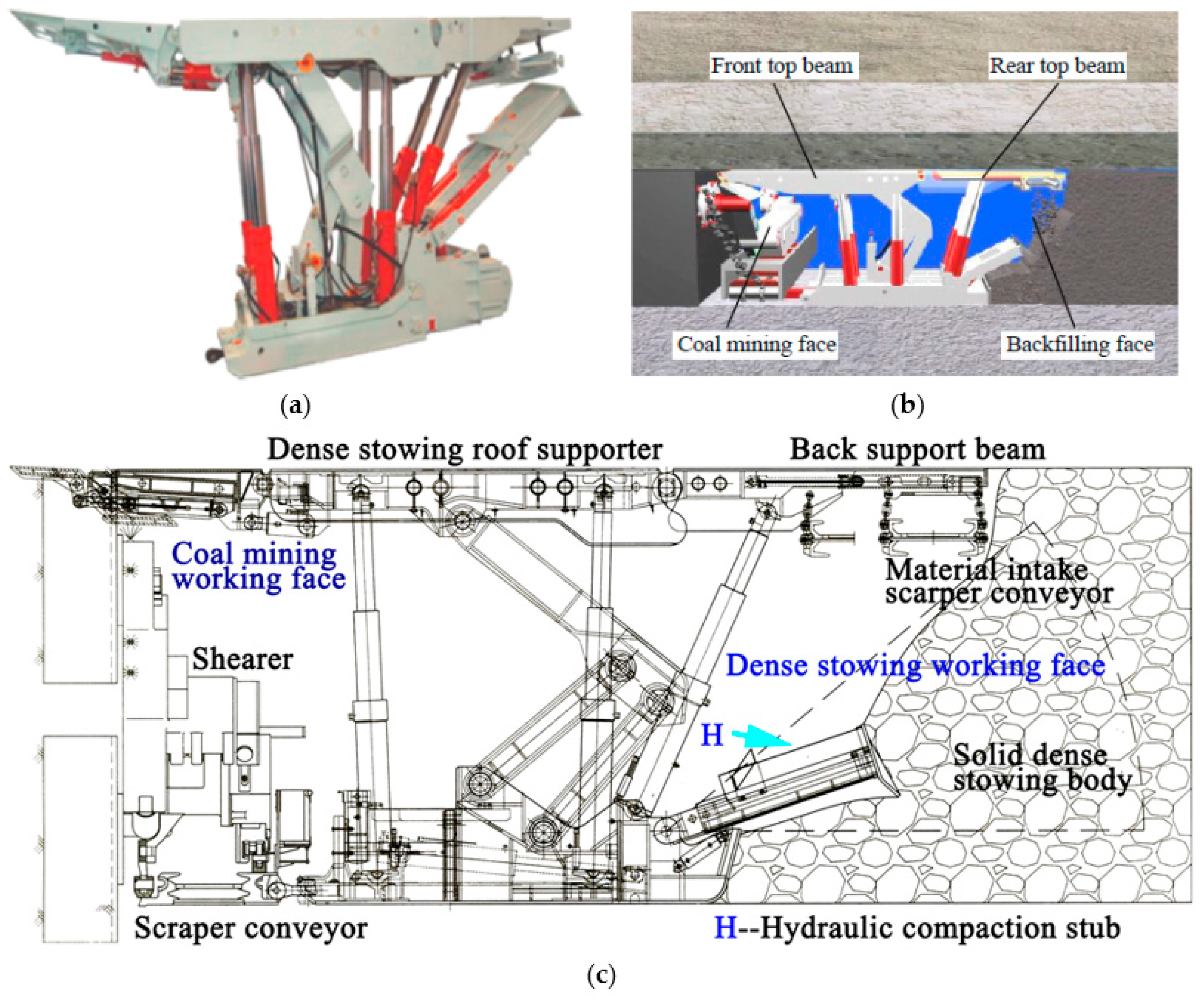

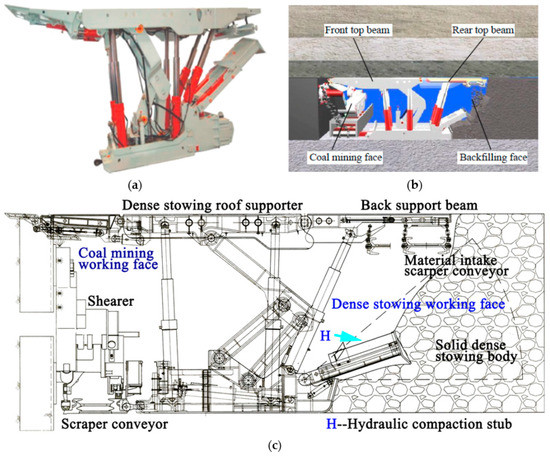

A fully mechanized dense stowing system has different designs and layouts with long-wall coal mine mining systems. The key equipment is the parallel mining/backfilling hydraulic roof supporter, which can realize the parallel manipulations of coal seam excavation and goaf space stowing at the same time. The parallel mining/backfilling hydraulic supporter and its structures are shown in Figure 3a–c.

Figure 3.

Combined solid dense stowing roof supporter, (a) practical equipment; (b) working scheme; (c) mechanical structure of the fully mechanized solid dense stowing roof supporter.

Our team has established a working face rock pressure model, provided the force interaction criterion of roof strata movement and the supporter, and then revealed the mechanism by which the supporter reinforces the roof actively rather than passive applying of the pressure in traditional coal mining. The newly designed parallel mining/backfilling roof supporter has an integrated coal mining supporter and goaf stowing hydraulic supporters, which realize the roof protection during parallel operations of fully mechanized coal mining and solid waste dense stowing. The supporter can ensure safe and effective coal mining and dense stowing at the same time.

As shown in Figure 3, the top beam of stowing/mining hydraulic supporter is divided into two parts: the front top beam and the back top beam. The two beams support protection for both coal excavation and goaf stowing operations at the same time, respectively. Two prop cylinders are connected to the back top beam, which give the back top beam more roof supporting force, so that the stowing material can be directly backfilled into the goaf through the space under back top beam. The hydraulic compaction stub—which is attached on the back of the support—can tamp the solid stowing material effectively (with a tamping pressure up to 2 MPa), according to the requirement of objective ground movement control. This stowing/mining hydraulic supporter is an original and innovative design.

With the newly designed dense stowing hydraulic supporter, the solid dense stowing working face is designed to locate behind the mining working face and towards the goaf space. The stowing material intake conveyor is designed to be arranged in the working face ventilation roadway. Dense materials are designed to be carried into the goaf by using stowing scraper conveyor which hangs from the back top beam of the supporter. The stowing material flow is designed to be passed along the goaf space and deposited in to the goaf through dumping pits on the bottom of the scraper conveyor. Then the goaf is compacted by the hydraulic compaction stub which is installed on the rear bottom of the dense stowing hydraulic supporter.

Figure 3b,c shows that the solid dense stowing roof supporter system could realize the coal seam excavation and goaf stowing operation at the same time. At the front of the roof supporter, the coal seam shearer works as a common long-wall working face for coal production. Meanwhile, at the back of the roof supporter system, the goaf spaces after the excavation of coal seam can be stowed immediately before serious fracture development occurs in the roof and overburdens the strata. This effect has been realized through three main technological innovations: reliable manipulation equipment and enough operational space; adequate stowing/compaction power, which is realized through hydraulic tamping; as well as the stowing material supply and transportation with high efficiency.

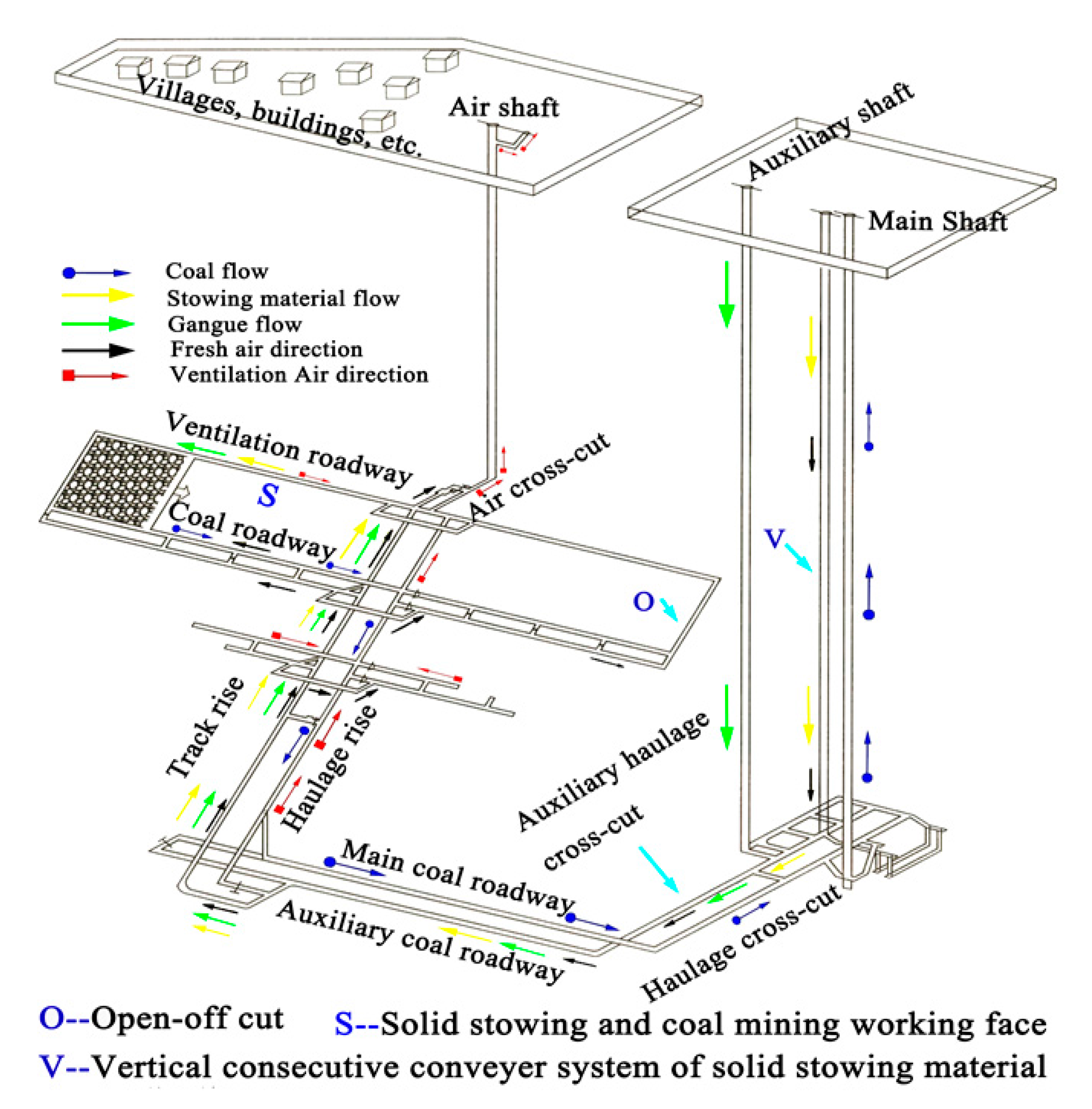

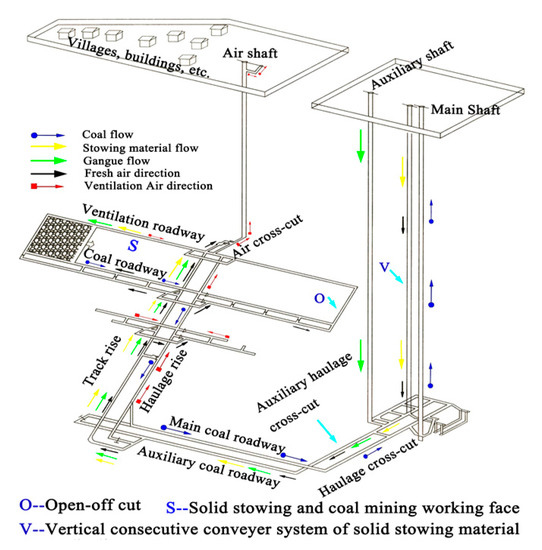

The fully mechanized solid dense stowing mining system consume large amount of stowing material with shot periods. Stowing materials were transported from surface waste dumps to the mine via a continuous vertical solid backfill material transportation system and, consequently, to the working faces. This process is illustrated in Figure 4.

Figure 4.

Stowing material flow system layout of fully mechanized solid dense stowing.

Then the materials were transported to the stowing/mining face by belt conveyor, and finally backfilled and tamped to the goaf with the scraper backfilling conveyor which is integrated on the dense stowing hydraulic supporter. The entire system layout is also shown in Figure 4. The stowing material transportation route is: surface–main shaft and vertical material conveying system–haulage main station–haulage cross-cut–auxiliary coal uplift roadway–haulage rise–ventilation roadway–stowing working face. Additional gangue material could also be transported through auxiliary shaft. The coal uplift transportation route is: coal mining working face–working face coal roadway–mining area haulage station–main coal roadway–main coal bunker–main shaft–surface. Transportation of both the downdraft (stowing material) and updraft (coal production) has no conflict and can be operated with high efficiency.

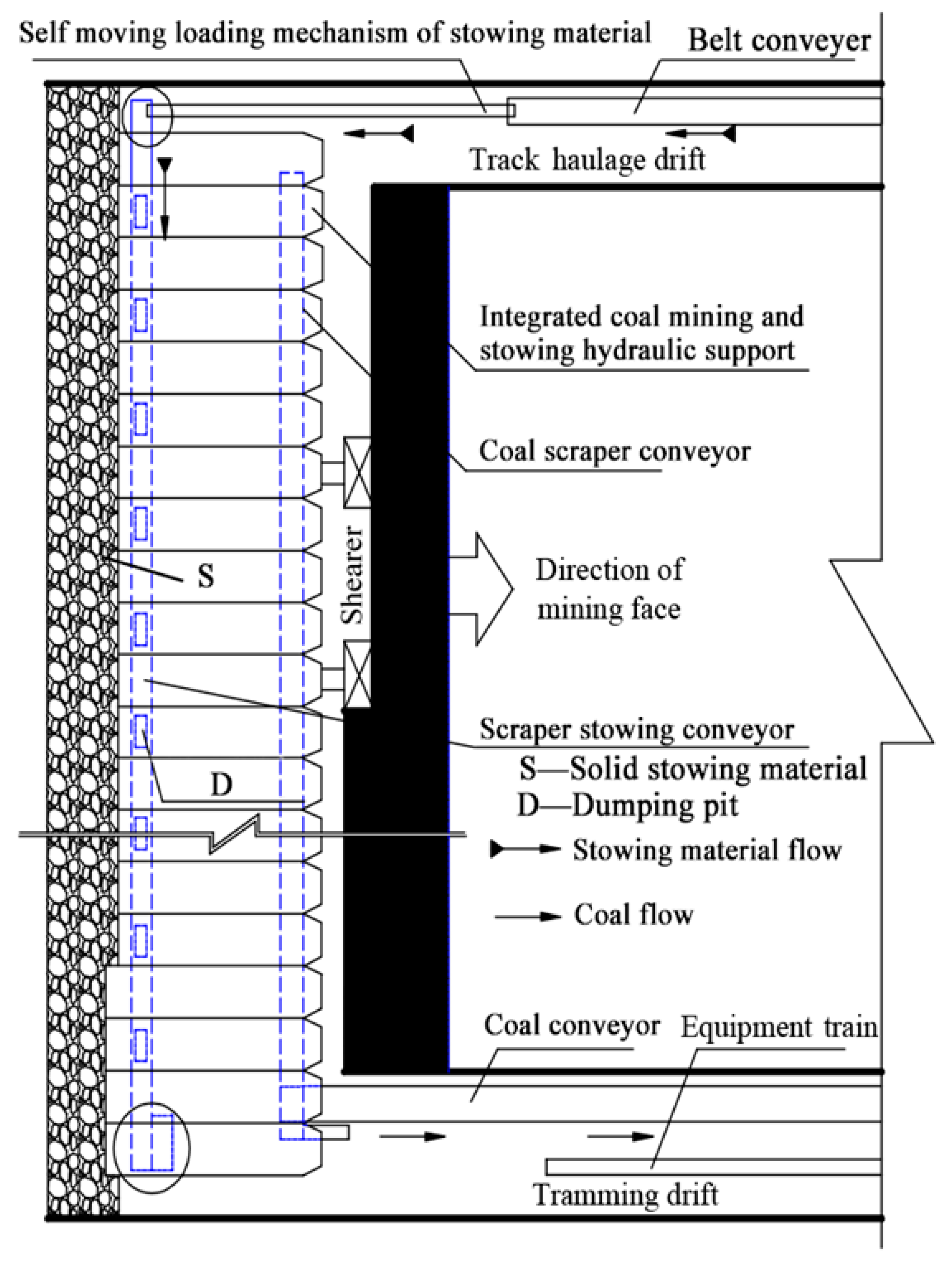

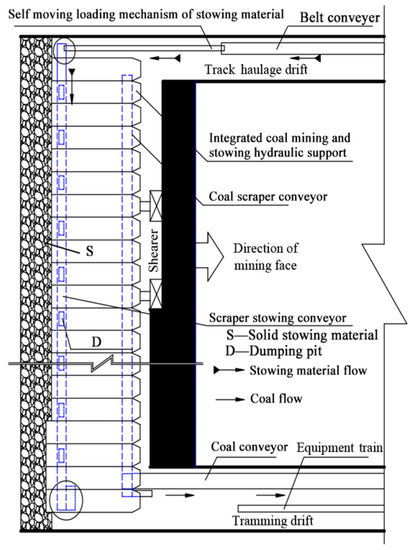

The layout of the goaf stowing working face is shown in Figure 5.

Figure 5.

Layout of fully mechanized solid dense stowing working face.

The schema of the mining/stowing working face is generally similar to a traditional fully mechanized coal mining face, the smart innovations are: the stowing face is combined to the back of the coal excavation working face, i.e., the goaf side of working face, and a belt conveyor was set in the track haulage drift to transport the solid stowing materials to the scraper backfilling conveyor which hangs on the back top beam of stowing/mining supporter. The produced coals are transported out through another track haulage crossheading without conflict with the stowing material inlet. The stowing materials are dumped into the goaf with dumping pit on the backfilling conveyor.

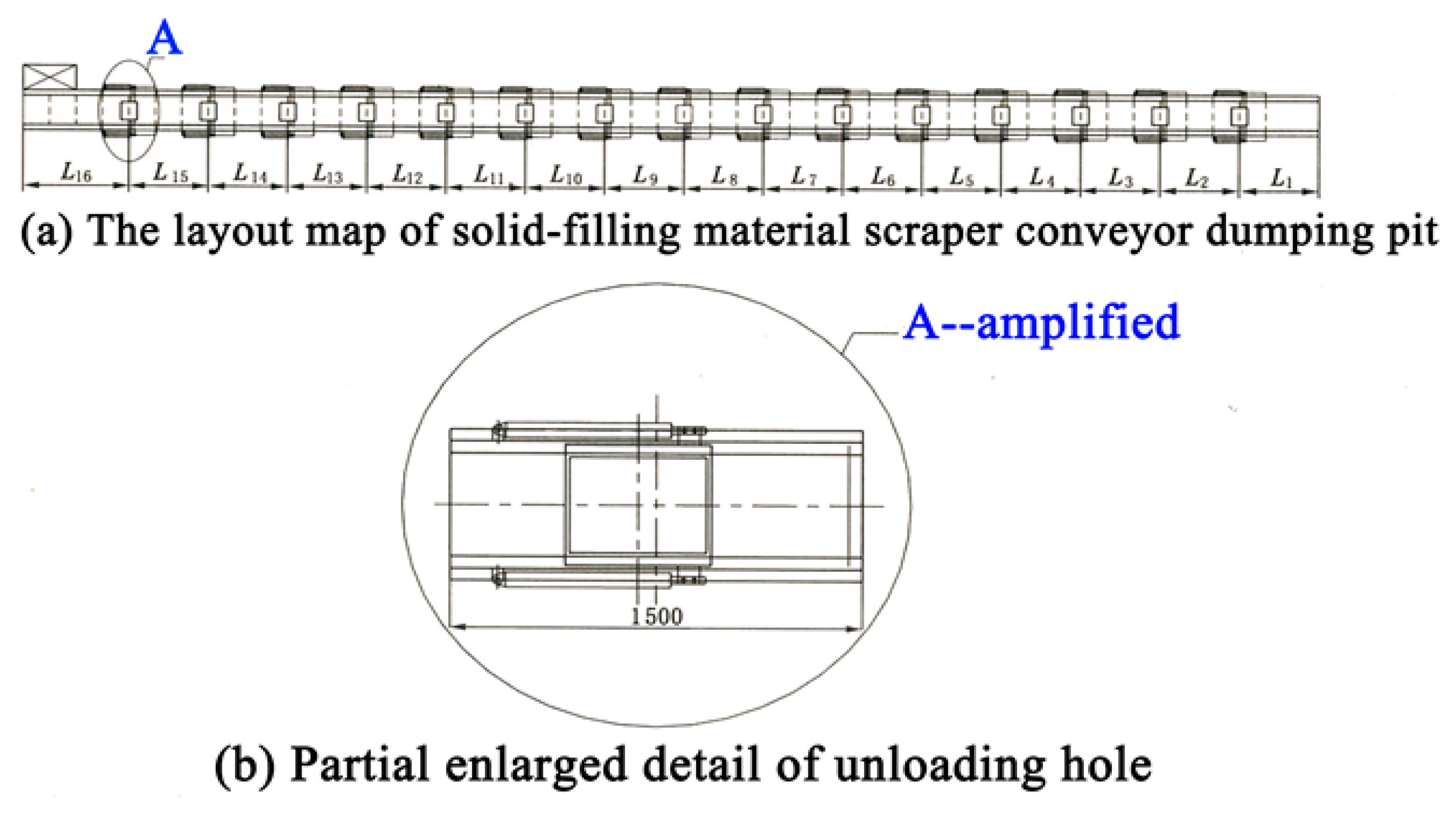

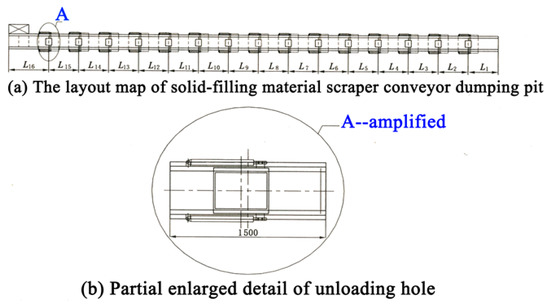

Figure 3c has shown that the scraper backfilling conveyor was hanged on the rear beam of the mining/stowing roof supporter, and the stowing materials fall into the goaf space through dumping pits on the scraper conveyor, which are shown in Figure 6.

Figure 6.

Design of dumping pits on the scraper conveyor (a) and its detail (b).

All of the dumping pits are controlled by hydraulic cylinders to be opened or shut. By controlling the order of stowing material unloading, the stowing materials could be dumped evenly in the goaf space with high efficiency.

2.2. Design of Solid Dense Stowing Material Mechanical Properties

Main stowing materials used for fully mechanized solid dense stowing mining method are coal mine gangue which came from coal mine roadway tunneling and coal processing as well as fly ash from coal combustion power plant. Gangue and fly ash are the most common solid waste of coal mine industries. In addition to gangue and fly ash, sometimes construction wastes and sand materials were also added in stowing material with fractions lower than 5%.

Coal mine gangue is a name of waste rocks which are generated during coal production. Gangues are generated during the roadway tunneling, roof strata in working face during excavation as well as coal washing and processing. Actually gangues have been used for dam and building foundation cushion. Many studies on mechanical properties of gangue has been made, such as compact fracture mechanism, particle size gradation, static, dynamic stress deformation etc. According to the relevant research results of our team, it had been found that the compaction degree was the most important property which directly influenced stowing effect, and further directly determined the surface subsidence degree. The buildings had also certain abilities to resist deformation. During the coal seam excavation/stowing process we need to control the surface deformation within permitted ranges of buildings.

Gangue is a kind of loose medium, the particle size gradation was the key factor of medium stress deformation behavior. Natural gangue materials consist of cracked rocks which have a greater proportion of large particle size and low proportion of small and fine particle size fractions. This kind of gradation is difficult to support overlying strata of mining goaf, since the large particle proportion leads to high porosity of dense stowing medium. Generally, the density of dense stowing medium decreased with increase of medium porosity; and with the increase of medium porosity, the stress plastic deformation of the dense stowing medium increased, finally leading to a high compaction rate of stowing medium, i.e., relative higher subsidence of surface. Hence pure gangue material was not appropriately utilized for solid dense stowing, its properties—such as porosity, gradation, and compaction rate—were required to be modified by adding more fine materials.

The compaction rate k is defined as

where Vys is the material volume after compaction, Vx is the material loose volume, and k is the compaction rate of stowing material.

Fly ash has been confirmed as a suitable material to mixed with gangue material, as it fills the spaces between gangue particles and optimizes the mechanical properties of solid dense stowing material [18,20,21,22]. Firstly, fly ash is easy to obtain, since around coal mines there are usually coal combustion power plants which generate fly ash regularly in large amounts. The particle sizes of fly ash range 0.5–300 μm, which are able to fill the spaces between gangue particles and increase the mechanical properties of dense medium to achieve stability after stress loaded. Fly ash also contains active ingredients like active Al2O3, f-CaO, and CaSO4, which could react with goaf humidity or coal mine seepage water and generate cementation effect inside the stowing medium, which increases its mechanical strength integrally to a certain extent.

Goaf stowing rate is the most important parameter of stowing effect, which represents the rate of the goaf space occupation by raw stowing material.

Stowing compaction rate determined the movement of overlying strata. Our team has also researched the compaction rates of stowing material with different gradation of gangue material as well as different fly ash proportions. All of the tests were implemented on MTS815.02 electro-hydraulic servo rock mechanics test instrument, which could simulate the roof strata pressure loaded on the dense stowing medium. The material container was a cylindrical steel tube with an inner diameter of 128 mm and depth of 165 mm. The gradation of gangue material was divided into six fractions, they are G1 to G6:

- G1: d ≤ 5 mm

- G2: 5 mm < d ≤ 10 mm

- G3: 10 mm < d ≤ 15 mm

- G4: 15 mm < d ≤ 20 mm

- G5: 20 mm < d ≤ 25 mm

- G6: d > 25 mm

The MTS815.02 electro-hydraulic servo rock mechanics test instrument is shown in Figure 7.

Figure 7.

MTS815.02 electro-hydraulic servo rock mechanics test instrument.

Four different fly ash mass proportion was also tested together with different gangue material gradations, they are:

- Gangue mass: Fly ash mass = 1:0.2

- Gangue mass: Fly ash mass = 1:0.4

- Gangue mass: Fly ash mass = 1:0.6

- Gangue mass: Fly ash mass = 1:0.8

All the tests and experiments were executed with the MTS815.02 electro-hydraulic servo rock mechanics test instrument.

By implementation of above-mentioned tests we found the appropriate material proportion and gradation for our dense stowing material. According to the experimental results, we also put the solid dense stowing material into actual application in several coal mines in eastern China. The performance of the actual implementations have shown a very positive effect on strata control and reduction of mining subsidence on surface.

Here we introduce the results of stowing material proportion/gradation of Xintai coal mine as an example. Gangue and fly ash materials are acquired directly from coal mines and power plants around the coal mine area, the solid dense stowing material was tested, gradated, and proportioned according to local mining wastes.

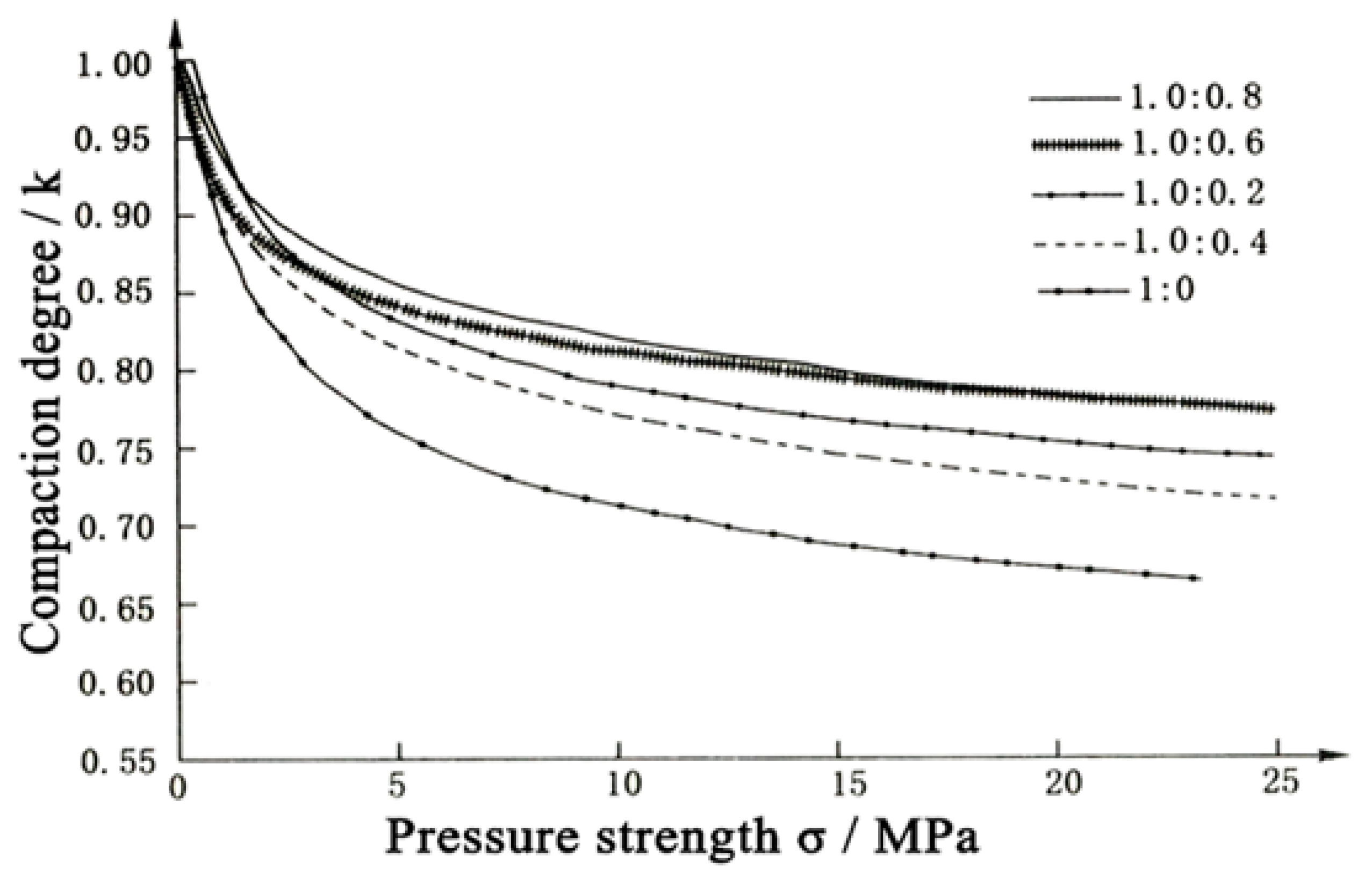

After testing on more than 20 kinds of stowing material proportions and gradations, the results of compaction tests of dense stowing material had shown that, with an evenly distributed gradation of gangue material i.e., the mass ratio was G1:G2:G3:G4:G5:G6 = 1:1:1:1:1:1, as well as the gangue and fly ash mass ratio was 1:0.6, the prepared dense stowing material could achieve a minimum decreasing of compaction rate within the compaction stress ranged from 0 to 25 MPa.

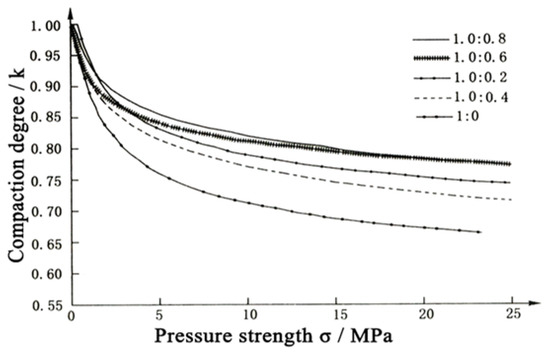

The results is shown in Figure 8.

Figure 8.

Compaction rate variation of different gangue/fly ash proportion with homogenous gradation of gangue material.

Figure 8 shows that the compaction rate k of stowing material and axial pressure/stress were nonlinearly related. At the beginning of compaction (σ ≤ 5 MPa), the compaction rate k decreased rapidly. Along with further increasing of pressure, the k value decline tended to occur more and more slowly, and gradually reached a stable value. Even distributed gradated gangue material has the best compaction properties, the reason could be the gangue particles with well distributed particle sizes could occupy the spaces between larger particles as much as possible and led to lower porosity of the dense stowing medium. With the increasing of gangue/fly ash proportion in stowing material up to 1:0.6, the compaction properties of dense stow material tended to achieve the best status, since the spaces between gangue particles were fully filled. Further increasing fly ash content could not optimize the compaction rate any more, since until 1:0.6, all spaces between gangue particles had been fulfilled by fly ashe i.e., the porosity of the dense stowing medium had been reduced to the minimum and the compaction properties depended on the aggregate material i.e., the gangues.

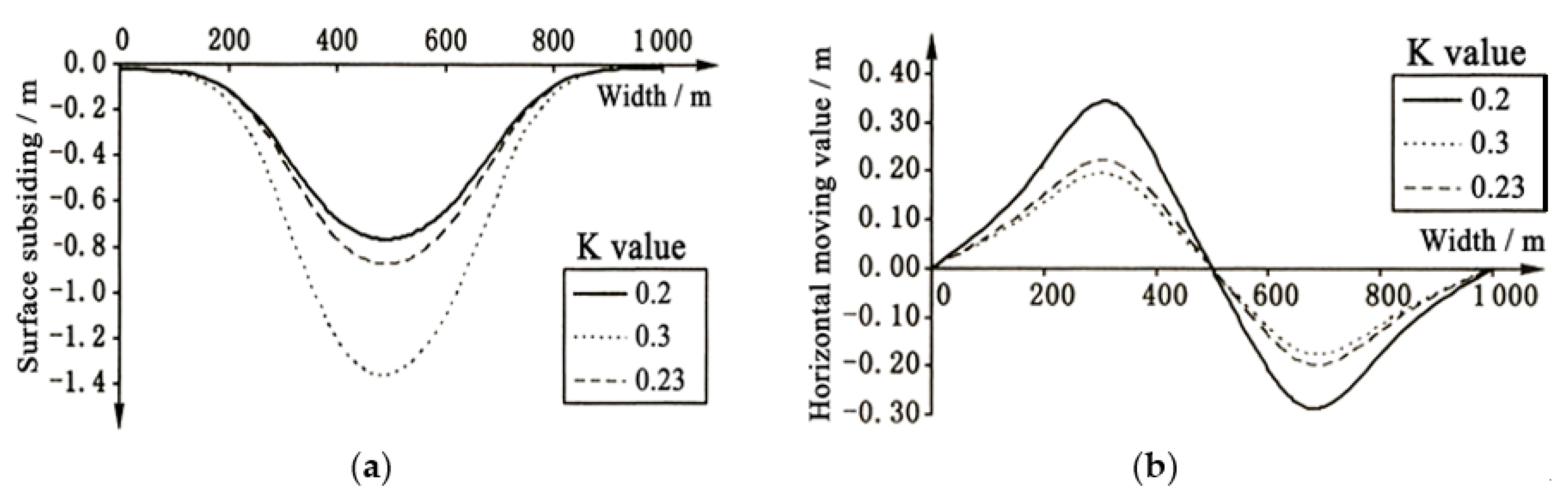

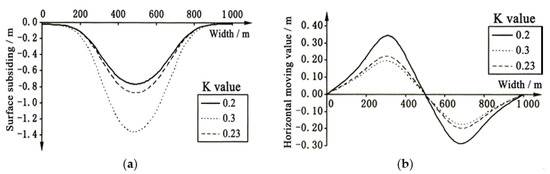

With this solid dense stowing method, the goaf space could be 100% fulfilled by the tamping mechanism which was installed on the stowing side of mining/stowing roof supporter, hence after the compaction of dense stowing medium had become stable, we could set the actual goaf roof strata subsidence rate as K = 1 − k. Then also through the triaxial stress experiment on equivalent overlying strata models, we have obtained the relationship between K and surface subsidence value as well as surface horizontal movements, they are shown in Figure 9 as follows.

Figure 9.

Relationship between surface subsidence and goaf roof subsiding rate (a) and the relationship between surface horizontal movements and goaf subsidence rate (b).

Figure 9 shows that both of the surface subsidence and horizontal movement raised significantly with the increasing of K value i.e., decreasing of the compaction rate k. The variance of dense stowing material proportion/gradation had very little influence on surface subsiding range.

3. Results and Discussion

The fully mechanized solid dense stowing mining technology has been implemented in more than 35 state owned key coal mines in China, such as Jizhong energy Xingtai coal mine, Jining Huayuan coal mine, Pingdingshan Tian’an No. 12 coal mine, Shandong Energy Group, Xuhzou Sanhejian coal mine, etc. The main effectiveness of this method is shown in Table 1 as follows.

Table 1.

Applied effectiveness of fully mechanized solid dense stowing mining method.

Table 1 shows that the fully mechanized solid dense stowing/mining method has been implemented in 10 coal mine enterprises in the last five years. Most of the coal mines have used this method more than two years. There are, in total, 33 dense stowing/mining working faces in the 10 coal mine enterprises and during their application period there has been 2.64 × 107 t of mining solid waste disposed by backfilling in goaf room; more than 2.31 × 107 t of coal resource has been released and produced from occupation under buildings, railways, and water bodies. With more than 500 hm2 of land resources being protected from subsidence caused by coal seam excavation. All of the 10 coal mine enterprises were located in east China, where the land is a precious resource. Meanwhile, most coal resources are located under towns, infrastructures and farmland, where mining subsidence are prohibited. By using this mining method with a solid waste dense stowing method, the contradictions around coal production, land resource conservation, and prevention mining contamination could be relieved to a great extent.

Perhaps the actual results and effectiveness demonstrated in Table 1 are not considered significant enough. However, please consider that coal mining and production is a long-term activity, which could continue for several decades or even over 100 years. Hence with the continuation of time and coal production, the effectiveness of this method can become more and more significant. These enterprises in Table 1 are old coal mines which have been operated for several decades, some of them have entered their later stages. With the help of this method, more occupied resources have become available, hence the life time of the old coal mines could be extended. Therefore, there is no need to exploit new coal resources around the same area for quite a long period. These enterprises have also estimated the results and effectiveness of this compaction method throughout their extended life time, which is shown in Table 2 as follows.

Table 2.

Estimation of effectiveness throughout extended life time of coal mine enterprises by using fully mechanized solid waste dense stowing mining method.

Table 2 demonstrates that, under actual exploitation plan of the 10 coal mines, implementation of this fully mechanized solid waste dense stowing/mining method could achieve significant and considerable effectiveness on mining solid waste disposal, land resources conservation, high efficiency of coal resources utilization and life time extension of coal mines at the same time. At the end of coal production, about 8.16 × 108 t solid mining waste could be disposed underground, 6.31 × 108 t occupied coal resources could be released and totally about 14,149 hm2 land resources could be protected from subsidence, as well as immovable assets on the land.

During the extended life time of actual coal mines, no more new coal mines will be needed; Land resources can be protected to the largest extent; no more gangue dump occupation and contaminations on the surface.

In this paper we choose Jizhong energy Xingtai coal mine and Jining Huayuan coal mine as an example to report and discuss the effect of fully mechanized solid dense stowing mining.

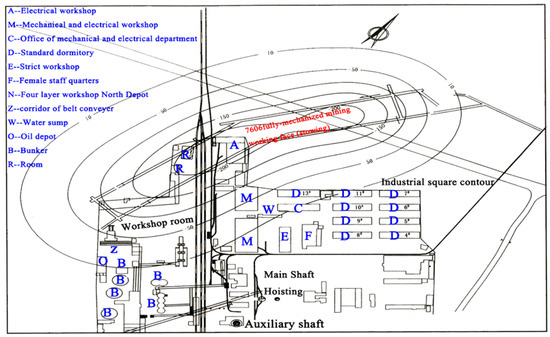

3.1. Applied Effectiveness and Results in Xingtai Coal Mine

Xingtai coal mine locates in Hebei province and belongs to Jizhong Energy Group. The coal mine area covers 3192 hm2. The coal mine has one coal processing plant and one coal combustion power plant, which supply enough raw stowing materials. Here we chose the 7606 mining working face which is located under the industrial square and in the middle of the mining area as an example to explain the results. The 7606 working face had a length of 100 m, the thickness of the coal seam was about 5.5 m and the actual mining height was 3 m, the average mining depth was 310 m and the average seam dip angle was about 9°. The mining advancing length of 7606 working face was about 1340 m and the advancing velocity was about 4–6 m/d. Along its advancing direction, there was about 820 m under the industrial square and infrastructures. After excavation of the coal seam with solid dense stowing, the final subsidence situation is shown in Figure 10 and Table 3 as follows.

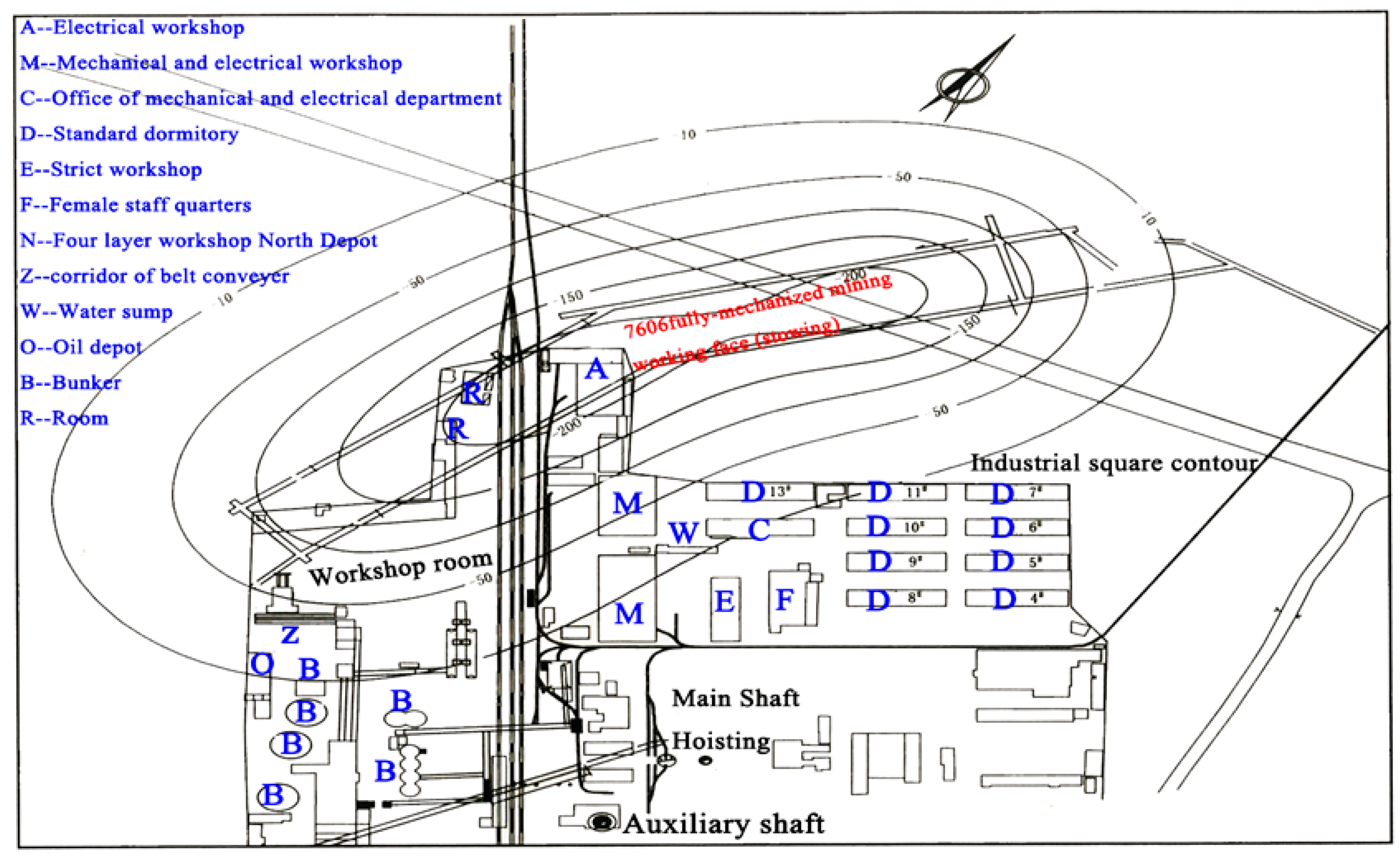

Figure 10.

Xingtai coal mine industrial square subsidence results with mining/solid dense stowing method of working face 7606 (Unit: mm).

Table 3.

Evaluation of buildings and facilities damage in Xingtai coal mine industrial square after 7606 working face mining with solid dense stowing method.

The results show that, after the coal seam excavation of working face 7606, the surface and buildings in the industrial square received only minor influence. The electrical workshop located in the middle of working face mining area showed maximum subsidence and deformations of about 110 mm and damage level I. All of the damage values were limited within level I according to Chinese mining damage evaluation regulations, the influence was very minor so that there is no need to administer any repairs.

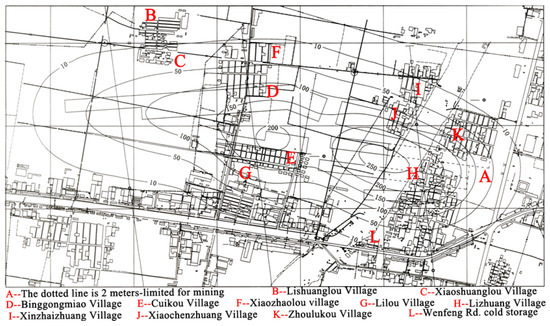

3.2. Applied Effectiveness and Results in Jining Huayuan Coal Mine

Jining Huayuan coal mine belongs to Jining energy Group, which locates in the west of Jinxiang city. The mine field is 6.7 km length along east and west, and 4.5 km width along south and north approximately, the mine field area is about 2806 hm2, the designed productivity is 4.5 × 105 t/a, the industrial reserve is 3.37 × 107 t, all of the coal is under civil buildings of villages. The coal seam was mined by using dense stowing mining area was No. 3 coal seam of Permian System. The mean thickness of the coal seam was about 2.50 m, the depth is about 500 m, the dip angle varies from 7 to 19 and is 13° in average.

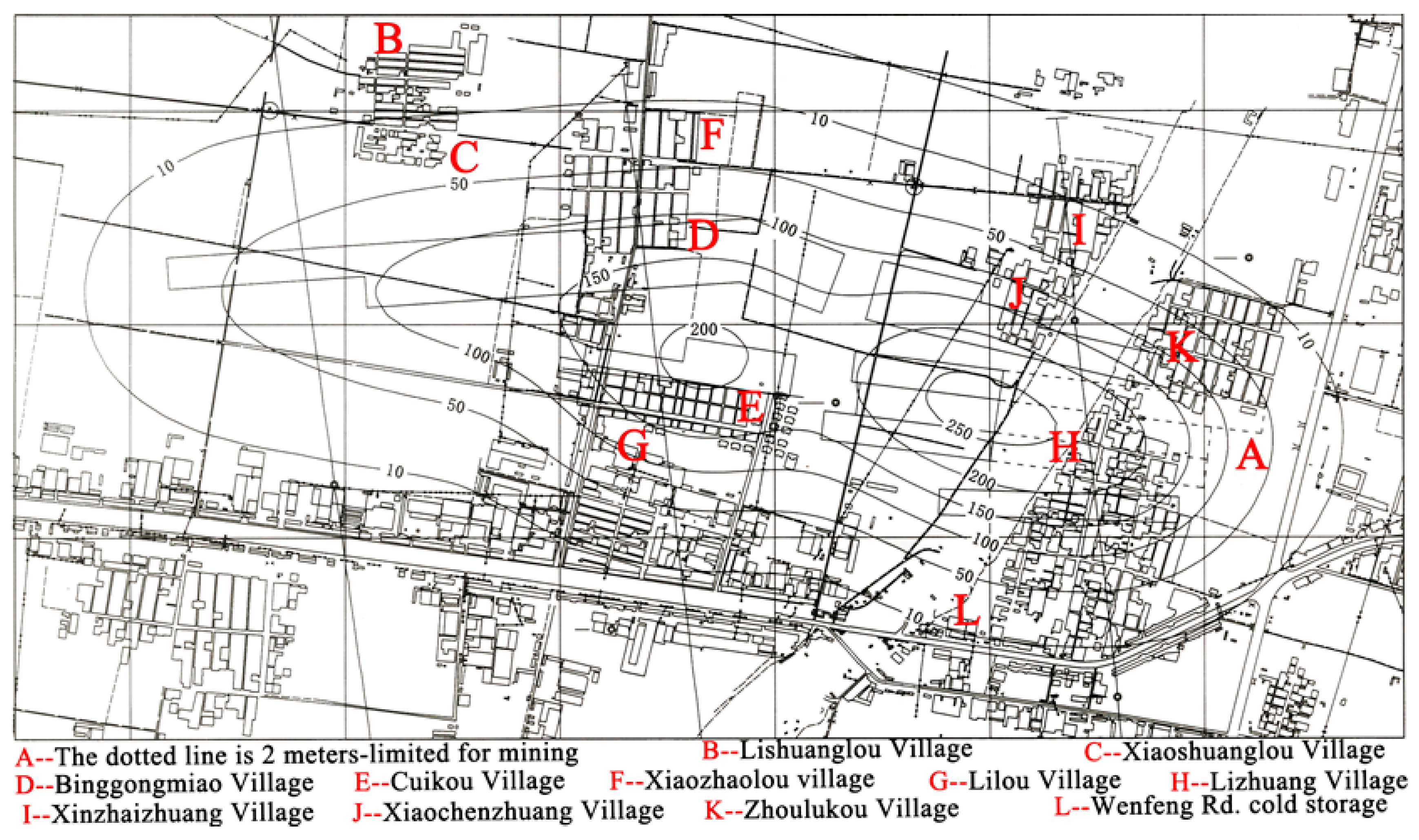

The results by solid dense stowing mining method in the mining area 3# seam of Huanyuan coal mine is shown in Figure 11 and Table 4 as follows.

Figure 11.

Huayuan coal mine 3 seam mining area subsidence results with mining/solid dense stowing method (Unit: mm).

Table 4.

Maximum damage value of village civil buildings in Huayuan coal mine 3 mining area after with solid dense stowing method.

Figure 11 and Table 4 demonstrate that, with the solid dense stowing mining method in Huayuan coal mine 3# seam mining area, the maximum subsidence, horizontal deformation and tilting deformation on surface village civil buildings are 242 mm, 0.72 mm/m and 0.7 mm/m, respectively. Hence all of the buildings’ deformation level are much less than risk control thresholds. The damages are limited within level I, so there is no need to do any repair steps.

According to both example pilot applications of this method which have been introduced in this paper, the average subsidence rate K (subsidence depth/seam mining height) of Xintai coal mine 7606 working face was about 19.43 mm/m and in Huayuan coal mine area it was about 38.47 mm/m. Both of the values were much better than normal roof management methods. The effect of solid dense stowing method in Xingtai coal mine was better than Huayuan coal mine area. Since in the overburdened strata of Xintai coal mine, the rock strata were much thicker than Huayuan coal mine area, which could further optimize the effect of goaf dense stowing. In the Huayuan coal mine area, the overburden was mostly in a huge thick clay layer.

4. Conclusions

The fully mechanized solid waste dense mining/stowing method has been proofed to be a significant innovation of mining technology with sufficient surface subsidence control for green and sustainable mining. Now this method has been used in more than 35 state coal mine enterprises and the results shows that:

- (1)

- With the fully mechanized solid waste dense stowing method and facilities, the roof and overlying strata could be well protected immediately after coal seam excavation from hazardous fractures and movements. Hence the subsidence which is normally caused by goaf roof can be reduced to the largest extent, and further greatly improve the sustainability of urban land resource and environmental ecology.

- (2)

- Tremendous amounts of solid waste from coal mining and power generation—i.e., the gangues and fly ash—could be directly utilized as stowing material and backfilled to the goaf, which could eliminate serious problems and disasters caused by gangue and fly ash dumps, like land resource occupation and contamination through leaching water and spontaneous combustion of dumps. The environmental and ecological sustainability of the mining area can be greatly optimized.

- (3)

- Occupied coal resources under buildings, railways, and water bodies become available, which can extend the lifetime of active coal mines and coal related enterprises, which increases the sustainability of coal industry. New exploitation of coal resources and movements of villages and residential spots could be avoided.

- (4)

- For coal production enterprises, the costs of waste discharge, land resource occupation, and damage and population resettlement of subsidence area could also be reduced significantly, since most of above-mentioned problems have been solved with this innovative method. The sustainability of economic performance can also be optimized.

Generally, the fully mechanized solid waste dense mining/stowing method could significantly increase the safety and sustainability of the coal industry, as well as improve the environment and ecology of the mining area and the regional economy. Of course, this method still has its own limits, the operation of this system is still complex, which requires relatively more human labor. For further development, automation could be an appropriate solution for a fully mechanized solid dense mining/stowing method.

Acknowledgments

This work was funded by the projects “National Natural Science Foundation of China 51504241”, “The Funds for Creative Research Groups of China 51421003”, “National Key Research and Development Program 2016YFC0501107”, and “China Fundamental Research Funds for the Central Universities 2015QNA28”.

Author Contributions

All authors contributed equally to this research paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bian, Z.F.; Miao, X.X.; Lei, S.G.; Chen, S.E.; Wang, W.F.; Struthers, S. The challenges of reusing mining and mineral-processing wastes. Science 2012, 337, 702–703. [Google Scholar] [CrossRef] [PubMed]

- Junker, M.; Witthaus, H. Progress in research and application of coal mining with stowing. Int. J. Min. Sci. Technol. 2013, 23, 7–12. [Google Scholar] [CrossRef]

- Miao, X.X.; Qian, M.G. Research on green mining of coal resource in China: Current status and future prospects. J. Min. Saf. Eng. 2009, 26, 1–14. [Google Scholar]

- Feng, X.W.; Zhang, N.; Gong, L.Y.; Xue, F.; Zheng, X.G. Application of a backfilling method in coal mining to realise an ecologically sensitive “Black Gold” industry. Energies 2015, 8, 3628–3639. [Google Scholar] [CrossRef]

- Miao, X.X.; Li, S.C.; Chen, Z.Q.; Liu, W.Q. Experimental study of seepage properties of broken sandstone under different porosities. Transp. Porous Med. 2011, 86, 805–814. [Google Scholar] [CrossRef]

- Howladar, M.F. Coal mining impacts on water environs around the Barapukuria coal mining area, Dinajpur, Bangladesh. Environ. Earth Sci. 2013, 70, 215–226. [Google Scholar] [CrossRef]

- Liu, L.; Liu, J.; Zhang, Z.G. Environmental justice and sustainability impact assessment: In search of solutions to ethnic conflicts caused by coal mining in inner Mongolia, China. Sustainability 2014, 6, 8756–8774. [Google Scholar] [CrossRef]

- Martens, P.N. Concepts of underground utilization and disposal of waste comparison and evaluation. Glückauf 1996, 132, 341–345. [Google Scholar]

- Kortnik, J. Backfilling waste material composites environmental impact assessment. J. S. Afr. Inst. Min. Metall. 2003, 103, 391–396. [Google Scholar]

- Karfakis, M.G.; Bowman, C.H.; Topuz, E. Characterization of coal-mine refuse as backfilling material. Geotech. Geol. Eng. 1996, 14, 129–150. [Google Scholar] [CrossRef]

- Skarzynska, K.M. Reuse of coal mining waste in civil engineering—Part 1. Properties of minestone. Waste Manag. 1995, 15, 3–42. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.X.; Huang, Y.L.; Ju, F. Backfilling technology and strata behaviors in fully mechanized coal mining working face. Int. J. Min. Sci. Technol. 2012, 22, 151–157. [Google Scholar] [CrossRef]

- Guo, G.L.; Zhu, X.J.; Zha, J.F. Subsidence prediction method based on equivalent mining height theory for solid backfilling mining. Trans. Nonferrous Met. Soc. China 2014, 24, 3302–3308. [Google Scholar] [CrossRef]

- Li, X.Z.; Cao, L.; Zhao, X.B. Assessment of potential impact of tunneling on the groundwater in Epi-Fissure-Karst-Zone and ecological environment. Environ. Earth Sci. 2012, 66, 967–976. [Google Scholar] [CrossRef]

- Ju, F.; Zhang, J.X.; Zhang, Q. Vertical transportation system of solid material for backfilling coal mining technology. Min. Sci. Technol. 2009, 19, 40–45. [Google Scholar] [CrossRef]

- Guo, G.L.; Feng, W.K.; Zha, J.F.; Liu, Y.X.; Wang, Q. Subsidence control and farmland conservation by solid backfilling mining technology. Trans. Nonferrous Met. Soc. China 2011, 21, 665–669. [Google Scholar] [CrossRef]

- Maucher, B. Bruchhohlraumverfüllung mit bergbaueigenen und bergbaufremden Rückständen auf dem Bergwerk Walsum der RBAG. Glückauf 1996, 132, 361–365. [Google Scholar]

- Huang, Y.L.; Zhang, J.X.; An, B.F.; Zhang, Q. Overlying strata movement law in fully mechanized coal mining and backfilling longwall face by similar physical simulation. J. Min. Sci. 2011, 47, 618–627. [Google Scholar]

- Tan, Y.L.; Yu, F.H.; Ning, J.G.; Zhao, T.B. Design and construction of entry retaining wall along a gob side under hard roof stratum. Int. J. Rock Mech. Min. Sci. 2015, 77, 115–121. [Google Scholar] [CrossRef]

- Zhu, X.J.; Guo, G.L.; Wang, J.; Fang, Q.; Chen, T. Analysis of strata and ground subsidence in fully mechanized solid backfilling mining: A case study of Huayuan coal mine. Trans. Inst. Min. Metall. 2016, 125, 1–9. [Google Scholar] [CrossRef]

- Liu, J.G.; Zhao, Q.B. Coal mining technology with fully mechanized solid backfilling under the building structures in Xingtai Mine. Coal Sci. Technol. 2010, 38, 18–21. [Google Scholar]

- Ma, Z.G.; Gong, P.; Fan, J.; Geng, M.; Zhang, G. Coupling mechanism of roof and supporting wall in gob-side entry retaining in fully-mechanized mining with gangue backfilling. Min. Sci. Technol. 2011, 21, 829–833. [Google Scholar] [CrossRef]

- Guan, D.B.; Klasen, S.; Hubacek, K.; Feng, K.S.; Liu, Z.; He, K.B.; Geng, Y.; Zhang, Q. Determinants of stagnating carbon intensity in China. Nat. Clim. Chang. 2014, 4, 1017–1023. [Google Scholar] [CrossRef]

- Harnischmacher, S.; Zepp, H. Mining and its impact on the earth surface in the Ruhr District (Germany). Z. Geomorphol. 2014, 58, 3–22. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.X.; Zhao, X.; Liu, Z.; Huang, Y.L. Industrial tests of waste rock direct backfilling underground in fully mechanized coal mining face. Environ. Eng. Manag. J. 2014, 13, 1291–1297. [Google Scholar]

- Xuan, D.Y.; Xu, J.L.; Zhu, W.B. Backfilling mining practice in China coal mines. J. Mines Met. Fuels 2013, 61, 225–234. [Google Scholar]

- Lian, X.G.; Jarosz, A.; Saavedra-Rosas, J.; Dai, H.Y. Extending dynamic models of mining subsidence. Trans. Nonferrous Met. Soc. China 2011, 21, 536–542. [Google Scholar] [CrossRef]

- Zhang, J.X.; Zhang, Q.; Sun, Q.; Gao, R.; Germain, D.; Abro, S. Surface subsidence control theory and application to backfill coal mining technology. Environ. Earth Sci. 2015, 74, 1439–1448. [Google Scholar] [CrossRef]

- Preuße, A.; Kateloe, H.J.; Sroka, A. Future demands on mining subsidence engineering in theory and practice. Gospod. Surowcami Miner. 2008, 24, 15–26. [Google Scholar]

- Miao, X.X.; Zhang, J.X.; Guo, G.L. Method and Technology of Fully Mechanized Coal Mining with Solid Waste Filling; China University of Mining and Technology Press: Xuzhou, China, 2010; pp. 22–39. [Google Scholar]

- Huang, Y.L.; Zhang, J.X.; Zhang, Q.; Nie, S. Backfilling technology of subsitituting waste and fly ash for coal underground in China coal Mining area. Environ. Eng. Manag. J. 2011, 10, 769–775. [Google Scholar]

- Li, J.; Zhang, J.X.; Huang, Y.L.; Zhang, Q.; Xu, J.M. An investigation of surface deformation after fully mechanized, solid back fill mining. Int. J. Min. Sci. Technol. 2012, 22, 453–457. [Google Scholar] [CrossRef]

- Zhou, N.; Zhang, Q.; Ju, F.; Liu, S. Pre-treatment research in solid backfill material in fully mechanized backfilling coal mining technology. Disaster Adv. 2013, 6, 118–125. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).