Creation of One Excavator as an Obstacle in C-Space for Collision Avoidance during Remote Control of the Two Excavators Using Pose Sensors

Abstract

:1. Introduction

2. Literature Review

3. Methdology

- The target to be expressed as an obstacle is just a typical excavator. The rest such as unknown debris are excluded because it becomes a meaningless object in the computation.

- Two excavators recognize each other as obstacles. However, from this point, the target excavator that will be the obstacle will be called “A” so that “B” will recognize Excavator A as an obstacle.

- Only kinematic information will be used. Therefore, the posture of the two excavators must be known, given, and measurable.

- The methodology is divided into two parts: when driving, and when manipulating the boom, stick, bucket, and swing.

- All links and the body are treated as segments for the computations.

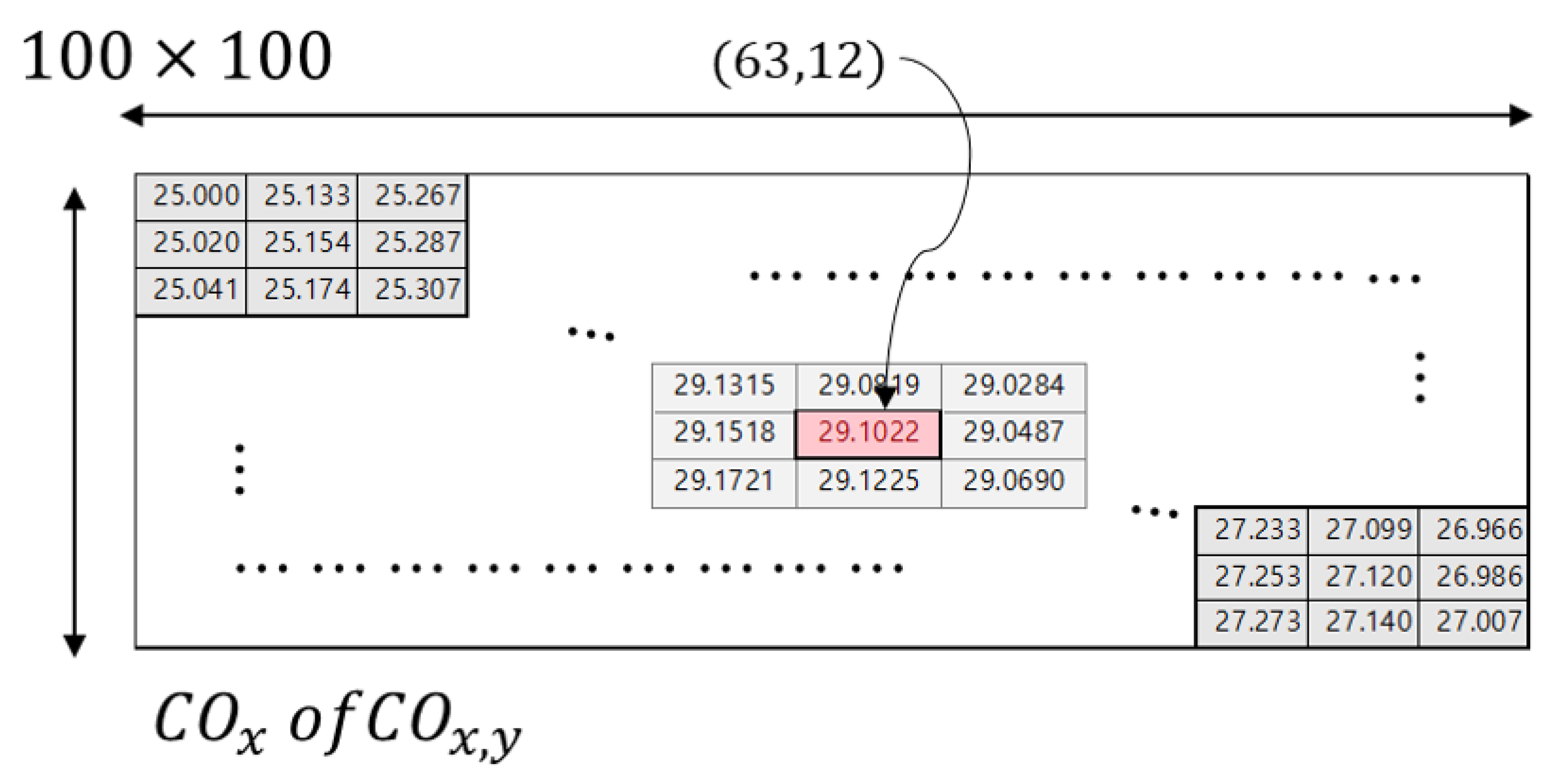

3.1. Obstacle Generation for Driving Guidance

- Position of the center of the cabin.

- The length from the center of the cabin to the end-point of the excavator when all the links are orthogonally projected onto .

- The artificial range covering around the link for the safety factor.

- The yaw angle of the links with respect to reference frame of UTM coordinate system, including cabin (body).

3.2. Obstacle Generation for Guidance in the Manipulation of the Excavator’s Arm

- Go back to Equation (10) for the specific yaw angle of Excavator A.

- and

- = =

4. Simulations

4.1. Simulation Results of Obstacle Generation for Driving Guidance to Avoid Collision

4.2. B. Simulation Results of Obstacle Generation for Guidance of Arm Manipulation to Avoid Collision

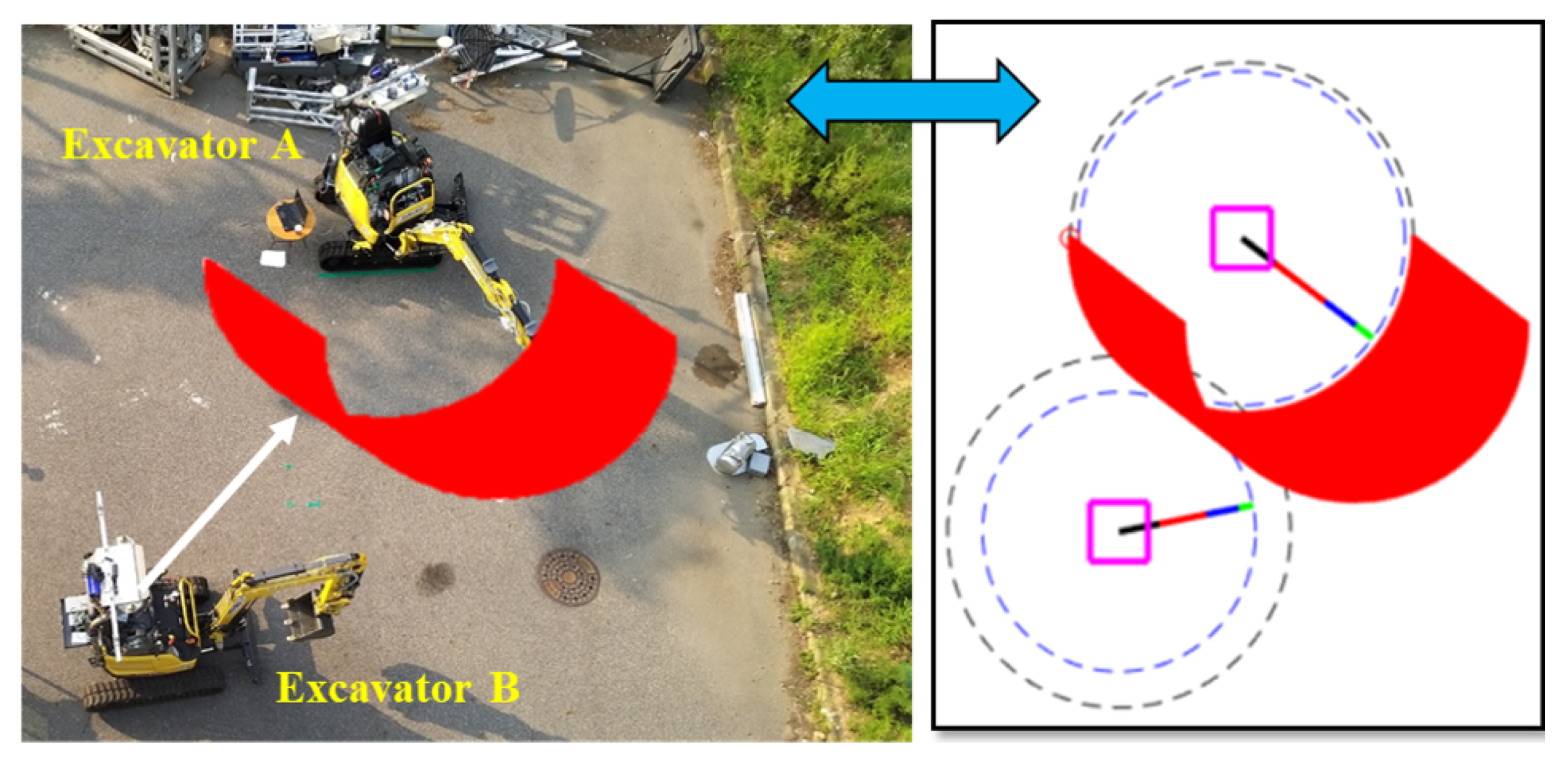

5. Experiments and Results

5.1. Experimental Setup: Sensors, Communication System, Excavators

5.2. Experiment Results of Obstacle Generation for Driving Guidance to Avoid the Collision

5.3. Experiment Results of Obstacle Generation for Guidance of Arm Manipulation to Avoid the Collision

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Lumelsky, V.; Cheung, E. Real-time collision avoidance in teleoperated whole-sensitive robot arm manipulator. IEEE Trans. Syst. Man Cybern. 1993, 23, 194–203. [Google Scholar] [CrossRef] [Green Version]

- Chang, C.; Chung, M.J.; Lee, B.H. Collision avoidance of two general robot manipulators by minimum delay time. IEEE Trans. Syst. Man Cybern. 1994, 24, 517–522. [Google Scholar] [CrossRef] [Green Version]

- Li, T.-Y.; Latombe, J.-C. On-line manipulation planning for two robot arms in a dynamic environment. Int. J. Robot. Res. 1997, 16, 144–167. [Google Scholar] [CrossRef]

- Lee, S.; Moradi, H. A real-time dual-arm collision avoidance algorithm for assembly. J. Robot. Syst. 2001, 18, 477–486. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Fukuda, S. Trajectory planning of multiple mobile manipulators with collision avoidance capability. In Proceedings of the 2002 IEEE International Conference on Robotics and Automation, Washington, DC, USA, 11–15 May 2002; pp. 3565–3570. [Google Scholar]

- Fei, Y.; FuQiang, D.; Xifang, Z. Collision-free motion planning of dual-arm reconfigurable robots. Robot. Comput. Manuf. 2004, 20, 351–357. [Google Scholar] [CrossRef]

- Tsai, Y.-C.; Huang, H.-P. Huang, Motion planning of a dual-arm mobile robot in the491configuration-time space. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems; Institute of Electrical and Electronics Engineers (IEEE), St Louis, MI, USA, 10–15 October 2009; pp. 2458–2463. [Google Scholar]

- Lee, D.-H.; Kim, D.-H.; Lee, J.Y.; Han, C.-S. Collision-free coordination of two dual-arm robots with assembly precedence constraint. In Proceedings of the 2014 14th International Conference on Control, Automation and Systems (ICCAS 2014); Institute of Electrical and Electronics Engineers (IEEE), Seoul, Korea, 22–25 October 2014; pp. 515–520. [Google Scholar]

- Davis, D.P. Collision Free Path planning of an Object Using Multiple Robot Manipulators. Marster’s Thesis, RHODE ISLAND University, Kingston, RI, USA, 2014. [Google Scholar]

- Harada, K.; Tsuji, T.; Laumond, J.-P.; Harada, K.; Tsuji, T. A manipulation motion planner for dual-arm industrial manipulators. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–5 June 2014; pp. 928–934. [Google Scholar]

- Ge, Q.; McCarthy, J. Equations for boundaries of joint obstacles for planar robots. In Proceedings of the 1989 International Conference on Robotics and Automation, Scottsdale, AZ, USA, 14–19 May 1989; pp. 164–169. [Google Scholar]

- Dooley, J.; McCarthy, J. Parameterized descriptions of the joint space obstacles for a 5r closed chain robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Cincinnati, OH, USA, 13–18 May 1990; pp. 1536–1541. [Google Scholar]

- Branicky, M.S.; Newman, W.S. Parameterized descriptions of the joint space obstacles for a 5r closed chain robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Cincinnati, OH, USA, 13–18 May 1990; pp. 304–310. [Google Scholar]

- Newman, W.; Branicky, M.S. Branicky, Real-time configuration space transforms for obstacle avoidance. Int. J. Robot. Res. 1990, 10, 650–667. [Google Scholar] [CrossRef]

- Pan, J.; Manocha, D. Efficient configuration space construction and optimization516for motion planning. Engineering 2015, 1, 046–057. [Google Scholar] [CrossRef] [Green Version]

- Vega, A.N. Development of a Real-Time Proximity Warning and 3-d Mapping System Based on Wireless Networks, Virtual Reality Graphics, and Gps to Improve Safety in Open-Pit Mines. Ph.D. Thesis, Colorado School of Mines, Golden, CO, USA, 2001. [Google Scholar]

- Nieto, A.; Dagdelen, K. Development and testing of a vehicle collision avoidance system based on gps and wireless networks for open-pit mines. In Proceedings of the Application of Computers and Operations Research in the Minerals Industries, Cape Town, South Africa, 14–16 May 2003. [Google Scholar]

- Ruff, T.M.; Holden, T.P. Preventing collisions involving surface mining equipment: a gps-based approach. J. Saf. Res. 2003, 34, 175–181. [Google Scholar] [CrossRef]

- Ruff, T.M. Recommendations for evaluating and implementing proximity warning systems on surface mining equipment. In Safety and Health at Work for All People Through Research and Prevention DHHS (NIOSH); Publication No. 2007-146; NIOSH: Washington, DC, USA, 2007. [Google Scholar]

- Ruff, T.M. Evaluation of a radar-based proximity warning system for off-highway dump trucks. Accid. Anal. Prev. 2006, 38, 92–98. [Google Scholar] [CrossRef]

- Kamat, V.R.; Martinez, J.C. Interactive collision detection in three-dimensional visualizations of simulated construction operations. Eng. Comput. 2007, 23, 79–91. [Google Scholar] [CrossRef]

- Marks, E.; Teizer, J. Proximity sensing and warning technology for heavy construction equipment operation. Construction Research Congress 2012: Construction Challenges in a Flat World. 2012. Available online: https://ascelibrary.org/doi/abs/10.1061/9780784412329.099 (accessed on 26 March 2020).

- Marks, E.; Teizer, J. Method for testing proximity detection and alert technology for safe construction equipment operation. Constr. Manag. Econ. 2013, 31, 636–646. [Google Scholar] [CrossRef]

- Teizer, J. Magnetic field proximity detection and alert technology for safe heavy construction equipment operation. In Proceedings of the 32nd International Symposium on Automation and Robotics in Construction and Mining (ISARC 2015), Oulu, Finland, 15–18 June 2015. [Google Scholar]

- Golovina, O.; Teizer, J.; Pradhananga, N. Heat map generation for predictive safety planning: Preventing struck-by and near miss interactions between workers-on-foot and construction equipment. Autom. Constr. 2016, 71, 99–115. [Google Scholar] [CrossRef]

- Wang, J.; Razavi, S. Two 4d models effective in reducing false alarms for struck-by equipment hazard prevention. J. Comput. Civ. Eng. 2016, 30. [Google Scholar] [CrossRef]

- Sivakumar, P.; Varghese, K.; Babu, N.R. Automated path planning of cooperative crane lifts using heuristic search. J. Comput. Civ. Eng. 2003, 17, 197–207. [Google Scholar] [CrossRef]

- Ali, M.S.A.D.; Babu, N.R.; Varghese, K. Collision free path planning of cooperative crane manipulators using genetic algorithm. J. Comput. Civ. Eng. 2005, 19, 182–193. [Google Scholar] [CrossRef]

- Kang, S.; Miranda, E. Planning and visualization for automated robotic crane erection processes in construction. Autom. Constr. 2006, 15, 398–414. [Google Scholar] [CrossRef]

- Li, Z.; Li, X.; Liu, S.; Jin, L. A study on trajectory planning of hydraulic robotic excavator based on movement stability. In Proceedings of the 2016 13th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Xian, China, 19–22 August 2015; pp. 582–586. [Google Scholar]

- Chae, S.; Yoshida, T. Application of rfid technology to prevention of collision accident with heavy equipment. Autom. Constr. 2010, 19, 368–374. [Google Scholar] [CrossRef]

- Jo, B.-W.; Lee, Y.; Kim, J.-H.; Kim, D.-K.; Choi, P.-H. Proximity warning and excavator control system for prevention of collision accidents. Sustainability 2017, 9, 1488. [Google Scholar] [CrossRef] [Green Version]

- Teizer, J.; Allread, B.S.; Fullerton, C.E.; Hinze, J. Autonomous pro-active real time construction worker and equipment operator proximity safety alert system. Autom. Constr. 2010, 19, 630–640. [Google Scholar] [CrossRef]

- Su, X.; Talmaki, S.; Cai, H.; Kamat, V.R. Uncertainty-aware visualization and proximity monitoring in urban excavation: A geospatial augmented reality approach. Vis. Eng. 2013, 1, 2. [Google Scholar] [CrossRef] [Green Version]

- Vahdatikhaki, F.; Hammad, A. Visibility and proximity based risk map of earthwork site using real-time simulation. In Proceedings of the 32nd International Symposium on Automation and Robotics in Construction and Mining (ISARC 2015), Oulu, Finland, 15–18 June 2015; Volume 32, p. 1. [Google Scholar]

- Shen, X.; Marks, E.; Pradhananga, N.; Cheng, T. Uncertainty-aware visualization and proximity monitoring in urban excavation: a geospatial augmented reality approach. J. Constr. Eng. Manag. 2016, 142, 05016001. [Google Scholar] [CrossRef]

- Gonon, D.; Jud, D.; Fankhauser, P.; Hutter, M.; Siegwart, R. Safe self-collision avoidance for versatile robots based on bounded potential. Springer Proc. Adv. Robot. 2017, 5, 19–33. [Google Scholar]

- Mastalli, C.; Fernández-López, G. A proposed architecture for autonomous operations in backhoe machines. Adv. Intell. Syst. Comput. 2015, 302, 1549–1559. [Google Scholar]

- Vahdatikhaki, F.; Langari, S.M.; Taher, A.; El Ammari, K.; Hammad, A. Enhancing coordination and safety of earthwork equipment operations using multi-agent system. Autom. Constr. 2017, 81, 267–285. [Google Scholar] [CrossRef]

- Craig, J. Introduction to Robotics: Mechanics and Control; PEARSON: London, UK, 2014. [Google Scholar]

- Sun, D. Simulation Code: Creation of One Excavator as an Obstacle in C-Space for Collision Avoidance during Two Excavator Cooperation, Hanyang University. 2019. Available online: http://repository.hanyang.ac.kr/handle/20.500.11754/601110426 (accessed on 13 September 2019).

- Lee, J.; Kim, B.; Sun, D.; Han, C.-S.; Ahn, Y.H. Development of unmanned excavator vehicle system for performing dangerous construction work. Sensors 2019, 19, 4853. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.-H.; Lee, Y.-S.; Sun, D.-I.; Lee, S.-K.; Yu, B.-H.; Jang, S.-H.; Kim, W.; Han, C.-S. Development of bulldozer sensor system for estimating the position of blade cutting edge. Autom. Constr. 2019, 106, 102890. [Google Scholar] [CrossRef]

- Vahdatikhaki, F.; Hammad, A.; Siddiqui, H. Optimization-based excavator pose estimation using real-time location systems. Autom. Constr. 2015, 56, 79–92. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values | Parameters | Values |

|---|---|---|---|---|---|

| 1(m) | 25(m) | ||||

| 1.72(m) | 25(m) | ||||

| 0.951(m) | |||||

| 0.7(m) |

| Parameters | Values | Parameters | Values | Parameters | Values |

|---|---|---|---|---|---|

| 1(m) | 35(m) | ||||

| 1.72(m) | 8(m) | ||||

| 0.951(m) | |||||

| 0.7(m) |

| Parameters | Values | Parameters | Values | Parameters | Values |

|---|---|---|---|---|---|

| 1(m) | 29(m) | ||||

| 1.72(m) | 27(m) | ||||

| 0.951(m) | |||||

| 0.7(m) |

| Parameters | Values | Parameters | Values | Parameters | Values |

|---|---|---|---|---|---|

| 1(m) | 308611.05(m) | ||||

| 1.72(m) | 4129957.348(m) | ||||

| 0.951(m) | |||||

| 0.7(m) |

| Parameters | Values | Parameters | Values | Parameters | Values |

|---|---|---|---|---|---|

| 1(m) | 308611.05(m) | ||||

| 1.72(m) | 4129957.348(m) | ||||

| 0.951(m) | |||||

| 0.7(m) |

| Parameters | Values | Parameters | Values | Parameters | Values |

|---|---|---|---|---|---|

| 1(m) | 308610.834(m) | ||||

| 1.72(m) | 4129952.567(m) | ||||

| 0.951(m) | |||||

| 0.7(m) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, D.; Hwang, S.; Kim, B.; Ahn, Y.; Lee, J.; Han, J. Creation of One Excavator as an Obstacle in C-Space for Collision Avoidance during Remote Control of the Two Excavators Using Pose Sensors. Remote Sens. 2020, 12, 1122. https://doi.org/10.3390/rs12071122

Sun D, Hwang S, Kim B, Ahn Y, Lee J, Han J. Creation of One Excavator as an Obstacle in C-Space for Collision Avoidance during Remote Control of the Two Excavators Using Pose Sensors. Remote Sensing. 2020; 12(7):1122. https://doi.org/10.3390/rs12071122

Chicago/Turabian StyleSun, Dongik, Seunghoon Hwang, Byeol Kim, Yonghan Ahn, Joosung Lee, and Jeakweon Han. 2020. "Creation of One Excavator as an Obstacle in C-Space for Collision Avoidance during Remote Control of the Two Excavators Using Pose Sensors" Remote Sensing 12, no. 7: 1122. https://doi.org/10.3390/rs12071122

APA StyleSun, D., Hwang, S., Kim, B., Ahn, Y., Lee, J., & Han, J. (2020). Creation of One Excavator as an Obstacle in C-Space for Collision Avoidance during Remote Control of the Two Excavators Using Pose Sensors. Remote Sensing, 12(7), 1122. https://doi.org/10.3390/rs12071122