1. Introduction

Weed control is a practice aimed at reducing competition among plants for water and nutrients. Cultivation techniques to control the development of weeds are commonly referred to as soil management. The application of herbicides at the beginning of the vegetative cycle is especially important in weed control because it is one of the critical factors for success [

1]. Automatic weed detection is one of the viable solutions for the efficient reduction in or exclusion of chemical products in the field. Studies have focused on modern approaches that automatically analyze and evaluate weeds in images (e.g., crop and weed segmentation).

Edge computing approaches have been proposed where the computation of data is performed locally, as in robots for agriculture. Examples of technical and technological solutions that can benefit from this approach can be found in [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12]. Furthermore, it is desired to balance accuracy, throughput, and power management, which is essential in various fields such as the Internet of Things (IoT), robotics, autonomous driving, and drone-based surveillance [

13]. Most modern computer vision systems for weed control are based on desktop computers (i.e., the computer is heavy, not portable, and must be connected to the power grid) [

14,

15,

16,

17,

18]. This means that these systems are heavy, expensive, and require much electrical power. These problems render this approach (i.e., desktop-based) impractical for use in small and low-cost orchard robots.

Milioto et al. [

14] proposed an encoder–decoder model based on convolutional neural networks (CNNs) for crop and weed segmentation. They used RGB images and produced the excess green, excess red, color index of vegetation extraction, and normalized difference vegetation indices as inputs to the model. The best performance was 59% mean intersection over union (mIOU) on the desktop device, and an inference time of 190 ms on the Jetson TX2. This model is relatively heavy compared to others, being able to perform only 5.2 frames per second (FPS) inferences at an image resolution of

on the Jetson TX2 device.

McCool et al. [

15] implemented a lightweight segmentation model based on deep convolutional neural networks (DCNNs) that could be used in robotic platforms to segment crops and weeds in images. They used a desktop computer with a graphics processing unit (GPU) card for training and inference. The model was trained on the Crop Weed Field Image Dataset (CWFID) with an image resolution of

, and achieved an accuracy of 93.9% with an inference time of 8.33s using an Inception-v3 backbone.

Khan et al. [

16] proposed the CED-NET encoder–decoder semantic segmentation method for crop and weed segmentation. Their model had four networks, where two networks are trained independently for segmenting crops, and the other two for weeds. They claimed that this approach to extract features at different scales provides coarse-to-fine predictions and reduces the number of network parameters. Using a desktop with a GPU, they achieved a performance of 77% mIOU in the CWFID dataset.

Wang et al. [

17] implemented an encoder–decoder deep-learning network for pixelwise semantic segmentation of crops and weeds. In addition, three images pre-processing were proposed to improve the model performance. They investigated the model by training and testing in two different datasets: sugar beet and oilseed. The best segmentation performance was 89% mIOU. Using a desktop with a GPU, the inference time for an image with a dimension of

was 100 ms.

Fawakherji et al. [

18] proposed a deep-learning-based method for crop and weed classification using two different convolutional neural networks (CNNs). The first network performs pixelwise segmentation between vegetation and soil. After segmentation, each plant is classified into crops or weeds using the second network. For the semantic segmentation network, they used the UNet structure with the VGG16 backbone. For the classification network, they used a fine-tuned model of VGG16 that leveraged deep CNN’s object classification capabilities. For training and testing, they used the NVIDIA GTX 1070 GPU and achieved 87% correctly detected crops and 77% correctly detected weeds.

Olsen [

19] proposed a real-time weed control system for a mobile robot. The author used a set of deep neural networks to classify nine types of weed images. In the Jetson Nano device, the MobileNetV2 model achieved an inference time of 29.0 ms; the ResNet-50 architecture achieved an inference time of 59.8 ms; the Inception model ran at 91.9 ms; and the VGG16 model achieved an inference speed of 166.3 ms. This work addresses the problem of image classification. That is, the model performs inference on whether weeds are present and which type they are. However, there is no spatial information (location) about the detected weeds in the image, unlike the semantic segmentation model.

Partel et al. [

20] developed an innovative sprayer that uses object detector Tiny Yolov3 to distinguish target portulaca plants, sedge weeds, from nontarget pepper plants and precisely spray to the desired location. Using an NVIDIA Jetson TX2 device and an image resolution of

, it achieved overall precision and recall of 59% and 44%, respectively, and the framework could handle 22 FPS. The experiment was carried out in a simulated field of crops and weeds that did not correspond to the natural environment, which is normally a dense vegetable field.

Using the SegNet encoder–decoder network for semantic segmentation, Abdalla et al. [

21] conducted a study on weed segmentation using fine-tuning and data-augmentation techniques. They used SegNet with a VGG16 backbone at an image resolution of

, and the model achieved an inference time of 230 ms (i.e., 4.3 FPS) and mIOU of 87% in a desktop computer equipped with a GPU card.

Asad and Bais [

22] used the SegNet and UNET semantic segmentation models with VGG16 and ResNet-50, classifying crop and background pixels as one class, and all other vegetation as the second class. At an image resolution of

, the SegNet model based on ResNet-50 showed the best results with an mIOU of 82%. The experiments were performed on a desktop computer equipped with a GPU card, and the authors did not report the inference time.

Ma et al. [

23] used the SegNet semantic segmentation model based on a fully convolutional network with the AlexNet backbone to segment rice seedlings, weeds, and the background. At an image resolution of

, the model achieved an mIOU of 62% and an inference time of 0.6 s (it could process 1.6 FPS). The experiments were performed on a desktop computer equipped with a GPU card.

Lameski et al. [

24] presented a carrot–weed dataset with RGB images of young carrot seedlings. The dataset contains 39 images with the same size of

. The dataset consists of 311,620,608 pixels, comprising 26,616,081 pixels of carrot plants, 18,503,308 pixels of weed plants, and 266,501,219 pixels of soil. The authors conducted the initial experiments on the dataset using the SegNet semantic segmentation model and achieved the best accuracy of 0.641 for the segmentation of weeds, plants, and soil. In this work, there is no information about the inference time and the device for training and inference.

Naushad et al. [

25] used VGG16 and wide residual networks (WRNs) to classify land use and land cover in RGB band images (at

resolution) from the EuroSAT dataset. A transfer-learning technique was used to improve the accuracy. The best accuracy was achieved by the WRN model with 99.17%.

Nanni et al. [

26] proposed an ensemble method for semantic segmentation combining DeepLabV3, HarDNet-MSEG, and Pyramid Vision Transformers. The model was trained and evaluated on different datasets covering five scenarios: polyp detection, skin detection, leukocyte recognition, environmental microorganism detection, and butterfly recognition. According to the authors, the model provides state-of-the-art results.

Autonomous mobile robots use remote-sensing techniques and technologies for several agricultural tasks such as monitoring, fertilizing, herbicide spraying, or harvesting.

Computer vision applications can run on mobile devices by using deep-learning frameworks (e.g., TensorRT or Tensorflow Lite) and accelerators. For this, some optimization is needed in the original or standard computer-vision models to minimize memory and computational footprints [

27]. Although preliminary studies investigated the inference performance for the semantic segmentation of crops and weeds in mobile edge devices [

14,

19,

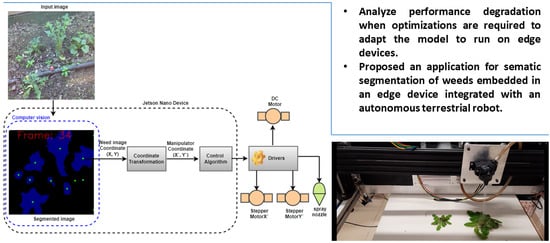

20], to the best of our knowledge, no study has been conducted to show the performance degradation (mIOU) when applying the required optimization to the model to operate in such edge devices. The purpose of this study is to:

Perceive the relationship between the model tuning hyperparameters of the DeeplabV3 semantic segmentation model with MobileNet backbone to improve inference time and its impact on segmentation performance (using the mIOU metric).

Evaluate the suitability of the Cityscapes, PASCAL, and ADE20K datasets for a transfer-learning strategy in crop and weed segmentation.

Propose and evaluate a real-time weed control application using a Jetson Nano Edge device and a spray mechanism.

The remainder of this paper is organized as follows. The hardware used to train and infer the model, the dataset used, an explanation of the semantic segmentation model, including the used backbone, the model optimization, and the practical application, are presented in

Section 2. The results of the proposed model when applied to the weed datasets and the practical application are presented along with the related analysis and discussion in

Section 3. The conclusion of the paper is in

Section 4.

3. Results and Discussions

This section presents the results of the DeepLabv3 experiments on the semantic segmentation of the WCFID dataset where hyperparameters were set, an optimization framework was applied, and fine tuning was performed.

3.1. Pretrained Models and Fine-Tuning Performance

To investigate how the pretrained models affected segmentation performance for the use case (i.e., crop and weed segmentation), experiments were conducted with the fine-tuning strategy using the Cityscape, ADE20k, and PASCAL datasets.

Table 6 shows the results for this experiment in combination with hyperparameters OS and DM = 1.0.

As shown in

Table 6, when fine tuned using hyperparameter OS = 8, the Cityscape dataset performed the best with 78% mIOU. However, when using OS = 16 and OS = 32, the performance for fine tuning with Cityscape and ADE20k was the same. OS = 8 gave the best result compared to OS = 16 and OS = 32 because it captured more spatial information from the input. The fine-tuning process uses knowledge gained from pretraining in other datasets. For example, the Cityscape dataset likely had more similarities with plants, e.g., the Vegetation class in the Nature group, which is probably the reason for the best result.

3.2. Model Optimization and Performance Degradation

This experiment investigates the relationship between model optimization (i.e., tuning hyperparameters and applying the TensorRT framework to improve inference time) and segmentation degradation. Although fine tuning with the Cityscape dataset gave the best results, as shown in a previous experiment, fine tuning in this experiment was used for the PASCAL dataset because a pretrained model with DM = 0.5 and DM = 1.0 was only available for the PASCAL dataset [

44].

Table 7 shows the computational cost of each model measured in giga floating-point operations (GFLOPs). It is clear how much the optimization reduced the computational cost: using hyperparameters DM = 0.5 and OS = 32 in the CNN backbone, the computational cost of the model was reduced from 81.9 to 4.4 GFLOPs. This performance was due to the reduction in convolutional layers in the MobileNet backbone by hyperparameters DM, which shrank the model by a factor of 0.5, and OS.

Table 8 shows how segmentation performance is affected by optimization to reduce inference time. The best model segmentation performance was 75% mIOU for the model with OS = 8 and DM = 1.0. The worst performance was 64% mIOU for the model with successive and more stringent optimization to improve the inference time, i.e., depth multiplier of 0.5, output stride of 32, and TensorRT. Reducing the model size to achieve fast inference time by using DM = 0.5 and OS = 32 led to a decrease in segmentation accuracy. The model became shallower and lost information about the features of the input image. An important result is also that using the TensorRT framework for enhancement did not affect the segmentation accuracy. TensorRT is an inference-oriented framework whose main purpose is efficient inference. It also supports dynamic graphs, which enables the efficient reuse of memory and improves inference performance [

27].

The corresponding segmentation quality results are shown in

Figure 10. Segmentation performance (quality) varied with different hyperparameters DM and OS. Comparing the results with the same OS but different DM (i.e., (c) with (h), (d) with (i), and (e) with (j)), the results with DM = 0.5 had more mis-segmentations between crops and weeds than those with DM = 1.0. This result can be explained by the fact that the DM hyperparameter affected the complexity of the model (size). A model with DM = 1.0 was deeper than a model with DM = 0.5.

If we now compare the results with the same DM but different OS (8, 16 and 32), we can see that the results with O = 8 were finer (fine details) than those with OS = 16 and OS = 32. The results with OS = 16 were finer than those of models with OS = 32. This result can be explained by the fact that the OS hyperparameter influenced the sparsity of the input calculation of the model.

Table 9 shows how optimization affected the time of model inference. The best result was 0.17 s using DM = 0.5, OS = 32 and TensorRT.

Table 7 shows that this configuration resulted in the smallest model, which reduced the inference time, as expected.

Table 10 and

Table 11 show the relationship (correlation) between model segmentation performance and inference time. The inference time could be accelerated by a factor of 14.8, while the segmentation performance (mIOU) decreased by 14.7%. With these optimizations and an image resolution of

, the model could perform segmentation in 5.9 FPS.

In addition, the results were compared with previously published segmentation work in the CWFID dataset. In

Table 12, Maxwell is a very small 128-core GPU integrated into the Jetson Nano developer kit, while Titan X is a standard 3584-cores GPU and Titan XP a 3840-cores GPU board.

For work comparison,

Table 12 shows the input size of the image, the GPU capabilities, the segmentation performance of the model in terms of accuracy or mIOU, and the inference performance FPS. Regarding GPU characteristics, our approach (DeepLabV3) uses the Maxwell embedded in the Jetson Nano, which is a portable device. In contrast, the other approaches use GPU cards that function in conjunction with a desktop.

Regarding the segmentation performance of the models, CED-Net and our model could be compared because the value of the results is presented in the same metric (mIOU). CED-Net outperformed our approach (DeepLabV3*) by only 2%.

Inference time performance could be compared between our approach and Adapted-IV3. Our approach (DeepLabV3**) outperformed Adapted-IV3 by about 50 times. The primary key to this performance is the use of the MobileNet backbone in the encoder part of the DeepLabV3 model, since the MobileNet DCNN provides light weight by performing depthwise separable convolutions. Another contribution to this performance was the setting of hyperparameters DM = 0.5 and OS = 32, and the use of the TensorRT framework.

3.3. Image Scale Analysis

In addition, smaller input images were considered to evaluate the inference time under this condition. The experiment was performed by cropping the WCFDI images in their center to a resolution of

.

Table 13 shows these results. For the quality segmentation shown in

Figure 11, an inference time of 0.04 s was achieved, corresponding to processing of 25 FPS.

3.4. Real-Time Application

The goal of this experiment was to demonstrate a practical application of the deep-learning-based computer-vision model, its reliability in real-time, and its integration with mechanical control.

After weeds had been detected by the computer-vision model, a series of actuators were controlled in sequence (e.g., the manipulator motor and the spray solenoid valve). The response time of each actuator was considered by setting the required delay time to finish the current step and start the next step.

We simulated a field soil with weeds by manually positioning them in the camera’s field of view.

Figure 12 shows the general view of the experiment. The window in which the input image coming from the camera is displayed. The window in which the segmented image is displayed. The area where the weed was placed.

Figure 13 illustrates the test result for a single image of the image acquisition. In (A), an image with two weeds is shown. In (B), two weeds were segmented with a high-quality border corresponding to the image in (A). The green dots in the center of the blue segmented regions are the references (location coordinates) for the Cartesian manipulator, as described in

Section 2.6.4. (C) shows the weeds in the field of view of the camera and the spray nozzle.

Figure 14 shows a sequence of four images. The upper-left partial image (Frame: 189) is an image without weeds. The remaining images (frame: 224, frame: 226, and frame: 241) show the image with the weeds (input) and the corresponding segmentation results (output). The blue segmented areas had high shape similarity with the corresponding weed image. The green dots indicating the center of gravity of the weeds are clearly visible in the center of each segmented area. Thus, these results show the good accuracy of the computer-vision model.

The computer-vision model was used in the Jetson Nano device to determine the reference position of the weeds for mechanism control (see

Section 2.6.3 and

Section 2.6.4). Given a set of weed references, the Cartesian manipulator positioned the nozzle on the particular weed and performed the spraying.

Figure 15 shows the exact positioning of the nozzle and the spray.

A video demonstration of the experiment result is available in the data-availability statement at the end of the manuscript.

3.5. Final Discussions

Taken together, these results provide important insights into the semantic segmentation accuracy and inference time performance of crop and weed detection when the necessary optimizations are conducted to the model to run it on edge devices. At the cost of worse segmentation performance, inference time can be dramatically increased, enabling real-time inference. The approach proposed in our study can render the inference time faster than that of the compared models even though it is a portable device, while the others are desktop-based. Compared to an approach with similar hardware and input size [

14], our proposed approach performed inference about 5 times faster. DeepLabV3 proved to be a very versatile model for segmentation tasks, since the trade-off between segmentation accuracy and inference time can be controlled by hyperparameters OS and DM.

In addition, fine tuning the model in the Cityscapes, PASCAL, and ADE20K datasets yielded good results. Cityscapes provided the marginally best performance compared to the PASCAL and ADE20K datasets. The results show that, when accuracy requirements are high, fine tuning with the pretrained Cityscape dataset is the best solution. If time inference is a requirement, then the best approach is to fine-tune with the pretrained Cityscape or ADE20k dataset, since both achieved the same accuracy performance. In the latter case, it is recommended to fine-tune with the PASCAL dataset if Cityscape and ADE20k are not available. Real-time application for weed spraying was also accurate and feasible. The segmentation model embedded in the edge device provided all the information (position references) needed to control the mechanism. According to the video demonstration, the mechanism precisely positioned the nozzle at all target weeds and applied the spray.

4. Conclusions

Edge devices play an important role when mobility is required. Computer-vision models running on such devices must be optimized due to the device’s limitations in terms of memory and computation. There are many studies and proposals for the optimization of deep learning models, but there is still a lack of research on how the performance of the models is affected by optimization. Moreover, there are not yet many real-world use cases of computer vision and its interaction with mechanisms in the domain of agriculture.

In this work, the optimization of the semantic segmentation model for weed was investigated, and its effects on inference time and segmentation performance were studied. The procedure can be described by using crop and weed images for training and validating the model; the procedure was applied for training the DeeplabV3 semantic segmentation model with the fine-tuning approach. Model optimization was performed before and after training by selecting different model hyperparameters and applying model quantization. Lastly, the performance of the model was evaluated.

Experimental results show that, by using hyperparameters DM = 0.5 and OS = 32 in the CNN backbone, the computational cost of the model was reduced from 81.9 to 4.4 GFLOPs. On the Jetson Nano device, the best inference time of the model was 0.17 s. Compared to the baseline model (i.e., the model without optimization), the inference time was accelerated by a factor of 14.8, while the segmentation performance (mIOU) was decreased by 14.7%. This result illustrates the potential of the optimizations for building lightweight models that still have good predictive accuracy.

Since the technique of fine tuning is important when only a small amount of training data is available, the effects of fine tuning on pretrained models were investigated. With respect to the PASCAL and ADE20K datasets, Cityscapes achieved the marginally best performance.

An extension of this work is to propose a practical application using the weed segmentation model presented in this study, an edge device, and a spraying mechanism. The results show that the proposed method is feasible, and has good accuracy and potential for weed control.

The limitation of this study was that the Cartesian robot manipulator operates in only one axis, while in practice, the other axis motion is the translational motion performed by the robot wheels. Since the practical application was carried out in a simulated environment (laboratory), the main objective of future work is to develop a complete system to study the performance of weed control in a real agricultural environment.

The results presented in this study demonstrate the potential of using lightweight models and portable edge devices for the real-time semantic segmentation of weeds.