InSAR Modeling and Deformation Prediction for Salt Solution Mining Using a Novel CT-PIM Function

Abstract

:1. Introduction

2. Materials and Methods

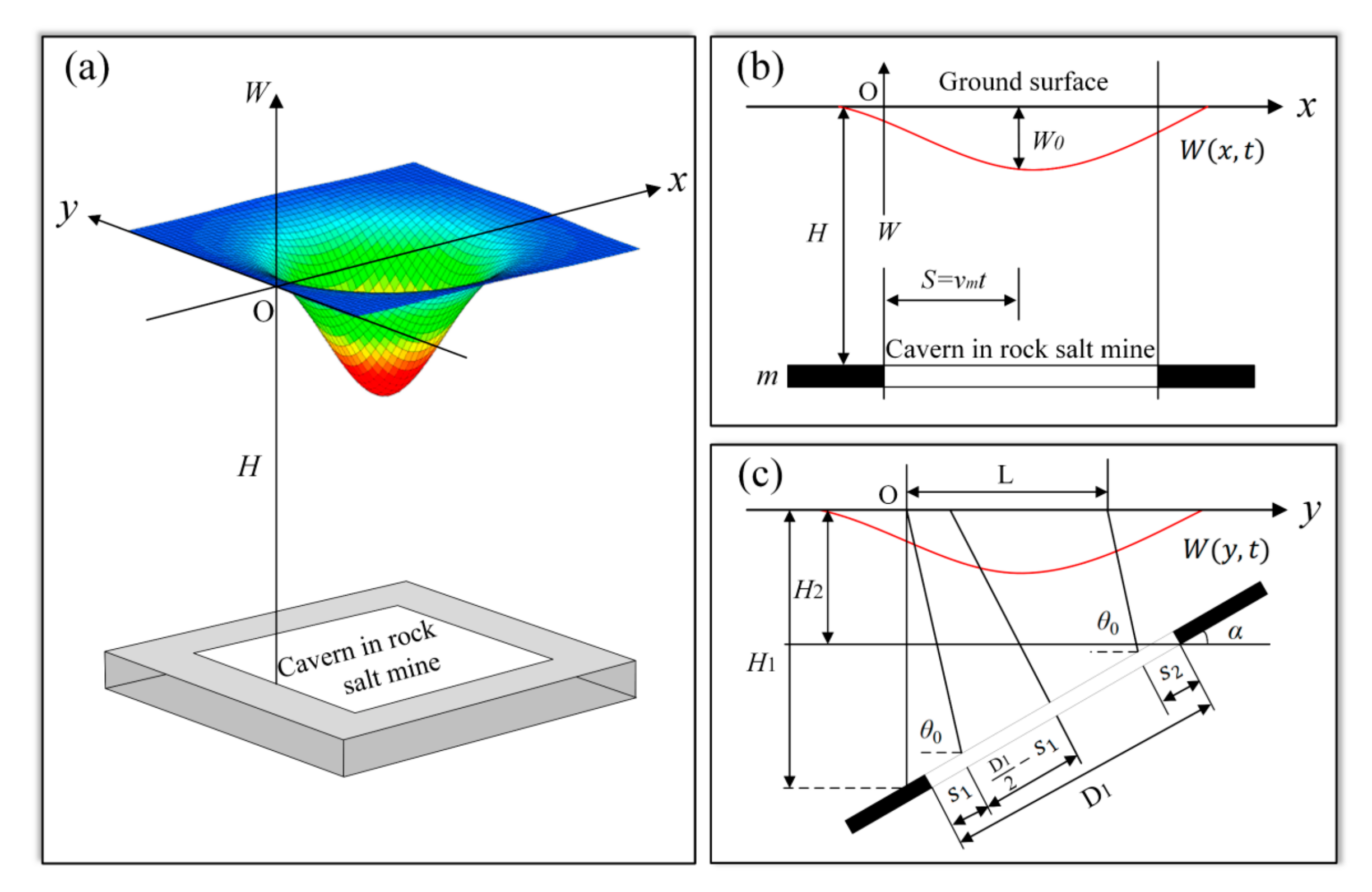

2.1. Dynamic Coordinate-Time Probability Integration Model

- (1)

- When the dip direction of the working face is under critical extraction, whereas the strike is under subcritical extraction. This happens in the practical condition that the advancing distance is longer than the depth along the dip direction. The ground subsidence can be written as (the schematic diagram is shown as Figure 1b) [23]:where can be calculated based on the principles of static PIM following the equation: ; is a probability integral function: (where is the integral parameter, is the main influence radius, ; is the mining depth and is the tangent of the main influence angle); is the starting distance, describing the advancing distance of the working face when the ground point starts to move; is the starting factor; is the static leading influence angle (in degrees); is the mining advancing speed; and the coefficients and can be expressed as and , respectively.

- (2)

- When the strike direction of working face is under critical extraction, whereas the dip is under subcritical extraction. This happens in the most practical condition of the coal mining activities, since the strike direction is better to contain a longer advancing distance (even up to several kilometers, much deeper than the depth along the strike), which can easily satisfy the critical extraction condition. The surface subsidence can be written as (the schematic diagram is shown as Figure 1c) [16]:where denotes the vertical coordinate of the ground point in the mining area; and represent the main influence radius along the down-dip, and up-dip directions, respectively, which can be expressed as and . and are the mining depths along the down-dip, and up-dip directions, respectively. Here, and ; is the estimated length of strike working face, which can be expressed as ; is the inclined length of working face; and are the offsets of inflection point along down-dip and up-dip directions of the working panel; is the mining influence angle, which can be calculated following .

2.2. InSAR Modeling Based on CT-PIM (InSAR-CTPIM)

2.3. CT-PIM Parameters Estimation Based on InSAR Phases

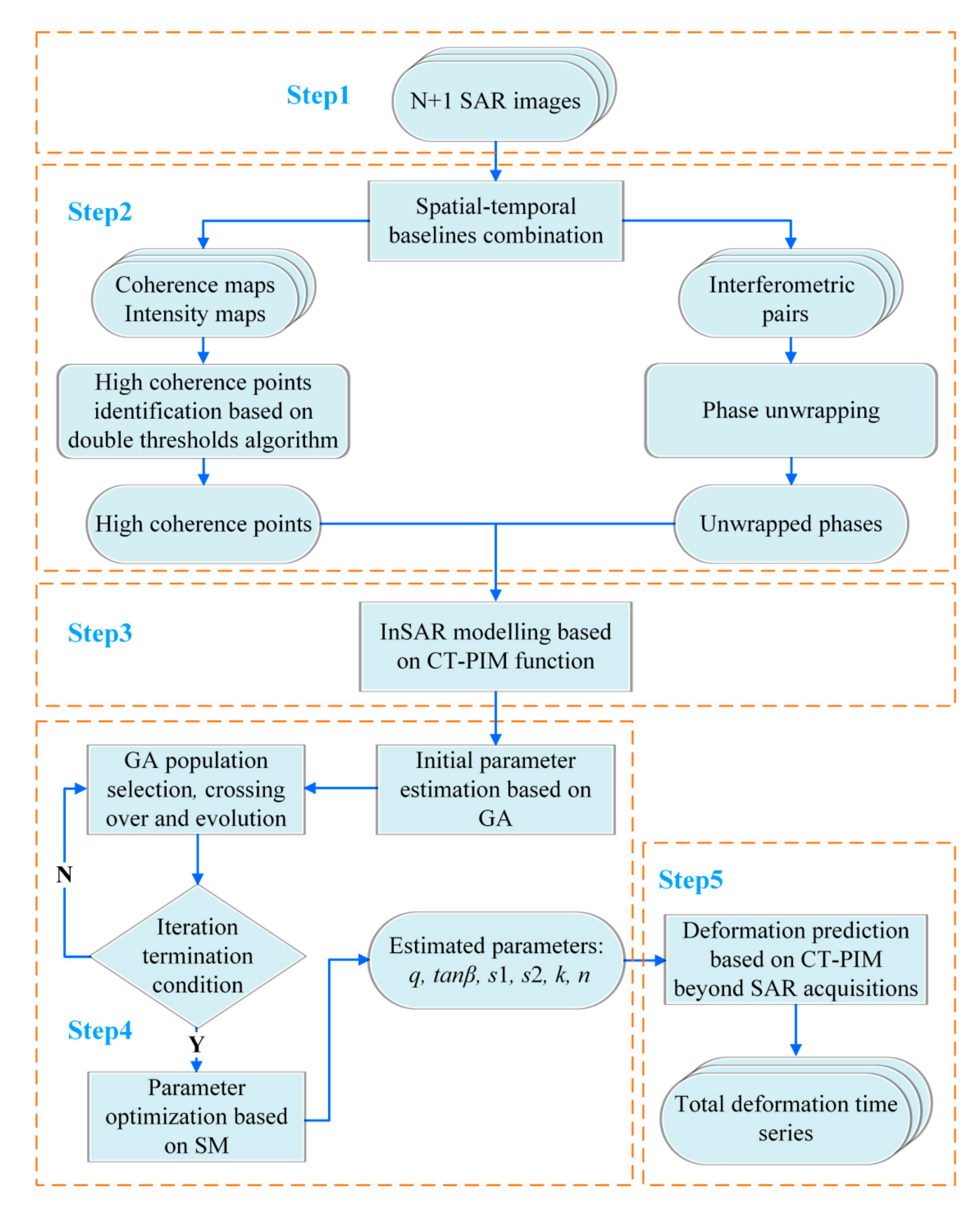

2.4. Flow Chart and Processing Steps

- Differential Interferometry according to the SAR images covering the study area.

- High-coherent candidates extraction considering both the average coherence and the amplitude dispersion index.

- InSAR modeling following the CT-PIM function, which establishes the functional relationship between InSAR phases and unknown PIM parameters.

- Forward dynamic subsidence prediction beyond the spans of SAR acquisitions based on CT-PIM function introduced as Equation (1).

3. Results

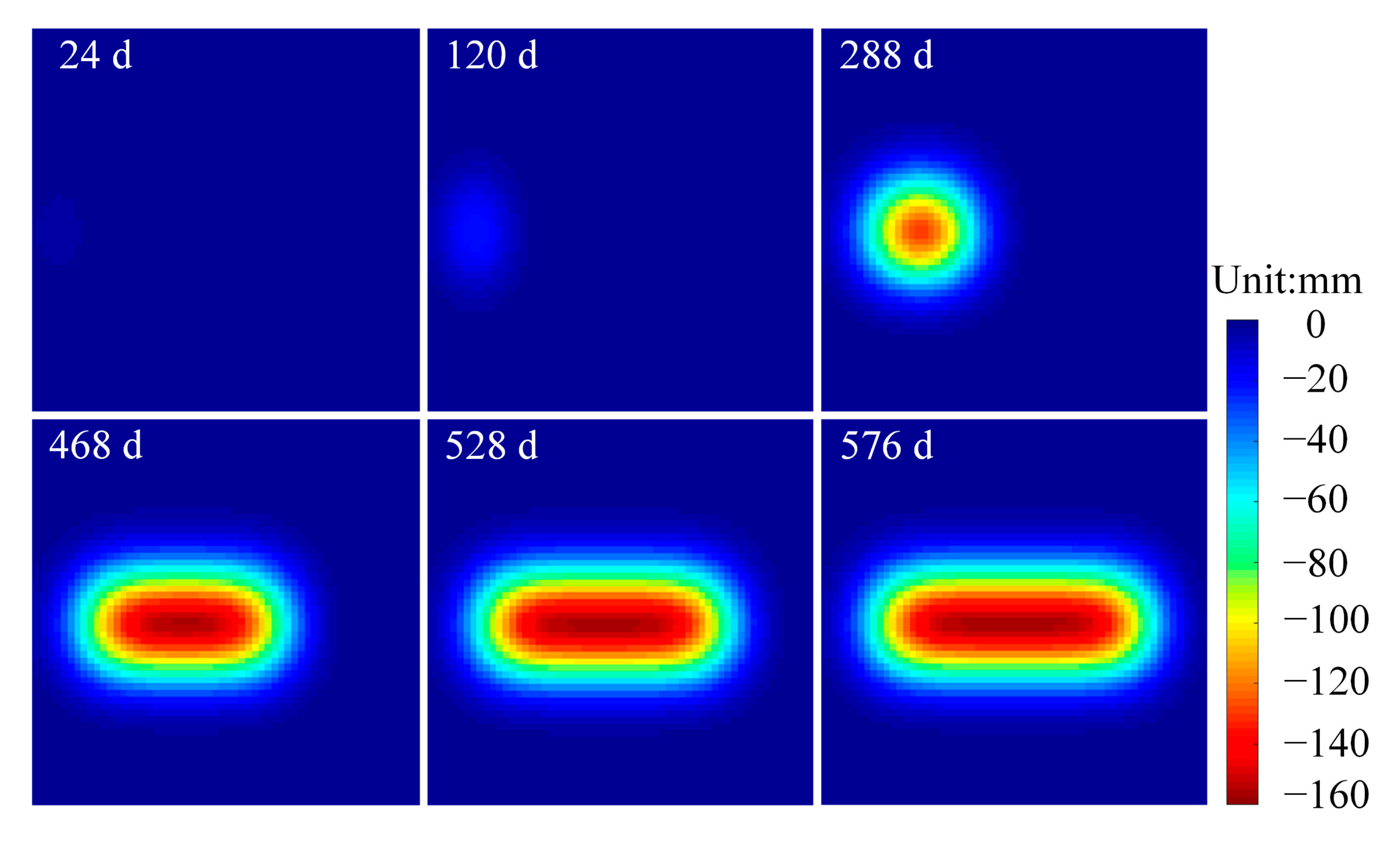

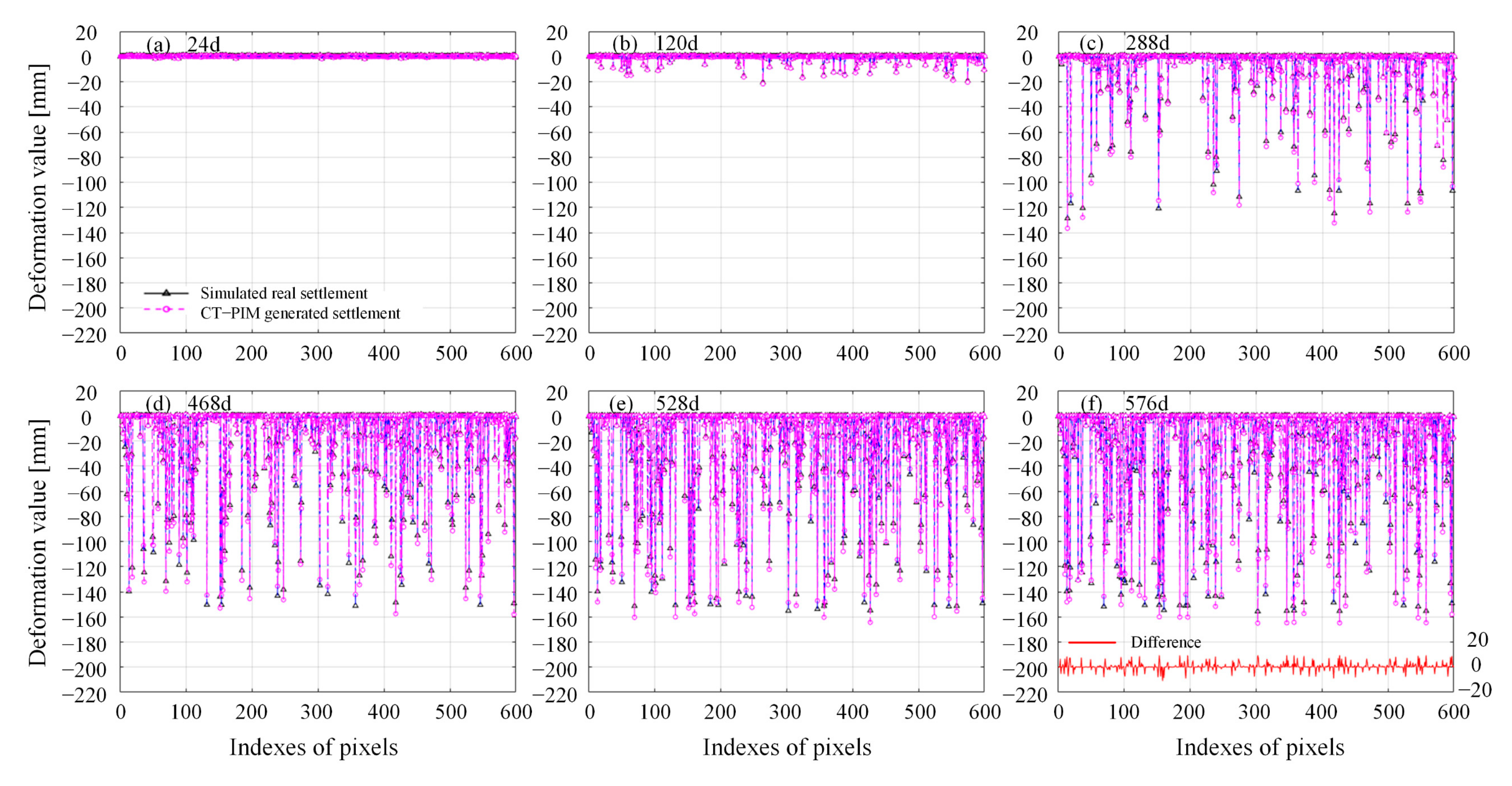

3.1. Simulated Experiment

3.2. Real Data Experiment

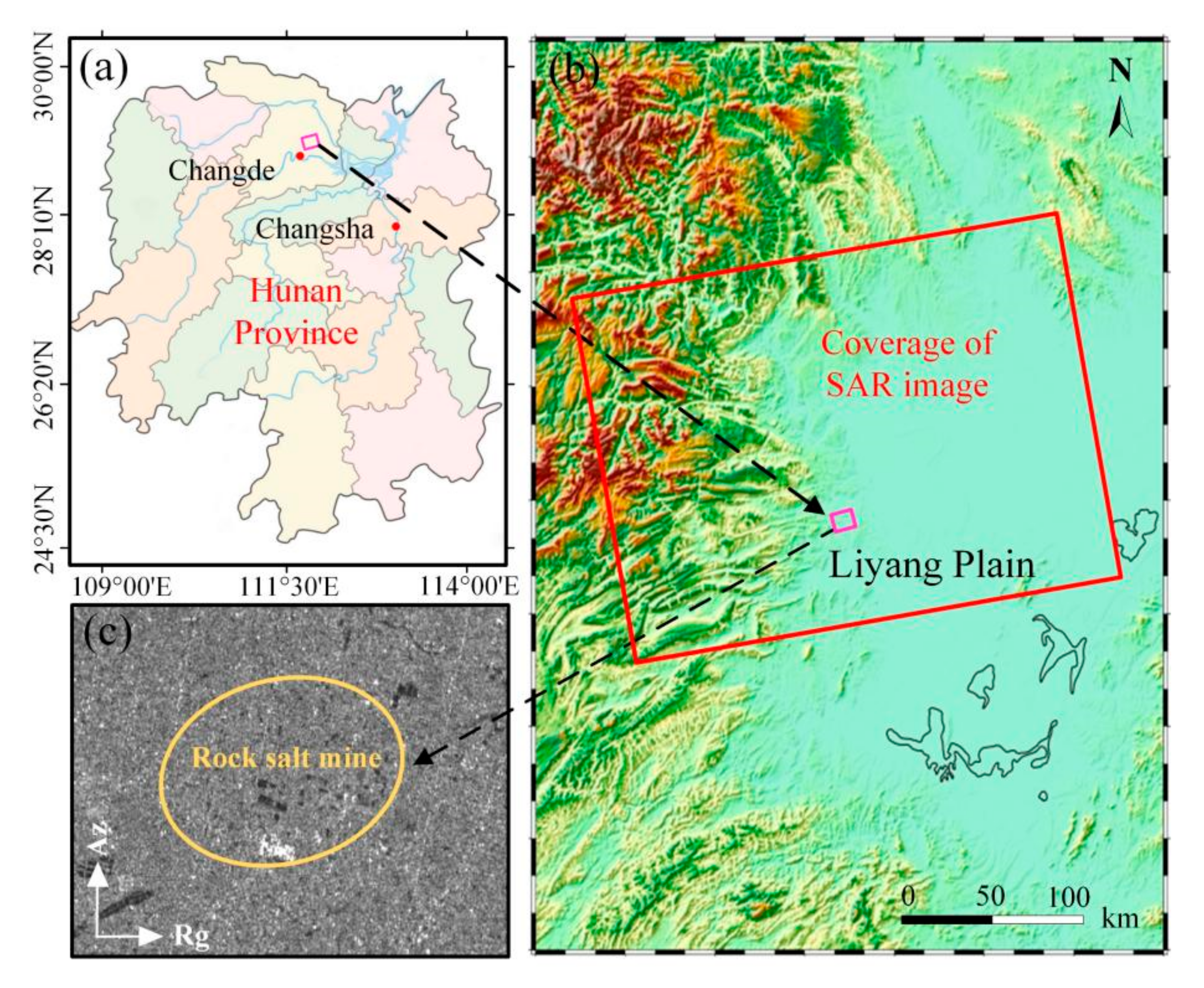

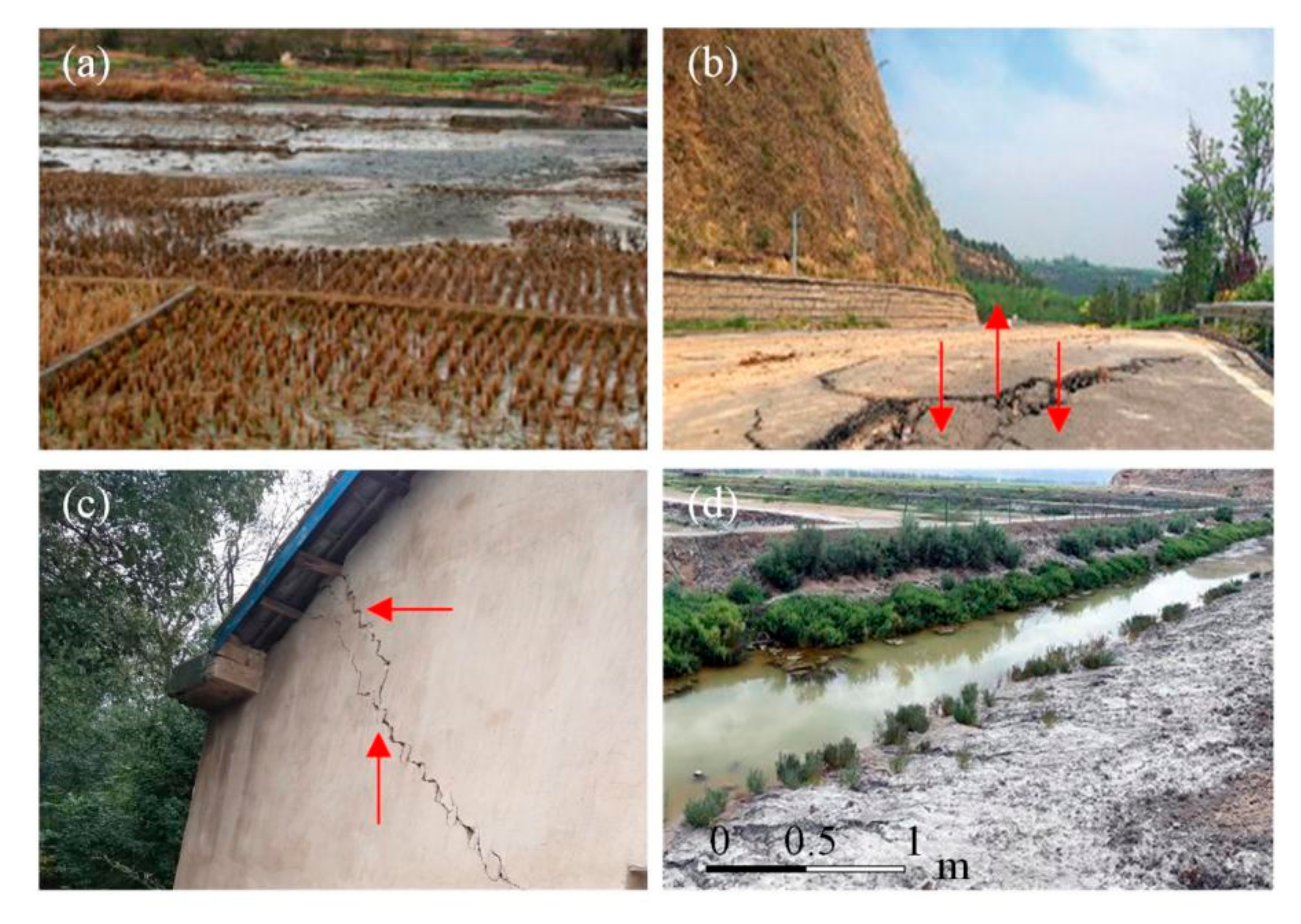

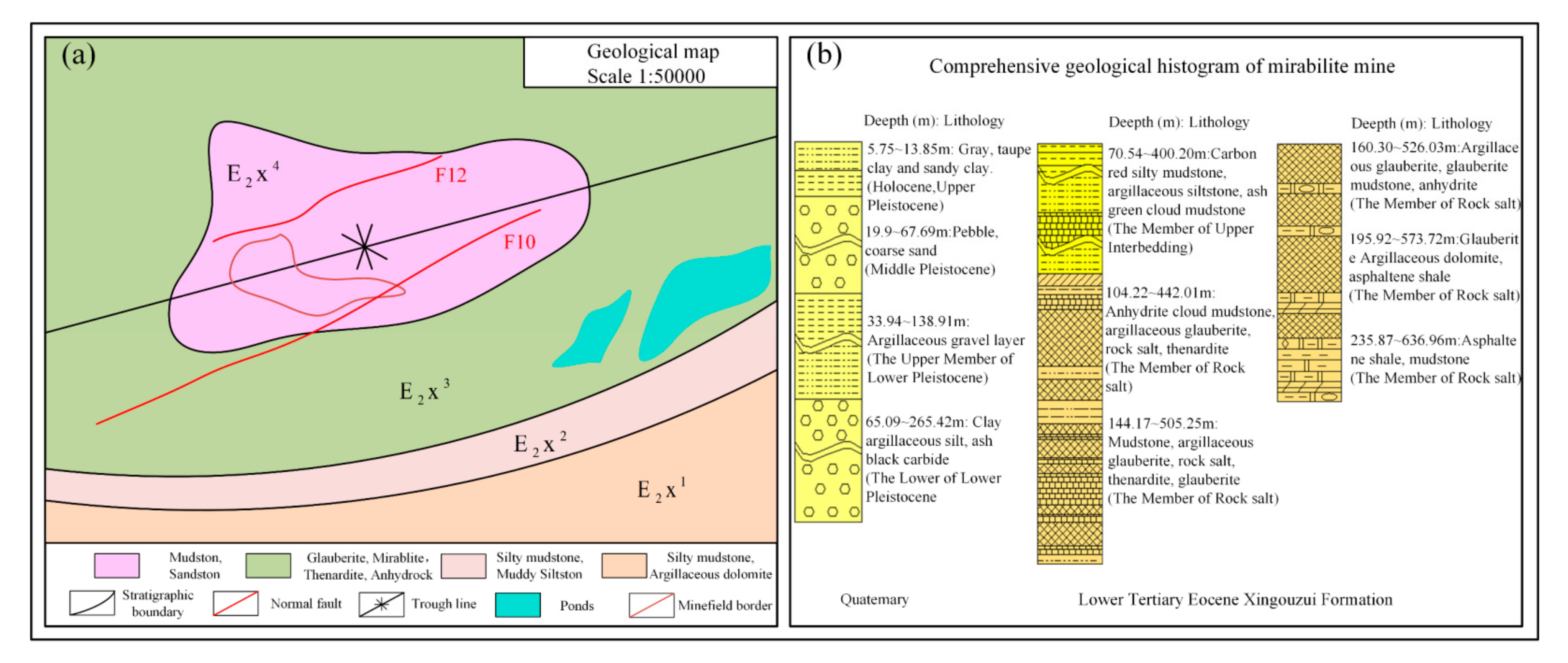

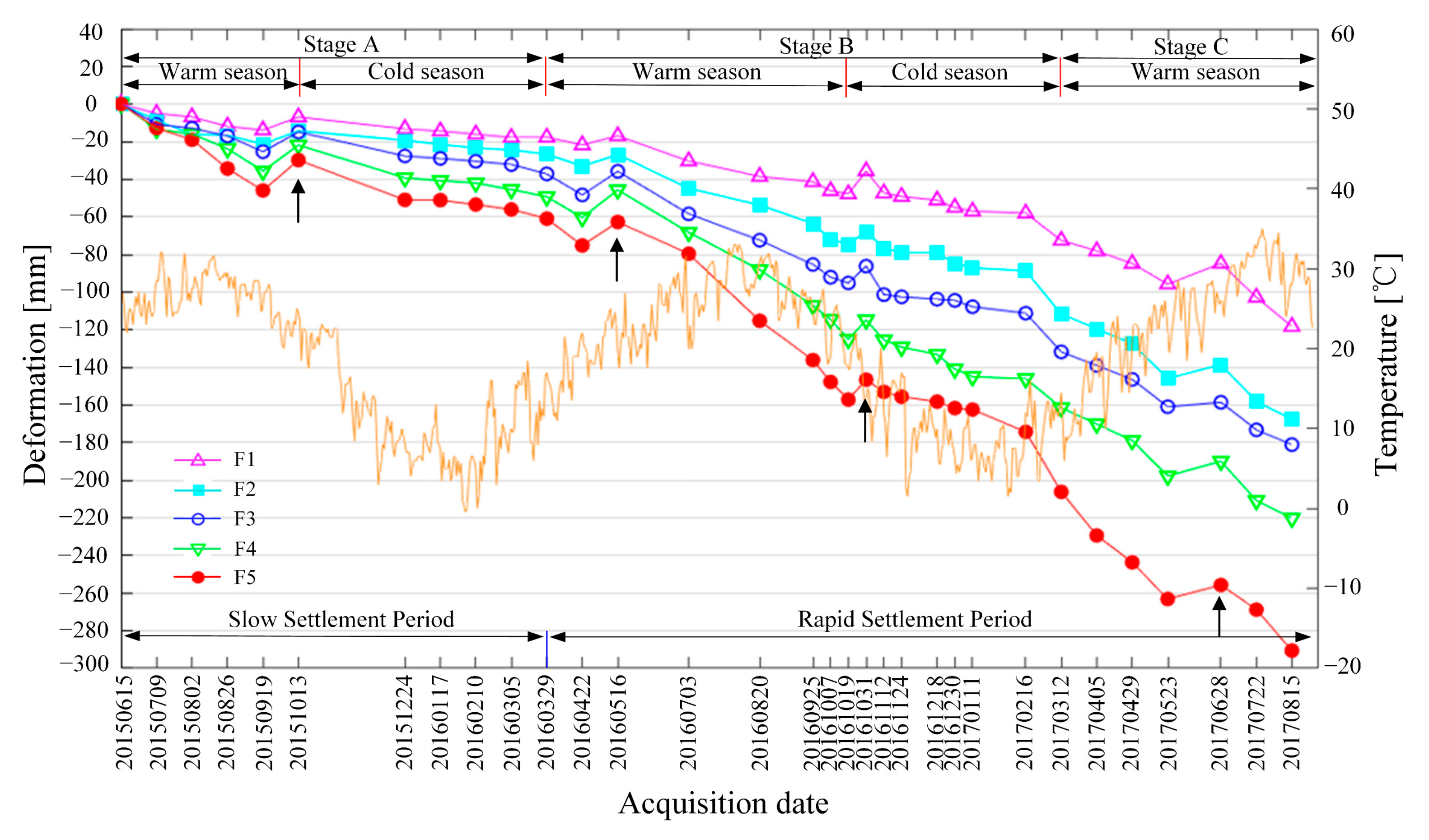

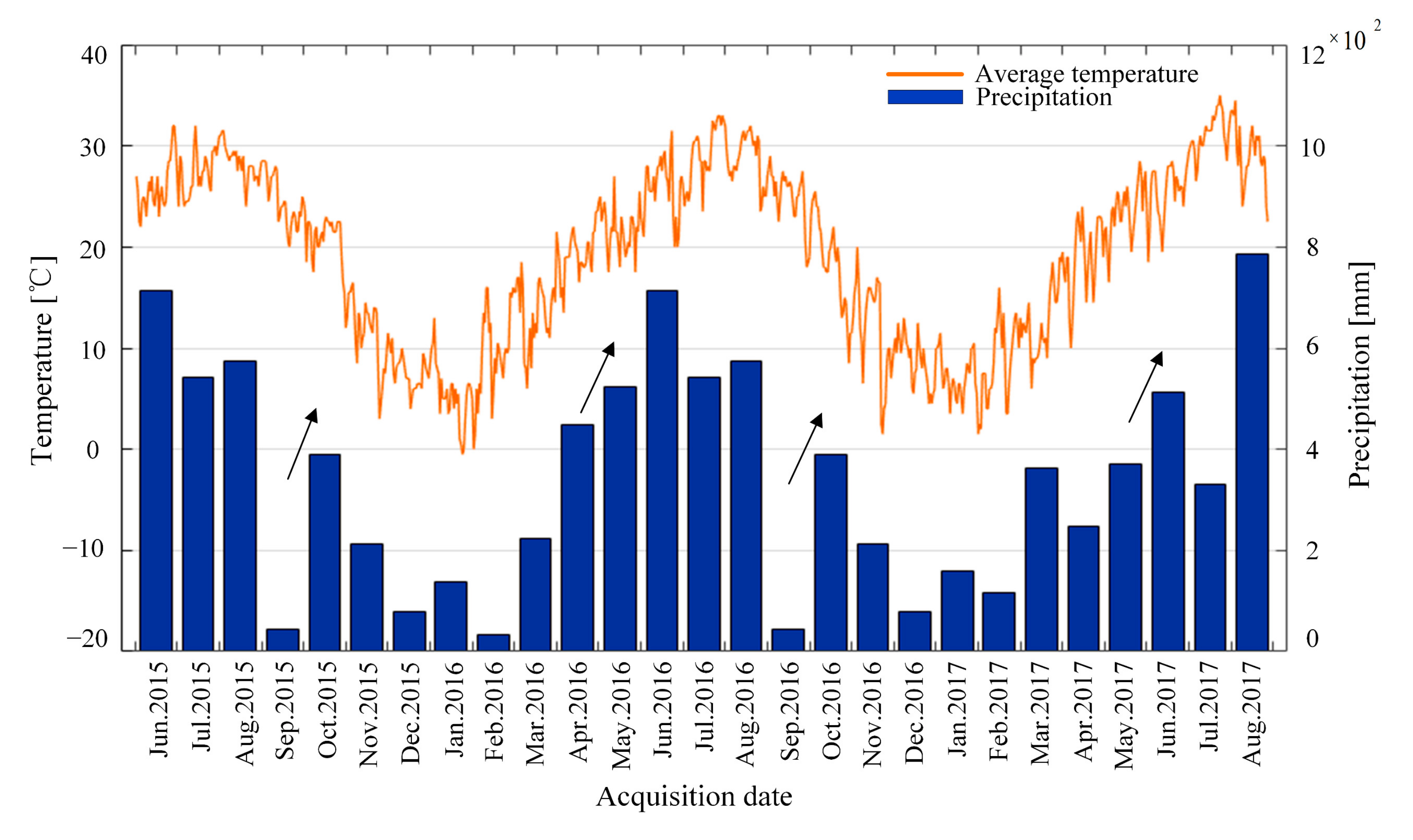

3.2.1. Study Area and SAR dataset

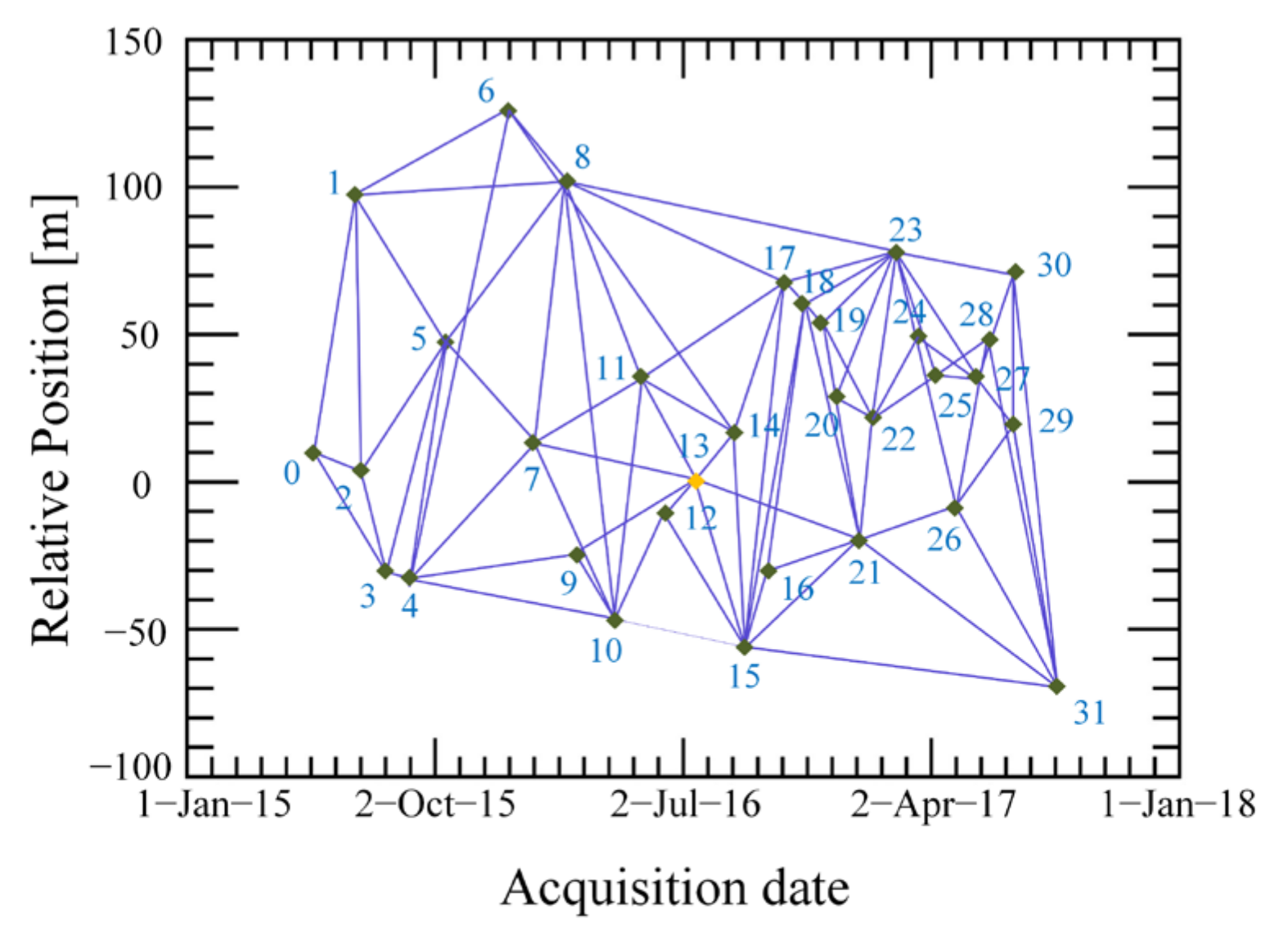

3.2.2. SAR Data Acquisition and Preprocessing

3.2.3. PIM Parameter Estimation Based on InSAR-CTPIM

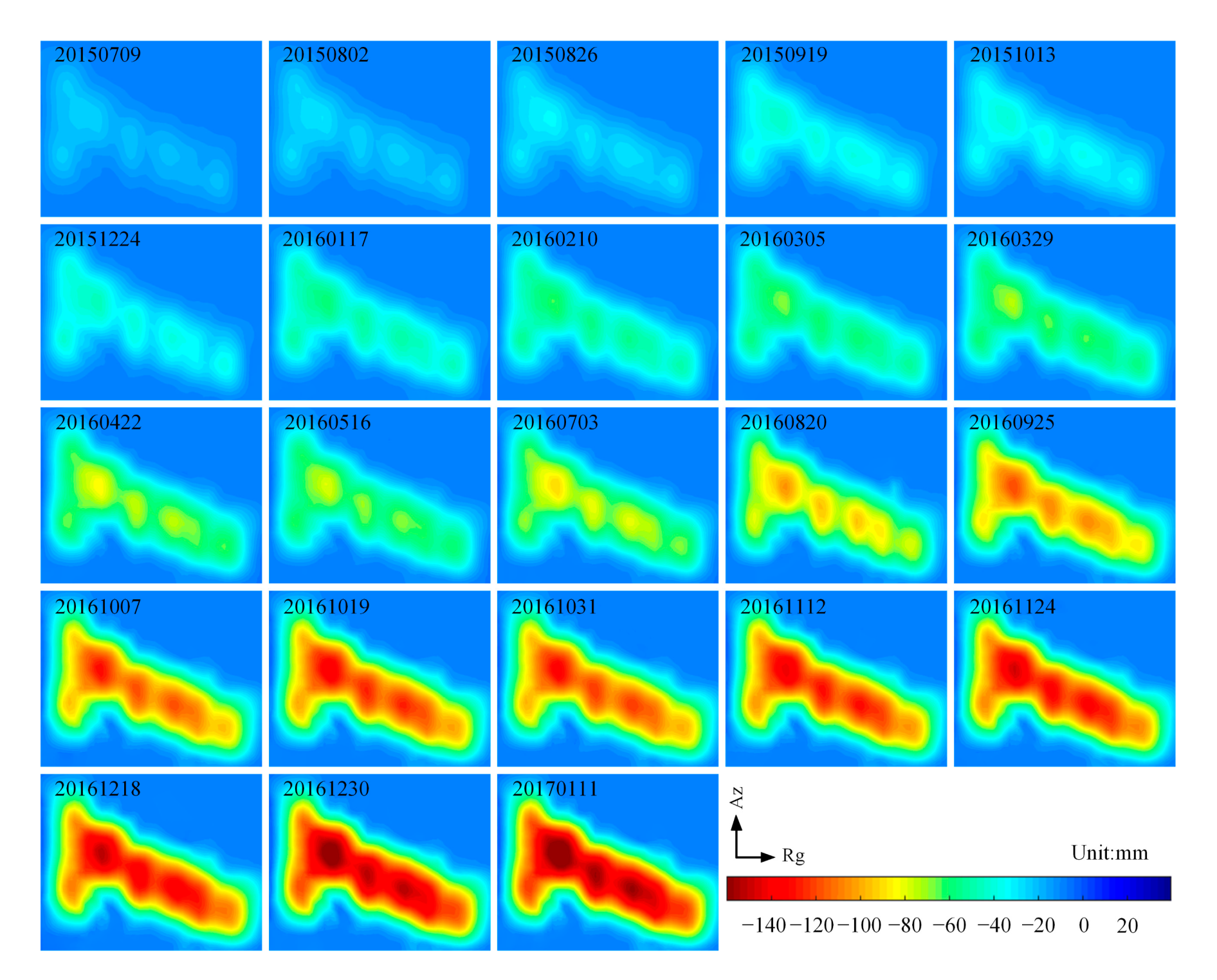

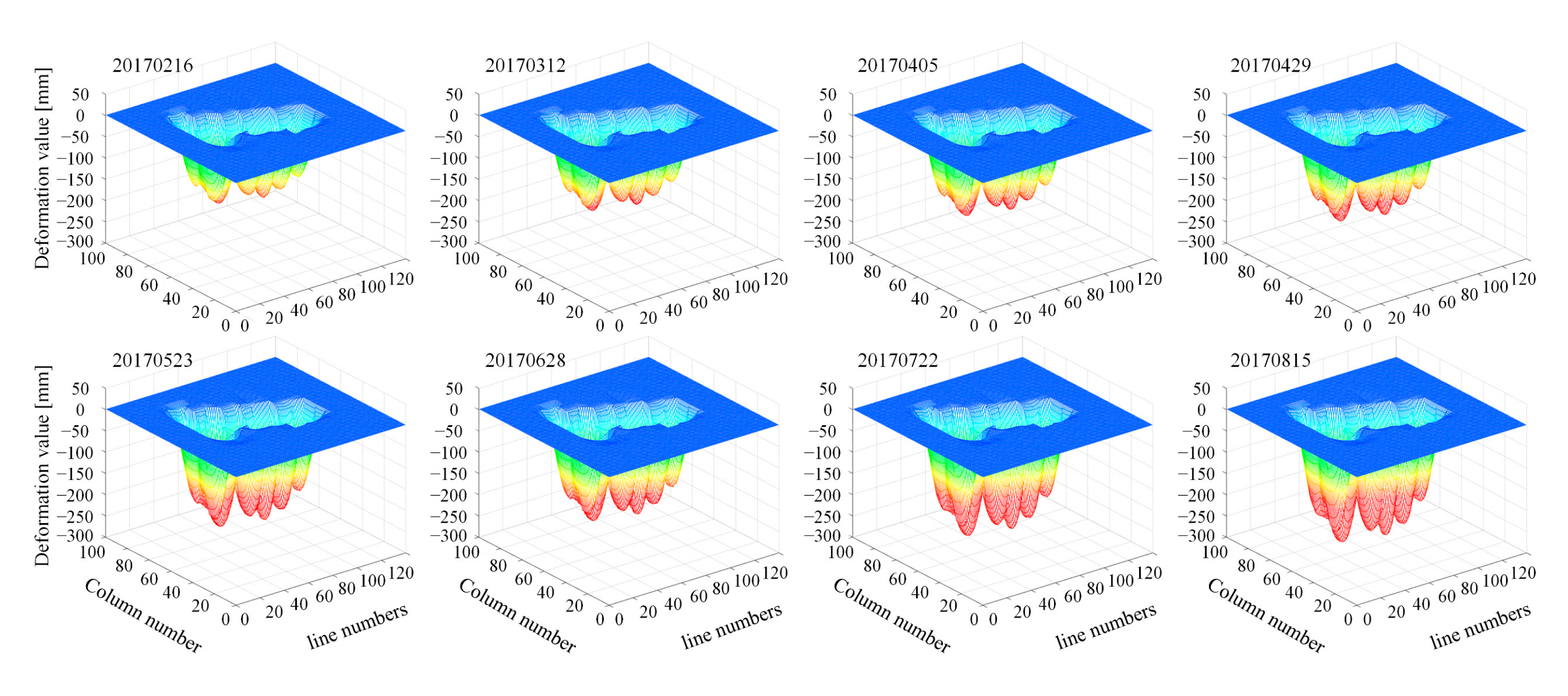

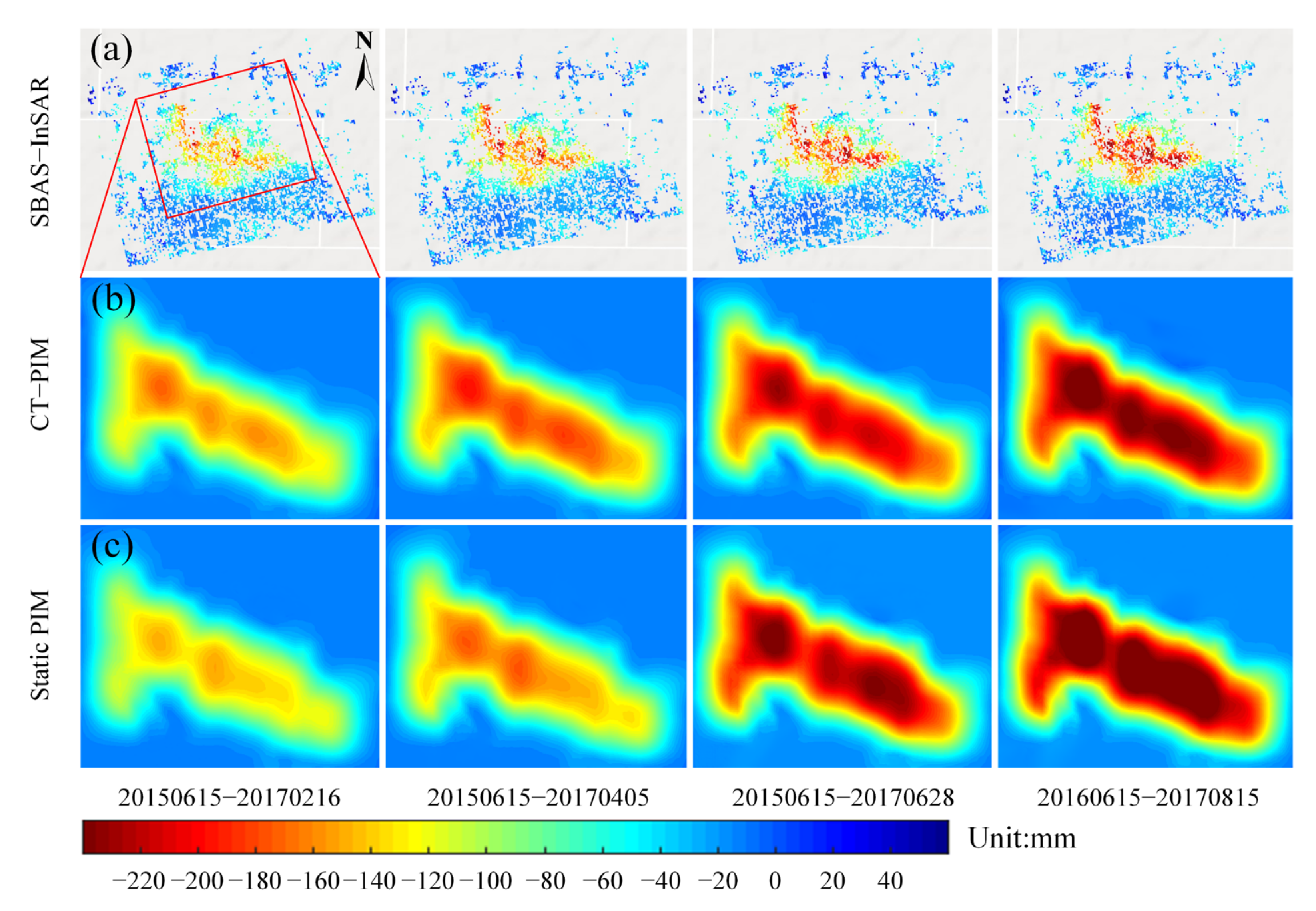

3.2.4. Deformation Prediction Based on CT-PIM

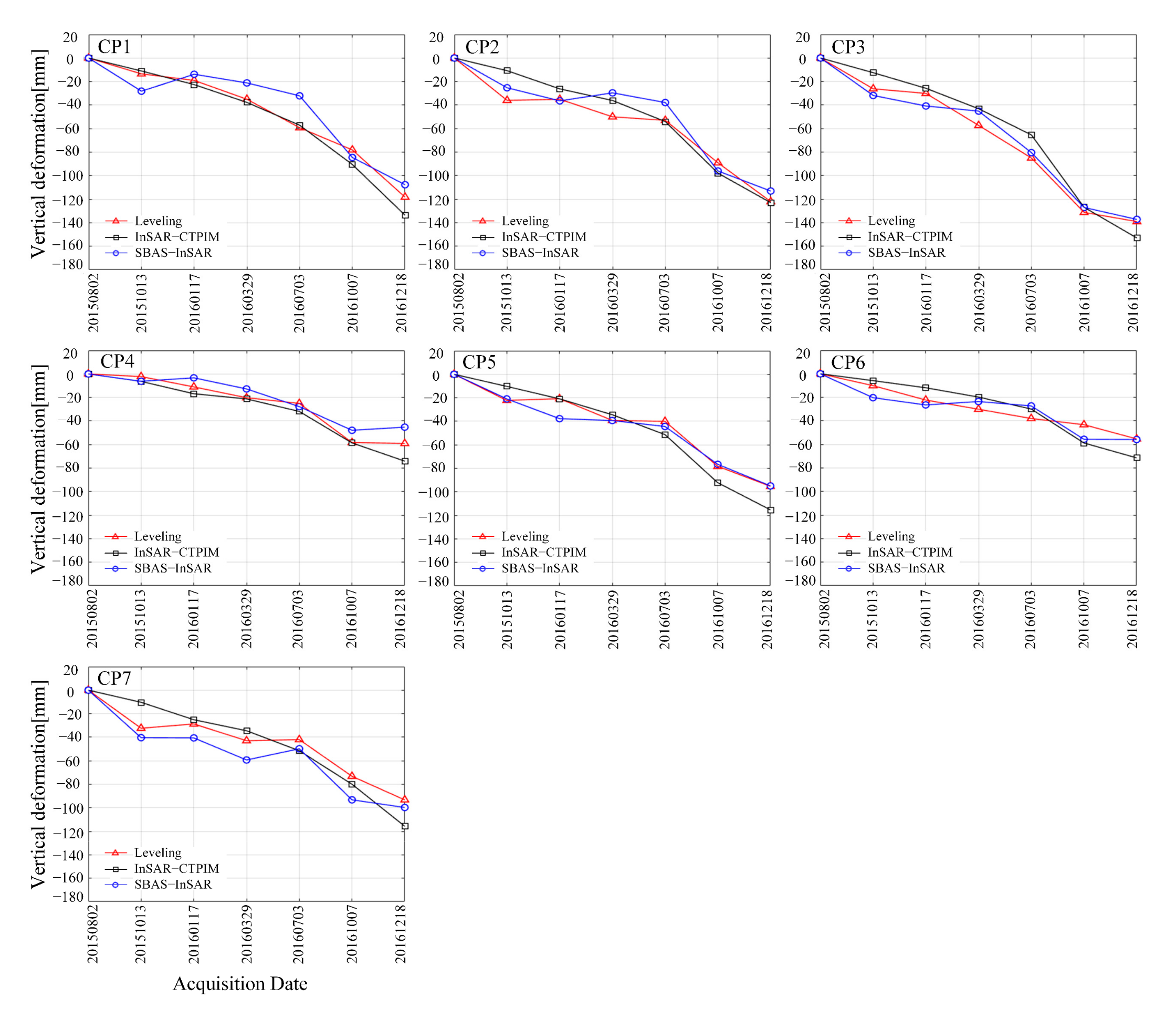

3.3. Accuracy Analysis

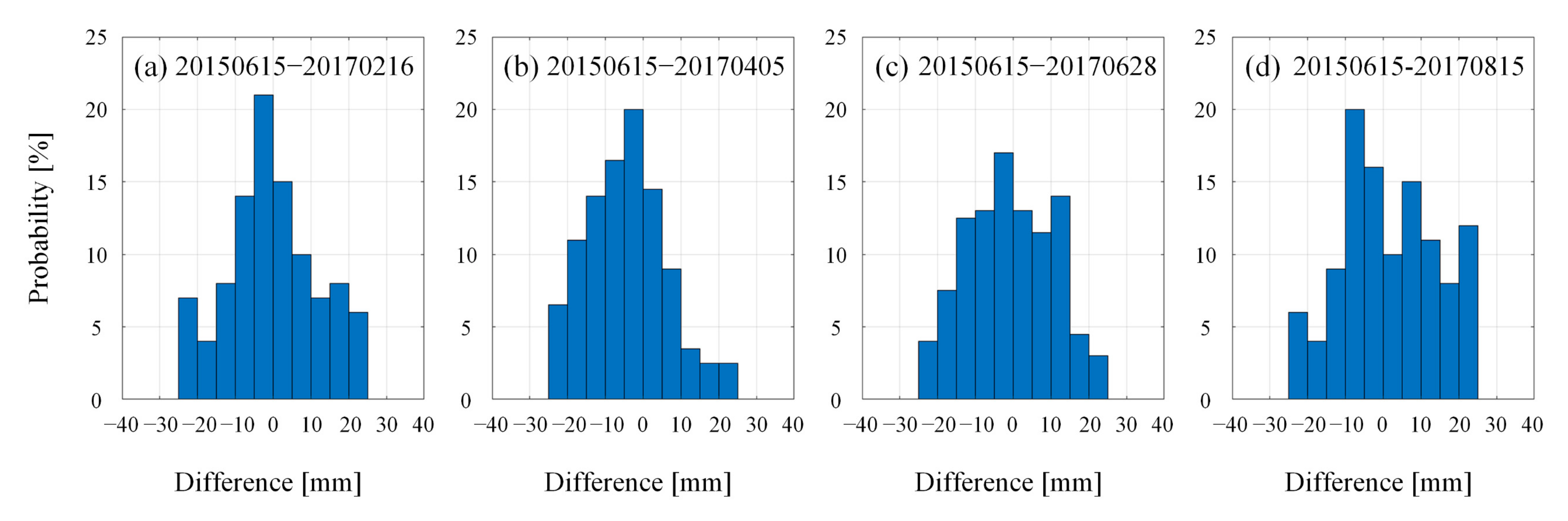

3.3.1. Accuracy Evaluation for InSAR-CTPIM Monitored Subsidence

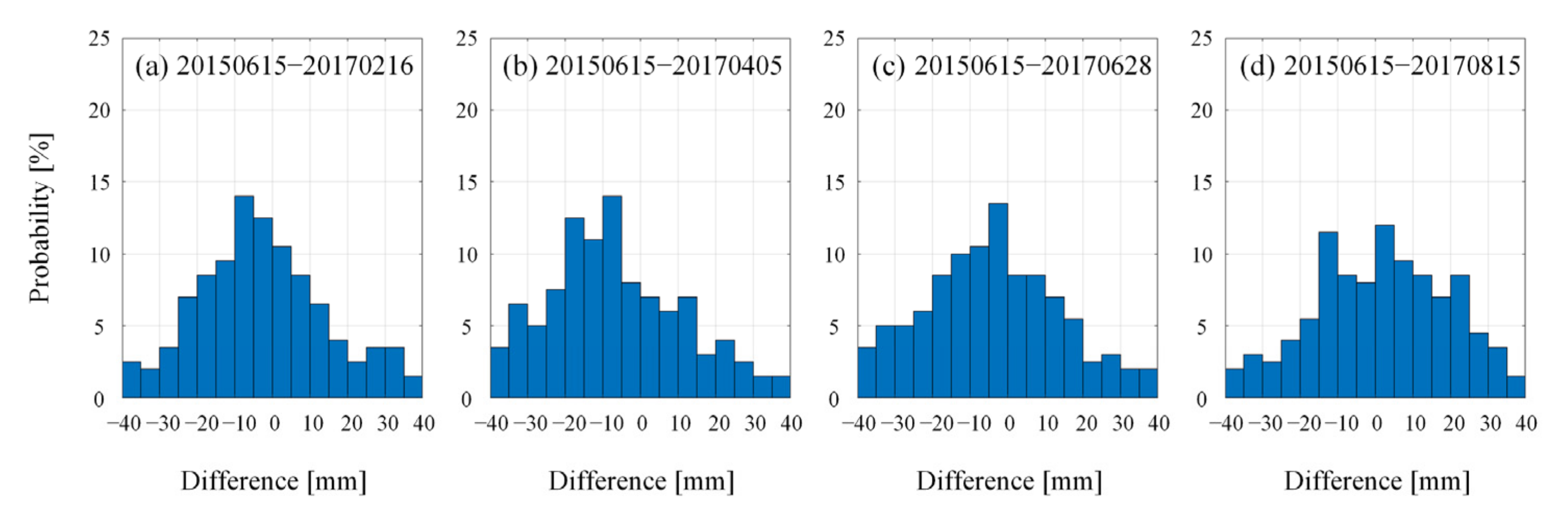

3.3.2. Accuracy Evaluation for CT-PIM Predicted Subsidence

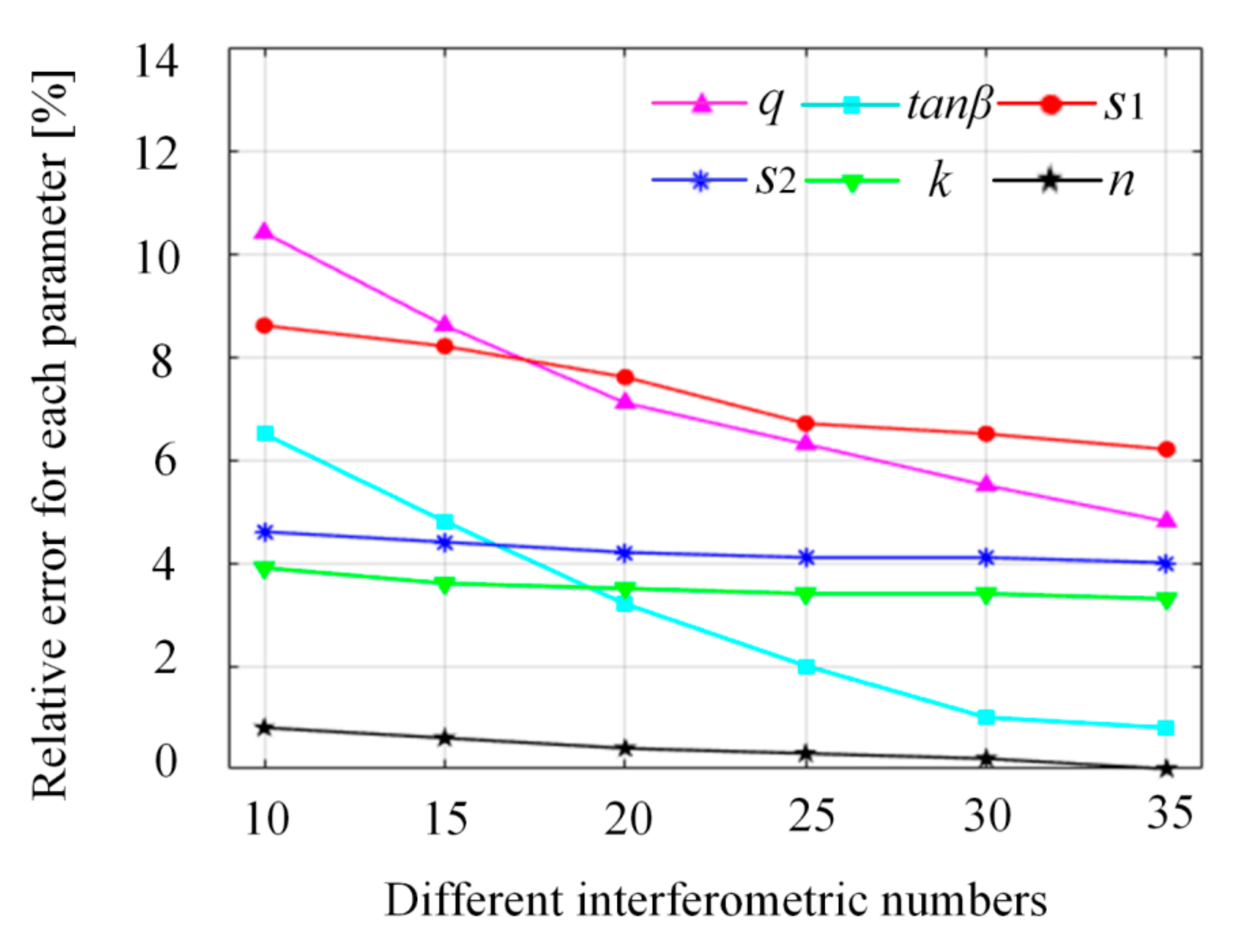

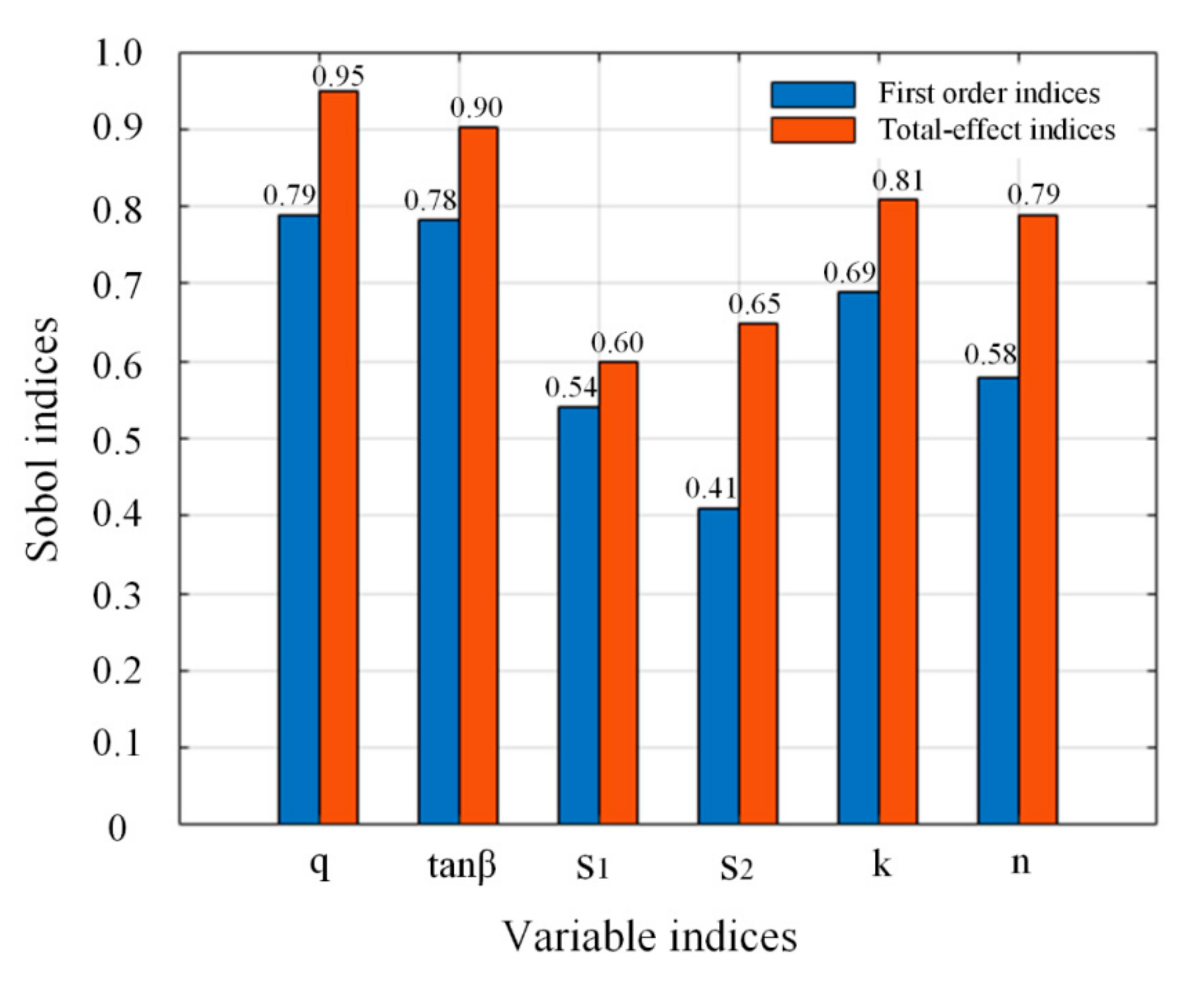

3.3.3. Sensitivity Analysis on CT-PIM Parameters

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Natural Resources. China Mineral Resources Report; Geological Publishing House: Beijing, China, 2019; pp. 2–6. [Google Scholar]

- Zhang, M.G.; Wang, Z.S.; Wang, L.J.; Chen, Y.L.; Wu, Y.; Ma, D.; Zhang, K. Mechanism of collapse sinkholes induced by solution mining of salt formations and measures for prediction and prevention. Bull. Eng. Geol. Environ. 2019, 78, 1401–1415. [Google Scholar] [CrossRef]

- Buchignani, V.; Avanzi, G.D.; Giannecchini, R.; Puccinelli, A. Evaporite karst and sinkholes: A synthesis on the case of Camaiore (Italy). Environ. Geol. 2008, 53, 1037–1044. [Google Scholar] [CrossRef]

- Solari, L.; Montalti, R.; Barra, A.; Monserrat, O.; Crosetto, M. Multi-temporal satellite interferometry for fast-motion detection: An application to salt solution mining. Remote Sens. 2020, 12, 3919. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, G.; Weingarten, M.; Niu, Y. InSAR evidence indicates a link between fluid injection for salt mining and the 2019 Changning (China) earthquake sequence. Geophys. Res. Lett. 2020, 47, e2020GL087603. [Google Scholar] [CrossRef]

- Furst, S.L.; Doucet, S.; Vernant, P.; Champollion, C.; Carme, J.L. Monitoring surface deformation of deep salt mining in vauvert (france), combining InSAR and leveling data for multi-source inversion. Solid Earth 2021, 12, 15–34. [Google Scholar] [CrossRef]

- Jung, J.; Kim, D.J.; Vadivel, P.S.K.; Yun, S.H. Long-term deflection monitoring for bridges using X and C-Band time-series SAR interferometry. Remote Sens. 2019, 11, 1258. [Google Scholar] [CrossRef] [Green Version]

- Tosti, F.; Gagliardi, V.; D’Amico, F.; Alani, A.M. Transport infrastructure monitoring by data fusion of GPR and SAR imagery information. Transp. Res. Procedia 2020, 45, 771–778. [Google Scholar] [CrossRef]

- Gagliardi, V.; Bianchini Ciampoli, L.; Trevisani, S.; D’Amico, F.; Alani, A.M.; Benedetto, A.; Tosti, F. Testing Sentinel-1 SAR interferometry data for Airport Runway monitoring: A Geostatistical Analysis. Sensors 2021, 21, 5769. [Google Scholar] [CrossRef]

- Zheng, M.; Deng, K.; Fan, H.; Du, S. Monitoring and analysis of surface deformation in mining area based on InSAR and GRACE. Remote Sens. 2018, 10, 1392. [Google Scholar] [CrossRef] [Green Version]

- Xiao, L.; He, Y.G.; Xing, X.M.; Wen, D.B.; Tong, C.G.; Chen, L.F.; Yu, X.Y. Time series subsidence analysis of drilling solution mining rock salt mines based on Sentinel-1 data and SBAS-InSAR technique. Int. J. Remote Sens. 2019, 23, 501–513. [Google Scholar]

- Ma, T.; Zhao, Y.J.; Zhang, W. Application of SBAS-InSAR technology in settlement monitoring of mining area. Geom. Spat. Inf. Tech. 2020, 11, 210–212. [Google Scholar]

- Chen, Y.; Tong, Y.X.; Tan, K. Coal mining deformation monitoring using SBAS-InSAR and offset tracking: A case study of Yu County, China. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2020, 13, 6077–6087. [Google Scholar] [CrossRef]

- Yang, Z.F.; Li, Z.W.; Zhu, J.J.; Hu, J.; Wang, Y.J.; Chen, G.L. InSAR-Based model parameter estimation of probability integral method and its application for predicting mining-induced horizontal and vertical displacements. IEEE Trans. Geosci. Remote Sens. 2016, 54, 4818–4832. [Google Scholar] [CrossRef]

- Fan, H.; Lu, L.; Yao, Y. Method combining probability integration model and a small baseline subset for time series monitoring of mining subsidence. Remote Sens. 2018, 10, 1444. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.J. A Mining Monitoring Method Based on InSAR Technology. Chinese Patent ZL201310011306.2, 8 May 2013. [Google Scholar]

- Li, Z.W.; Yang, Z.F.; Zhu, J.J.; Hu, J.; Wang, Y.J.; Li, P.X.; Chen, G.L. Retrieving three-dimensional displacement fields of mining areas from a single InSAR pair. J. Geod. 2015, 89, 17–32. [Google Scholar] [CrossRef]

- Yang, Z.F.; Li, Z.W.; Zhu, J.J.; Preusse, A.; Yi, H.W.; Wang, Y.J.; Papst, M. An extension of the InSAR-Based probability integral method and its Application for Predicting 3-D Mining-Induced Displacements Under Different Extraction Conditions. IEEE Trans. Geosci. Remote Sens. 2017, 55, 3835–3845. [Google Scholar] [CrossRef]

- Yang, Z.F.; Li, Z.W.; Zhu, J.J.; Feng, G.C.; Wang, Q.J.; Hu, J.; Wang, C.C. Deriving time-series three-dimensional displacements of mining areas from a single-geometry InSAR dataset. J. Geod. 2018, 92, 529–544. [Google Scholar] [CrossRef]

- Xing, X.M.; Zhu, Y.K.; Yuan, Z.H.; Xiao, L.; Liu, X.B.; Chen, L.F.; Xia, Q.; Liu, B. Predicting mining-induced dynamic deformations for drilling solution rock salt mine based on probability integral method and weibull temporal function. Int. J. Remote Sens. 2020, 42, 639–671. [Google Scholar] [CrossRef]

- Wang, L.Y.; Deng, K.Z.; Zheng, M.N. Research on ground deformation monitoring method in mining areas using the probability integral model fusion D-InSAR, sub-band InSAR and offset-tracking. Int. J. Appl. Earth Obs. 2020, 85, 101981. [Google Scholar] [CrossRef]

- Xing, X.M.; Xiao, L.; Bao, L.; Chen, L.F.; Yuan, Z.H. An InSAR Prediction Method for Mining Subsidence in Drilling Water-Soluble Salt Mines. Chinese Patent ZL201910168502.8, 16 March 2021. [Google Scholar]

- Zhu, G.Y.; Shen, H.X.; Wang, L.G. Study of dynamic prediction function of surface movement and deformation. Chin. J. Rock Mech. Eng. 2011, 30, 1889–1895. [Google Scholar]

- Berardino, P.; Fornaro, G.; Lanari, R.; Sansosti, E. A new algorithm for surface deformation monitoring based on small baseline differential SAR interferograms. IEEE Trans. Geosci. Remote Sens. 2002, 40, 2375–2383. [Google Scholar] [CrossRef] [Green Version]

- Lauknes, T.R.; Zebker, H.A.; Larsen, Y. InSAR Deformation Time Series Using an L1-Norm Small-Baseline Approach. IEEE Trans. Geosci. Remote Sens. 2010, 49, 536–546. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Deng, K.Z.; Gao, X.X.; Niu, H.P. Monitoring and analysis of surface subsidence in mining areas based on SBAS-InSAR. Geom. Inf. Sci. Wuhan Univ. 2018, 43, 1531–1537. [Google Scholar]

- Zhang, Y.; Meng, X.M.; Jordan, C.; Novellino, A.; Dijkstra, T.; Chen, G. Investigating slow-moving landslides in the Zhouqu region of China using InSAR time series. Landslides 2018, 5, 1299–1315. [Google Scholar] [CrossRef]

- Wang, Q.M. Water-Soluble Salt Mine Mining and Design; Chemical Industry Press: Beijing, China, 2016; pp. 46–71. [Google Scholar]

- Yao, L.; Sethares, W.A. Nonlinear parameter estimation via the genetic algorithm. IEEE Trans. Signal Process. 1994, 42, 927–935. [Google Scholar]

- Xing, X.M.; Chang, H.C.; Chen, L.F.; Zhang, J.H.; Yuan, Z.H.; Shi, Z.N. Radar Interferometry Time Series to Investigate Deformation of Soft Clay Subgrade Settlement—A Case Study of Lungui Highway, China. Remote Sens. 2019, 11, 429. [Google Scholar] [CrossRef] [Green Version]

- Tian, Y.G. Study on Genetic Algorithm for Nonlinear Least Squares Estimation; Wuhan University Press: Wuhan, China, 2003. [Google Scholar]

- Xiao, H.F.; Tan, G.Z. Study on Fusing Simplex Search into Genetic Algorithm. Comput. Eng. Appl. 2008, 44, 30–33. [Google Scholar]

- Yang, Z.F.; Li, Z.W.; Zhu, J.J.; Yi, H.W.; Feng, G.C. Deriving Dynamic Subsidence of Coal Mining Areas Using InSAR and Logistic Model. Remote Sens. 2017, 9, 125. [Google Scholar] [CrossRef] [Green Version]

- Duan, M.; Xu, B.; Li, Z.W.; Wu, W.H.; Liu, J.H. Adaptively selecting interferograms for SBAS-InSAR based on graph theory and turbulence atmosphere. IEEE Access 2020, 99, 112898–112909. [Google Scholar] [CrossRef]

- Goldstein, R.M.; Werner, C.L. Radar interferogram filtering for geophysical applications. Geophys. Res. Lett. 1998, 25, 4035–4038. [Google Scholar] [CrossRef] [Green Version]

- Costantini, M.; Rosen, P.A. A generalized phase unwrapping approach for sparse data. In Proceedings of the IEEE International Geoscience and Remote Sensing Symposium, Hamburg, Germany, 28 June–2 July 1999; pp. 267–269. [Google Scholar]

- Li, Z.W.; Ding, X.L.; Zheng, D.W.; Huang, C. Least squares-based filter for remote sensing image noise reduction. IEEE Trans. Geosci. Remote Sens. 2008, 46, 2044–2049. [Google Scholar] [CrossRef]

- Fan, H.D.; Cheng, D.; Deng, K.Z.; Chen, B.Q.; Zhu, C.G. Subsidence monitoring using D-InSAR and probability integral prediction modelling in deep mining areas. Surv. Rev. 2015, 47, 438–445. [Google Scholar] [CrossRef]

- Cannavo, F. Sensitivity analysis for volcanic source modeling quality assessment and model selection. Comput. Geosci. 2012, 44, 52–59. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Nie, C.X.; Wang, R.T. Geological Basis and Mining Technology of Well and Mineral Salt; National Mine Salt Industry Science and Technology Information Station: Chengdu, China, 1992; pp. 82–115. [Google Scholar]

- Fomelis, M.; Papageorgiou, E.; Stamatopoulos, C. Episodic ground deformation signals in Thessaly Plain (Greece) revealed by data mining of SAR interferometry time series. Int. J. Remote Sens. 2016, 37, 3696–3711. [Google Scholar] [CrossRef]

- Precipitation and Temperature Data of Lixian City, China. Available online: https://tianqi.911cha.com/lixian/2016.html (accessed on 15 December 2021).

| Parameters | Simulated Real Value | CT-PIM Generated Value | Error | Relative Error |

|---|---|---|---|---|

| 0.504 | 0.559 | 0.055 | 10.4 | |

| 1.560 | 1.662 | 0.102 | 6.4 | |

| 30.310 | 27.801 | 2.509 | 8.6 | |

| 16.080 | 15.340 | 0.740 | 4.5 | |

| 0.524 | 0.504 | 0.020 | 3.9 | |

| 0.167 | 0.166 | 0.001 | 0.6 |

| Parameters | Simulated Real Value | CT-PIM Generated Value | Error | Relative Error |

|---|---|---|---|---|

| 0.504 | 0.528 | 0.024 | 4.8 | |

| 1.560 | 1.572 | 0.012 | 0.8 | |

| 30.310 | 28.431 | 1.879 | 6.2 | |

| 16.080 | 15.437 | 0.643 | 4.0 | |

| 0.524 | 0.507 | 0.017 | 3.3 | |

| 0.167 | 0.167 | 0 | 0 |

| Geological Parameters | ||||||

|---|---|---|---|---|---|---|

| value | 3 | 5.7 | 240 | 258 | 80 | 0.056 |

| Image No. | Acquisition Date (yyyy/mm/dd) | Perpendicular Baseline (m) | Temporal Baseline (Days) |

|---|---|---|---|

| 0 | 2015/06/15 | 10.32 | −384 |

| 1 | 2015/07/09 | 94.46 | −360 |

| 2 | 2015/08/02 | 8.65 | −336 |

| 3 | 2015/08/26 | −25.59 | −312 |

| 4 | 2015/09/19 | −27.87 | −288 |

| 5 | 2015/10/13 | 42.76 | −264 |

| 6 | 2015/12/24 | 125.03 | −192 |

| 7 | 2016/01/17 | 19.96 | −168 |

| 8 | 2016/02/10 | 99.87 | −144 |

| 9 | 2016/03/05 | −21.75 | −120 |

| 10 | 2016/03/29 | −48.25 | −96 |

| 11 | 2016/04/22 | 37.12 | −72 |

| 12 | 2016/05/16 | −9.33 | −48 |

| 13 | 2016/07/03 | 0 | 0 |

| 14 | 2016/08/20 | 15.15 | 48 |

| 15 | 2016/09/25 | −54.32 | 84 |

| 16 | 2016/10/07 | −27.33 | 96 |

| 17 | 2016/10/19 | 63.93 | 108 |

| 18 | 2016/10/31 | 57.18 | 120 |

| 19 | 2016/11/12 | 52.15 | 132 |

| 20 | 2016/11/24 | 26.62 | 144 |

| 21 | 2016/12/18 | 25.12 | 168 |

| 22 | 2016/12/30 | 20.94 | 180 |

| 23 | 2017/01/11 | 76.93 | 192 |

| 24 | 2017/02/16 | 48.78 | 228 |

| 25 | 2017/03/12 | 34.61 | 252 |

| 26 | 2017/04/05 | −16.41 | 276 |

| 27 | 2017/04/29 | 34.59 | 300 |

| 28 | 2017/05/23 | 47.07 | 324 |

| 29 | 2017/06/28 | 16.92 | 360 |

| 30 | 2017/07/22 | 63.26 | 384 |

| 31 | 2017/08/15 | −69.95 | 408 |

| Parameters | A1 | A2 | A3 | A4 | A5 | A6 | A7 |

|---|---|---|---|---|---|---|---|

| 0.832 | 0.882 | 0.919 | 0.741 | 0.957 | 0.750 | 0.974 | |

| 3.060 | 3.128 | 3.473 | 3.362 | 3.732 | 3.608 | 2.995 | |

| 39.170 | 40.694 | 44.933 | 49.888 | 42.297 | 47.468 | 31.116 | |

| 36.481 | 38.631 | 32.001 | 39.813 | 48.184 | 47.374 | 26.701 | |

| 0.518 | 0.623 | 0.743 | 0.693 | 0.658 | 0.702 | 0.718 | |

| 0.150 | 0.162 | 0.182 | 0.196 | 0.145 | 0.193 | 0.166 |

| Correlation Extent | Ranges of Sensitivity Indices |

|---|---|

| Very important | 0.8 1 |

| Important | 0.5 0.8 |

| Unimportant | 0.3 0.5 |

| Not correlated | 0 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, X.; Zhang, T.; Chen, L.; Yang, Z.; Liu, X.; Peng, W.; Yuan, Z. InSAR Modeling and Deformation Prediction for Salt Solution Mining Using a Novel CT-PIM Function. Remote Sens. 2022, 14, 842. https://doi.org/10.3390/rs14040842

Xing X, Zhang T, Chen L, Yang Z, Liu X, Peng W, Yuan Z. InSAR Modeling and Deformation Prediction for Salt Solution Mining Using a Novel CT-PIM Function. Remote Sensing. 2022; 14(4):842. https://doi.org/10.3390/rs14040842

Chicago/Turabian StyleXing, Xuemin, Tengfei Zhang, Lifu Chen, Zefa Yang, Xiangbin Liu, Wei Peng, and Zhihui Yuan. 2022. "InSAR Modeling and Deformation Prediction for Salt Solution Mining Using a Novel CT-PIM Function" Remote Sensing 14, no. 4: 842. https://doi.org/10.3390/rs14040842

APA StyleXing, X., Zhang, T., Chen, L., Yang, Z., Liu, X., Peng, W., & Yuan, Z. (2022). InSAR Modeling and Deformation Prediction for Salt Solution Mining Using a Novel CT-PIM Function. Remote Sensing, 14(4), 842. https://doi.org/10.3390/rs14040842