Geometric Quality Assessment of Prefabricated Steel Box Girder Components Using 3D Laser Scanning and Building Information Model

Abstract

:1. Introduction

2. Literature Review

2.1. Point-Cloud Data Segmentation

2.2. Point-Cloud-Based Object Recognition

2.3. Point-Cloud-Based Location Recognition of Structural Components

2.4. Point-Cloud-Based Quality Assurance and Control

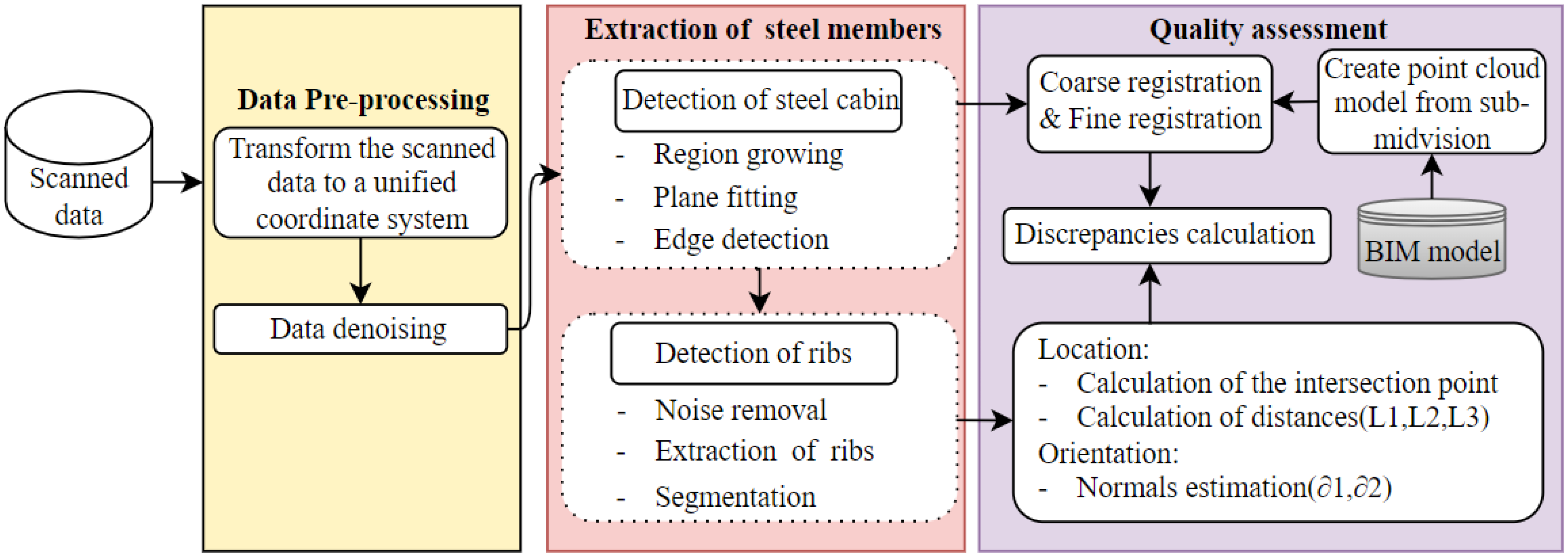

3. Methodology

3.1. Data Preprocessing

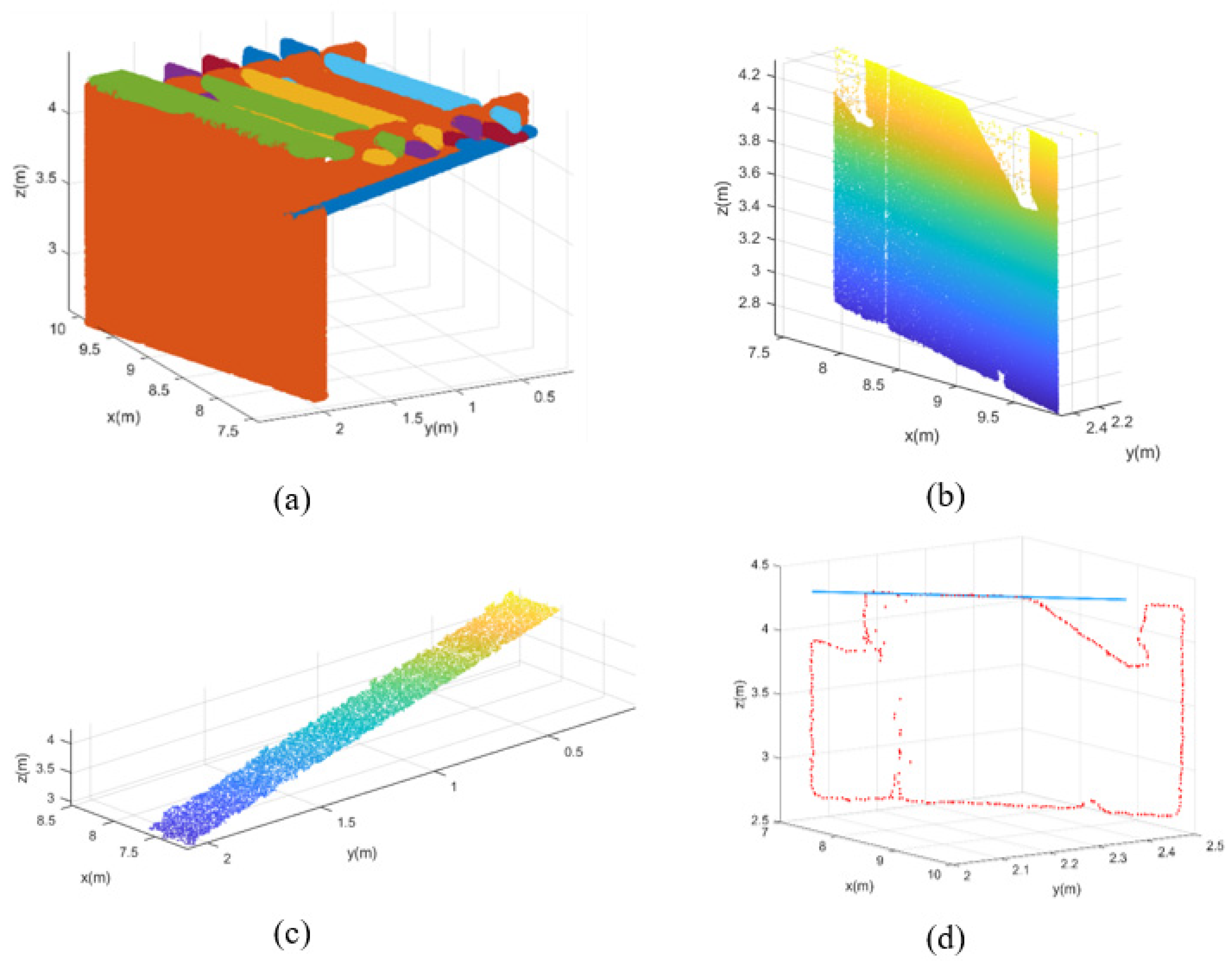

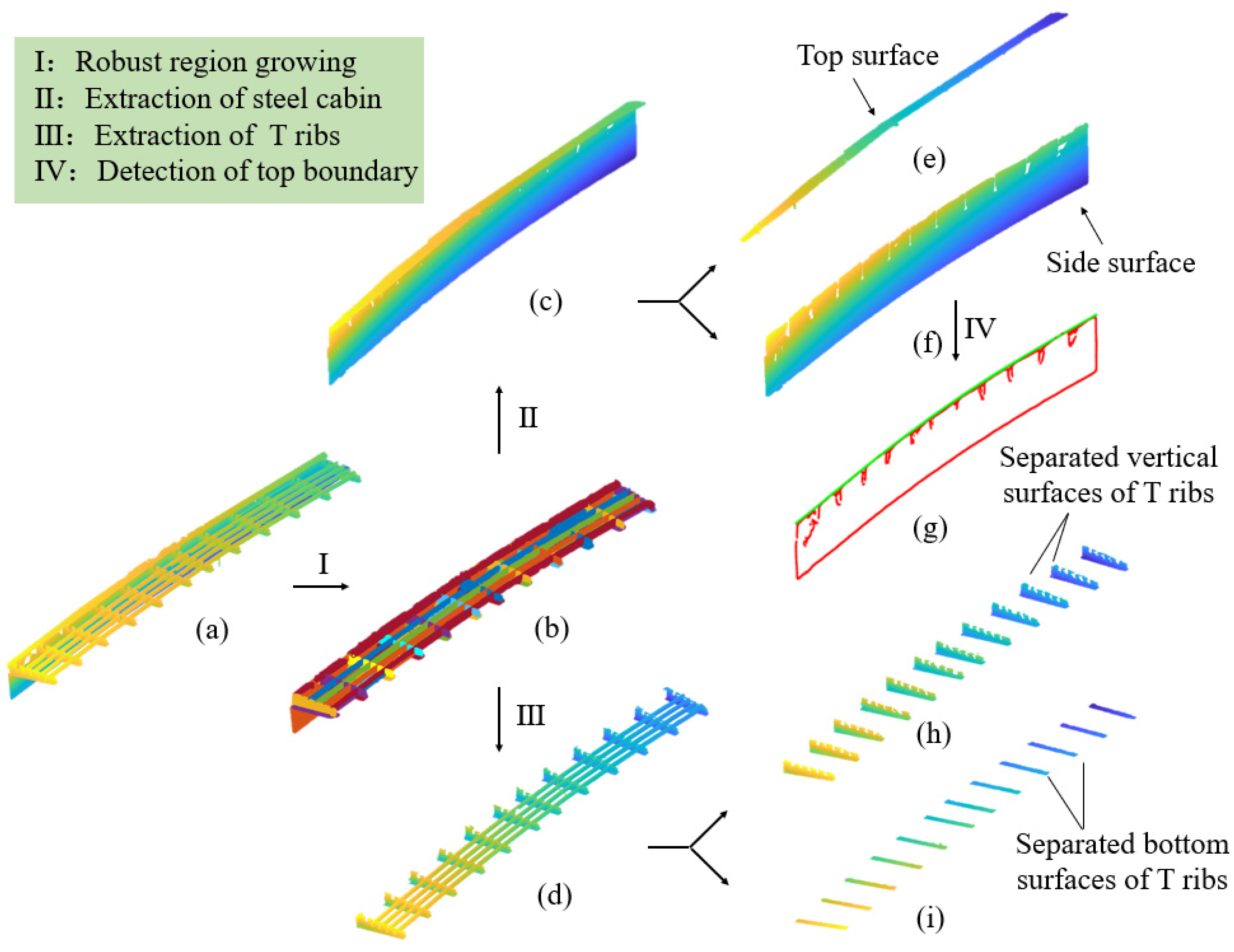

3.2. Extraction of the Steel Cabin

3.2.1. Extraction of Side Surface

3.2.2. Extraction of Top Surface

3.2.3. Detection of Top Boundary

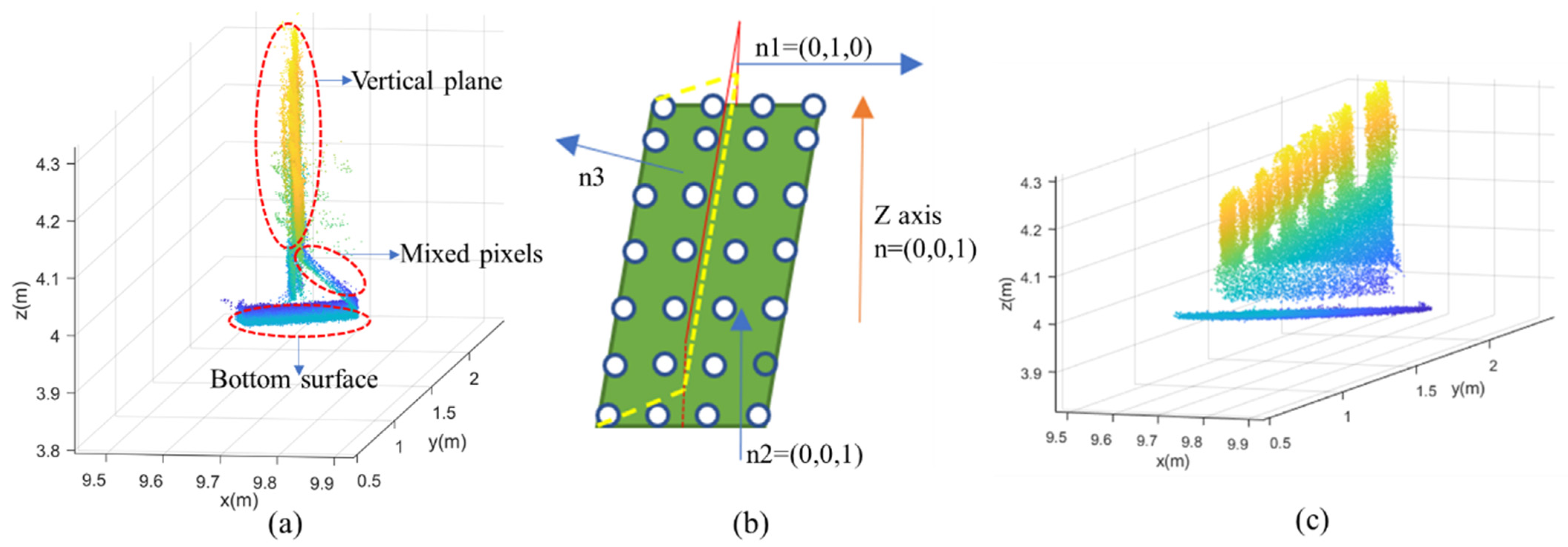

3.3. Extraction of the T Ribs

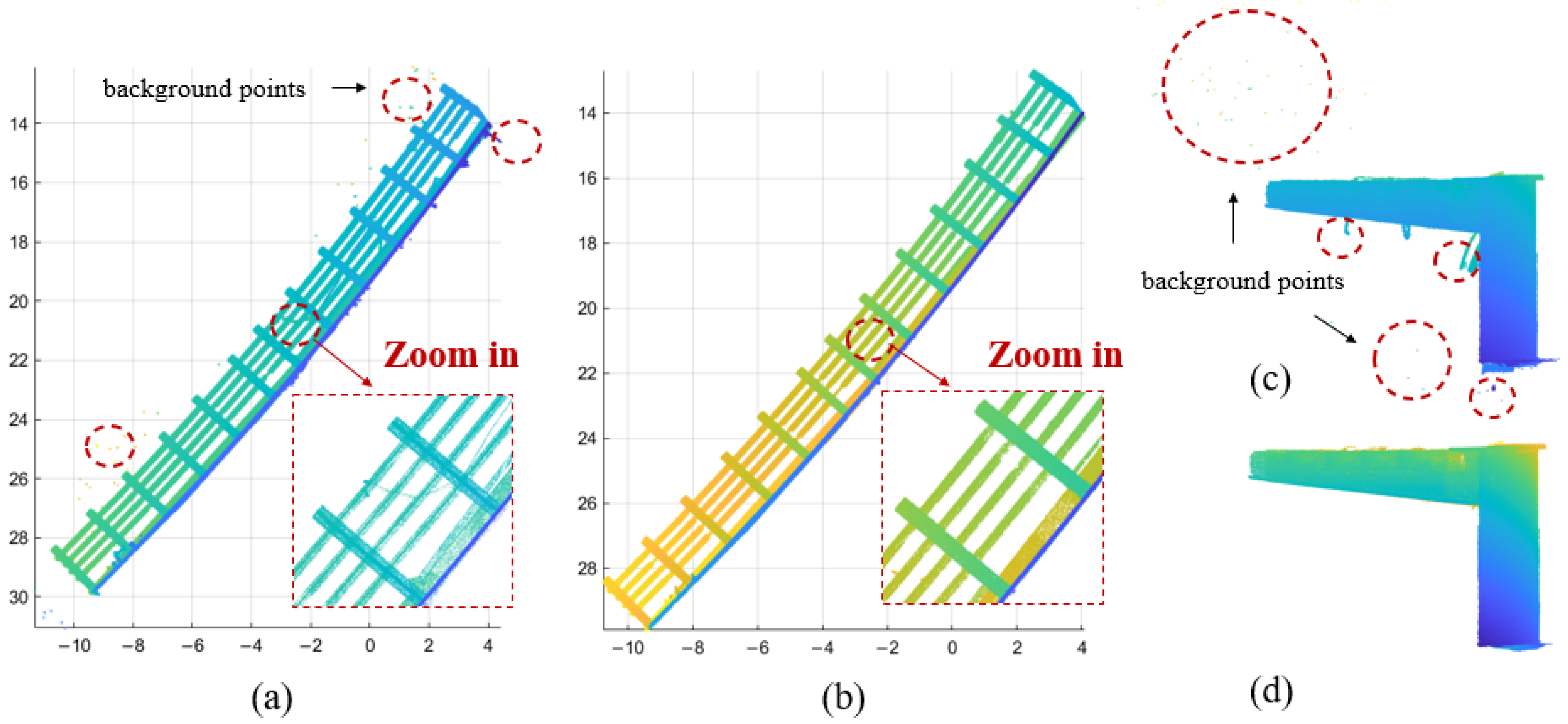

3.3.1. Extraction of Scanned Data Related to T Ribs

3.3.2. Mixed-Pixel Removal for T Ribs

4. Geometric Quality Assessment

4.1. Assessment of Steel Cabin

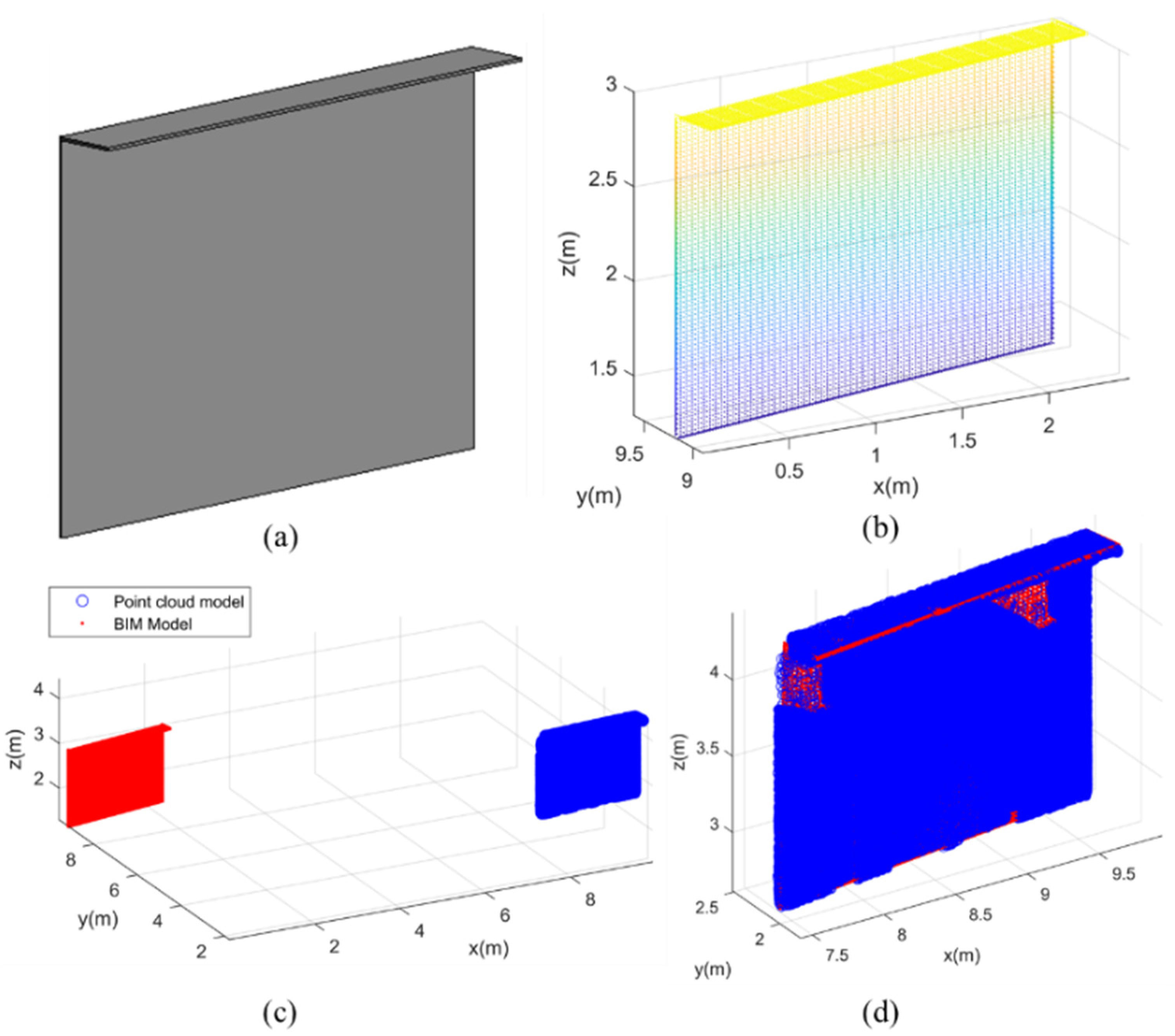

4.1.1. Data Format Conversion

4.1.2. Coarse Registration and Fine Registration

4.1.3. Calculation of Deviation

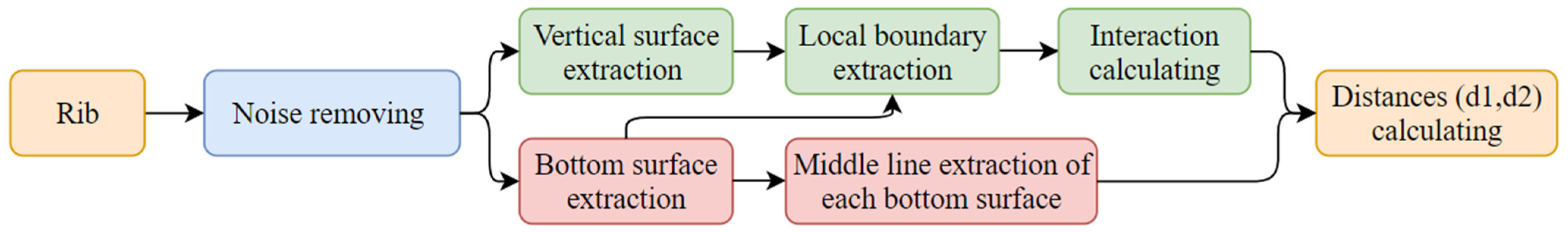

4.2. Assessment of T Ribs

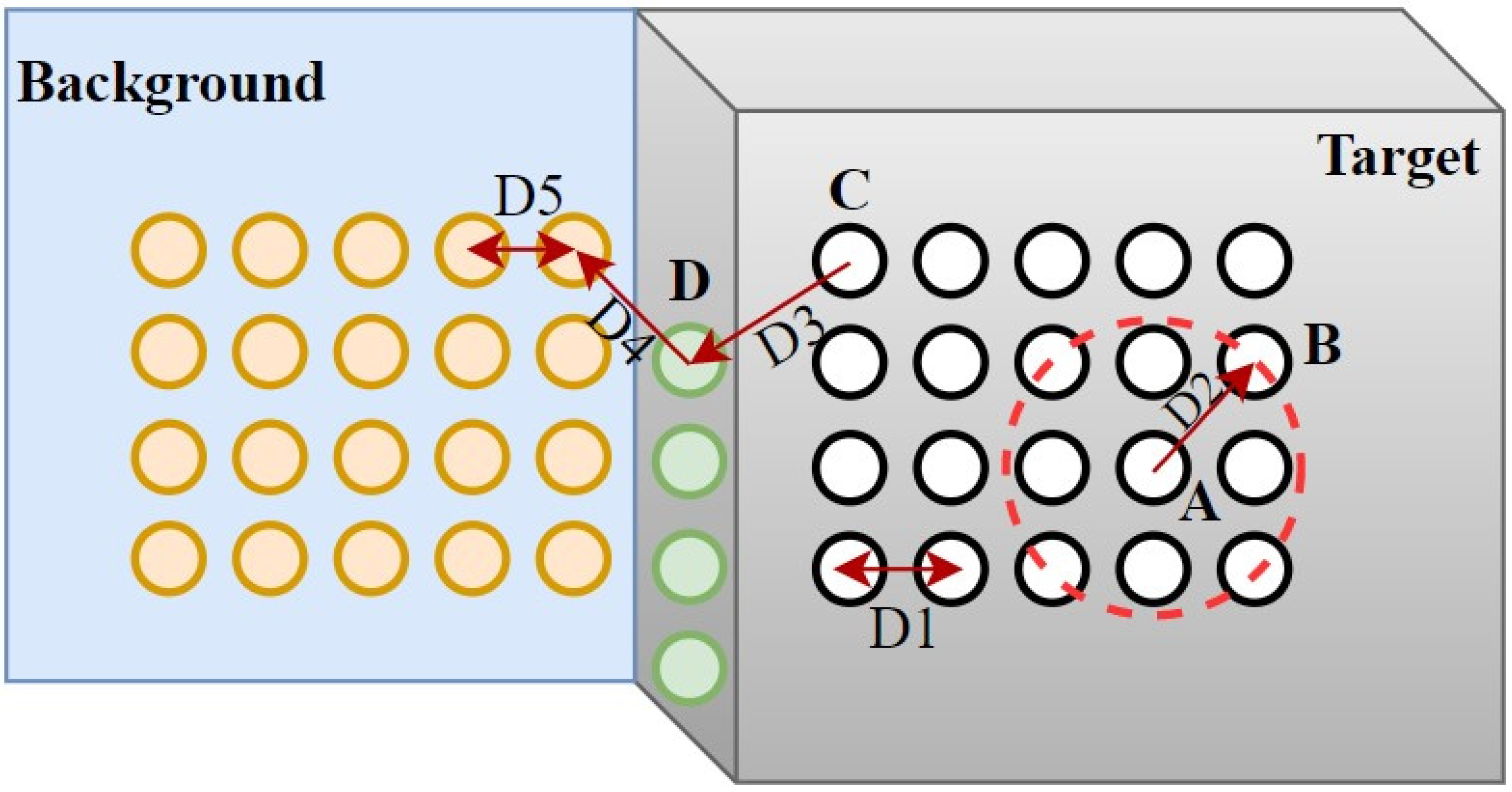

4.2.1. Calculation of Locations

4.2.2. Calculation of Orientations

5. Case Study

5.1. Collection of Laser-Scanned Data

5.2. Experimental Results

5.3. Feasibility of the Proposed Method

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiang, Y.; Zhu, S.; Zhao, Y. Research and Development on Accelerated Bridge Construction Technology. China J. Highw. Transp. 2018, 31, 1–27. [Google Scholar]

- Deng, Y.; Li, A. Fatigue reliability analysis for welds of U ribs in steel box girders based on fracture mechanics and long-term monitoring data. J. Southeast Univ. Nat. Sci. Ed. 2019, 49, 68–75. [Google Scholar] [CrossRef]

- Abu Dabous, S.; Feroz, S. Condition monitoring of bridges with non-contact testing technologies. Autom. Constr. 2020, 116, 103224. [Google Scholar] [CrossRef]

- Guan, G.; Gu, W.W. Reconstruction of propeller and complex ship hull surface based on reverse engineering. J. Mar. Sci. Technol.-Taiwan 2019, 27, 498–504. [Google Scholar] [CrossRef]

- Tang, P.B.; Huber, D.; Akinci, B.; Lipman, R.; Lytle, A. Automatic reconstruction of as-built building information models from laser-scanned point clouds: A review of related techniques. Autom. Constr. 2010, 19, 829–843. [Google Scholar] [CrossRef]

- Barbarella, M.; Cuomo, A.; Di Benedetto, A.; Fiani, M.; Guida, D. Topographic Base Maps from Remote Sensing Data for Engineering Geomorphological Modelling: An Application on Coastal Mediterranean Landscape. Geosciences 2019, 9, 500. [Google Scholar] [CrossRef] [Green Version]

- Siebert, S.; Teizer, J. Mobile 3D mapping for surveying earthwork projects using an Unmanned Aerial Vehicle (UAV) system. Autom. Constr. 2014, 41, 1–14. [Google Scholar] [CrossRef]

- Olsen Michael, J.; Kuester, F.; Chang Barbara, J.; Hutchinson Tara, C. Terrestrial Laser Scanning-Based Structural Damage Assessment. J. Comput. Civ. Eng. 2010, 24, 264–272. [Google Scholar] [CrossRef]

- Xi, C.X.; Zhou, Z.-X.; Xiang, X.; He, S.; Hou, X. Monitoring of long-span bridge deformation based on 3D laser scanning. Instrum. Mes. Metrol. 2018, 18, 113–130. [Google Scholar] [CrossRef]

- Bosché, F.; Guillemet, A.; Turkan, Y.; Haas, C.T.; Haas, R. Tracking the Built Status of MEP Works: Assessing the Value of a Scan-vs.-BIM System. J. Comput. Civ. Eng. 2013, 28, 05014004. [Google Scholar] [CrossRef] [Green Version]

- Tan, Y.; Li, S.; Wang, Q. Automated Geometric Quality Inspection of Prefabricated Housing Units Using BIM and LiDAR. Remote Sens. 2020, 12, 2492. [Google Scholar] [CrossRef]

- Guo, J.J.; Wang, Q. Dimensional Quality Inspection of Prefabricated MEP Modules with 3D Laser Scanning. In Proceedings of the ASCE International Conference on Computing in Civil Engineering (i3CE), Atlanta, GA, USA, 17–19 June 2019; pp. 171–177. [Google Scholar]

- Wang, Q.; Kim, M.K.; Cheng, J.C.P.; Sohn, H. Automated quality assessment of precast concrete elements with geometry irregularities using terrestrial laser scanning. Autom. Constr. 2016, 68, 170–182. [Google Scholar] [CrossRef]

- Wang, Q.; Cheng, J.C.P.; Sohn, H. Automated Estimation of Reinforced Precast Concrete Rebar Positions Using Colored Laser Scan Data. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 787–802. [Google Scholar] [CrossRef]

- Liu, J.D.; Zhang, Q.L.; Wu, J.; Zhao, Y.C. Dimensional accuracy and structural performance assessment of spatial structure components using 3D laser scanning. Autom. Constr. 2018, 96, 324–336. [Google Scholar] [CrossRef]

- Castillo, E.; Liang, J.; Zhao, H. Point Cloud Segmentation and Denoising via Constrained Nonlinear Least Squares Normal Estimates. In Innovations for Shape Analysis: Models and Algorithms; Springer: Berlin/Heidelberg, Germany, 2013; pp. 283–299. [Google Scholar]

- Pu, S.; Vosselman, G. Knowledge based reconstruction of building models from terrestrial laser scanning data. ISPRS J. Photogramm. Remote Sens. 2009, 64, 575–584. [Google Scholar] [CrossRef]

- Li, Y.; Wu, B.; Ge, X. Structural segmentation and classification of mobile laser scanning point clouds with large variations in point density. ISPRS J. Photogramm. Remote Sens. 2019, 153, 151–165. [Google Scholar] [CrossRef]

- Patraucean, V.; Armeni, I.; Nahangi, M.; Yeung, J.M.; Brilakis, I.; Haas, C. State of research in automatic as-built modelling. Adv. Eng. Inform. 2015, 29, 162–171. [Google Scholar] [CrossRef] [Green Version]

- Date, H.; Kaneta, Y.; Hatsukaiwa, A.; Onosato, M.; Kanai, S. Object Recognition in Terrestrial Laser Scan Data using Spin Images. Comput.-Aided Des. Appl. 2012, 9, 187–197. [Google Scholar] [CrossRef] [Green Version]

- Yokoyama, H.; Date, H.; Kanai, S.; Takeda, H. Pole-like objects recognition from Mobile Laser Scanning Data using smoothing and principal component analysis. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2012, 38, 115–120. [Google Scholar] [CrossRef] [Green Version]

- Yan, Y.J.; Hajjar, J.F. Automated extraction of structural elements in steel girder bridges from laser point clouds. Autom. Constr. 2021, 125, 103582. [Google Scholar] [CrossRef]

- Riveiro, B.; DeJong, M.J.; Conde, B. Automated processing of large point clouds for structural health monitoring of masonry arch bridges. Autom. Constr. 2016, 72, 258–268. [Google Scholar] [CrossRef]

- Sommer, C.; Yumin, S.; Guibas, L.; Cremers, D.; Birdal, T. From Planes to Corners: Multi-Purpose Primitive Detection in Unorganized 3D Point Clouds. IEEE Robot. Autom. Lett. 2020, 5, 1764–1771. [Google Scholar] [CrossRef] [Green Version]

- Wu, Q.; Zhu, S.; Zhou, Y.; Wan, C.; He, T. Regular sticks pose position and orientation recognition based on RANSAC. Transducer Microsyst. Technol. 2019, 38, 137–140. [Google Scholar]

- Zhe, L.; Shunbo, Z.; Chuanzhe, S.; Yingtian, L.; Yun-Hui, L.; Hesheng, W. LPD-Net: 3D Point Cloud Learning for Large-scale Environment Analysis and Place Recognition. arXiv 2019, arXiv:1812.07050v2[cs.CV], 2831–2840. [Google Scholar]

- Ren, B.; Wei, K.; Dai, Y. A novel method of target recognition and 3D pose estimation in unstructured environment. J. Harbin Inst. Technol. 2019, 51, 38–44. [Google Scholar]

- Akizuki, S.; Hashimoto, M. Stable Position and Pose Estimation of Industrial Parts Using Evaluation of Observability of 3D Vector Pairs. J. Robot. Mechatron. 2015, 27, 174–181. [Google Scholar] [CrossRef]

- Kim, M.K.; Wang, Q.; Park, J.W.; Cheng, J.C.P.; Sohn, H.; Chang, C.C. Automated dimensional quality assurance of full-scale precast concrete elements using laser scanning and BIM. Autom. Constr. 2016, 72, 102–114. [Google Scholar] [CrossRef]

- Anil, E.B.; Tang, P.B.; Akinci, B.; Huber, D. Deviation analysis method for the assessment of the quality of the as-is Building Information Models generated from point cloud data. Autom. Constr. 2013, 35, 507–516. [Google Scholar] [CrossRef]

- Ghahremani, K.; Safa, M.; Yeung, J.; Walbridge, S.; Haas, C.; Dubois, S. Quality assurance for high-frequency mechanical impact (HFMI) treatment of welds using handheld 3D laser scanning technology. Weld. World 2015, 59, 391–400. [Google Scholar] [CrossRef]

- Bosché, F.; Ahmed, M.; Turkan, Y.; Haas, C.T.; Haas, R. The value of integrating Scan-to-BIM and Scan-vs-BIM techniques for construction monitoring using laser scanning and BIM: The case of cylindrical MEP components. Autom. Constr. 2015, 49, 201–213. [Google Scholar] [CrossRef]

- Vaghefi, K.; Ahlborn, T.M.; Harris, D.K.; Brooks, C.N. Combined Imaging Technologies for Concrete Bridge Deck Condition Assessment. J. Perform. Constr. Facil. 2015, 29, 04014102. [Google Scholar] [CrossRef]

- Heymsfield, E.; Kuss, M. Implementing Gigapixel Technology in Highway Bridge Inspections. J. Perform. Constr. Facil. 2013, 29, 04014074. [Google Scholar] [CrossRef]

- Vetrivel, A.; Gerke, M.; Kerle, N.; Vosselman, G. Identification of damage in buildings based on gaps in 3D point clouds from very high resolution oblique airborne images. ISPRS J. Photogramm. Remote Sens. 2015, 105, 61–78. [Google Scholar] [CrossRef]

- Park, J.-W.; Lee, J.-J.; Jung, H.-J.; Myung, H. Vision-based displacement measurement method for high-rise building structures using partitioning approach. NDT E Int. 2010, 43, 642–647. [Google Scholar] [CrossRef]

- Huang, F.H.; Yu, Y.; Feng, T.H. Automatic building change image quality assessment in high resolution remote sensing based on deep learning. J. Vis. Commun. Image Represent. 2019, 63, 10. [Google Scholar] [CrossRef]

- Guldur, B.; Yan, Y.J.; Hajjar, J.F. Condition Assessment of Bridges Using Terrestrial Laser Scanners; American Society of Civil Engineers: New York, NY, USA, 2015; pp. 355–366. [Google Scholar]

- Cha, G.; Park, S.; Oh, T. A Terrestrial LiDAR-Based Detection of Shape Deformation for Maintenance of Bridge Structures. J. Constr. Eng. Manag. 2019, 145, 04019075. [Google Scholar] [CrossRef]

- An, Y.-K.; Min Kim, J.; Sohn, H. Laser lock-in thermography for detection of surface-breaking fatigue cracks on uncoated steel structures. NDT E Int. 2014, 65, 54–63. [Google Scholar] [CrossRef]

- Ester, M.; Kriegel, H.-P.; Sander, J.; Xu, X. A density-based algorithm for discovering clusters in large spatial databases with noise. In Proceedings of the Second International Conference on Knowledge Discovery and Data Mining, Portland, OR, USA, 25 August–1 September 2012; pp. 226–231. [Google Scholar]

- Hoppe, H.; Derose, T.; Duchamp, T.; Mcdonald, J.; Stuetzle, W. Surface reconstruction from unorganized points. SIGGRAPH Computer Graphics. ACM SIGGRAPH Comput. Graph. 1996, 26, 71–78. [Google Scholar] [CrossRef]

- Pauly, M.; Keiser, R.; Gross, M. Multi-scale feature extraction on point-sampled surfaces. Comput. Graph. Forum 2003, 22, 281–289. [Google Scholar] [CrossRef] [Green Version]

- Kawashima, K.; Kanai, S.; Date, H. As-built modeling of piping system from terrestrial laser-scanned point clouds using normal-based region growing. J. Comput. Des. Eng. 2014, 1, 13–26. [Google Scholar] [CrossRef] [Green Version]

- Khaloo, A.; Lattanzi, D. Robust normal estimation and region growing segmentation of infrastructure 3D point cloud models. Adv. Eng. Inform. 2017, 34, 1–16. [Google Scholar] [CrossRef]

- Nurunnabi, A.; Belton, D.; West, G. Diagnostic-robust statistical analysis for Local Surface Fitting in 3D Point Cloud Data. In Proceedings of the XXII Congress of International Society for Photogrammetry & Remote Sensing, Melbourne, Australia, 5–9 July 2012. [Google Scholar]

- Rousseeuw, P.J.; Driessen, K.V. A fast algorithm for the minimum covariance determinant estimator. Technometrics 1999, 41, 212–223. [Google Scholar] [CrossRef]

- Nurunnabi, A.; West, G.; Belton, D. Outlier detection and robust normal-curvature estimation in mobile laser scanning 3D point cloud data. Pattern Recognit. J. Pattern Recognit. Soc. 2015, 48, 1404–1419. [Google Scholar] [CrossRef] [Green Version]

- Ferraz, A.; Bretar, F.; Jacquemoud, S.; Goncalves, G.; Pereira, L.; Tome, M.; Soares, P. 3-D mapping of a multi-layered Mediterranean forest using ALS data. Remote Sens. Environ. 2012, 121, 210–223. [Google Scholar] [CrossRef]

- Yang, L.; Cheng, J.C.P.; Wang, Q. Semi-automated generation of parametric BIM for steel structures based on terrestrial laser scanning data. Autom. Constr. 2020, 112, 103037. [Google Scholar] [CrossRef]

- Weber, C.; Hahmann, S.; Hagen, H. Sharp Feature Detection in Point Clouds. In Proceedings of the 2010 Shape Modeling International Conference, Aix en Provence, France, 21–23 June 2010; pp. 175–186. [Google Scholar]

- Zhao, Y.Z. On the use of dimension reduction techniques in quasi-Monte Carlo methods. Math. Comput. Model. 2008, 48, 1925–1937. [Google Scholar] [CrossRef]

- Bergen, G.V.D. Efficient Collision Detection of Complex Deformable Models using AABB Trees. J. Graph. Tools 1997, 2, 1–13. [Google Scholar] [CrossRef]

- Dutta, S.; Cai, Y.Y.; Huang, L.H.; Zheng, J.M. Automatic re-planning of lifting paths for robotized tower cranes in dynamic BIM environments. Autom. Constr. 2020, 110, 19. [Google Scholar] [CrossRef]

| Parameter | Definition | Setting Value |

|---|---|---|

| ϵ neighborhood | The radius of neighborhoods around a datapoint pi | 0.5 |

| MinPts | The minimum number of points in the neighborhood | 1.2 |

| Element | Category | Inspection Checklist | Tolerance |

|---|---|---|---|

| T rib | Location | (1) Distance from the intersection point to the upper boundary (L1) (2) Distance between adjacent T ribs (L2) | 5 mm |

| T rib | Orientation | Deviation between the normal vector of the steel cabin and the direction of the T ribs | 1° |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | 0.4975 | 0.4918 | 0.4866 | 0.5057 | 0.5011 | 0.5072 | 0.495 | 0.4873 | 0.4985 | 0.4889 | 0.4951 | 0.4989 | 0.5020 |

| L1′ | 0.5003 | 0.4942 | 0.4927 | 0.4993 | 0.5019 | 0.5030 | 0.5003 | 0.4998 | 0.4987 | 0.4980 | 0.4990 | 0.4980 | 0.4988 |

| |ΔL1| | 0.0028 | 0.0024 | 0.0061 | 0.0064 | 0.0008 | 0.0042 | 0.0053 | 0.0125 | 0.0002 | 0.0091 | 0.0039 | 0.0009 | 0.0032 |

| L2 | 1.7579 | 1.7381 | 1.8441 | 1.7056 | 1.8098 | 1.3492 | 1.6656 | 1.7985 | 1.7335 | 1.7758 | 1.7474 | 1.6240 | |

| L2′ | 1.7600 | 1.7399 | 1.8405 | 1.6980 | 1.8102 | 1.3474 | 1.6663 | 1.7983 | 1.7317 | 1.7724 | 1.7508 | 1.6279 | |

| |ΔL2| | 0.0021 | 0.0018 | 0.0036 | 0.0076 | 0.0004 | 0.0018 | 0.0007 | 0.0002 | 0.0018 | 0.0034 | 0.0034 | 0.0039 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8.4512° | 8.4840° | 8.0882° | 8.3251° | 8.5672° | 8.3347° | 8.3878° | 8.0848° | 8.5815° | 8.5261° | 8.1246° | 8.9150° | |

| 8.5000° | 8.5000° | 8.5000° | 8.5000° | 8.5000° | 8.5000° | 8.5000° | 8.5000° | 8.5000° | 8.5000° | 8.5000° | 8.5000° | |

| 0.0488° | 0.0160° | 0.4118° | 0.1749° | 0.0672° | 0.1653° | 0.1122° | 0.4152° | 0.0815° | 0.0261° | 0.3754° | 0.4150° |

| Site-Scan Planning | Data Acquisition | Data Processing | Total Time | |

|---|---|---|---|---|

| The proposed method | 10 min | 136 min | 99 min | 245 min |

| The manual method | 360 min | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Y.; Chen, L.; Wang, Q.; Li, S.; Deng, T.; Tang, D. Geometric Quality Assessment of Prefabricated Steel Box Girder Components Using 3D Laser Scanning and Building Information Model. Remote Sens. 2023, 15, 556. https://doi.org/10.3390/rs15030556

Tan Y, Chen L, Wang Q, Li S, Deng T, Tang D. Geometric Quality Assessment of Prefabricated Steel Box Girder Components Using 3D Laser Scanning and Building Information Model. Remote Sensing. 2023; 15(3):556. https://doi.org/10.3390/rs15030556

Chicago/Turabian StyleTan, Yi, Limei Chen, Qian Wang, Shenghan Li, Ting Deng, and Dongdong Tang. 2023. "Geometric Quality Assessment of Prefabricated Steel Box Girder Components Using 3D Laser Scanning and Building Information Model" Remote Sensing 15, no. 3: 556. https://doi.org/10.3390/rs15030556