4D Printing of Multi-Hydrogels Using Direct Ink Writing in a Supporting Viscous Liquid

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

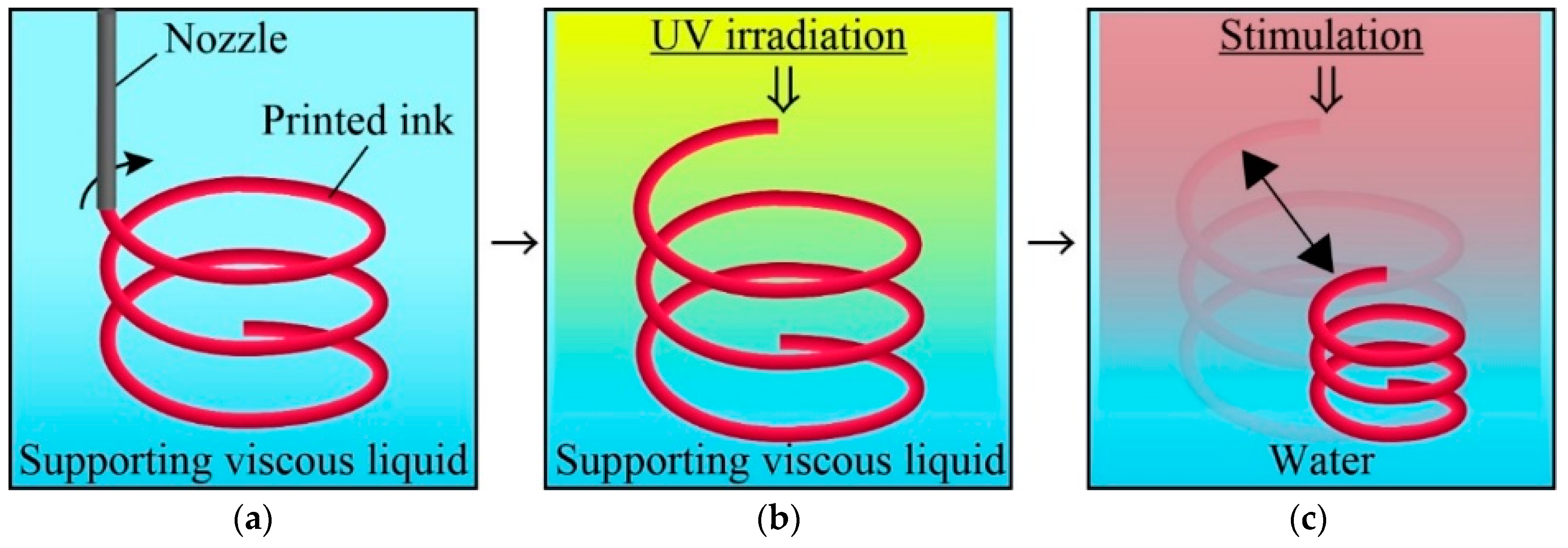

2.2. Set Up for 4D Printing

2.3. Evaluation of Printed Ink Patterns in Supporting Material

2.4. Polymerization of Printed Ink in Supporting Viscous Liquid

2.5. Responsivity of Polymerized Printed Ink

2.6. Printing of Multi-Hydrogels Structures

2.7. Demonstration of 4D Printing

3. Results

3.1. Position of Printed Ink in Supporting Viscous Liquid

3.2. Width of Printed Ink in Supporting Viscous Liquid

3.3. Evaluation of Printed Ink Patterns

3.4. Polymerization of Printed Ink in Supporting Viscous Liquid

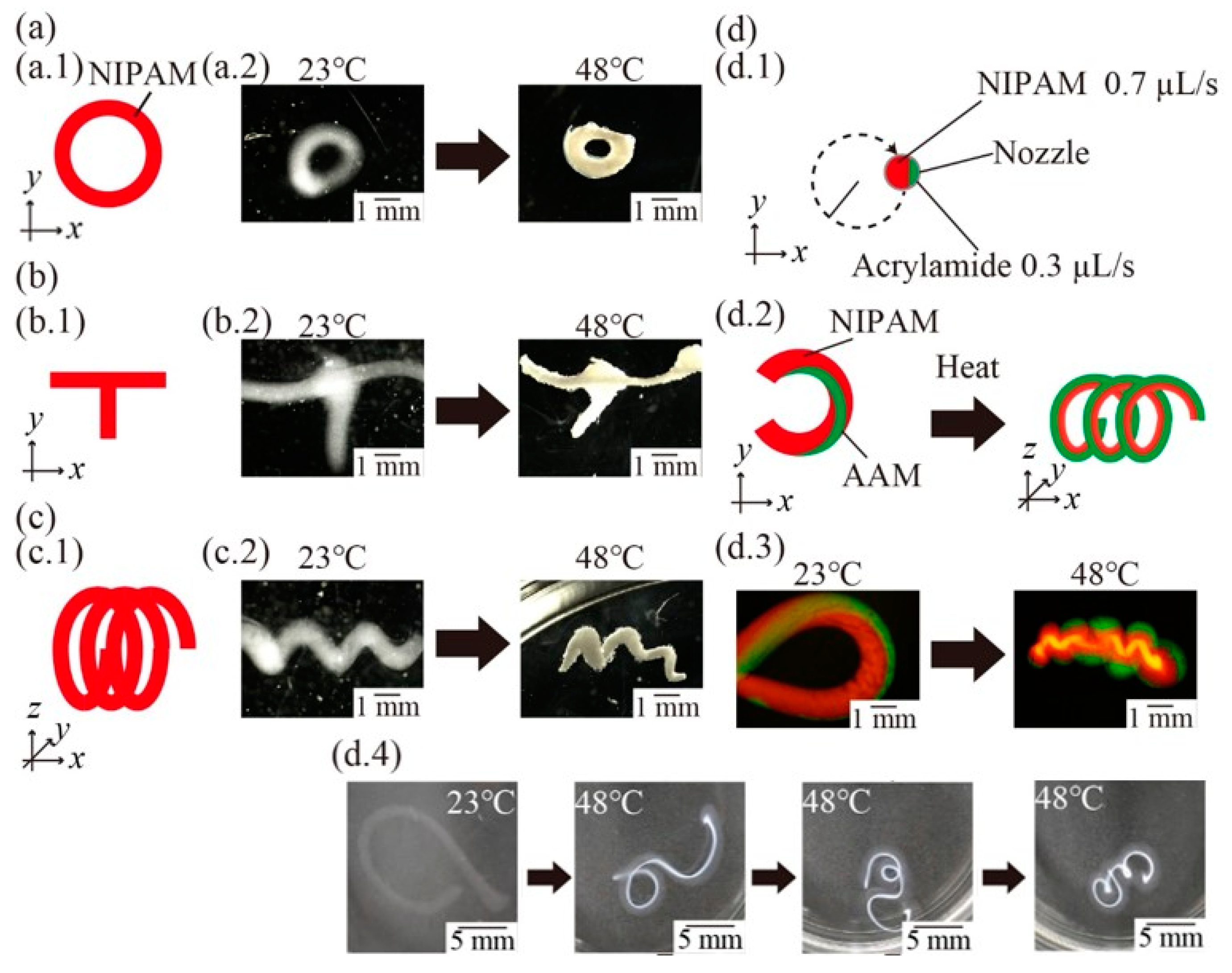

3.5. Responsivity of External Stimuli

3.6. Printing of Multi-Hydrogels Structures

3.7. Demonstration of 4D Printing

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Momeni, F.; M.Mehdi Hassani.N., S.; Liu, X.; Ni, J. A review of 4D printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Ding, H.; Zhang, X.; Liu, Y. Review of mechanisms and deformation behaviors in 4D printing. Int. J. Adv. Manuf. Technol. 2019, 1–17. [Google Scholar] [CrossRef]

- Kuang, X.; Roach, D.J.; Wu, J.; Hamel, C.M.; Ding, Z.; Wang, T.; Dunn, M.L.; Qi, H.J. Advances in 4D Printing: Materials and Applications. Adv. Funct. Mater. 2019, 29, 1–23. [Google Scholar] [CrossRef]

- Zhang, Z.; Demir, K.G.; Gu, G.X. Developments in 4D-printing: A review on current smart materials, technologies, and applications. Int. J. Smart Nano Mater. 2019, 1–20. [Google Scholar] [CrossRef]

- Pei, E. 4D printing: Dawn of an emerging technology cycle. Assem. Autom. 2014, 34, 310–314. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, W.M.; Kang, S.F.; Wu, X.L.; Lu, H.B.; Fu, J.; Cui, H. From 3D to 4D printing: Approaches and typical applications. J. Mech. Sci. Technol. 2015, 29, 4281–4288. [Google Scholar] [CrossRef]

- Campbell, T.A.; Tibbits, S.; Garrett, B. The Programmable World. Sci. Am. 2014, 311, 60–65. [Google Scholar] [CrossRef] [PubMed]

- Taylor, D.L.; in het Panhuis, M. Self-Healing Hydrogels. Adv. Mater. 2016, 28, 9060–9093. [Google Scholar] [CrossRef]

- Lendlein, A.; Kelch, S. Shape-Memory Effect; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Beebe, D.J.; Moore, J.; Bauer, J.M.; Yu, Q.; Liu, R.H.; Devadoss, C.; Jo, B.H. Functional hydrogel structures for autonomous ow control inside micro- uidic channels. Nature 2000, 404, 588. [Google Scholar] [CrossRef]

- Yoon, C.; Xiao, R.; Park, J.; Cha, J.; Nguyen, T.D.; Gracias, D.H. Functional stimuli responsive hydrogel devices by self-folding. Smart Mater. Struct. 2014, 23, 094008. [Google Scholar] [CrossRef]

- Nakajima, S.; Kawano, R.; Onoe, H. Stimuli-responsive hydrogel microfibers with controlled anisotropic shrinkage and cross-sectional geometries. Soft Matter 2017, 13, 3710–3719. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Lu, W.; Yang, X.; He, J.; Le, X.; Wang, L.; Zhang, J.; Serpe, M.J.; Huang, Y.; Chen, T. Bioinspired Anisotropic Hydrogel Actuators with On–Off Switchable and Color-Tunable Fluorescence Behaviors. Adv. Funct. Mater. 2018, 28, 1–7. [Google Scholar] [CrossRef]

- Breger, J.C.; Yoon, C.; Xiao, R.; Kwag, H.R.; Wang, M.O.; Fisher, J.P.; Nguyen, T.D.; Gracias, D.H. Self-folding thermo-magnetically responsive soft microgrippers. ACS Appl. Mater. Interfaces 2015, 7, 3398–3405. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.J.; Zhu, C.N.; Hong, W.; Wu, Z.L.; Zheng, Q. Programmed planar-to-helical shape transformations of composite hydrogels with bioinspired layered fibrous structures. J. Mater. Chem. B 2016, 4, 7075–7079. [Google Scholar] [CrossRef]

- Thérien-Aubin, H.; Wu, Z.L.; Nie, Z.; Kumacheva, E. Multiple shape transformations of composite hydrogel sheets. J. Am. Chem. Soc. 2013, 135, 4834–4839. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.L.; Moshe, M.; Greener, J.; Therien-Aubin, H.; Nie, Z.; Sharon, E.; Kumacheva, E. Three-dimensional shape transformations of hydrogel sheets induced by small-scale modulation of internal stresses. Nat. Commun. 2013, 4, 1586–1587. [Google Scholar] [CrossRef]

- Zhou, Y.; Hauser, A.W.; Bende, N.P.; Kuzyk, M.G.; Hayward, R.C. Waveguiding Microactuators Based on a Photothermally Responsive Nanocomposite Hydrogel. Adv. Funct. Mater. 2016, 26, 5447–5452. [Google Scholar] [CrossRef]

- Sydney Gladman, A.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D printing. Nat. Mater. 2016, 15, 413–418. [Google Scholar] [CrossRef]

- Naficy, S.; Gately, R.; Gorkin, R.; Xin, H.; Spinks, G.M. 4D Printing of Reversible Shape Morphing Hydrogel Structures. Macromol. Mater. Eng. 2017, 302, 1–9. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, R.; Zhang, L.; Cao, X. 4D printing of robust hydrogels consisted of agarose nanofibers and polyacrylamide. ACS Macro Lett. 2018, 7, 442–446. [Google Scholar] [CrossRef]

- Zhang, M.; Vora, A.; Han, W.; Wojtecki, R.J.; Maune, H.; Le, A.B.A.; Thompson, L.E.; McClelland, G.M.; Ribet, F.; Engler, A.C.; et al. Dual-Responsive Hydrogels for Direct-Write 3D Printing. Macromolecules 2015, 48, 6482–6488. [Google Scholar] [CrossRef]

- Raviv, D.; Zhao, W.; McKnelly, C.; Papadopoulou, A.; Kadambi, A.; Shi, B.; Hirsch, S.; Dikovsky, D.; Zyracki, M.; Olguin, C.; et al. Active printed materials for complex self-evolving deformations. Sci. Rep. 2014, 4, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, K.; Nakajima, S.; Kawano, R.; Onoe, H. Spring-shaped stimuli-responsive hydrogel actuator with large deformation. Sens. Actuators B Chem. 2018, 272, 361–368. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Zhang, Y.Y.; Wu, X.G.; He, X.W.; Li, W.Y. Rapid facile in situ synthesis of the Au/Poly(N-isopropylacrylamide) thermosensitive gels as temperature sensors. Mater. Lett. 2015, 143, 326–329. [Google Scholar] [CrossRef]

- Zhang, X.; Pint, C.L.; Lee, M.H.; Schubert, B.E.; Jamshidi, A.; Takei, K.; Ko, H.; Gillies, A.; Bardhan, R.; Urban, J.J.; et al. Optically- and thermally-responsive programmable materials based on carbon nanotube-hydrogel polymer composites. Nano Lett. 2011, 11, 3239–3244. [Google Scholar] [CrossRef] [PubMed]

- Na, J.H.; Evans, A.A.; Bae, J.; Chiappelli, M.C.; Santangelo, C.D.; Lang, R.J.; Hull, T.C.; Hayward, R.C. Programming reversibly self-folding origami with micropatterned photo-crosslinkable polymer trilayers. Adv. Mater. 2015, 27, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Highley, C.B.; Rodell, C.B.; Burdick, J.A. Direct 3D Printing of Shear-Thinning Hydrogels into Self-Healing Hydrogels. Adv. Mater. 2015, 27, 5075–5079. [Google Scholar] [CrossRef] [PubMed]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Deconinck, A.; Lewis, J.A. Omnidirectional printing of 3D microvascular networks. Adv. Mater. 2011, 23, 178–183. [Google Scholar] [CrossRef]

- Bhattacharjee, T.; Zehnder, S.M.; Rowe, K.G.; Jain, S.; Nixon, R.M.; Sawyer, W.G.; Angelini, T.E. Writing in the granular gel medium. Sci. Adv. 2015, 1, e1500655. [Google Scholar] [CrossRef] [Green Version]

| Material | Abbreviation |

|---|---|

| N-isopropylacrylamide | NIPAM |

| carboxymethyl cellulose | CMC |

| Acrylamide | AAM |

| sodium alginate | NaAlg |

| Parameter | Value | Unit |

|---|---|---|

| Concentration of NaAlg, CNaA | 1.0, 2.0, 3.0 | % (w/w) |

| Concentration of CMC, CCMC | 0.4, 1.0, 1.6 | % (w/w) |

| Flow rate of a syringe pump, Q | 0.5, 1.0, 1.5 | µL/s |

| Stage speed, v | 0.5, 1.0, 1.5 | mm/s |

| Diameter of a nozzle, d | 400, 500, 800 | µm |

| Depth of a nozzle, h | 5.0, 7.5, 10 | mm |

| Define | Symbol |

|---|---|

| Maximum position of printed ink | ztop |

| Minimum position of printed ink | zbottom |

| z-axis width of printed ink | wz |

| y-axis width of printed ink | wy |

| Dragged area of the patterned ink at the corner | Aerror |

| Diameter of polymerized ink | dpolymer |

| Diameter of printed ink | dinitial |

| Diameter of polymerized ink before stimuli | d0 |

| Diameter of polymerized ink after stimuli | dn |

| Patterned ratio of pAAM gel in multi-hydrogel structure | PA |

| Patterned ratio of pNIPAMgel in multi-hydrogel structure | PN |

| Width of pAAM gel in multi-hydrogel structure | wA |

| Width of pNIPAM gel in multi-hydrogel structure | wN |

| Total width of multi-hydrogel structure | wH |

| Parameter | ztop, zbottom | wz | wy |

|---|---|---|---|

| CNaA↑ | ↓ | ↑ | → |

| CCMC↑ | ↑ | ↓ | → |

| d↑ | ↑ | → | |

| Q↑ | ↓ | ↑ | |

| v↑ | ↑ | ↓ | |

| h↑ | ↑ | → | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uchida, T.; Onoe, H. 4D Printing of Multi-Hydrogels Using Direct Ink Writing in a Supporting Viscous Liquid. Micromachines 2019, 10, 433. https://doi.org/10.3390/mi10070433

Uchida T, Onoe H. 4D Printing of Multi-Hydrogels Using Direct Ink Writing in a Supporting Viscous Liquid. Micromachines. 2019; 10(7):433. https://doi.org/10.3390/mi10070433

Chicago/Turabian StyleUchida, Takuya, and Hiroaki Onoe. 2019. "4D Printing of Multi-Hydrogels Using Direct Ink Writing in a Supporting Viscous Liquid" Micromachines 10, no. 7: 433. https://doi.org/10.3390/mi10070433

APA StyleUchida, T., & Onoe, H. (2019). 4D Printing of Multi-Hydrogels Using Direct Ink Writing in a Supporting Viscous Liquid. Micromachines, 10(7), 433. https://doi.org/10.3390/mi10070433