Design and Fabrication of a Kirigami-Inspired Electrothermal MEMS Scanner with Large Displacement

Abstract

:1. Introduction

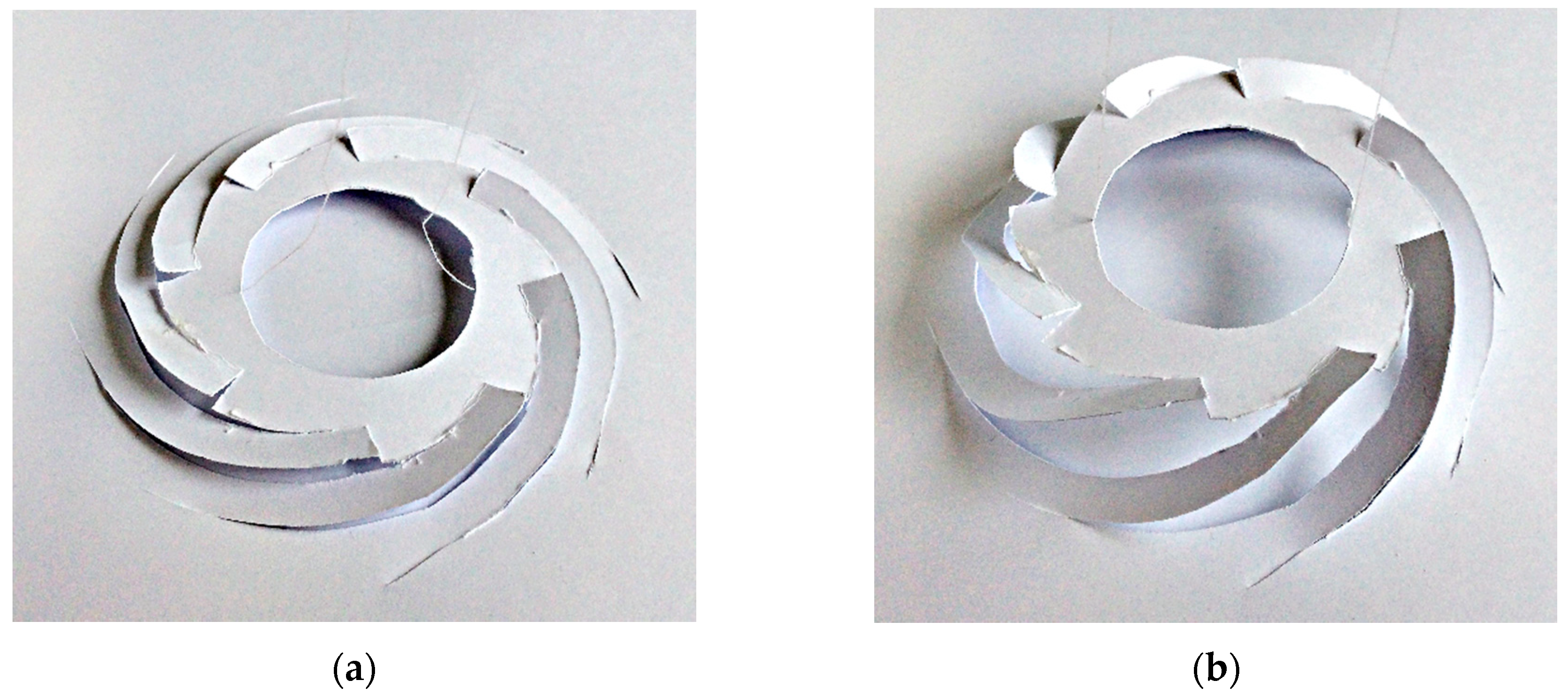

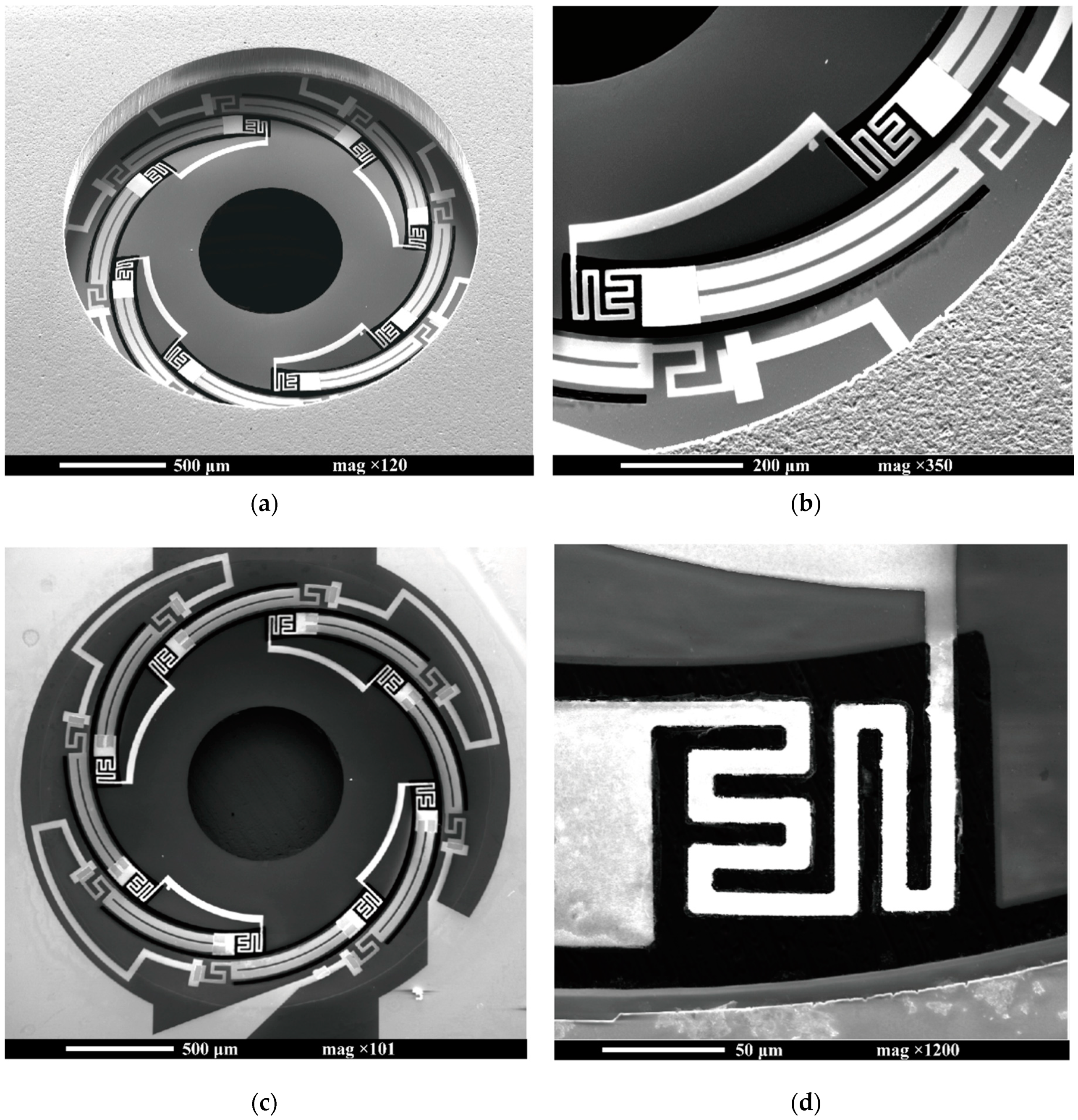

2. Kirigami-Inspired Electrothermal MEMS Scanner

2.1. Design

2.2. Simulation Analysis

3. Fabrication

4. Experimental Tests

4.1. Static Response

4.2. Dynamic Response

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, P.; Pan, L.F.; Zappe, H. Three-Axis Actuator for Positioning a Polymer Microlens in an Optical Pickup. J. Microelectromech. Syst. 2014, 23, 128–136. [Google Scholar] [CrossRef]

- Li, H.J.; Duan, X.Y.; Li, G.M.; Oldham, K.R.; Wang, T.D. An Electrostatic MEMS Translational Scanner with Large Out-of-Plane Stroke for Remote Axial-Scanning in Multi-Photon Microscopy. Micromachines 2017, 8, 159. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Chen, J.P.; Zivkovic, A.S.; Xie, H.K. A Fourier Transform Spectrometer Based on an Electrothermal MEMS Mirror with Improved Linear Scan Range. Sensors 2016, 16, 1611. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, H.P.; Li, M.Y.; Zhang, Y.; Xie, H.K.; Chen, C.; Peng, Z.M.; Su, S.H. H∞ Robust Control of a Large-Piston MEMS Micromirror for Compact Fourier Transform Spectrometer Systems. Sensors 2018, 18, 508. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, L.; Wang, E.K.; Zhang, X.Y.; Liang, W.X.; Li, X.D.; Xie, H.K. MEMS-based 3D confocal scanning microendoscope using MEMS scanners for both lateral and axial scan. Sens. Actuator A Phys. 2014, 215, 89–95. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tanguy, Q.A.A.; Bargiel, S.; Xie, H.K.; Passilly, N.; Barthes, M.; Gaiffe, O.; Rutkowski, J.; Lutz, P.; Gorecki, C. Design and Fabrication of a 2-Axis Electrothermal MEMS Micro-Scanner for Optical Coherence Tomography. Micromachines 2017, 8, 146. [Google Scholar] [CrossRef]

- Matoba, Y.; Taguchi, Y.; Nagasaka, Y. Micro optical diffusion sensor using a comb-driven micro Fresnel mirror. Opt. Express 2015, 23, 477–483. [Google Scholar] [CrossRef]

- Kiuchi, Y.; Taguchi, Y.; Nagasaka, Y. Fringe-tunable electrothermal Fresnel mirror for use in compact and high-speed diffusion sensor. Opt. Express 2017, 25, 758–767. [Google Scholar] [CrossRef]

- Kiuchi, Y.; Taguchi, Y.; Nagasaka, Y. Decay time control of mass diffusion in a transient grating using a fringe-tunable electrothermal Fresnel mirror. J. Therm. Sci. Technol. 2017, 12, JTST0027. [Google Scholar] [CrossRef] [Green Version]

- Bargiel, S.; Gorecki, C.; Verdot, T.; Laszczyk, K.; Albero, J.; El Fissi, L. Electrostatically driven optical Z-axis scanner with thermally bonded glass microlens. In Proceedings of the Eurosensors XXIV, 2010, Linz, Austria, 5–8 September 2010; pp. 762–765. [Google Scholar]

- Oda, K.; Takao, H.; Terao, K.; Suzuki, T.; Shimokawa, F.; Ishimaru, I.; Ohira, F. Vertical comb-drive MEMS mirror with sensing function for phase-shift device. Sens. Actuator A.Phys. 2012, 181, 61–69. [Google Scholar] [CrossRef]

- Chen, S.H.; Michael, A.; Kwok, C.Y. Design and Modeling of Piezoelectrically Driven Micro-Actuator with Large Out-of-Plane and Low Driving Voltage for Micro-Optics. J. Microelectromech. Syst. 2019, 28, 919–932. [Google Scholar] [CrossRef]

- Siu, C.P.B.; Zeng, H.; Chiao, M. Magnetically actuated MEMS microlens scanner for in vivo medical imaging. Opt. Express 2007, 15, 11154–11166. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.Y.; Zhou, L.; Xie, H.K. A fast, large-stroke electrothermal MEMS mirror based on Cu/W bimorph. Micromachines 2015, 6, 1876–1889. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, X.Y.; Xie, H.K. An Electrothermal Cu/W Bimorph Tip-Tilt-Piston MEMS Mirror with High Reliability. Micromachines 2019, 10, 323. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Liu, Y.B.; Wang, D.L.; Liu, H.; Liu, W.G.; Xie, H.K. Stability Study of an Electrothermally-Actuated MEMS Mirror with Al/SiO2 Bimorphs. Micromachines 2019, 10, 693. [Google Scholar] [CrossRef] [Green Version]

- Blees, M.K.; Barnard, A.W.; Rose, P.A.; Roberts, S.P.; McGill, K.L.; Huang, P.Y.; Ruyack, A.R.; Kevek, J.W.; Kobrin, B.; Muller, D.A.; et al. Graphene kirigami. Nature 2015, 524, 204–207. [Google Scholar] [CrossRef]

- Silverberg, J.L.; Evans, A.A.; McLeod, L.; Hayward, R.C.; Hull, T.; Santangelo, C.D.; Cohen, I. Using origami design principles to fold reprogrammable mechanical metamaterials. Science 2014, 345, 647–650. [Google Scholar] [CrossRef]

- Han, T.W.; Scarpa, F.; Allan, N.L. Super, stretchable hexagonal boron nitride Kirigami. Thin Solid Film. 2017, 632, 35–43. [Google Scholar] [CrossRef] [Green Version]

- Dias, M.A.; McCarron, M.P.; Rayneau-Kirkhope, D.; Hanakata, P.Z.; Campbell, D.K.; Park, H.S.; Holmes, D.P. Kirigami actuators. Soft Matter 2017, 13, 9087–9092. [Google Scholar] [CrossRef] [Green Version]

- Shyu, T.C.; Damasceno, P.F.; Dodd, P.M.; Lamoureux, A.; Xu, L.Z.; Shlian, M.; Shtein, M.; Glotzer, S.C.; Kotov, N.A. A kirigami approach to engineering elasticity in nanocomposites through patterned defects. Nat. Mater. 2015, 14, 785–789. [Google Scholar] [CrossRef] [Green Version]

- Baldwin, A.; Meng, E. Kirigami Strain Sensors Microfabricated From Thin-Film Parylene C. J. Microelectromech. Syst. 2018, 27, 1082–1088. [Google Scholar] [CrossRef]

- Moshe, M.; Esposito, E.; Shankar, S.; Bircan, B.; Cohen, I.; Nelson, D.R.; Bowick, M.J. Kirigami Mechanics as Stress Relief by Elastic Charges. Phys. Rev. Lett. 2019, 122, 048001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lamoureux, A.; Lee, K.; Shlian, M.; Forrest, S.R.; Shtein, M. Dynamic kirigami structures for integrated solar tracking. Nat. Commun. 2015, 6, 8092. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.G.; Du, H.F.; Li, J.F.; Lu, L.; Li, Z.Y.; Fang, N.X. Nano-kirigami with giant optical chirality. Sci. Adv. 2016, 4, eaat4436. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.J.; Jing, L.Q.; Yao, K.; Yang, Y.H.; Zheng, B.; Soukoulis, C.M.; Chen, H.S.; Liu, Y.M. Origami-based reconfigurable metamaterials for tunable chirality. Adv. Mater. 2017, 29, 1700412. [Google Scholar] [CrossRef]

- Choi, W.J.; Cheng, G.; Huang, Z.Y.; Zhang, S.; Norris, T.B.; Kotov, N.A. Terahertz circular dichroism spectroscopy of biomaterials enabled by kirigami polarization modulators. Nat. Mater. 2019, 18, 820–826. [Google Scholar] [CrossRef]

- Kuribayashi, K.; Tsuchiya, K.; You, Z.; Tomus, D.; Umemoto, M.; Ito, T.; Sasaki, M. Self-deployable origami stent grafts as a biomedical application of Ni-rich TiNi shape memory alloy foil. Mater. Sci. Eng. A. 2006, 419, 131–137. [Google Scholar] [CrossRef]

- Kuribayashi, K.; Onoe, H.; Takeuchi, S. Cell origami: Self-folding of three-dimensional cell-laden microstructures driven by cell traction force. PLoS ONE 2012, 7, e51085. [Google Scholar] [CrossRef]

- Randall, C.L.; Gultepe, E.; Gracias, D.H. Self-folding devices and materials for biomedical applications. Trend. Biotechnol. 2012, 30, 138–146. [Google Scholar] [CrossRef] [Green Version]

- Rossiter, J.; Sareh, S. Kirigami design and fabrication for biomimetic robotics. Proceedings of Bioinspiration, Biomimetics, and Bioreplication 2014, San Diego, CA, USA, 10–12 March 2014. [Google Scholar] [CrossRef]

- Wu, C.S.; Wang, X.; Lin, L.; Guo, H.Y.; Wang, Z.L. Paper-Based Triboelectric Nanogenerators Made of Stretchable Interlocking Kirigami Patterns. ACS Nano 2016, 10, 4652–4659. [Google Scholar] [CrossRef]

- Song, Z.M.; Wang, X.; Lv, C.; An, Y.H.; Liang, M.B.; Ma, T.; He, D.; Zheng, Y.J.; Huang, S.Q.; Yu, H.Y.; et al. Kirigami-based stretchable lithium-ion batteries. Sci. Rep. 2015, 5, 10988. [Google Scholar] [CrossRef]

- Fonseca, L.M.; Rodrigues, G.V.; Savi, M.A.; Paiva, A. Nonlinear dynamics of an origami wheel with shape memory alloy actuators. Chaos Solitons Fractals 2019, 122, 245–261. [Google Scholar] [CrossRef] [Green Version]

- Tolley, M.T.; Felton, S.M.; Miyashita, S.; Aukes, D.; Rus, D.; Wood, R.J. Self-folding origami: Shape memory composites activated by uniform heating. Smart Mater. Struct. 2014, 23, 094006. [Google Scholar] [CrossRef]

- Hernandez, E.A.P.; Hartl, D.J.; Malak, R.J.; Akleman, E.; Gonen, O.; Kung, H.W. Design Tools for Patterned Self-Folding Reconfigurable Structures Based on Programmable Active Laminates. J. Mech. Robot. 2016, 8, 031015. [Google Scholar] [CrossRef]

- Jamal, M.; Zarafshar, A.M.; Gracias, D.H. Differentially photo-crosslinked polymers enable self-assembling microfluidics. Nat. Commun. 2011, 2, 527. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.; Nandan, B.; Luchnikov, V.; Simon, F.; Vyalikh, A.; Scheler, U.; Stamm, M. A Novel Approach for the Fabrication of Silica and Silica/Metal Hybrid Microtubes. Chem. Mat. 2009, 21, 4282–4287. [Google Scholar] [CrossRef]

- Ryu, J.; D’Amato, M.; Cui, X.D.; Long, K.N.; Qi, H.J.; Dunn, M.L. Photo-origami—Bending and folding polymers with light. Appl. Phys. Lett. 2012, 100, 161908. [Google Scholar] [CrossRef]

- Javed, H.; Merle, B.; Preiss, E.; Hivet, R.; Benedetto, A.; Goken, M. Mechanical characterization of metallic thin films by bulge and scratch testing. Surf. Coat. Technol. 2016, 289, 69–74. [Google Scholar] [CrossRef]

- Edwards, R.L.; Coles, G.; Sharpe, W.N. Comparison of Tensile and Bulge Tests for Thin-Film Silicon Nitride. Exp. Mech. 2014, 44, 49–54. [Google Scholar] [CrossRef]

- Vayrette, R.; Galceran, M.; Coulombier, M.; Godet, S.; Raskin, J.P.; Pardoen, T. Size dependent fracture strength and cracking mechanisms in freestanding polycrystalline silicon films with nanoscale thickness. Eng. Fract. Mech. 2016, 168, 190–203. [Google Scholar] [CrossRef]

- Davoudi, K. Temperature dependence of the yield strength of aluminum thin films: Multiscale modeling approach. Scr. Mater. 2017, 131, 63–66. [Google Scholar] [CrossRef] [Green Version]

- Hatty, V.; Kahn, H.; Heuer, A.H. Fracture Toughness, Fracture Strength, and Stress Corrosion Cracking of Silicon Dioxide Thin Films. J. Microelectromech. Syst. 2008, 17, 943–947. [Google Scholar] [CrossRef]

- Pal, S.; Zhou, L.; Zhang, X.; Xie, H.K. Electrothermally actuated MEMS mirrors: Design, modeling, and applications. In Optical MEMS, Nanophotonics, and Their Applications; CRC Press: Boca Raton, FL, USA, 2017; pp. 173–200. [Google Scholar]

- Griffin, A.J.; Brotzen, F.R.; Loos, P.J. The effective transverse thermal conductivity of amorphous Si3N4 thin films. J. Appl. Phys. 1994, 76, 4007–4011. [Google Scholar] [CrossRef]

- Tarraf, A.; Daleiden, J.; Irmer, S.; Prasai, D.; Hillmer, H. Stress investigation of PECVD dielectric layers for advanced optical MEMS. J. Micromech. Microeng. 2004, 14, 317–323. [Google Scholar] [CrossRef]

- Mezin, A. Coating internal stress measurement through the curvature method: A geometry-based criterion delimiting the relevance of Stoney’s formula. Surf. Coat. Technol. 2006, 200, 5259–5267. [Google Scholar] [CrossRef]

- Shen, Y.G.; Mai, Y.W.; Zhang, Q.C.; McKenzie, D.R.; McFall, W.D.; McBride, W.E. Residual stress, microstructure, and structure of tungsten thin films deposited by magnetron sputtering. J. Appl. Phys. 2000, 87, 177–187. [Google Scholar] [CrossRef]

- Al-masha’al, A.; Bunting, A.; Cheung, R. Evaluation of residual stress in sputtered tantalum thin-film. Appl. Surf. Sci. 2016, 371, 571–575. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashimoto, M.; Taguchi, Y. Design and Fabrication of a Kirigami-Inspired Electrothermal MEMS Scanner with Large Displacement. Micromachines 2020, 11, 362. https://doi.org/10.3390/mi11040362

Hashimoto M, Taguchi Y. Design and Fabrication of a Kirigami-Inspired Electrothermal MEMS Scanner with Large Displacement. Micromachines. 2020; 11(4):362. https://doi.org/10.3390/mi11040362

Chicago/Turabian StyleHashimoto, Masaaki, and Yoshihiro Taguchi. 2020. "Design and Fabrication of a Kirigami-Inspired Electrothermal MEMS Scanner with Large Displacement" Micromachines 11, no. 4: 362. https://doi.org/10.3390/mi11040362

APA StyleHashimoto, M., & Taguchi, Y. (2020). Design and Fabrication of a Kirigami-Inspired Electrothermal MEMS Scanner with Large Displacement. Micromachines, 11(4), 362. https://doi.org/10.3390/mi11040362