Micro-Drilling of Sapphire Using Electro Chemical Discharge Machining

Abstract

:1. Introduction

2. Methodology

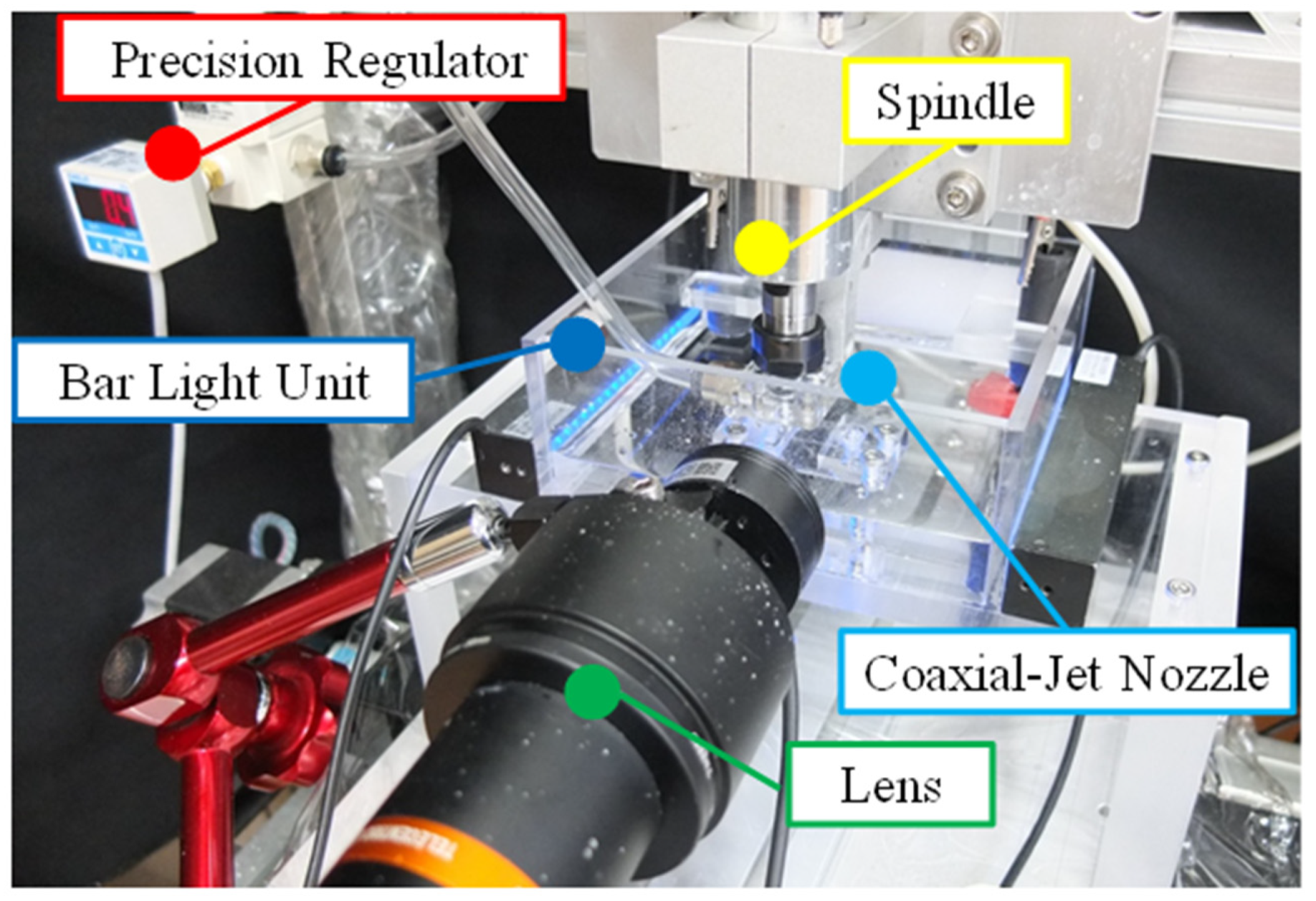

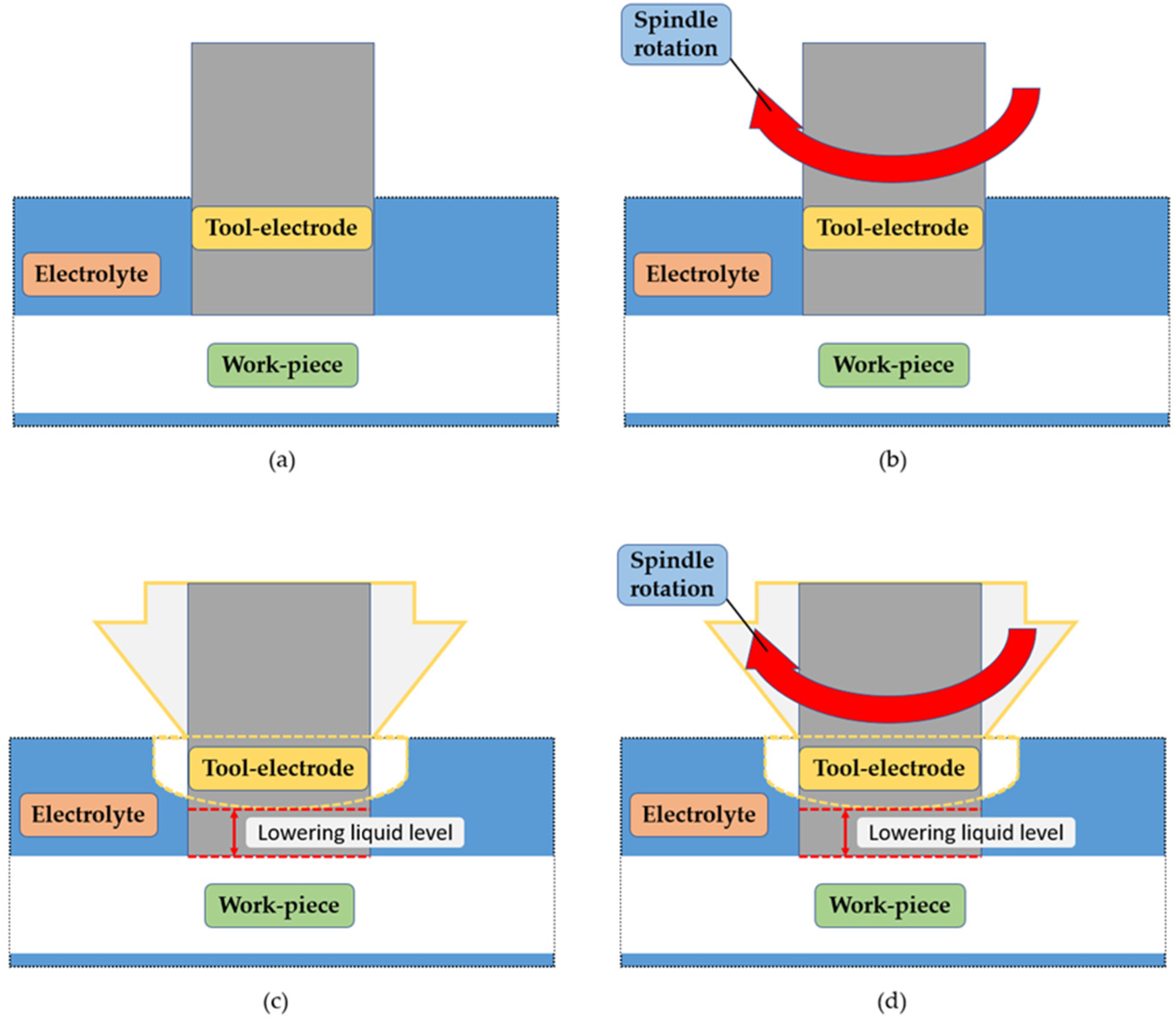

2.1. Electrode Rotation Combined with the Coaxial Jet Assisted Mechanism

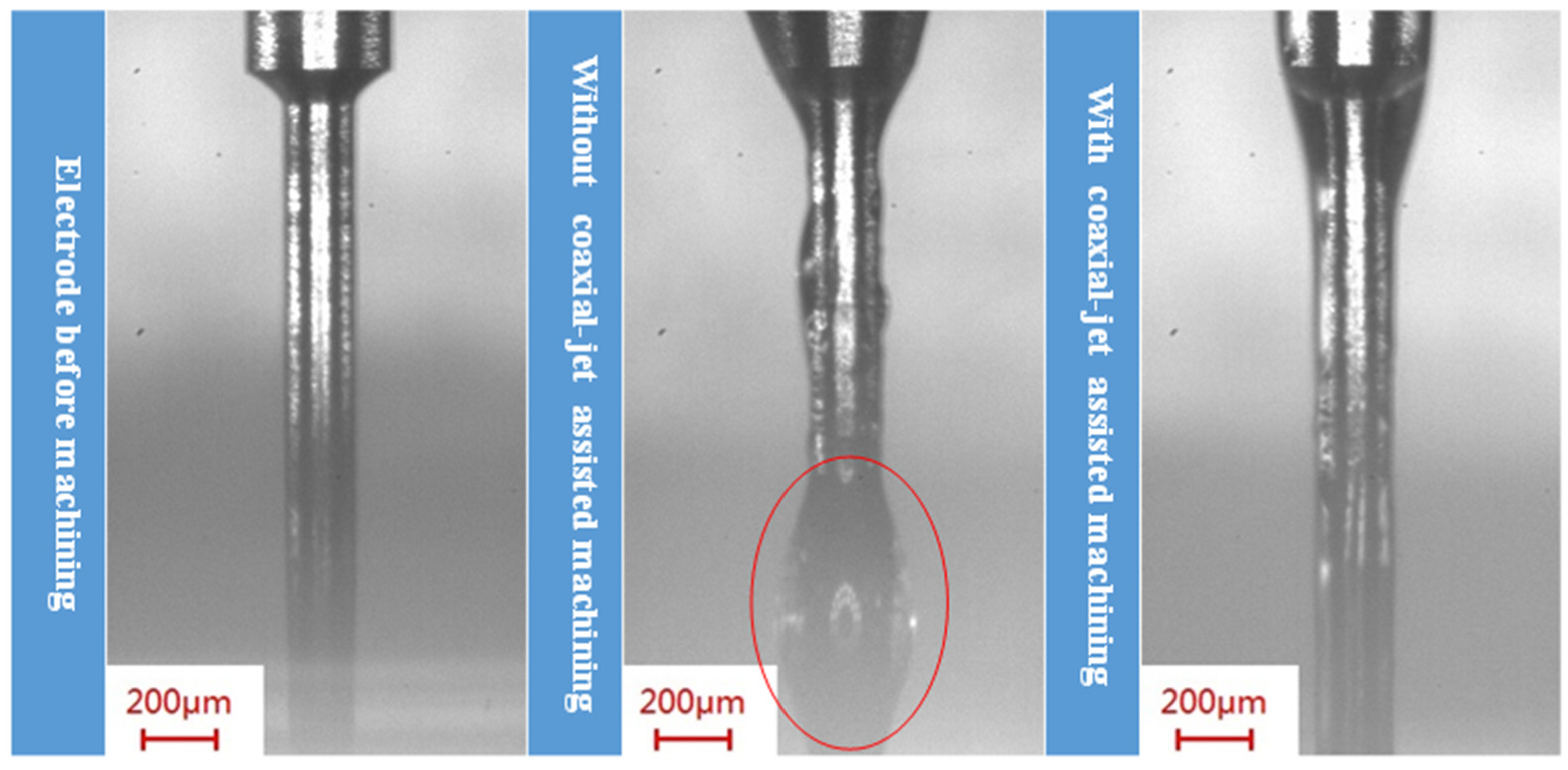

2.2. Machining Electrode Wear Measurement Experiment

3. Experimental Result

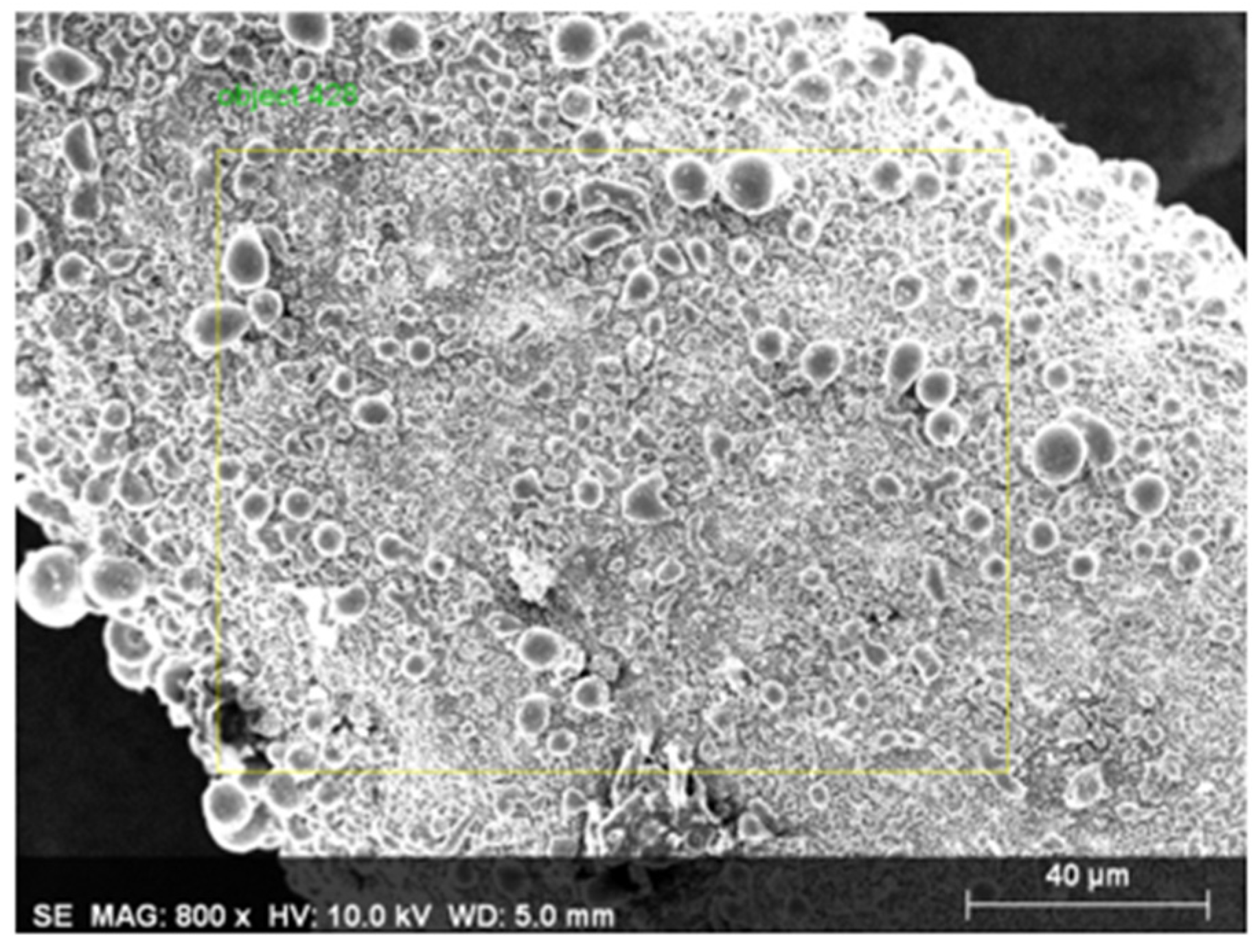

3.1. Machining Electrode Wear Measurement Experimental Results

3.2. Sapphire Machining Result

3.3. Machining Electrode Wear Measurement Experiment

3.4. Sapphire Machining Experiment

4. Conclusions

- We researched and developed an assisted nozzle capable of combining two types of assisted methods of the tool electrode rotation and coaxial-jet at the same time.

- We established an experimental system architecture for the online observation of the ECDM experiment.

- The combinational machining assisted method proposed in this research indicated a reduction of axial wear by 39.29% and radial wear by 84.09% in comparison to the tool electrode without assisted machining. In addition, we discussed the tungsten carbide tool electrode wear principle during ECDM.

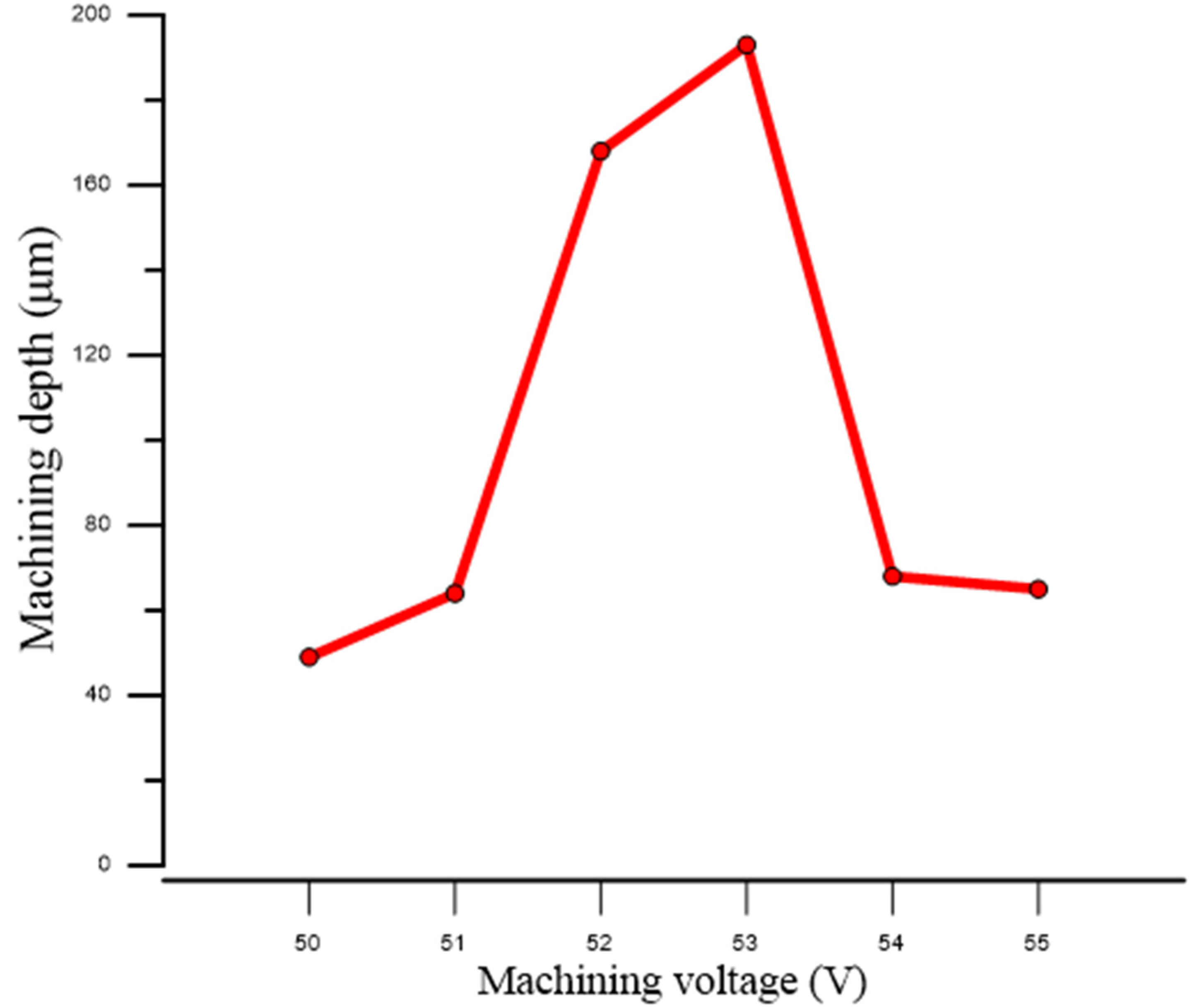

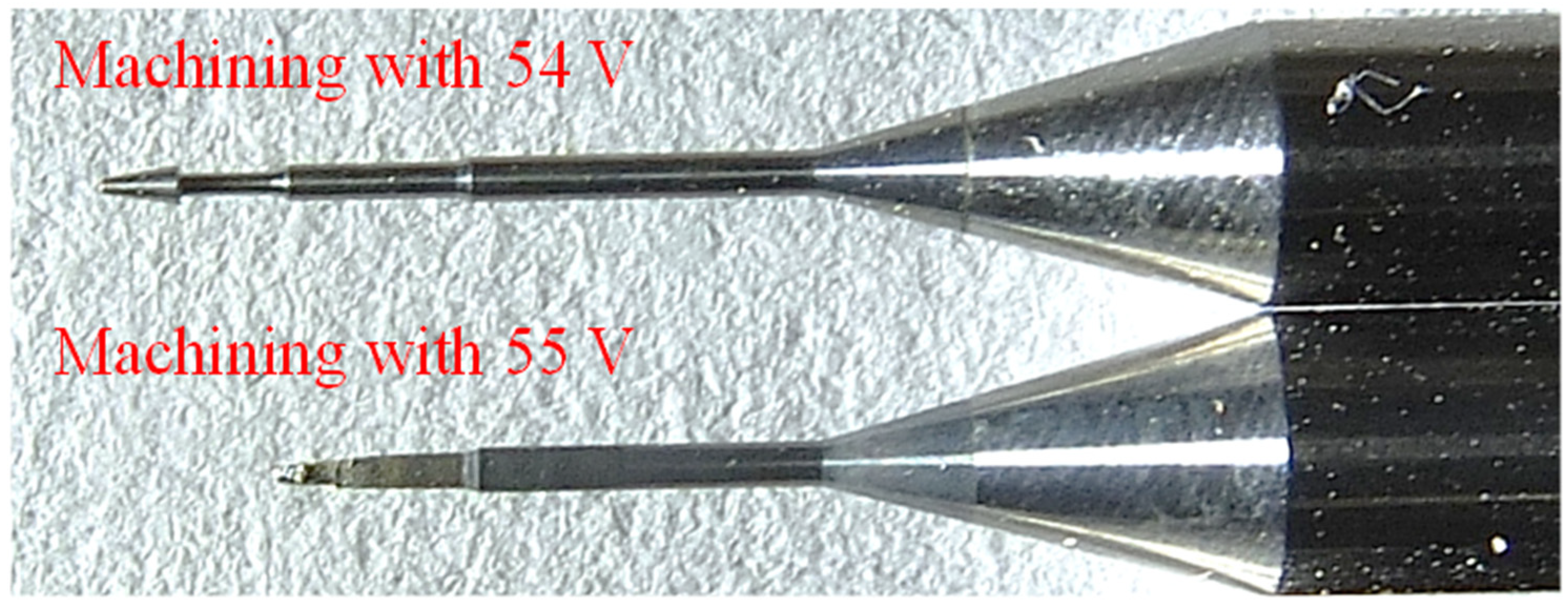

- The method of ECDM was used to perform the machining of sapphire with a voltage of 53 V in KOH electrolyte at a concentration of 5 M, and the machining depth reached 193 μm.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.; Pickrell, G.R.; Qi, B.; Safaai-Jazi, A.; Wang, A. Single-crystal sapphire based optical polarimetric sensor for high temperature measurement. Sensors 2006, 6, 823–834. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.J. Vertical chip of gan-based blue light-emitting diode. Solid-State Electron. 2005, 49, 1153–1157. [Google Scholar] [CrossRef]

- Takahashi, K.; Cline, J.A.; Bartels, D.M.; Jonah, C.D. Design of an optical cell for pulse radiolysis of supercritical water. Rev. Sci.Instrum. 2000, 71, 3345–3350. [Google Scholar] [CrossRef]

- Sinani, A.; Dynkin, N.; Lytvinov, L.; Konevsky, P.; Andreev, E. Sapphire hardness in different crystallographic directions. Bull. Russ. Acad. Sci. Phys 2009, 73, 1380. [Google Scholar] [CrossRef]

- Xiao, H.; Deng, J.; Pickrell, G.; May, R.G.; Wang, A. Single-crystal sapphire fiber-based strain sensor for high-temperature applications. J. Light. Technol. 2003, 21, 2276. [Google Scholar] [CrossRef]

- Litvinov, L.; Druzenko, T.; Potapova, V.; Blank, A. Corrosion resistance of sapphire surface as a function of its crystallographic characteristics. Crystallogr. Rep. 2001, 46, 303–305. [Google Scholar] [CrossRef]

- Petkovšek, M.; Dular, M. Experimental Study of the Thermodynamic Effect in a Cavitating Flow on a Simple Venturi Geometry. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2015; p. 012179. [Google Scholar]

- Oshima, T.; Okuno, T.; Fujita, S. Ga2o3 thin film growth on c-plane sapphire substrates by molecular beam epitaxy for deep-ultraviolet photodetectors. Jpn. J. Appl. Phys. 2007, 46, 7217. [Google Scholar] [CrossRef]

- Dobrovinskaya, E.R.; Lytvynov, L.A.; Pishchik, V. Sapphire: Material, Manufacturing, Applications; Springer: New York, NY, USA, 2009. [Google Scholar]

- Pawar, P.; Ballav, R.; Kumar, A. Machining processes of sapphire: An overview. Int. J. Mod. Manuf. Technol. 2017, 9, 47–72. [Google Scholar]

- Li, Z.; Pei, Z.; Funkenbusch, P. Machining processes for sapphire wafers: A literature review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 975–989. [Google Scholar] [CrossRef]

- Shamir, A.; Ishaaya, A. Large volume ablation of sapphire with ultra-short laser pulses. Appl. Surf. Sci. 2013, 270, 763–766. [Google Scholar] [CrossRef]

- Zhang, C.L.; Feng, P.F.; Pei, Z.J.; Cong, W.L. Rotary ultrasonic machining of sapphire: Feasibility study and designed experiments. Key Neuroeng. Mater. 2014, 589–590, 523–528. [Google Scholar] [CrossRef]

- Liu, M.; Hu, Y.; Sun, X.; Wang, C.; Zhou, J.; Dong, X.; Yin, K.; Chu, D.; Duan, J.A. Chemical etching mechanism and properties of microstructures in sapphire modified by femtosecond laser. Appl. Phys. A 2017, 123, 99. [Google Scholar] [CrossRef]

- Plaza, J.A.; Lopez, M.J.; Moreno, A.; Duch, M.; Cané, C. Definition of high aspect ratio glass columns. Sens. Actuators A Phys. 2003, 105, 305–310. [Google Scholar] [CrossRef]

- Bu, M.; Melvin, T.; Ensell, G.J.; Wilkinson, J.S.; Evans, A.G.R. A new masking technology for deep glass etching and its microfluidic application. Sens. Actuators A Phys. 2004, 115, 476–482. [Google Scholar] [CrossRef]

- Indrajit, B.; Amitabha, G. Mechanism of material removal in electrochemical discharge machining: A theoretical model and experimental verification. J. Mater. Process. Technol. 1997, 71, 350–359. [Google Scholar]

- Ho, C.C.; Wu, D.S. Characteristics of the arcing plasma formation effect in spark-assisted chemical engraving of glass, based on machine vision. Materials 2018, 11, 470. [Google Scholar] [CrossRef] [Green Version]

- Jui, S.; Kamaraj, A.B.; Sundaram, M.M. High aspect ratio micromachining of glass by electrochemical discharge machining (ECDM). J. Manuf. Process. 2013, 15, 460–466. [Google Scholar] [CrossRef]

- Gautam, N.; Jain, V.K. Experimental investigations into ECSD process using various tool kinematics. Int. J. Mach. Tools Manuf. 1998, 38, 15–27. [Google Scholar] [CrossRef]

- Yang, C.T.; Ho, S.S.; Yan, B.H. Micro hole machining of borosilicate glass through electrochemical discharge machining (ECDM). Key Eng. Mater. 2001, 196, 149–155. [Google Scholar] [CrossRef]

- Jiang, B.; Lan, S.; Ni, J.; Zhang, Z. Experimental investigation of spark generation in electrochemical discharge machining of non-conducting materials. J. Mater. Process. Technol. 2014, 214, 892–898. [Google Scholar] [CrossRef]

- Jiang, B.; Lan, S.; Wilt, K.; Ni, J. Modeling and experimental investigation of gas film in micro-electrochemical discharge machining process. Int. J. Mach. Tools Manuf. 2015, 90, 8–15. [Google Scholar] [CrossRef]

- Chung, S.F. Study on the Application of Electrochemical Discharge Machining on Sapphire. Master’s Thesis, National Central University, Taoyuan, Taiwan, 2015. [Google Scholar]

- Wüthrich, R.; Abia Hof, L. The gas film in spark assisted chemical engraving (SACE)—A key element for micro-machining applications. Int. J. Mach. Tools Manuf. 2006, 46, 828–835. [Google Scholar] [CrossRef]

- Jahan, M.P.; Perveen, A.; Rumsey, A.M. A review on the conventional, non-conventional, and hybrid micromachining of glass. Mach. Sci. Technol. 2019, 23, 264–338. [Google Scholar] [CrossRef]

- Paul, L.; Antony, D. Effect of tool diameter in ECDM process with powder mixed electrolyte. IOP Conf. Ser. Mater. Sci. Eng. 2008, 396, 01207g. [Google Scholar] [CrossRef]

- Chak, S.K.; Rao, P.V. The drilling of Al2O3 using a pulsed dc supply with a rotary abrasive electrode by the electrochemical discharge process. Int. J. Adv. Manuf. Technol. 2008, 39, 633–641. [Google Scholar] [CrossRef]

- Ho, C.C.; Wu, D.S.; Chen, J.C. Flow-jet-assisted electrochemical discharge machining for quartz glass based on machine vision. Measurement 2018, 128, 71–83. [Google Scholar] [CrossRef]

- Thoe, T.B.; Aspinwall, D.K.; Wise, M.L.H. Review on ultrasonic machining. Int. J. Mach. Tools Manuf. 1998, 38, 239–255. [Google Scholar] [CrossRef]

| Electrolyte | 5 M KOH Solution |

|---|---|

| Machining voltage | 50 V |

| Electrode immersion depth | 1 mm |

| Machining feed pressure | 0.15 kgf |

| Spindle rotational speed | 300 rpm |

| Nozzle input pressure | 0.2 kPa |

| Machining Method | (1) Dimension Wear (μm) | (2) Dimension Wear (μm) | (3) Dimension Wear (μm) |

|---|---|---|---|

| Fixed electrode machining | 27 | 44 | 25 |

| Electrode rotation machining | 56 | 24 | 11 |

| Jet assisted machining | 20 | 7 | 4 |

| Combinational assisted machining | 34 | 2 | 2 |

| Machining Voltage (V) | Machining Depth (μm) | Machining Voltage (V) | Machining Depth (μm) |

|---|---|---|---|

| 50 | 49 | 53 | 193 |

| 51 | 64 | 54 | 68 |

| 52 | 168 | 55 | 65 |

| El | AN | Series | Net | Unn. C [wt.%] | Norm. C [wt.%] | Atom. C [at.%] | Error [wt.%] |

|---|---|---|---|---|---|---|---|

| Si | 14 | K-series | 0 | 0.00 | 0.00 | 0.01 | 0.0 |

| K | 19 | K-series | 102 | 1.65 | 4.46 | 8.00 | 0.2 |

| Cr | 24 | K-series | 145 | 6.07 | 16.40 | 22.13 | 0.6 |

| Co | 27 | L-series | 1650 | 18.15 | 49.03 | 58.38 | 3.6 |

| W | 74 | M-series | 723 | 11.14 | 30.10 | 11.49 | 0.7 |

| Total: | 37.02 | 100.00 | 100.00 |

| El | AN | Series | Net | Unn. C [wt.%] | Norm. C [wt.%] | Atom. C [at.%] | Error [wt.%] |

|---|---|---|---|---|---|---|---|

| Si | 14 | K-series | 0 | 0.00 | 0.00 | 0.01 | 0.0 |

| Cr | 24 | K-series | 119 | 0.61 | 1.29 | 3.98 | 0.1 |

| Co | 27 | K-series | 345 | 2.56 | 5.42 | 14.74 | 0.2 |

| W | 74 | L-series | 1557 | 44.07 | 93.29 | 81.27 | 2.1 |

| Total: | 47.24 | 100.00 | 100.00 |

| El | AN | Series | Net | Unn. C [wt.%] | Norm. C [wt.%] | Atom. C [at.%] | Error [wt.%] |

|---|---|---|---|---|---|---|---|

| Si | 14 | K-series | 0 | 0.00 | 0.00 | 0.01 | 0.0 |

| K | 19 | K-series | 77 | 0.87 | 2.54 | 3.86 | 0.1 |

| Cr | 24 | K-series | 115 | 4.64 | 13.56 | 15.49 | 0.5 |

| Co | 27 | L-series | 3034 | 26.77 | 78.22 | 78.82 | 4.6 |

| W | 74 | M-series | 155 | 1.95 | 5.68 | 1.84 | 0.2 |

| Total: | 34.23 | 100.00 | 100.00 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, C.-C.; Chen, J.-C. Micro-Drilling of Sapphire Using Electro Chemical Discharge Machining. Micromachines 2020, 11, 377. https://doi.org/10.3390/mi11040377

Ho C-C, Chen J-C. Micro-Drilling of Sapphire Using Electro Chemical Discharge Machining. Micromachines. 2020; 11(4):377. https://doi.org/10.3390/mi11040377

Chicago/Turabian StyleHo, Chao-Ching, and Jia-Chang Chen. 2020. "Micro-Drilling of Sapphire Using Electro Chemical Discharge Machining" Micromachines 11, no. 4: 377. https://doi.org/10.3390/mi11040377

APA StyleHo, C.-C., & Chen, J.-C. (2020). Micro-Drilling of Sapphire Using Electro Chemical Discharge Machining. Micromachines, 11(4), 377. https://doi.org/10.3390/mi11040377