Blister Formation in Film Insert Moulding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

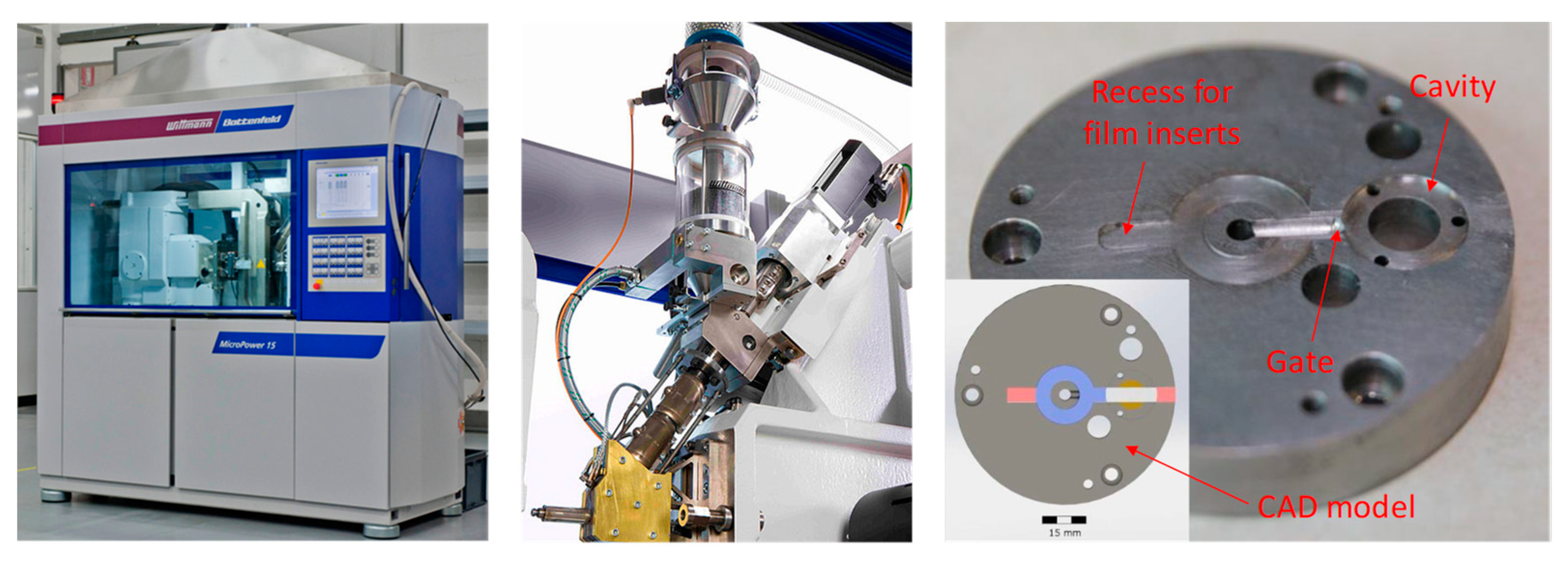

2.2. Part Design

2.3. Moulding Experiments

2.4. Simulations

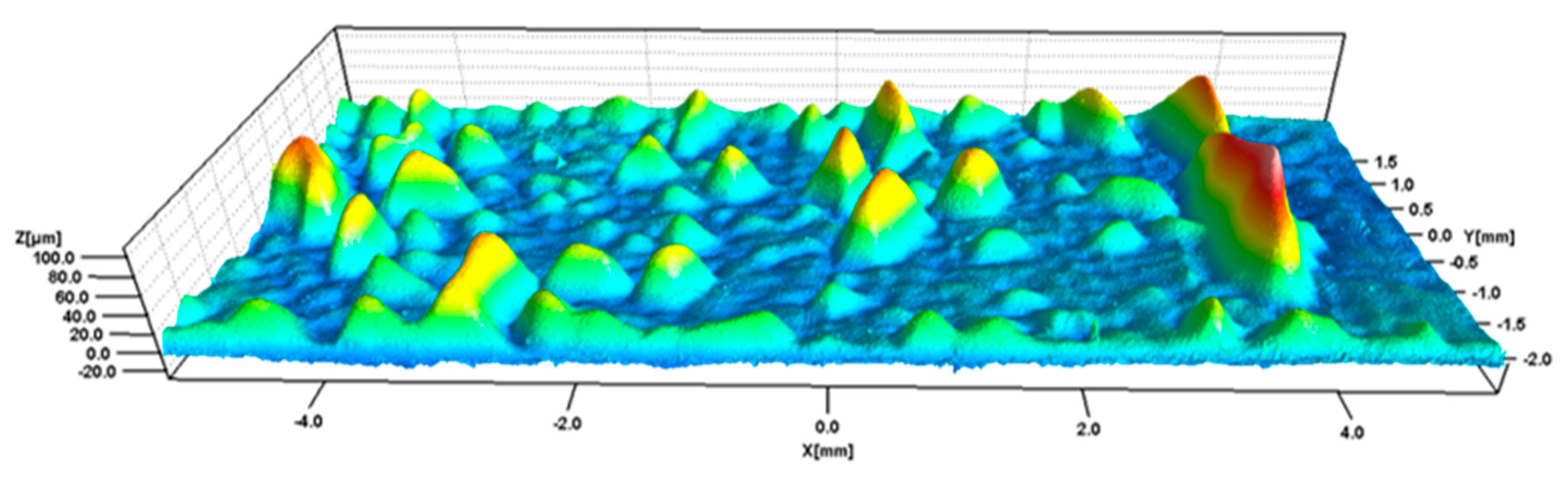

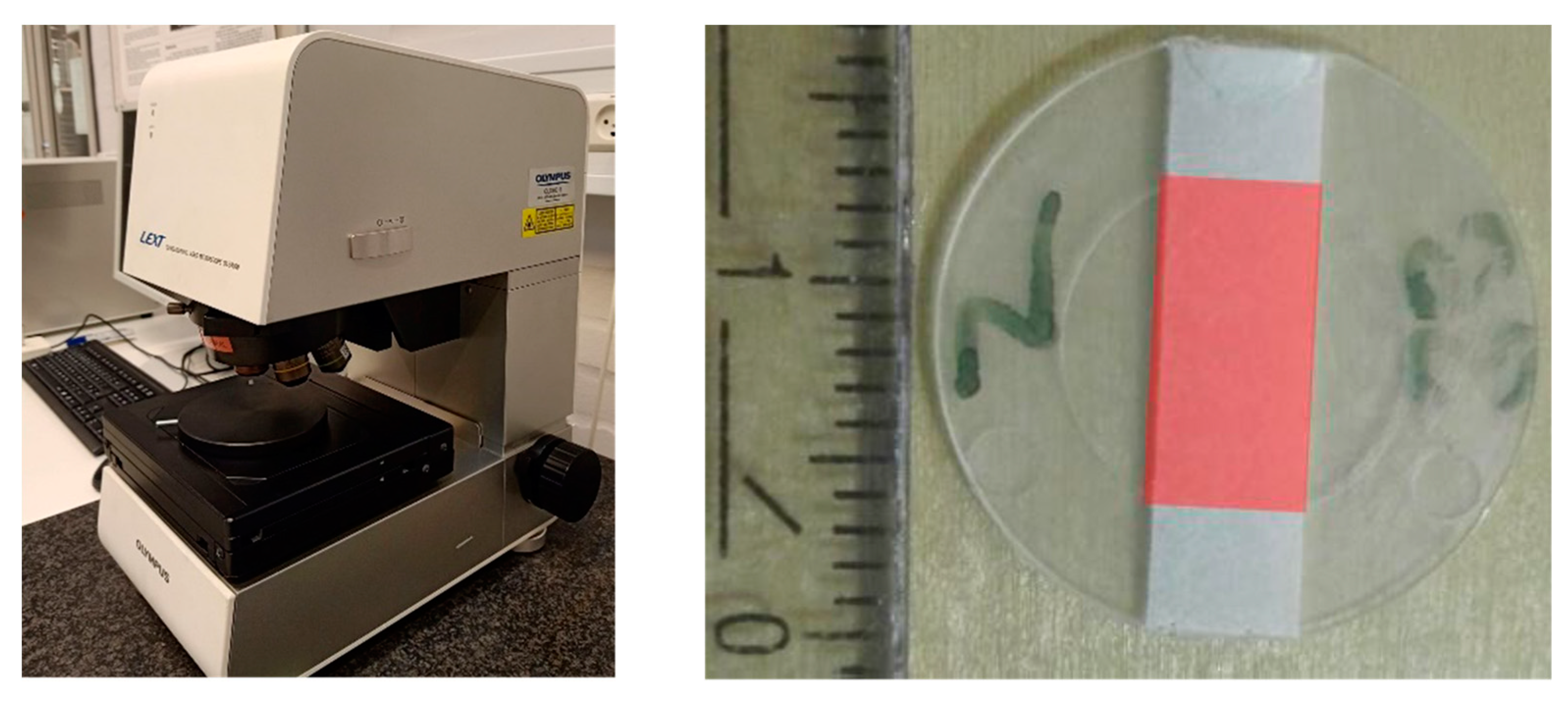

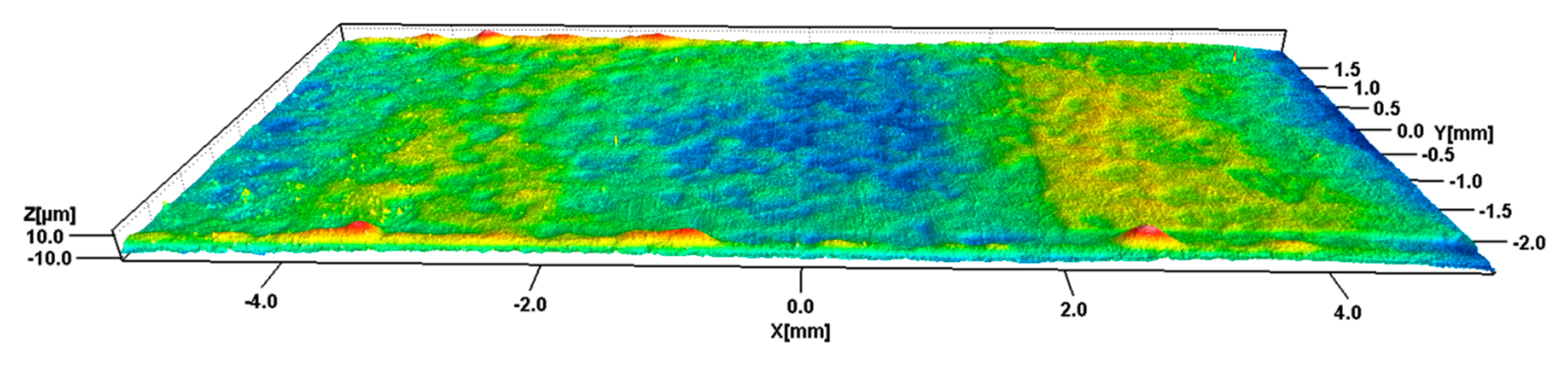

2.5. Metrology

3. Results and Analysis

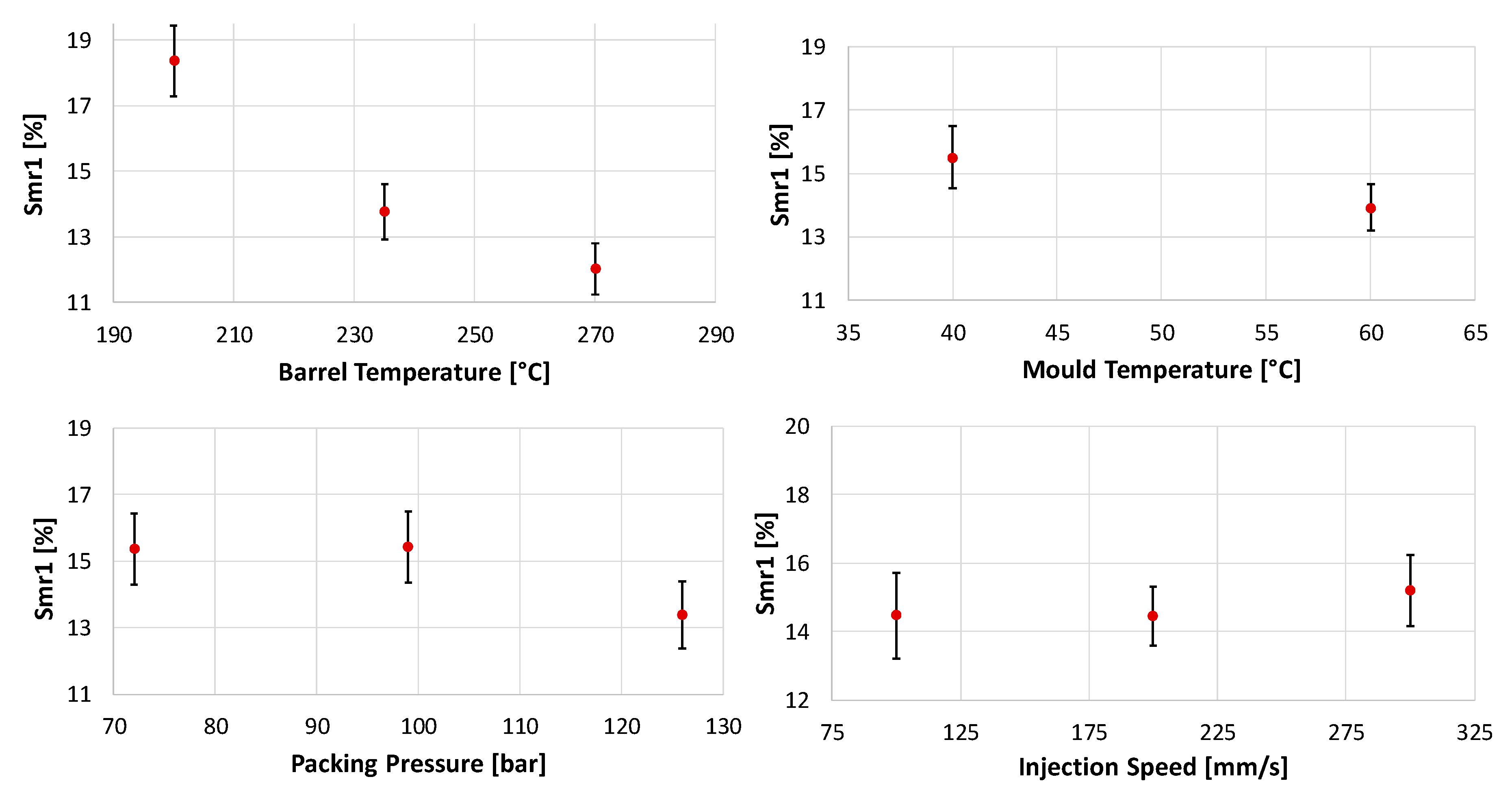

3.1. Smr1

3.2. Spk

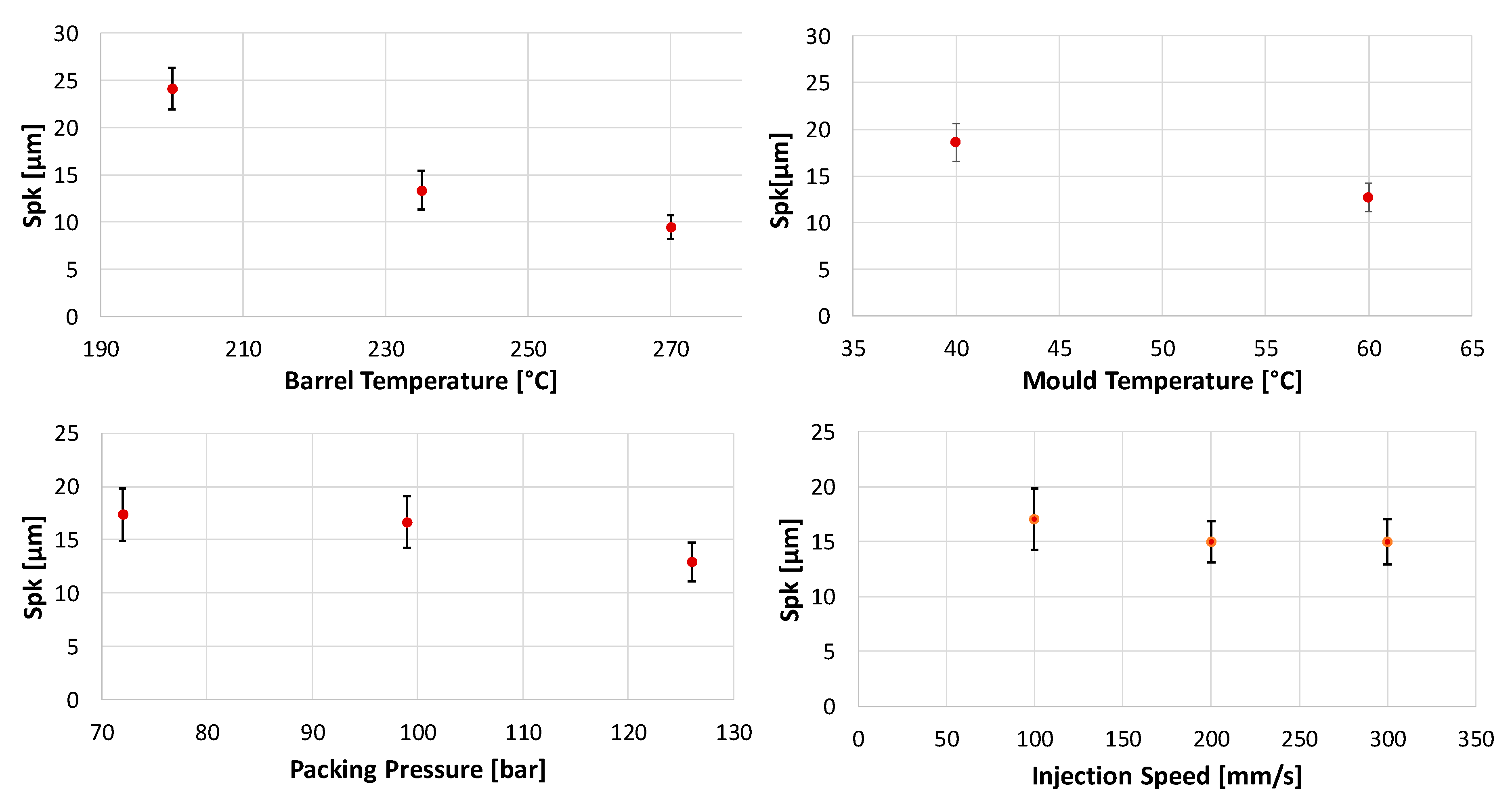

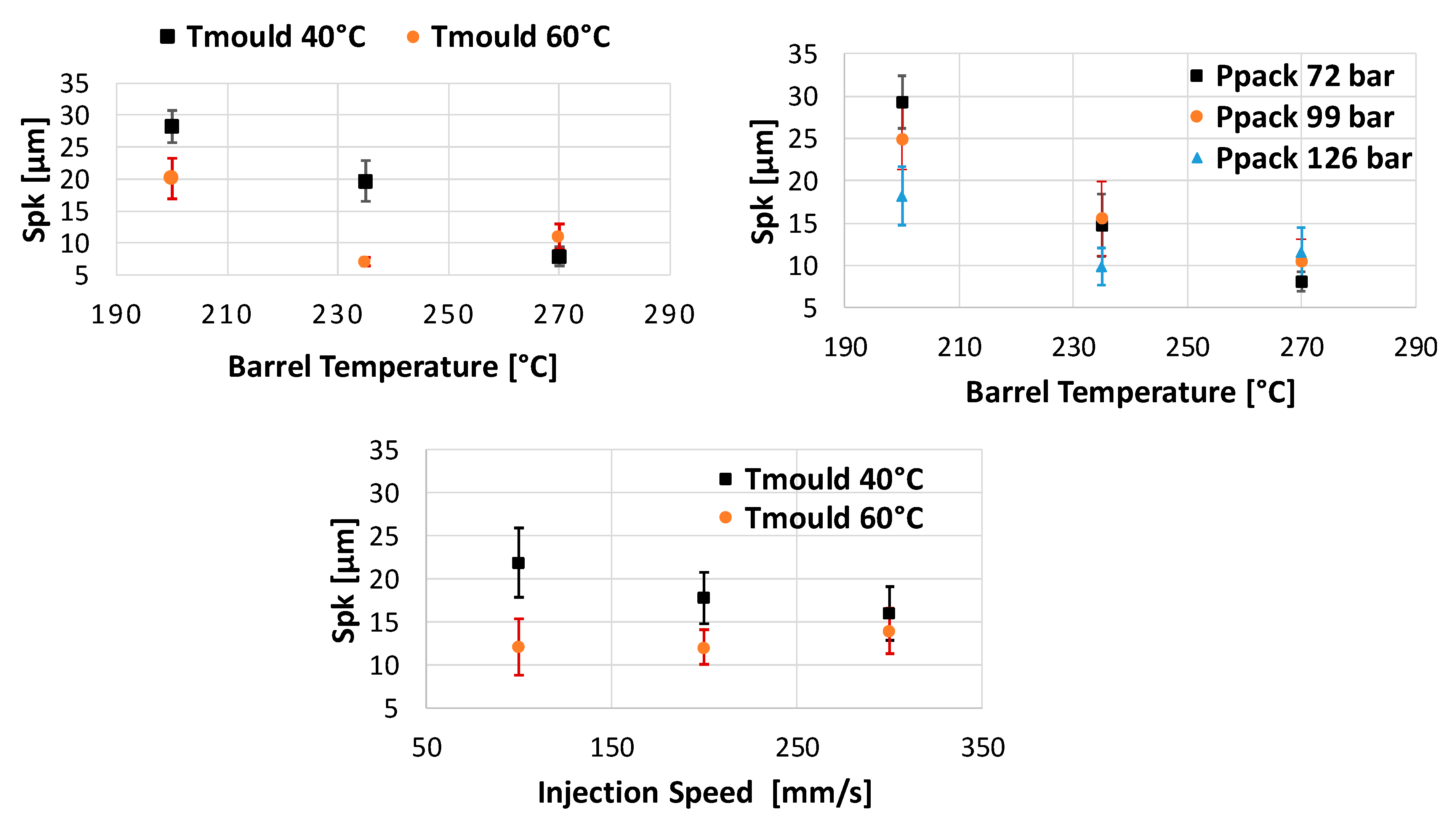

3.3. Average Volumetric Shrinkage under the Film Insert

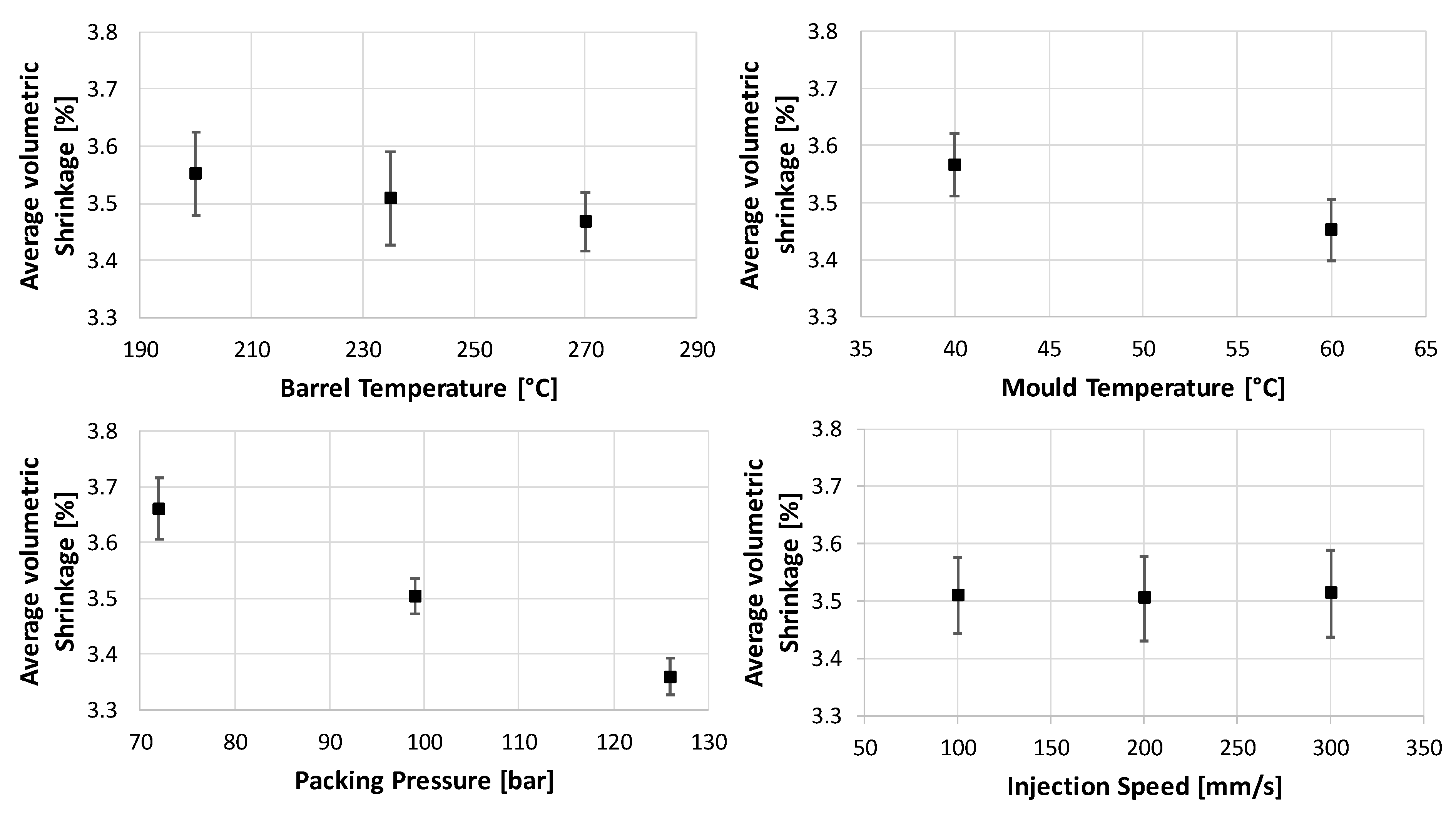

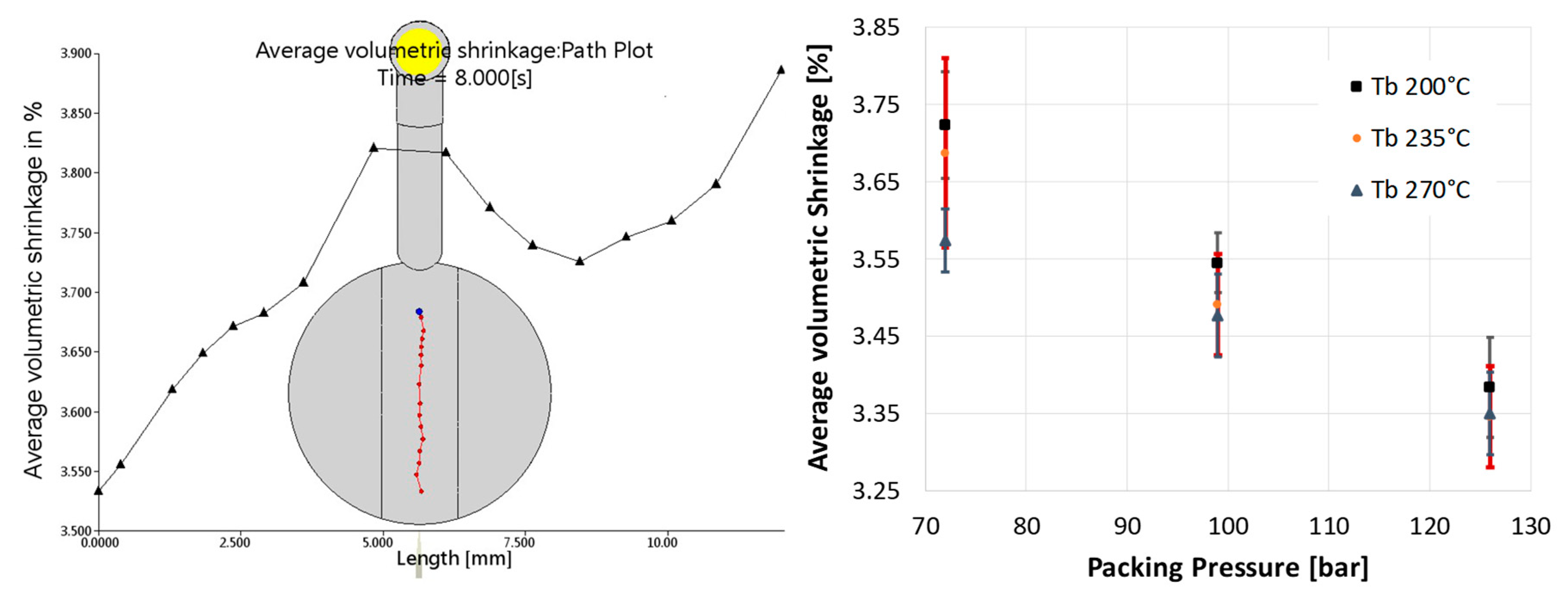

4. Discussion

5. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Kim, S.Y.; Kim, S.H.; Oh, H.J.; Lee, S.H.; Youn, J.R. Residual stress and viscoelastic deformation of film insert molded automotive parts. J. Appl. Polym. Sci. 2010, 118, 2530–2540. [Google Scholar] [CrossRef]

- Kim, S.H.; Jeong, J.H.; Youn, J.R. Nanopattern insert molding. Nanotechnology 2010, 21, 205302. [Google Scholar] [CrossRef] [PubMed]

- Weigelt, K.; Hambsch, M.; Karacs, G.; Zillger, T.; Hubler, A.C. Labeling the World: Tagging Mass Products with Printing Processes. IEEE Pervasive Comput. 2010, 9, 59–63. [Google Scholar] [CrossRef]

- Leong, Y.W.; Umemura, T.; Hamada, H. Film insert molding as a novel weld-line inhibition and strengthening technique. Polym. Eng. Sci. 2008, 48, 2147–2158. [Google Scholar] [CrossRef]

- Oh, H.J.; Song, Y.S.; Lee, S.H.; Youn, J.R. Development of Warpage and Residual Stresses in Film Insert Molded Parts. Polym. Eng. Sci. 2009, 49, 1389–1399. [Google Scholar] [CrossRef]

- Kim, S.Y.; Sung, H.K.; Hwa, J.O.; Seung, H.L.; Soo, J.B.; Jae, R.Y.; Sung, H.L.; Sun, W.K. Molded geometry and viscoelastic behavior of film insert molded parts. J. Appl. Polym. Sci. 2009, 111, 642–650. [Google Scholar] [CrossRef]

- Chen, H.L.; Chen, S.C.; Liao, W.H.; Chien, R.D.; Lin, Y.T. Effects of insert film on asymmetric mold temperature and associated part warpage during in-mold decoration injection molding of PP parts. Int. Commun. Heat Mass Transf. 2013, 41, 34–40. [Google Scholar] [CrossRef]

- Kim, S.Y.; Lee, J.T.; Kim, J.Y.; Youn, J.R. Effects of film and substrate dimensions on warpage of film insert molded parts. Polym. Eng. Sci. 2010, 50, 1205–1213. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kim, S.Y.; Song, Y.S.; Youn, J.R. Relationship between the crystallization behavior and the warpage of film-insert-molded part. J. Appl. Polym. Sci. 2011, 120, 1539–1546. [Google Scholar] [CrossRef]

- Wöhner, T.; Hansen, H.N.; Tosello, G.; Islam, A. Characterization method for blisters created in film insert moulding. In Proceedings of the Euspen’s 15th International Conference & Exhibition, Leuven, Belgium, 1–6 June 2015. [Google Scholar]

- Islam, A.; Hansen, H.; Bondo, M. Experimental investigation of the factors influencing the polymer-polymer bond strength during two-component injection moulding. Int. J. Adv. Manuf. Technol. 2010, 50, 101–111. [Google Scholar] [CrossRef]

- Kim, S.Y.; Oh, H.J.; Kim, S.H.; Kim, C.H.; Lee, S.H.; Youn, J.R. Prediction of Residual Stress and Viscoelastic Deformation of Film Insert Molded Parts. Polym. Eng. Sci. 2008, 48, 1840–1847. [Google Scholar] [CrossRef]

- Chen, S.C.; Li, H.M.; Huang, S.T.; Wang, Y.C. Effect of Decoration Film on Mold Surface Temperature during in-Mold Decoration Injection Molding Process. Int. Commun. Heat Mass Transf. 2010, 37, 501–505. [Google Scholar] [CrossRef]

- Leong, Y.W.; Yamaguchi, S.; Mizoguchi, M.; Hamada, H.; Ishiaku, U.S.; Tsuji, T. The effect of molding conditions on mechanical and morphological properties at the interface of film insert injection molded polypropylene-film/polypropylene matrix. Polym. Eng. Sci. 2004, 44, 2327–2334. [Google Scholar] [CrossRef]

- Leong, T.W.; Kotaki, M.; Hamada, H. Effects of the molecular orientation and crystallization on film–substrate interfacial adhesion in poly (ethylene terephthalate) film-insert moldings. J. Appl. Polym. Sci. 2007, 104, 2100–2107. [Google Scholar] [CrossRef]

- Hales, J.H.; Kallesøe, C.; Lund-Olesen, T.; Johansson, A.; Fanøe, H.C.; Yu, Y.-j.; Lund, P.B.; Vig, A.L.; Tynelius, O.; Christensen, L.H. Micro fuel cells power the hearing aids of the future. Fuel Cellls Bull. 2012, 2012, 12–16. [Google Scholar] [CrossRef]

- Wöhner, T.; Senkbeil, S.; Olesen, T.L.; Hansen, H.N.; Islam, A.; Tosello, G. Mould Design and Material Selection for Film Insert Moulding of Direct Methanol Fuel Cell Packaging. In Proceedings of the 4M/ICOMM2015 Conference, Milan, Italy, 31 March–2 April 2015; pp. 259–262. [Google Scholar]

- Marhöfer, M.; Tosello, G.; Islam, A.; Hansen, H. Gate Design in Injection Molding of Microfluidic Components Using Process Simulations. ASME J. Micro Nano-Manuf. 2016, 4, 025001-1–025001-8. [Google Scholar]

- Marhöfer, D.M.; Tosello, G.; Islam, A.; Hansen, H.N. Comparative analysis of different process simulation settings of a micro injection molded part featuring conformal cooling. In Proceedings of the Euspen’s 15th International Conference and Exhibition, Leuven, Belgium, 1–5 June 2015; pp. 65–66. [Google Scholar]

- Costa, F.S.; Tosello, G.; Whiteside, B.R. Best practice strategies for validation of micro moulding process simulation. In Proceedings of the Polymer Process Engineering Conference, Galati, Romania, 22–23 October 2009; pp. 259–261. [Google Scholar]

- Doagou-Rad, S.; Islam, A.; Jensen, J.S.; Alnasser, A. Interaction of nanofillers in injectionmolded graphene/carbon nanotube reinforced PA66 hybrid nanocomposites. J. Polym. Eng. 2018, 38, 971–981. [Google Scholar] [CrossRef]

- Moldflow Insight. In-Mold Labels Modeling (Procedure), Autodesk Knowledge Network. Available online: https://knowledge.autodesk.com/support/moldflow-insight/learn-explore/caas/CloudHelp/cloudhelp/2017/ENU/MoldflowInsight/files/GUID-A089CAEF-0F2B-4B90-8FF4-A2A79DF82080-htm.html (accessed on 10 February 2020).

- Baek, S.J.; Kim, S.Y.; Lee, S.H.; Youn, J.R.; Lee, S.H. Effect of Processing Conditions on Warpage of Film Insert Molded Parts. Fibers Polym. 2008, 9, 747–754. [Google Scholar] [CrossRef]

- Zheng, R.; Kennedy, P.K. A model for post-flow induced crystallization: General equations and predictions. J. Rheol. 2004, 48, 823. [Google Scholar] [CrossRef]

- Moldflow Insight. Crystallization Analysis (Concept), Autodesk Knowledge Network. Available online: https://knowledge.autodesk.com/support/moldflow-insight/learn-explore/caas/CloudHelp/cloudhelp/2016/ENU/MFIA-WhatsNew/files/GUID-29607A41-680E-4A30-9F4B-8B86DEC8F117-htm.html (accessed on 8 April 2020).

- Islam, A.; Li, X.; Wirska, M. Injection Moulding Simulation and Validation of Thin Wall Components for Precision Applications. In Advances in Manufacturing II; Springer: Berlin, Germany, 2019; pp. 96–107. [Google Scholar]

- Lee, H.S.; Isayev, A.I. Numerical Simulation of Flow-Induced Birefringence: Comparison of Injection and Injection/ Compression Molding. Int. J. Precis. Eng. Manuf. 2007, 8, 66–72. [Google Scholar]

- Chen, S.C.; Chen, Y.C.; Peng, H.S.; Huang, L.T. Simulation of Injection Compression Molding Process. Part 3: Effect of process conditions on part birefringence. Adv. Polym. Technol. 2002, 21, 177–187. [Google Scholar] [CrossRef]

- Lee, H.; Park, J. Experimental study of injection-compression molding of film insert molded plates. Int. J. Precis. Eng. Manuf. 2014, 15, 455–461. [Google Scholar] [CrossRef]

- Lee, H.S.; Yoo, Y.G. Effects of Processing Conditions on Cavity Pressure during Injection-Compression Molding. Int. J. Precis. Eng. Manuf. 2012, 13, 2155–2161. [Google Scholar] [CrossRef]

| Parameter | Low Level | Medium Level | High Level |

|---|---|---|---|

| Tm | 40 °C | - | 60 °C |

| Tb | 200 °C | 235 °C | 270 °C |

| Vi | 100 mm/s | 200 mm/s | 300 mm/s |

| Pp | 72 bar | 99 bar | 126 bar |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wöhner, T.; Islam, A.; Hansen, H.N.; Tosello, G.; Whiteside, B.R. Blister Formation in Film Insert Moulding. Micromachines 2020, 11, 424. https://doi.org/10.3390/mi11040424

Wöhner T, Islam A, Hansen HN, Tosello G, Whiteside BR. Blister Formation in Film Insert Moulding. Micromachines. 2020; 11(4):424. https://doi.org/10.3390/mi11040424

Chicago/Turabian StyleWöhner, Timo, Aminul Islam, Hans N. Hansen, Guido Tosello, and Ben R. Whiteside. 2020. "Blister Formation in Film Insert Moulding" Micromachines 11, no. 4: 424. https://doi.org/10.3390/mi11040424

APA StyleWöhner, T., Islam, A., Hansen, H. N., Tosello, G., & Whiteside, B. R. (2020). Blister Formation in Film Insert Moulding. Micromachines, 11(4), 424. https://doi.org/10.3390/mi11040424