Design and Manufacturing of a High-Sensitivity Cutting Force Sensor Based on AlSiCO Ceramic

Abstract

:1. Introduction

2. Materials and Methods

2.1. Principle of Sensor Measurement

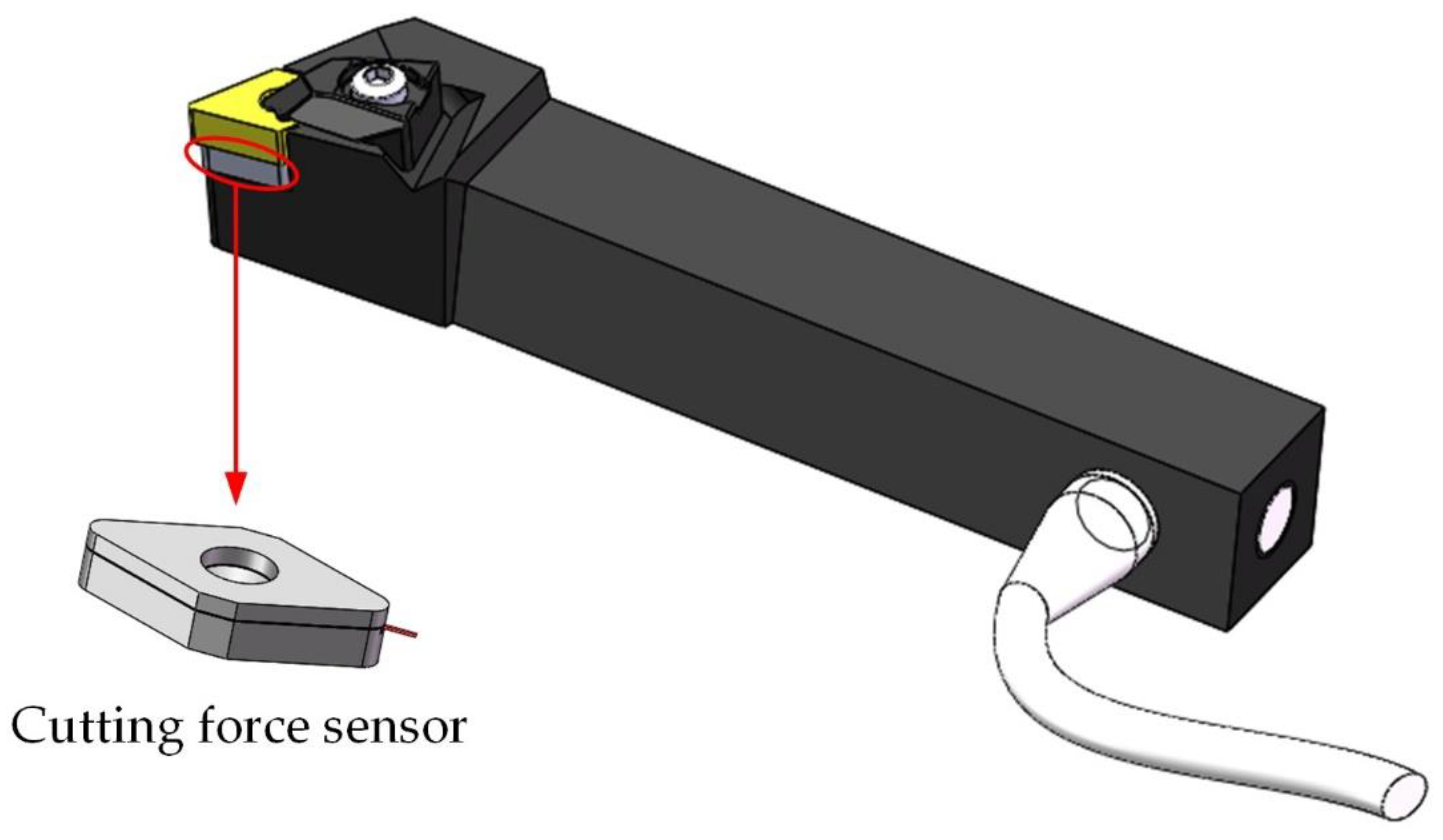

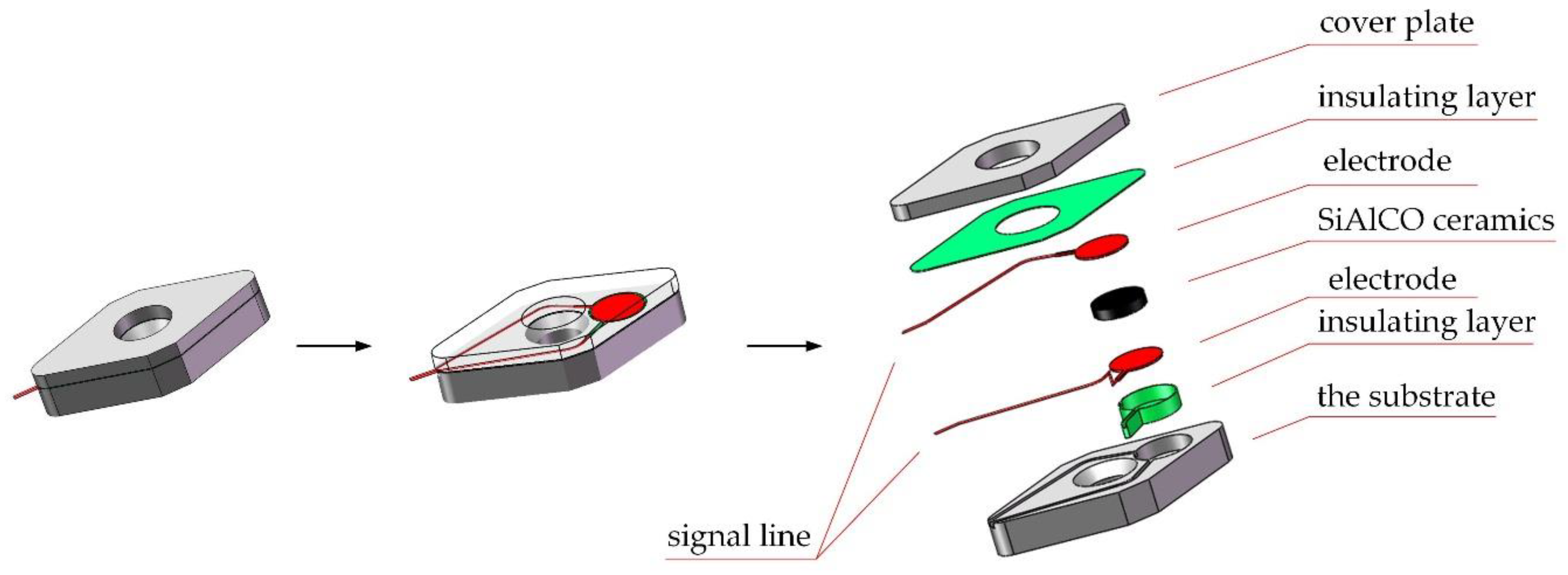

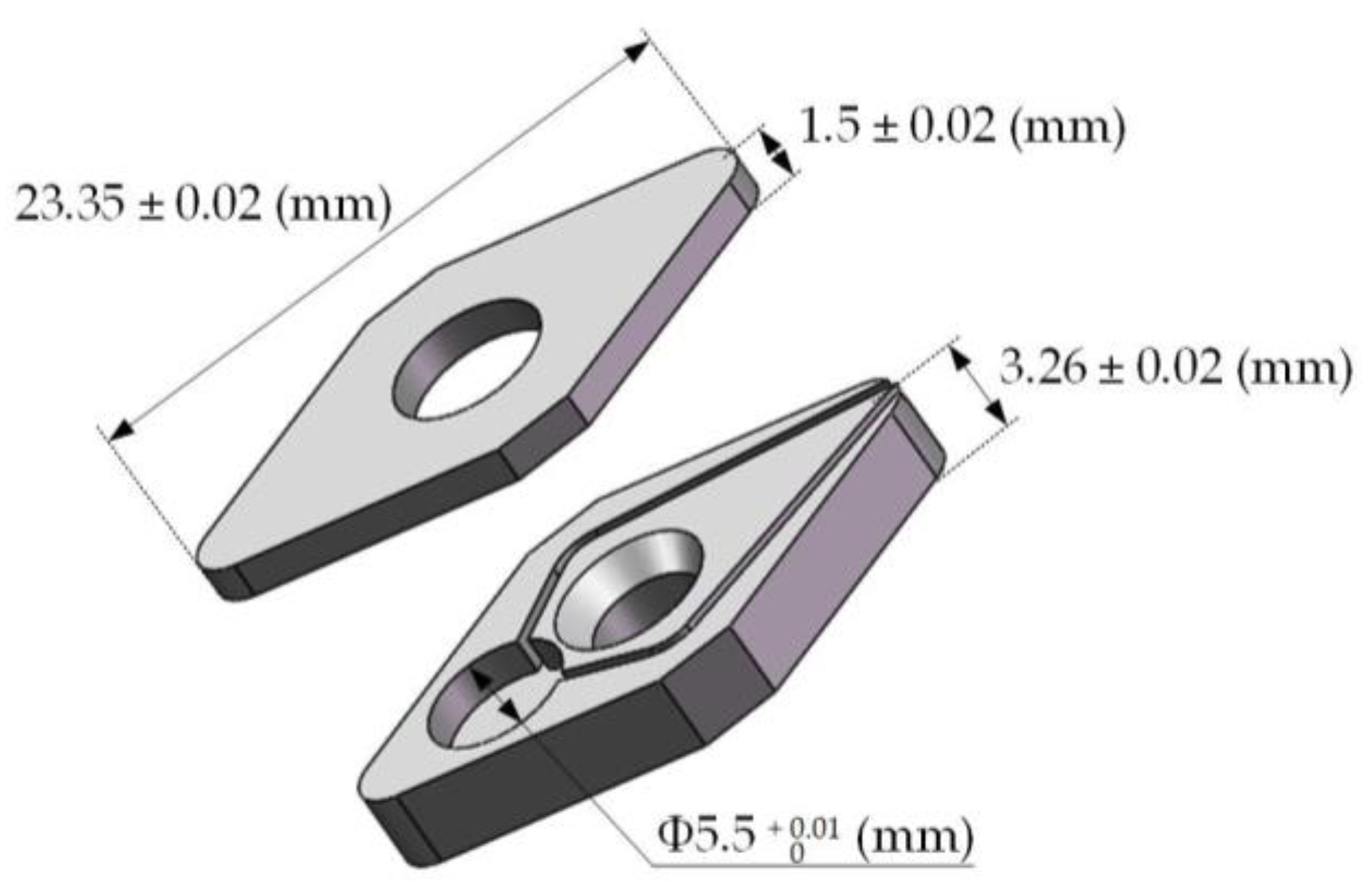

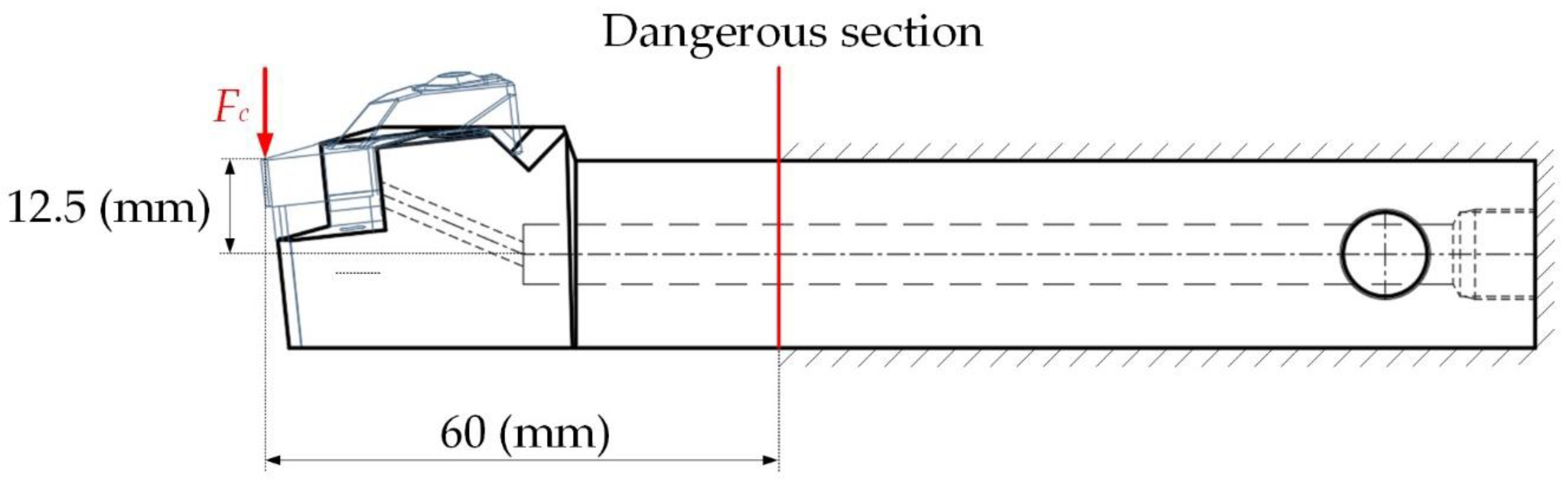

2.2. Structure Design

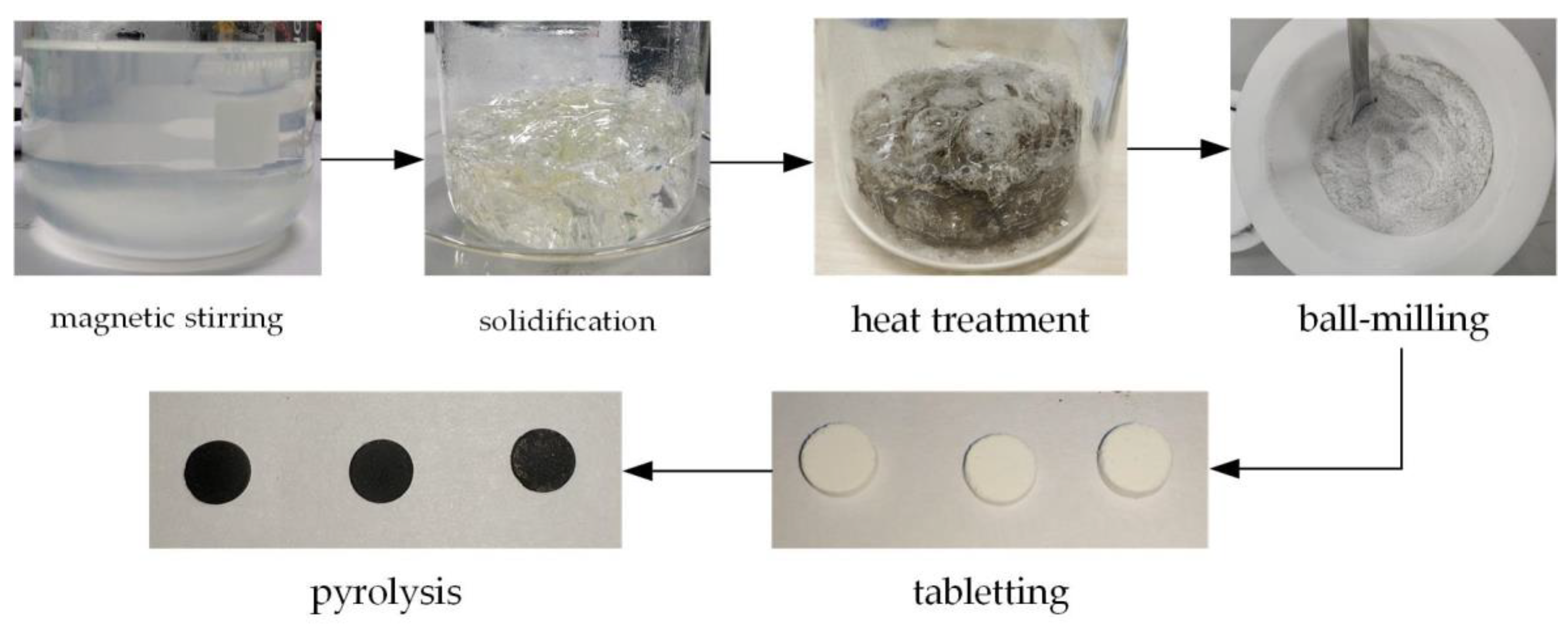

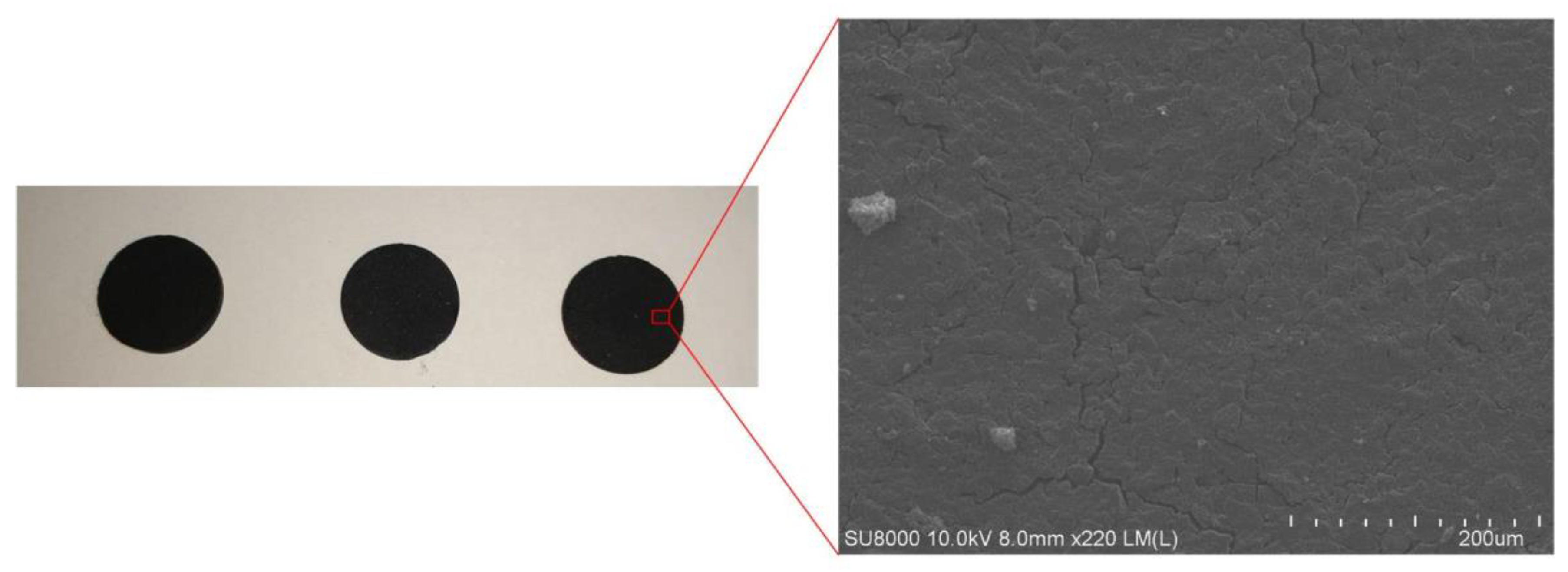

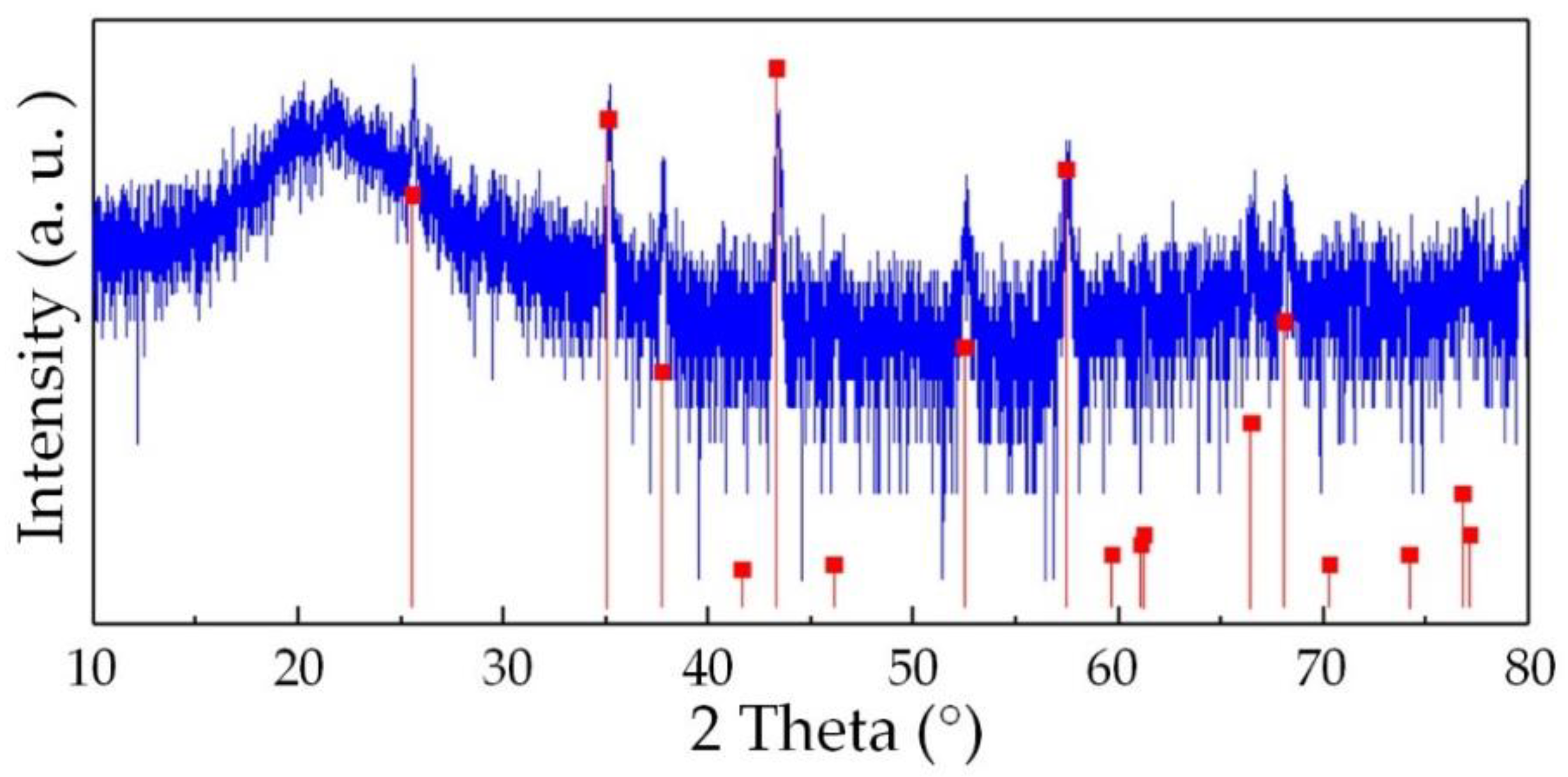

2.3. Sensitive Unit Manufacturing

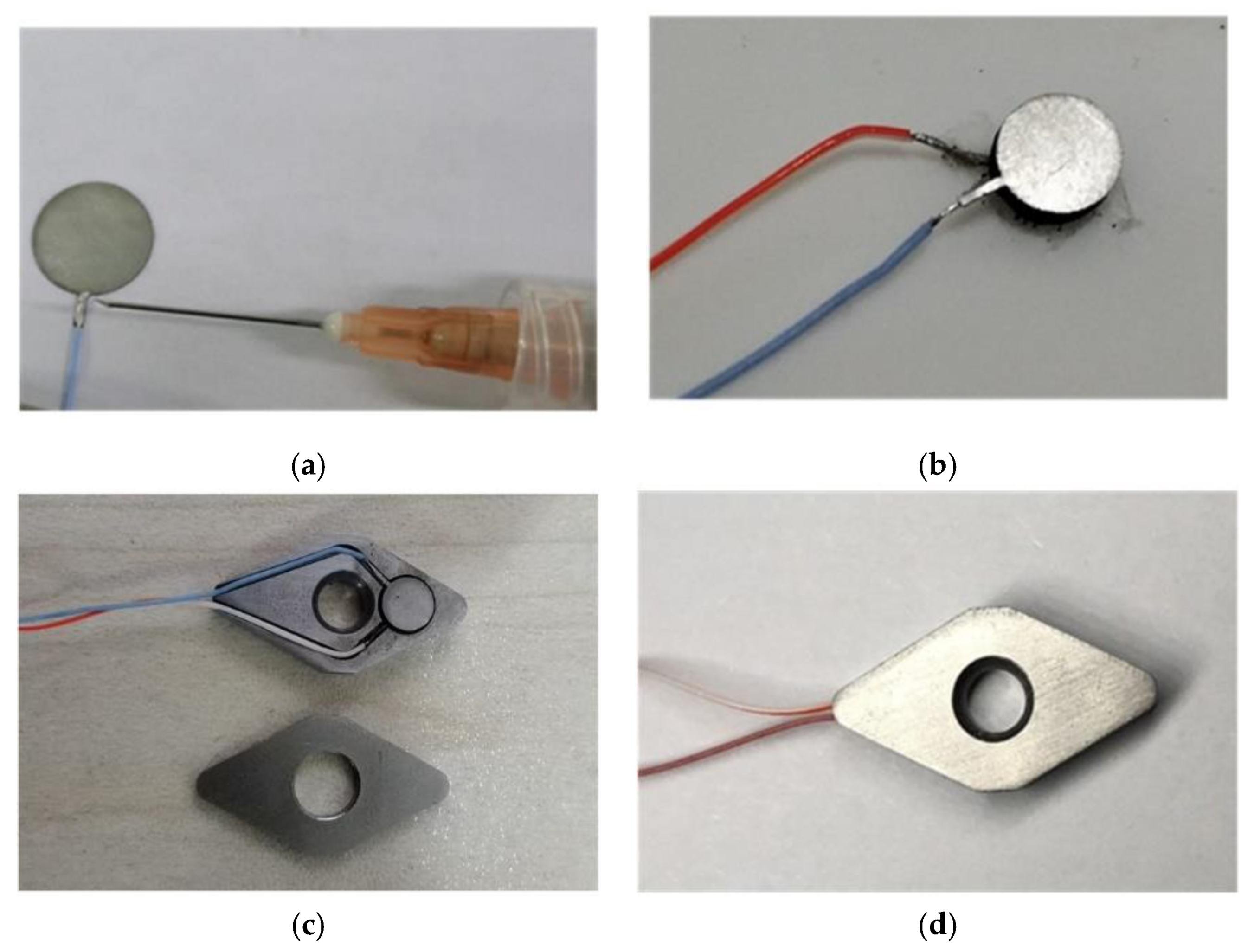

2.4. Sensor Packaging

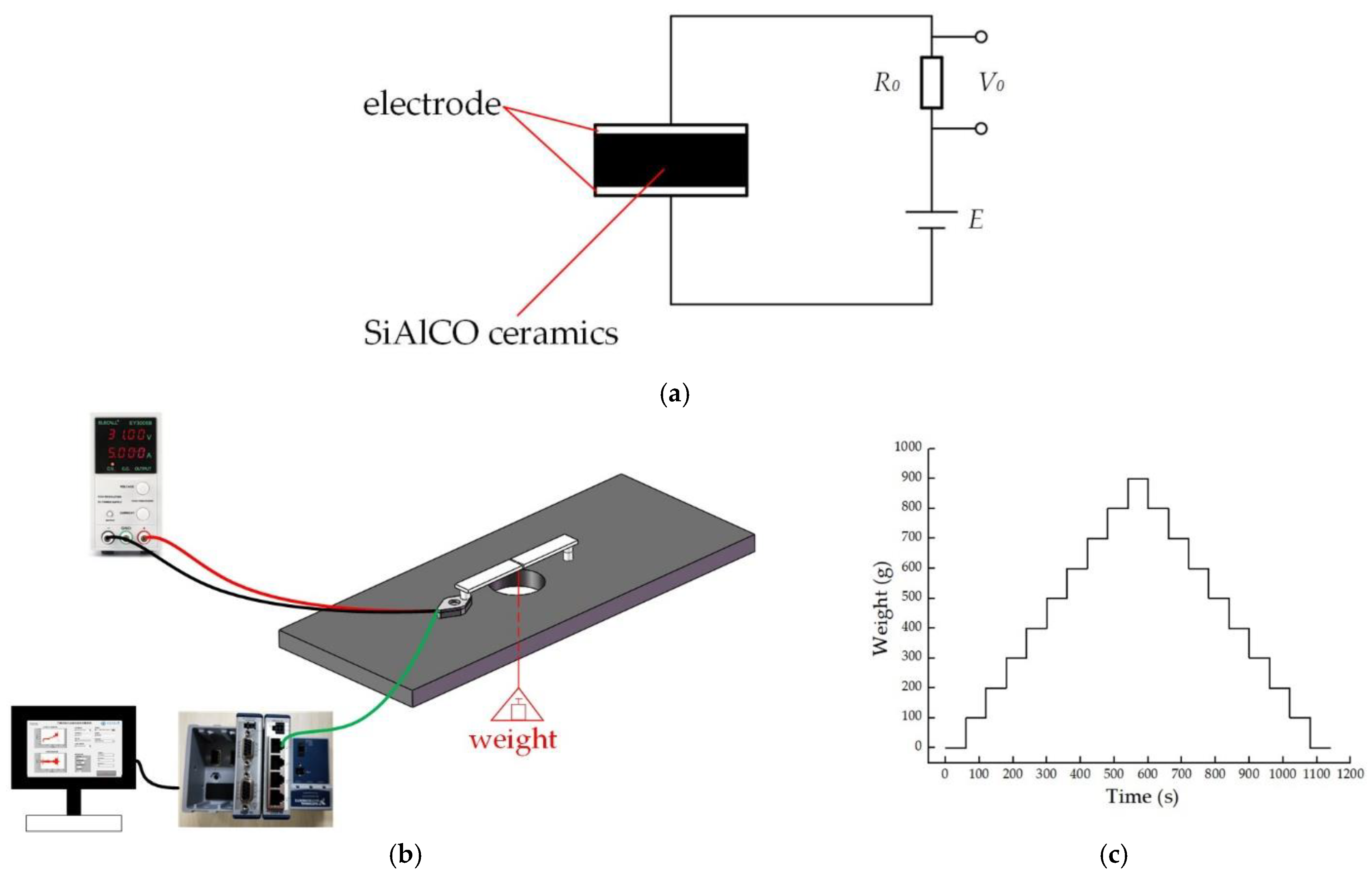

2.5. Sensor Test Plan

2.6. The Data Acquisition System

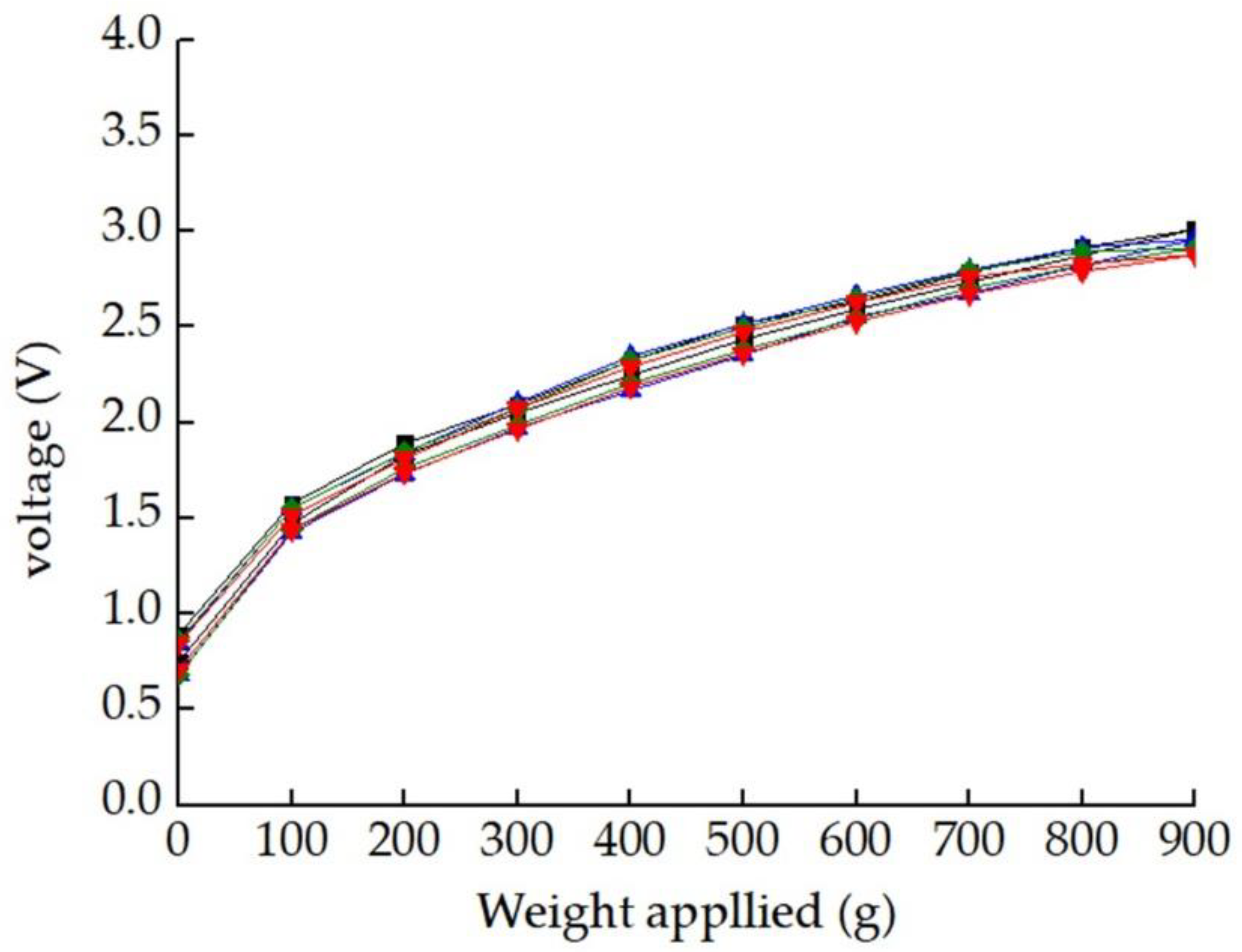

3. Results and Discussion

4. Summary and Conclusions

- (1)

- The cutting force sensor developed in this paper has easy-to-obtain manufacturing materials, mature processing methods, and mature packaging technology. SiAlCO ceramic has the potential to be a sensitive element of a high-sensitivity cutting force sensor. According to the test results, the sensitivity of the cutting force sensor based on SiAlCO ceramic reached 219.38 mV/N.

- (2)

- Preliminary research results showed that the linearity and repeatability of the cutting force sensor are not ideal, which was related to the purity and internal defects of the AlSiCO sample.

- (3)

- The next step is to improve and adjust the preparation process to solve the problems of purity and internal defects of AlSiCO samples to ensure the linearity and repeatability of the sensor. At the same time, in order to improve the performance of the sensor, a pre-tightening force will be added during the packaging process to make the working area of the sensor avoid areas with poor performance, and the cutting force sensor will be used in the actual cutting experiment to study the effects of the process parameters on the measured force components.

Author Contributions

Funding

Conflicts of Interest

References

- Xie, Z.; Lu, Y.; Li, J. Development and testing of an integrated smart tool holder for four-component cutting force measurement. Mech. Syst. Signal Process. 2017, 93, 225–240. [Google Scholar] [CrossRef]

- Han, J.; Cao, K.; Xiao, L.; Tan, X.; Li, T.; Xu, L.; Tang, Z.; Liao, G.; Shi, T. In situ measurement of cutting edge temperature in turning using a near-infrared fiber-optic two-color pyrometer. Measurement 2020, 156, 107595. [Google Scholar] [CrossRef]

- Zhou, C.A.; Guo, K.; Zhao, Y.; Zan, Z.; Sun, J. Development and testing of a wireless rotating triaxial vibration measuring tool holder system for milling process. Measurement 2020, 163, 108034. [Google Scholar] [CrossRef]

- Liang, Q.; Zhang, D.; Coppola, G.; Mao, J.; Sun, W.; Wang, Y.; Ge, Y. Design and Analysis of a Sensor System for Cutting Force Measurement in Machining Processes. Sensors 2016, 16, 70. [Google Scholar] [CrossRef]

- Xiao, C.; Ding, H.; Cheng, K.; Chen, S. Design of an innovative smart turning tool with application to real-time cutting force measurement. Proc. Inst. Mech. Eng. Part B 2014, 229, 563–568. [Google Scholar] [CrossRef]

- Chen, F.; Liu, G. Active damping of machine tool vibrations and cutting force measurement with a magnetic actuator. Int. J. Adv. Manuf. Technol. 2016, 89, 691–700. [Google Scholar] [CrossRef]

- Liu, T.-I.; Song, S.-D.; Liu, G.; Wu, Z. Online monitoring and measurements of tool wear for precision turning of stainless steel parts. Int. J. Adv. Manuf. Technol. 2012, 65, 1397–1407. [Google Scholar] [CrossRef]

- Shi, X.; Wang, X.; Jiao, L.; Wang, Z.; Yan, P.; Gao, S. A real-time tool failure monitoring system based on cutting force analysis. Int. J. Adv. Manuf. Technol. 2017, 95, 2567–2583. [Google Scholar] [CrossRef]

- Rezvani, S.; Kim, C.J.; Park, S.S.; Lee, J. Simultaneous Clamping and Cutting Force Measurements with Built-In Sensors. Sensors 2020, 20, 3736. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Lu, Y.; Chen, X. A multi-sensor integrated smart tool holder for cutting process monitoring. Int. J. Adv. Manuf. Technol. 2020, 110, 853–864. [Google Scholar] [CrossRef]

- Liu, M.; Bing, J.; Xiao, L.; Yun, K.; Wan, L. Development and Testing of an Integrated Rotating Dynamometer Based on Fiber Bragg Grating for Four-Component Cutting Force Measurement. Sensors 2018, 18, 1254. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghani, J.A.; Rizal, M. Design and construction of a strain gauge-based dynamometer for a 3-axis cutting force measurement in turning process. J. Mech. Eng. Sci. 2018, 12, 4072–4087. [Google Scholar]

- Luo, M.; Chong, Z.; Liu, D. Cutting Forces Measurement for Milling Process by Using Working Tables with Integrated PVDF Thin-Film Sensors. Sensors 2018, 18, 4031. [Google Scholar] [CrossRef] [Green Version]

- Uddin, M.S.; Rajasekar, R.; Shankar, S.; Mohanraj, T. Design, development, calibration, and testing of indigenously developed strain gauge based dynamometer for cutting force measurement in the milling process. J. Mech. Eng. Sci. 2020, 14, 6594–6609. [Google Scholar]

- Huang, J.; Pham, D.T.; Ji, C.; Zhou, Z. Smart Cutting Tool Integrated With Optical Fiber Sensors for Cutting Force Measurement in Turning. IEEE Trans. Instrum. Meas. 2020, 69, 1720–1727. [Google Scholar] [CrossRef]

- Li, X.; Wu, W.; Cheng, Y.; Liu, L. Structure design and optimization for a cutting force measurement tool with embedded nickel–chromium film sensor. Adv. Mech. Eng. 2018, 10, 1687814018759887. [Google Scholar] [CrossRef]

- Riedel, R.; Kienzle, A.; Dressler, W.; Ruwisch, L.; Bill, J.; Aldinger, F. A silicoboron carbonitride ceramic stable to 2000 °C. Nature 1996, 382, 796–798. [Google Scholar] [CrossRef]

- Ryu, H.-Y.; Wang, Q.; Raj, R. Ultrahigh-Temperature Semiconductors Made from Polymer-Derived Ceramics. J. Am. Ceram. Soc. 2010, 93, 1668–1676. [Google Scholar] [CrossRef]

- Cao, Y.; Yang, X.; Zhao, R.; Chen, Y.; Li, N.; An, L. Giant piezoresistivity in polymer-derived amorphous SiAlCO ceramics. J. Mater. Sci. 2016, 51, 5646–5650. [Google Scholar] [CrossRef]

- Liew, L.-A.; Zhang, W.; Bright, V.M.; An, L.; Dunn, M.L.; Raj, R. Fabrication of SiCN ceramic MEMS using injectable polymer-precursor technique. Sens. Actuators A Phys. 2001, 89, 64–70. [Google Scholar] [CrossRef]

- Yu, Y.; Li, J.; Niu, J.; Yi, F.; Meng, S. The stability and repeatability of high temperature electrical properties of SiAlCN ceramic sensor heads. Ceram. Int. 2019, 45, 7588–7593. [Google Scholar] [CrossRef]

- Zhao, R.; Shao, G.; Cao, Y.; An, L.; Xu, C. Temperature sensor made of polymer-derived ceramics for high-temperature applications. Sens. Actuators A Phys. 2014, 219, 58–64. [Google Scholar] [CrossRef] [Green Version]

- Leo, A.; Andronenko, S.; Stiharu, I.; Bhat, R.B. Characterization of thick and thin film SiCN for pressure sensing at high temperatures. Sensors 2010, 10, 1338–1354. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Shao, G.; Ebadi, S.; Ren, X.; Harris, K.; Liu, J.; Xu, C.; An, L.; Gong, X. Evanescent-mode-resonator-based and antenna-integrated wireless passive pressure sensors for harsh-environment applications. Sens. Actuators A Phys. 2014, 220, 22–33. [Google Scholar] [CrossRef] [Green Version]

- Li, N.; Cao, Y.; Zhao, R.; Xu, Y.; An, L. Polymer-derived SiAlOC ceramic pressure sensor with potential for high-temperature application. Sens. Actuators A Phys. 2017, 263, 174–178. [Google Scholar] [CrossRef]

- Yu, M.-h. Advances in strength theories for materials under complex stress state in the 20th Century. Appl. Mech. Rev. 2002, 55, 169–218. [Google Scholar] [CrossRef]

- Zhu, Z.; Lu, Y.; Xie, Q.; Li, D.; Gao, N. Mechanical properties and dynamic constitutive model of 42CrMo steel. Mater. Des. 2017, 119, 171–179. [Google Scholar] [CrossRef]

- Cao, Y.; An, L. Anomalous piezo-dielectricity of a polymer-derived amorphous silicoaluminum oxycarbide (SiAlCO). Ceram. Int. 2018, 44, 1467–1470. [Google Scholar] [CrossRef]

- Dresselhaus, G.; Lockwood, D.J.; Cardona, M.; Ulbrich, R.G.; Guentherodt, G.; Hayes, W.; Sandercock, J.R.; Klein, M.V.; Weisbuch, C.; Dresselhaus, M.S. Light scattering in solids. III. Opt. Acta Int. J. Opt. 1982, 31, 1210. [Google Scholar]

- Handbook of Modern Sensors; Springer: Berlin/Heidelberg, Germany, 2010.

- Zhao, Y.; Zhao, Y.; Wang, C.; Liang, S.; Cheng, R.; Qin, Y.; Wang, P.; Li, Y.; Li, X.; Hu, T. Design and development of a cutting force sensor based on semi-conductive strain gauge. Sens. Actuators A Phys. 2016, 237, 119–127. [Google Scholar] [CrossRef]

- Panzera, T.H.; Souza, P.R.; Rubio, J.C.C.; Abrão, A.M.; Mansur, T.R. Development of a three-component dynamometer to measure turning force. Int. J. Adv. Manuf. Technol. 2011, 62, 913–922. [Google Scholar] [CrossRef]

- Farahmandjou, M.; Golabiyan, N. New pore structure of nano-alumina (Al2O3) prepared by sol gel method. J. Ceram. Process. Res. 2015, 16, 1. [Google Scholar]

| The Data Acquisition Card | Number of Channels | ADC Resolution | Sampling Mode | Frequency |

|---|---|---|---|---|

| NI 9218 | 2 analog input channels | 24 bits | Simultaneous | 13.1072 MHz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, T.; Zhao, Y.; Zhao, Y.; Wang, L.; Yang, Y.; Ren, W. Design and Manufacturing of a High-Sensitivity Cutting Force Sensor Based on AlSiCO Ceramic. Micromachines 2021, 12, 63. https://doi.org/10.3390/mi12010063

Gong T, Zhao Y, Zhao Y, Wang L, Yang Y, Ren W. Design and Manufacturing of a High-Sensitivity Cutting Force Sensor Based on AlSiCO Ceramic. Micromachines. 2021; 12(1):63. https://doi.org/10.3390/mi12010063

Chicago/Turabian StyleGong, Taobo, You Zhao, Yulong Zhao, Lukang Wang, Yu Yang, and Wei Ren. 2021. "Design and Manufacturing of a High-Sensitivity Cutting Force Sensor Based on AlSiCO Ceramic" Micromachines 12, no. 1: 63. https://doi.org/10.3390/mi12010063