Progress in Piezoelectric Nanogenerators Based on PVDF Composite Films

Abstract

:1. Introduction

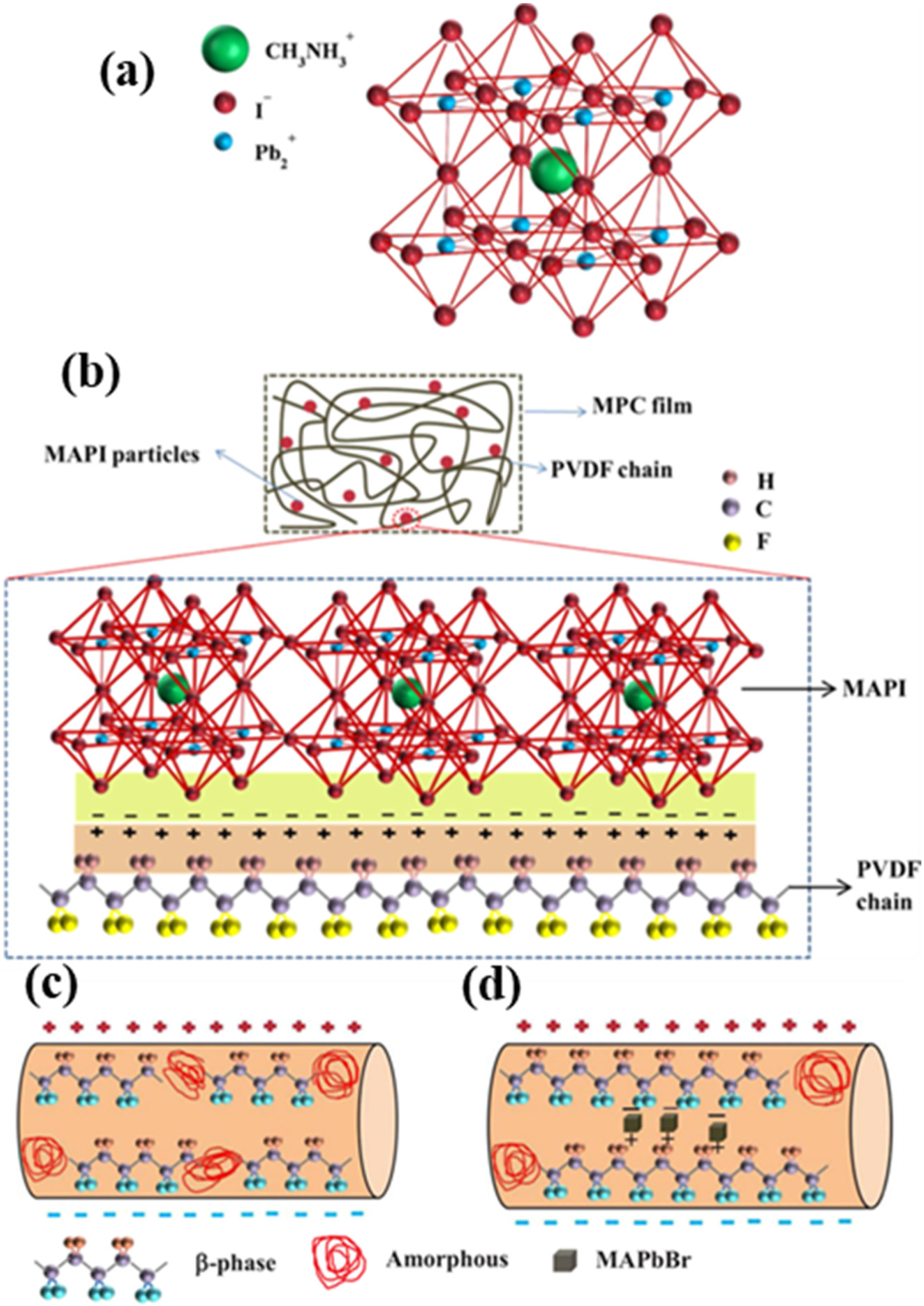

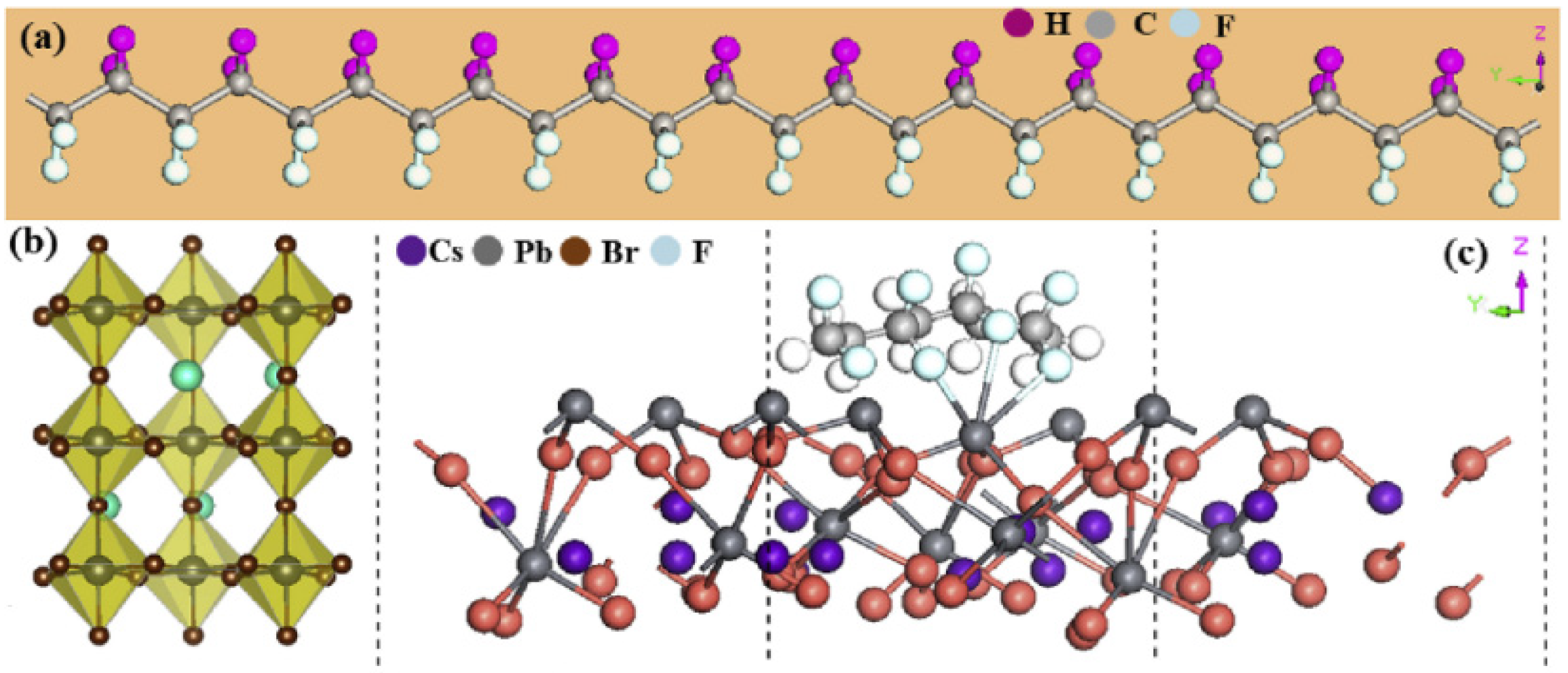

2. Embedding with Metal Halide Perovskites

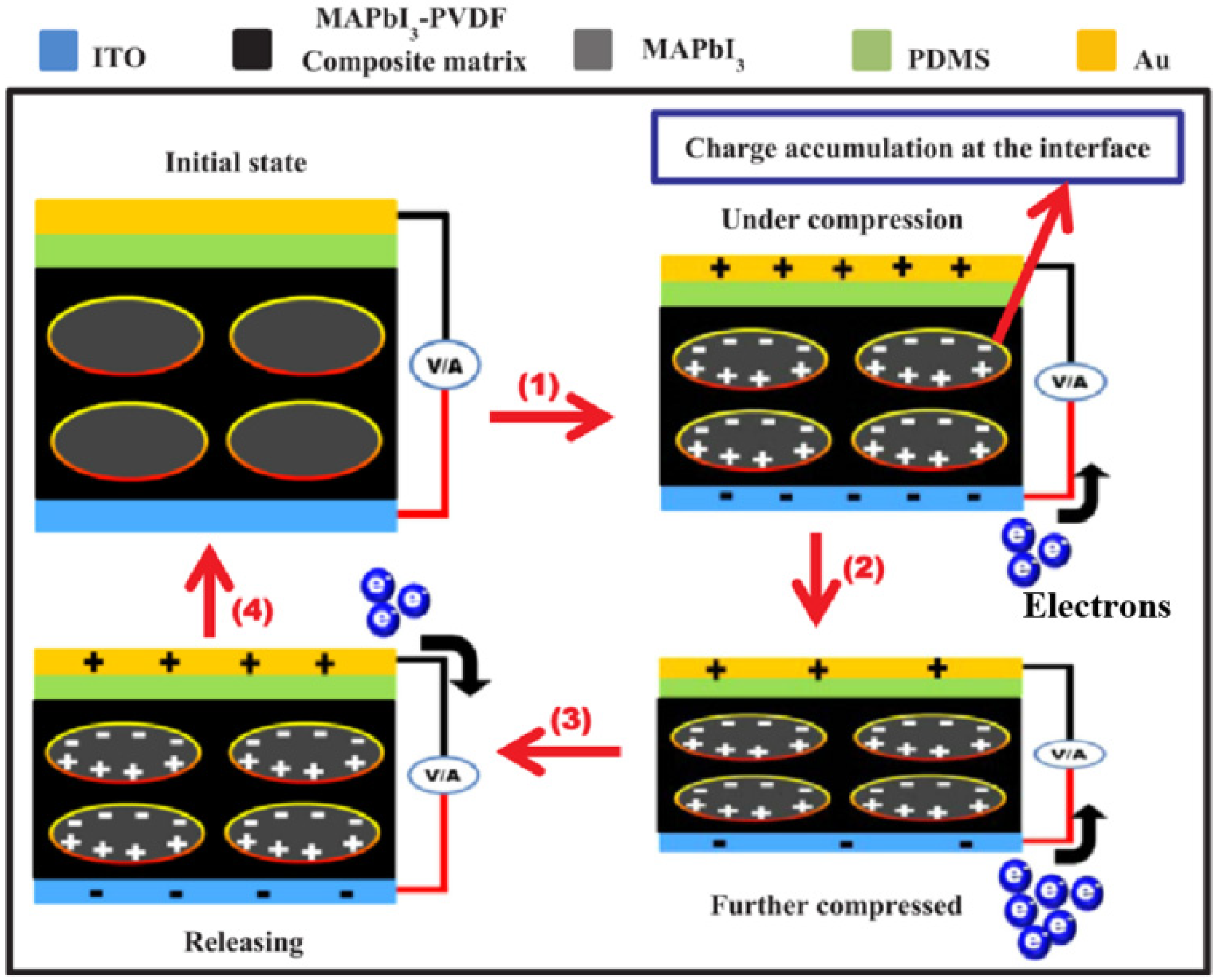

2.1. Organic–Inorganic Lead Halide Perovskites

2.2. Organic–Inorganic Lead Halide Perovskites

3. Embedding with Perovskite–Type Oxides

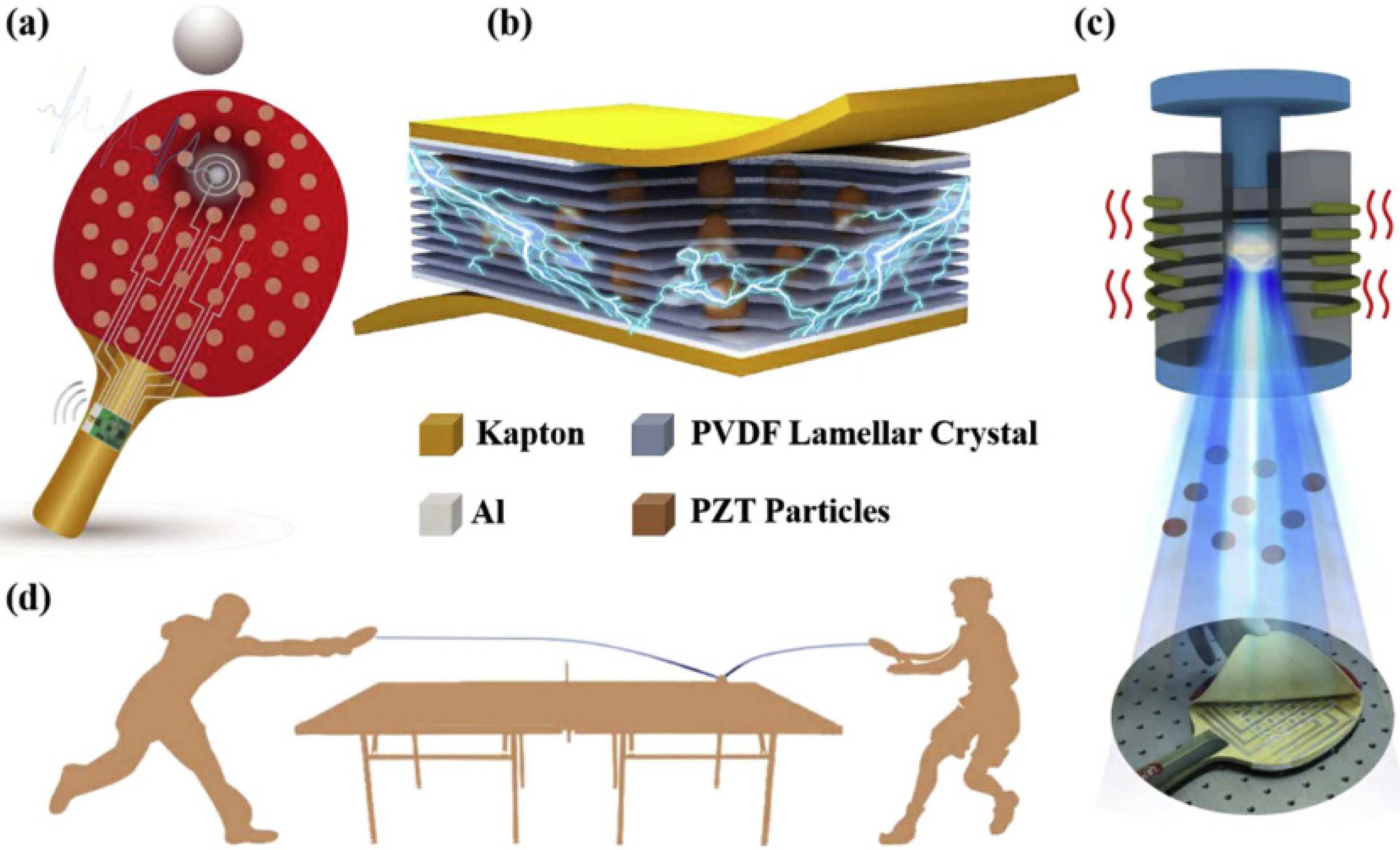

3.1. Lead Zirconia Titanate (PZT)

3.2. Barium Titanate (BaTiO3, also abbreviated as BT or BTO)

3.3. Potassium Sodium Niobate (KNN)

4. Semiconductor Piezoelectric Materials

5. Rare Earth Ions

6. Other NFs

7. Self–Poled PVDF-Based PENGs with Long–Term Stability

8. Perspective

- (1)

- The piezoelectric effect in PVDF is improved after other functional materials are added, generally because of the increase of the content of the β phase. It is necessary to gain a deeper understanding into the mechanism of how different NFs induce the compounds to form a β phase.

- (2)

- Although at present there are many studies, the comparison of properties has not achieved the true uniformity of parameters, such as thickness, area, density, mass and operation method, and there is a lack of a unified standard which allows us to truly understand the property enhancement.

- (3)

- In addition to incorporating NFs into the PVDF matrix, we should also pay attention to the innovative designs of the device structure. A novel structural design can not only promote the sensitivity of nanogenerators, but also satisfy other needs, such as wearable electronics in the field of textiles.

Author Contributions

Funding

Conflicts of Interest

References

- Yan, J.; Liu, M.; Jeong, Y.G.; Kang, W.; Li, L.; Zhao, Y.; Deng, N.; Cheng, B.; Yang, G. Performance enhancements in poly(vinylidene fluoride)-based piezoelectric nanogenerators for efficient energy harvesting. Nano Energy 2019, 56, 662–692. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Z.L. Recent progress in piezoelectric nanogenerators as a sustainable power source in self-powered systems and active sensors. Nano Energy 2015, 14, 3–14. [Google Scholar] [CrossRef] [Green Version]

- Gu, L.; Liu, J.; Cui, N.; Xu, Q.; Du, T.; Zhang, L.; Wang, Z.; Long, C.; Qin, Y. Enhancing the current density of a piezoelectric nanogenerator using a three-dimensional intercalation electrode. Nat. Commun. 2020, 11, 1030. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ali, F.; Raza, W.; Li, X.; Gul, H.; Kim, K.-H. Piezoelectric energy harvesters for biomedical applications. Nano Energy 2019, 57, 879–902. [Google Scholar] [CrossRef]

- Cao, X.; Xiong, Y.; Sun, J.; Zhu, X.; Sun, Q.; Wang, Z.L. Piezoelectric Nanogenerators Derived Self-Powered Sensors for Multifunctional Applications and Artificial Intelligence. Adv. Funct. Mater. 2021, 31, 2102983. [Google Scholar] [CrossRef]

- Yang, F.; Li, J.; Long, Y.; Zhang, Z.; Wang, L.; Sui, J.; Dong, Y.; Wang, Y.; Taylor, R.; Ni, D.; et al. Wafer-scale heterostructured piezoelectric bio-organic thin films. Science 2021, 373, 337–342. [Google Scholar] [CrossRef]

- Purusothaman, Y.; Alluri, N.R.; Chandrasekhar, A.; Venkateswaran, V.; Kim, S.-J. Piezophototronic gated optofluidic logic computations empowering intrinsic reconfigurable switches. Nat. Commun. 2019, 10, 4831. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.L.; Song, J. Piezoelectric Nanogenerators Based on Zinc Oxide Nanowire Arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, Z.L. Electrostatic Potential in a Bent Piezoelectric Nanowire. The Fundamental Theory of Nanogenerator and Nanopiezotronics. Nano Lett. 2007, 7, 2499–2505. [Google Scholar] [CrossRef]

- Wang, Z.L. Towards Self-Powered Nanosystems: From Nanogenerators to Nanopiezotronics. Adv. Funct. Mater. 2008, 18, 3553–3567. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wu, W. Nanotechnology-Enabled Energy Harvesting for Self-Powered Micro-/Nanosystems. Angew. Chem. Int. Ed. 2012, 51, 11700–11721. [Google Scholar] [CrossRef]

- Kumar, B.; Kim, S.-W. Energy harvesting based on semiconducting piezoelectric ZnO nanostructures. Nano Energy 2012, 1, 342–355. [Google Scholar] [CrossRef]

- Surmenev, R.A.; Orlova, T.N.; Chernozem, R.V.; Ivanova, A.A.; Bartasyte, A.; Mathur, S.; Surmeneva, M.A. Hybrid Lead-Free Polymer-Based Scaffolds with Improved Piezoelectric Response for Biomedical Energy-Harvesting Applications: A Review. Nano Energy 2019, 62, 475–506. [Google Scholar] [CrossRef] [Green Version]

- Vivekananthan, V.; Raj, N.P.M.J.; Alluri, N.R.; Purusothaman, Y.; Chandrasekhar, A.; Kim, S.-J. Substantial improvement on electrical energy harvesting by chemically modified/sandpaper-based surface modification in micro-scale for hybrid nanogenerators. Appl. Surf. Sci. 2020, 514, 145904. [Google Scholar] [CrossRef]

- Abisegapriyan, K.S.; Joseph Raj, N.P.M.; Alluri, N.R.; Chandrasekhar, A.; Kim, S.-J. All in One Transitional Flow-Based Integrated Self-Powered Catechol Sensor Using BiFeO3 Nanoparticles. Sensor. Actuat. B—Chem. 2020, 320, 128417. [Google Scholar]

- Shi, K.; Sun, B.; Huang, X.; Jiang, P. Synergistic effect of graphene nanosheet and BaTiO3 nanoparticles on performance enhancement of electrospun PVDF nanofiber mat for flexible piezoelectric nanogenerators. Nano Energy 2018, 52, 153–162. [Google Scholar] [CrossRef]

- Shi, K.; Chai, B.; Zou, H.; Shen, P.; Sun, B.; Jiang, P.; Shi, Z.; Huang, X. Interface Induced Performance Enhancement in Flexible BaTiO3/PVDF-TrFE Based Piezoelectric Nanogenerators. Nano Energy 2021, 80, 105515. [Google Scholar] [CrossRef]

- Park, K.-I.; Son, J.H.; Hwang, G.-T.; Jeong, C.K.; Ryu, J.; Koo, M.; Choi, I.; Lee, S.H.; Byun, M.; Wang, Z.L.; et al. Highly-Efficient, Flexible Piezoelectric PZT Thin Film Nanogenerator on Plastic Substrates. Adv. Mater. 2014, 26, 2514–2520. [Google Scholar] [CrossRef]

- Hu, Y.; Xu, C.; Zhang, Y.; Lin, L.; Snyder, R.L.; Wang, Z.L. A Nanogenerator for Energy Harvesting from a Rotating Tire and its Application as a Self-Powered Pressure/Speed Sensor. Adv. Mater. 2011, 23, 4068–4071. [Google Scholar] [CrossRef]

- Jella, V.; Ippili, S.; Eom, J.-H.; Pammi, S.; Jung, J.-S.; Tran, V.-D.; Nguyen, V.H.; Kirakosyan, A.; Yun, S.; Kim, D.; et al. A comprehensive review of flexible piezoelectric generators based on organic-inorganic metal halide perovskites. Nano Energy 2019, 57, 74–93. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Joe, P.; Tuzman, O.L.; Park, K.-I.; Lee, K.J.; Shi, Y.; Huang, Y.; Rogers, J.A. Recent progress in flexible and stretchable piezoelectric devices for mechanical energy harvesting, sensing and actuation. Extrem. Mech. Lett. 2016, 9, 269–281. [Google Scholar] [CrossRef] [Green Version]

- Yuan, H.; Lei, T.; Qin, Y.; Yang, R. Flexible electronic skins based on piezoelectric nanogenerators and piezotronics. Nano Energy 2019, 59, 84–90. [Google Scholar] [CrossRef]

- Wang, W.; Zheng, Y.; Jin, X.; Sun, Y.; Lu, B.; Wang, H.; Fang, J.; Shao, H.; Lin, T. Unexpectedly high piezoelectricity of electrospun polyacrylonitrile nanofiber membranes. Nano Energy 2019, 56, 588–594. [Google Scholar] [CrossRef]

- Egusa, S.; Wang, Z.; Chocat, N.; Ruff, Z.; Stolyarov, A.M.; Shemuly, D.; Sorin, F.; Rakich, P.T.; Joannopoulos, J.D.; Fink, Y. Multimaterial piezoelectric fibres. Nat. Mater. 2010, 9, 643–648. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, H.; Tian, H.; Yang, Y.; Xie, D.; Zhang, Y.-C.; Liu, X.; Ma, S.; Zhao, H.-M.; Ren, T.-L. A novel flexible nanogenerator made of ZnO nanoparticles and multiwall carbon nanotube. Nanoscale 2013, 5, 6117–6123. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Shang, Y.; Zhang, J.; Zhang, C. Ionic Liquid-Assisted 3D Printing of Self-Polarized β-PVDF for Flexible Piezoelectric Energy Harvesting. ACS Appl. Mater. Interfaces 2021, 13, 14334–14341. [Google Scholar] [CrossRef]

- Soleymani, H.; Noormohammadi, M.; Kashi, M.A.; Amiri, M.H.; Michels, J.J.; Asadi, K.; Abolhasani, M.M. Self-Poled Sausage-Like PVDF Nanowires Produced by Confined Phase Inversion as Novel Piezoelectric Nanogenerators. Adv. Mater. Interfaces 2021, 8, 2001734. [Google Scholar] [CrossRef]

- Lu, L.; Ding, W.; Liu, J.; Yang, B. Flexible PVDF based piezoelectric nanogenerators. Nano Energy 2020, 78, 105251. [Google Scholar] [CrossRef]

- Gaur, A.; Kumar, C.; Shukla, R.; Maiti, P. Induced Piezoelectricity in Poly(vinylidene fluoride) Hybrid as Efficient Energy Harvester. Chemistryselect 2017, 2, 8278–8287. [Google Scholar] [CrossRef]

- Kabir, E.; Khatun, M.; Nasrin, L.; Raihan, M.J.; Rahman, M. Pure β-Phase Formation in Polyvinylidene Fluoride (PVDF)-Carbon Nanotube Composites. J. Phys. D Appl. Phys. 2017, 50, 163002. [Google Scholar] [CrossRef]

- Ye, S.; Cheng, C.; Chen, X.; Chen, X.; Shao, J.; Zhang, J.; Hu, H.; Tian, H.; Li, X.; Ma, L.; et al. High-Performance Piezoelectric Nanogenerator Based on Microstructured P(VDF-TrFE)/BNNTs Composite for Energy Harvesting and Radiation Protection in Space. Nano Energy 2019, 60, 701–714. [Google Scholar] [CrossRef]

- Singh, H.H.; Khare, N. Flexible ZnO-PVDF/PTFE Based Piezo-Tribo Hybrid Nanogenerator. Nano Energy 2018, 51, 216–222. [Google Scholar] [CrossRef]

- Fu, J.; Hou, Y.; Gao, X.; Zheng, M.; Zhu, M. Highly durable piezoelectric energy harvester based on a PVDF flexible nanocomposite filled with oriented BaTi2O5 nanorods with high power density. Nano Energy 2018, 52, 391–401. [Google Scholar] [CrossRef]

- Chen, X.; Li, X.; Shao, J.; An, N.; Tian, H.; Wang, C.; Han, T.; Wang, L.; Lu, B. High-Performance Piezoelectric Nanogenerators with Imprinted P(VDF-TrFE)/BaTiO3 Nanocomposite Micropillars for Self-Powered Flexible Sensors. Small 2017, 13, 1604245. [Google Scholar] [CrossRef]

- Im, J.-H.; Jang, I.-H.; Pellet, N.; Grätzel, M.; Park, N.-G. Growth of CH3NH3PbI3 cuboids with controlled size for high-efficiency perovskite solar cells. Nat. Nanotechnol. 2014, 9, 927–932. [Google Scholar] [CrossRef]

- Yang, W.S.; Noh, J.H.; Jeon, N.J.; Kim, Y.C.; Ryu, S.; Seo, J.; Seok, S.I. High-performance photovoltaic perovskite layers fabricated through intramolecular exchange. Science 2015, 348, 1234–1237. [Google Scholar] [CrossRef]

- Jeong, J.; Kim, M.; Seo, J.; Lu, H.; Ahlawat, P.; Mishra, A.; Yang, Y.; Hope, M.A.; Eickemeyer, F.T.; Kim, M.; et al. Pseudo-Halide Anion Engineering for α-FaPbI3 Perovskite Solar Cells. Nature 2021, 592, 381–385. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, K. Organic–inorganic hybrid lead halide perovskites for optoelectronic and electronic applications. Chem. Soc. Rev. 2016, 45, 655–689. [Google Scholar] [CrossRef]

- Ding, R.; Zhang, X.; Chen, G.; Wang, H.; Kishor, R.; Xiao, J.; Gao, F.; Zeng, K.; Chen, X.; Sun, X.W.; et al. High-performance piezoelectric nanogenerators composed of formamidinium lead halide perovskite nanoparticles and poly(vinylidene fluoride). Nano Energy 2017, 37, 126–135. [Google Scholar] [CrossRef]

- Jella, V.; Ippili, S.; Eom, J.-H.; Choi, J.; Yoon, S.-G. Enhanced output performance of a flexible piezoelectric energy harvester based on stable MAPbI3-PVDF composite films. Nano Energy 2018, 53, 46–56. [Google Scholar] [CrossRef]

- Sultana, A.; Sadhukhan, P.; Alam, M.; Das, S.; Middya, T.R.; Mandal, D. Organo-Lead Halide Perovskite Induced Electroactive β-Phase in Porous PVDF Films: An Excellent Material for Photoactive Piezoelectric Energy Harvester and Photodetector. ACS Appl. Mater. Interfaces 2018, 10, 4121–4130. [Google Scholar] [CrossRef]

- Sultana, A.; Alam, M.; Sadhukhan, P.; Ghorai, U.K.; Das, S.; Middya, T.R.; Mandal, D. Organo-lead halide perovskite regulated green light emitting poly(vinylidene fluoride) electrospun nanofiber mat and its potential utility for ambient mechanical energy harvesting application. Nano Energy 2018, 49, 380–392. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Eom, J.-H.; Kim, J.; Hong, S.; Choi, J.-S.; Tran, V.-D.; Van Hieu, N.; Kim, Y.-J.; Kim, H.-J.; et al. An eco-friendly flexible piezoelectric energy harvester that delivers high output performance is based on lead-free MASnI3 films and MASnI3-PVDF composite films. Nano Energy 2019, 57, 911–923. [Google Scholar] [CrossRef]

- Mondal, S.; Paul, T.; Maiti, S.; Das, B.K.; Chattopadhyay, K.K. Human motion interactive mechanical energy harvester based on all inorganic perovskite-PVDF. Nano Energy 2020, 74, 104870. [Google Scholar] [CrossRef]

- Nie, J.; Zhu, L.; Zhai, W.; Berbille, A.; Li, L.; Wang, Z.L. Flexible Piezoelectric Nanogenerators Based on P(VDF-Trfe)/CsPbBr3 Quantum Dot Composite Films. ACS Appl. Electron. Mater. 2021, 3, 2136–2144. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, L.; Fang, Z.; Wang, S.; Yang, T.; Zhu, L.; Hou, X.; Wang, H.; Wang, Z.L. Piezoelectric Nanogenerator Based on In Situ Growth All-Inorganic CsPbBr3 Perovskite Nanocrystals in PVDF Fibers with Long-Term Stability. Adv. Funct. Mater. 2021, 31, 2011073. [Google Scholar] [CrossRef]

- Wankhade, S.H.; Tiwari, S.; Gaur, A.; Maiti, P. PVDF–PZT nanohybrid based nanogenerator for energy harvesting applications. Energy Rep. 2020, 6, 358–364. [Google Scholar] [CrossRef]

- Tian, G.; Deng, W.; Gao, Y.; Xiong, D.; Yan, C.; He, X.; Yang, T.; Jin, L.; Chu, X.; Zhang, H.; et al. Rich lamellar crystal baklava-structured PZT/PVDF piezoelectric sensor toward individual table tennis training. Nano Energy 2019, 59, 574–581. [Google Scholar] [CrossRef]

- Zhao, Y.; Liao, Q.; Zhang, G.; Zhang, Z.; Liang, Q.; Liao, X.; Zhang, Y. High output piezoelectric nanocomposite generators composed of oriented BaTiO3 NPs@PVDF. Nano Energy 2015, 11, 719–727. [Google Scholar] [CrossRef]

- Hu, P.; Yan, L.; Zhao, C.; Zhang, Y.; Niu, J. Double-layer structured PVDF nanocomposite film designed for flexible nanogenerator exhibiting enhanced piezoelectric output and mechanical property. Compos. Sci. Technol. 2018, 168, 327–335. [Google Scholar] [CrossRef]

- Zhou, X.; Parida, K.; Halevi, O.; Liu, Y.; Xiong, J.; Magdassi, S.; Lee, P.S. All 3D-printed stretchable piezoelectric nanogenerator with non-protruding kirigami structure. Nano Energy 2020, 72, 104676. [Google Scholar] [CrossRef]

- Alluri, N.R.; Saravanakumar, B.; Kim, S.-J. Flexible, Hybrid Piezoelectric Film (BaTi(1–X)ZrxO3)/PVDF Nanogenerator as a Self-Powered Fluid Velocity Sensor. ACS Appl. Mater. Inter. 2015, 7, 9831–9840. [Google Scholar] [CrossRef]

- Shin, S.-H.; Kim, Y.-H.; Lee, M.H.; Jung, J.-Y.; Nah, J. Hemispherically Aggregated BaTiO3 Nanoparticle Composite Thin Film for High-Performance Flexible Piezoelectric Nanogenerator. ACS Nano 2014, 8, 2766–2773. [Google Scholar] [CrossRef]

- Guan, X.; Xu, B.; Gong, J. Hierarchically Architected Polydopamine Modified BaTiO3@P(VDF-TrFE) Nanocomposite Fiber Mats for Flexible Piezoelectric Nanogenerators and Self-Powered Sensors. Nano Energy 2020, 70, 104516. [Google Scholar] [CrossRef]

- Shuai, C.; Liu, G.; Yang, Y.; Qi, F.; Peng, S.; Yang, W.; He, C.; Wang, G.; Qian, G. A strawberry-like Ag-decorated barium titanate enhances piezoelectric and antibacterial activities of polymer scaffold. Nano Energy 2020, 74, 104825. [Google Scholar] [CrossRef]

- Xu, K.; Li, J.; Lv, X.; Wu, J.; Zhang, X.; Xiao, D.; Zhu, J. Superior Piezoelectric Properties in Potassium-Sodium Niobate Lead-Free Ceramics. Adv. Mater. 2016, 28, 8519–8523. [Google Scholar] [CrossRef]

- Teka, A.; Bairagi, S.; Shahadat, M.; Joshi, M.; Ahammad, S.Z.; Ali, S.W. Poly(vinylidene fluoride) (PVDF)/potassium sodium niobate (KNN)-based nanofibrous web: A unique nanogenerator for renewable energy harvesting and investigating the role of KNN nanostructures. Polym. Adv. Technol. 2018, 29, 2537–2544. [Google Scholar] [CrossRef]

- Bairagi, S.; Ali, S.W. Influence of High Aspect Ratio Lead-Free Piezoelectric Fillers in Designing Flexible Fibrous Nanogenerators: Demonstration of Significant High Output Voltage. Energy Technol. 2019, 7, 1900538. [Google Scholar] [CrossRef]

- Bairagi, S.; Ali, S.W. Flexible lead-free PVDF/SM-KNN electrospun nanocomposite based piezoelectric materials: Significant enhancement of energy harvesting efficiency of the nanogenerator. Energy 2020, 198, 117385. [Google Scholar] [CrossRef]

- Vivekananthan, V.; Alluri, N.R.; Purusothaman, Y.; Chandrasekhar, A.; Kim, S.-J. A flexible, planar energy harvesting device for scavenging road side waste mechanical energy via the synergistic piezoelectric response of K0.5Na0.5NbO3-BaTiO3/PVDF composite films. Nanoscale 2017, 9, 15122–15130. [Google Scholar] [CrossRef] [PubMed]

- Bhavanasi, V.; Kumar, V.; Parida, K.; Wang, J.; Lee, P.S. Enhanced Piezoelectric Energy Harvesting Performance of Flexible PVDF-TrFE Bilayer Films with Graphene Oxide. ACS Appl. Mater. Inter. 2016, 8, 521–529. [Google Scholar] [CrossRef]

- Ai, Y.; Lou, Z.; Chen, S.; Chen, D.; Wang, Z.M.; Jiang, K.; Shen, G. All RGO-on-PVDF-Nanofibers Based Self-Powered Electronic Skins. Nano Energy 2017, 35, 121–127. [Google Scholar] [CrossRef]

- Choi, M.; Murillo, G.; Hwang, S.; Kim, J.W.; Jung, J.H.; Chen, C.-Y.; Lee, M. Mechanical and Electrical Characterization of PVDF-ZnO Hybrid Structure for Application to Nanogenerator. Nano Energy 2017, 33, 462–468. [Google Scholar] [CrossRef] [Green Version]

- Shin, K.-Y.; Lee, J.S.; Jang, J. Highly sensitive, wearable and wireless pressure sensor using free-standing ZnO nanoneedle/PVDF hybrid thin film for heart rate monitoring. Nano Energy 2016, 22, 95–104. [Google Scholar] [CrossRef]

- Thakur, P.; Kool, A.; Hoque, N.A.; Bagchi, B.; Khatun, F.; Biswas, P.; Brahma, D.; Roy, S.; Banerjee, S.; Das, S. Superior performances of in situ synthesized ZnO/PVDF thin film based self-poled piezoelectric nanogenerator and self-charged photo-power bank with high durability. Nano Energy 2018, 44, 456–467. [Google Scholar] [CrossRef]

- He, H.; Fu, Y.; Zang, W.; Wang, Q.; Xing, L.; Zhang, Y.; Xue, X. A Flexible Self-Powered T-ZnO/PVDF/Fabric Electronic-Skin with Multi-Functions of Tactile-Perception, Atmosphere-Detection and Self-Clean. Nano Energy 2017, 31, 37–48. [Google Scholar] [CrossRef]

- Wang, J.; Lin, M.-F.; Park, S.; Lee, P.S. Deformable conductors for human–machine interface. Mater. Today 2018, 21, 508–526. [Google Scholar] [CrossRef]

- Deng, W.; Yang, T.; Jin, L.; Yan, C.; Huang, H.; Chu, X.; Wang, Z.; Xiong, D.; Tian, G.; Gao, Y.; et al. Cowpea-structured PVDF/ZnO nanofibers based flexible self-powered piezoelectric bending motion sensor towards remote control of gestures. Nano Energy 2019, 55, 516–525. [Google Scholar] [CrossRef]

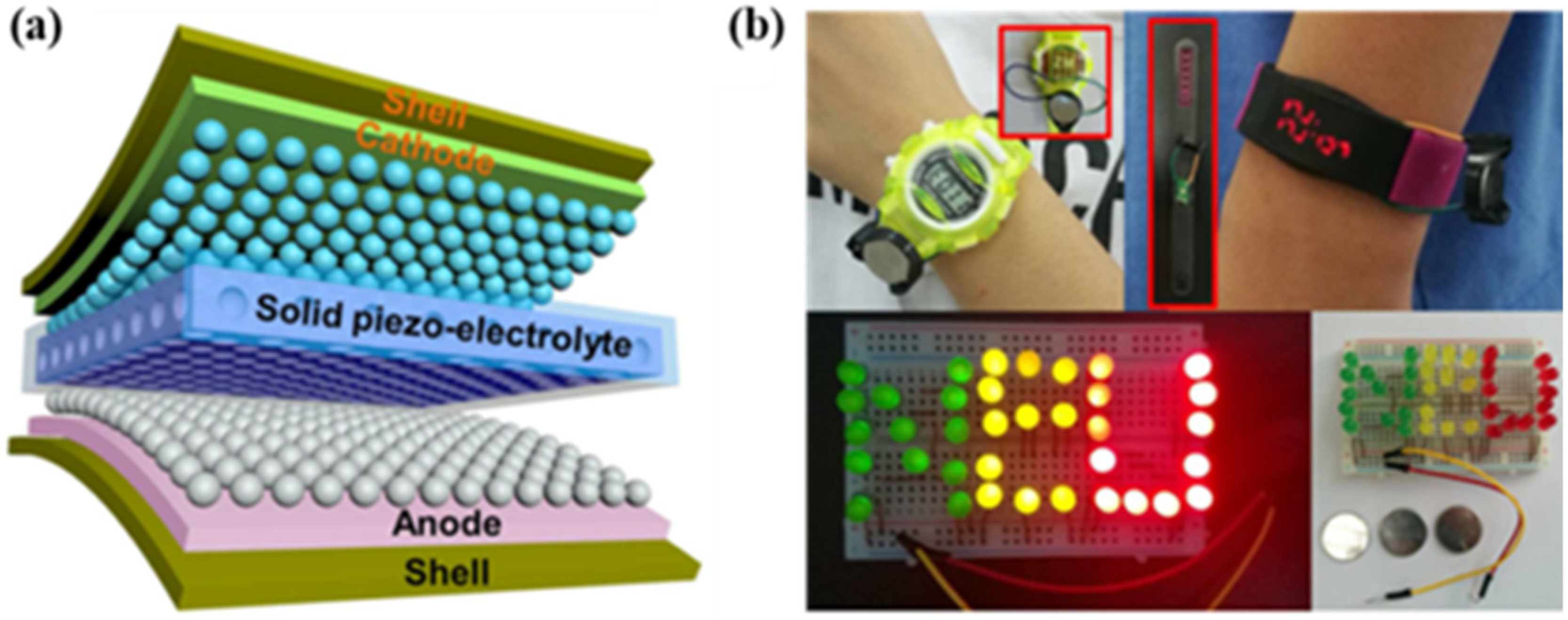

- He, H.; Fu, Y.; Zhao, T.; Gao, X.; Xing, L.; Zhang, Y.; Xue, X. All-solid-state flexible self-charging power cell basing on piezo-electrolyte for harvesting/storing body-motion energy and powering wearable electronics. Nano Energy 2017, 39, 590–600. [Google Scholar] [CrossRef]

- Zhai, W.; Lai, Q.; Chen, L.; Zhu, L.; Wang, Z.L. Flexible Piezoelectric Nanogenerators Based on P(VDF–TrFE)/GeSe Nanocomposite Films. ACS Appl. Electron. Mater. 2020, 2, 2369–2374. [Google Scholar] [CrossRef]

- Bagchi, B.; Hoque, N.A.; Janowicz, N.; Das, S.; Tiwari, M.K. Re-usable self-poled piezoelectric/piezocatalytic films with exceptional energy harvesting and water remediation capability. Nano Energy 2020, 78, 105339. [Google Scholar] [CrossRef]

- Zhai, W.; Zhu, L.; Berbille, A.; Wang, Z.L. Flexible and wearable piezoelectric nanogenerators based on P(VDF-TrFE)/SnS nanocomposite micropillar array. J. Appl. Phys. 2021, 129, 095501. [Google Scholar] [CrossRef]

- Zhai, W.; Nie, J.; Zhu, L. Enhanced Flexible Poly(vinylidene fluoride-trifluorethylene) Piezoelectric Nanogenerators by SnSe Nanosheet Doping and Solvent Treatment. ACS Appl. Mater. Interfaces 2021, 13, 32278–32285. [Google Scholar] [CrossRef] [PubMed]

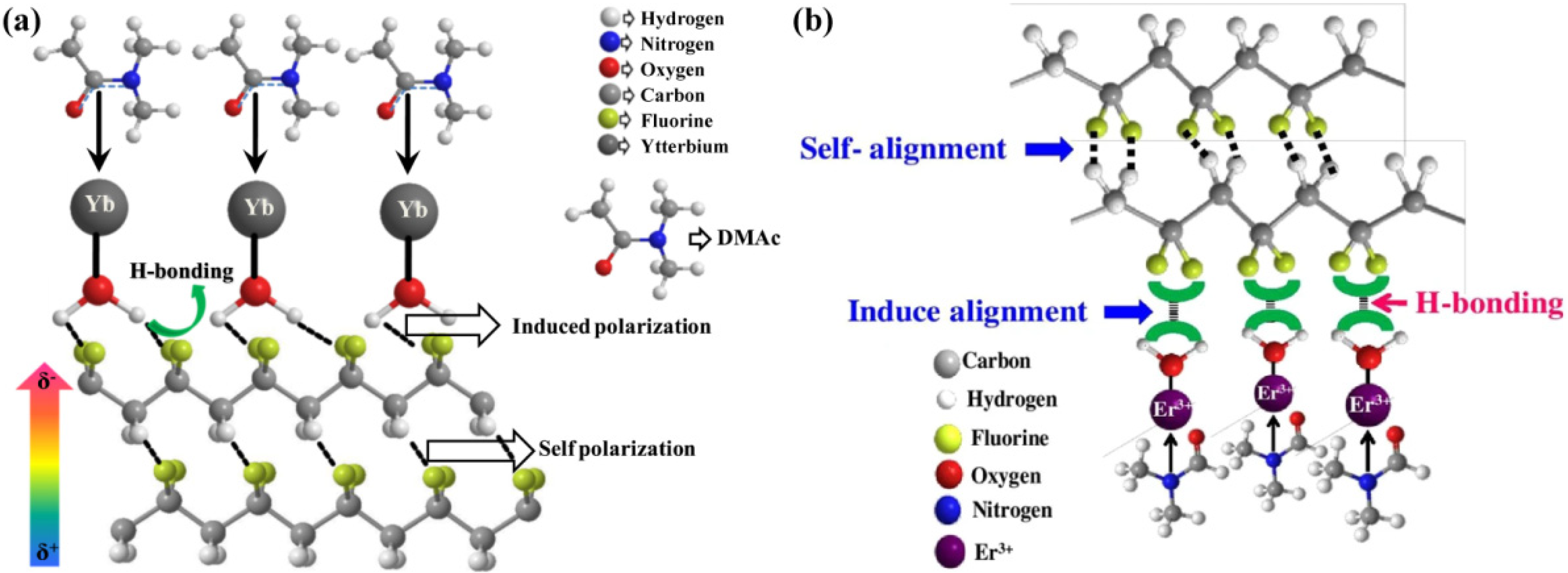

- Ghosh, S.K.; Biswas, A.; Sen, S.; Das, C.; Henkel, K.; Schmeisser, D.; Mandal, D. Yb3+ assisted self-polarized PVDF based ferroelectretic nanogenerator: A facile strategy of highly efficient mechanical energy harvester fabrication. Nano Energy 2016, 30, 621–629. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Xie, M.; Bowen, C.R.; Davies, P.R.; Morgan, D.J.; Mandal, D. A hybrid strain and thermal energy harvester based on an infra-red sensitive Er3+ modified poly(vinylidene fluoride) ferroelectret structure. Sci. Rep. 2017, 7, 16703. [Google Scholar] [CrossRef] [Green Version]

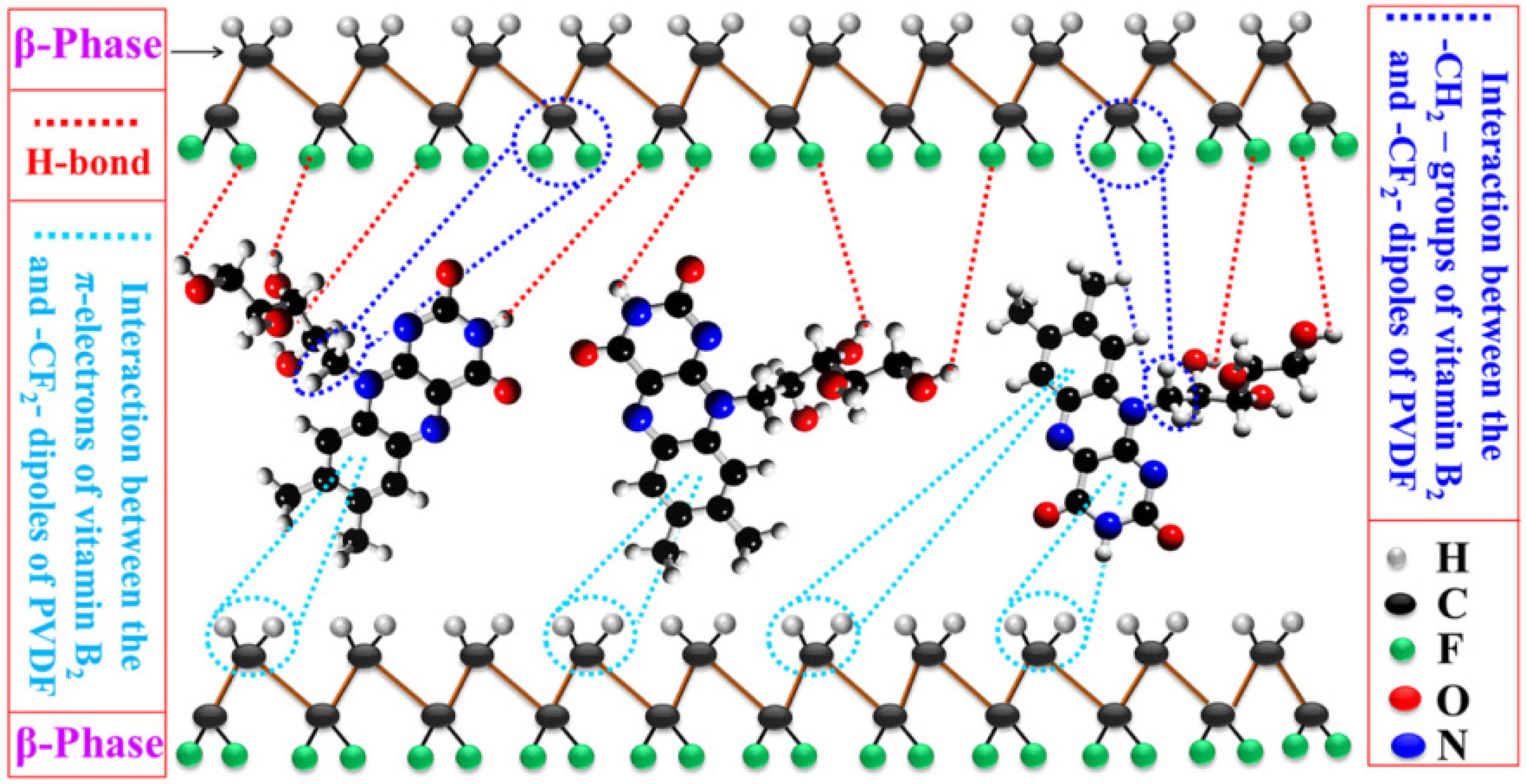

- Karan, S.K.; Maiti, S.; Agrawal, A.K.; Das, A.K.; Maitra, A.; Paria, S.; Bera, A.; Bera, R.; Halder, L.; Mishra, A.K.; et al. Designing high energy conversion efficient bio-inspired vitamin assisted single-structured based self-powered piezoelectric/wind/acoustic multi-energy harvester with remarkable power density. Nano Energy 2019, 59, 169–183. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Mandal, D. Synergistically enhanced piezoelectric output in highly aligned 1D polymer nanofibers integrated all-fiber nanogenerator for wearable nano-tactile sensor. Nano Energy 2018, 53, 245–257. [Google Scholar] [CrossRef]

- Hanani, Z.; Izanzar, I.; Amjoud, M.; Mezzane, D.; Lahcini, M.; Uršič, H.; Prah, U.; Saadoune, I.; El Marssi, M.; Luk’Yanchuk, I.A.; et al. Lead-free nanocomposite piezoelectric nanogenerator film for biomechanical energy harvesting. Nano Energy 2021, 81, 105661. [Google Scholar] [CrossRef]

- Pusty, M.; Sinha, L.; Shirage, P.M. A flexible self-poled piezoelectric nanogenerator based on a rGO–Ag/PVDF nanocomposite. New J. Chem. 2019, 43, 284–294. [Google Scholar] [CrossRef]

- Yadav, P.; Raju, T.; Badhulika, S. Self-Poled hBN-PVDF Nanofiber Mat-Based Low-Cost, Ultrahigh-Performance Piezoelectric Nanogenerator for Biomechanical Energy Harvesting. ACS Appl. Electron. Mater. 2020, 2, 1970–1980. [Google Scholar] [CrossRef]

| Materials | Preparation Methods | Sample Size | Poling | Force or Pressure | Voc | ISC/JSC | Power@ Resistive Load (RL) | Refernece |

|---|---|---|---|---|---|---|---|---|

| FAPbBr3NPs/PVDF | Solution casting | 1.2 × 1.4 cm2 | 50 kV cm−1 | 0.5 MPa | 30 V | 6.2 μA cm−2 | - | [39] |

| MAPbI3/PVDF | Spin coating | 1 × 1 cm2 | 80 kV cm−1 | 50 N | 9.43 V | 0.76 µA cm−2 | - | [40,41] |

| MAPbI3/PVDF | Solution casting | - | Not supplied | 2 kPa | 1.8 V | 37.5 nA | 2.5 µW cm−2@0.6 MΩ | [41] |

| MAPbBr3/PVDF | Electrospinning | 2.4 × 1.5 cm2 | Not supplied | 9.8 kPa | 5 V | 60 nA | 0.28 µW cm−2@0.7 MΩ | [42] |

| MASnI3/PVDF | Spin coating | 1 × 1 cm2 | 60 kV cm−1 | 0.5 MPa | 12.0 V | 4.0 μA cm−2 | 22 µW cm−2@3 MΩ | [43] |

| CsPbBr3/PVDF | Solution casting | - | Not supplied | 100 MPa | 120 V | 35 μA | 30 µW@3 MΩ | [44] |

| CsPbBr3@PVDF fibers | Electrospinning method and in situ growth | 0.80 cm2 | 5 kV | - | 103 V | 170 µA cm−2 | - | [46] |

| Materials | Preparation Methods | Sample Size | Poling | Force or Pressure | Voc | ISC/JSC | Power@RL | Ref. |

|---|---|---|---|---|---|---|---|---|

| PZT/PVDF | Solution casting | 2 × 0.9 cm2 | Not needed | 8.5 kPa | 55 V | - | 35 µW cm−2@10 MΩ | [47] |

| PZT/PVDF | Hot pressing | - | Not needed | 85.6 kPa | 2.51 V | 78.43 nA | - | [48] |

| BaTiO3 NPs/PVDF | Solution casting | 1 × 1 cm2 | 2 kV | 10 MPa | 150 V | 1500 nA | - | [49] |

| BaTiO3 NPs/P(VDF-HFP) | Spin coating | 4 cm2 | 100 kV cm−1 | 0.23 MPa | 75 V | 15 μA | - | [53] |

| BaTiO3 NPs/P(VDF-TrFE) | Spin coating | - | Not needed | 50 N | 13.2 V | 0.33 μA cm−2 | 12.5 µW cm−2@4 MΩ | [34] |

| BaTiO3 NPs/PVDF | Solution casting | 1.5 × 2 cm2 | Not needed | 1 N | 6.7 V | 2.4 μA | - | [50] |

| BaTiO3 NPs/P(VDF-TrFE) | 3D printing | - | 50 V µm−1 | 60 N | 6 V | 2 μA cm−2 | 2 µW cm−2@10 MΩ | [51] |

| PMMA@BaTiO3 NW/P(VDF-TrFE) | Electrospinning | 2.5 × 2.5 cm2 | Not supplied | - | 12.6 V | 1.30 μA | 4.25 μW@7.2 MΩ | [17] |

| BaTi2O5/PVDF | Hot pressing | 4 × 2 cm2 | Not needed | - | 26 V | - | 4.1 μW@22 MΩ | [33] |

| graphene/BaTiO3/PVDF | Electrospinning | 2.5 × 2.5 cm2 | 12 kV | - | 11 V | - | 4 μW @ 8 MΩ | [16] |

| polydopamine/BaTiO3/P(VDF-TrFE) | Electrospinning | 2.5 × 2.5 cm2 | 25 kV | 700 N | 6 V | 1.5 μA | 0.85 µW cm−2@4 MΩ | [54] |

| Ag/polydopamine/BaTiO3/PVDF | Selective laser sintering | 0.9 × 1 cm2 | Not supplied | - | 10 V | 142 nA | - | [55] |

| BaTi0.9Zr0.1O3/PVDF | Solution casting | 2.5 × 2.5 cm2 | 8 kV | 11 N | 11.9 V | 1.35 μA | 0.15 µW cm−2@10 MΩ | [52] |

| KNN nanorods/PVDF | Electrospinning | 2 × 2 cm2 | 20 kV | 1 kPa | 17.5 V | 0.522 μA | - | [58] |

| silane/KNN nanorods/PVDF | Electrospinning | 22 cm2 | 20 kV | 1.1 kPa | 21 V | 22 μA | - | [59] |

| (1 − x)K0.5Na0.5NbO3–xBaTiO3/PVDF | Solution casting | 3 × 3 cm2 | 10 kV | 0.4 N | 100 V | 225 nA | 1.4 µW cm−2@100 MΩ | [60] |

| Materials | Preparation Methods | Sample Size | Poling | Force or Pressure | VOC | ISC/JSC | Power@RL | Reference |

|---|---|---|---|---|---|---|---|---|

| GO/P(VDF-TrFE) | Solution casting | - | 30 MV m−1 | 0.32 MPa | 4 V | 1.88 μA | 4.4 µW cm−2@1 MΩ | [61] |

| rGO/PVDF | Electrospinning | - | Not supplied | 20 kPa | - | 0.5 μA | - | [62] |

| ZnO/PVDF | Solution casting | 8 × 8 mm2 | Not needed | 28 N | 24.5 V | 1.7 μA | 32 mW cm−3 | [65] |

| BNNTs/P(VDF-TrFE) | Solution casting | 1 × 1 cm2 | 10 MV m−1 | 0.4 MPa | 22 V | 600 nA | 11.3 μW cm−2@6 MΩ | [31] |

| GeSe NSs/P(VDF-TrFE) | Solution casting | 1 × 1 cm2 | 70 MV m−1 | 50 N | 17.58 V | 1.14 μA | 9.5 μW cm−2@4 MΩ | [70] |

| MoS2/PVDF | Solution casting | 1 × 1 cm2 | Not needed | 27.5 N | 84 V | 3.05 μA | 47 mW cm−3@30 MΩ | [71] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhu, L.; Du, C. Progress in Piezoelectric Nanogenerators Based on PVDF Composite Films. Micromachines 2021, 12, 1278. https://doi.org/10.3390/mi12111278

Wang Y, Zhu L, Du C. Progress in Piezoelectric Nanogenerators Based on PVDF Composite Films. Micromachines. 2021; 12(11):1278. https://doi.org/10.3390/mi12111278

Chicago/Turabian StyleWang, Yuan, Laipan Zhu, and Cuifeng Du. 2021. "Progress in Piezoelectric Nanogenerators Based on PVDF Composite Films" Micromachines 12, no. 11: 1278. https://doi.org/10.3390/mi12111278

APA StyleWang, Y., Zhu, L., & Du, C. (2021). Progress in Piezoelectric Nanogenerators Based on PVDF Composite Films. Micromachines, 12(11), 1278. https://doi.org/10.3390/mi12111278