Effect of Interface Pretreatment of Al Alloy on Bonding Strength of the Laser Joined Al/CFRTP Butt Joint

Abstract

1. Introduction

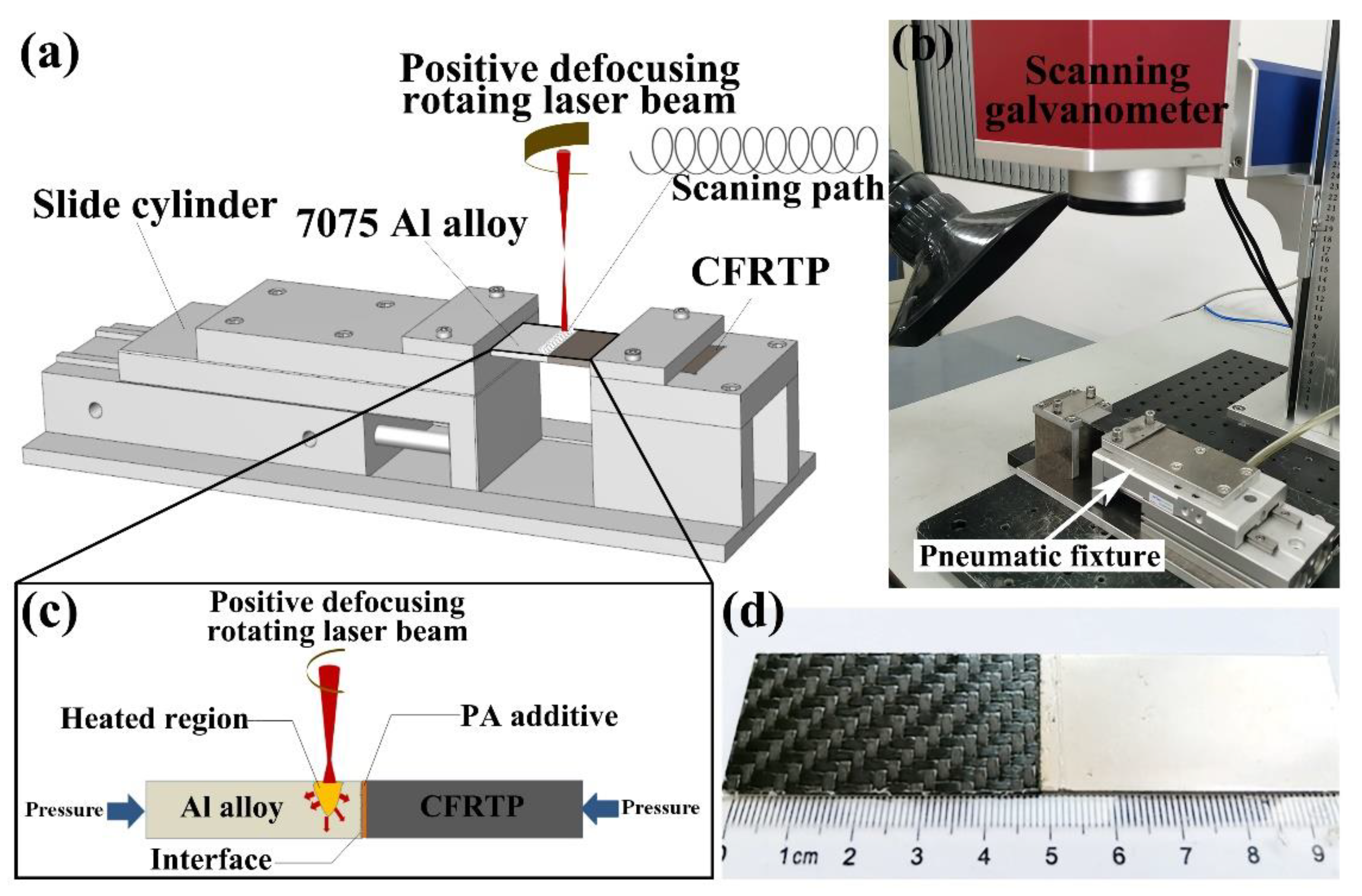

2. Materials and Methods

2.1. Materials and Preparation

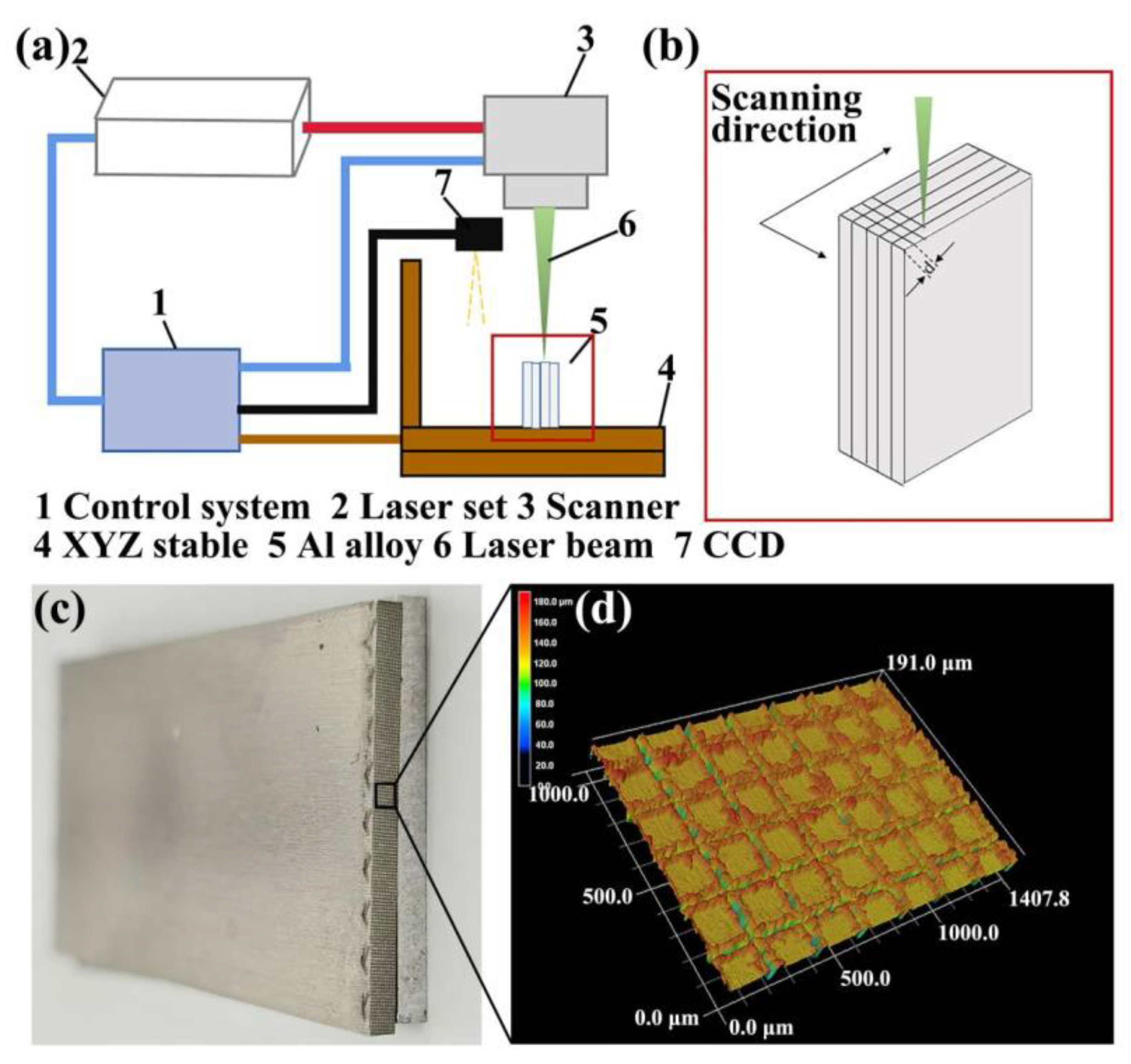

2.2. Material Surface Pretreatment

2.2.1. Laser Micro-Texturing Pretreatment

2.2.2. Anodizing Pretreatment

2.2.3. Hybrid Pretreatment of Laser Micro-Texturing and Anodizing

2.3. Laser Joining

2.4. Surface Characterization and Bonding Strength

3. Results and Discussion

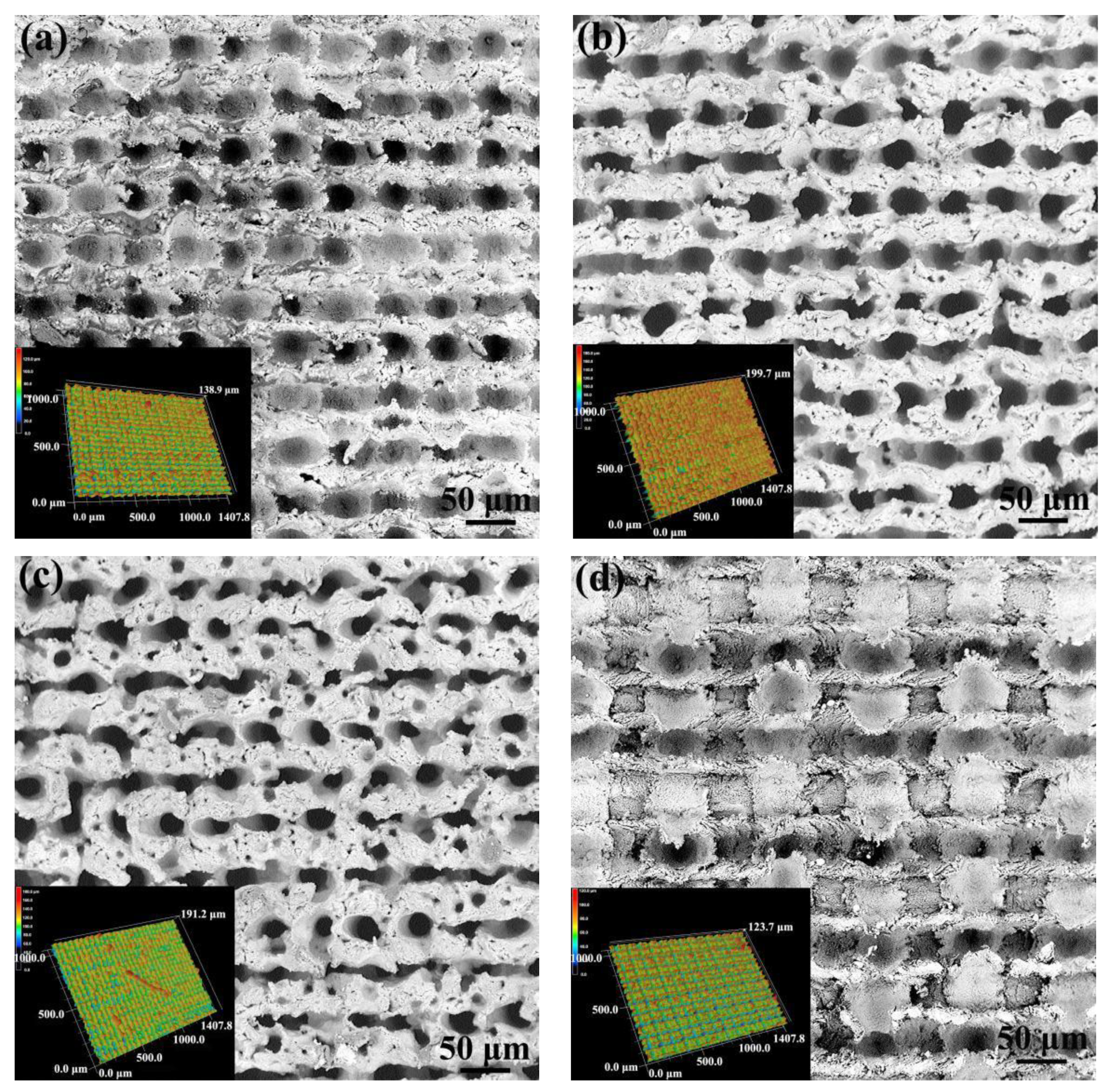

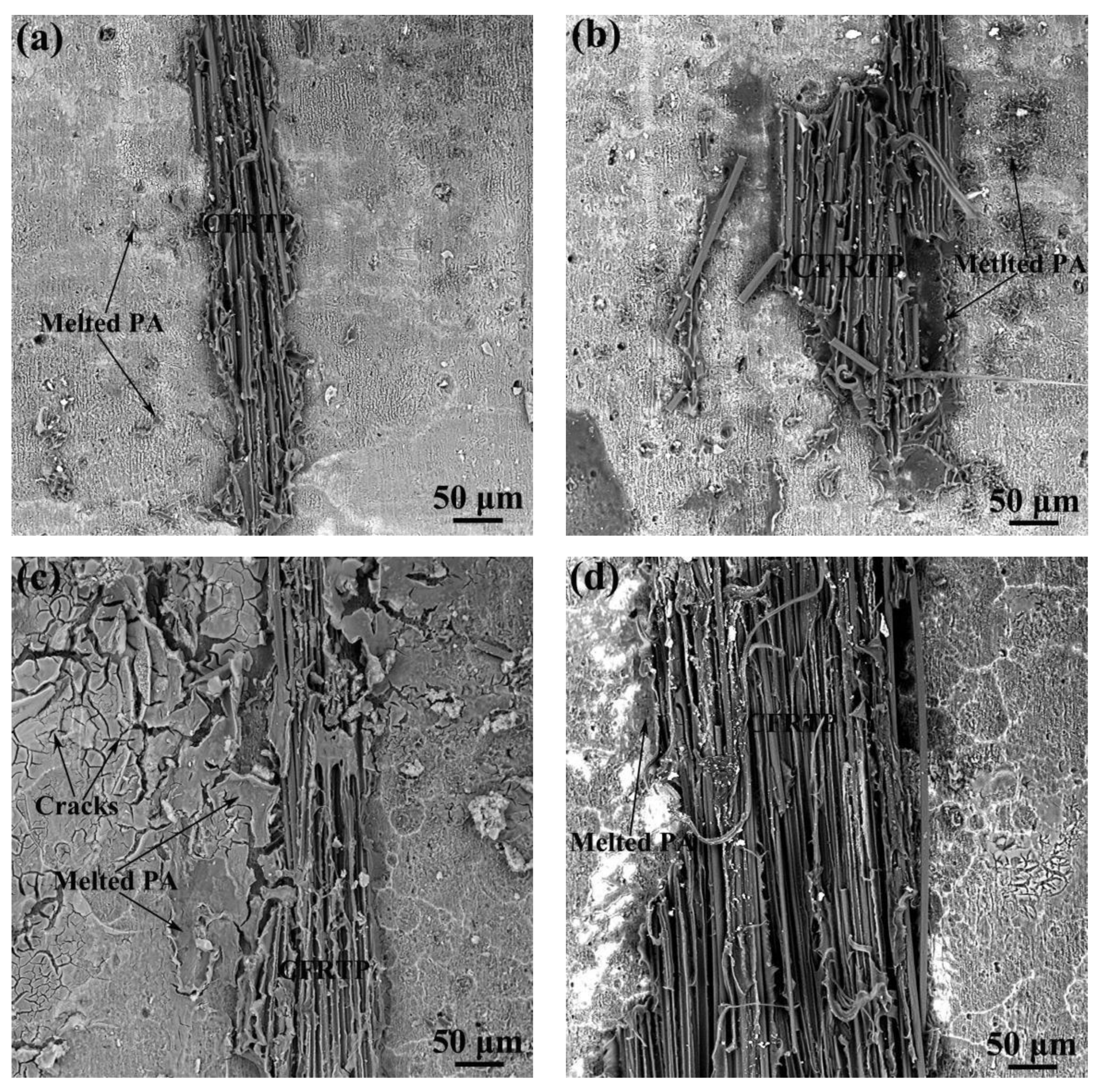

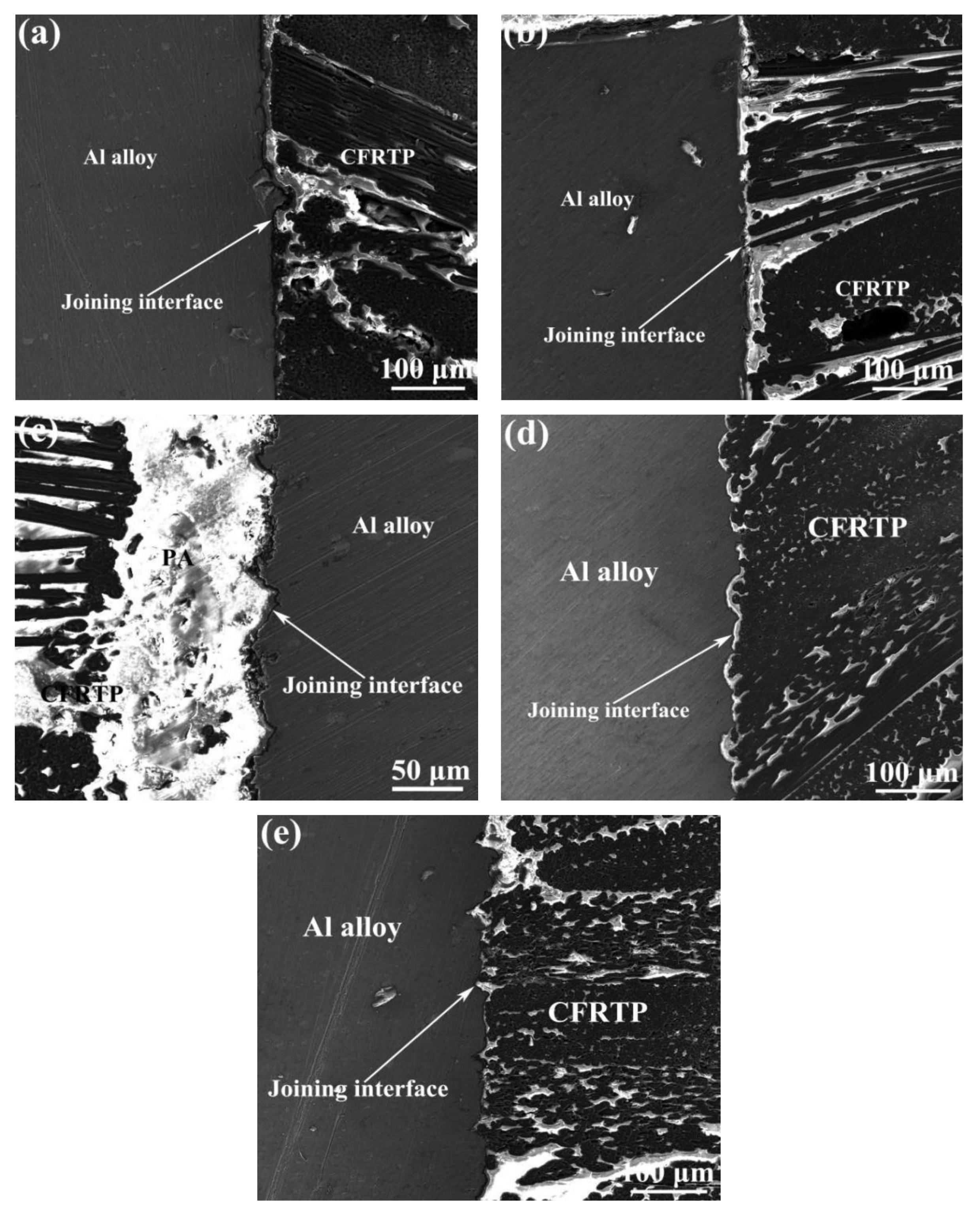

3.1. The Al/CFRTP Butt Joint with Laser Micro-Texturing Pretreatment

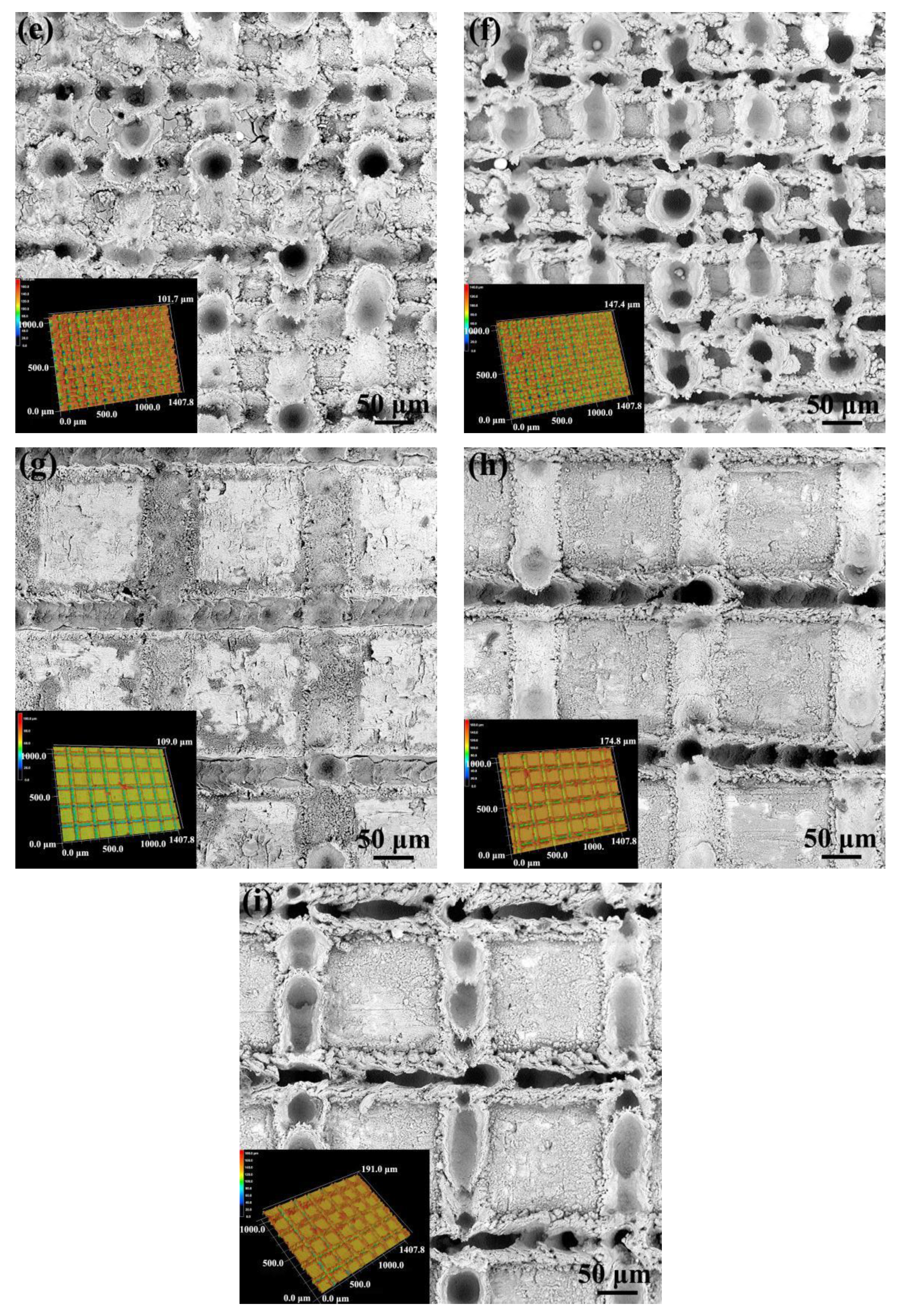

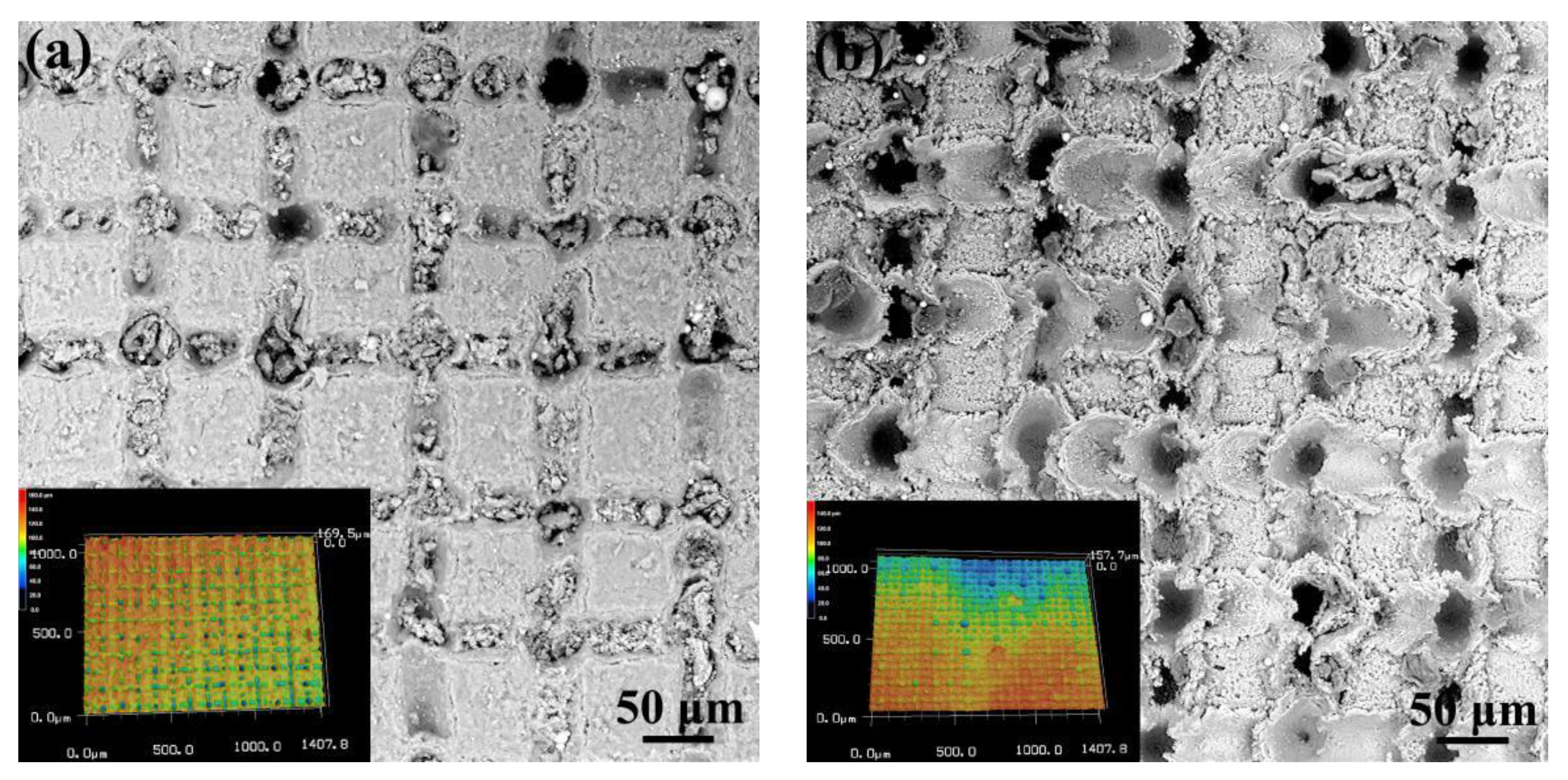

3.2. The Al/CFRTP Butt Joint with Anodizing Pretreatment

3.3. The Al/CFRTP Butt Joint with Micro-Texturing and Anodizing Hybrid Pretreatment

4. Conclusions

- The laser micro-texturing has processed the micro-pit or micro-furrow in the Al joining interface. With the increasing of laser scanning times, the size of the micro-pit or micro-furrow decreases, when the laser scanning distance is defined. With the increasing of laser scanning distance and time, the bonding strength of the Al/CFRTP butt joint firstly decreases gradually and then increases. After reaching the maximum value of 20 MPa at laser scanning distance of 0.1 mm and 1 time laser scanning, the bonding strength of the Al/CFRTP butt joint decreases again and reaches the minimum value at laser scanning distance of 0.2 mm and 1 time laser scanning, and then, the bonding strength of the Al/CFRTP butt joint increases again.

- The anodizing pretreatment has formed the Al2O3 oxide layer on the Al joining interface. With the increase in anodizing time, the bonding strength of the Al/CFRTP butt joint increases firstly and reaches the maximum value of 11 MPa at anodizing time of 10 min. The further increase in anodizing time would decrease the bonding strength of the Al/CFRTP butt joint and reach minimum value at anodizing time of 15 min. Thereafter, the bonding strength of the Al/CFRTP butt joint would increase again.

- The hybrid pretreatment of micro-texturing firstly and anodizing lastly fabricates the regular grid structure with smooth micro-furrow and micro-pit, while the hybrid pretreatment of anodizing firstly and micro-texturing lastly processes the Al joining interface with explosive micro-pit and micro-furrow. The bonding strength of the Al/CFRTP butt joint with Al joining interface pretreated by hybrid pretreatment is relative better than that of the Al/CFRTP butt joint with Al joining interface pretreated by anodizing but almost lower than that of the Al/CFRTP butt joint with Al joining interface pretreated by micro-texturing. Such results should be attributed to the surface morphology of the Al joining interface.

- Considering the influence of the Al joining interface, the interface morphology and interfacial film structure still needs to be optimized in future work. The effect of morphology, dimension, and distribution of micro-texture on the bonding strength of the Al/CFRTP butt joint should be studied systematically. Moreover, the interfacial film with reasonable morphology and structure should be explored to improve the bonding strength of the Al/CFRTP butt joint. In addition, the optimal combination of the surface morphology processing and interfacial film should be studied further.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Zhu, P.; Chen, G. Lightweight design of automotive front side rail based on robust optimisation. Thin Walled Struct. 2007, 45, 670–676. [Google Scholar] [CrossRef]

- Liu, Q.; Lin, Y.; Zong, Z.; Sun, G.; Li, Q. Lightweight design of carbon twill weave fabric composite body structure for electric vehicle. Compos. Struct. 2013, 97, 231–238. [Google Scholar] [CrossRef]

- Sun, Q.; Zhou, G.; Meng, Z.; Jain, M.; Su, X. An integrated computational materials engineering framework to analyze the failure behaviors of carbon fiber reinforced polymer composites for lightweight vehicle applications. Compos. Sci. Technol. 2021, 202, 108560. [Google Scholar] [CrossRef] [PubMed]

- Arash, B.; Wang, Q.; Varadan, V.K. Mechanical properties of carbon nanotube/polymer composites. Scientific Reports. 2015, 4, 6479. [Google Scholar] [CrossRef] [PubMed]

- Balakrishnan, V.S.; Seidlitz, H. Potential repair techniques for automotive composites: A review. Compos. Part B Eng. 2018, 145, 28–38. [Google Scholar] [CrossRef]

- Sheng, L.; Jiao, J.; Du, B.; Wang, F.; Wang, Q. Influence of processing parameters on laser direct joining of CFRTP and stainless steel. Adv. Mater. Sci. Eng. 2018, 2530521. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, X.; Pan, K.; Yang, C. J-Integral based correlation evaluation between microstructure and mechanical strength for FSSW joints made of automotive aluminum alloys. J. Manuf. Process. 2019, 44, 62–71. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Xi, T.F.; Lai, C.; Ye, H.Q. Influence of heat treatment on interface of Cu/Al bimetal composite fabricated by cold rolling. Compos. Part B Eng. 2011, 42, 1468–1473. [Google Scholar] [CrossRef]

- Hirsch, J. Recent development in aluminium for automotive applications. Trans. Nonferr. Met. Soc. China 2014, 24, 1995–2002. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Cheung, K.C.; Gershenfeld, N. Reversibly assembled cellular composite. Mater. Sci. 2013, 341, 1219–1221. [Google Scholar]

- Pramanik, A.; Basak, A.K.; Dong, Y.; Sarker, P.K.; Uddin, M.S.; Littlefair, G.; Dixit, A.R.; Chattopadhyaya, S. Joining of carbon fibre reinforced polymer (CFRP) composites and aluminium Alloys-A review. Compos. Part A Appl. Sci. Manuf. 2017, 101, 1–29. [Google Scholar] [CrossRef]

- Vorderbrüggen, J.; Meschut, G. Investigations on a material-specific joining technology for CFRP hybrid joints along the automotive process chain. Compos. Struct. 2019, 230. [Google Scholar] [CrossRef]

- Kirchdoerfer, T.; Liebscher, A.; Ortiz, M. CTH shock physics simulation of non-linear material effects within an aerospace CFRP fastener assembly due to direct lightning attachment. Compos. Struct. 2018, 189, 357–365. [Google Scholar] [CrossRef]

- Marannano, G.; Zuccarello, B. Numerical experimental analysis of hybrid double lap Aluminum-CFRP joints. Compos. Part B Eng. 2015, 71, 28–39. [Google Scholar] [CrossRef]

- Machado, J.J.M.; Nunes, P.D.P.; Marques, E.A.S.; Silva, L.F.M. Adhesive joints using aluminium and CFRP substrates tested at low and high temperatures under quasi-static and impact conditions for the automotive industry. Compos. Part B Eng. 2019, 158, 102–116. [Google Scholar] [CrossRef]

- Kumar, S.B.; Sridhar, I.; Sivashanker, S.; Osiyemi, S.O.; Bag, A. Tensile failure of adhesively bonded CFRP composite scarf joints. Mater. Sci. Eng. B 2006, 132, 113–120. [Google Scholar] [CrossRef]

- Li, J.; Yan, Y.; Zhang, T.; Liang, Z. Experimental study of adhesively bonded CFRP joints subjected to tensile loads. Int. J. Adhes. Adhes. 2015, 57, 95–104. [Google Scholar] [CrossRef]

- Staab, F.; Balle, F. Ultrasonic torsion welding of ageing-resistant Al/CFRP joints: Properties, microstructure and joint formation. Ultrasonics 2019, 93, 139–144. [Google Scholar] [CrossRef] [PubMed]

- Ren, S.; Ma, Y.; Saeki, S.; Iwamoto, Y.; Chen, C.; Ma, N. Fracture mechanism and strength evaluation of Al5052/CFRP joint produced by coaxial one-side resistance spot welding. Compos. Struct. 2020, 252, 112766. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Xie, Y.; Li, J.; Guan, M.; Wan, L.; Dong, Z.; Cao, J. Friction self-riveting welding between polymer matrix composites and metals. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105624. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Wang, F.Y.; Wang, Q.; Jiao, J.K. Shear strength optimization of laser-joined polyphenylene sulfide-based CFRTP and stainless steel. Strength Mater. 2018, 50, 824–831. [Google Scholar] [CrossRef]

- Reitz, V.; Meinhard, D.; Ruck, S.; Riegel, H.; Knoblauch, V. A comparison of IR- and UV-laser pretreatment to increase the bonding strength of adhesively joined aluminum/CFRP components. Compos. Part A Appl. Sci. Manuf. 2017, 96, 18–27. [Google Scholar] [CrossRef]

- Gennaa, S.; Lambiaseb, F.; Leone, C. Effect of laser cleaning in laser assisted joining of CFRP and PC sheets. Compos. Part B Eng. 2018, 145, 206–214. [Google Scholar] [CrossRef]

- Su, J.; Tan, C.; Wu, Z.; Wu, L.; Gong, X.; Chen, B.; Song, X.; Feng, J. Influence of defocus distance on laser joining of CFRP to titanium alloy. Opt. Laser Technol. 2020, 124, 106006. [Google Scholar] [CrossRef]

- Jung, K.W.; Kawahito, Y.; Katayama, S. Laser direct joining of carbon fibre reinforced plastic to stainless steel. Sci. Technol. Weld. Join 2013, 16, 676–680. [Google Scholar] [CrossRef]

- Jung, K.; Kawahito, Y.; Takahashi, M.; Katayama, S. Laser direct joining of carbon fiber reinforced plastic to aluminum alloy. J. Laser Appl. 2013, 25, 32003. [Google Scholar] [CrossRef]

- Roesner, A.; Scheik, S.; Olowinsky, A.; Guillner, A.; Reisgen, U.; Schleser, M. Laser assisted joining of plastic metal hybrids. Phys. Procedia 2011, 12, 370–377. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S. Experimental analysis of laser assisted joining of Al-Mg aluminium alloy with polyetheretherketone (PEEK). Int. J. Adhes. Adhes. 2018, 84, 265–274. [Google Scholar] [CrossRef]

- Zhang, Z.; Shan, J.; Tan, X.; Zhang, J. Effect of anodizing pretreatment on laser joining CFRP to aluminum alloy A6061. Int. J. Adhes. Adhes. 2016, 70, 142–151. [Google Scholar] [CrossRef]

- Zhang, Z.; Shan, J.; Tan, X.; Zhang, J. Improvement of the laser joining of CFRP and aluminum via laser pre-treatment. Int. J. Adv. Manuf. Technol. 2017, 90, 3465–3472. [Google Scholar] [CrossRef]

- Jiao, J.; Xu, Z.; Wang, Q.; Sheng, L.; Zhang, W. CFRTP and stainless steel laser joining: Thermal defects analysis and joining parameters optimization. Opt. Laser Technol. 2018, 103, 170–176. [Google Scholar] [CrossRef]

- Jiao, J.; Jia, S.; Xu, Z.; Ye, Y.; Sheng, L.; Zhang, W. Laser direct joining of CFRTP and aluminium alloy with a hybrid surface pre-treating method. Compos. Part B Eng. 2019, 173, 106911. [Google Scholar] [CrossRef]

- Jiao, J.; Ye, Y.; Jia, S.; Xu, Z. CFRTP-Al alloy laser assisted joining with a high speed rotational welding technology. Opt. Laser Technol. 2020, 127, 106187. [Google Scholar] [CrossRef]

- Mohitfar, S.H.; Mahdavi, S.; Etminanfar, M.; Khalil-Allafi, J. Characteristics and tribological behavior of the hard anodized 6061-T6 Al alloy. J. Alloys Compd. 2020, 842, 155988. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Lai, C.; Xu, Z.F.; Jiao, J.K. Effect of the surface texture on laser joining of a carbon fiber-reinforced thermosetting plastic and stainless steel. Strength Mater. 2019, 51, 122–129. [Google Scholar] [CrossRef]

- Lim, S.J.; Cheon, J.; Kim, M. Effect of laser surface treatments on a thermoplastic PA 6/carbon composite to enhance the bonding strength. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105989. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Jiao, J.K.; Lai, C. Assessment of the microstructure and mechanical properties of a laser-joined carbon fiber-reinforced thermosetting plastic and stainless steel. Strength Mater. 2018, 50, 752–763. [Google Scholar] [CrossRef]

- Li, Y.; Bu, H.; Yang, H.; Liu, G.; Yao, J.; Zhan, X. Effect of laser heat input on the interface morphology during laser joining of CFRTP and 6061 aluminum alloy. J. Manuf. Process. 2020, 50, 366–379. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Du, B.N.; Hu, Z.Y.; Qiao, Y.X.; Xiao, Z.P.; Wang, B.J.; Xu, D.K.; Zheng, Y.F.; Xi, T.F. Effects of annealing treatment on microstructure and tensile behavior of the Mg-Zn-Y-Nd alloy. J. Magnes. Alloy 2020, 8, 601–613. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Xi, T.F.; Guo, J.T.; Ye, H.Q. Microstructure evolution and mechanical properties of Ni3Al/Al2O3 composite during self-propagation high-temperature synthesis and hot extrusion. Mater. Sci. Eng. A 2012, 555, 131–138. [Google Scholar] [CrossRef]

| Laser Scanning Distance d (mm) | Laser Scanning Times n | ||

|---|---|---|---|

| 1 | 2 | 4 | |

| 0.05 | MS1 | MS2 | MS4 |

| 0.1 | MM1 | MM2 | MM4 |

| 0.2 | MB1 | MB2 | MB4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Y.; Zou, Q.; Xiao, Y.; Jiao, J.; Du, B.; Liu, Y.; Sheng, L. Effect of Interface Pretreatment of Al Alloy on Bonding Strength of the Laser Joined Al/CFRTP Butt Joint. Micromachines 2021, 12, 179. https://doi.org/10.3390/mi12020179

Ye Y, Zou Q, Xiao Y, Jiao J, Du B, Liu Y, Sheng L. Effect of Interface Pretreatment of Al Alloy on Bonding Strength of the Laser Joined Al/CFRTP Butt Joint. Micromachines. 2021; 12(2):179. https://doi.org/10.3390/mi12020179

Chicago/Turabian StyleYe, Yiyun, Qi Zou, Yinan Xiao, Junke Jiao, Beining Du, Yuezhan Liu, and Liyuan Sheng. 2021. "Effect of Interface Pretreatment of Al Alloy on Bonding Strength of the Laser Joined Al/CFRTP Butt Joint" Micromachines 12, no. 2: 179. https://doi.org/10.3390/mi12020179

APA StyleYe, Y., Zou, Q., Xiao, Y., Jiao, J., Du, B., Liu, Y., & Sheng, L. (2021). Effect of Interface Pretreatment of Al Alloy on Bonding Strength of the Laser Joined Al/CFRTP Butt Joint. Micromachines, 12(2), 179. https://doi.org/10.3390/mi12020179