Liquid Crystal Devices for Beam Steering Applications

Abstract

:1. Introduction

1.1. Static Properties of Nematic Liquid Crystals

1.2. Dynamic Properties of Nematic Liquid Crystals

1.3. Refractive and Diffractive LC Beam Steering Devices

2. Refractive NLC Optical Devices

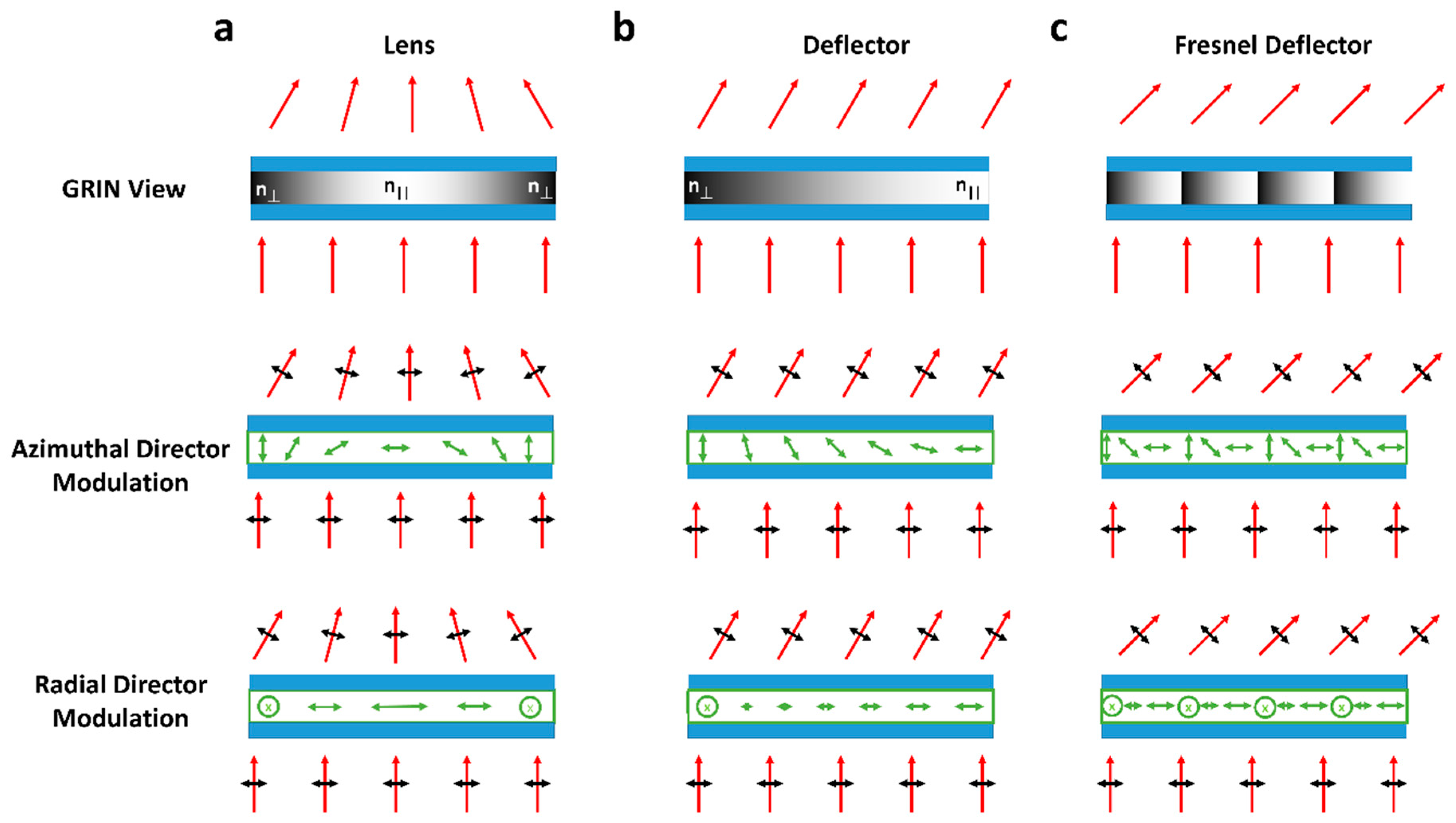

2.1. Refractive Optical Components

2.2. Uniaxial Optical Components

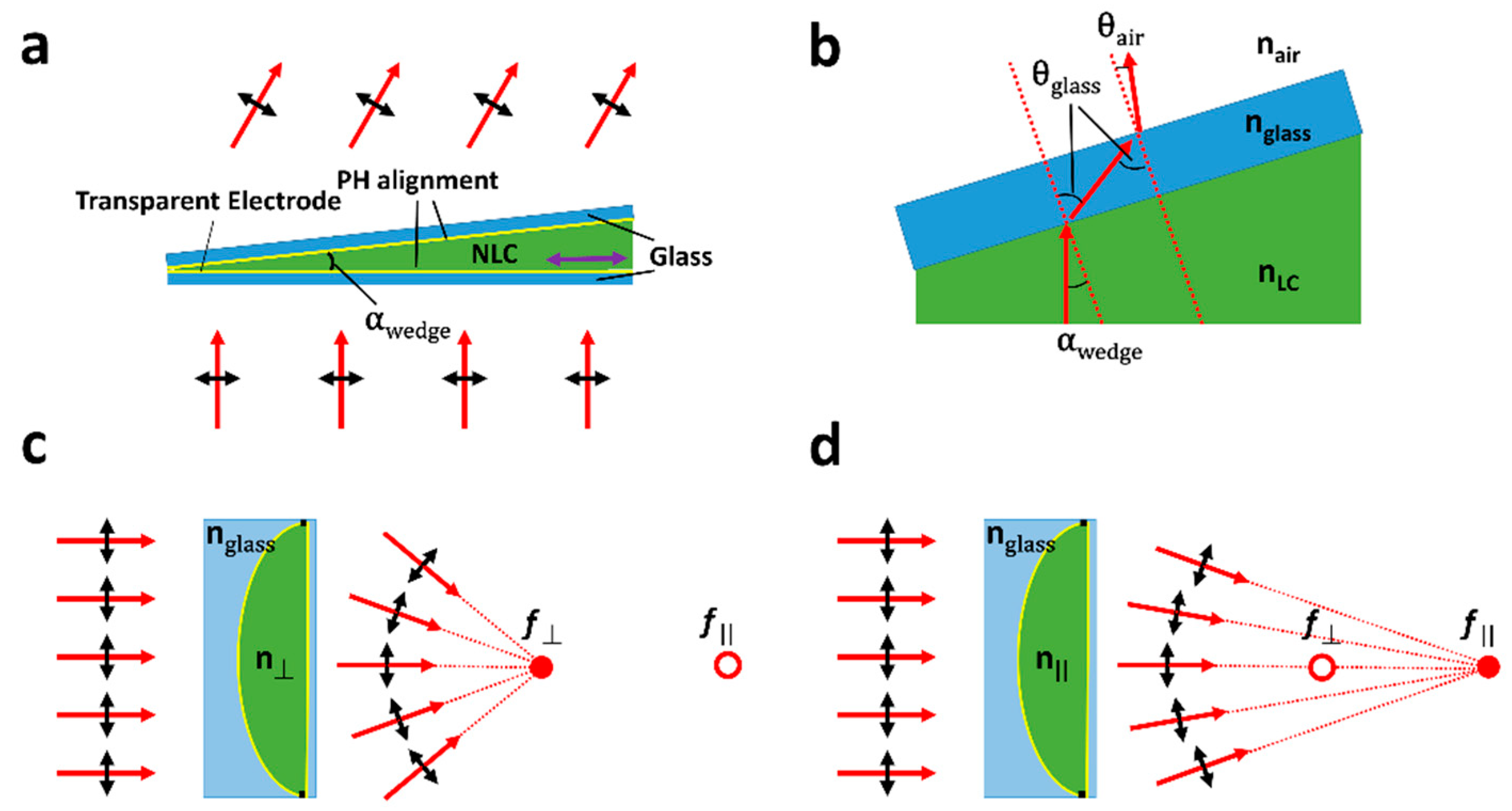

2.3. Geometric Prisms and Lenses

2.4. Refractive Fringing Field Devices

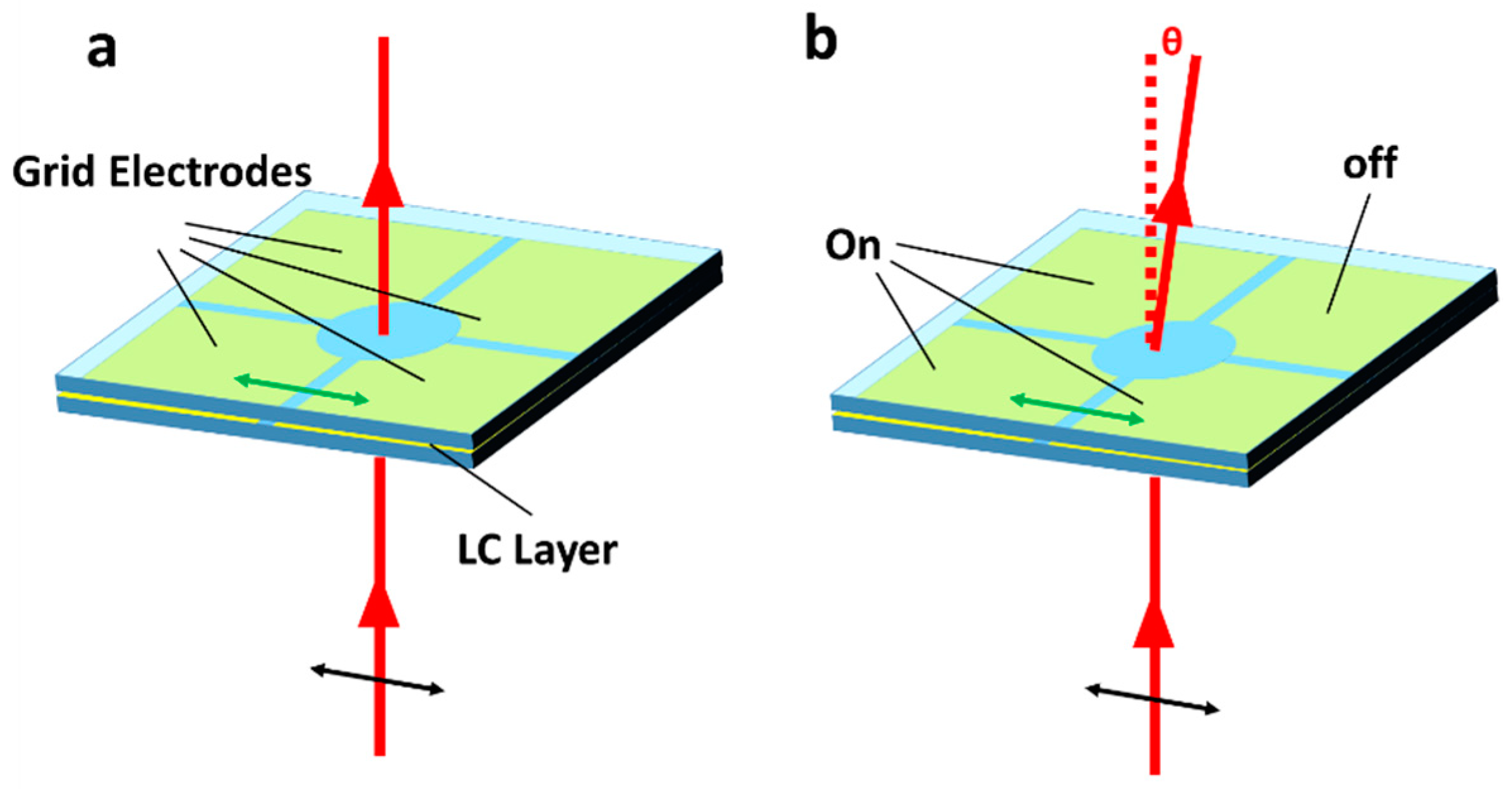

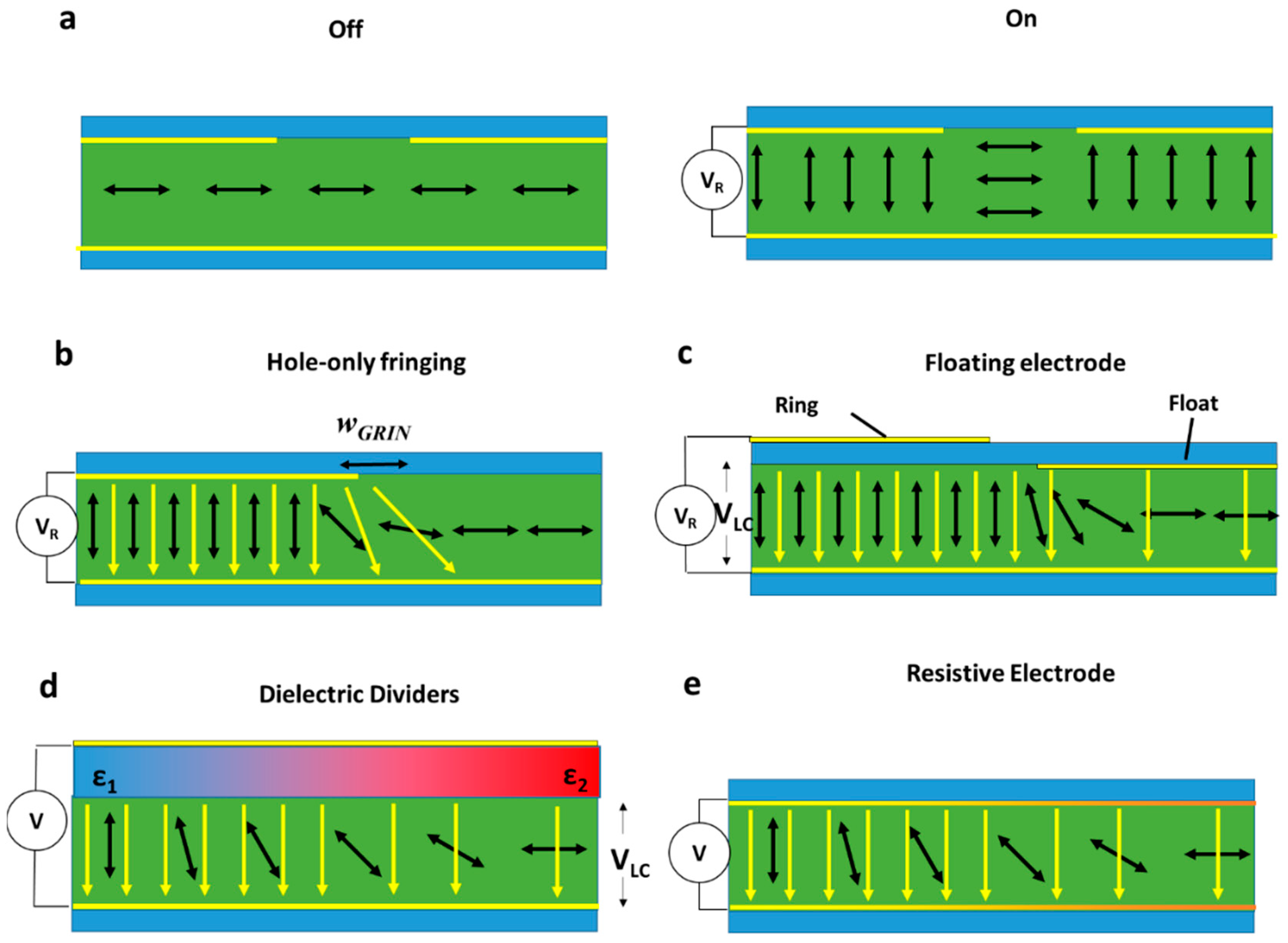

2.4.1. Beam Deflectors

2.4.2. Lenses

2.5. Alignment Controlled Refractive Beam Steering

2.5.1. Stacked Alignment Layers

2.5.2. Photoalignment

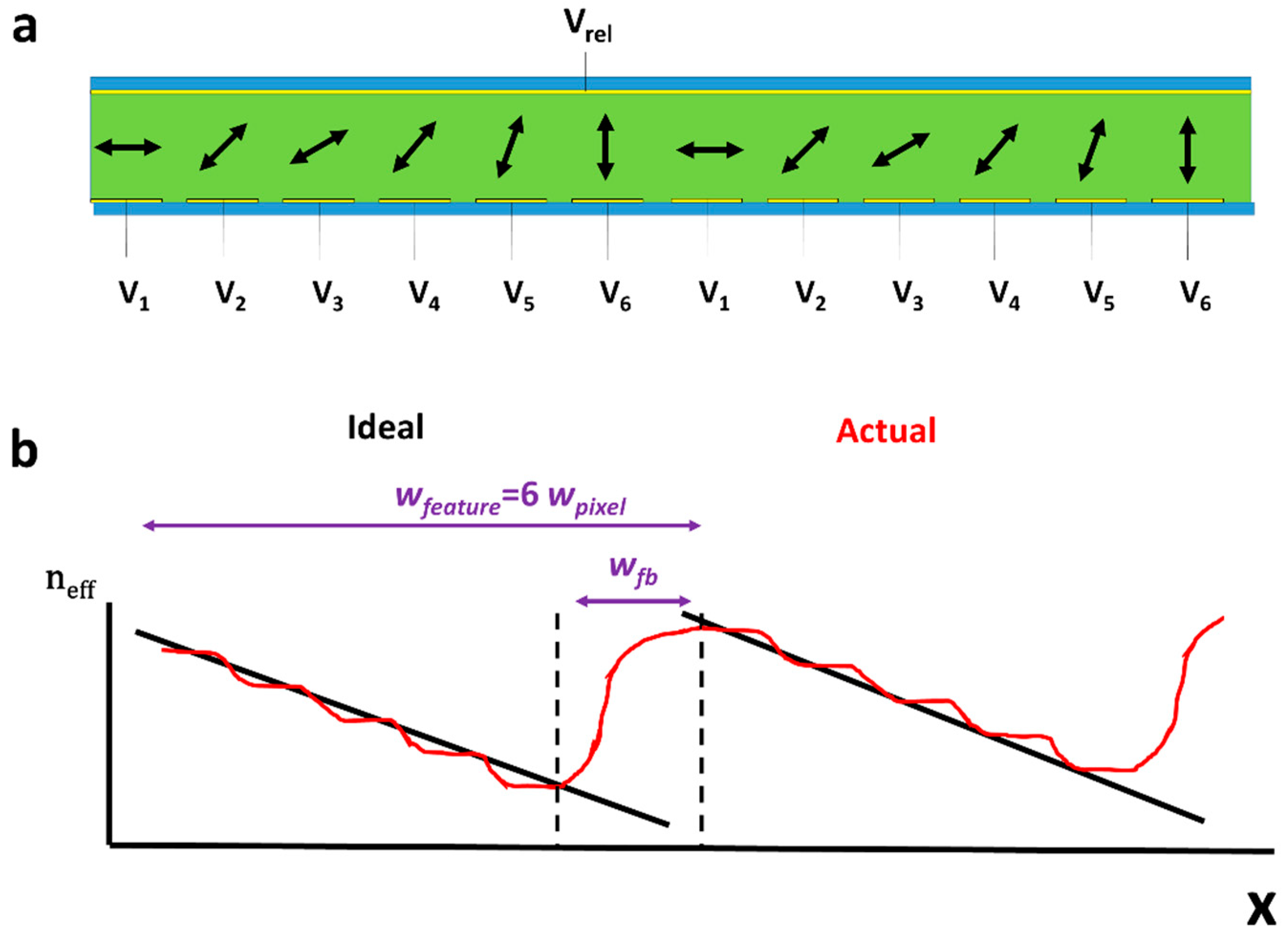

2.6. Electronically Addressed Refractive Spatial Light Modulators

2.7. Optically Addressed Refractive Spatial Light Modulators

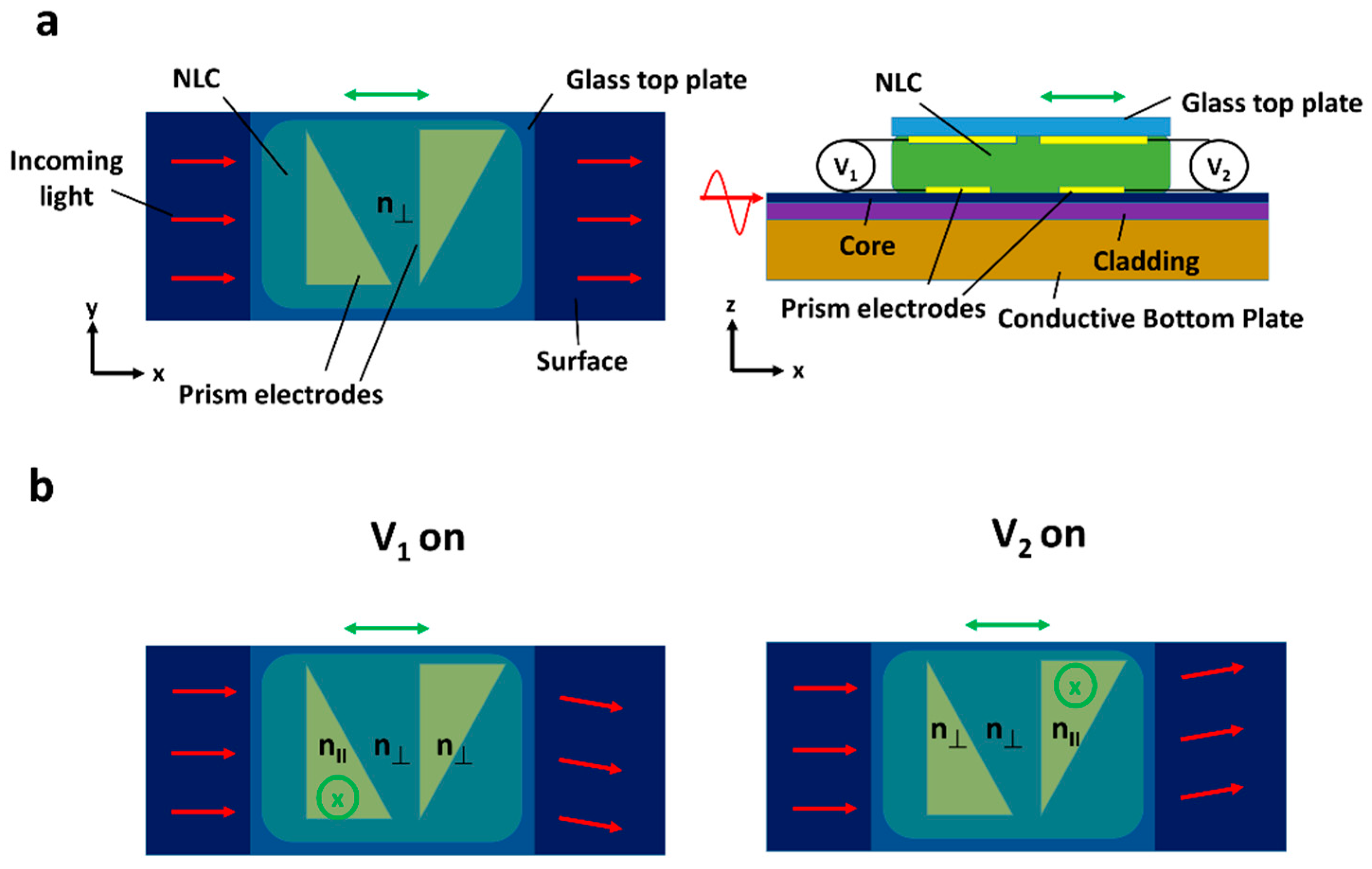

2.8. Optical Waveguides

2.9. Polarisation Independent Devices

3. Diffractive NLC Optical Devices

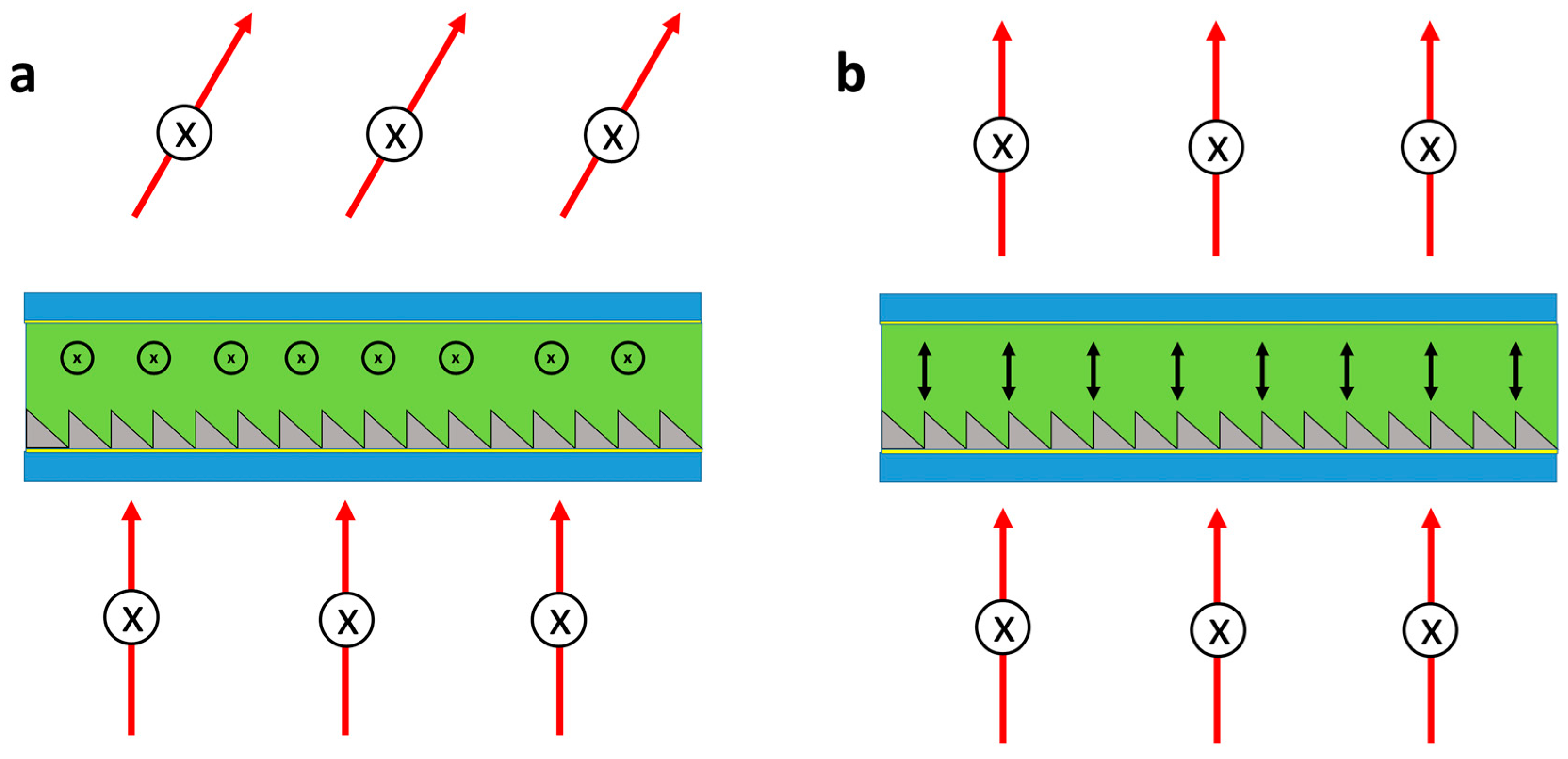

3.1. Raman-Nath Diffractive Optical Components

3.2. Bragg Diffraction

3.3. Diffractive Dielectric Inclusions and Exclusions

3.4. Single Patterned Electrode Devices

3.5. Electronically Addressed Diffractive Spatial Light Modulators

3.6. Volume Bragg Gratings

3.7. Diffractive Alignment Gratings

3.7.1. Diffractive Stacked Alignment Layers

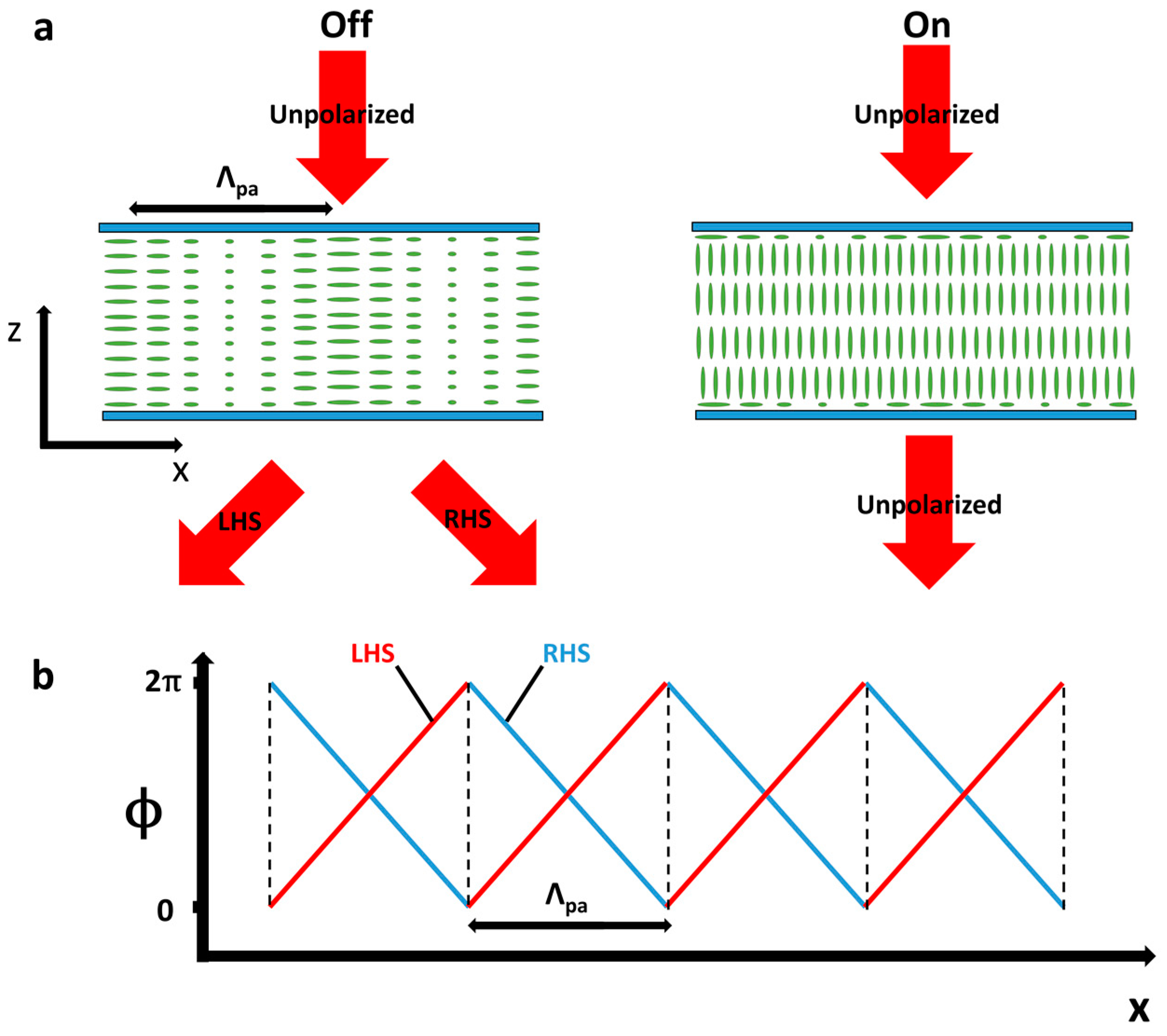

3.7.2. Pancharatnum–Berry Devices

3.8. Flow-Induced Patterns

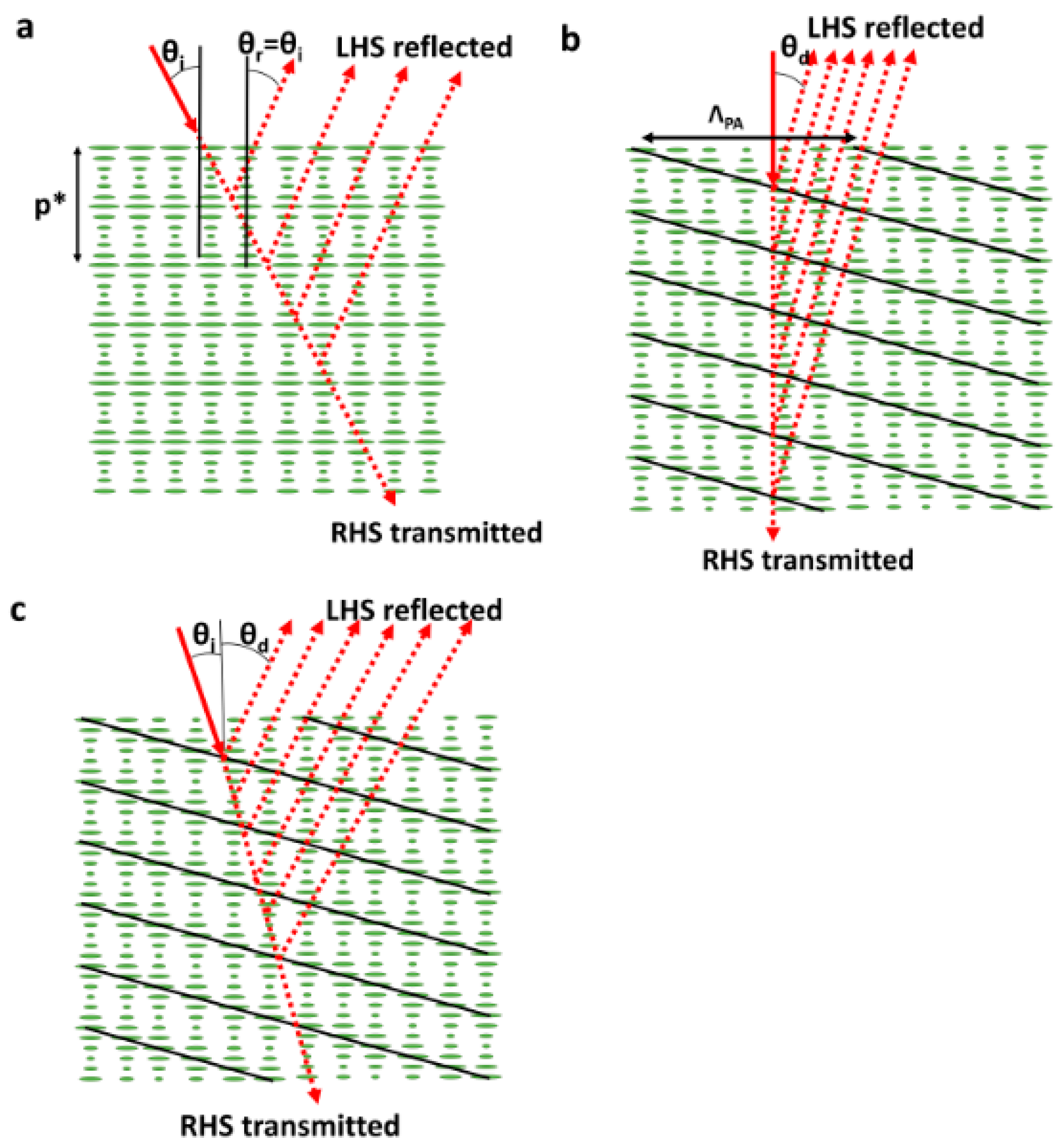

3.9. Cholesteric Gratings

4. Discussion

4.1. Figures of Merit

4.2. Refractive NLC Devices

4.3. Diffractive NLC Devices

4.4. Non-Nematic Liquid Crystal Devices

4.4.1. Isotropic LC Phases

4.4.2. Nematic Twist Bend

4.4.3. Ferroelectric LCs

4.5. Summary

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schadt, M.; Helfrich, W. Voltage-dependent optical activity of a twisted nematic liquid crystal. Appl. Phys. Lett. 1971, 18, 127–128. [Google Scholar] [CrossRef]

- Heilmeier, G.H.; Zanoni, L.A.; Barton, L.A. Dynamic scattering in nematic liquid crystals. Appl. Phys. Lett. 1968, 13, 46–47. [Google Scholar] [CrossRef]

- Chang, C.; Bang, K.; Wetzstein, G.; Lee, B.; Gao, L. Toward the next-generation VR/AR optics: A review of holographic near-eye displays from a human-centric perspective. Optica 2020, 7, 1563. [Google Scholar] [CrossRef]

- Chen, H.; Weng, Y.; Xu, D.; Tabiryan, N.V.; Wu, S.-T. Beam steering for virtual/augmented reality displays with a cycloidal diffractive waveplate. Opt. Express 2016, 24, 7287. [Google Scholar] [CrossRef] [Green Version]

- Cakmakci, O.; Rolland, J. Head-worn displays: A review. IEEE/OSA J. Disp. Technol. 2006, 2, 199–216. [Google Scholar] [CrossRef]

- Hikmet, R.A.M.; Kemperman, H. Electrically switchable mirrors and optical components made from liquid-crystal gels. Nature 1998. [Google Scholar] [CrossRef]

- Milton, H.E.; Morgan, P.B.; Clamp, J.H.; Gleeson, H.F. Electronic liquid crystal contact lenses for the correction of presbyopia. Opt. Express 2014, 22, 8035. [Google Scholar] [CrossRef]

- Bailey, J.; Morgan, P.; Gleeson, H.; Jones, J. Switchable Liquid Crystal Contact Lenses for the Correction of Presbyopia. Crystals 2018, 8, 29. [Google Scholar] [CrossRef] [Green Version]

- Bailey, J.; Kaur, S.; Morgan, P.B.; Gleeson, H.F.; Clamp, J.H.; Jones, J.C. Design considerations for liquid crystal contact lenses. J. Phys. D Appl. Phys. 2017, 50, 485401. [Google Scholar] [CrossRef]

- Tsou, Y.-S.; Lin, Y.-H.; Wei, A.-C. Concentrating Photovoltaic System Using a Liquid Crystal Lens. IEEE Photonics Technol. Lett. 2012, 24, 2239–2242. [Google Scholar] [CrossRef]

- Wilkinson, T. Holography and Information Storage. In Handbook of Liquid Crystals; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2014; pp. 1–41. [Google Scholar]

- Huh, J.-W.; Choi, T.-H.; Woo, J.-H.; Kim, J.-H.; Do, S.-M.; Seo, J.-H.; Yoon, T.-H. Bistable Liquid-Crystal Phase Grating Device for Smart Window and Window Display Applications. In Proceedings of the Emerging Liquid Crystal Technologies XV, San Francisco, CA, USA, 1–6 February 2020; Chien, L.-C., Broer, D.J., Eds.; SPIE: Bellingham, WA, USA, 2020; p. 18. [Google Scholar]

- Susumu Sato, L.; Sugiyama, A.; Sato, R.; Sato, S.; Susumu Sato, L.; Sugiyama, A.; Sato, R.; Sato, S. Liquid-crystal lens-cells with variable focal length. Jpn. J. Appl. Phys. 1979, 18, 1679–1684. [Google Scholar] [CrossRef]

- Beeckman, J. Liquid-crystal photonic applications. Opt. Eng. 2011, 50, 081202. [Google Scholar] [CrossRef] [Green Version]

- Kashnow, R.A.; Bigelow, J.E. Diffraction from a Liquid Crystal Phase Grating. Appl. Opt. 1973, 12, 2302. [Google Scholar] [CrossRef] [PubMed]

- Subacius, D.; Bos, P.J.; Lavrentovich, O.D. Switchable diffractive cholesteric gratings. Appl. Phys. Lett. 1997. [Google Scholar] [CrossRef] [Green Version]

- Stockley, J.; Serati, S. Advances in Liquid Crystal Beam Steering. In Proceedings of the Free-Space Laser Communications IV, Denver, CO, USA, 2–6 August 2004; Ricklin, J.C., Voelz, D.G., Eds.; SPIE: Bellingham, WA, USA, 2004; Volume 5550, p. 32. [Google Scholar]

- Kim, J.; Oh, C.; Serati, S.; Escuti, M.J. Wide-angle, nonmechanical beam steering with high throughput utilizing polarization gratings. Appl. Opt. 2011, 50, 2636. [Google Scholar] [CrossRef]

- Love, G.D.; Major, J.V.; Purvis, A. Liquid-crystal prisms for tip-tilt adaptive optics. Opt. Lett. 1994, 19, 1170. [Google Scholar] [CrossRef]

- Love, G. Handbook of Liquid Crystals: Volume 8: Chapter 12 Adaptive Optics and Lenses; Goodby, J.W., Collings, P.J., Kato, T., Yschierske, C., Gleeson, H.F., Raynes, P., Eds.; Wiley: Hoboken, NJ, USA, 2015; Volume 24, ISBN 9783527620555. [Google Scholar]

- He, Z.; Gou, F.; Chen, R.; Yin, K.; Zhan, T.; Wu, S.-T. Liquid Crystal Beam Steering Devices: Principles, Recent Advances, and Future Developments. Crystals 2019, 9, 292. [Google Scholar] [CrossRef] [Green Version]

- McManamon, P.F.; Ataei, A. Progress and opportunities in the development of nonmechanical beam steering for electro-optical systems. Opt. Eng. 2019, 58, 1. [Google Scholar] [CrossRef]

- Frank, F.C. On the theory of liquid crystals. Discuss. Faraday Soc. 1958, 25, 19. [Google Scholar] [CrossRef]

- Oseen, C.W. The theory of liquid crystals. Trans. Faraday Soc. 1933, 29, 883. [Google Scholar] [CrossRef]

- De Gennes, P.G.; Prost, J. Static Distortions in Nematic Liquid Crystal. In The Physics of Liquid Crystals; Oxford University Press: Oxford, UK, 1993; pp. 98–162. [Google Scholar]

- Blinov, L.M.; Kabayenkov, A.Y.; Sonin, A.A. Experimental studies of the anchoring energy of nematic liquid crystals. Liq. Cryst. 1989, 5, 645–661. [Google Scholar] [CrossRef]

- Rapini, A.; Papoular, M. Distorsion d’une lamelle nématique sous champ magnétique conditions d’ancrage aux parois. Le J. Phys. Colloq. 1969, 30, C4-54–C4-56. [Google Scholar] [CrossRef]

- Kim, Y.B.; Olin, H.; Park, S.Y.; Choi, J.W.; Komitov, L.; Matuszczyk, M.; Lagerwall, S.T. Rubbed polyimide films studied by scanning force microscopy. Appl. Phys. Lett. 1995, 66, 2218–2219. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, S.; Kuroda, K.; Matsuo, M.; Nishikawa, M. Alignment Films for Liquid Crystal Devices. In The Liquid Crystal Display Story; Springer: Tokyo, Japan, 2014; pp. 59–80. ISBN 9784431548591. [Google Scholar]

- Ito, T.; Nakanishi, K.; Nishikawa, M.; Yokoyama, Y.; Takeuchi, Y. Regularity and narrowness of the intervals of the microgrooves on the rubbed polymer surfaces for liquid crystal alignment. Polym. J. 1995, 27, 240–246. [Google Scholar] [CrossRef] [Green Version]

- Toney, M.F.; Russell, T.P.; Logan, J.A.; Kikuchi, H.; Sands, J.M.; Kumar, S.K. Near-surface alignment of polymers in rubbed films. Nature 1995, 374, 709–711. [Google Scholar] [CrossRef]

- Uchida, T.; Ohgawara, M.; Wada, M. Liquid crystal orientation on the surface of obliquely-evaporated silicon monoxide with homeotropic surface treatment. Jpn. J. Appl. Phys. 1980, 19, 2127–2136. [Google Scholar] [CrossRef]

- Jones, J.C.; Bryan-Brown, G.P.; Wood, E.L.; Graham, A.; Brett, P.; Hughes, J.R. Novel Bistable Liquid Crystal Displays Based on Grating Alignment. In Proceedings of the Liquid Crystal Materials, Devices, and Flat Panel Displays, San Jose, CA, USA, 22–28 January 2000; SPIE: Bellingham, WA, USA, 2000; Volume 3955, p. 84. [Google Scholar]

- Berreman, D.W. Solid surface shape and the alignment of an adjacent nematic liquid crystal. Phys. Rev. Lett. 1972, 28, 1683–1686. [Google Scholar] [CrossRef]

- Creagh, L.T.; Kmetz, A.R. Mechanism of Surface Alignment in Nematic Liquid Crystals. Mol. Cryst. Liq. Cryst. 1973, 24, 59–68. [Google Scholar] [CrossRef]

- Jerome, B. Surface effects and anchoring in liquid crystals. Rep. Prog. Phys. 1991, 54, 391–451. [Google Scholar] [CrossRef]

- Yaroshchuk, O.; Reznikov, Y. Photoalignment of Liquid Crystals: Basics and Current Trends; The Royal Society of Chemistry: London, UK, 2012; Volume 22, pp. 286–300. [Google Scholar]

- Jackson, P.O.; O’Neill, M.; Duffy, L.W.; Hindmarsh, P.; Kelly, S.M.; Owen, G.J. An investigation of the role of cross-linking and photodegradation of side-chain coumarin polymers in the photoalignment of liquid crystals. Chem. Mater. 2001, 13, 694–703. [Google Scholar] [CrossRef]

- Obi, M.; Morino, S.; Ichimura, K. Factors affecting photoalignment of liquid crystals induced by polymethacrylates with coumarin side chains. Chem. Mater. 1999, 11, 656–664. [Google Scholar] [CrossRef]

- Chigrinov, V.; Sun, J.; Wang, X. Photoaligning and photopatterning: New LC technology. Crystals 2020, 10, 323. [Google Scholar] [CrossRef] [Green Version]

- Chigrinov, V. Photoaligning and Photopatterning—A New Challenge in Liquid Crystal Photonics. Crystals 2013, 3, 149–162. [Google Scholar] [CrossRef] [Green Version]

- Sze-Yan Yeung, F.; Xie, F.-C.; Tsz-Kai Wan, J.; Kay Lee, F.C.; Tsui, O.K.; Sheng, P.; Kwok, H.-S. Liquid crystal pretilt angle control using nanotextured surfaces. J. Appl. Phys. Appl. Phys. Lett. Appl. Phys. Lett. 2006, 99, 124506–151910. [Google Scholar] [CrossRef] [Green Version]

- Yeung, F.S.; Ho, J.Y.; Li, Y.W.; Xie, F.C.; Tsui, O.K.; Sheng, P.; Kwok, H.S. Variable liquid crystal pretilt angles by nanostructured surfaces. Appl. Phys. Lett. 2006, 88, 1–3. [Google Scholar] [CrossRef] [Green Version]

- De Gennes, P.G.; Prost, J. Dynamical Properties of Nematics. In The Physics of Liquid Crystals; Oxford University Press: Oxford, UK, 1993; pp. 198–262. [Google Scholar]

- Fréedericksz, V.; Zolina, V. Forces causing the orientation of an anisotropic liquid. Trans. Faraday Soc. 1933, 29, 919–930. [Google Scholar] [CrossRef]

- Nagaï, S.; Peters, A.; Candau, S. Acousto-optical effects in a nematic liquid crystal. Rev. Phys. Appliquée 1977, 12, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Williams, R. Domains in Liquid Crystals. J. Chem. Phys. 1963, 39, 384–388. [Google Scholar] [CrossRef]

- Jones, J.C. Liquid Crystal Displays. In The Handbook of Optoelectronics; CRC Press: Boca Raton, FL, USA, 2017; pp. 137–224. ISBN 9781315156996. [Google Scholar]

- Sinzinger, S.; Jahns, J. Refractive microoptics. In Microoptics; Wiley: Hoboken, NJ, USA, 2003; pp. 93–131. [Google Scholar]

- Saleh, B.E.A.; Teich, M.C. Ray Optics. In Fundamentals of Photonics; John Wiley & Sons, Inc.: New York, NY, USA, 1991; Volume 5, pp. 1–40. ISBN 0471839655. [Google Scholar]

- Teichman, J.A. Measurement of gradient index materials by beam deflection, displacement, or mode conversion. Opt. Eng. 2013, 52, 112112. [Google Scholar] [CrossRef] [Green Version]

- Beliakov, G.; Chan, D.Y.C. Analysis of inhomogeneous optical systems by the use of ray tracing II Three-dimensional systems with symmetry. Appl. Opt. 1998, 37, 5106. [Google Scholar] [CrossRef] [Green Version]

- Žukauskas, A.; Matulaitienė, I.; Paipulas, D.; Niaura, G.; Malinauskas, M.; Gadonas, R. Tuning the refractive index in 3D direct laser writing lithography: Towards GRIN microoptics. Laser Photon. Rev. 2015, 9, 706–712. [Google Scholar] [CrossRef]

- Moore, D.T. Gradient-index optics: A review. Appl. Opt. 1980, 19, 1035. [Google Scholar] [CrossRef]

- Beliakov, G.; Chan, D.Y.C. Analysis of inhomogeneous optical systems by the use of ray tracing I Planar systems. Appl. Opt. 1997, 36, 5303. [Google Scholar] [CrossRef] [PubMed]

- Suhara, T.; Kobayashi, K.; Nishihara, H.; Koyama, J. Graded-index Fresnel lenses for integrated optics. Appl. Opt. 1982, 21, 1966. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Wang, B.; Sato, S. Liquid-crystal lens with a focal length that is variable in a wide range. Appl. Opt. 2004, 43, 6407. [Google Scholar] [CrossRef] [PubMed]

- Titus, C.M.; Bos, P.J.; Lavrentovich, O.D. Efficient Accurate Liquid Crystal Digital Light Deflector. In Proceedings of the Diffractive and Holographic Technologies, Systems, and Spatial Light Modulators VI, San Jose, CA, USA, 23–29 January 1999; Cindrich, I., Lee, S.H., Sutherland, R.L., Eds.; SPIE: Bellingham, WA, USA, 1999; pp. 244–253. [Google Scholar]

- Masuda, S.; Takahashi, S.; Nose, T.; Sato, S.; Ito, H. Liquid-crystal microlens with a beam-steering function. Appl. Opt. 1997. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Wang, B.; Sato, S. Study of liquid crystal lens with focus movable in focal plane by wave front analysis. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 2006, 45, 6320–6322. [Google Scholar] [CrossRef]

- Nose, T.; Masuda, S.; Sato, S. A Liquid Crystal Microlens with Hole-Patterned Electrodes on Both Substrates. Jpn. J. Appl. Phys. 1992, 31, 1643–1646. [Google Scholar] [CrossRef]

- Li, L.; Bryant, D.; Van Heugten, T.; Bos, P.J. Near-diffraction-limited and low-haze electro-optical tunable liquid crystal lens with floating electrodes. Opt. Express 2013, 21, 8371–8381. [Google Scholar] [CrossRef]

- Hsu, C.; Jhang, J.; Huang, C.-Y. Large aperture liquid crystal lens with an imbedded floating ring electrode. Opt. Express 2016, 24, 16722. [Google Scholar] [CrossRef]

- Sova, O.; Galstian, T. Liquid crystal lens with optimized wavefront across the entire clear aperture. Opt. Commun. 2019, 433, 290–296. [Google Scholar] [CrossRef]

- Hsu, C.J.; Jhang, J.J.; Jhang, J.C.; Huang, C.Y. Influence of floating-ring-electrode on large-aperture liquid crystal lens. Liq. Cryst. 2018, 45, 40–48. [Google Scholar] [CrossRef]

- Tabirian, N.; Roberts, D. Polarization-Independent Switchable Lens System. U.S. Patent 10,274,805 B2, 30 April 2019. [Google Scholar]

- Sova, O.; Reshetnyak, V.; Galstian, T.; Asatryan, K. Electrically variable liquid crystal lens based on the dielectric dividing principle. J. Opt. Soc. Am. A 2015, 32, 803. [Google Scholar] [CrossRef] [PubMed]

- Asatryan, K.; Presnyakov, V.; Tork, A.; Zohrabyan, A.; Bagramyan, A.; Galstian, T. Optical lens with electrically variable focus using an optically hidden dielectric structure. Opt. Express 2010, 18, 13981. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.-C.; Lin, Y.-H. An electrically tunable-focusing liquid crystal lens with a low voltage and simple electrodes. Opt. Express 2012, 20, 2045. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.; Wu, S.-T. Adaptive liquid crystal lens with large focal length tunability. Opt. Express 2006, 14, 11292. [Google Scholar] [CrossRef]

- Hassanfiroozi, A.; Huang, Y.-P.; Javidi, B.; Shieh, H.-P.D. Dual layer electrode liquid crystal lens for 2D/3D tunable endoscopy imaging system. Opt. Express 2016, 24, 8527. [Google Scholar] [CrossRef]

- Chang, Y.-C.; Jen, T.-H.; Ting, C.-H.; Huang, Y.-P. High-resistance liquid-crystal lens array for rotatable 2D/3D autostereoscopic display. Optics Express 2014. [Google Scholar] [CrossRef] [Green Version]

- Naumov, A.F.; Loktev, M.Y.; Guralnik, I.R.; Vdovin, G. Liquid-crystal adaptive lenses with modal control. Opt. Lett. 1998, 23, 992. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Bryant, D.; Bos, P.J. Liquid crystal lens with concentric electrodes and inter-electrode resistors. Liq. Cryst. Rev. 2014, 2, 130–154. [Google Scholar] [CrossRef]

- Li, L.; Bryant, D.; Van Heugten, T.; Bos, P.J. Physical limitations and fundamental factors affecting performance of liquid crystal tunable lenses with concentric electrode rings. Appl. Opt. 2013, 52, 1978–1986. [Google Scholar] [CrossRef] [PubMed]

- Jamali, A.; Bryant, D.; Zhang, Y.; Grunnet-Jepsen, A.; Bhowmik, A.; Bos, P.J. Design of a large aperture tunable refractive Fresnel liquid crystal lens. Appl. Opt. 2018, 57, B10. [Google Scholar] [CrossRef] [PubMed]

- Jamali, A.; Bryant, D.; Bhowmick, A.K.; Bos, P.J. Large area liquid crystal lenses for correction of presbyopia. Opt. Express 2020. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Chu, F.; Tian, L.-L.; Gu, X.-Q.; Zhou, X.-Y.; Wang, Q.-H. Liquid crystal lenticular lens array with extended aperture by using gradient refractive index compensation. Liq. Cryst. 2020, 1–7. [Google Scholar] [CrossRef]

- Galstian, T.; Asatryan, K.; Presniakov, V.; Zohrabyan, A.; Tork, A.; Bagramyan, A.; Careau, S.; Thiboutot, M.; Cotovanu, M. High optical quality electrically variable liquid crystal lens using an additional floating electrode. Opt. Lett. 2016, 41, 3265. [Google Scholar] [CrossRef]

- Algorri, J.F.; Zografopoulos, D.C.; Urruchi, V.; Sánchez-Pena, J.M. Recent Advances in Adaptive Liquid Crystal Lenses. Crystals 2019, 9, 272. [Google Scholar] [CrossRef] [Green Version]

- Ishihara, S.; Mizusaki, M. Alignment control technology of liquid crystal molecules. J. Soc. Inf. Disp. 2020, 28, 44–74. [Google Scholar] [CrossRef]

- Tseng, M.-C.; Fan, F.; Lee, C.-Y.; Murauski, A.; Chigrinov, V.; Kwok, H.-S. Tunable lens by spatially varying liquid crystal pretilt angles. J. Appl. Phys. 2011, 109, 083109. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.-J.; Gwag, J.S.; Kim, Y.-K.; Jo, S.I.; Kang, S.-G.; Park, Y.R.; Kim, J.-H. Control of liquid crystal pretilt angle by anchoring competition of the stacked alignment layers. Appl. Phys. Lett. 2009, 94, 041113. [Google Scholar] [CrossRef]

- Patel, J.S.; Rastani, K. Electrically controlled polarization-independent liquid-crystal Fresnel lens arrays. Opt. Lett. 1991, 16, 532. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.C.; Park, H.G.; Lee, J.H.; Jang, S.B.; Oh, B.Y.; Seo, D.S. Ion beam-induced topographical and chemical modification on the poly(styrene-co-allyl alcohol) and its effect on the molecular interaction between the modified surface and liquid crystals. Mater. Chem. Phys. 2016, 182, 94–100. [Google Scholar] [CrossRef]

- Gorkunov, M.V.; Kasyanova, I.V.; Artemov, V.V.; Mamonova, A.V.; Palto, S.P. Precise local control of liquid crystal pretilt on polymer layers by focused ion beam nanopatterning. Beilstein J. Nanotechnol. 2019, 10, 1691–1697. [Google Scholar] [CrossRef]

- Chigrinov, V.G.; Kozenkov, V.M.; Kwok, H.-S. Photoalignment of LCs. In Photoalignment of Liquid Crystalline Materials; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2008; pp. 69–100. [Google Scholar]

- Bezruchenko, V.S.; Muravsky, A.A.; Murauski, A.A.; Stankevich, A.I.; Mahilny, U.V. Tunable Liquid Crystal Lens Based on Pretilt Angle Gradient Alignment. Mol. Cryst. Liq. Cryst. 2016, 626, 222–228. [Google Scholar] [CrossRef]

- Smith, N.; Gass, P.; Tillin, M.; Raptis, C.; Burbridge, D. Micropatterned Alignment of Liquid Crystals. Sharp Tech. J. 2005, 9, 5–10. [Google Scholar]

- Wang, X.-Q.; Srivastava, A.K.; Chigrinov, V.G.; Kwok, H.-S. Switchable Fresnel lens based on micropatterned alignment. Opt. Lett. 2013. [Google Scholar] [CrossRef] [PubMed]

- Nishimoto, Y. Variable-Focal-Length Lens Using an Electrooptic Effect. U.S. Patent 4,466,703, 21 August 1982. [Google Scholar]

- Kowel, S.T.; Cleverly, D.S.; Kornreich, P.G. Focusing by electrical modulation of refraction in a liquid crystal cell. Appl. Opt. 1984, 23, 278. [Google Scholar] [CrossRef] [PubMed]

- Beeckman, J.; Yang, T.-H.; Nys, I.; George, J.P.; Lin, T.-H.; Neyts, K. Multi-electrode tunable liquid crystal lenses with one lithography step. Opt. Lett. 2018, 43, 271. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Valley, P.; Mathine, D.L.; Dodge, M.R.; Schwiegerling, J.; Peyman, G.; Peyghambarian, N. Tunable-focus flat liquid-crystal diffractive lens. Opt. Lett. 2010, 35, 336. [Google Scholar] [CrossRef]

- McKnight, D.J.; Johnson, K.M.; Serati, R.A. 256 × 256 liquid-crystal-on-silicon spatial light modulator. Appl. Opt. 1994, 33, 2775. [Google Scholar] [CrossRef]

- Love, G.D. Wave-front correction and production of Zernike modes with a liquid-crystal spatial light modulator. Appl. Opt. 1997, 36, 1517–1520. [Google Scholar] [CrossRef]

- Zhang, Z.; You, Z.; Chu, D. Fundamentals of phase-only liquid crystal on silicon (LCOS) devices. Light Sci. Appl. 2014, 3, e213. [Google Scholar] [CrossRef]

- Huang, Y.; Liao, E.; Chen, R.; Wu, S.-T. Liquid-Crystal-on-Silicon for Augmented Reality Displays. Appl. Sci. 2018, 8, 2366. [Google Scholar] [CrossRef] [Green Version]

- De Boer, D.K.G.; Hiddink, M.G.H.; Sluijter, M.; Willemsen, O.H.; de Zwart, S.T. Switchable Lenticular Based 2D/3D Displays. In Proceedings of the Stereoscopic Displays and Virtual Reality Systems XIV, San Jose, CA, USA, 28 January–1 February 2007; Woods, A.J., Dodgson, N.A., Merritt, J.O., Bolas, M.T., McDowall, I.E., Eds.; SPIE: Bellingham, WA, USA, 2007; Volume 6490, p. 64900R. [Google Scholar]

- Johnson, K.M.; McKnight, D.J.; Underwood, I. Smart Spatial Light Modulators Using Liquid Crystals on Silicon. IEEE J. Quantum Electron. 1993, 29, 699–714. [Google Scholar] [CrossRef]

- Wang, X. Performance evaluation of a liquid-crystal-on-silicon spatial light modulator. Opt. Eng. 2004, 43, 2769. [Google Scholar] [CrossRef]

- Wang, X.; Wang, B.; Pouch, J.; Miranda, F.; Fisch, M.; Anderson, J.E.; Sergan, V.; Bos, P.J. Liquid crystal on silicon(LCOS) wavefront corrector and beam steerer. Proc. SPIE 2003, 5162, 139–146. [Google Scholar] [CrossRef]

- Inoue, T.; Tanaka, H.; Fukuchi, N.; Takumi, M.; Matsumoto, N.; Hara, T.; Yoshida, N.; Igasaki, Y.; Kobayashi, Y. LCOS Spatial Light Modulator Controlled by 12-Bit Signals for Optical Phase-Only Modulation. In Proceedings of the Emerging Liquid Crystal Technologies II, San Jose, CA, USA, 20–25 January 2007; Chien, L.-C., Ed.; SPIE: Bellingham, WA, USA, 2007; Volume 6487, p. 64870Y. [Google Scholar]

- Chen, H.-M.; Yang, J.-P.; Yen, H.-T.; Hsu, Z.-N.; Huang, Y.; Wu, S.-T. Pursuing High Quality Phase-Only Liquid Crystal on Silicon (LCoS) Devices. Appl. Sci. 2018, 8, 2323. [Google Scholar] [CrossRef] [Green Version]

- Efron, U.; Grinberg, J.; Braatz, P.O.; Little, M.J.; Reif, P.G.; Schwartz, R.N. The silicon liquid-crystal light valve. J. Appl. Phys. 1985, 57, 1356–1368. [Google Scholar] [CrossRef]

- McManamon, P.F.; Bos, P.J.; Escuti, M.J.; Heikenfeld, J.; Serati, S.; Xie, H.; Watson, E.A. A Review of Phased Array Steering for Narrow-Band Electrooptical Systems. Proc. IEEE 2009, 97, 1078–1096. [Google Scholar] [CrossRef]

- Cotter, L.K.; Drabik, T.J.; Dillon, R.J.; Handschy, M.A. Ferroelectric-liquid-crystal/silicon-integrated-circuit spatial light modulator. Opt. Lett. 1990, 15, 291. [Google Scholar] [CrossRef]

- Yang, J.-P.; Chen, H.-M.P.; Huang, Y.; Wu, S.-T.; Hsu, C.; Ting, L.; Hsu, R. Sub-KHz 4000-PPI LCoS Phase Modulator for Holographic Displays. SID Symp. Dig. Tech. Pap. 2018, 49, 772–775. [Google Scholar] [CrossRef]

- HOLOEYE Photonics AG GAEA-2 10 Megapixel Phase Only LCOS-SLM. Available online: https://holoeye.com/gaea-4k-phase-only-spatial-light-modulator/ (accessed on 11 March 2019).

- Thie, M.W.; Lukins, J.T.; Gregory, D.A. Optically Addressed SLM-Based Holographic Display. In Proceedings of the Visual Information Processing IV, Orlando, FL, USA, 17–21 April 1995; Huck, F.O., Juday, R.D., Eds.; SPIE: Bellingham, WA, USA, 1995; Volume 2488, pp. 408–416. [Google Scholar]

- Lin, S.-H.; Huang, B.-Y.; Li, C.-Y.; Yu, K.-Y.; Chen, J.-L.; Kuo, C.-T. Electrically and optically tunable Fresnel lens in a liquid crystal cell with a rewritable photoconductive layer. Opt. Mater. Express 2016, 6, 2229. [Google Scholar] [CrossRef]

- Schaal, F.; Rutloh, M.; Weidenfeld, S.; Stumpe, J.; Michler, P.; Pruss, C.; Osten, W.; Seki, T.; Hosoki, A.; Aoki, K. Optically addressed modulator for tunable spatial polarization control. Opt. Imaging Metrol. 2012, 2, 12328–12338. [Google Scholar] [CrossRef]

- Khoo, I.C.; Wood, M.; Shih, M.Y.; Chen, P. Extremely nonlinear photosensitive liquid crystals for image sensing and sensor protection. Opt. Express 1999, 4, 432. [Google Scholar] [CrossRef] [PubMed]

- Tabiryan, N.V.; Sukhov, A.V.; Zel’dovich, B.Y. Orientational Optical Nonlinearity of Liquid Crystals. Mol. Cryst. Liq. Cryst. 1986, 136, 1–139. [Google Scholar] [CrossRef]

- Tabiryan, N.V.; Nersisyan, S.R. Large-angle beam steering using all-optical liquid crystal spatial light modulators. Appl. Phys. Lett. 2004, 84, 5145–5147. [Google Scholar] [CrossRef]

- Whinnery, J.R.; Hu, C.; Kwon, Y.S. Liquid-Crystal Waveguides for Integrated Optics. IEEE J. Quantum Electron. 1977, 13, 262–267. [Google Scholar] [CrossRef]

- Andersen, M.H.; Rommel, S.D.; Davis, S.R. Liquid Crystal Waveguide for Dynamically Controlling Polarized Light. U.S. Patent US 8,989,523 B2, 24 March 2015. [Google Scholar]

- Anderson, M.; Davis, S.; Rommel, S. Tunable Laser Having Liquid Crystal Waveguide. U.S. Patent US772,011,6B2, 18 May 2005. [Google Scholar]

- Davis, S.R.; Farca, G.; Rommel, S.D.; Martin, A.W.; Anderson, M.H. Analog, Non-Mechanical Beam-Steerer with 80 Degree Field of Regard. In Proceedings of the Acquisition, Tracking, Pointing, and Laser Systems Technologies XXII, Orlando, FL, USA, 16–20 March 2008; Chodos, S.L., Thompson, W.E., Eds.; SPIE: Bellingham, WA, USA, 2008; Volume 6971, p. 69710G. [Google Scholar]

- Davis, S.R.; Farca, G.; Rommel, S.D.; Johnson, S.; Anderson, M.H. Liquid Crystal Waveguides: New Devices Enabled by >1000 Waves of Optical Phase Control; Chien, L.-C., Ed.; SPIE: Bellingham, WA, USA, 2010. [Google Scholar]

- Jones, J.C.; Wahle, M.; Bailey, J.; Moorhouse, T.; Snow, B.; Sargent, J. Polarisation independent liquid crystal lenses and contact lenses using embossed reactive mesogens. J. Soc. Inf. Disp. 2020, 28, 211–223. [Google Scholar] [CrossRef] [Green Version]

- Wahle, M.; Snow, B.; Sargent, J.; Jones, J.C. Embossing Reactive Mesogens: A Facile Approach to Polarization-Independent Liquid Crystal Devices. Adv. Opt. Mater. 2019, 7, 1801261. [Google Scholar] [CrossRef]

- Chen, J.; Bos, P.J.; Vithana, H.; Johnson, D.L. An electro-optically controlled liquid crystal diffraction grating. Appl. Phys. Lett. 1995, 67, 2588. [Google Scholar] [CrossRef]

- Lin, C.-H.; Huang, H.-Y.; Wang, J.-Y. Polarization-Independent Liquid-Crystal Fresnel Lenses Based on Surface-Mode Switching of 90 Degree Twisted-Nematic Liquid Crystals. IEEE Photon. Technol. Lett. 2010, 22, 137–139. [Google Scholar] [CrossRef]

- Goodman, J.W. Fresnel and Fraunhofer Diffraction. In Introduction to Fourier Optics; Roberts & Company: Doylestown, PA, USA, 2005; pp. 63–96. ISBN 0974707724. [Google Scholar]

- Goodman, J.W. Foundations of Scalar Diffraction Theory. In Introduction to Fourier Optics; Roberts and Company: Doylestown, PA, USA, 2005; pp. 31–62. ISBN 0974707724. [Google Scholar]

- Early, J.T.; Hyde, R.; Baron, R.L. Twenty-Meter Space Telescope Based on Diffractive Fresnel Lens. In Proceedings of the UV/Optical/IR Space Telescopes: Innovative Technologies and Concepts, San Diego, CA, USA, 3–8 August 2004; MacEwen, H.A., Ed.; SPIE: Bellingham, WA, USA, 2004; Volume 5166, p. 148. [Google Scholar]

- Márquez, A.; Martínez-Guardiola, F.J.; Francés, J.; Neipp, C.; Ramírez, M.G.; Calzado, E.M.; Morales-Vidal, M.; Gallego, S.; Beléndez, A.; Pascual, I. Analytical modeling of blazed gratings on two-dimensional pixelated liquid crystal on silicon devices. Opt. Eng. 2020, 59, 1. [Google Scholar] [CrossRef]

- Gaylord, T.K.; Moharam, M.G. Thin and thick gratings: Terminology clarification. Appl. Opt. 1981, 20, 3271. [Google Scholar] [CrossRef] [PubMed]

- Otón, J.M.; Otón, E.; Quintana, X.; Geday, M.A. Liquid-crystal phase-only devices. J. Mol. Liq. 2018, 267, 469–483. [Google Scholar] [CrossRef]

- Sweeney, D.W.; Sommargren, G.E. Harmonic diffractive lenses. Appl. Opt. 1995, 34, 2469. [Google Scholar] [CrossRef] [PubMed]

- Kogelnik, H. Coupled Wave Theory for Thick Hologram Gratings. Bell Syst. Tech. J. 1969, 48, 2909–2947. [Google Scholar] [CrossRef]

- Shang, X.; Tan, J.Y.; Willekens, O.; De Smet, J.; Joshi, P.; Cuypers, D.; Islamaj, E.; Beeckman, J.; Kristiaan, N.; Vervaeke, M.; et al. Electrically Controllable Liquid Crystal Component for Efficient Light Steering. IEEE Photonics J. 2015, 7. [Google Scholar] [CrossRef]

- Wang, X.; Wilson, D.; Muller, R.; Maker, P.; Psaltis, D. Liquid-crystal blazed-grating beam deflector. Appl. Opt. 2000, 39, 6545. [Google Scholar] [CrossRef] [Green Version]

- Bryan-Brown, G.; Wood, E.; Sage, I. Weak surface anchoring of liquid crystals. Lett. to Nat. 1999, 399, 338–340. [Google Scholar] [CrossRef]

- Hallam, B.T.; Sambles, J.R. Liquid Crystals Groove depth dependence of the anchoring strength of a zero order grating-aligned liquid crystal Groove depth dependence of the anchoring strength of a zero order grating-aligned liquid crystal. Liq. Cryst. 2000, 27. [Google Scholar] [CrossRef]

- Shang, X.; Cuypers, D.; Baghdasaryan, T.; Vervaeke, M.; Thienpont, H.; Beeckman, J.; Neyts, K.; Li, Q.; Wu, C.; Li, H.; et al. Active Optical Beam Shaping Based on Liquid Crystals and Polymer Micro-Structures. Crystals 2020, 10, 977. [Google Scholar] [CrossRef]

- Lindquist, R.G.; Leslie, T.M.; Kulick, J.H.; Nordin, G.P.; Jarem, J.M.; Kowel, S.T.; Friends, M. High-resolution liquid-crystal phase grating formed by fringing fields from interdigitated electrodes. Opt. Lett. 1994, 19, 670. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.; Tan, G.; Wu, S.-T. Large-angle and high-efficiency tunable phase grating using fringe field switching liquid crystal. Opt. Express 2015, 23, 12274. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.Y.; Huang, B.Y.; Kang, C.C.; Kuo, C.T. Diffraction and polarization properties of electrically-tunable nematic liquid crystal grating. Polymers 2020, 12, 1929. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Tan, G.; Huang, Y.; Weng, Y.; Choi, T.H.; Yoon, T.H.; Wu, S.T. A Low Voltage Liquid Crystal Phase Grating with Switchable Diffraction Angles. Sci. Rep. 2017. [Google Scholar] [CrossRef]

- Choi, Y.; Park, J.-H.; Kim, J.-H.; Lee, S.-D. Fabrication of a focal length variable microlens array based on a nematic liquid crystal. Opt. Mater. 2003, 21, 643–646. [Google Scholar] [CrossRef]

- Fan, Y.-H.; Ren, H.; Liang, X.; Wang, H.; Wu, S.-T. Liquid Crystal Microlens Arrays with Switchable Positive and Negative Focal Lengths. J. Disp. Technol. 2005, 1, 151–156. [Google Scholar] [CrossRef]

- Matic, R.M. Blazed Phase Liquid Crystal Beam Steering. In Proceedings of the Laser Beam Propagation and Control, Los Angeles, CA, USA, 23–29 January 1994; Weichel, H., DeSandre, L.F., Eds.; International Society for Optics and Photonics: Los Angeles, CA, USA, 1994; Volume 2120, pp. 194–205. [Google Scholar]

- Klaus, W.; Ide, M.; Morokawa, S.; Tsuchiya, M.; Kamiya, T. Angle-independent beam steering using a liquid crystal grating with multi-resistive electrodes. Opt. Commun. 1997, 138, 151–157. [Google Scholar] [CrossRef]

- Lingel, C.; Haist, T.; Osten, W. Optimizing the diffraction efficiency of SLM-based holography with respect to the fringing field effect. Appl. Opt. 2013, 52, 6877–6883. [Google Scholar] [CrossRef]

- Apter, B.; Efron, U.; Bahat-Treidel, E. On the fringing-field effect in liquid-crystal beam-steering devices. Appl. Opt. 2004, 43, 11. [Google Scholar] [CrossRef]

- Nys, I.; Stebryte, M.; Ussembayev, Y.Y.; Beeckman, J.; Neyts, K. Tilted Chiral Liquid Crystal Gratings for Efficient Large-Angle Diffraction. Adv. Opt. Mater. 2019, 7, 1901364. [Google Scholar] [CrossRef]

- Kobashi, J.; Mohri, Y.; Yoshida, H.; Ozaki, M. Circularly-polarized, large-angle reflective deflectors based on periodically patterned cholesteric liquid crystals. Opt. Data Process. Storage 2017, 3, 61–66. [Google Scholar] [CrossRef]

- Mitov, M. Cholesteric liquid crystals with a broad light reflection band. Adv. Mater. 2012, 24, 6260–6276. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Yin, K.; Wu, S.-T. Reflective polarization volume gratings for high efficiency waveguide-coupling augmented reality displays. Opt. Express 2017. [Google Scholar] [CrossRef] [PubMed]

- Ozaki, R.; Hashimura, S.; Yudate, S.; Kadowaki, K.; Yoshida, H.; Ozaki, M. Optical properties of selective diffraction from Bragg-Berry cholesteric liquid crystal deflectors. OSA Contin. 2019, 2. [Google Scholar] [CrossRef]

- Denisov, A.; De Bougrenet De La Tocnaye, J.L. Resonant gratings in planar Grandjean cholesteric composite liquid crystals. Appl. Opt. 2007, 46, 6680–6687. [Google Scholar] [CrossRef] [PubMed]

- Babakhanova, G.; Parsouzi, Z.; Paladugu, S.; Wang, H.; Nastishin, Y.A.; Shiyanovskii, S.V.; Sprunt, S.; Lavrentovich, O.D. Elastic and viscous properties of the nematic dimer CB7CB. Phys. Rev. E 2017, 96, 062704. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Paterson, D.A.; Abberley, J.P.; Harrison, W.T.; Storey, J.M.; Imrie, C.T. Cyanobiphenyl-based liquid crystal dimers and the twist-bend nematic phase. Liq. Cryst. 2017, 44, 1–20. [Google Scholar] [CrossRef]

- Imrie, C.T.; Henderson, P.A. Liquid crystal dimers and higher oligomers: Between monomers and polymers. Chem. Soc. Rev. 2007, 36, 2096–2124. [Google Scholar] [CrossRef]

- Mandle, R.J.; Stevens, M.P.; Goodby, J.W. Developments in liquid-crystalline dimers and oligomers. Liq. Cryst. 2017, 44, 2046–2059. [Google Scholar] [CrossRef] [Green Version]

- Adlem, K.; Copič, M.; Luckhurst, G.R.; Mertelj, A.; Parri, O.; Richardson, R.M.; Snow, B.D.; Timimi, B.A.; Tuffin, R.P.; Wilkes, D. Chemically induced twist-bend nematic liquid crystals, liquid crystal dimers, and negative elastic constants. Phys. Rev. E 2013, 88, 22503. [Google Scholar] [CrossRef]

- Lavrentovich, O.D. Electromagnetically tunable cholesterics with oblique helicoidal structure [Invited]. Opt. Mater. Express 2020. [Google Scholar] [CrossRef]

- Xiang, J.; Shiyanovskii, S.V.; Imrie, C.; Lavrentovich, O.D. Electrooptic response of chiral nematic liquid crystals with oblique helicoidal director. Phys. Rev. Lett. 2014. [Google Scholar] [CrossRef] [Green Version]

- Honma, M.; Nose, T.; Yanase, S.; Yamaguchi, R.; Sato, S. Liquid-Crystal Blazed Gratings with Spatially Distributed Pretilt Angle. Jpn. J. Appl. Phys. 2010, 49, 061701. [Google Scholar] [CrossRef]

- Gorkunov, M.V.; Kasyanova, I.V.; Artemov, V.V.; Ezhov, A.A.; Mamonova, A.V.; Simdyankin, I.V.; Palto, S.P. Liquid-Crystal Metasurfaces Self-Assembled on Focused Ion Beam Patterned Polymer Layers: Electro-Optical Control of Light Diffraction and Transmission. ACS Appl. Mater. Interfaces 2020, 12, 30823. [Google Scholar] [CrossRef] [PubMed]

- Crawford, G.P.; Eakin, J.N.; Radcliffe, M.D.; Callan-Jones, A.; Pelcovits, R.A. Liquid-crystal diffraction gratings using polarization holography alignment techniques. J. Appl. Phys. 2005, 98, 123102. [Google Scholar] [CrossRef] [Green Version]

- Pancharatnam, S. Achromatic combinations of birefringent plates. Proc. Indian Acad. Sci. Sect. A 1955, 41, 137–144. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Tan, G.; Zhan, T.; Weng, Y.; Liu, G.; Gou, F.; Peng, F.; Tabiryan, N.V.; Gauza, S.; Wu, S.-T. Recent progress in Pancharatnam-Berry phase optical elements and the applications for virtual/augmented realities. Opt. Data Process. Storage 2017. [Google Scholar] [CrossRef]

- Xiang, X.; Kim, J.; Komanduri, R.; Escuti, M.J. Nanoscale liquid crystal polymer Bragg polarization gratings. Opt. Express 2017, 25, 19298. [Google Scholar] [CrossRef] [Green Version]

- Weng, Y.; Xu, D.; Zhang, Y.; Li, X.; Wu, S.-T. Polarization volume grating with high efficiency and large diffraction angle. Opt. Express 2016, 24, 17746. [Google Scholar] [CrossRef]

- Escuti, M.J.; Oh, C.; Sánchez, C.; Bastiaansen, C.; Broer, D.J. Simplified Spectropolarimetry Using Reactive Mesogen Polarization Gratings. In Proceedings of the Imaging Spectrometry XI, San Diego, CA, USA, 13–17 August 2006; SPIE: Bellingham, WA, USA, 2006; Volume 6302, p. 630207. [Google Scholar]

- Wen, B.; Petschek, R.G.; Rosenblatt, C. Nematic Liquid-Crystal Polarization Gratings by Modification of Surface Alignment. Appl. Opt. 2002. [Google Scholar] [CrossRef]

- Zola, R.S.; Bisoyi, H.K.; Wang, H.; Urbas, A.M.; Bunning, T.J.; Li, Q. Dynamic Control of Light Direction Enabled by Stimuli-Responsive Liquid Crystal Gratings; Wiley-VCH Verlag: Hoboken, NJ, USA, 2019; Volume 31, p. 1806172. [Google Scholar]

- Madhusudana, N.V. Electroconvective instabilities in nematic liquid crystals. Phase Trans. A Multinatl. J. 1994, 50, 177–191. [Google Scholar] [CrossRef]

- Buka, A.; Eber, N.; Pesch, W. Convective Patterns in Liquid Crystal Driven by Electric Field: An overview of the onset behaviour. Electron. Cryst. Commun. 2005, 218, 1–27. [Google Scholar] [CrossRef]

- Kramer, L.; Bodenschatz, E.; Pesch, W.; Thom, W.; Zimmermann, W. Invited Lecture. New results on the electrohydrodynamic instability in nematics. Liq. Cryst. 1989, 5, 699–715. [Google Scholar] [CrossRef]

- John, T.; Behn, U.; Stannarius, R. Laser diffraction by periodic dynamic patterns in anisotropic fluids. Eur. Phys. J. B 2003, 35, 267–278. [Google Scholar] [CrossRef]

- Morris, R.; Jones, J.C.; Nagaraj, M. Variable pitch hydrodynamic electro-optic gratings utilising bent liquid crystal dimers. Soft Matter 2020, 16, 10439–10453. [Google Scholar] [CrossRef]

- Morris, R.; Jones, J.C.; Nagaraj, M. Continuously variable diffraction gratings using electroconvection in liquid crystals for beam steering applications. J. Appl. Phys. 2019, 126, 224505. [Google Scholar] [CrossRef]

- Bohley, C.; Heuer, J.; Stannarius, R. Optical properties of electrohydrodynamic convection patterns: Rigorous and approximate methods. J. Opt. Soc. Am. A 2005, 22, 2818. [Google Scholar] [CrossRef]

- Ryabchun, A.; Yakovlev, D.; Bobrovsky, A.; Katsonis, N. Dynamic Diffractive Patterns in Helix-Inverting Cholesteric Liquid Crystals. ACS Appl. Mater. Interfaces 2019, 11, 10895–10904. [Google Scholar] [CrossRef] [Green Version]

- Gvozdovskyy, I.; Yaroshchuk, O.; Serbina, M.; Yamaguchi, R. Photoinduced helical inversion in cholesteric liquid crystal cells with homeotropic anchoring. Opt. Express 2012, 20, 3499. [Google Scholar] [CrossRef]

- Ryabchun, A.; Bobrovsky, A. Cholesteric Liquid Crystal Materials for Tunable Diffractive Optics. Adv. Opt. Mater. 2018, 6, 1800335. [Google Scholar] [CrossRef]

- Zhan, Y.; Lu, H.; Jin, M.; Zhou, G. Electrohydrodynamic instabilities for smart window applications. Liq. Cryst. 2019, 1–7. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Chen, H.-S.; Chen, M.-S. Electrically-Tunable Liquid Crystal Lenses and Applications. In Proceedings of the Emerging Liquid Crystal Technologies VIII, San Francisco, CA, USA, 2–7 February 2013; SPIE: Bellingham, WA, USA, 2013; Volume 8642, p. 86420C. [Google Scholar]

- Thalhammer, G.; Bowman, R.W.; Love, G.D.; Padgett, M.J.; Ritsch-Marte, M. Speeding up liquid crystal SLMs using overdrive with phase change reduction. Opt. Express 2013, 21, 1779. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, G.; Mathine, D.L.; Valley, P.; Äyräs, P.; Haddock, J.N.; Giridhar, M.S.; Williby, G.; Schwiegerling, J.; Meredith, G.R.; Kippelen, B.; et al. Switchable electro-optic diffractive lens with high efficiency for ophthalmic applications. Proc. Natl. Acad. Sci. USA 2006, 103, 6100–6104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Coles, H.J.; Pivnenko, M.N. Liquid crystal “blue phases” with a wide temperature range. Nature 2005, 436, 997–1000. [Google Scholar] [CrossRef]

- Gleeson, H.F.; Miller, R.J.; Tian, L.; Görtz, V.; Goodby, J.W. Liquid crystal blue phases: Stability, field effects and alignment. Liq. Cryst. 2015, 42, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Cao, W.; Muñoz, A.; Palffy-Muhoray, P.; Taheri, B. Lasing in a three-dimensional photonic crystal of the liquid crystal blue phase II. Nat. Mater. 2002, 1, 111–113. [Google Scholar] [CrossRef]

- Milton, H.E.; Nagaraj, M.; Kaur, S.; Jones, J.C.; Morgan, P.B.; Gleeson, H.F. Field-induced refractive index variation in the dark conglomerate phase for polarization-independent switchable liquid crystal lenses. Appl. Opt. 2014, 53, 7278. [Google Scholar] [CrossRef] [Green Version]

- Nagaraj, M.; Görtz, V.; Goodby, J.W.; Gleeson, H.F. Electrically tunable refractive index in the dark conglomerate phase of a bent-core liquid crystal. Appl. Phys. Lett. 2014, 104, 021903. [Google Scholar] [CrossRef]

- Nagaraj, M. Dark conglomerate phases of bent-core liquid crystals. Liq. Cryst. 2016, 43, 2244–2253. [Google Scholar] [CrossRef]

- Ren, H.; Fan, Y.H.; Wu, S.T. Tunable Fresnel lens using nanoscale polymer-dispersed liquid crystals. Appl. Phys. Lett. 2003, 83, 1515–1517. [Google Scholar] [CrossRef]

- Ren, H.; Lin, Y.H.; Fan, Y.H.; Wu, S.T. Polarization-independent phase modulation using a polymer-dispersed liquid crystal. Appl. Phys. Lett. 2005, 86, 1–3. [Google Scholar] [CrossRef]

- Kikuchi, H.; Yokota, M.; Hisakado, Y.; Yang, H.; Kajiyama, T. Polymer-stabilized liquid crystal blue phases. Nat. Mater. 2002, 1, 64–68. [Google Scholar] [CrossRef]

- Yoshida, H.; Tanaka, Y.; Kawamoto, K.; Kubo, H.; Tsuda, T.; Fujii, A.; Kuwabata, S.; Kikuchi, H.; Ozaki, M. Nanoparticle-Stabilized Cholesteric Blue Phases. Appl. Phys. Express 2009, 2, 121501. [Google Scholar] [CrossRef]

- Hyman, R.M.; Lorenz, A.; Morris, S.M.; Wilkinson, T.D. Polarization-independent phase modulation using a blue-phase liquid crystal over silicon device. Appl. Opt. 2014, 53, 6925. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.-H.; Wang, Y.-Y.; Hsieh, C.-W. Polarization-independent and high-diffraction-efficiency Fresnel lenses based on blue phase liquid crystals. Opt. Lett. 2011, 36, 502. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wu, S.-T. Polarization independent adaptive microlens with a blue-phase liquid crystal. Opt. Express 2011, 19, 8045. [Google Scholar] [CrossRef]

- Joshi, P.; Willekens, O.; Shang, X.; De Smet, J.; Cuypers, D.; Van Steenberge, G.; Beeckman, J.; Neyts, K.; De Smet, H. Tunable light beam steering device using polymer stabilized blue phase liquid crystals. Photon. Lett. Pol. 2017, 9, 11–13. [Google Scholar] [CrossRef] [Green Version]

- Tian, L.L.; Chu, F.; Duan, W.; Li, R.; Gu, X.Q.; Li, L.; Wang, Q.H. Beam steering device based on blue phase liquid crystal. Opt. Commun. 2021, 481, 126525. [Google Scholar] [CrossRef]

- Chu, F.; Dou, H.; Li, G.-P.; Song, Y.-L.; Li, L.; Wang, Q.-H. A polarisation-independent blue-phase liquid crystal lens array using gradient electrodes. Liq. Cryst. 2018, 45, 715–720. [Google Scholar] [CrossRef]

- Cui, J.P.; Fan, H.X.; Wang, Q.H. A polarisation-independent blue-phase liquid crystal microlens using an optically hidden dielectric structure. Liq. Cryst. 2017, 44, 643–647. [Google Scholar] [CrossRef]

- Trbojevic, N.; Read, D.J.; Nagaraj, M. Dielectric properties of liquid crystalline dimer mixtures exhibiting the nematic and twist-bend nematic phases. Phys. Rev. E 2017, 96, 52703. [Google Scholar] [CrossRef]

- Balachandran, R.; Panov, V.P.; Vij, J.K.; Kocot, A.; Tamba, M.G.; Kohlmeier, A.; Mehl, G.H. Elastic properties of bimesogenic liquid crystals. Liq. Cryst. 2013, 40, 681–688. [Google Scholar] [CrossRef]

- Dozov, I. On the spontaneous symmetry breaking in the mesophases of achiral banana-shaped molecules. Europhys. Lett. 2001, 56, 247–253. [Google Scholar] [CrossRef]

- Jákli, A. Liquid crystals of the twenty-first century—Nematic phase of bent-core molecules. Liq. Cryst. Rev. 2013, 1, 65–82. [Google Scholar] [CrossRef]

- Ali, M.; Gorecka, E.; Pociecha, D.; Vaupotič, N. Structure and grating efficiency of thin cells filled by a twist-bend nematic liquid crystal. Phys. Rev. E 2020, 102, 032704. [Google Scholar] [CrossRef] [PubMed]

- Vaupotič, N.; Ali, M.; Majewski, P.W.; Gorecka, E.; Pociecha, D. Polarization Gratings Spontaneously Formed from a Helical Twist-Bend Nematic Phase. ChemPhysChem 2018, 19, 2566–2571. [Google Scholar] [CrossRef] [Green Version]

- You, R.; Paterson, D.A.; Storey, J.M.D.; Imrie, C.T.; Yoon, D.K. Formation of periodic zigzag patterns in the twist-bend nematic liquid crystal phase by surface treatment. Liq. Cryst. 2017, 1–9. [Google Scholar] [CrossRef]

- Beresnev, L.A.; Blinov, L.M.; Osipov, M.A.; Pikin, S.A. Ferroelectric Liquid Crystals. Mol. Cryst. Liq. Cryst. Inc. Nonlinear Opt. 1988, 158, 1–150. [Google Scholar] [CrossRef]

- Meyer, R.B.; Liebert, L.; Strzelecki, L.; Keller, P. Ferroelectric liquid crystals. J. Phys. Lett. 1975, 36, 69–71. [Google Scholar] [CrossRef]

- Meyer, R.B. Ferroelectric Liquid Crystals; A Review. Mol. Cryst. Liq. Cryst. 1977, 40, 33–48. [Google Scholar] [CrossRef]

- Lagerwall, S.T. Surface-stabilized ferroelectric liquid crystal electro-optics: New multistate structures and devices. Ferroelectrics 1984, 59, 25–67. [Google Scholar] [CrossRef]

- Armitage, D.; Thackara, J.I.; Clark, N.A.; Handschy, M.A. Ferroelectric Liquid Crystal Spatial Light Modulator. Mol. Cryst. Liq. Cryst. 1987, 144, 309–316. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Ma, Y.; Chigrinov, V.G.; Kong, H.; Hoi, S.K. Field Sequential Color Ferroelectric Liquid Crystal Display Cell. U.S. Patent 9,366,934 B2, 14 June 2016. [Google Scholar]

- Forth Dimmension Displays FLCoS Operation-Forth Dimension Displays. Available online: https://www.forthdd.com/technology/flcos-operation/ (accessed on 23 January 2021).

- Wakita, N.; Uemura, T.; Ohnishi, H.; Mizuno, H.; Yamazoe, H. Shock-problem free flcds and mechanism of alignment destruction by mechanical shock. Ferroelectrics 1993, 149, 229–238. [Google Scholar] [CrossRef]

- Wyatt, P.J.M. Grating Aligned Ferroelectric Liquid Crystal Devices. Ph.D. Thesis, University of Leeds, Leeds, UK, 2019. [Google Scholar]

- Chen, X.; Korblova, E.; Dong, D.; Wei, X.; Shao, R.; Radzihovsky, L.; Glaser, M.A.; MacLennan, J.E.; Bedrov, D.; Walba, D.M.; et al. First-principles experimental demonstration of ferroelectricity in a thermotropic nematic liquid crystal: Polar domains and striking electro-optics. Proc. Natl. Acad. Sci. USA 2020, 117, 14021–14031. [Google Scholar] [CrossRef] [PubMed]

- Lavrentovich, O.D. Ferroelectric nematic liquid crystal, a century in waiting. Proc. Natl. Acad. Sci. USA 2020, 117, 14629–14631. [Google Scholar] [CrossRef] [PubMed]

| Device Type | Key Advantages | Key Disadvantages | fn (%) | ||

|---|---|---|---|---|---|

| f1 | f2 | f3 | |||

| Geometric Prisms and Lenses [19,58] | Simple Fabrication High η (80%) | Low θ (1°) High d | 0.1 | 0.9 | 0 |

| Fringing Field Refraction Devices [60] | Simple Fabrication High η (80%) | Low θ (0.1°) | 0.001 | 0.1 | 0 |

| Alignment Prisms/Lenses [88] | High η (80%) | Low θ (1°) Complex Fabrication | 0.02 | 0.2 | 0 |

| Refractive EASLM [106,183] | High η at small angles (99% at 0.1°) | Reflection only using LCOS η decreases with θ (90% at 1°) | 0.2 | 7 | 0 |

| Optical Waveguides [120] | High η (80%) High θ (40°) Continuous Steering | Small A (20 μm × 1 cm) Not flat-panel | 500 | 40 | 0.3 |

| Device Type | Key Advantages | Key Disadvantages | fn (%) | ||

|---|---|---|---|---|---|

| f1 | f2 | f3 | |||

| Dielectric Inclusions and Exclusions [134] | High η (80%) High θ (10°) | Discreet Diffraction High Voltage | 1 | 0 | 80 |

| Single Patterned Electrode [184] | High θ (10°) | Low η (30%) | 3 | 0 | 30 |

| Diffractive EASLM [106,183] | High η at small angles (90% at 1°) | η decreases at wide angles (25% at 10°) | 0.4 | 7 | 30 |

| SAL Gratings [161] | Reasonable η (68%) | Small θ (0.2°) | 0.02 | 0 | 0 |

| Photoconductive gratings [111] | Reasonable θ (2°) | Low η (35%) | 0.0001 | 1 | 0 |

| PB gratings [165] | Excellent η (99.5%) Wide-angle steering (40°) | Discrete Steering Angles | 60 | 0 | 100 |

| EHDI Gratings [176] | Continuously Variable Reasonable θ (8°) | Low η (15%) Material Degradation | 0.002 | 0.7 | 4 |

| VBGs [151,153] | High η (90%) High θ (50°) | Reflection only | 3 | 0 | 90 |

| N* GM E-field [178] | Reasonable θ (7°) | Low η (25%) | 0.03 | N/A | N/A |

| N* DM E-field [178] | Reasonable θ (12°) Continuously Variable | Low η (15%) | 0.03 | 0 | N/A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morris, R.; Jones, C.; Nagaraj, M. Liquid Crystal Devices for Beam Steering Applications. Micromachines 2021, 12, 247. https://doi.org/10.3390/mi12030247

Morris R, Jones C, Nagaraj M. Liquid Crystal Devices for Beam Steering Applications. Micromachines. 2021; 12(3):247. https://doi.org/10.3390/mi12030247

Chicago/Turabian StyleMorris, Rowan, Cliff Jones, and Mamatha Nagaraj. 2021. "Liquid Crystal Devices for Beam Steering Applications" Micromachines 12, no. 3: 247. https://doi.org/10.3390/mi12030247

APA StyleMorris, R., Jones, C., & Nagaraj, M. (2021). Liquid Crystal Devices for Beam Steering Applications. Micromachines, 12(3), 247. https://doi.org/10.3390/mi12030247