Fabrication of Multi-Layered Microspheres Based on Phase Separation for Drug Delivery

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

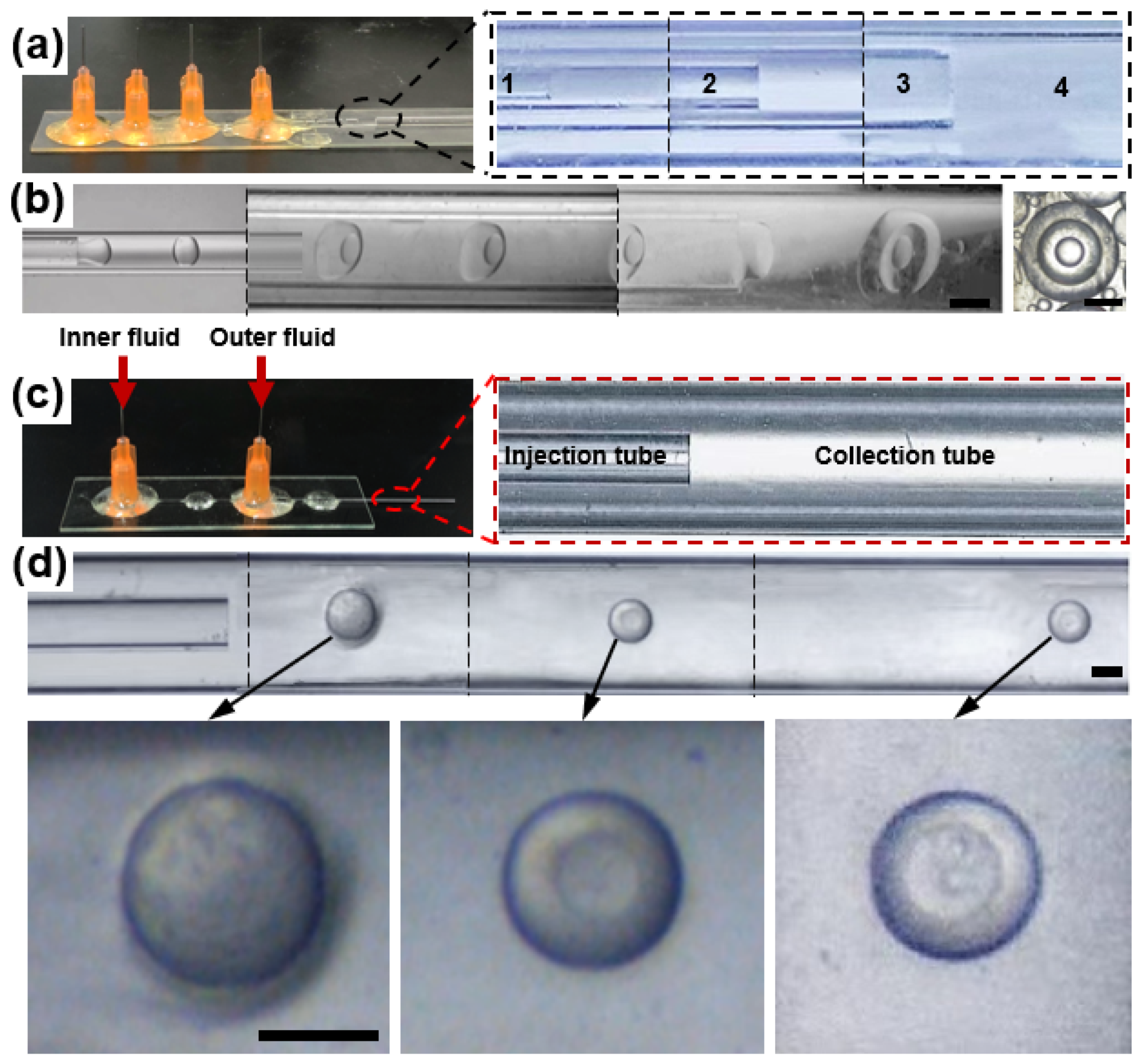

2.2. Microfluidic Device Setup

2.3. Preparation of Emulsion Droplets with Different Layers

2.4. Preparation of Microparticles with Different Layers

2.5. Drug Loading and Controlled Release

2.6. Characterization

3. Results and Discussion

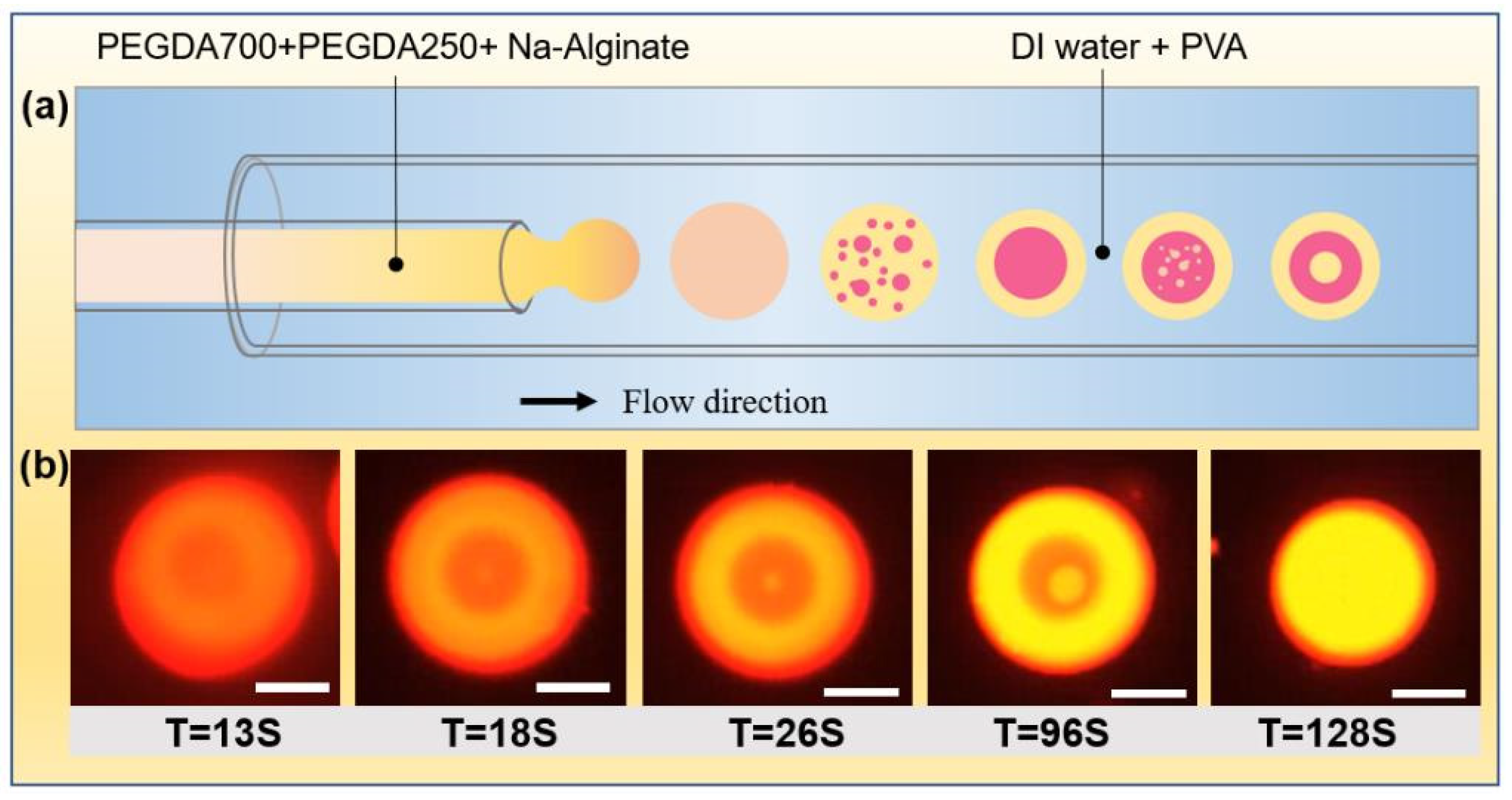

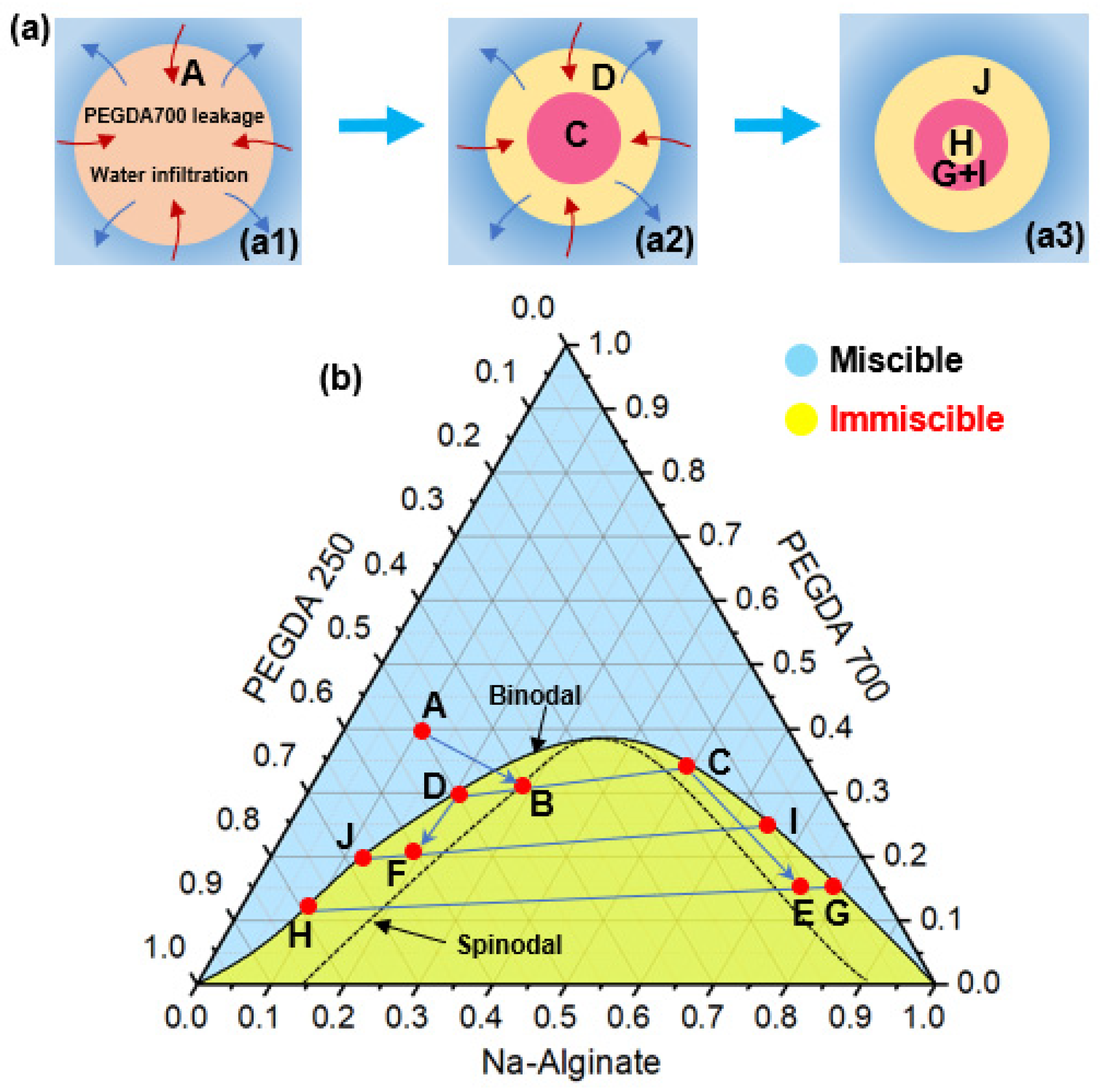

3.1. Preparation of Emulsion Droplets with Different Layers

3.2. Preparation of Microparticles with Different Layers

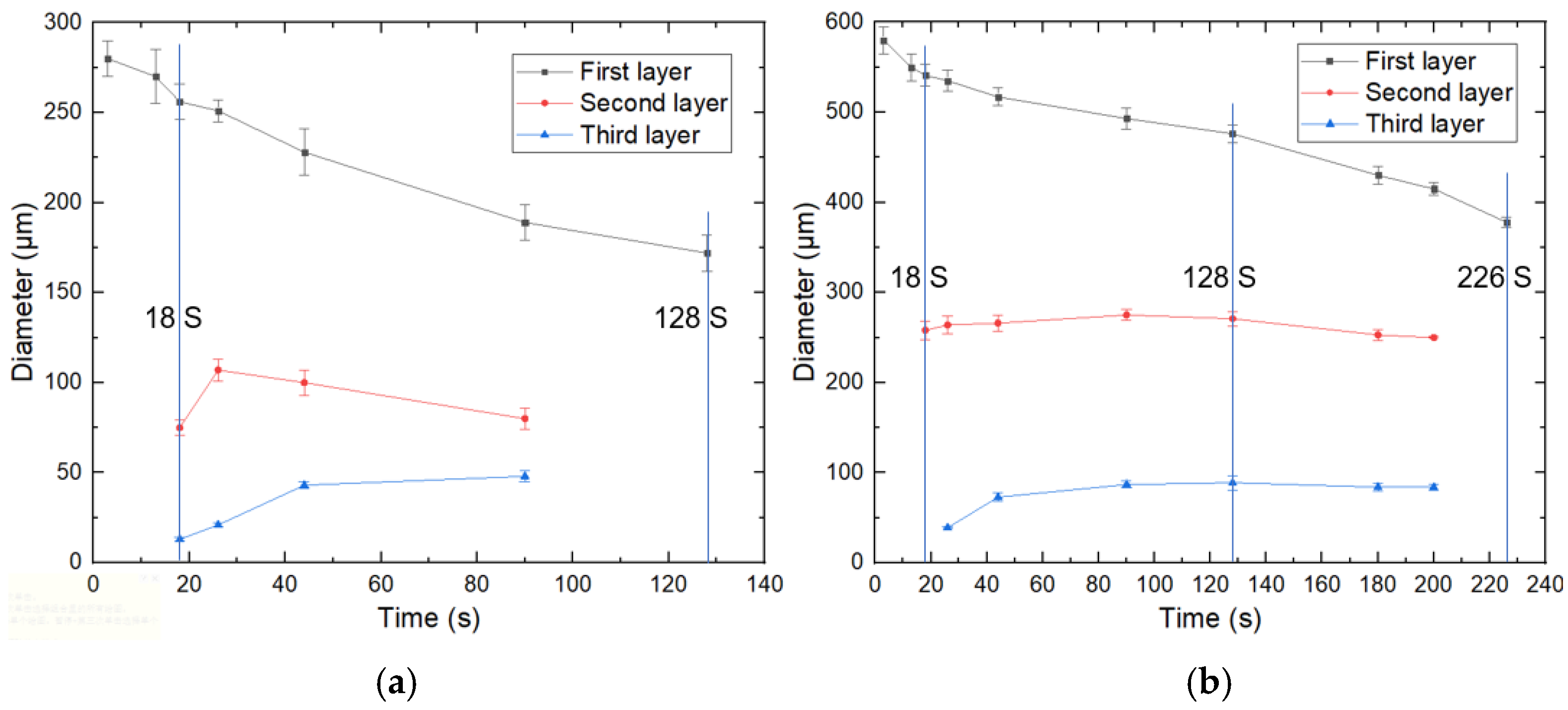

3.3. The Effect of Droplet Size on Phase Separation Process

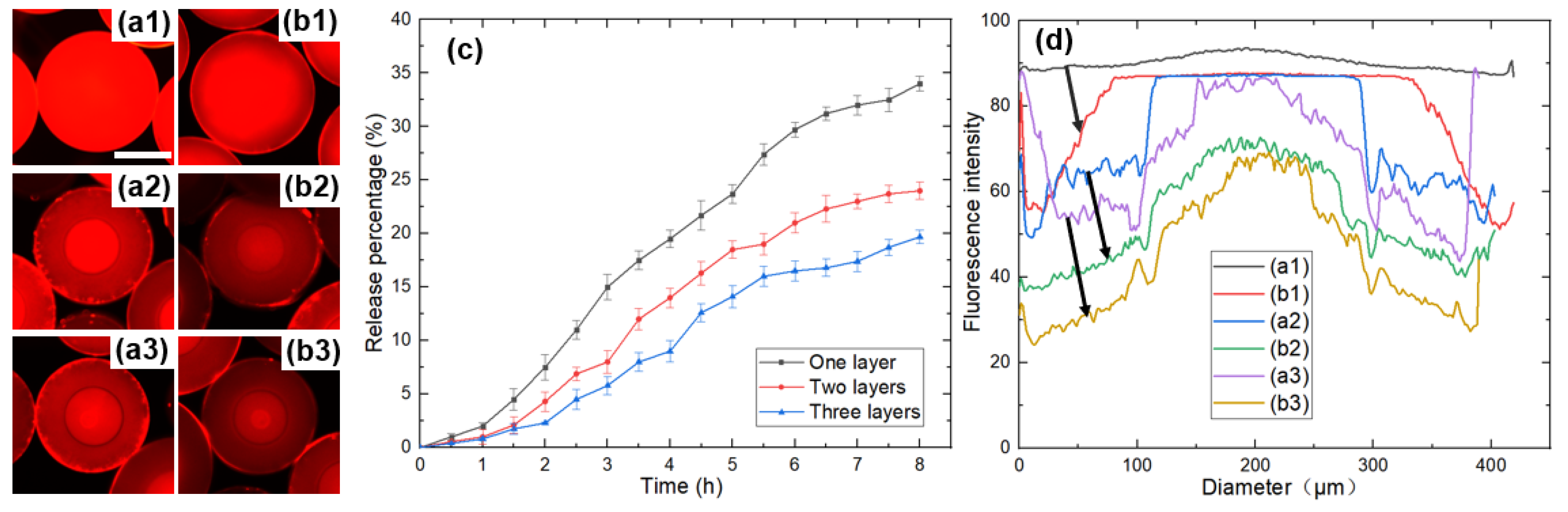

3.4. Drug Controlled Release of Microspheres

3.5. Preparation of “Cup-Shaped” Microparticles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, S.-H.; Kim, J.W.; Cho, J.-C.; Weitz, D.A. Double-emulsion drops with ultra-thin shells for capsule templates. Lab Chip 2017, 17, 567. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.Y.; Choi, T.M.; Shim, T.S.; Frijns, R.A.M.; Kim, S.-H. Microfluidic production of multiple emulsions and functional microcapsules. Lab Chip 2016, 16, 3415–3440. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.-T.; Chen, R.; Xu, J.-H.; Wang, Y.-D.; Luo, G.-S. One-step microfluidic production of gas-in-water-in-oil multi-cores double emulsions. Chem. Eng. J. 2015, 263, 412–418. [Google Scholar] [CrossRef]

- Lone, S.; Kim, S.H.; Nam, S.W.; Park, S.; Joo, J.; Cheong, I.W. Microfluidic synthesis of Janus particles by UV-directed phase separation. Chem. Commun. 2011, 47, 2634–2636. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-H.; Jeon, S.-J.; Jeong, W.C.; Park, H.S.; Yang, S.-M. Optofluidic Synthesis of Electroresponsive Photonic Janus Balls with Isotropic Structural Colors. Adv. Mater. 2008, 20, 4129–4134. [Google Scholar] [CrossRef]

- Haase, M.F.; Brujic, J. Tailoring of High-Order Multiple Emulsions by the Liquid-Liquid Phase Separation of Ternary Mixtures. Angew. Chem. Int. Ed. 2014, 53, 11793–11797. [Google Scholar] [CrossRef]

- Zhao, C.-X. Multiphase flow microfluidics for the production of single or multiple emulsions for drug delivery. Adv. Drug Deliv. Rev. 2013, 65, 1420–1446. [Google Scholar] [CrossRef]

- Hernandez, R.M.; Orive, G.; Murua, A.; Luis Pedraz, J. Microcapsules and microcarriers for in situ cell delivery. Adv. Drug Deliv. Rev. 2010, 62, 711–730. [Google Scholar] [CrossRef]

- Champion, J.A.; Katare, Y.K.; Mitragotri, S. Particle shape: A new design parameter for micro- and nanoscale drug delivery carriers. J. Control. Release 2007, 121, 3–9. [Google Scholar] [CrossRef]

- Xiong, B.; Ren, K.; Shu, Y.; Chen, Y.; Shen, B.; Wu, H. Recent Developments in Microfluidics for Cell Studies. Adv. Mater. 2014, 26, 5525–5532. [Google Scholar] [CrossRef]

- Agresti, J.J.; Antipov, E.; Abate, A.R.; Ahn, K.; Rowat, A.C.; Baret, J.-C.; Marquez, M.; Klibanov, A.M.; Griffiths, A.D.; Weitz, D.A. Ultrahigh-throughput screening in drop-based microfluidics for directed evolution. Proc. Natl. Acad. Sci. USA 2010, 107, 4004–4009. [Google Scholar] [CrossRef]

- Gallarate, M.; Carlotti, M.E.; Trotta, M.; Bovo, S. On the stability of ascorbic acid in emulsified systems for topical and cosmetic use. Int. J. Pharm. 1999, 188, 233–241. [Google Scholar] [CrossRef]

- Sekine, T.; Yoshida, K.; Matsuzaki, F.; Yanaki, T.; Yamaguchi, M. A novel method for preparing oil-in-water-in-oil type multiple emulsions using organophilic montmorillonite clay mineral. J. Surfactants Deterg. 1999, 2, 309–315. [Google Scholar] [CrossRef]

- Ma, C.; Li, J.; Zhang, B.; Liu, C.; Zhang, J.; Liu, Y. Hydrogel Microparticles Functionalized with Engineered Escherichia coli as Living Lactam Biosensors. Sensors 2019, 19, 5556. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Zhang, L.; Ge, X.; Xu, B.; Zhang, W.; Qu, L.; Choi, C.-H.; Xu, J.; Zhang, A.; Lee, H.; et al. Microfluidic fabrication of microparticles for biomedical applications. Chem. Soc. Rev. 2018, 47, 5646–5683. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.N.; Yan, D.; Fu, F.F.; Liu, Y.X.; Zhang, B.; Wang, J.; Shang, L.R.; Gu, Z.; Zhao, Y. Composite core-shell microparticles from microfluidics for synergistic drug delivery. Sci. China-Mater. 2017, 60, 543–553. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, X.; Man, J.; Li, J.; Cui, X.; Zhang, C.; Shi, W.; Li, D.; Zhang, S.; Li, J. Histone Deacetylase Inhibitor-loaded Calcium Alginate Microspheres for Acute Kidney Injury Treatment. Acs Appl. Bio Mater. 2020, 3, 6457–6465. [Google Scholar] [CrossRef]

- Yu, L.; Sun, Q.; Hui, Y.; Seth, A.; Petrovsky, N.; Zhao, C.-X. Microfluidic formation of core-shell alginate microparticles for protein encapsulation and controlled release. J. Colloid Interface Sci. 2019, 539, 497–503. [Google Scholar] [CrossRef] [PubMed]

- Herranz-Blanco, B.; Arriaga, L.R.; Makila, E.; Correia, A.; Shrestha, N.; Mirza, S.; Weitz, D.A.; Salonen, J.; Hirvonen, J.; Santos, H.A. Microfluidic assembly of multistage porous silicon-lipid vesicles for controlled drug release. Lab Chip 2014, 14, 1083–1086. [Google Scholar] [CrossRef]

- Huang, X.; Brazel, C.S. On the importance and mechanisms of burst release in matrix-controlled drug delivery systems. J. Control. Release 2001, 73, 121–136. [Google Scholar] [CrossRef]

- Huang, X.; Fu, Q.; Deng, Y.; Wang, F.; Xia, B.; Chen, Z.; Chen, G. Surface roughness of silk fibroin/alginate microspheres for rapid hemostasis in vitro and in vivo. Carbohydr. Polym. 2021, 253, 117256. [Google Scholar] [CrossRef]

- Hayashi, K.; Yamada, S.; Sakamoto, W.; Usugi, E.; Watanabe, M.; Yogo, T. Red Blood Cell-Shaped Microparticles with a Red Blood Cell Membrane Demonstrate Prolonged Circulation Time in Blood. Acs Biomater. Sci. Eng. 2018, 4, 2729–2732. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wei, W.; Lv, P.; Wang, L.; Ma, G. Preparation and evaluation of alginate-chitosan microspheres for oral delivery of insulin. Eur. J. Pharm. Biopharm. 2011, 77, 11–19. [Google Scholar] [CrossRef]

- Abate, A.R.; Weitz, D.A. High-Order Multiple Emulsions Formed in Poly(dimethylsiloxane) Microfluidics. Small 2009, 5, 2030–2032. [Google Scholar] [CrossRef] [PubMed]

- Utada, A.S.; Chu, L.Y.; Fernandez-Nieves, A.; Link, D.R.; Holtze, C.; Weitz, D.A. Dripping, jetting, drops, and wetting: The magic of microfluidics. MRS Bull. 2007, 32, 702–708. [Google Scholar] [CrossRef]

- Hennequin, Y.; Pannacci, N.; de Torres, C.P.; Tetradis-Meris, G.; Chapuliot, S.; Bouchaud, E.; Tabeling, P. Synthesizing Microcapsules with Controlled Geometrical and Mechanical Properties with Microfluidic Double Emulsion Technology. Langmuir 2009, 25, 7857–7861. [Google Scholar] [CrossRef]

- Van der Graaf, S.; Schroen, C.; Boom, R.M. Preparation of double emulsions by membrane emulsification—A review. J. Membr. Sci. 2005, 251, 7–15. [Google Scholar] [CrossRef]

- Garti, N. Double emulsions—Scope, limitations and new achievements. Colloid Surf. A-Physicochem. Eng. Asp. 1997, 123, 233–246. [Google Scholar] [CrossRef]

- Altria, K.; Broderick, M.; Donegan, S.; Power, J. Preliminary study on the use of water-in-oil microemulsion eluents in HPLC. Chromatographia 2005, 62, 341–348. [Google Scholar] [CrossRef]

- Shang, L.; Cheng, Y.; Zhao, Y. Emerging Droplet Microfluidics. Chem. Rev. 2017, 117, 7964–8040. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Y.; Wang, F.; Guo, F.; Nestler, B. Phase-Field Modeling of Multiple Emulsions Via Spinodal Decomposition. Langmuir ACS J. Surf. Colloids 2021, 37, 5275–5281. [Google Scholar] [CrossRef] [PubMed]

- Haase, M.F.; Stebe, K.J.; Lee, D. Continuous Fabrication of Hierarchical and Asymmetric Bijel Microparticles, Fibers, and Membranes by Solvent Transfer-Induced Phase Separation (STRIPS). Adv. Mater. 2015, 27, 7065–7071. [Google Scholar] [CrossRef] [PubMed]

- Udoh, C.E.; Garbin, V.; Cabral, J.T. Microporous Polymer Particles via Phase Inversion in Microfluidics: Impact of Nonsolvent Quality. Langmuir 2016, 32, 8131–8140. [Google Scholar] [CrossRef]

- Zarzar, L.D.; Sresht, V.; Sletten, E.M.; Kalow, J.A.; Blankschtein, D.; Swager, T.M. Dynamically reconfigurable complex emulsions via tunable interfacial tensions. Nature 2015, 518, 520–524. [Google Scholar] [CrossRef]

- Zhu, A.-D.; Guo, M.-Y. Single emulsion microfluidic production of Janus and core-shell particles via off-chip polymerization. Chin. J. Polym. Sci. 2016, 34, 367–377. [Google Scholar] [CrossRef]

- Guo, S.; Yao, T.; Ji, X.; Zeng, C.; Wang, C.; Zhang, L. Versatile Preparation of Nonspherical Multiple Hydrogel Core PAM/PEG Emulsions and Hierarchical Hydrogel Microarchitectures. Angew. Chem. Int. Ed. 2014, 53, 7504–7509. [Google Scholar] [CrossRef] [PubMed]

- Jeong, W.-C.; Choi, M.; Lim, C.H.; Yang, S.-M. Microfluidic synthesis of atto-liter scale double emulsions toward ultrafine hollow silica spheres with hierarchical pore networks. Lab. Chip 2012, 12, 5262–5271. [Google Scholar] [CrossRef]

- Zhang, F.; Jiang, L.; Zeng, C.; Wang, C.; Wang, J.; Ke, X.; Zhang, L. Complex emulsions for shape control based on mass transfer and phase separation. Soft Matter 2020, 16, 5981–5989. [Google Scholar] [CrossRef]

- Wang, L.; Yu, L.; Zeng, C.; Wang, C.; Zhang, L. Fabrication of PAA-PETPTA Janus Microspheres with Respiratory Function for Controlled Release of Guests with Different Sizes. Langmuir 2018, 34, 7106–7116. [Google Scholar] [CrossRef]

- Liang, S.; Li, J.; Man, J.; Chen, H. Mass-Transfer-Induced Multistep Phase Separation in Emulsion Droplets: Toward Self-Assembly Multilayered Emulsions and Onionlike Microspheres. Langmuir 2016, 32, 7882–7887. [Google Scholar] [CrossRef]

- Mazzoccoli, J.P.; Feke, D.L.; Baskaran, H.; Pintauro, P.N. Mechanical and cell viability properties of crosslinked low- and high-molecular weight poly(ethylene glycol) diacrylate blends. J. Biomed. Mater. Res. Part A 2010, 93, 558–566. [Google Scholar] [CrossRef] [PubMed]

- Castro, D.; Ingram, P.; Kodzius, R.; Conchouso, D.; Yoon, E.; Foulds, I.G.; Ingram, P. characterization of solid uv cross-linked pegda for biological applications. In Proceedings of the 26th Ieee International Conference on Micro Electro Mechanical Systems, Taipei, Taiwan, 20–24 January 2013; pp. 457–460. [Google Scholar]

- Soodak, K.F.; Brennecka, C.R.; Vernon, B.L. In vitro characteristics of a gelling PEGDA-QT polymer system with model drug release for cerebral aneurysm embolization. J. Biomed. Mater. Res. Part B Appl. Biomater. 2013, 101, 1477–1488. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Ballester, N.M.; Soulairol, I.; Bataille, B.; Sharkawi, T. Flexible heteroionic calcium-magnesium alginate beads for controlled drug release. Carbohydr. Polym. 2019, 207, 224–229. [Google Scholar] [CrossRef] [PubMed]

- Jing, Z.; Xu, X.Y.; Chen, X.S.; Liang, Q.Z.; Bian, X.C.; Yang, L.X.; Jing, X.B. Biodegradable electrospun fibers for drug delivery. J. Control. Release 2003, 92, 227–231. [Google Scholar]

- Tan, G.; Wang, Y.; Li, J.; Zhang, S. Synthesis and characterization of injectable photocrosslinking poly (ethylene glycol) diacrylate based hydrogels. Polym. Bull. 2008, 61, 91–98. [Google Scholar] [CrossRef]

- Van de Witte, P.; Dijkstra, P.J.; van den Berg, J.W.A.; Feijen, J. Phase separation processes in polymer solutions in relation to membrane formation. J. Membr. Sci. 1996, 117, 1–31. [Google Scholar] [CrossRef]

- McAvoy, K.; Jones, D.; Thakur, R.R.S. Synthesis and Characterisation of Photocrosslinked poly(ethylene glycol) diacrylate Implants for Sustained Ocular Drug Delivery. Pharm. Res. 2018, 35, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Singh, T.R.R.; McCarron, P.A.; Woolfson, A.D.; Donnelly, R.F. Investigation of swelling and network parameters of poly(ethylene glycol)-crosslinked poly(methyl vinyl ether-co-maleic acid) hydrogels. Eur. Polym. J. 2009, 45, 1239–1249. [Google Scholar] [CrossRef]

- Zhang, Y.; Shitta, A.; Meredith, J.C.; Behrens, S.H. Bubble Meets Droplet: Particle-Assisted Reconfi guration of Wetting Morphologies in Colloidal Multiphase Systems. Small (Weinh. Der Bergstr. Ger.) 2016, 12, 4307. [Google Scholar] [CrossRef]

- Kwan, J.J.; Myers, R.; Coviello, C.M.; Graham, S.M.; Shah, A.R.; Stride, E.; Carlisle, R.C.; Coussios, C.C. Ultrasound-Propelled Nanocups for Drug Delivery. Small 2015, 11, 5305–5314. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, H.; Li, A.; Man, J.; Li, J.; Li, J. Fabrication of Multi-Layered Microspheres Based on Phase Separation for Drug Delivery. Micromachines 2021, 12, 723. https://doi.org/10.3390/mi12060723

Xia H, Li A, Man J, Li J, Li J. Fabrication of Multi-Layered Microspheres Based on Phase Separation for Drug Delivery. Micromachines. 2021; 12(6):723. https://doi.org/10.3390/mi12060723

Chicago/Turabian StyleXia, He, Ang Li, Jia Man, Jianyong Li, and Jianfeng Li. 2021. "Fabrication of Multi-Layered Microspheres Based on Phase Separation for Drug Delivery" Micromachines 12, no. 6: 723. https://doi.org/10.3390/mi12060723

APA StyleXia, H., Li, A., Man, J., Li, J., & Li, J. (2021). Fabrication of Multi-Layered Microspheres Based on Phase Separation for Drug Delivery. Micromachines, 12(6), 723. https://doi.org/10.3390/mi12060723