1. Introduction

SMPs, as programmable phase change materials, can be deformed to a temporary shape under given conditions and then reversed to their original permanent shape upon external stimulus [

1,

2,

3,

4]. Compared with other traditional SMPs, such as shape memory alloys and shape memory ceramics, SMPs have the advantages of light weight, low cost, good biocompatibility, and great deformation recovery [

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15]. Taking into account these excellent characteristics of SMPs, many researchers have applied them in the fields of aerospace [

16,

17,

18,

19], biomedical research [

20,

21,

22], intelligent textiles [

23], and self-healing materials [

24,

25,

26].

SMPs, due to their advantages described herein, can be developed into technology platforms that allow the tailored multifunctional design. In this way, defined movements of implants triggered either directly or indirectly [

27,

28]; tailored mechanical properties [

29,

30]; and capability for sterilization [

31,

32], biodegradability [

33], biocompatibility [

34,

35], and controlled drug release [

33,

36,

37] can be achieved [

20]. Lendlein et al. introduced a group of degradable thermoplastic polymers that were able to change their shape when the loaded temperature was increased, whereby the shape memory capability of the specimens enabled bulky implants to be placed in the body through small incisions and allowed complex mechanical deformation processes to be performed automatically [

33]. Yakacki et al. developed novel SMP networks with capability for free recovery at body temperature, which were suitable for specific applications in minimally invasive cardiovascular devices [

36]. Neffe et al. developed a ureteral stent using SMPs that can be anchored in the ureter, which could have a significant impact in terms of controlled drug release [

38].

SMPs can be temporarily fixed and readily formed because they are strong below the glass transition temperature and deformable above the glass transition temperature [

4,

39,

40,

41]. The aforementioned excellent performance means that SMPs have great application potential in aerospace, especially for large deployable antenna structures in aerospace satellites, including hinges, solar panels, deployable panels, suspenders, and reflector antennas [

42,

43]. Leng et al. designed and fabricated a deployable hinge based on SMPs and used it in a deployable driving structure for deployable space solar panels [

44]. A smart deployable space antenna with a diameter of 10 m based on SMPs was studied by NASA’s Air Propulsion Laboratory, in which the antenna could be deployed in orbit and the shape of the antenna was further maintained after deployment [

45].

There have been many theoretical studies on SMPs [

46], which can be categorized into studies on rheological models [

9,

47,

48,

49] and phase transition models [

41,

50,

51,

52,

53,

54]; however, the above models might be difficult to popularize to a certain degree, as they are hindered by the complexity of the parameter determination process [

55]. Tao et al. simulated the shape memory effects of deployable hinged shells of SMPs using the UMAT compiled by ABAQUS [

56]. The variable stiffness of an integrated SMPC hinge at different temperatures was calculated and simulated by Liu’s group, in which good shape memory performance was obtained [

57]. Liu et al. simulated the bending and recovery process of a cylindrical tube using finite element analysis, and the stress distribution of the cylindrical tube in the bent state was obtained [

58]; hence, in order to maintain the stability and reliability of a spacecraft in space, it is necessary to fully characterize the mechanical properties of space deployment structures based on SMPs. It is particularly important to develop a complete and reliable method of simulation analysis.

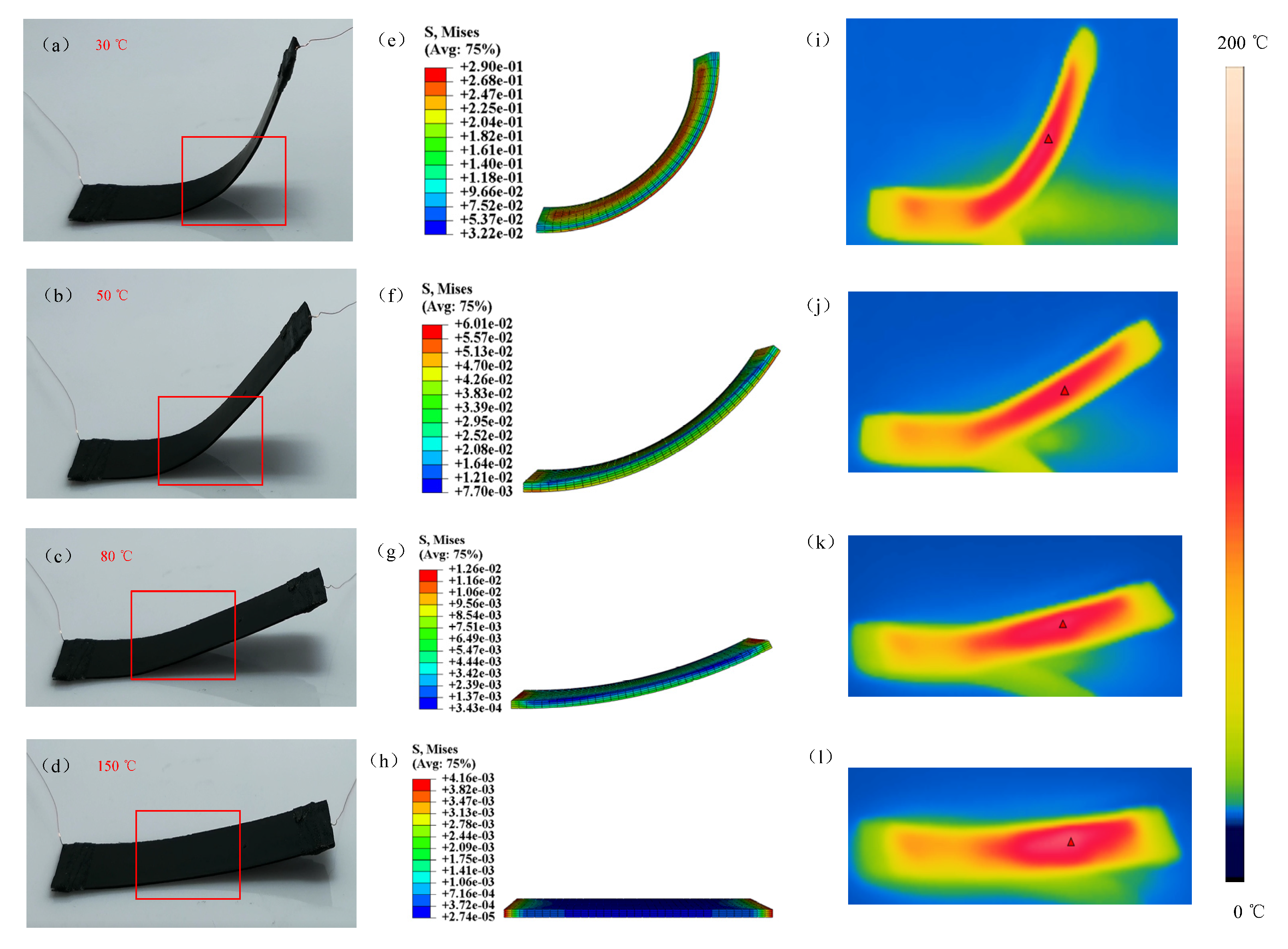

In this paper, a coupled FEM was established based on the generalized Maxwell model and TTEP. The mechanical deformation of the SMPs was decomposed into the hyperelastic part (which was expressed using the neo-Hookean model) and viscoelastic part (which was expressed using the generalized Maxwell model and Williams–Landel–Ferry (WLF) equations), considering the large deformation behavior of the studied object. The TTEP was used to describe the response characteristics of SMPs at different temperatures. Based on the experimental data from the tension and relaxation tests of the E-SMP, the numerical model parameters were calculated using ABAQUS. The accuracy of the numerical analysis model was verified by calculating the same analysis model as in the tensile experiment. The thermodynamic behavior and shape memory effect of the S-DS and F-DS of the electrically driven epoxy resin SMPs prepared in the laboratory were studied and analyzed. The variations of the torque in the X-axis and bending angle of the S-DS in the response process were calculated. The relative internal energy and stress cloud map of the F-DS during simultaneous and step-by-step driving were obtained.

3. Constitutive Modeling of the E-SMP

E-SMP has appealing shape memory effects. The constitutive equation used to characterize these effects is interesting. Referring to the deformation behavior of the material studied in this paper, the generalized Maxwell model and TTEP method outlined in [

9,

61] were used to describe the shape memory behavior of SMPs. The generalized Maxwell model consists of Maxwell and hyperelasticity components. It is assumed that the effect of the thermal expansion on SMPs is independent of the mechanical behavior, as shown in

Figure 5, where

is the Young’s modulus of the elastic term,

is the Young’s modulus of the Maxwell element,

presents the relaxation time of the Maxwell element, and

denotes the number of Maxwell components.

The strain Equation in the above model can be deduced as follows:

where

denotes the total strain of the model,

denotes the mechanical strain, and

denotes the thermal strain.

The thermal strain is defined as:

where

is the coefficient of thermal expansion,

is the glass transition temperature, and

is the current temperature.

According to the theoretical model in [

9], the constitutive model in the coupled FEM can be derived as:

where

is the total stress;

is the Young’s modulus of the elastic term;

and

are the Young’s modulus and relaxation time of the Maxwell element, respectively;

is the strain of the model;

is the real time; and

is the number of Maxwell components.

The mechanical deformation of E-SMP is decomposed into hyperelastic and viscoelastic parts; thus, the total strain energy can be expressed as the sum of the two parts [

62]:

where

denotes the free energy of the rubbery state of the material and

is the free energy of the viscoelastic part of the material.

For

, a hyperelastic term (instead of an elastic term) is added to enable a better agreement because of the large strain of the space expansion structure of SMPs [

22]. Here, we chose the neo-Hookean hyperelastic equation:

where

is the first stress invariant,

and

are the temperature correlation coefficients, and

is the elastic volume strain, which can be obtained by fitting the experimental data.

Herein, the generalized Maxwell model and WLF equations were used to express

. According to the literature, the generalized Maxwell model and the WLF equation show the relationship between time and temperature. In addition, the model has already been shown to be reliable under a large deformation range [

63]. In the generalized Maxwell model, the relaxation modulus

can be expressed using the Prony series:

where

is the shear modulus in infinite time and

is the shear modulus of the Maxwell element.

To obtain the effective relaxation modulus

, a Fourier transform is applied in Equation (7):

where

is the storage modulus,

is the loss modulus,

is the initial shear modulus of the material, and

and

are a series of relaxation moduli and relaxation times, which can be obtained by fitting the force relaxation curve data at different temperatures.

To describe the response characteristics of SMPs at different temperatures, the TTEP was introduced [

64]. It is known that prolonging the observation time and increasing the temperature are equivalent to the motion of molecules and the viscoelastic behavior of polymers; therefore, the WLF equation can be used to describe the time temperature effect of SMPs [

65], which is shown as follows:

where

is the time temperature superposition shift factor in the WLF equation,

and

are material parameters, and

is the reference temperature, which can be obtained by fitting the experimental data.

The relaxation time

of the SMPs in the non-isothermal response process can be expressed by the following equation:

The theoretical model parameters mentioned above can be processed using the material module in ABAQUS. By using ABAQUS [

66,

67], the analysis efficiency of the E-SMP structure can be greatly improved.

5. Verification of Numerical Analysis

To verify the accuracy of the theoretical method, the three-dimensional model structure used for simulation was the same as that in the experiment. As shown in

Figure 13, in order to match equipment range and for convenience of preparation, the model size was 30 mm × 5 mm × 1 mm. In the experiment, 10 mm sections at the two ends of the test piece were clamped and the middle 10 mm sections was tested in the actual experiments.

To maintain the same effect as that in the experiment, the two ends of the structure measuring 10 mm were constrained by MCP in the FEM. In the simulation, a 0.1 mm grid (C3D8RH; with an 8-node linear brick, hybrid and constant pressure, reduced integration, and hourglass control) was used. The software version was DS Simulia suite 2018, Multi.x64, run in Windows. Moreover, the specific material parameters were obtained from the above test data. The hyperelastic parameters are shown in

Table 1, viscosity parameters in

Table 4, WLF parameters in

Table 3, and thermal expansion coefficients in

Figure 4.

The simulation model was the same as that used in the actual test. A tensile rate of 15 mm/min was used in the tensile tests. The tensile simulation models at a low temperature of 30 °C, medium temperature of 80 °C, and high temperature of 130 °C were calculated and the results are shown in

Figure 14. In the stress relaxation simulation at 30 °C, the loading rate was 2 mm/min, the tensile distance was 1 mm, and the strain was retained for 1800 s, the results for which are displayed in

Figure 15. In

Figure 14 and

Figure 15, the simulation data are highly consistent with the experimental data; hence, the accuracy of the theoretical and simulation methods is demonstrated.

Furthermore, the mesh independence was verified. Tensile test data at 50 °C were selected and grids with dimensions of 1 mm, 0.5 mm, 0.25 mm, and 0.1 mm were used. The results are presented in

Figure 16. It can be seen from the figure that the smaller the grid, the closer the simulation results were to the experimental results; hence, to improve the computational efficiency, a 0.25 mm grid was selected.