A Numerical Investigation on Hydrothermal Performance of Micro Channel Heat Sink with Periodic Spatial Modification on Sidewalls

Abstract

:1. Introduction

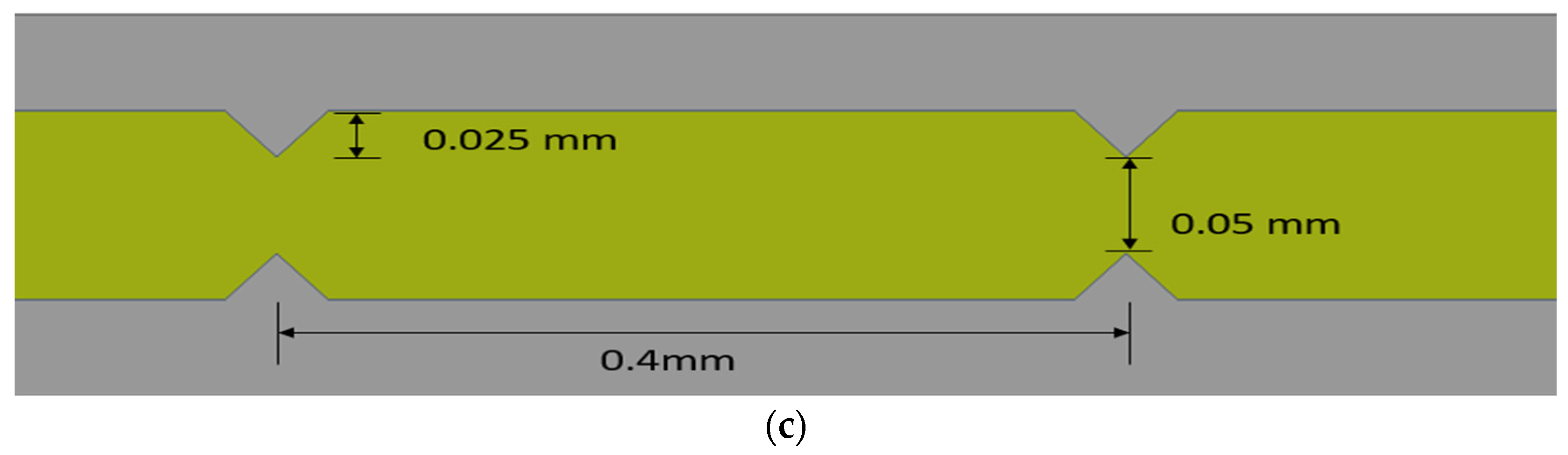

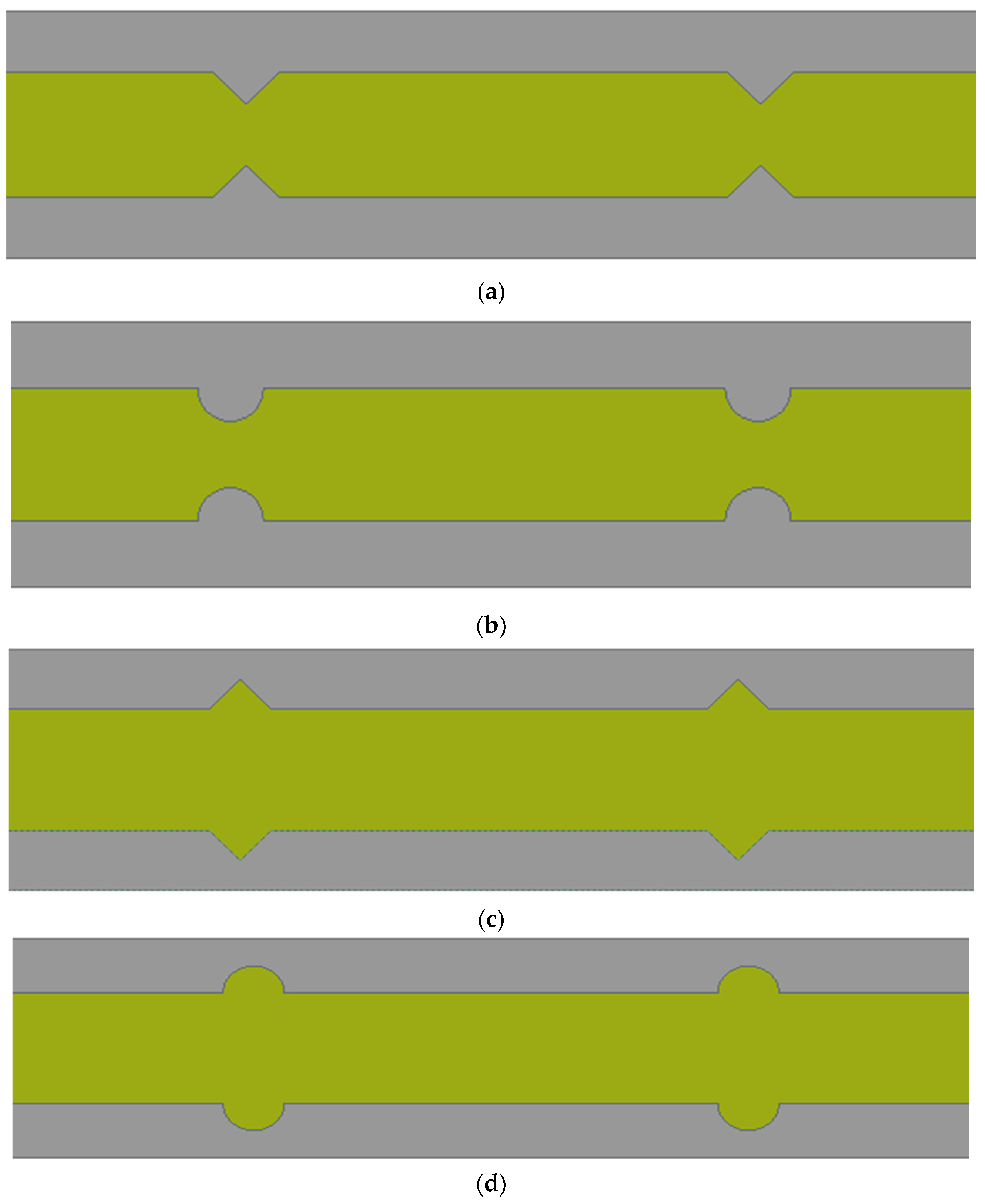

2. Details of MCHS Domain

2.1. Computational Domain

2.2. Conservation Equations

2.3. Thermophysical Properties of MCHS and Fluid Domain

2.4. Boundary Conditions and Computational Procedure

2.5. Meshing and Grid Independent Test

2.6. Data Reduction and Formulation

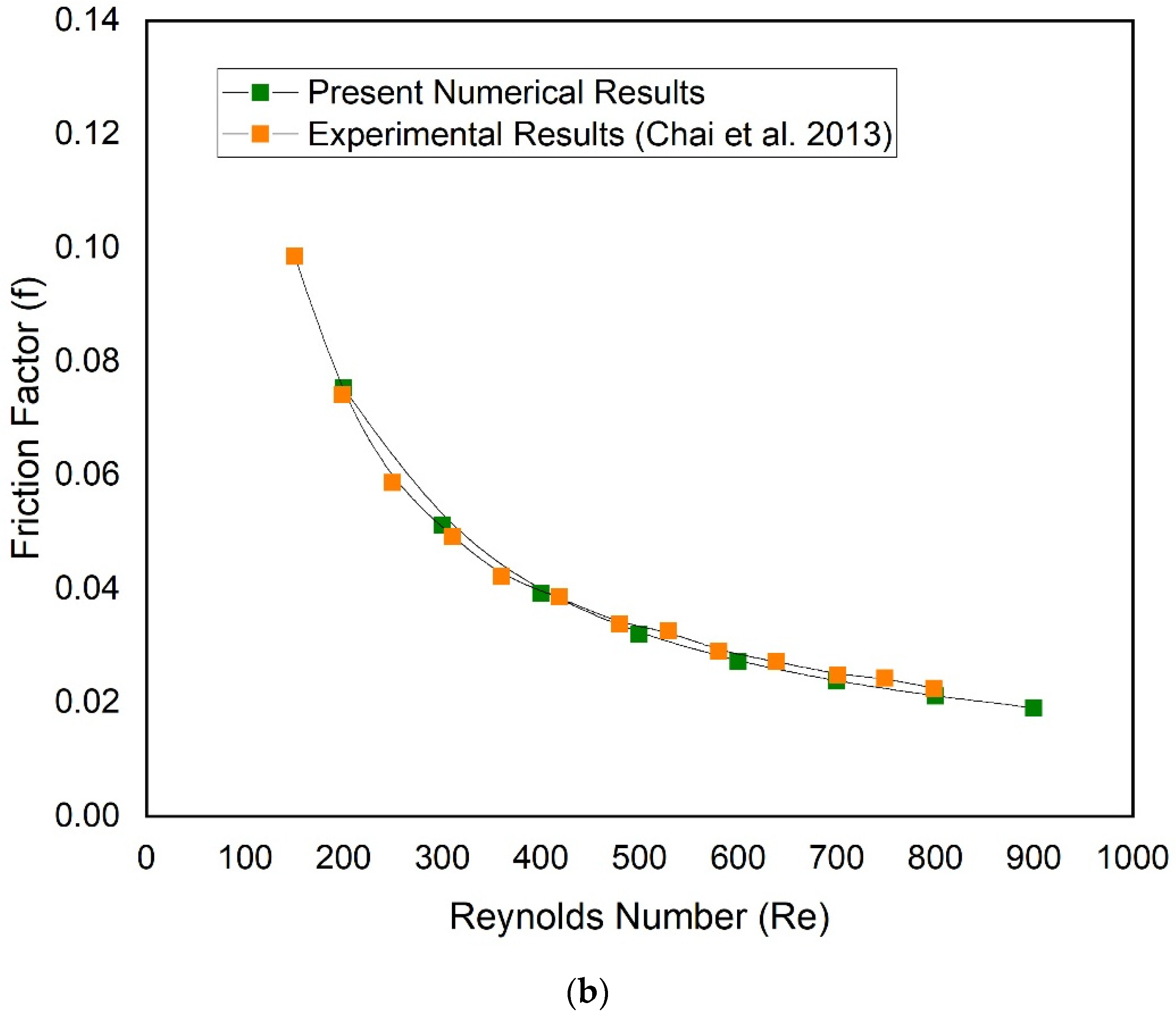

2.7. Model Validation

3. Result and Discussion

3.1. Velocity Distribution

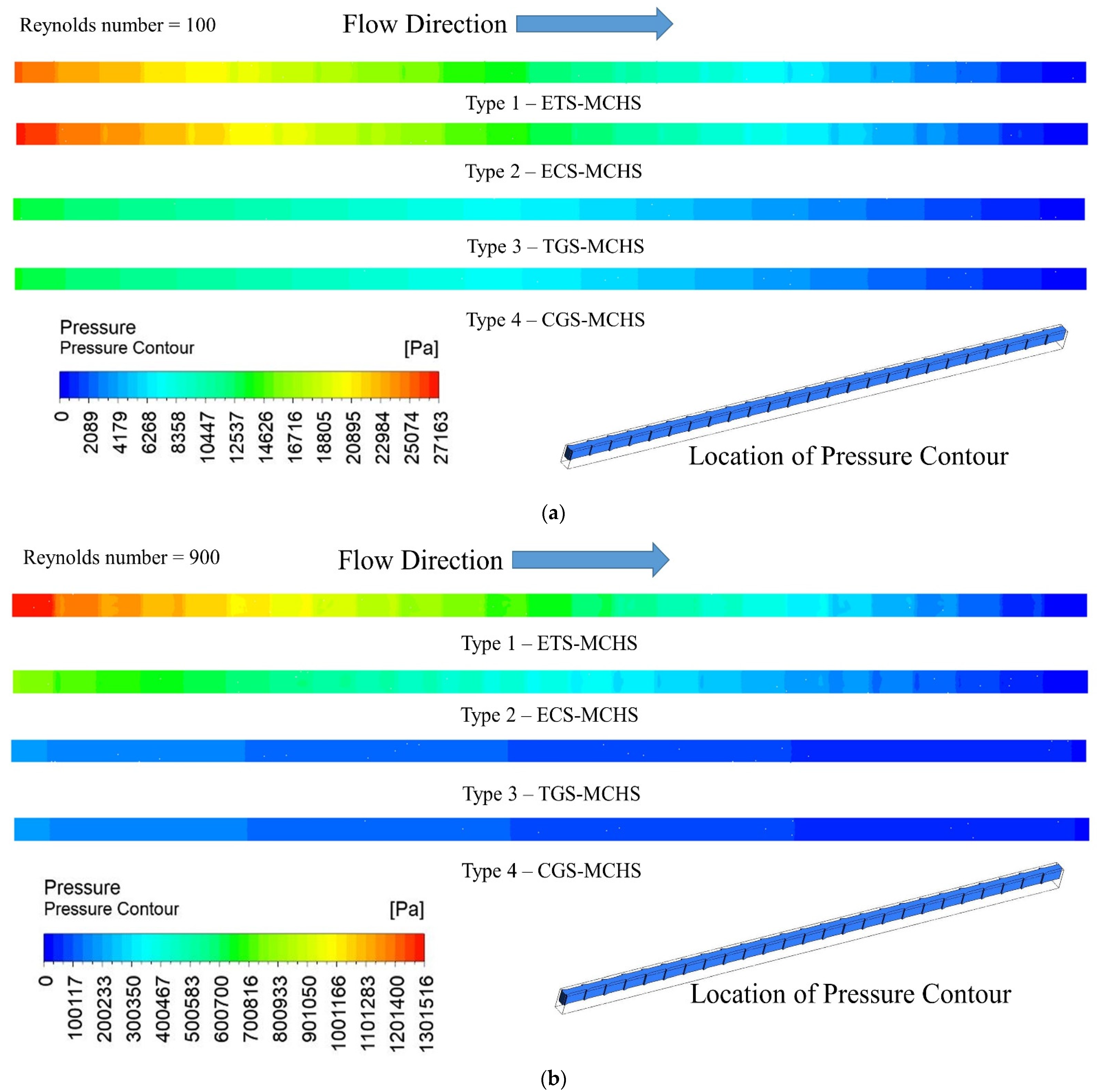

3.2. Pressure Drop Distribution

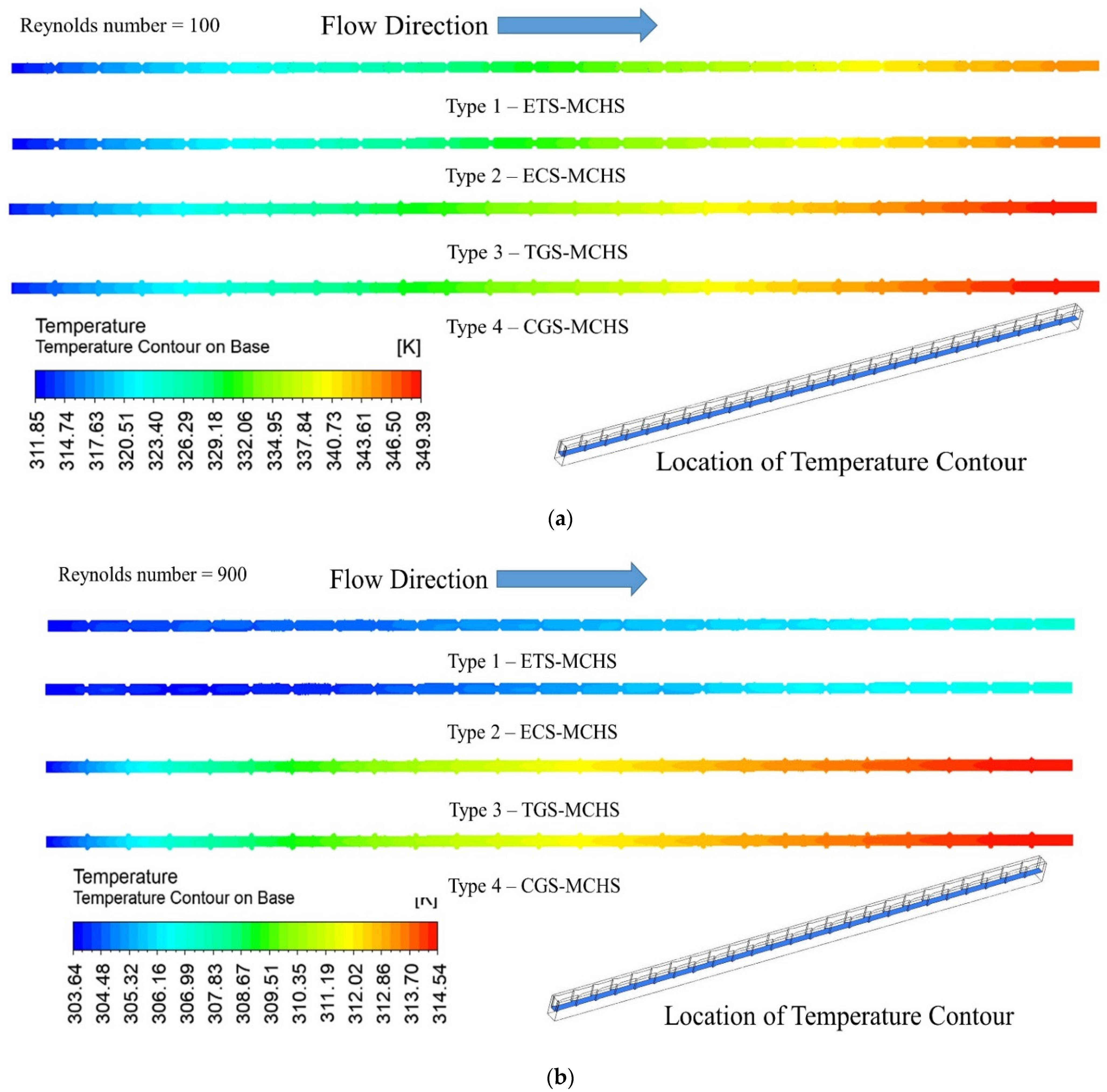

3.3. Temperature Distribution

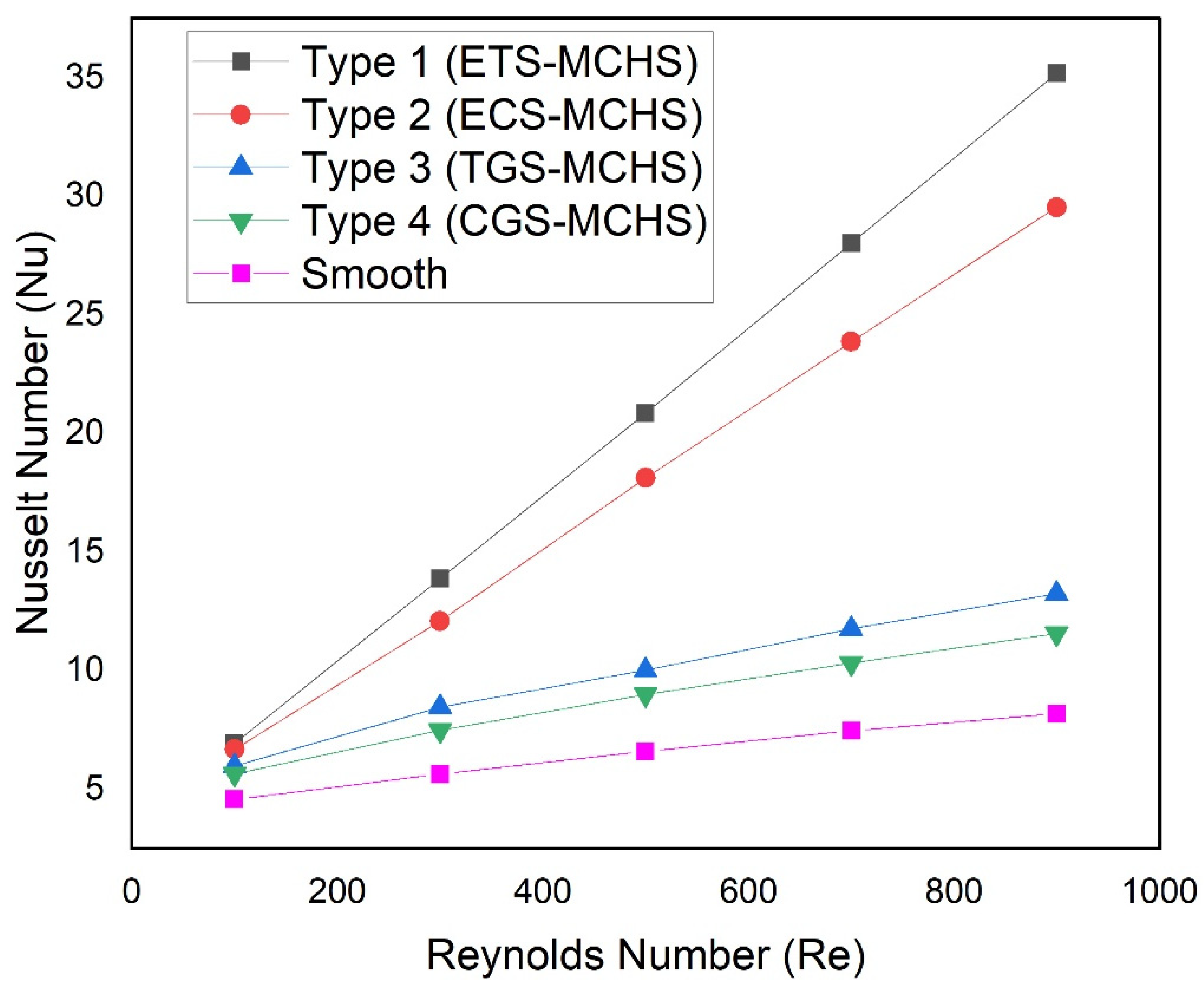

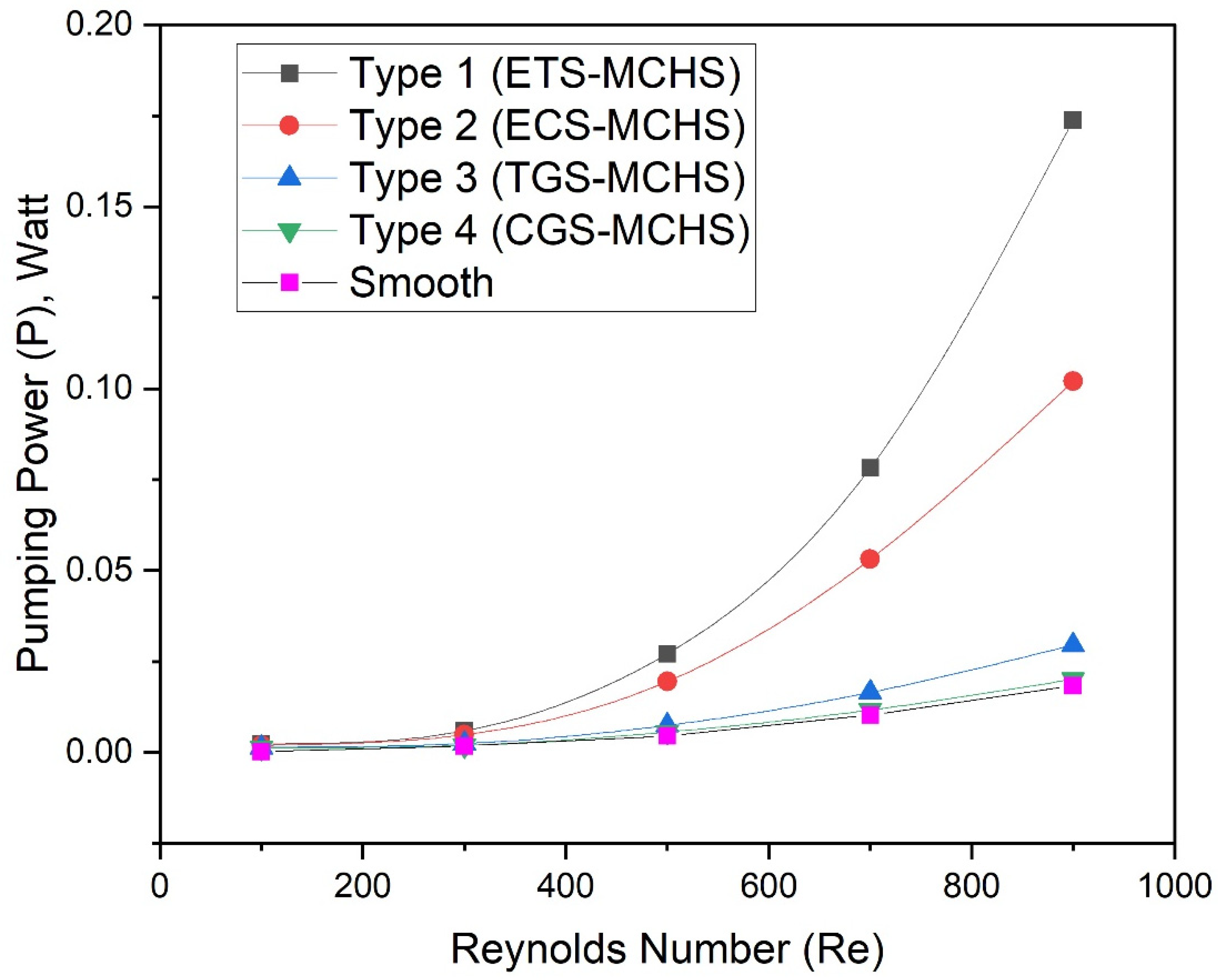

3.4. Performance Analysis

4. Conclusions

- The highest Nusselt number has been observed in the case of the Type 1 (ETS-MCHS) in the range of 6.92–35.19, while lowest Nusselt number was observed in the case of Type 2 (ECS-MCHS) in the range of 5.63–11.55. Similarly, the highest friction factor has been observed in the case of Type 1 (ETS-MCHS) in the range of 0.3–0.140, while lowest was observed in the case of Type 2 (ECS-MCHS) in the range of 0.165–0.032;

- Nu and f enhancement factors have been determined. The maximum enhancement of Nu and f are found to be 4.3 and 7.33 in the case of Type 1 (ETS-MCHS), while the minimum enhancement of Nu and f are found to be 1.23 and 1.12 in the case of Type 4 (CGS-MCHS);

- Pumping power is showed to be significantly higher for Type 1 (ETS-MCHS) and Type 2 (ECS-MCHS), whereas Type 3 (TGS-MCH) and Type 4 (CGS-MCHS) geometries do not contribute to considerable pumping power;

- Comparatively higher thermal performance parameters (THPPs) are found for Type 1 (ETS-MCHS) and Type 2 (ECS-MCHS), which have advantages over Type 3 (TGS-MCH), Type 4 (CGS-MCHS), and those without geometrical modifications.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Ac | Convective heat transfer area (mm2) |

| Aq | Base Area of Channel (mm2) |

| Cp | Specific Heat (J/kg⋅K) |

| Dh | Hydraulic Diameter (mm) |

| E | Young Moduls (GPa) |

| f | Friction Factor |

| L | Length (mm) |

| h | Convective eat transfer coefficient (W/mm2·°K) |

| H | Height of passage (mm) |

| k | Thermal Conductivity (W/m·°K) |

| Nu | Nusselt Number |

| p | Pressure (Pa) |

| ∆p | Pressure Drop |

| P | Pumping power (w) |

| q | Heat Flux (W/m2) |

| Re | Reynolds Number |

| T | Temperature (K) |

| u | Velocity (m/s) |

| W | Width of microchannel (m) |

| Greek letters | |

| α | Poisson’s ratio |

| β | Thermal expansion [1/K] |

| μ | Dynamic Viscosity (N·s/m2) |

| η | Thermohydraulic performance parameters (THPP) |

| Density (kg/m3) | |

| Subscripts | |

| in | Inlet |

| o | Outlet |

| mc | Microchannel base |

| f | Fluid (coolant) |

| s | Conventional |

References

- Siddiqui, O.K.; Zubair, S.M. Efficient energy utilization through proper design of microchannel heat exchanger manifolds: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 74, 969–1002. [Google Scholar] [CrossRef]

- Kumar, A.; Verma, S.K. Design and development of e-smart robotics-based underground solid waste storage and transportation system. J. Clean. Prod. 2022, 343, 1–34. [Google Scholar] [CrossRef]

- Sadiq Al-Baghdadi, M.A.R.; Noor, Z.M.H.; Zeiny, A.; Burns, A.; Wen, D. CFD analysis of a nanofluid-based microchannel heat sink. Therm. Sci. Eng. Prog. 2020, 20, 100685. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar Verma, S. Performance estimation of Triangular Solar air heater roughened absorber surface: An experimental and simulation modeling. Sustain. Energy Technol. Assessments 2022, 52, 13–15. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar Verma, S. Numerical investigation of performance analysis of Triangular Solar air heater using Computational Fluid Dynamics (CFD). IOP Conf. Ser. Mater. Sci. Eng. 2021, 1116, 012047. [Google Scholar] [CrossRef]

- Verma, G.; Singh, S.; Chander, S.; Dhiman, P. Numerical investigation on transient thermal performance predictions of phase change material embedded solar air heater. J. Energy Storage 2022, 47, 20–22. [Google Scholar] [CrossRef]

- Alam, T.; Balam, N.B.; Kulkarni, K.S.; Siddiqui, M.I.H.; Kapoor, N.R.; Meena, C.S.; Kumar, A.; Cozzolino, R. Performance augmentation of the flat plate solar thermal collector: A review. Energies 2021, 14, 6203. [Google Scholar] [CrossRef]

- Vatsa, A.; Alam, T.; Siddiqui, M.I.H.; Ali, M.A.; Dobrotă, D. Performance of Microchannel Heat Sink Made of Silicon Material with the Two-Sided Wedge. Materials 2022, 15, 4740. [Google Scholar] [CrossRef]

- Pandey, A.K.; Kumar, R.R.; B, K.; Laghari, I.A.; Samykano, M.; Kothari, R.; Abusorrah, A.M.; Sharma, K.; Tyagi, V.V. Utilization of solar energy for waste water treatment: Challenges and progressive research trends. J. Environ. Manag. 2021, 297, 113300. [Google Scholar] [CrossRef]

- Chai, L.; Wang, L.; Bai, X. Thermohydraulic performance of microchannel heat sinks with triangular ribs on sidewalls—Part 1: Local fluid flow and heat transfer characteristics. Int. J. Heat Mass Transf. 2018, 127, 1124–1137. [Google Scholar] [CrossRef]

- Park, M.C.; Ma, S.B.; Kim, K.Y. Optimization of a wavy microchannel heat sink with grooves. Processes 2021, 9, 373. [Google Scholar] [CrossRef]

- Khetib, Y.; Abo-Dief, H.M.; Alanazi, A.K.; Sajadi, S.M.; Sharifpur, M.; Meyer, J.P. A computational fluid dynamic study on efficiency of a wavy microchannel/heat sink containing various nanoparticles. Micromachines 2021, 12, 1192. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Huang, J.; Wang, J.; Li, H. Heat transfer and fluid flow characteristics of microchannel with oval-shaped micro pin fins. Entropy 2021, 23, 1482. [Google Scholar] [CrossRef]

- Wang, G.; Feng, L.; Altanji, M.; Sharma, K.; Nisar, K.S.; Khorasani, S. Proposing novel “L” shaped fin to boost the melting performance of a vertical PCM enclosure. Case Stud. Thermal Eng. 2021, 28, 101465. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, S.; Mustafa, M.K.A.; Shalan, A.E. Effect of 2D perovskite layer and multivalent defect on the performance of 3D/2D bilayered perovskite solar cells through computational simulation studies. Solar Energy. 2021, 223, 616–626. [Google Scholar] [CrossRef]

- He, W.; Mashayekhi, R.; Toghraie, D.; Akbari, O.A.; Li, Z.; Tlili, I. Hydrothermal performance of nanofluid flow in a sinusoidal double layer microchannel in order to geometric optimization. Int. Commun. Heat Mass Transf. 2020, 117, 104700. [Google Scholar] [CrossRef]

- Eneren, P.; Aksoy, Y.T.; Vetrano, M.R. Experiments on Single-Phase Nanofluid Heat Transfer Mechanisms in Microchannel Heat Sinks: A Review. Energies 2022, 15, 2525. [Google Scholar] [CrossRef]

- Yadav, V.; Baghel, K.; Kumar, R.; Kadam, S.T. Numerical investigation of heat transfer in extended surface microchannels. Int. J. Heat Mass Transf. 2016, 93, 612–622. [Google Scholar] [CrossRef]

- Duan, Z.; Ma, H.; He, B.; Su, L.; Zhang, X. Pressure drop of microchannel plate fin heat sinks. Micromachines 2019, 10, 80. [Google Scholar] [CrossRef] [Green Version]

- Ligrani, P.M.; Harrison, J.L.; Mahmmod, G.I.; Hill, M.L. Flow structure due to dimple depressions on a channel surface. Phys. Fluids 2001, 13, 3442–3451. [Google Scholar] [CrossRef]

- Parashar, A.K.; Gupta, A. Investigation of the effect of bagasse ash, hooked steel fibers and glass fibers on the mechanical properties of concrete. Mater. Today Proc. 2021, 44, 801–807. [Google Scholar] [CrossRef]

- Derakhshanpour, K.; Kamali, R.; Eslami, M. Effect of rib shape and fillet radius on thermal-hydrodynamic performance of microchannel heat sinks: A CFD study. Int. Commun. Heat Mass Transf. 2020, 119, 104928. [Google Scholar] [CrossRef]

- Tuckerman, D.B.; Pease, R.F.W. High-Performance Heat Sinking for VLSI. IEEE Electron Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Steinke, M.E.; Kandlikar, S.G. Single-phase liquid friction factors in microchannels. Int. J. Therm. Sci. 2006, 45, 1073–1083. [Google Scholar] [CrossRef]

- Huang, B.; Li, H.; Xu, T. Experimental investigation of the flow and heat transfer characteristics in microchannel heat exchangers with reentrant cavities. Micromachines 2020, 11, 403. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chai, L.; Xia, G.; Wang, L.; Zhou, M.; Cui, Z. Heat transfer enhancement in microchannel heat sinks with periodic expansion-constriction cross-sections. Int. J. Heat Mass Transf. 2013, 62, 741–751. [Google Scholar] [CrossRef]

- Doan, M.; Dang, T.; Nguyen, X. The effects of gravity on the pressure drop and heat transfer characteristics of steam in microchannels: An experimental study. Energies 2020, 13, 3575. [Google Scholar] [CrossRef]

- Gaikwad, V.P.; Mohite, S.S. Performance analysis of microchannel heat sink with flow disrupting pins. J. Therm. Eng. 2022, 8, 402–425. [Google Scholar] [CrossRef]

- Kumar, S.R.; Singh, S. CFD analysis for heat transfer and fluid flow in microchannel heat sink with micro inserts. Mater. Today Proc. 2021, 46, 11213–11216. [Google Scholar] [CrossRef]

- Shui, L.; Sun, J.; Gao, F.; Zhang, C. Flow and heat transfer in the tree-like branching microchannel with/without dimples. Entropy 2018, 20, 379. [Google Scholar] [CrossRef]

- Ambreen, T.; Kim, M.H. Effects of variable particle sizes on hydrothermal characteristics of nanofluids in a microchannel. Int. J. Heat Mass Transf. 2018, 120, 490–498. [Google Scholar] [CrossRef]

- Gunnasegaran, P.; Mohammed, H.A.; Shuaib, N.H.; Saidur, R. The effect of geometrical parameters on heat transfer characteristics of microchannels heat sink with different shapes. Int. Commun. Heat Mass Transf. 2010, 37, 1078–1086. [Google Scholar] [CrossRef]

- Mahmood, G.I.; Ligrani, P.M. Heat transfer in a dimpled channel: Combined influences of aspect ratio, temperature ratio, Reynolds number, and flow structure. Int. J. Heat Mass Transf. 2002, 45, 2011–2020. [Google Scholar] [CrossRef]

- Saha, S.; Alam, T.; Siddiqui, M.I.H.; Kumar, M.; Ali, M.A.; Gupta, N.K.; Dobrotă, D. Analysis of Microchannel Heat Sink of Silicon Material with Right Triangular Groove on Sidewall of Passage. Materials 2022, 15, 7020. [Google Scholar] [CrossRef] [PubMed]

- Pandey, L.; Singh, S. Numerical analysis for heat transfer augmentation in a circular tube heat exchanger using a triangular perforated Y-shaped insert. Fluids 2021, 6, 247. [Google Scholar] [CrossRef]

- Mashali, F.; Languri, E.M.; Davidson, J.; Kerns, D.; Johnson, W.; Nawaz, K.; Cunningham, G. Thermo-physical properties of diamond nanofluids: A review. Int. J. Heat Mass Transf. 2019, 129, 1123–1135. [Google Scholar] [CrossRef]

- Ali, A.M.; Rona, A.; Kadhim, H.T.; Angelino, M.; Gao, S. Thermo-hydraulic performance of a circular microchannel heat sink using swirl flow and nanofluid. Appl. Therm. Eng. 2021, 191, 116817. [Google Scholar] [CrossRef]

- Datta, A.; Sharma, V.; Sanyal, D.; Das, P. A conjugate heat transfer analysis of performance for rectangular microchannel with trapezoidal cavities and ribs. Int. J. Therm. Sci. 2019, 138, 425–446. [Google Scholar] [CrossRef]

- Khalesi, J.; Sarunac, N. Numerical analysis of flow and conjugate heat transfer for supercritical CO2 and liquid sodium in square microchannels. Int. J. Heat Mass Transf. 2019, 132, 1187–1199. [Google Scholar] [CrossRef]

- Boonloi, A.; Jedsadaratanachai, W. Thermo-hydraulic performance improvement, heat transfer, and pressure loss in a channel with sinusoidal-wavy surface. Adv. Mech. Eng. 2019, 11, 1–17. [Google Scholar] [CrossRef]

- Madhava Reddy, H.; Venu Vinod, A. CFD simulation of the heat transfer using nanofluids in microchannel with dimple and protrusion. Indian Chem. Eng. 2019, 61, 40–51. [Google Scholar] [CrossRef]

- Colgan, E.G.; Furman, B.; Gaynes, M.; Graham, W.S.; LaBianca, N.C.; Magerlein, J.H.; Polastre, R.J.; Rothwell, M.B.; Bezama, R.J.; Choudhary, R.; et al. A practical implementation of silicon microchannel coolers for high power chips. IEEE Trans. Components Packag. Technol. 2007, 30, 218–225. [Google Scholar] [CrossRef]

| Fluid | Density [kg/m3] | Dynamic Viscosity μ [Pa·s] | Specific Heat Cp [J/kg·K] | Thermal Conductivity k [W/m·K] |

|---|---|---|---|---|

| Water | 998.2 | 0.001 | 4182 | 0.60 |

| Material | Density ρs [kg/m3] | Poisson’s Ratio α | Specific Heat Cps [J/kg·K] | Thermal Conductivity ks [W/m·K] | Thermal Expansion β [1/K] | Young’s Modulus Es [Pa] |

|---|---|---|---|---|---|---|

| Silicon | 2329 | 0.28 | 700 | 130 | 2.6 × 10−6 | 170 × 109 |

| Location | Boundary Conditions |

|---|---|

| Inlet | Velocity inlet based on the Reynolds number at 300 °K |

| Outlet | Zero pressure gauge |

| Bottom of the MCHS | Heat flux 1.0 × 106 W/m2 |

| Side Walls of MCHS | Symmetry |

| Serial Number | Nodes | Element | Friction Factor (f) | Percentage Variation in Friction Factor (f) |

|---|---|---|---|---|

| 1 | 6,28,778 | 32,51,880 | 0.1569 | - |

| 2 | 10,59,696 | 55,99,292 | 0.1573 | 0.25 |

| 3 | 14,30,704 | 76,57,556 | 0.1575 | 0.135 |

| 4 | 19,89,479 | 1,08,08,376 | 0.1577 | 0.098 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumari, N.; Alam, T.; Ali, M.A.; Yadav, A.S.; Gupta, N.K.; Siddiqui, M.I.H.; Dobrotă, D.; Rotaru, I.M.; Sharma, A. A Numerical Investigation on Hydrothermal Performance of Micro Channel Heat Sink with Periodic Spatial Modification on Sidewalls. Micromachines 2022, 13, 1986. https://doi.org/10.3390/mi13111986

Kumari N, Alam T, Ali MA, Yadav AS, Gupta NK, Siddiqui MIH, Dobrotă D, Rotaru IM, Sharma A. A Numerical Investigation on Hydrothermal Performance of Micro Channel Heat Sink with Periodic Spatial Modification on Sidewalls. Micromachines. 2022; 13(11):1986. https://doi.org/10.3390/mi13111986

Chicago/Turabian StyleKumari, Nikita, Tabish Alam, Masood Ashraf Ali, Anil Singh Yadav, Naveen Kumar Gupta, Md Irfanul Haque Siddiqui, Dan Dobrotă, Ionela Magdalena Rotaru, and Abhishek Sharma. 2022. "A Numerical Investigation on Hydrothermal Performance of Micro Channel Heat Sink with Periodic Spatial Modification on Sidewalls" Micromachines 13, no. 11: 1986. https://doi.org/10.3390/mi13111986

APA StyleKumari, N., Alam, T., Ali, M. A., Yadav, A. S., Gupta, N. K., Siddiqui, M. I. H., Dobrotă, D., Rotaru, I. M., & Sharma, A. (2022). A Numerical Investigation on Hydrothermal Performance of Micro Channel Heat Sink with Periodic Spatial Modification on Sidewalls. Micromachines, 13(11), 1986. https://doi.org/10.3390/mi13111986