Improved VMD-ELM Algorithm for MEMS Gyroscope of Temperature Compensation Model Based on CNN-LSTM and PSO-SVM

Abstract

:1. Introduction

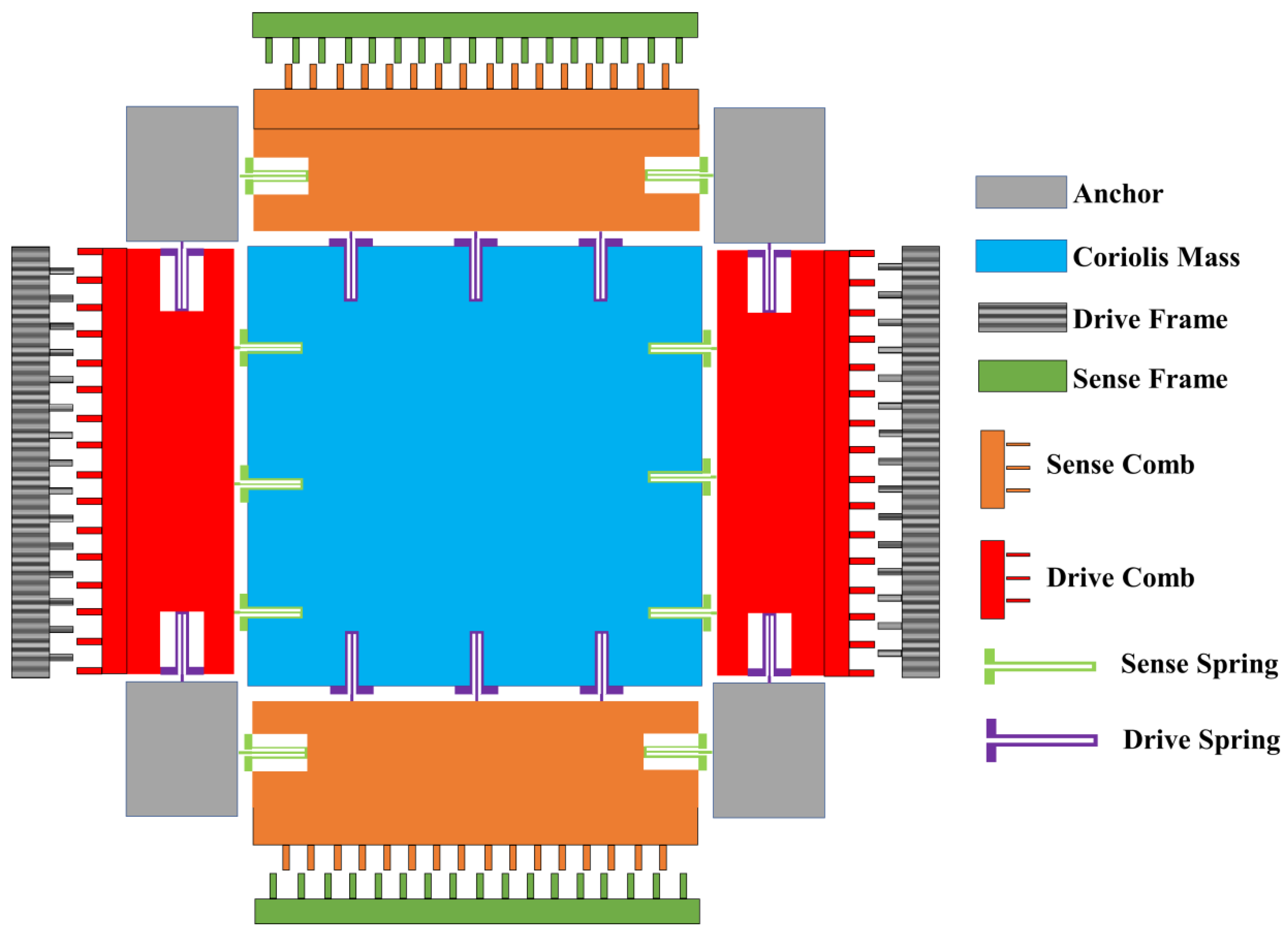

2. Structure of MEMS Gyroscope

3. Algorithms

3.1. The Algorithm of VMD

- (1)

- Initialize , let .

- (2)

- , start the cycle.

- (3)

- Update according to Equations (3)–(17), update according to Equations (3)–(20).

- (4)

- , repeat step (3). If , the cycle ends, and if , the cycle continues.

- (5)

- is updated according to the following expression.

- (6)

- Steps (2) to (5) are repeated, with the given precision convergence criterion, and is judged to whether it is satisfied. If so, turn to this step and stop the iteration to obtain IMF components. Otherwise, skip to step (2).

3.2. The Algorithm of CNN-LSTM

| Algorithm 1. CNN model |

| Input: Output: For each positionjin the signal, perform | | End //Max pooling operation |

| Algorithm 2. LSTM mode |

| Input: Signal with noise Output: Signal For each time step t, perform | | | | | | End |

3.3. The Algorithm of PSO-SVM

- Step1: For each particle in the population, its fitness needs to be calculated.

- Step2: For each particle, the best fitness value passed by it is compared with the fitness value. If it is better, it is treated as a locally optimal particle.

- Step3: For each generation of optimal particles, the global optimal particle is compared with its fitness value, and if it is better, it can be taken as the global optimal particle.

- Step4: The speed and position of the particles are adjusted according to the above formula.

- Step5: If the corresponding conditions are not met, go back to step 1.

- The termination condition of the algorithm iteration is that the optimal position searched by the particle swarm reaches the minimum fitness threshold or the algorithm has iterated to the set maximum number of iterations.

3.4. The Algorithm of ELM

- Step1:Given a training set , the activation function is , the number of hidden layer nodes is , the random initialization input weight is , and the hidden layer node offset is .

- Step2: Calculate the hidden layer output matrix .

- Step3: Calculate the output weight matrix .

4. The Improved VMD and ELM Algorithm Based on CNN-LSTM and PSO-SVM

5. Experiment and Analysis

5.1. Experiment Process

5.2. Data Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, M.; Huang, Y.; Wang, W.; Cao, H. MEMS Gyroscope Temperature Compensation Based on Drive Mode Vibration Characteristic Control. Micromachines 2019, 10, 248. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cui, J.; Yan, G.; Zhao, Q. Enhanced temperature stability of scale factor in MEMS gyroscope based on multi parameters fusion compensation method. Measurement 2019, 148, 106947. [Google Scholar] [CrossRef]

- Yin, T.; Lin, Y.; Yang, H.; Wu, H. A Phase Self-Correction Method for Bias TemperatureDrift Suppression of MEMS Gyroscopes. J. Circuits Syst. Comput. 2020, 29, 12. [Google Scholar] [CrossRef]

- Bu, F.; Fan, B.; Xu, D.; Guo, S.; Zhao, H. Bandwidth and noise analysis of high-Q MEMS gyroscope under force rebalance closed-loop control. J. Micromech. Microeng. 2021, 31, 065002. [Google Scholar] [CrossRef]

- Xia, D.; Yu, C.; Kong, L. The Development of Micromachined Gyroscope Structure and Circuitry Technology. Sensors 2014, 14, 1394–1473. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pistorio, F.; Saleem, M.M.; Somà, A. A Dual-Mass Resonant MEMS Gyroscope Design with Electrostatic Tuning for Frequency Mismatch Compensation. Appl. Sci. 2021, 11, 1129. [Google Scholar] [CrossRef]

- Nesterenko, T.G.; Koleda, A.N.; Barbin, E.S.; Uchaikin, S.V. Temperature Error Compensation in Two-Component Microelectromechanical Gyroscope. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1598–1605. [Google Scholar] [CrossRef]

- Guo, Z.; Fu, P.; Liu, D.; Huang, M. Design and FEM simulation for a novel resonant silicon MEMS gyroscope with temperature compensation function. Microsyst. Technol. 2017, 24, 1453–1459. [Google Scholar] [CrossRef]

- Fu, Q.; Di, X.-P.; Chen, W.-P.; Yin, L.; Liu, X.-W. A temperature characteristic research and compensation design for micro-machined gyroscope. Mod. Phys. Lett. B 2017, 31, 17500646. [Google Scholar] [CrossRef]

- Cao, H.; Li, H.; Shao, X.; Liu, Z.; Kou, Z.; Shan, Y.; Shi, Y.; Shen, C.; Liu, J. Sensing mode coupling analysis for dual-mass MEMS gyroscope and bandwidth expansion within wide-temperature range. Mech. Syst. Signal Process. 2018, 98, 448–464. [Google Scholar] [CrossRef]

- Cao, H.; Liu, Y.; Zhang, Y.; Shao, X.; Gao, J.; Huang, K.; Shi, Y.; Tang, J.; Shen, C.; Liu, J. Design and Experiment of Dual-Mass MEMS Gyroscope Sense Closed System Based on Bipole Compensation Method. IEEE Access 2019, 7, 49111–49124. [Google Scholar] [CrossRef]

- Cao, H.; Cao, H.; Xue, R.; Xue, R.; Cai, Q.; Cai, Q.; Gao, J.; Gao, J.; Zhao, R.; Zhao, R.; et al. Design and Experiment for Dual-Mass MEMS Gyroscope Sensing Closed-Loop System. IEEE Access 2020, 8, 48074–48087. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Zhang, Y.; Fu, Q. A digital output MEMS DRG on-chip temperature compensation method based on virtual sensor. Mod. Phys. Lett. B 2020, 34, 2050422. [Google Scholar] [CrossRef]

- Chong, S.; Song, R.; Li, J.; Zhang, M.; Tang, J.; Shi, B.; Liu, J.; Cao, H. Temperature drift modeling of MEMS gyroscope based on genetic-Elman neural network. Mech. Syst. Signal Process. 2016, 72, 897–905. [Google Scholar] [CrossRef]

- Cao, H.; Zhang, Y.; Shen, C.; Liu, Y.; Wang, X. Temperature Energy Influence Compensation for MEMS Vibration Gyroscope Based on RBF NN-GA-KF Method. Shock Vib. 2018, 2018, 2830686. [Google Scholar] [CrossRef]

- Shen, C.; Li, J.; Zhang, X.; Tang, J.; Cao, H.; Liu, J. Multi-scale parallel temperature error processing for dual-mass MEMS gyroscope. Sens. Actuators A Phys. 2016, 245, 160–168. [Google Scholar] [CrossRef]

- Wu, Y.; Shen, C.; Cao, H.; Che, X.; Wu, Y.C.; Shen, C.; Cao, H.L.; Chen, X. Improved Morphological Filter Based on Variational Mode Decomposition for MEMS Gyroscope De-Noising. Micromachines 2018, 9, 246. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, H.; Hu, S.; Zhang, J. LSTM based prediction algorithm and abnormal change detection for temperature in aerospace gyroscope shell. Int. J. Intell. Comput. Cybern. 2019, 12, 274–291. [Google Scholar] [CrossRef]

- Ma, T.; Li, Z.; Cao, H.; Shen, C.; Wang, Z. A Parallel Denoising Model for Dual-Mass MEMS Gyroscope Based on PE-ITD and SA-ELM. IEEE Access 2019, 7, 169979–169991. [Google Scholar] [CrossRef]

- Chang, L.; Cao, H.; Shen, C. Dual-Mass MEMS Gyroscope Parallel Denoising and Temperature Compensation Processing Based on WLMP and CS-SVR. Micromachines 2020, 11, 586. [Google Scholar] [CrossRef] [PubMed]

- Gu, H.; Zhao, B.; Zhou, H.; Liu, X.; Su, W. MEMS Gyroscope Bias Drift Self-Calibration Based on Noise-Suppressed Mode Reversal. Micromachines 2019, 10, 823. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, J.; Shi, Z.; Du, B.; Han, L.; Wang, H.; Wang, Z. MEMS gyroscope wavelet de-noising method based on redundancy and sparse representation. Microelectron. Eng. 2019, 217, 111112. [Google Scholar] [CrossRef]

- Ding, M.K.; Shi, Z.; Du, B.; Wang, H.; Han, L. A signal de-noising method for a MEMS gyroscope based on improved VMD-WTD. Meas. Sci. Technol. 2021, 32, 095112. [Google Scholar] [CrossRef]

- Zhang, R.; Xu, B.; Wei, Q.; Yang, T.; Zhao, W.; Zhang, P. Serial-Parallel Estimation Model-Based Sliding Mode Control of MEMS Gyroscopes. IEEE Trans. Syst. Man Cybern. Syst. 2020, 51, 7764–7775. [Google Scholar] [CrossRef]

- Wang, P.; Li, G.; Gao, Y. A compensation method for gyroscope random drift based on unscented Kalman filter and support vector regression optimized by adaptive beetle antennae search algorithm. Appl. Intell. 2022, 1–16. [Google Scholar] [CrossRef]

- Huang, F.; Wang, Z.; Xing, L.; Gao, C. A MEMS IMU Gyroscope Calibration Method Based on Deep Learning. IEEE Trans. Instrum. Meas. 2022, 71, 1–9. [Google Scholar] [CrossRef]

- Cao, H.; Li, H.; Kou, Z.; Shi, Y.; Tang, J.; Ma, Z.; Shen, C.; Liu, J. Optimization and Experimentation of Dual-Mass MEMS Gyroscope Quadrature Error Correction Methods. Sensors 2016, 16, 71. [Google Scholar] [CrossRef] [Green Version]

- Cao, H.; Cai, Q.; Zhang, Y.; Shen, C.; Shi, Y.; Liu, J. Design, Fabrication, and Experiment of a Decoupled Multi-Frame Vibration MEMS Gyroscope. IEEE Sens. J. 2021, 21, 19815–19824. [Google Scholar] [CrossRef]

- Cao, H.; Wei, W.; Liu, L.; Ma, T.; Zhang, Z.; Zhang, W.; Shen, C.; Duan, X. A Temperature Compensation Approach for Dual-Mass MEMS Gyroscope Based on PE-LCD and ANFIS. IEEE Access 2021, 9, 95180–95193. [Google Scholar] [CrossRef]

- Ma, T.; Cao, H.; Shen, C. A Temperature Error Parallel Processing Model for MEMS Gyroscope based on a Novel Fusion Algorithm. Electronics 2020, 9, 499. [Google Scholar] [CrossRef]

- Li, Z.; Gu, Y.; Yang, J.; Cao, H.; Wang, G. A Noise Reduction Method for Four-Mass Vibration MEMS Gyroscope Based on ILMD and PTTFPF. Micromachines 2022, 13, 1807. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Specific Operation |

|---|---|

| Number of CNN-LSTM modules | 4 |

| Input | Noise |

| Data normalization | Min–Max |

| Number of LSTM units | 5 |

| Number of LSTM layers | 2 |

| Softmax layer | Softmax |

| Loss function | MSE |

| Number of iteration rounds | 500 |

| Original Signal | Denoising Signal | |||

|---|---|---|---|---|

| Allan | −40–60 °C | 60—40 °C | −40–60 °C | 60—40 °C |

| Q () | 1.2419 × 10−4 | 2.9808 × 10−4 | 1.0533 × 10−6 | 2.4430 × 10−6 |

| N () | 2.0978 × 10−5 | 4.5072 × 10−5 | 1.4985 × 10−6 | 1.0523 × 10−5 |

| B () | 0.0087 | 0.0145 | 1.8772 × 10−4 | 7.2426 × 10−4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Cao, H. Improved VMD-ELM Algorithm for MEMS Gyroscope of Temperature Compensation Model Based on CNN-LSTM and PSO-SVM. Micromachines 2022, 13, 2056. https://doi.org/10.3390/mi13122056

Wang X, Cao H. Improved VMD-ELM Algorithm for MEMS Gyroscope of Temperature Compensation Model Based on CNN-LSTM and PSO-SVM. Micromachines. 2022; 13(12):2056. https://doi.org/10.3390/mi13122056

Chicago/Turabian StyleWang, Xinwang, and Huiliang Cao. 2022. "Improved VMD-ELM Algorithm for MEMS Gyroscope of Temperature Compensation Model Based on CNN-LSTM and PSO-SVM" Micromachines 13, no. 12: 2056. https://doi.org/10.3390/mi13122056