Influencing Effects of Fabrication Errors on Performances of the Dielectric Metalens

Abstract

1. Introduction

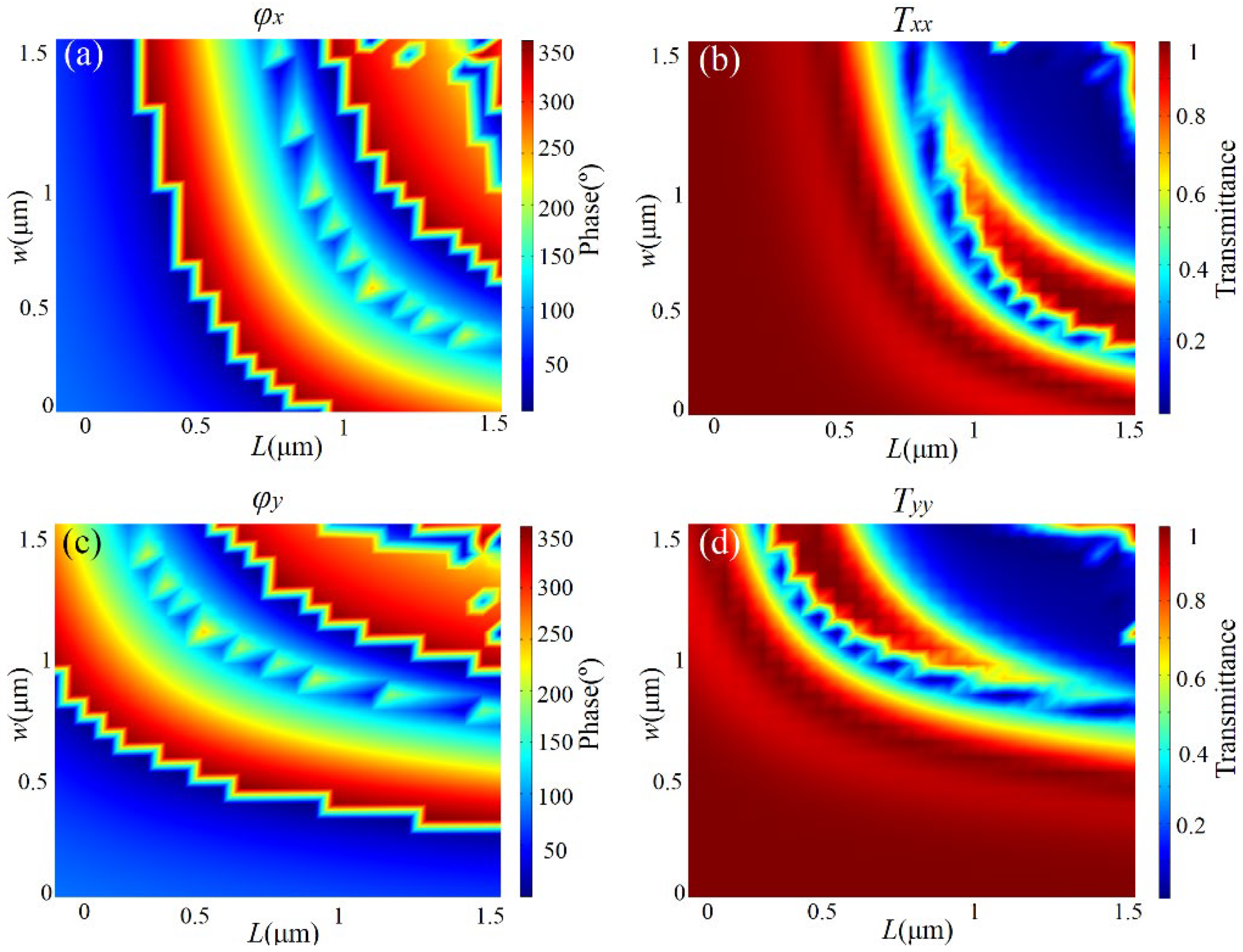

2. Structure Design

3. Results and Discussions

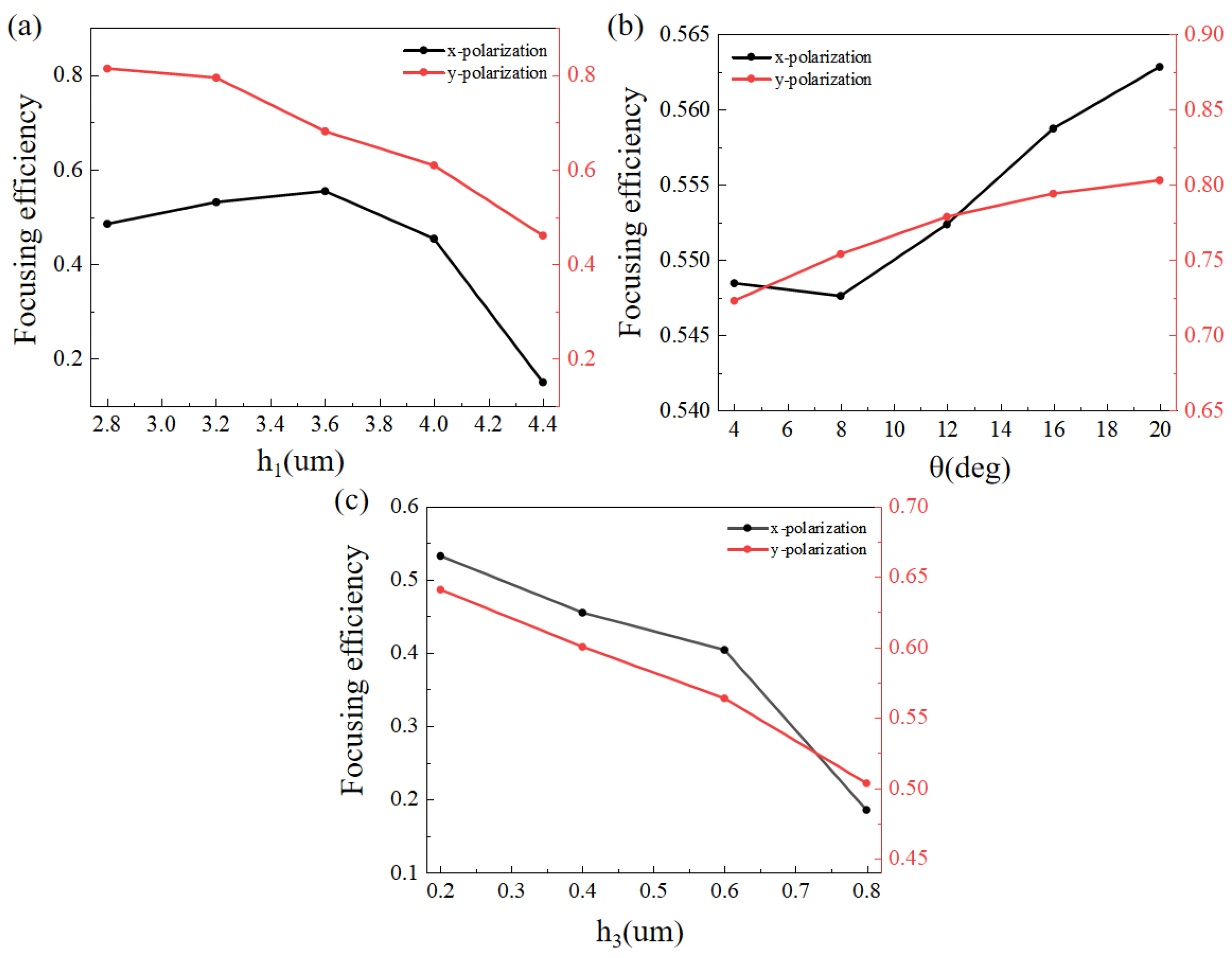

3.1. Deviation of Height

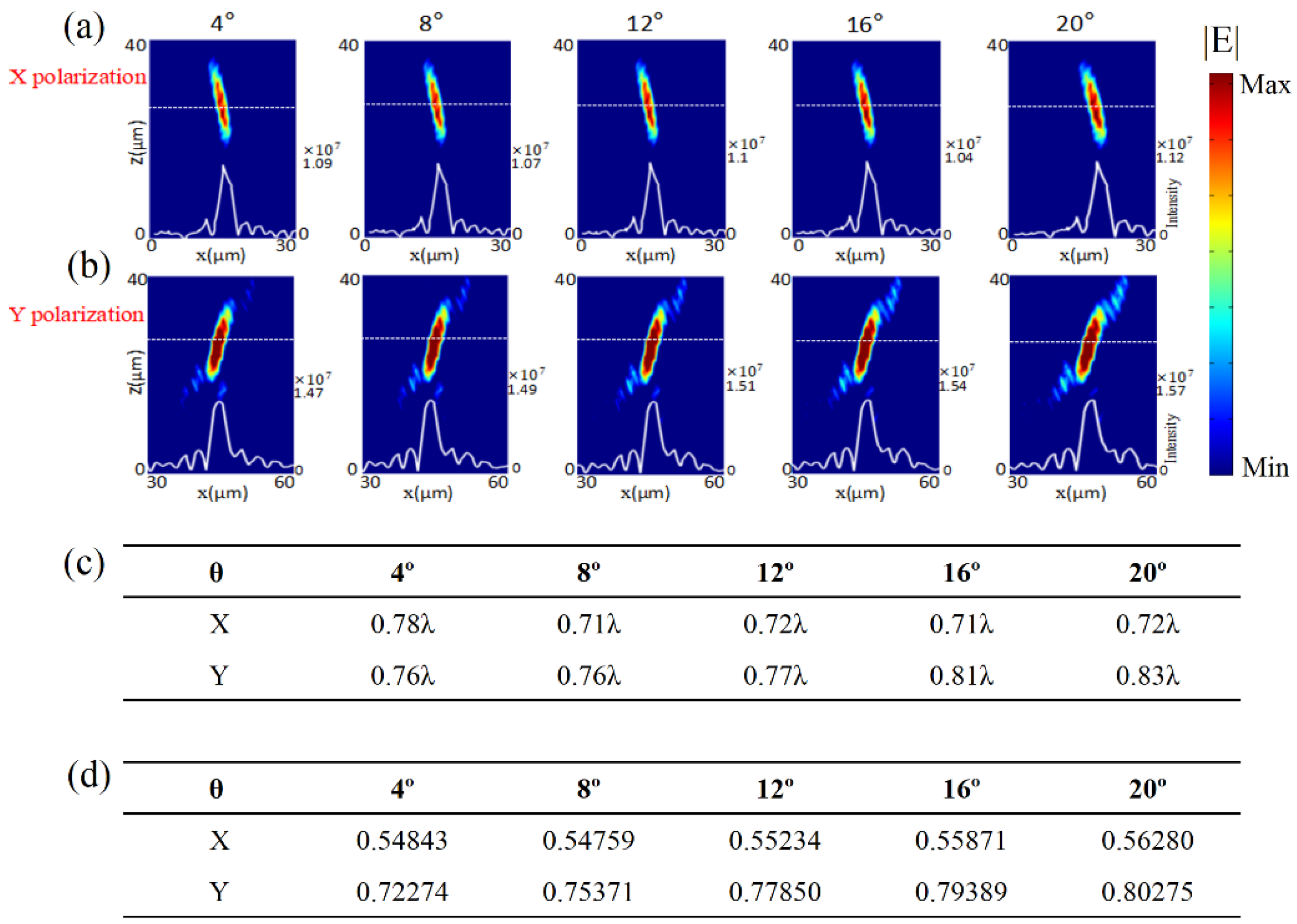

3.2. Trapezoidal Error

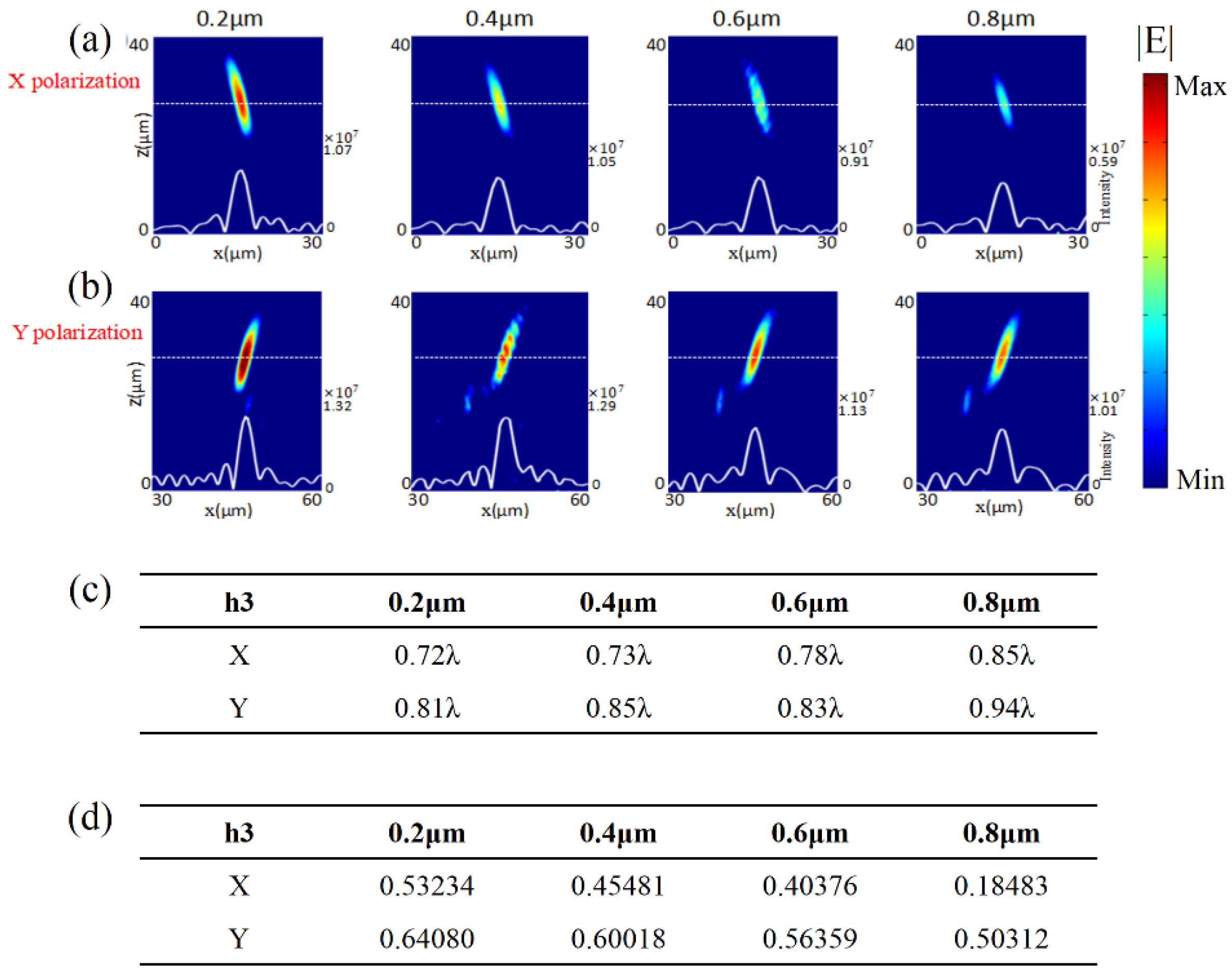

3.3. Elliptical Error

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Assouar, B.; Liang, B.; Wu, Y.; Li, Y.; Cheng, J.C.; Jing, Y. Acoustic metasurfaces. Nat. Rev. Mater. 2018, 3, 460–472. [Google Scholar] [CrossRef]

- Glybovski, S.B.; Tretyakov, S.A.; Belov, P.A.; Kivshar, Y.S.; Simovski, C.R. Metasurfaces: From microwaves to visible. Phys. Rep. 2016, 634, 1–72. [Google Scholar] [CrossRef]

- Wang, B.; Dong, F.; Li, Q.T.; Yang, D.; Sun, C.; Chen, J.; Li, Y. Visible-frequency dielectric metasurfaces for mul-tiwavelength achromatic and highly dispersive holograms. Nano Lett. 2016, 16, 5235–5240. [Google Scholar] [CrossRef]

- Ding, F.; Chang, B.; Wei, Q.; Huang, L.; Guan, X.; Bozhevolnyi, S.I. Versatile polarization generation and manipu-lation using dielectric metasurfaces. Laser Photonics Rev. 2020, 14, 2000116. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhou, C.; Yuan, B.G.; Wu, D.J.; Wei, Q.; Liu, X.J. Ultra-sparse metasurface for high reflection of low-frequency sound based on artificial Mie resonances. Nat. Mater. 2015, 14, 1013–1019. [Google Scholar] [CrossRef] [PubMed]

- Cheben, P.; Halir, R.; Schmid, J.H.; Atwater, H.A.; Smith, D.R. Subwavelength integrated photonics. Nature 2018, 560, 565–572. [Google Scholar] [CrossRef]

- Tsilipakos, O.; Koschny, T.; Soukoulis, C.M. Antimatched Electromagnetic Metasurfaces for Broadband Arbitrary Phase Manipulation in Reflection. ACS Photonics 2018, 5, 1101–1107. [Google Scholar] [CrossRef]

- Galiffi, E.; Pendry, J.; Huidobro, P.A. Broadband Tunable THz Absorption with Singular Graphene Metasurfaces. ACS Nano 2018, 12, 1006–1013. [Google Scholar] [CrossRef]

- Sobucki, K.; Śmigaj, W.; Rychły, J.; Krawczyk, M.; Gruszecki, P. Resonant subwavelength control of the phase of spin waves reflected from a Gires–Tournois interferometer. Sci. Rep. 2021, 11, 4428. [Google Scholar] [CrossRef]

- Zhang, Y.; Fowler, C.; Liang, J.; Azhar, B.; Shalaginov, M.Y.; Deckoff-Jones, S.; Hu, J. Electrically reconfigurable non-volatile metasurface using low-loss optical phase-change material. Nat. Nanotechnol. 2021, 16, 661–666. [Google Scholar] [CrossRef]

- Monticone, F.; Alù, A. Metamaterials and plasmonics: From nanoparticles to nanoantenna arrays, metasurfaces, and metamaterials. Chin. Phys. B 2014, 23, 047809. [Google Scholar] [CrossRef]

- Aoni, R.A.; Rahmani, M.; Xu, L.; Kamali, K.Z.; Komar, A.; Yan, J.; Neshev, D.; Miroshnichenko, A.E. High-Efficiency Visible Light Manipulation Using Dielectric Metasurfaces. Sci. Rep. 2019, 9, 3923. [Google Scholar] [CrossRef] [PubMed]

- Mueller, J.P.B.; Rubin, N.A.; Devlin, R.C.; Groever, B.; Capasso, F. Metasurface Polarization Optics: Independent Phase Control of Arbitrary Orthogonal States of Polarization. Phys. Rev. Lett. 2017, 118, 113901. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.F.; Zhu, A.Y.; Paniagua-Dominguez, R.; Fu, Y.H.; Luk’yanchuk, B.; Kuznetsov, A.I. High-transmission dielectric metasurface with 2π phase control at visible wavelengths. Laser Photonics Rev. 2015, 9, 412–418. [Google Scholar] [CrossRef]

- Zhang, X.G.; Jiang, W.X.; Jiang, H.L.; Wang, Q.; Tian, H.W.; Bai, L.; Luo, Z.J.; Sun, S.; Luo, Y.; Qiu, C.-W.; et al. An optically driven digital metasurface for programming electromagnetic functions. Nat. Electron. 2020, 3, 165–171. [Google Scholar] [CrossRef]

- Guo, K.; Xu, H.; Peng, Z.; Liu, X.; Guo, Z. High-Efficiency Full-Vector Polarization Analyzer Based on GaN Metasurface. IEEE Sensors J. 2019, 19, 3654–3659. [Google Scholar] [CrossRef]

- Guo, Z.; Tian, L.; Shen, F.; Zhou, H.; Guo, K. Mid-infrared polarization devices based on the double-phase modulating dielectric metasurface. J. Phys. D Appl. Phys. 2017, 50, 254001. [Google Scholar] [CrossRef]

- Shi, Z.; Zhu, A.Y.; Li, Z.; Huang, Y.-W.; Chen, W.T.; Qiu, C.-W.; Capasso, F. Continuous angle-tunable birefringence with freeform metasurfaces for arbitrary polarization conversion. Sci. Adv. 2020, 6, eaba3367. [Google Scholar] [CrossRef]

- Ding, X.; Kang, Q.; Guo, K.; Guo, Z. Tunable GST metasurfaces for chromatic aberration compensation in the mid-infrared. Opt. Mater. 2020, 109, 110284. [Google Scholar] [CrossRef]

- Wan, W.; Gao, J.; Yang, X. Full-Color Plasmonic Metasurface Holograms. ACS Nano 2016, 10, 10671–10680. [Google Scholar] [CrossRef]

- Guo, Z.; Xu, H.; Guo, K.; Shen, F.; Zhou, H.; Zhou, Q.; Gao, J.; Yin, Z. High-Efficiency Visible Transmitting Polarizations Devices Based on the GaN Metasurface. Nanomaterials 2018, 8, 333. [Google Scholar] [CrossRef] [PubMed]

- Dorrah, A.H.; Rubin, N.A.; Zaidi, A.; Tamagnone, M.; Capasso, F. Metasurface optics for on-demand polarization transformations along the optical path. Nat. Photonics 2021, 15, 287–296. [Google Scholar] [CrossRef]

- Wei, Q.; Huang, L.; Li, X.; Liu, J.; Wang, Y. Broadband Multiplane Holography Based on Plasmonic Metasurface. Adv. Opt. Mater. 2017, 5, 1700434. [Google Scholar] [CrossRef]

- Intaravanne, Y.; Han, J.; Wang, R.; Ma, A.; Li, S.; Chen, S.; Chen, X. Phase Manipulation-Based Polarization Profile Realization and Hybrid Holograms Using Geometric Metasurface. Adv. Photonics Res. 2021, 2, 2000046. [Google Scholar] [CrossRef]

- Yildirim, B.K.; Bor, E.; Kurt, H.; Turduev, M. Zones optimized multilevel diffractive lens for polarization-insensitive light focusing. J. Phys. D Appl. Phys. 2020, 53, 495109. [Google Scholar] [CrossRef]

- Overvig, A.C.; Shrestha, S.; Malek, S.C.; Lu, M.; Stein, A.; Zheng, C.; Yu, N. Dielectric metasurfaces for complete and independent control of the optical amplitude and phase. Light Sci. Appl. 2019, 8, 92. [Google Scholar] [CrossRef]

- Yin, Z.; Zheng, Q.; Guo, K.; Guo, Z. Tunable Beam Steering, Focusing and Generating of Orbital Angular Momentum Vortex Beams Using High-Order Patch Array. Appl. Sci. 2019, 9, 2949. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, J.; Guo, K.; Shen, F.; Zhou, Q.; Yin, Z.; Guo, Z. High-efficiency terahertz dual-function devices based on the dielectric metasurface. Superlattices Microstruct. 2018, 120, 759–765. [Google Scholar] [CrossRef]

- Zhuang, Z.-P.; Chen, R.; Fan, Z.-B.; Pang, X.-N.; Dong, J.-W. High focusing efficiency in subdiffraction focusing metalens. Nanophotonics 2019, 8, 1279–1289. [Google Scholar] [CrossRef]

- Li, Y.; Hong, M. Parallel Laser Micro/Nano-Processing for Functional Device Fabrication. Laser Photon. Rev. 2020, 14, 1900062. [Google Scholar] [CrossRef]

- Taghvaee, H.; Cabellos-Aparicio, A.; Georgiou, J.; Abadal, S. Error analysis of programmable metasurfaces for beam steering. IEEE J. Emerg. Sel. Top. Circuits Syst. 2020, 10, 62–74. [Google Scholar] [CrossRef]

- Brière, G.; Ni, P.; Héron, S.; Chenot, S.; Vézian, S.; Brändli, V.; Genevet, P. An etching-free approach toward large-scale light-emitting metasurfaces. Adv. Opt. Mater. 2019, 7, 1801271. [Google Scholar] [CrossRef]

- Ou, K.; Yu, F.; Li, G.; Wang, W.; Chen, J.; Miroshnichenko, A.E.; Huang, L.; Li, T.; Li, Z.; Chen, X.; et al. Broadband Achromatic Metalens in Mid-Wavelength Infrared. Laser Photonics Rev. 2021, 15, 2100020. [Google Scholar] [CrossRef]

- Jia, D.; Tian, Y.; Ma, W.; Gong, X.; Yu, J.; Zhao, G.; Yu, X. Transmissive terahertz metalens with full phase control based on a dielectric metasurface. Opt. Lett. 2017, 42, 4494–4497. [Google Scholar] [CrossRef]

- Adelin, P.; Gonzague, A.; Christian, G.; Vincent, P.; Peter, R.W.; Aurélie, L.; Franck, C.; Guilhem, L.; Arnaud, A. Challenges in nanofabrication for efficient optical metasurfaces. Sci. Rep. 2017, 7, 2286. [Google Scholar]

- Zhu, Y.; Wang, W.; Yu, F.; Liu, Q.; Guo, Z.; Li, G.; Chen, P.; Lu, W. The Impact of Manufacturing Imperfections on the Performance of Metalenses and a Manufacturing-Tolerant Design Method. Micromachines 2022, 13, 1531. [Google Scholar] [CrossRef]

- Han-Youl, R.; Jeongsang, P.; Hyun, Y.R. Light Extraction Effificiency of GaN-Based Micro-Scale Light-Emitting Diodes Investigated Using Finite-Difference Time-Domain Simulation. IEEE Photonics J. 2020, 12, 2. [Google Scholar]

- Stafeev, S.S.; Nalimov, A.G.; O’Faolain, L.; Kotlyar, M.V. Effects of fabrication errors on the focusing performance of a sector metalens. Comput. Opt. 2018, 42, 970–976. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, W.; Huo, P.; Feng, L.; Song, M.; Zhang, C.; Xu, T. Multifunctional metasurfaces enabled by simultaneous and independent control of phase and amplitude for orthogonal polarization states. Light Sci. Appl. 2021, 10, 107. [Google Scholar] [CrossRef]

- Luo, J.; Zeng, B.; Wang, C.; Gao, P.; Liu, K.; Pu, M.; Jin, J.; Zhao, Z.; Li, X.; Yu, H.; et al. Fabrication of anisotropically arrayed nano-slots metasurfaces using reflective plasmonic lithography. Nanoscale 2015, 7, 18805–18812. [Google Scholar] [CrossRef]

- Einck, V.J.; Torfeh, M.; McClung, A.; Jung, D.E.; Mansouree, M.; Arbabi, A.; Watkins, J.J. Scalable Nanoimprint Lithography Process for Manufacturing Visible Metasurfaces Composed of High Aspect Ratio TiO2 Meta-Atoms. ACS Photonics 2021, 8, 2400–2409. [Google Scholar] [CrossRef]

- Palik, E.D. (Ed.) Handbook of Optical Constants of Solids; Academic Press: Cambridge, MA, USA, 1998; Volume 3. [Google Scholar]

- Wang, S.; Wu, P.C.; Su, V.-C.; Lai, Y.-C.; Chen, M.K.; Kuo, H.Y.; Chen, B.H.; Chen, Y.H.; Huang, T.-T.; Wang, J.-H.; et al. A broadband achromatic metalens in the visible. Nat. Nanotechnol. 2018, 13, 227–232. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Guo, Z.; Li, R.; Zhang, J.; Liu, Y.; Wang, X.; Qu, S. Ultra-thin, planar, broadband, dual-polarity plasmonic metalens. Photonics Res. 2015, 3, 68–71. [Google Scholar] [CrossRef]

- Guo, Z.; Zhu, L.; Shen, F.; Zhou, H.; Gao, R. Dielectric metasurface based high-efficiency polarization splitters. RSC Adv. 2017, 7, 9872–9879. [Google Scholar] [CrossRef]

- Shalaev, M.I.; Sun, J.; Tsukernik, A.; Pandey, A.; Nikolskiy, K.; Litchinitser, N.M. High-Efficiency All-Dielectric Metasurfaces for Ultracompact Beam Manipulation in Transmission Mode. Nano Lett. 2015, 15, 6261–6266. [Google Scholar] [CrossRef] [PubMed]

| Element No. | Phase (deg.) | L (μm) | w (μm) | Element No. | Phase (deg.) | L (μm) | w (μm) |

|---|---|---|---|---|---|---|---|

| 1 | 38 | 0.8 | 0.55 | 18 | 132 | 0.85 | 1.25 |

| 2 | 312 | 0.7 | 0.95 | 19 | 232 | 0.9 | 0.7 |

| 3 | 234 | 1.4 | 0.35 | 20 | 340 | 0.65 | 0.95 |

| 4 | 165 | 1.2 | 0.7 | 21 | 211 | 1 | 0.9 |

| 5 | 107 | 1.15 | 0.85 | 22 | 340 | 0.8 | 1.2 |

| 6 | 61 | 0.4 | 0.8 | 23 | 89 | 0.95 | 0.4 |

| 7 | 28 | 0.48 | 1.1 | 24 | 204 | 0.9 | 1.29 |

| 8 | 17 | 0.5 | 1.45 | 25 | 323 | 1 | 0.6 |

| 9 | 0 | 0.65 | 0.75 | 26 | 86 | 0.75 | 0.65 |

| 10 | 7 | 0.6 | 1 | 27 | 211 | 1.45 | 0.5 |

| 11 | 27 | 1.29 | 0.9 | 28 | 340 | 1.1 | 0.48 |

| 12 | 61 | 0.4 | 0.95 | 29 | 110 | 0.8 | 0.4 |

| 13 | 108 | 1.2 | 0.8 | 30 | 242 | 0.85 | 1.15 |

| 14 | 166 | 0.9 | 1 | 31 | 16 | 0.7 | 1.2 |

| 15 | 234 | 0.95 | 0.65 | 32 | 151 | 0.35 | 1.4 |

| 16 | 340 | 0.7 | 0.9 | 33 | 288 | 0.95 | 0.7 |

| 17 | 38 | 1.25 | 0.85 | 34 | 350 | 0.55 | 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, G.; Kang, Q.; Fan, X.; Yang, G.; Guo, K.; Guo, Z. Influencing Effects of Fabrication Errors on Performances of the Dielectric Metalens. Micromachines 2022, 13, 2098. https://doi.org/10.3390/mi13122098

Xu G, Kang Q, Fan X, Yang G, Guo K, Guo Z. Influencing Effects of Fabrication Errors on Performances of the Dielectric Metalens. Micromachines. 2022; 13(12):2098. https://doi.org/10.3390/mi13122098

Chicago/Turabian StyleXu, Guoqing, Qianlong Kang, Xueqiang Fan, Guanghui Yang, Kai Guo, and Zhongyi Guo. 2022. "Influencing Effects of Fabrication Errors on Performances of the Dielectric Metalens" Micromachines 13, no. 12: 2098. https://doi.org/10.3390/mi13122098

APA StyleXu, G., Kang, Q., Fan, X., Yang, G., Guo, K., & Guo, Z. (2022). Influencing Effects of Fabrication Errors on Performances of the Dielectric Metalens. Micromachines, 13(12), 2098. https://doi.org/10.3390/mi13122098