A Piezoelectrically Excited ZnO Nanowire Mass Sensor with Closed-Loop Detection at Room Temperature

Abstract

1. Introduction

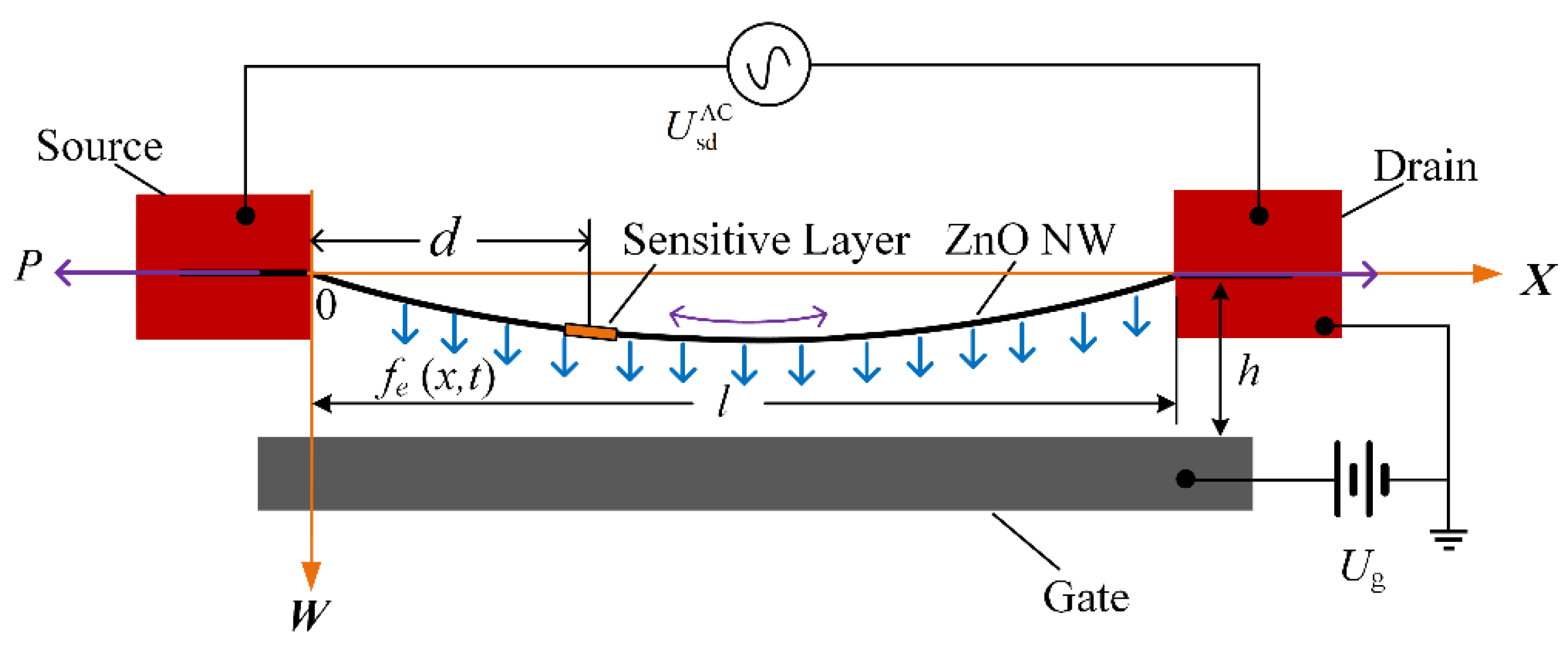

2. Dynamic Model of the ZnO NW Sensor

2.1. The Forced Vibration Model

2.2. Differential Equation of Forced Vibration

2.3. Frequency Formula and Nonlinear Amplitude-Frequency Characteristic Formula

3. Design and Fabrication of the ZnO NW Sensor

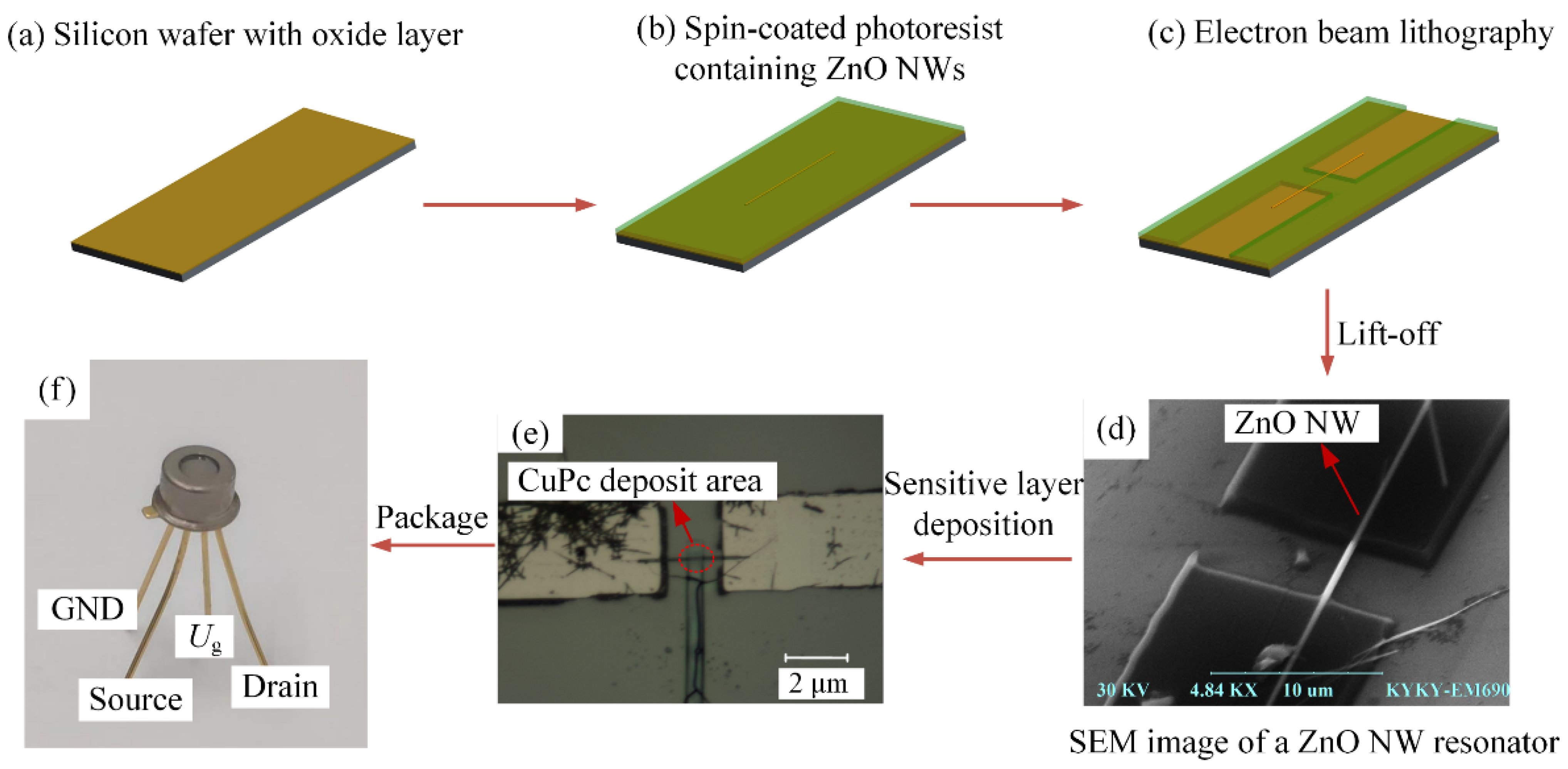

3.1. Fabrication of the ZnO NW Sensor

3.2. Closed-Loop Detection of the ZnO NW Sensor

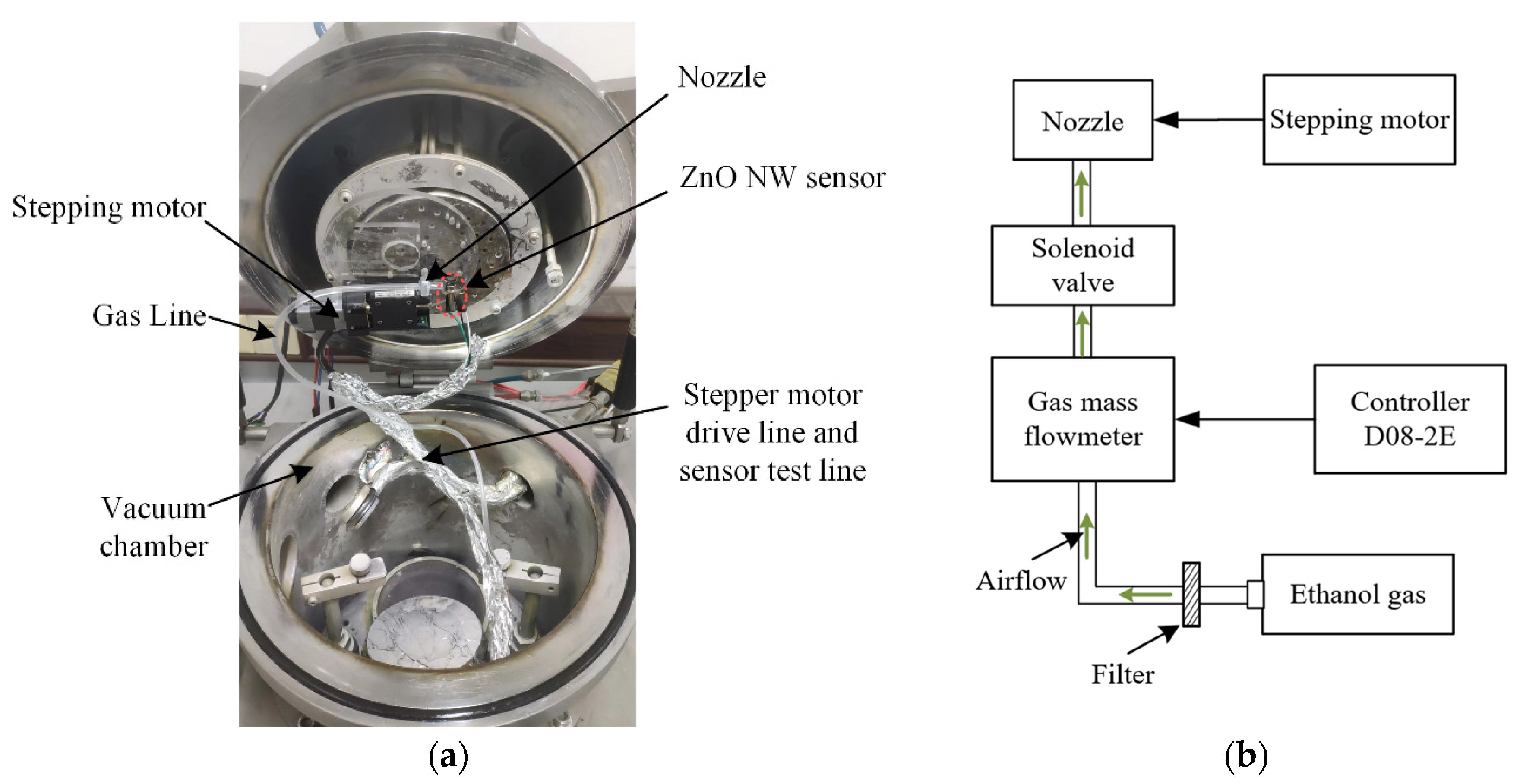

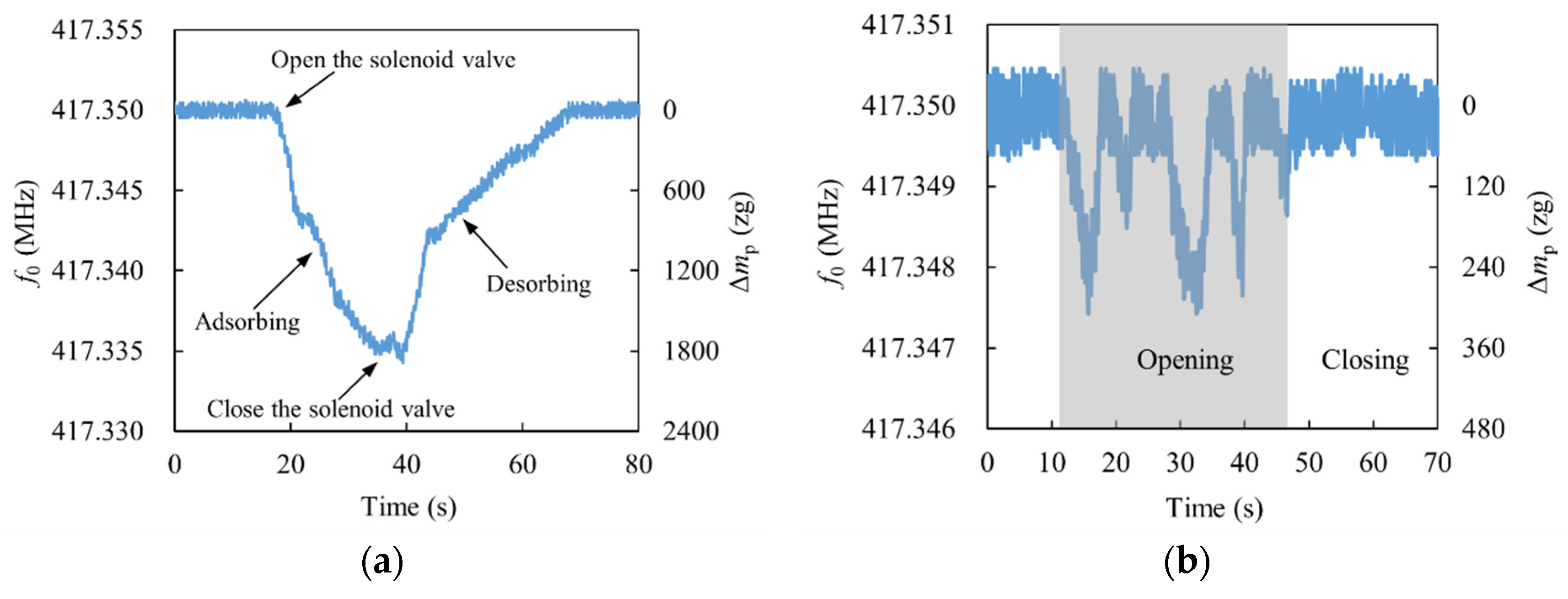

4. Response of the ZnO NW Sensor to Ethanol Gas

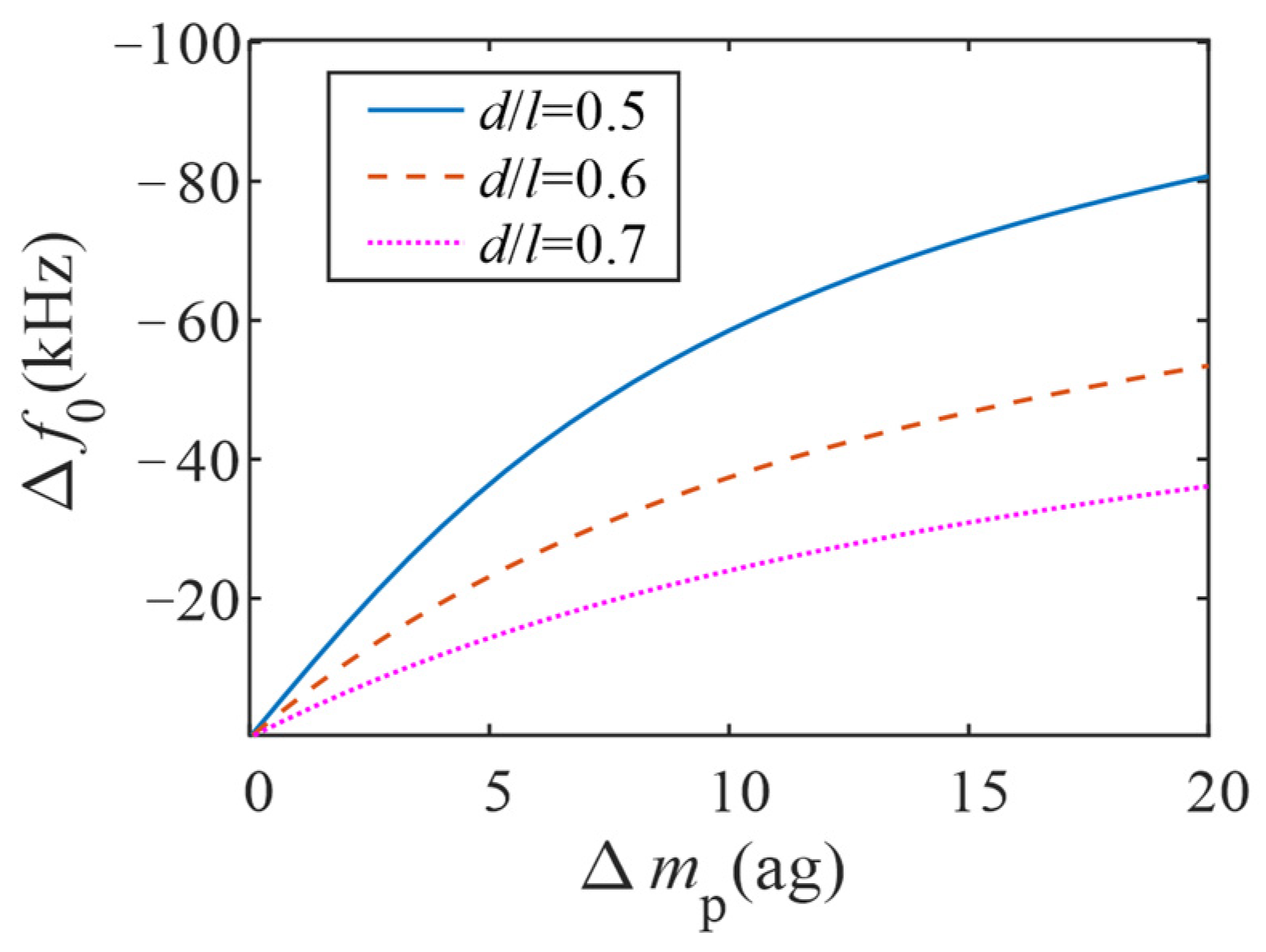

4.1. Sensitivity and Working Range

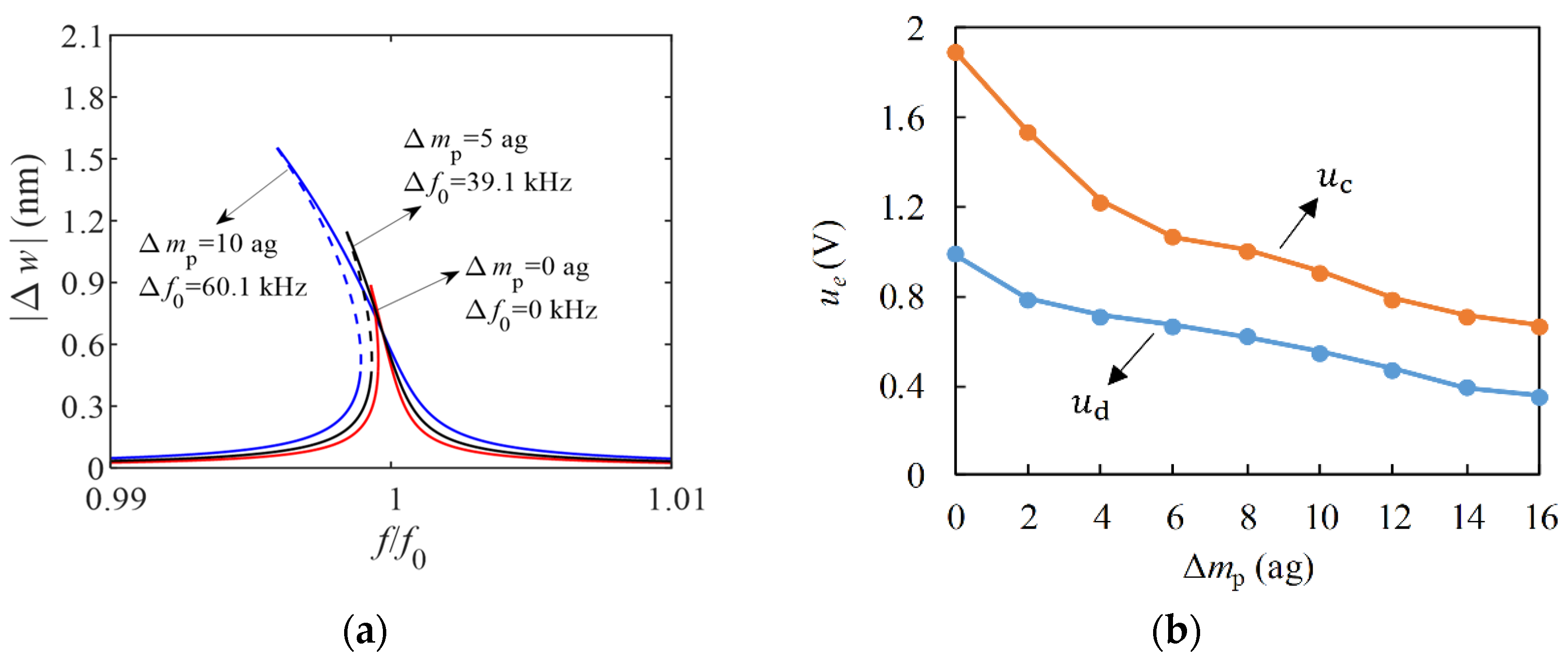

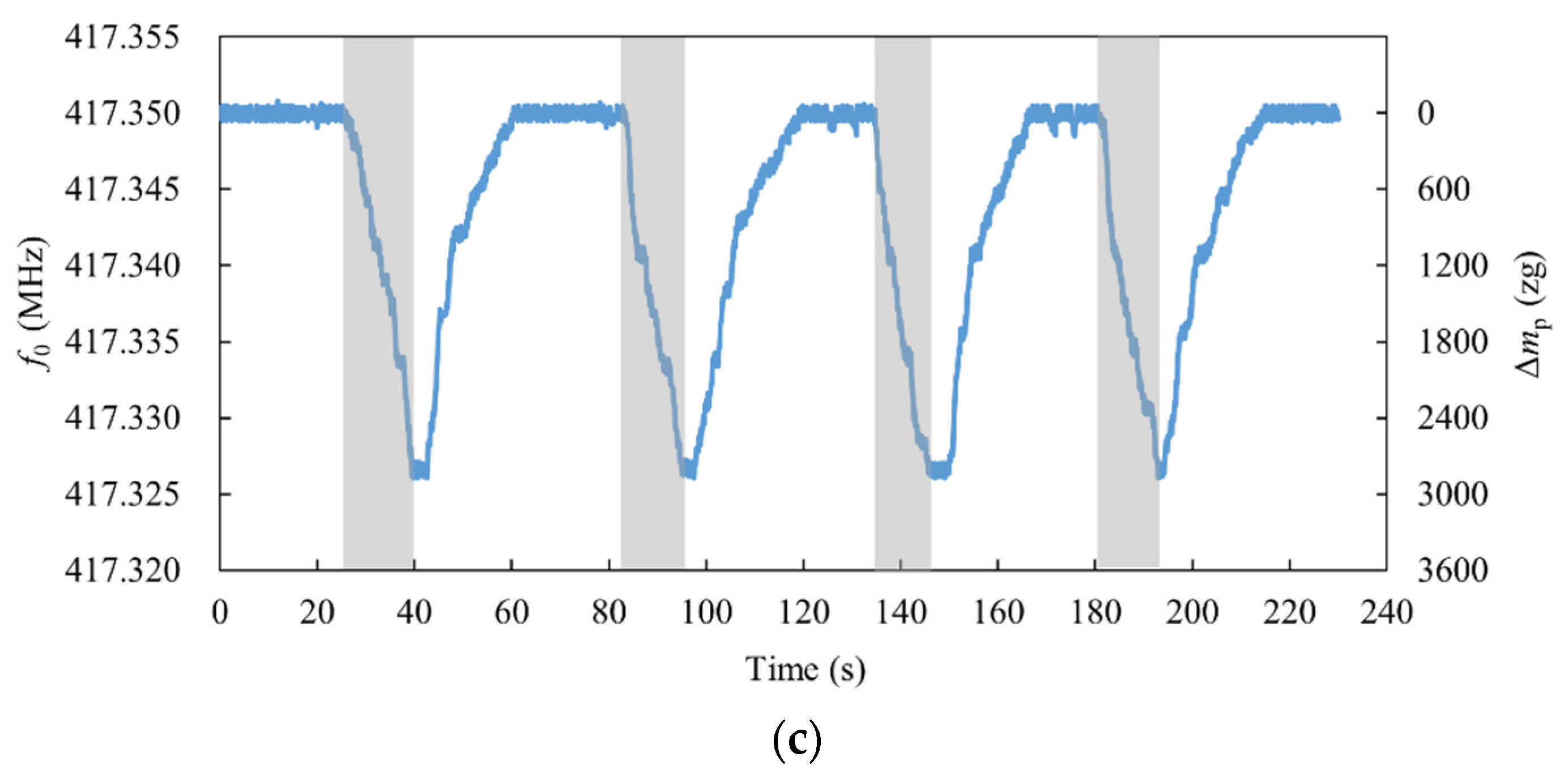

4.2. Response of the ZnO NW Sensor to Ethanol Gas

4.3. Response of the ZnO NW Sensor to Human Exhaled Ethanol Molecules

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- You, K.R.; Li, C.; Zhou, D.D.; Bi, K.D. A piezoelectrically tunable resonator based on carbon and boron nitride coaxial heteronanotubes. Appl. Phys. A 2022, 128, 667. [Google Scholar] [CrossRef]

- Lin, F.K.; Wang, D.W.; Zhao, W.S.; Yu, Y.F.; Qian, C. An ultrahigh-sensitivity microwave angular displacement sensor with a wide dynamic range. Microw. Opt. Technol. Lett. 2022, 64, 1700–1706. [Google Scholar] [CrossRef]

- Nazemi, H.; Joseph, A.; Park, J.; Emadi, A. Advanced Micro- and Nano-Gas Sensor Technology: A Review. Sensors 2019, 19, 1285. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.L.; White, C.J.; Hajimiri, A.; Roukes, M.L. A self-sustaining ultrahigh-frequency nanoelectromechanical oscillator. Nat. Nanotechnol. 2008, 3, 342–346. [Google Scholar] [CrossRef] [PubMed]

- Chaste, J.; Eichler, A.; Moser, J.; Ceballos, G.; Rurali, R.; Bachtold, A. A nanomechanical mass sensor with yoctogram resolution. Nat. Nanotechnol. 2012, 7, 301–304. [Google Scholar] [CrossRef]

- Sage, E.; Brenac, A.; Alava, T.; Morel, R.; Dupre, C.; Hanay, M.S.; Roukes, M.L.; Duraffourg, L.; Masselon, C.; Hentz, S. Neutral particle mass spectrometry with nanomechanical systems. Nat. Commun. 2015, 6, 6482. [Google Scholar] [CrossRef]

- Zhu, J.X.; Liu, X.M.; Shi, Q.F.; He, T.Y.Y.; Sun, Z.D.; Guo, X.G.; Liu, W.X.; Bin Sulaiman, O.; Dong, B.W.; Lee, C. Development Trends and Perspectives of Future Sensors and MEMS/NEMS. Micromachines 2020, 11, 7. [Google Scholar] [CrossRef]

- Lassagne, B.; Garcia-Sanchez, D.; Aguasca, A.; Bachtold, A. Ultrasensitive Mass Sensing with a Nanotube Electromechanical Resonator. Nano Lett. 2008, 8, 3735–3738. [Google Scholar] [CrossRef]

- Chiu, H.Y.; Hung, P.; Postma, H.W.C.; Bockrath, M. Atomic-Scale Mass Sensing Using Carbon Nanotube Resonators. Nano Lett. 2008, 8, 4342–4346. [Google Scholar] [CrossRef]

- Sader, J.E.; Hanay, M.S.; Neumann, A.P.; Roukes, M.L. Mass Spectrometry Using Nanomechanical Systems: Beyond the Point-Mass Approximation. Nano Lett. 2018, 18, 1608–1614. [Google Scholar] [CrossRef]

- Erdogan, R.T.; Alkhaled, M.; Kaynak, B.E.; Alhmoud, H.; Pisheh, H.S.; Kelleci, M.; Karakurt, I.; Yanik, C.; Sen, Z.B.; Sari, B.; et al. Atmospheric Pressure Mass Spectrometry of Single Viruses and Nanoparticles by Nanoelectromechanical Systems. Acs Nano 2022, 16, 3821–3833. [Google Scholar] [CrossRef] [PubMed]

- SoltanRezaee, M.; Bodaghi, M. Simulation of an electrically actuated cantilever as a novel biosensor. Sci. Rep. 2020, 10, 3385. [Google Scholar] [CrossRef] [PubMed]

- Guha, A.; Ahmad, O.S.; Guerreiro, A.; Karim, K.; Sandstrom, N.; Ostanin, V.P.; van der Wijngaart, W.; Piletsky, S.A.; Ghosh, S.K. Direct detection of small molecules using a nano-molecular imprinted polymer receptor and a quartz crystal resonator driven at a fixed frequency and amplitude. Biosens. Bioelectron. 2020, 158, 112176. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Hwang, K.S.; Park, J.; Yoon, K.H.; Yoon, D.S.; Kim, T.S. Immunoassay of prostate-specific antigen (PSA) using resonant frequency shift of piezoelectric nanomechanical microcantilever. Biosens. Bioelectron. 2005, 20, 2157–2162. [Google Scholar] [CrossRef] [PubMed]

- O’Connell, A.D.; Hofheinz, M.; Ansmann, M.; Bialczak, R.C.; Lenander, M.; Lucero, E.; Neeley, M.; Sank, D.; Wang, H.; Weides, M.; et al. Quantum ground state and single-phonon control of a mechanical resonator. Nature 2010, 464, 697–703. [Google Scholar] [CrossRef] [PubMed]

- Grzebyk, T.; Szmajda, T.; Szyszka, P.; Gorecka-Drzazga, A.; Dziuban, J. Glow-discharge ion source for MEMS mass spectrometer. Vacuum 2020, 171, 109008. [Google Scholar] [CrossRef]

- Kambara, H.; Matsui, T.; Niimi, Y.; Fukuyama, H. Construction of a dilution refrigerator based ultra-low temperature scanning tunneling microscope. Jpn. J. Appl. Phys. 2006, 45, 1909–1912. [Google Scholar] [CrossRef]

- Cheng, Y.P.; Liu, Y.J.; Hu, J.; Li, S.; Shao, L.; Wu, Z.X.; Chen, C.L. Recent advances in MEMS mass spectrometers. Chin. J. Anal. Chem. 2022, 50, 60–72. [Google Scholar] [CrossRef]

- Alfaifi, A.; Alhomoudi, I.A.; Nabki, F.; El-Gamal, M.N. In-Plane High-Sensitivity Capacitive Accelerometer in a 3-D CMOS-Compatible Surface Micromachining Process. J. Microelectromech. Syst. 2019, 28, 14–24. [Google Scholar] [CrossRef]

- Rong, Y.P.; Wang, Q.J.; Lu, S.L.; Li, G.L.; Lu, Y.; Xu, J.Z. Improving attitude detection performance for spherical motors using a MEMS inertial measurement sensor. IET. Electr. Power Appl. 2019, 13, 198–205. [Google Scholar] [CrossRef]

- Tamayo, J.; Humphris, A.D.L.; Malloy, A.M.; Miles, M.J. Chemical sensors and biosensors in liquid environment based on microcantilevers with amplified quality factor. Ultramicroscopy 2001, 86, 167–173. [Google Scholar] [CrossRef] [PubMed]

- Dulin, D.; Lipfert, J.; Moolman, M.C.; Dekker, N.H. Studying genomic processes at the single-molecule level: Introducing the tools and applications. Nat. Rev. Genet. 2013, 14, 9–22. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; He, G.; Ueno, H.; Jia, C.C.; Noji, H.; Qi, C.M.; Guo, X.F. Direct real-time detection of single proteins using silicon nanowire-based electrical circuits. Nanoscale 2016, 8, 16172–16176. [Google Scholar] [CrossRef] [PubMed]

- Tamersit, K.; Djeffal, F. Carbon Nanotube Field-Effect Transistor with Vacuum Gate Dielectric for Label-Free Detection of DNA Molecules: A Computational Investigation. IEEE. Sens. J. 2019, 19, 9263–9270. [Google Scholar] [CrossRef]

- Armani, A.M.; Kulkarni, R.P.; Fraser, S.E.; Flagan, R.C.; Vahala, K.J. Label-free, single-molecule detection with optical microcavities. Science 2007, 317, 783–787. [Google Scholar] [CrossRef] [PubMed]

- Kravets, V.G.; Schedin, F.; Jalil, R.; Britnell, L.; Gorbachev, R.V.; Ansell, D.; Thackray, B.; Novoselov, K.S.; Geim, A.K.; Kabashin, A.V.; et al. Singular phase nano-optics in plasmonic metamaterials for label-free single-molecule detection. Nat. Mater. 2013, 12, 304–309. [Google Scholar] [CrossRef] [PubMed]

- Li, C.Y.; Duan, S.; Yi, J.; Wang, C.; Radjenovic, P.M.; Tian, Z.Q.; Li, J.F. Real-time detection of single-molecule reaction by plasmon-enhanced spectroscopy. Sci. Adv. 2020, 6, eaba6012. [Google Scholar] [CrossRef]

- Ko, J.H.; Jeong, J.; Choi, J.; Cho, M. Quality factor in clamping loss of nanocantilever resonators. Appl. Phys. Lett. 2011, 98, 171909. [Google Scholar] [CrossRef]

- Hao, Z.; Erbil, A.; Ayazi, F. An analytical model for support loss in micromachined beam resonators with in-plane flexural vibrations. Sens. Actuat. A-Phys. 2003, 109, 156–164. [Google Scholar] [CrossRef]

- Xu, S.G.; Guo, W.H.; Du, S.W.; Loy, M.M.T.; Wang, N. Piezotronic Effects on the Optical Properties of ZnO Nanowires. Nano Lett. 2012, 12, 5802–5807. [Google Scholar] [CrossRef]

- Zhu, R.; Wang, D.Q.; Xiang, S.Q.; Zhou, Z.Y.; Ye, X.Y. Piezoelectric characterization of a single zinc oxide nanowire using a nanoelectromechanical oscillator. Nanotechnology 2008, 19, 285712. [Google Scholar] [CrossRef] [PubMed]

- Farokhi, H.; Paidoussis, M.R.; Misra, A.K. Nonlinear behaviour and mass detection sensitivity of geometrically imperfect cantilevered carbon nanotube resonators. Commun. Nonlinear Sci. Numer. Simul. 2018, 65, 272–298. [Google Scholar] [CrossRef]

- Kiani, K. Non local continuous models for forced vibration analysis of two- and three-dimensional ensembles of single-walled carbon nanotubes. Physica. E 2014, 60, 229–245. [Google Scholar] [CrossRef]

- Wang, B.; Deng, Z.C.; Ouyang, H.J.; Zhang, K. Wave characteristics of single-walled fluid-conveying carbon nanotubes subjected to multi-physical fields. Physica. E 2013, 52, 97–105. [Google Scholar] [CrossRef]

- Cai, X.; Xu, L. Multifield Coupled Dynamics Model of Resonant Carbon Nanotube Mass Sensor Based on Nonlocal Elastic and Electromagnetic Effects. IEEE. Trans. Ind. Electron. 2021, 68, 11511–11522. [Google Scholar] [CrossRef]

- Lee, H.; Park, J.; Han, S.A.; Lee, D.; Kim, K.B.; Lee, N.S.; Park, J.Y.; Seo, Y.; Lee, S.; Choi, Y.J. The stress-dependent piezoelectric coefficient of ZnO wire measured by piezoresponse force microscopy. Scr. Mater. 2012, 66, 101–104. [Google Scholar] [CrossRef]

- Devoe, D.L.J.S.; Physical, A.A. Piezoelectric thin film micromechanical beam resonators. Sens. Actuat. A-Phys. 2001, 88, 263–272. [Google Scholar] [CrossRef]

- Zhou, L.L.; Zhu, L.P.; Yang, T.; Hou, X.M.; Du, Z.T.; Cao, S.; Wang, H.L.; Chou, K.C.; Wang, Z.L. Ultra-Stable and Durable Piezoelectric Nanogenerator with All-Weather Service Capability Based on N Doped 4H-SiC Nanohole Arrays. Nano-Micro Lett. 2022, 14, 30. [Google Scholar] [CrossRef]

- Zhou, L.L.; Yang, T.; Fang, Z.; Zhou, J.D.; Zheng, Y.P.; Guo, C.Y.; Zhu, L.P.; Wang, E.H.; Hou, X.M.; Chou, K.C.; et al. Boosting of water splitting using the chemical energy simultaneously harvested from light, kinetic energy and electrical energy using N doped 4H-SiC nanohole arrays. Nano Energy 2022, 104, 107876. [Google Scholar] [CrossRef]

- Zhou, L.L.; Yang, T.; Zhu, L.P.; Li, W.J.; Wang, S.Z.; Hou, X.M.; Mao, X.P.; Wang, Z.L. Piezoelectric nanogenerators with high performance against harsh conditions based on tunable N doped 4H-SiC nanowire arrays. Nano Energy 2021, 83, 105826. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, L.P.; Du, C.F. Progress in Piezoelectric Nanogenerators Based on PVDF Composite Films. Micromachines 2021, 12, 1278. [Google Scholar] [CrossRef]

- Cai, X.F.; Xu, L.Z. A Precise Closed-Loop Controlled ZnO Nanowire Resonator Operating at Room Temperature. Micromachines 2022, 13, 952. [Google Scholar] [CrossRef] [PubMed]

- Ha, J.S.; Lee, S.W.; Lee, H.J.; Lee, H.J.; Lee, S.H.; Goto, H.; Kato, T.; Fujii, K.; Cho, M.W.; Yao, T. The fabrication of vertical light-emitting diodes using chemical lift-off process. IEEE. Photonics Technol. Lett. 2008, 20, 175–177. [Google Scholar] [CrossRef]

- Lin, C.F.; Dai, J.J.; Wang, G.M.; Lin, M.S. Chemical Lift-Off Process for Blue Light-Emitting Diodes. Appl. Phys. Express 2010, 3, 92101. [Google Scholar] [CrossRef]

- Witkamp, B.; Poot, M.; van der Zant, H.S.J. Bending-mode vibration of a suspended nanotube resonator. Nano Lett. 2006, 6, 2904–2908. [Google Scholar] [CrossRef]

- Ning, Z.Y.; Fu, M.Q.; Wu, G.T.; Qiu, C.G.; Shu, J.P.; Guo, Y.; Wei, X.L.; Gao, S.; Chen, Q. Remarkable influence of slack on the vibration of a single-walled carbon nanotube resonator. Nanoscale 2016, 8, 8658–8665. [Google Scholar] [CrossRef] [PubMed]

- Comi, C.; Corigliano, A.; Zega, V.; Zerbini, S. Non linear response and optimization of a new z-axis resonant micro-accelerometer. Mechatronics 2016, 40, 235–243. [Google Scholar] [CrossRef]

- Mohanty, P.; Harrington, D.A.; Ekinci, K.L.; Yang, Y.T.; Murphy, M.J.; Roukes, M.L. Intrinsic dissipation in high-frequency micromechanical resonators. Phys. Rev. B 2002, 66, 85416. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, P.; Zhu, J.; Liu, Z.; Eichler, A.; Zheng, X.-Q.; Lee, J.; Dash, A.; More, S.; Wu, S.; et al. Nanomechanical Resonators: Toward Atomic Scale. ACS Nano 2022, 16, 15545–15585. [Google Scholar] [CrossRef]

- Peng, H.B.; Chang, C.W.; Aloni, S.; Yuzvinsky, T.D.; Zettl, A. Ultrahigh frequency nanotube resonators. Phys. Rev. Lett. 2006, 97, 87203. [Google Scholar] [CrossRef]

- Toombs, C.F.; Insko, M.A.; Wintner, E.A.; Deckwerth, T.L.; Usansky, H.; Jamil, K.; Goldstein, B.; Cooreman, M.; Szabo, C. Detection of exhaled hydrogen sulphide gas in healthy human volunteers during intravenous administration of sodium sulphide. Br. J. Clin. Pharmacol. 2010, 69, 626–636. [Google Scholar] [CrossRef] [PubMed]

- Kunze-Szikszay, N.; Walliser, K.; Luther, J.; Cambiaghi, B.; Reupke, V.; Dullin, C.; Vautz, W.; Bremmer, F.; Telgheder, U.; Zscheppank, C.; et al. Detecting Early Markers of Ventilator-Associated Pneumonia by Analysis of Exhaled Gas. Crit. Care Med. 2019, 47, E234–E240. [Google Scholar] [CrossRef] [PubMed]

- Sen, S.; Nilabh, A.; Kundu, S. Room temperature acetone sensing performance of Pt/Sb2O3 impregnated Fe2O3 thin film: Noninvasive diabetes detection. Microchem. J. 2021, 165, 106111. [Google Scholar] [CrossRef]

- Kalidoss, R.; Umapathy, S.; Sivalingam, Y. An investigation of GO-SnO2-TiO2 ternary nanocomposite for the detection of acetone in diabetes mellitus patient’s breath. Appl. Surf. Sci. 2018, 449, 677–684. [Google Scholar] [CrossRef]

- Malan, D.; van der Walt, S.J.; Rohwer, E.R. A high-repetition-rate, fast temperature-programmed gas chromatograph and its online coupling to a supercritical fluid chromatograph (SFC × GC). Rev. Sci. Instrum. 2020, 91, 34101. [Google Scholar] [CrossRef]

- Sazonova, V.; Yaish, Y.; Ustunel, H.; Roundy, D.; Arias, T.A.; McEuen, P.L. A tunable carbon nanotube electromechanical oscillator. Nature 2004, 431, 284–287. [Google Scholar] [CrossRef]

| l (μm) | r (nm) | h (nm) | mp (ag) | Ug (V) | E (Pa) | ρ (kg/m3) | c (Ns/m) |

|---|---|---|---|---|---|---|---|

| 1.2 | 50 | 100 | 500 | 5 | 2.1 × 1011 | 5.67 × 103 | 2.5 × 10−11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, X.; Xu, L. A Piezoelectrically Excited ZnO Nanowire Mass Sensor with Closed-Loop Detection at Room Temperature. Micromachines 2022, 13, 2242. https://doi.org/10.3390/mi13122242

Cai X, Xu L. A Piezoelectrically Excited ZnO Nanowire Mass Sensor with Closed-Loop Detection at Room Temperature. Micromachines. 2022; 13(12):2242. https://doi.org/10.3390/mi13122242

Chicago/Turabian StyleCai, Xianfa, and Lizhong Xu. 2022. "A Piezoelectrically Excited ZnO Nanowire Mass Sensor with Closed-Loop Detection at Room Temperature" Micromachines 13, no. 12: 2242. https://doi.org/10.3390/mi13122242

APA StyleCai, X., & Xu, L. (2022). A Piezoelectrically Excited ZnO Nanowire Mass Sensor with Closed-Loop Detection at Room Temperature. Micromachines, 13(12), 2242. https://doi.org/10.3390/mi13122242