Experimental Characterization of Laser Trepanned Microholes in Superalloy GH4220 with Water-Based Assistance

Abstract

:1. Introduction

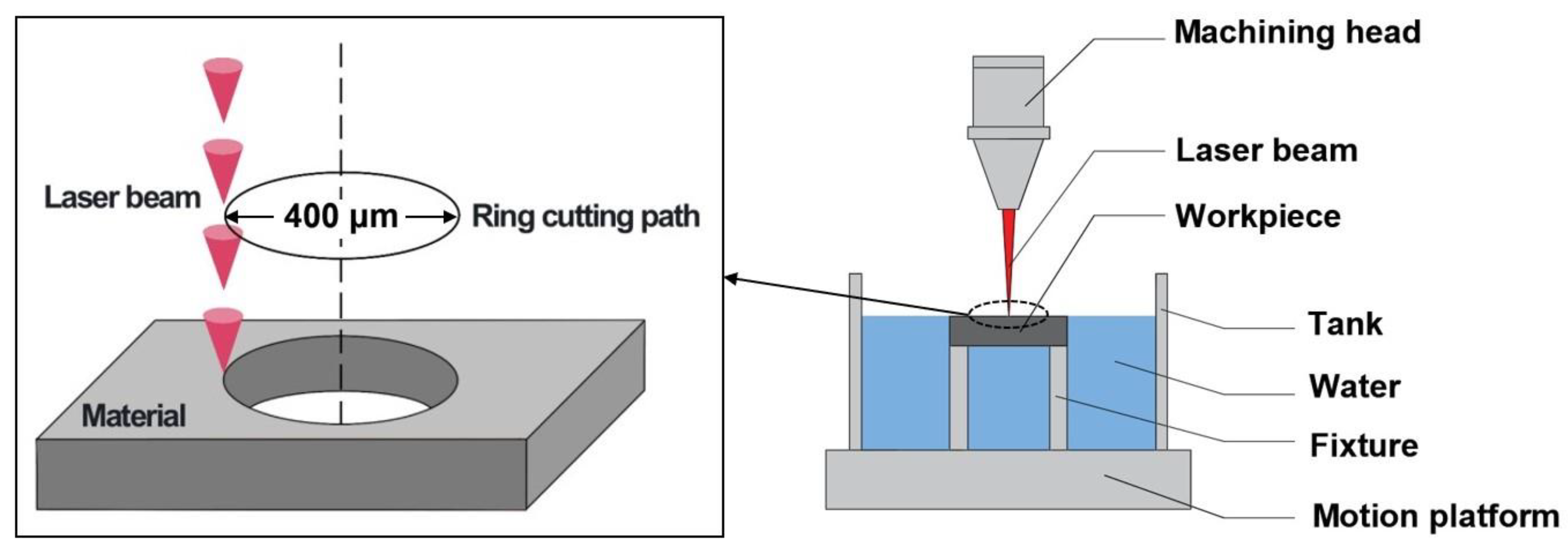

2. Materials and Methods

3. Results and Discussion

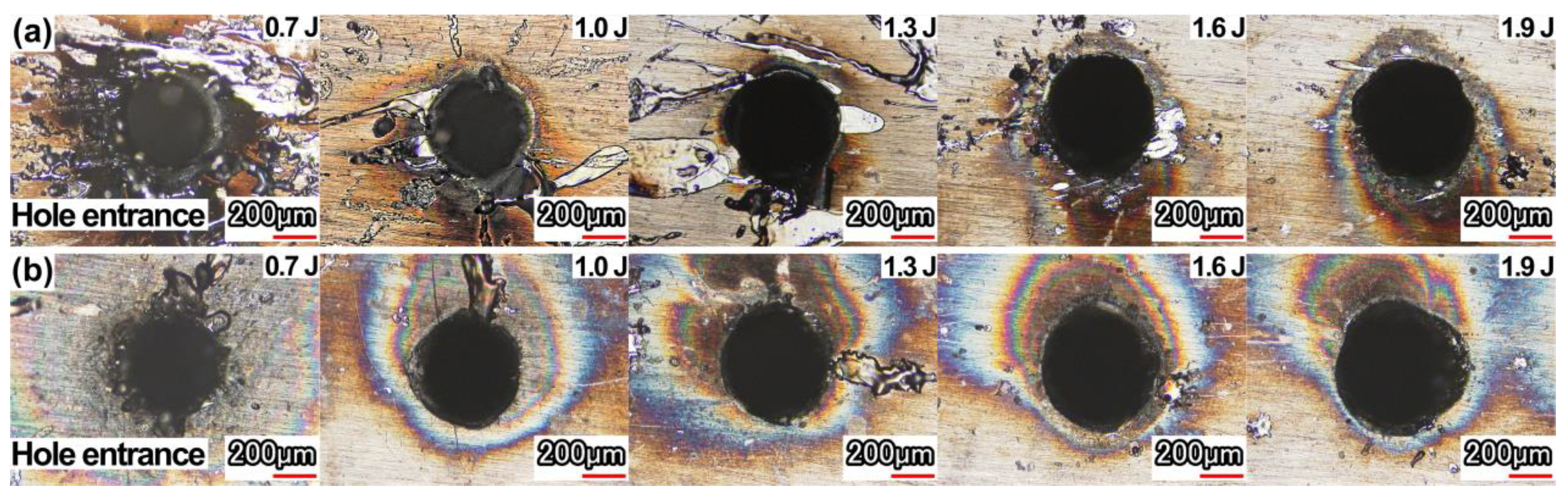

3.1. Spatter around the Hole Entrance

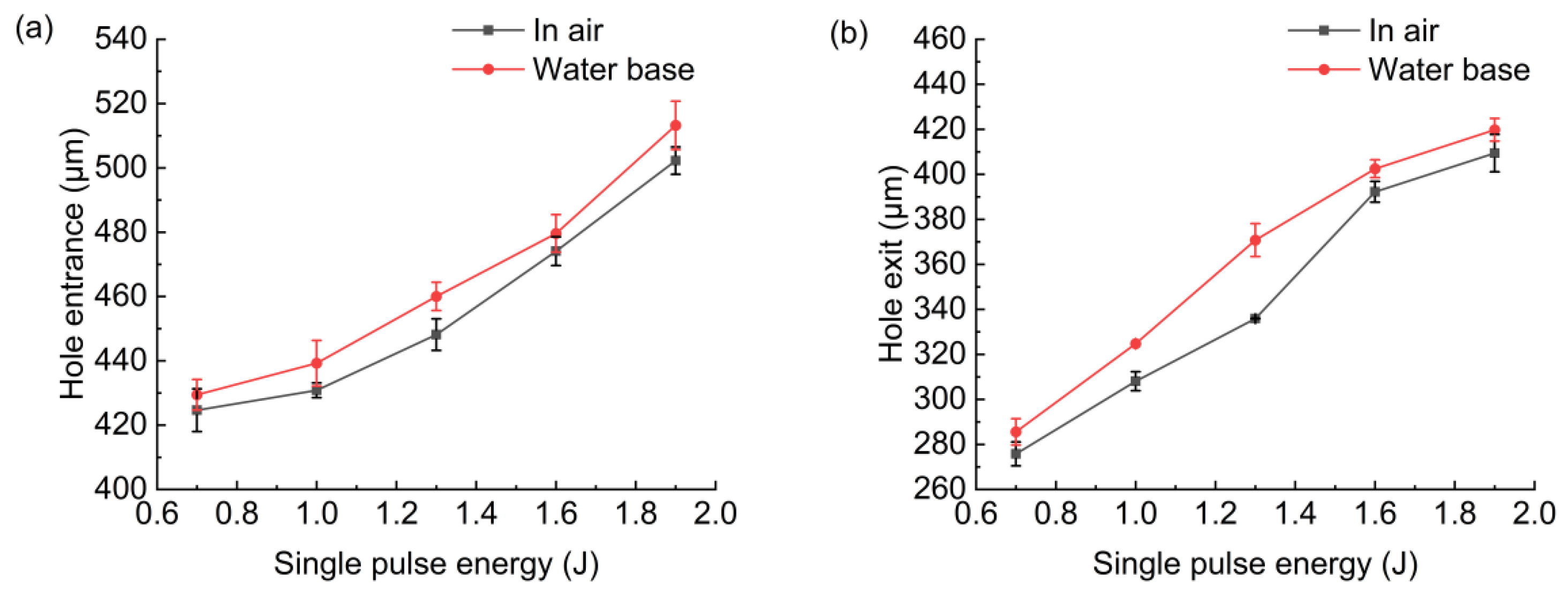

3.2. Hole Entrance/Exit Diameter, Roundness

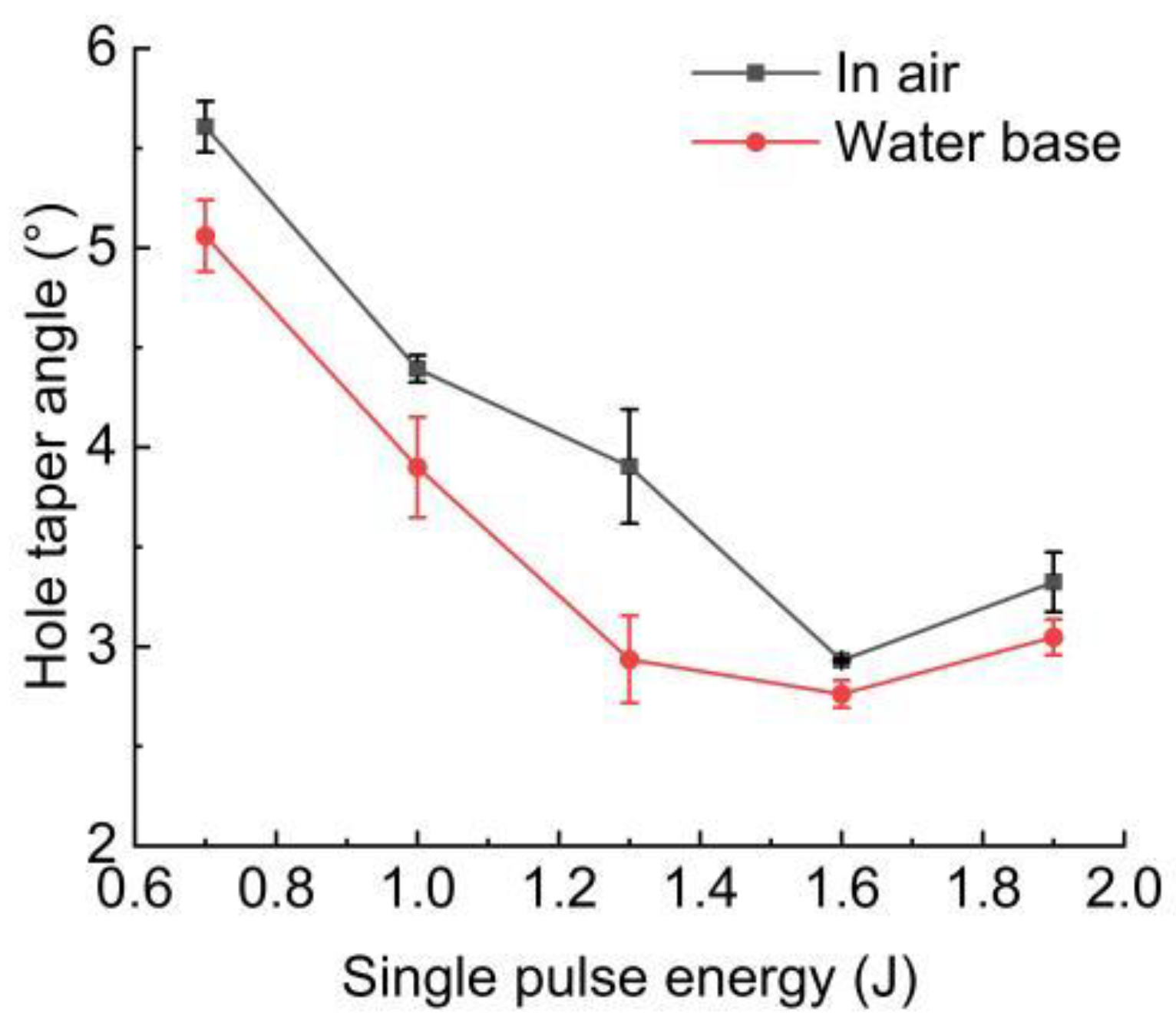

3.3. Hole Cross-Section Morphology, Taper Angle

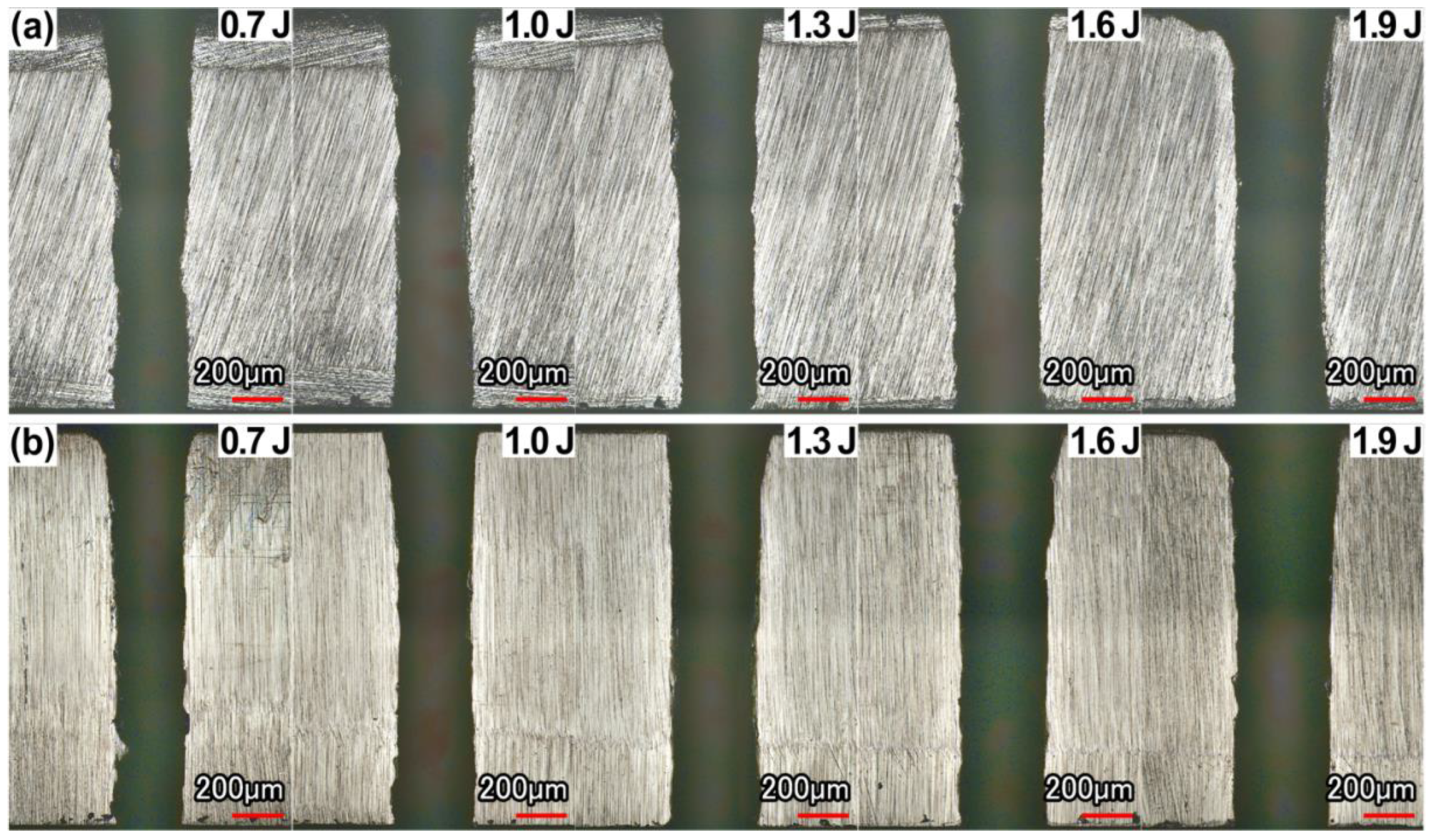

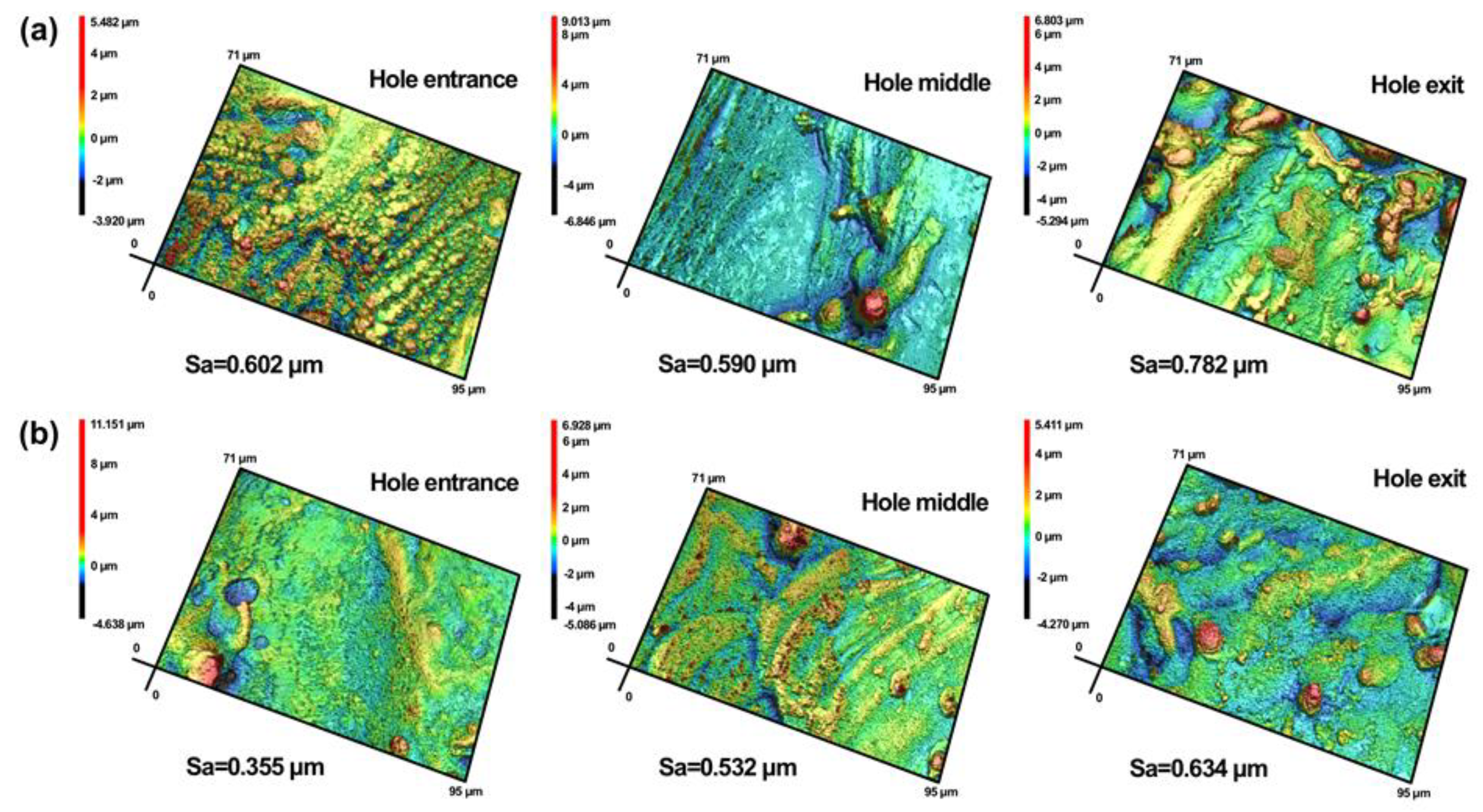

3.4. Hole Sidewall Morphology and Roughness

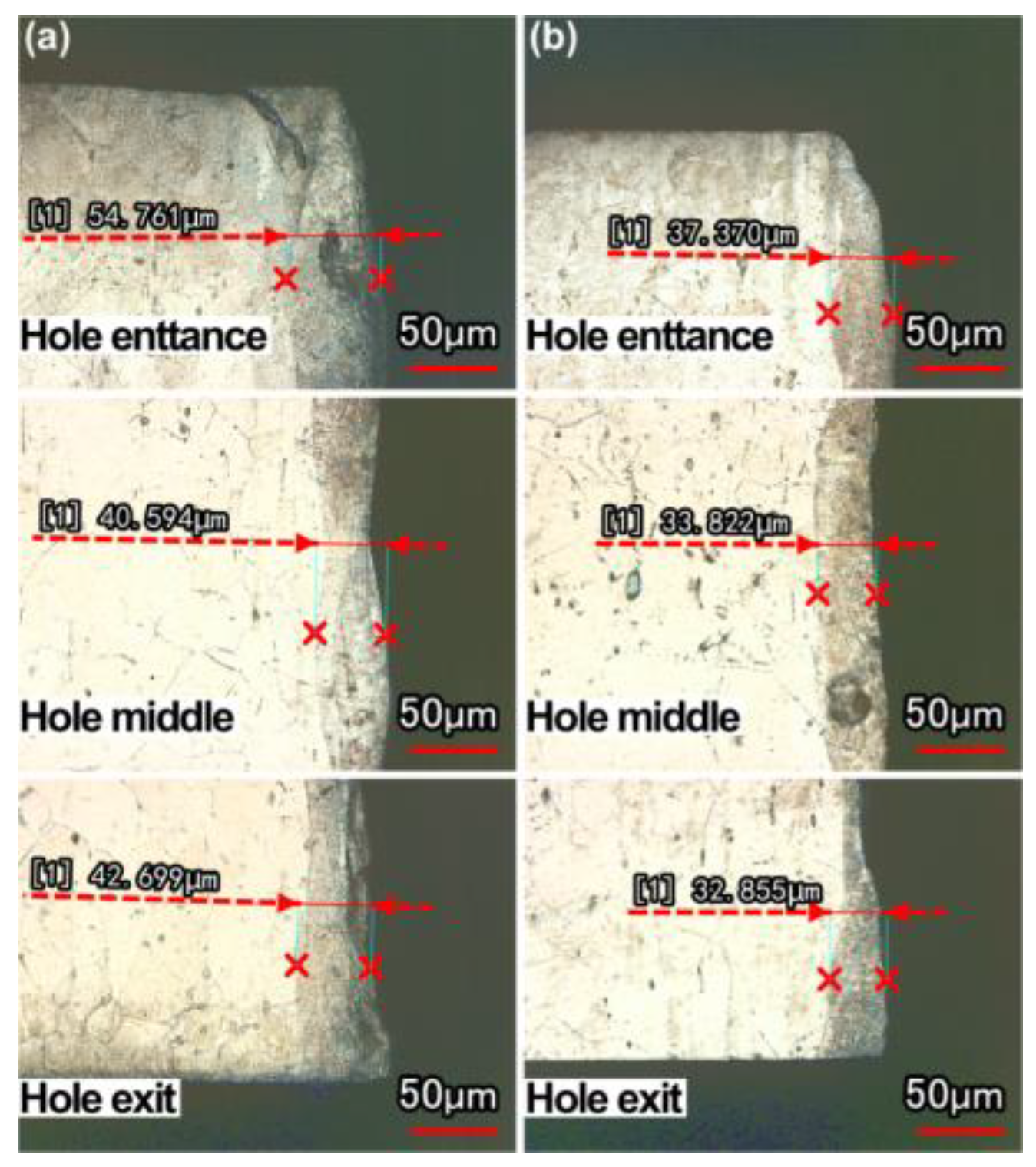

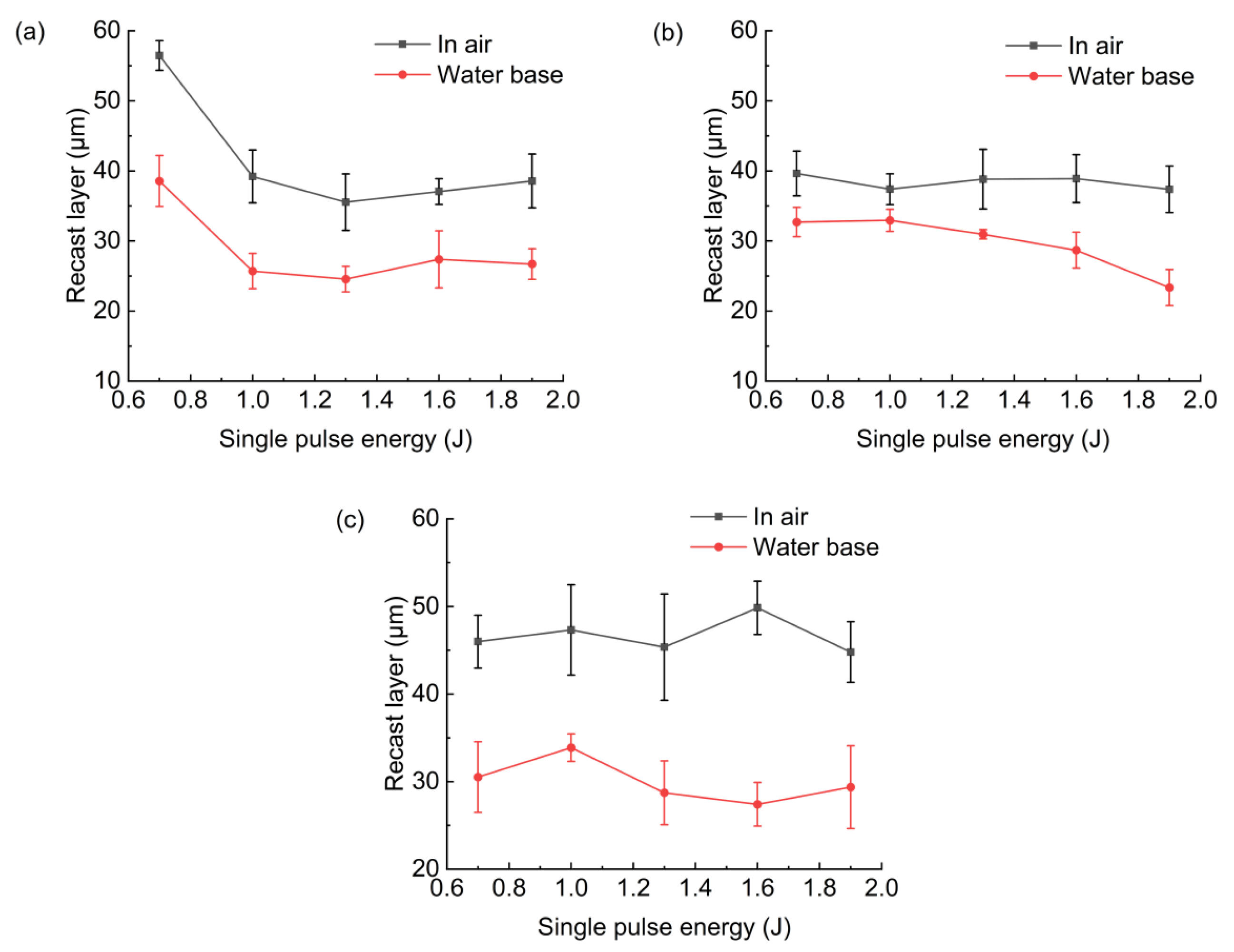

3.5. Recast Layer

4. Conclusions

- (1)

- With the increase in pulse energy, the spatter around the hole entrance and exit decreased in air and with water-based assistance. The spatter around the hole entrance with water-based assistance was less than that in the case of air.

- (2)

- With the increase in pulse energy, the hole entrance and exit diameter increased because the material removal rate was increased with the increase in pulse energy. Under the water-based assistance condition, the hole roundness was better than that under the air condition. This was because after the workpiece was drilled through, the water promoted the removal of molten material and suppressed the shielding effect of plasma during laser drilling. Moreover, the absorption of laser energy by the material on the hole sidewall was more uniform, resulting in better roundness than that under the air condition. With the increase in pulse energy, the roundness of the hole entrance and exit in these two environments was not changed significantly.

- (3)

- With the increase in pulse energy, the material removal rate increased, and the hole taper angle decreased. However, when the pulse energy increased to a certain range, the hole taper angle tended to become larger, and the hole taper angle at 1.9 J was larger than 1.6 J. Water−based assistance could reduce the hole taper angle.

- (4)

- The hole sidewall morphology in the water-based assistance conditions was better than that in the case of air, and the hole sidewall roughness was less than that in air. When the pulse energy was 0.7 J, the hole sidewall roughness at the hole entrance, middle, and exit with water-based assistance was reduced by 41%, 10%, and 19%, respectively, compared with that in air. The sidewall roughness at the hole exit was larger than that of other parts.

- (5)

- The recast layer thickness of the hole drilled with water-based assistance was smaller than that in the case of air. This was mainly because after the workpiece was drilled through, the molten material produced during laser drilling could be effectively removed under the combined action of the water and steam, the residual amount of molten material on the hole sidewall was reduced, and the thickness of the recast layer was reduced. When the pulse energy was 0.7 J, the recast layer thickness at the hole entrance, middle, and exit with water-based assistance was reduced by 32%, 17%, and 23%, respectively, compared with that in air.

- (6)

- Compared with the air condition, water-based assistance could improve the material removal rate and the hole quality. The hole entrance and exit diameter increased, the roundness increased, the taper angle decreased, the hole sidewall roughness decreased, and the recast layer thickness decreased. At the same time, the hole sidewall surface morphology was better with water-based assistance. Compared with the air condition, the spatter around the hole entrance was reduced, but the oxidation phenomenon formed by the thermal effect surrounding the hole entrance with water-based assistance was more obvious.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- McNally, C.A.; Folkes, J.; Pashby, I.R. Laser drilling of cooling holes in aeroengines: State of the art and future challenges. Mater. Sci. Technol. 2004, 20, 805–813. [Google Scholar] [CrossRef]

- Gautam, G.D.; Pandey, A.K. Pulsed Nd: YAG laser beam drilling: A review. Opt. Lasers Technol. 2018, 100, 183–215. [Google Scholar] [CrossRef]

- Weck, A.; Crawford, T.H.R.; Wilkinson, D.S.; Haugen, H.K.; Preston, J.S. Laser drilling of high aspect ratio holes in copper with femtosecond, picosecond and nanosecond pulses. Appl. Phys. A-Mater. 2008, 90, 537–543. [Google Scholar] [CrossRef]

- Hasan, M.; Zhao, J.W.; Jiang, Z.Y. A review of modern advancements in micro drilling techniques. J. Manuf. Process. 2017, 29, 343–375. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.J.; Wang, K.D.; Dong, X.; Fan, Z.J.; Duan, W.Q.; Mei, X.S.; Wang, W.J.; Cui, J.L.; Zhang, S. An experimental investigation into the defects of laser-drilled holes in thermal barrier coated Inconel 718 superalloys. Int. J. Adv. Manuf. Technol. 2018, 96, 1467–1481. [Google Scholar] [CrossRef]

- Tagliaferri, F.; Genna, S.; Leone, C.; Palumbo, B.; De Chiara, G. Experimental study of fibre laser microdrilling of aerospace superalloy by trepanning technique. Int. J. Adv. Manuf. Technol. 2017, 93, 3203–3210. [Google Scholar] [CrossRef] [Green Version]

- Marimuthu, S.; Smith, B.; Kiely, A.; Liu, Y. Millisecond pulse laser machining of thermal barrier coatings. CIRP J. Manuf. Sci. Tec. 2020, 28, 107–117. [Google Scholar] [CrossRef]

- Marimuthu, S.; Antar, M.; Dunleavey, J. Characteristics of micro-hole formation during fibre laser drilling of aerospace superalloy. Precis. Eng. 2019, 55, 339–348. [Google Scholar] [CrossRef]

- Marimuthu, S.; Antar, M.; Dunleavey, J.; Hayward, P. Millisecond fibre laser trepanning drilling of angular holes. Int. J. Adv. Manuf. Technol. 2019, 102, 2833–2843. [Google Scholar] [CrossRef]

- Saini, S.K.; Dubey, A.K.; Upadhyay, B.N. Study and optimization of recast layer thickness and surface quality in laser trepan drilling of ZTA. Int. J. Adv. Manuf. Technol. 2019, 103, 2977–2989. [Google Scholar] [CrossRef]

- Zhu, S.J.; Zhang, Z.Y.; Chu, S.L.; Yang, Z.Y.; Zhang, X.S.; Wang, A.B. Research and application of massive micropores water-assisted picosecond laser processing technology. Chin. J. Lasers 2020, 47, 0302002. [Google Scholar]

- Behera, R.R.; Sankar, M.R. State of the art on under liquid laser beam machining. Mater. Today-Proc. 2015, 2, 1731–1740. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, H.J.; Lin, D.T.; Zuo, F.; Zhao, Z.X.; Lin, H.T. Characterization of hole taper in laser drilling of silicon nitride ceramic under water. Ceram. Int. 2018, 44, 13449–13452. [Google Scholar] [CrossRef]

- Feng, D.C.; Shen, H. Hole quality control in underwater drilling of yttria-stabilized zirconia using a picosecond laser. Opt. Lasers Technol. 2019, 113, 141–149. [Google Scholar] [CrossRef]

- Wang, W.J.; Song, H.W.; Liao, K.; Mei, X.S. Water-assisted femtosecond laser drilling of 4H-SiC to eliminate cracks and surface material shedding. Int. J. Adv. Manuf. Technol. 2021, 112, 553–562. [Google Scholar] [CrossRef]

- Wang, L.; Guan, R.; Zhang, Q.Y.; Xia, K.B.; Ren, N.F. Characterization of micro hole on super alloy GH4037 and stainless steel 304 by millisecond-pulsed Nd:YAG laser processing. Mater. Express 2021, 11, 1975–1987. [Google Scholar] [CrossRef]

- Ren, N.F.; Xia, K.B.; Yang, H.Y.; Gao, F.Q.; Song, S.W. Water-assisted femtosecond laser drilling of alumina ceramics. Ceram. Int. 2021, 47, 11465–11473. [Google Scholar] [CrossRef]

- Tiwari, D.; Bellouard, Y.; Dietzel, A.; Ren, M.S.; Rubingh, E.; Meinders, E. Dynamical observation of femtosecond-laser-induced bubbles in water using a single laser source for probing and sensing. Appl. Phys. Express 2010, 3, 127101. [Google Scholar] [CrossRef] [Green Version]

- Kruusing, A. Underwater and water-assisted laser processing: Part 2—Etching, cutting and rarely used methods. Opt. Lasers Eng. 2004, 41, 329–352. [Google Scholar] [CrossRef]

| Case | Pulse Duration (ms) | Pulse Repetition Rate (Hz) | Pulse Energy (J) | Number of Circles | Scanning Speed (mm/min) | Environment |

|---|---|---|---|---|---|---|

| I | 0.8 | 60 | 0.7–1.9 | 2 | 50 | In air |

| II | 0.8 | 60 | 0.7–1.9 | 2 | 50 | Water-based assistance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Yang, H.; Ren, N.; Wu, Z.; Xia, K. Experimental Characterization of Laser Trepanned Microholes in Superalloy GH4220 with Water-Based Assistance. Micromachines 2022, 13, 2249. https://doi.org/10.3390/mi13122249

Wang L, Yang H, Ren N, Wu Z, Xia K. Experimental Characterization of Laser Trepanned Microholes in Superalloy GH4220 with Water-Based Assistance. Micromachines. 2022; 13(12):2249. https://doi.org/10.3390/mi13122249

Chicago/Turabian StyleWang, Liang, Huayu Yang, Naifei Ren, Zhengtian Wu, and Kaibo Xia. 2022. "Experimental Characterization of Laser Trepanned Microholes in Superalloy GH4220 with Water-Based Assistance" Micromachines 13, no. 12: 2249. https://doi.org/10.3390/mi13122249