A Thermal Actuated Bistable Structure for Generating On-Chip Shock Loads

Abstract

:1. Introduction

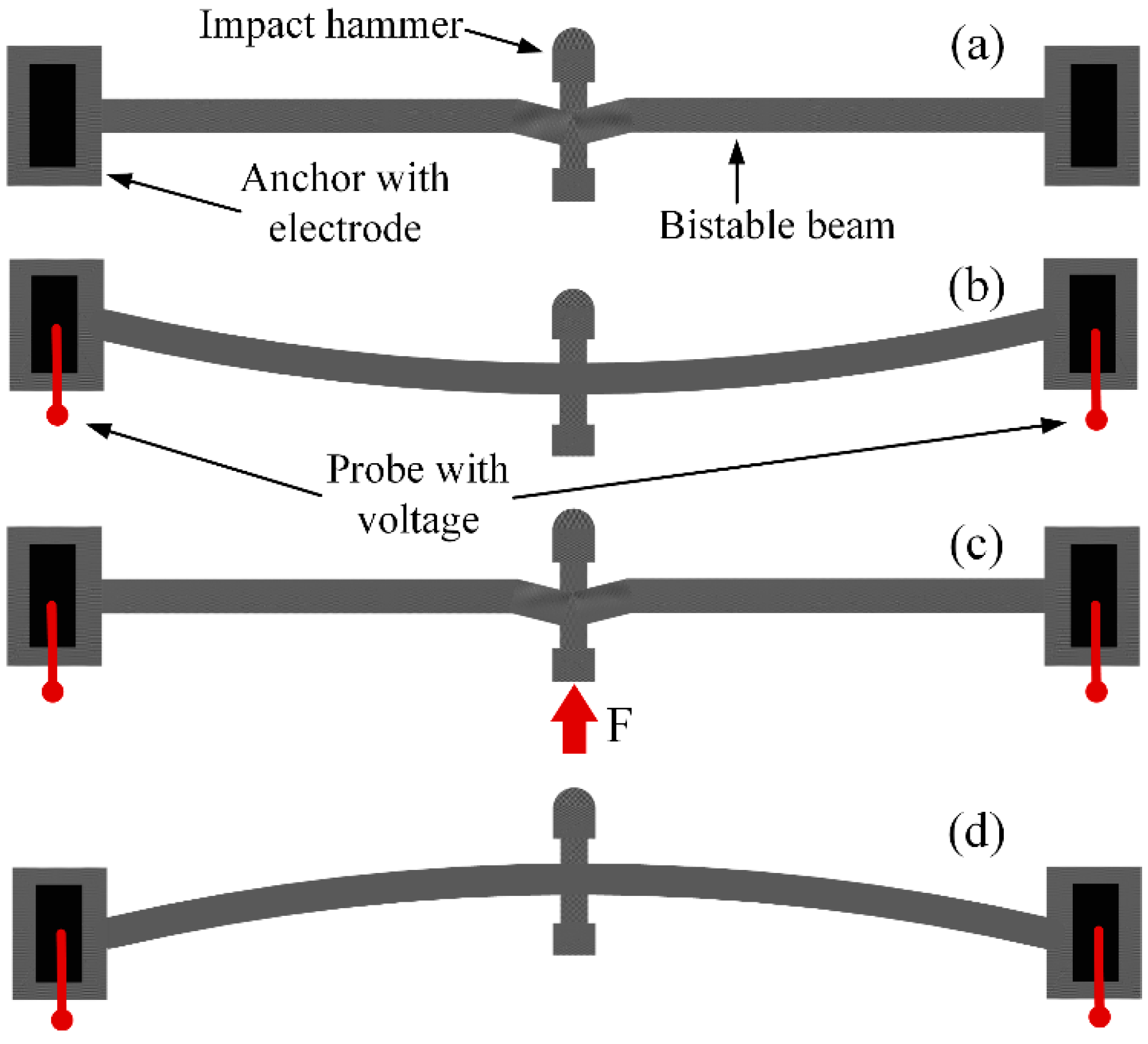

2. Principle and Design

2.1. Bistable Shock Structure

2.2. Shock Tester

3. Fabrication

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Yu, R.; Zhang, D. An on-chip bistable structure for extracting the shock fracture strength of the microstructure. In Proceedings of the 2022 IEEE 35th International Conference on Micro Electro Mechanical Systems Conference (MEMS), Tokyo, Japan, 9–13 January 2022; pp. 573–576. [Google Scholar]

- Comtois, J.H.; Bright, V.M.; Phipps, M.W. Thermal microactuators for surface-micromachining processes. In Proceedings of the Micromachining and Microfabrication Process Technology, Austin, TX, USA, 23–24 October 1995; Volume 2642, pp. 10–21. [Google Scholar]

- Zhang, D.; Cai, A.; Zhao, Y.; Hu, T. Macro Modeling of V-Shaped Electro-Thermal MEMS Actuator with Human Error Factor. Micromachines 2021, 12, 622. [Google Scholar] [CrossRef] [PubMed]

- Riethmuller, W.; Benecke, W. Thermally excited silicon microactuators. IEEE Trans. Electron Devices 1988, 35, 758–763. [Google Scholar] [CrossRef]

- Mankame, N.D.; Ananthasuresh, G.K. Comprehensive thermal modelling and characterization of an electro-thermal-compliant microactuator. J. Micromech. Microeng. 2001, 11, 452–462. [Google Scholar] [CrossRef]

- Gianchandani, Y.B.; Najafi, K. Bent-beam strain sensors. J. Microelectromech. Syst. 1996, 5, 52–58. [Google Scholar] [CrossRef]

- Chiao, M.; Lin, L. Microactuators Based on Electrothermal Expansion of Clamped-Clamped Beams. ASME Int. Mech. Eng. Congr. Expo. 1997, 18435, 75–80. [Google Scholar] [CrossRef]

- Que, L.; Park, J.-S.; Gianchandani, Y. Bent-beam electrothermal actuators-Part I: Single beam and cascaded devices. J. Microelectromech. Syst. 2001, 10, 247–254. [Google Scholar] [CrossRef] [Green Version]

- Eniko, E.T.; Shantanu, S.S.; Lazarov, K.V. Analytical Model for Analysis and Design of V-Shaped Thermal Microactuators. J. Microelectromech. Syst. 2005, 14, 788–798. [Google Scholar] [CrossRef]

- Li, L.; Uttamchandani, D. Dynamic response modelling and characterization of a vertical electrothermal actuator. J. Micromech. Microeng. 2009, 19, 075014. [Google Scholar] [CrossRef]

- Seki, T.; Sakata, M.; Nakajima, T.; Matsumoto, M. Thermal buckling actuator for micro relays. In Proceedings of the International Solid State Sensors and Actuators Conference (Transducers’97), Chicago, IL, USA, 19 June 1997. [Google Scholar] [CrossRef]

- Zheng, L.-S.; Lu, M.S.-C. A large-displacement CMOS micromachined thermal actuator with comb electrodes for capacitive sensing. Sens. Actuators A Phys. 2007, 136, 697–703. [Google Scholar] [CrossRef]

- Jensen, B.D.; Howell, L.L. Identification of Compliant Pseudo-Rigid-Body Four-Link Mechanism Configurations Resulting in Bistable Behavior. J. Mech. Des. 2003, 125, 701–708. [Google Scholar] [CrossRef]

- Hälg, B. On a nonvolatile memory cell based on micro-electro-mechanics. In Proceedings of the IEEE Proceedings on Micro Electro Mechanical Systems, An Investigation of Micro Structures, Sensors, Actuators, Machines and Robots, Napa Valley, CA, USA, 11–14 February 1990. [Google Scholar]

- Vangbo, M.; Bäcklund, Y. A lateral symmetrically bistable buckled beam. J. Micromech. Microeng. 1998, 8, 29–32. [Google Scholar] [CrossRef]

- Parkinson, M.B.; Jensen, B.D.; Roach, G.M. Optimization-Based Design of a Fully-Compliant Bistable Micromechanism. In Proceedings of the 26th Biennial Mechanisms and Robotics Conference, Baltimore, MD, USA, 10–13 September 2000; pp. 635–641. [Google Scholar] [CrossRef]

- Li, R.; Yang, F.; He, J.; Zhang, L.; Guan, T.; Fan, Z.; Cheng, L.; Zhang, D. A universal structure for self-aligned in situ on-chip micro tensile fracture strength test. In Proceedings of the International Conference on Micro Electro Mechanical Systems Conference (MEMS), Las Vegas, NV, USA, 22–26 January 2017; pp. 640–643. [Google Scholar]

- Zhu, Y.; Corigliano, A.; Espinosa, H.D. A thermal actuator for nanoscale in situ microscopy testing: Design and characterization. J. Micromech. Microeng. 2006, 16, 242–253. [Google Scholar] [CrossRef] [Green Version]

- Kahn, H.; Ballarini, R.; Mullen, R.L.; Heuer, A.H. Electrostatically actuated failure of microfabricated polysilicon fracture mechanics specimens. In Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences; Royal Society: London, UK, 1999; Volume 455, pp. 3807–3823. [Google Scholar]

- Tsutsui, W.; Raghunathan, N.; Chen, W.; Peroulis, D. Testing Techniques for Shock Accelerometers below 10,000 g. Dyn. Behav. Mater. 2013, 1, 333–340. [Google Scholar] [CrossRef]

- Tanner, D.M.; Walraven, J.A.; Helgesen, K.; Irwin, L.W.; Brown, F.; Smith, N.F.; Masters, N. MEMS reliability in shock environments. In Proceedings of the IEEE International Reliability Physics Symposium, San Jose, CA, USA, 10–13 April 2000; pp. 129–138. [Google Scholar]

- Duesterhaus, M.A.; Bateman, V.I.; Hoke, D.A. Shock testing of surface micromachined MEMS devices. In Proceedings of the 47th Auunual Fuze Conference, New Orleans, LA, USA, 8–10 April 2003. [Google Scholar]

- Kimberley, J.; Cooney, R.; Lambros, J.; Chasiotis, I.; Barker, N. Failure of Au RF-MEMS switches subjected to dynamic loading. Sens. Actuators A Phys. 2009, 154, 140–148. [Google Scholar] [CrossRef]

- Peng, X.; Jing, Z.; Zu-Seng, L. The Study of Buffer Structure of On-Board Test’s Circuit Module in High Shock. IEEE Trans. Instrum. Meas. 2004, 53, 1224–1226. [Google Scholar] [CrossRef]

- Robinson, C.H.; Wood, R.H.; Hoang, T.Q.; Hollingsworth, D. Development and demonstration of a MEMS-based safety and arming device for the 20-mm OICW fuze. In Proceedings of the NDIA Joint Services Small Arms Conference, Atlantic City, NJ, USA, 13–16 May 2002. [Google Scholar]

- Younis, M.I.; Jordy, D.; Pitarresi, J.M. Computationally Efficient Approaches to Characterize the Dynamic Response of Microstructures under Mechanical Shock. J. Microelectromech. Syst. 2007, 16, 628–638. [Google Scholar] [CrossRef]

- Lott, C.; McLain, T.; Harb, J.; Howell, L. Modeling the thermal behavior of a surface-micromachined linear-displacement thermomechanical microactuator. Sens. Actuators A Phys. 2002, 101, 239–250. [Google Scholar] [CrossRef] [Green Version]

- Hickey, R.; Sameoto, D.; Hubbard, T.; Kujath, M. Time and frequency response of two-arm micromachined thermal actuators. J. Micromech. Microeng. 2003, 13, 40–46. [Google Scholar] [CrossRef]

- Hu, T.; Ren, W.; Zhao, Y.; Xue, Y. The Research on Actuation Performance of MEMS Safety-and-Arming Device with Interlock Mechanism. Micromachines 2019, 10, 76. [Google Scholar] [CrossRef] [Green Version]

- Cragun, R. Constrained thermal expansion micro-actuator. In Proceedings of the ASME 1998 International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 15–20 November 1998; pp. 365–371. [Google Scholar]

- Wortman, J.J.; Evans, R.A. Young’s modulus, shear modulus, and Poisson’s ratio in silicon and germanium. J. Appl. Phys. 1965, 36, 153–156. [Google Scholar] [CrossRef]

- Okada, Y.; Tokumaru, Y. Precise determination of lattice parameter and thermal expansion coefficient of silicon between 300 and 1500 K. J. Appl. Phys. 1984, 56, 314–320. [Google Scholar] [CrossRef]

- Shanks, H.R.; Maycock, P.D.; Sidles, P.H.; Danielson, G.C. Thermal Conductivity of Silicon from 300 to 1400°K. Phys. Rev. 1963, 130, 1743–1748. [Google Scholar] [CrossRef]

- Barin, I. Thermochemical Data of Pure Substances, 3rd ed.; Wiley: Hoboken, NJ, USA, 1997. [Google Scholar]

- Abbas, K.; Alaie, S.; Leseman, Z.C. Design and characterization of a low temperature gradient and large displacement thermal actuators for in situ mechanical testing of nanoscale materials. J. Micromech. Microeng. 2012, 22, 125027. [Google Scholar] [CrossRef]

- Vedde, J.; Gravesen, P. The fracture strength of nitrogen doped silicon wafers. Mater. Sci. Eng. B 1996, 36, 246–250. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Young modulus (E) | 169 GPa [31] |

| Poisson ratio | 0.28 [31] |

| Density | 2330 kg/m3 |

| Thermal expansion | 2.6 × 10−6 [32] |

| Thermal conductivity | 150 W m−1 K−1 [33] |

| Resistivity | 0.002 Ω cm |

| Specific heat | 730 J kg−1 K−1 [34] |

| Convective heat transfer coefficient | 100 W m−2 K−1 [28] |

| Dimension | Value |

|---|---|

| Length of bistable beam | 1000 μm |

| Width of bistable beam | 20 μm |

| Length of thermal beam | 1000 μm |

| Width of thermal beam | 10 μm |

| Angle of thermal beam | 6° |

| Number of thermal beams | 20 |

| Thickness of structure | 60 μm |

| Part | Dimension | Value |

|---|---|---|

| Thermal actuator at both ends of the bistable beam | Length Width | 200 μm 10 μm |

| Angle | 6° | |

| Number | 10 | |

| V-shaped lever | Length Width | 1150 μm 40 μm |

| Angle | 4° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, R.; Zhang, D. A Thermal Actuated Bistable Structure for Generating On-Chip Shock Loads. Micromachines 2022, 13, 569. https://doi.org/10.3390/mi13040569

Yu R, Zhang D. A Thermal Actuated Bistable Structure for Generating On-Chip Shock Loads. Micromachines. 2022; 13(4):569. https://doi.org/10.3390/mi13040569

Chicago/Turabian StyleYu, Runze, and Dacheng Zhang. 2022. "A Thermal Actuated Bistable Structure for Generating On-Chip Shock Loads" Micromachines 13, no. 4: 569. https://doi.org/10.3390/mi13040569