Development of a Fault Detection Instrument for Fiber Bragg Grating Sensing System on Airplane

Abstract

:1. Introduction

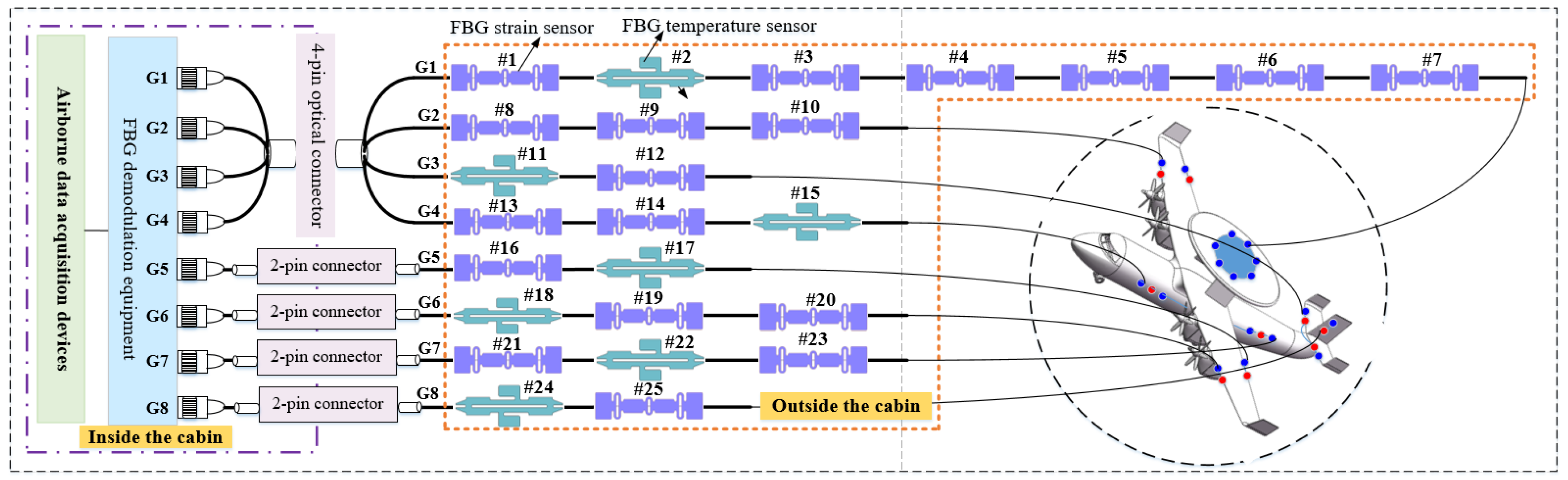

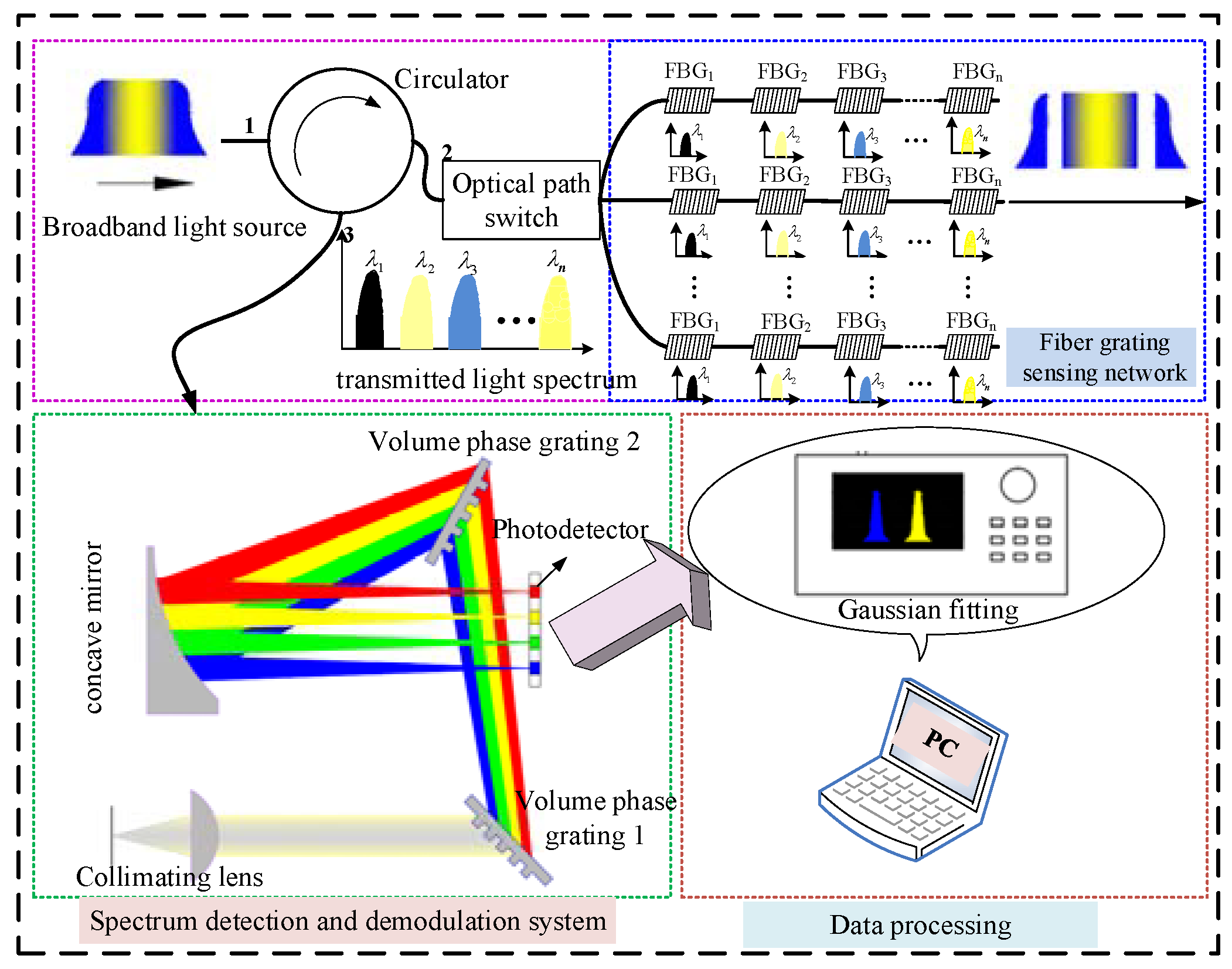

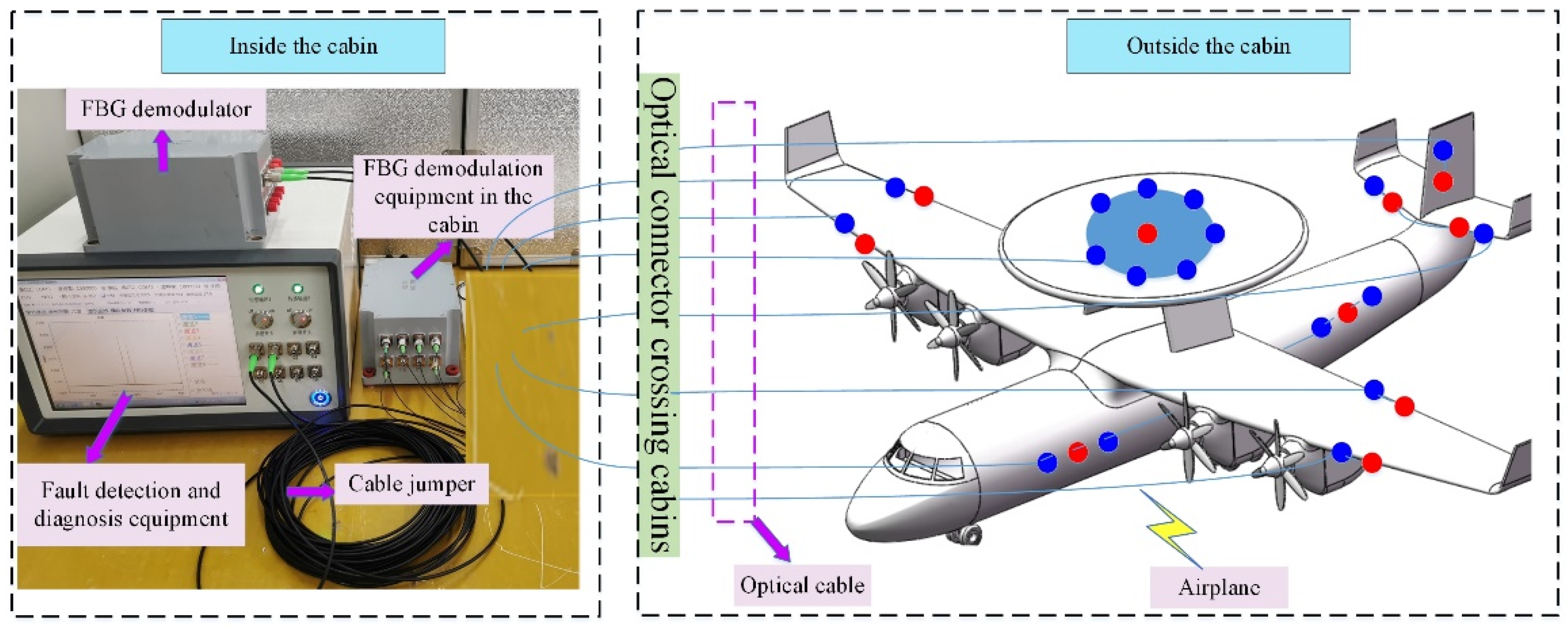

2. Fiber Bragg Grating Sensing System on the Airplane

3. System Design and Implementation

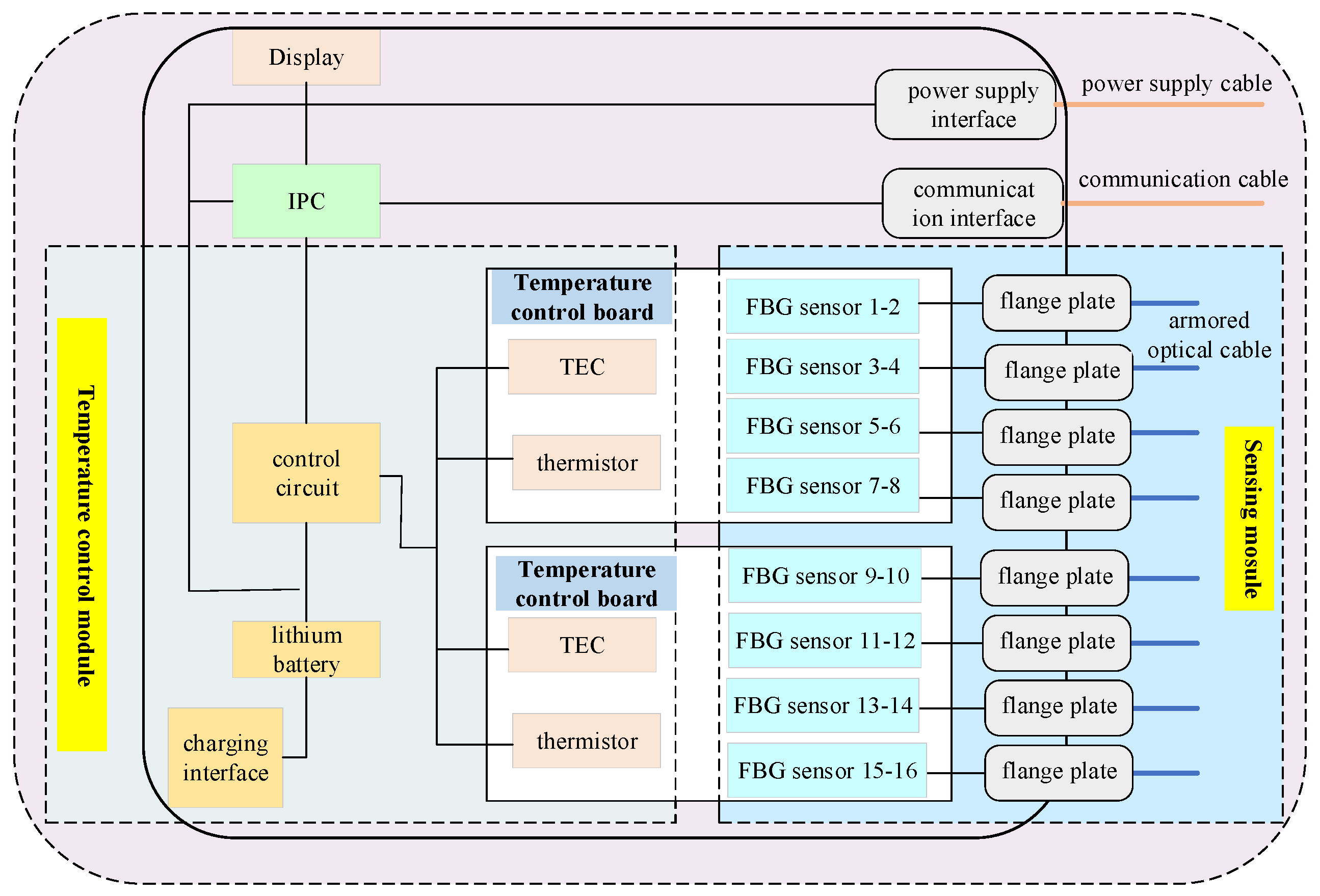

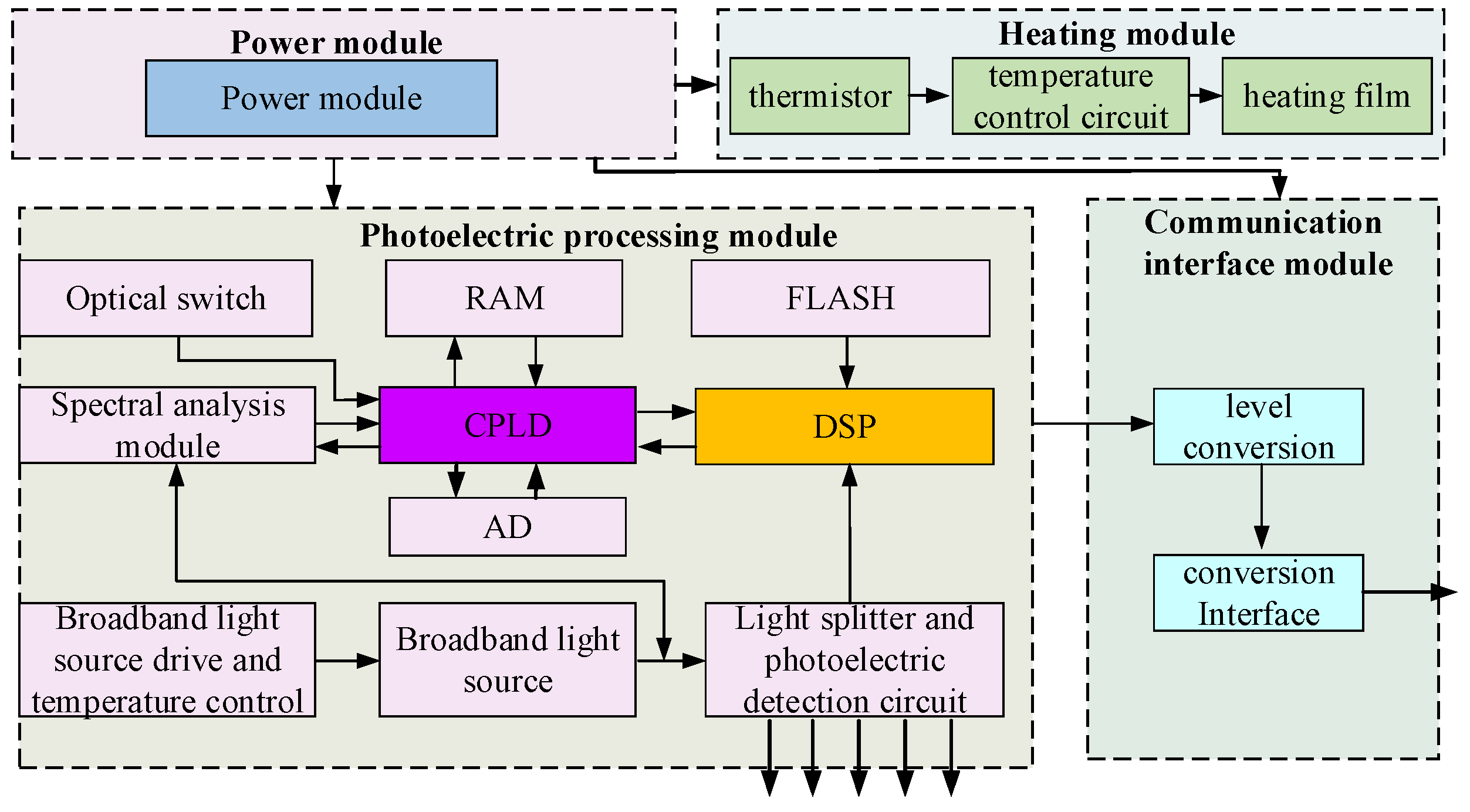

3.1. Hardware Design of Fault Detection Instrument

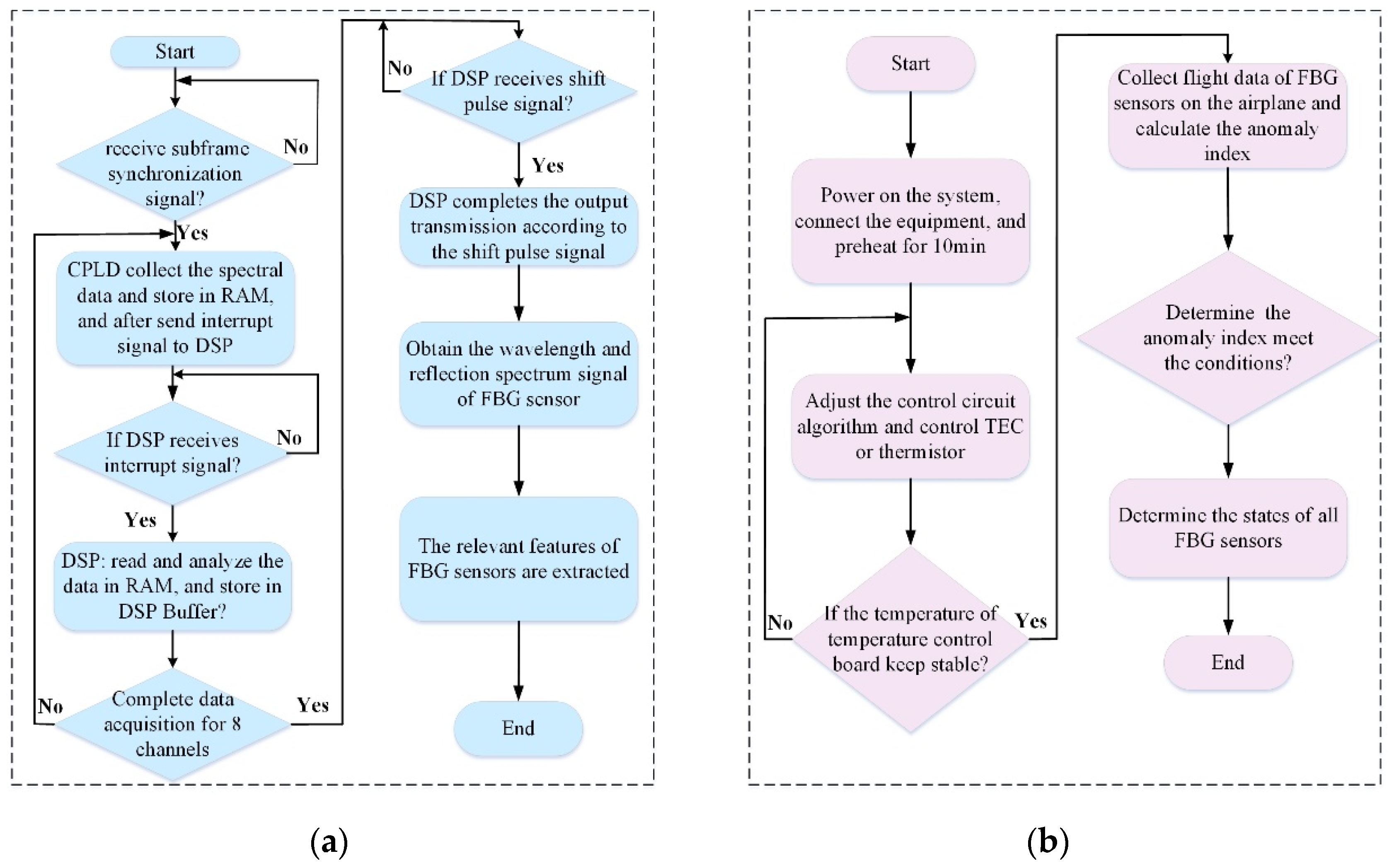

3.2. Software Design of Fault Detection Device

4. Wavelength Demodulation and Fault Detection Methods

4.1. Wavelength Demodulation Method

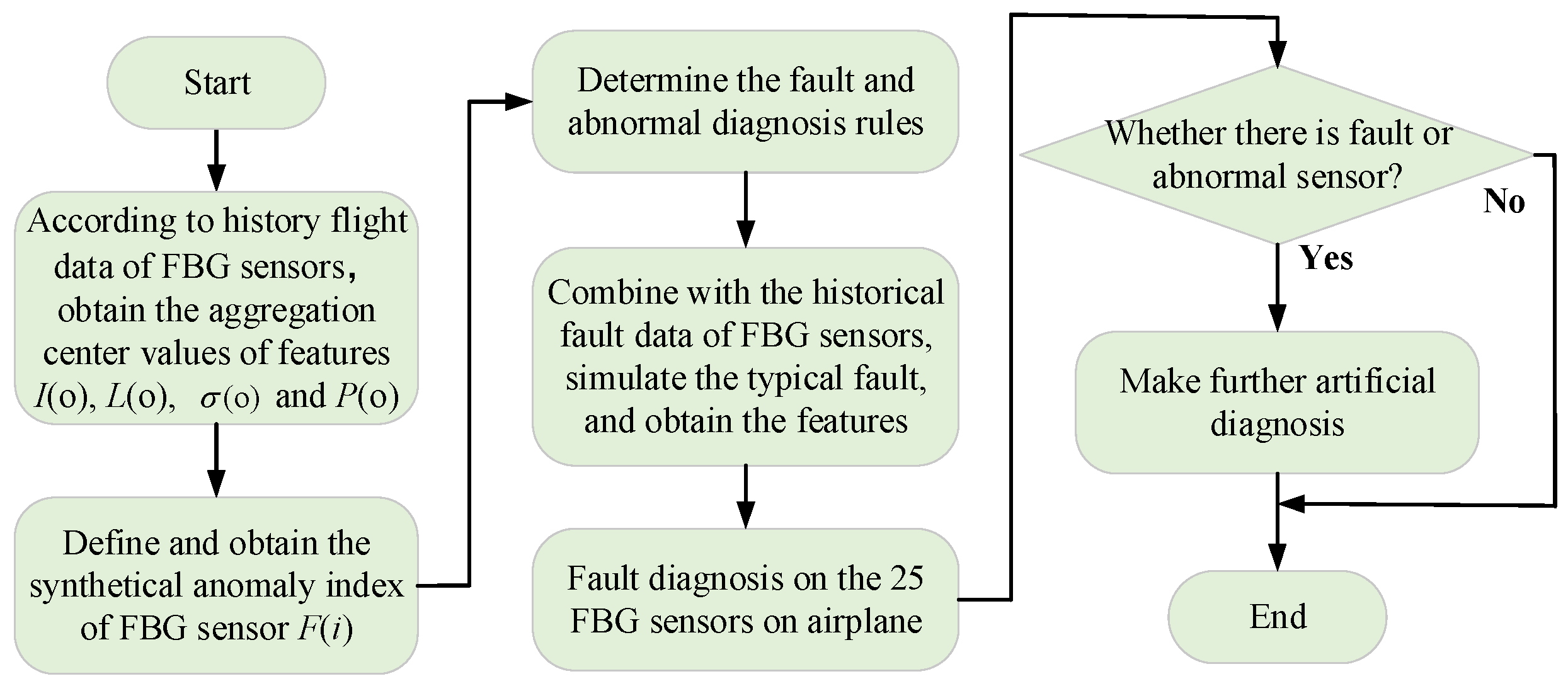

4.2. Fault Detection Method

4.3. Fault Detection Process

5. Experimental Verification and Discussion

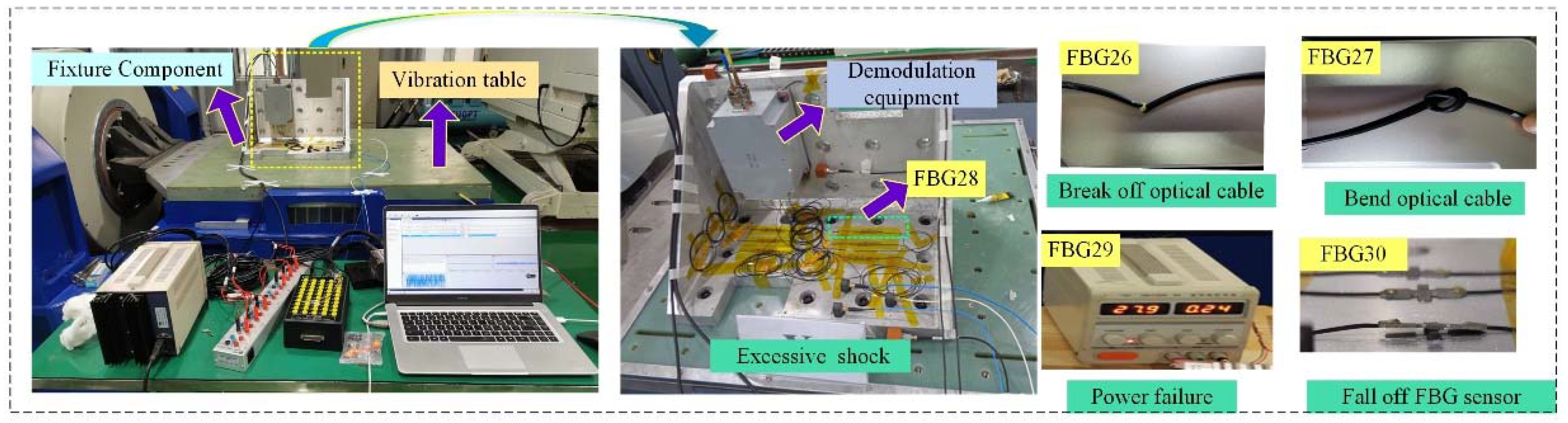

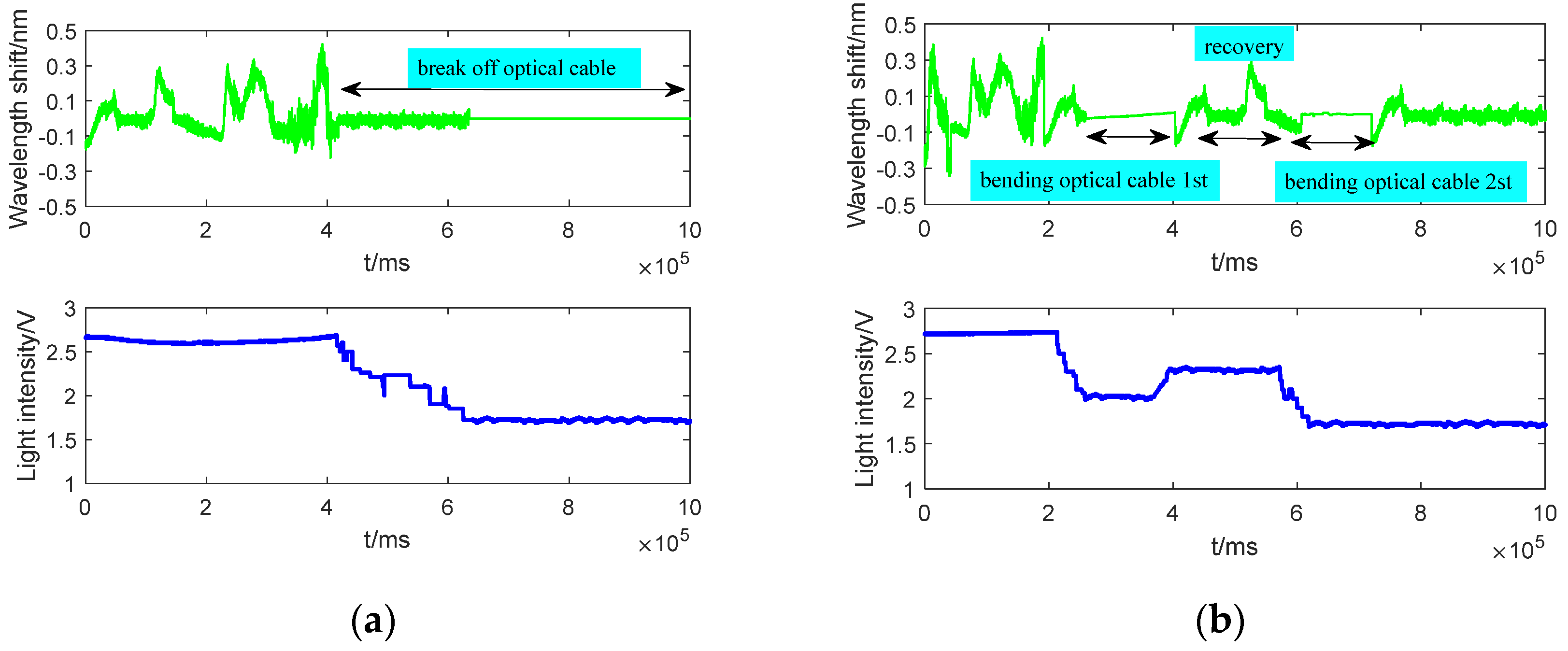

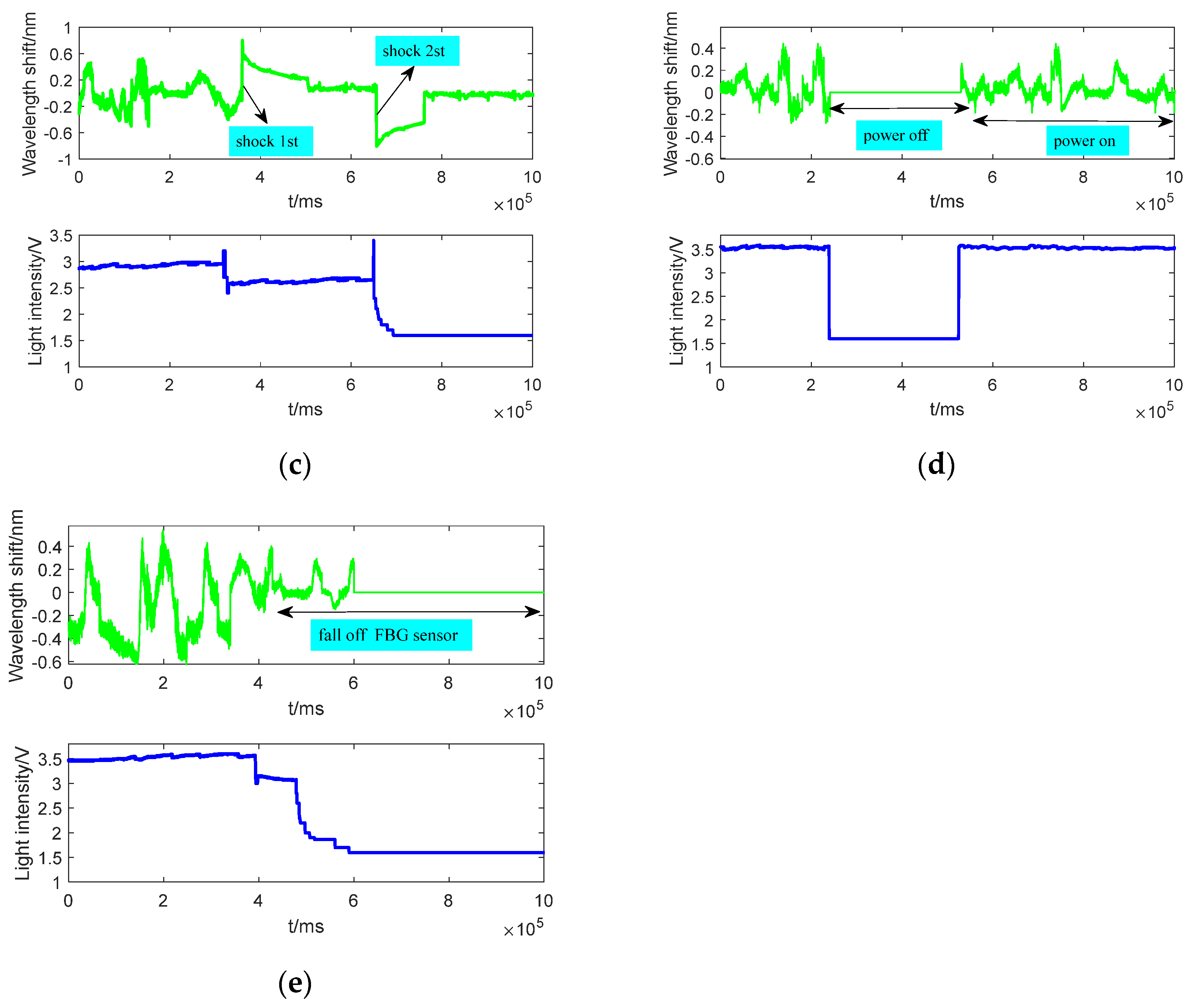

5.1. Typical Fault Simulation Test

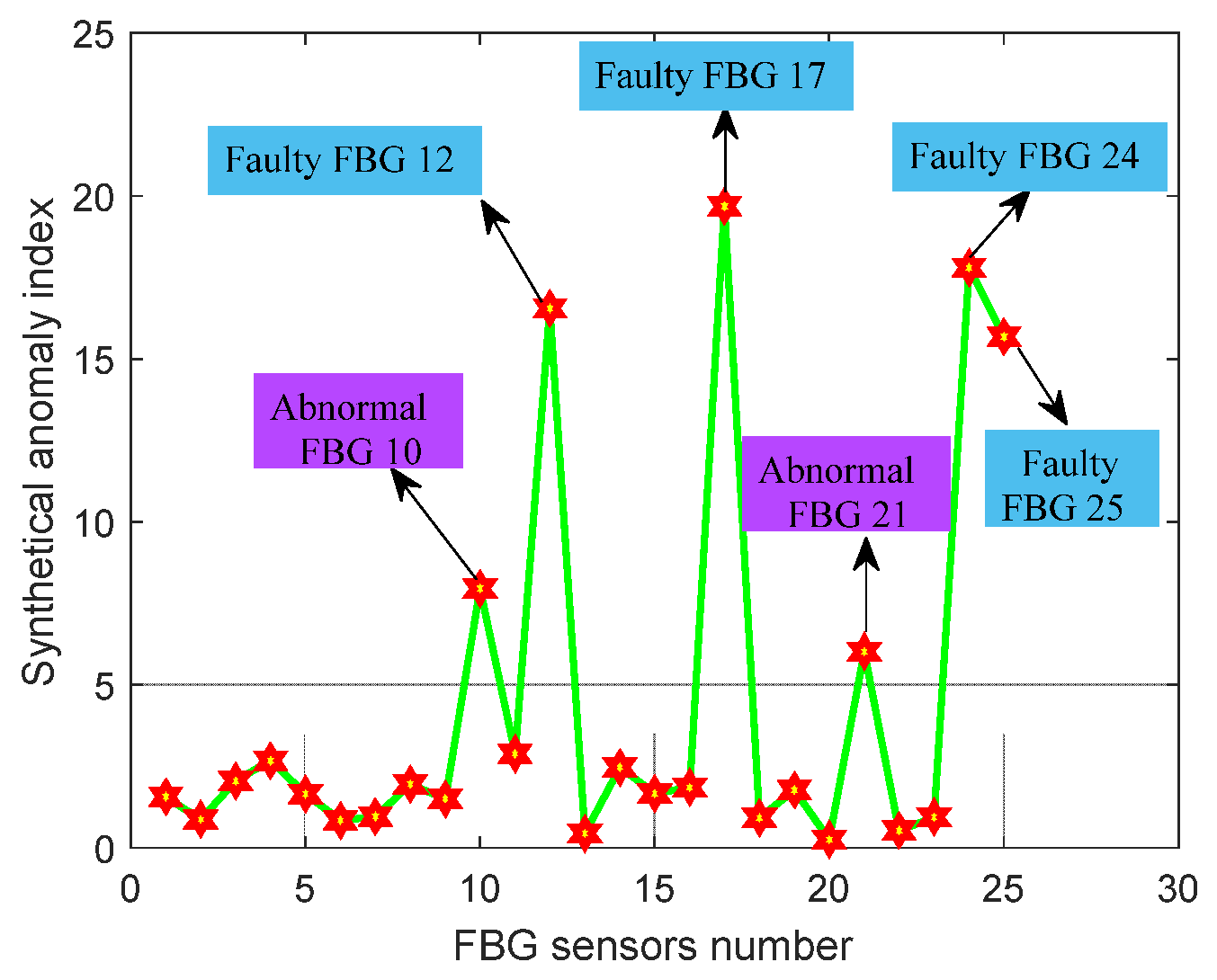

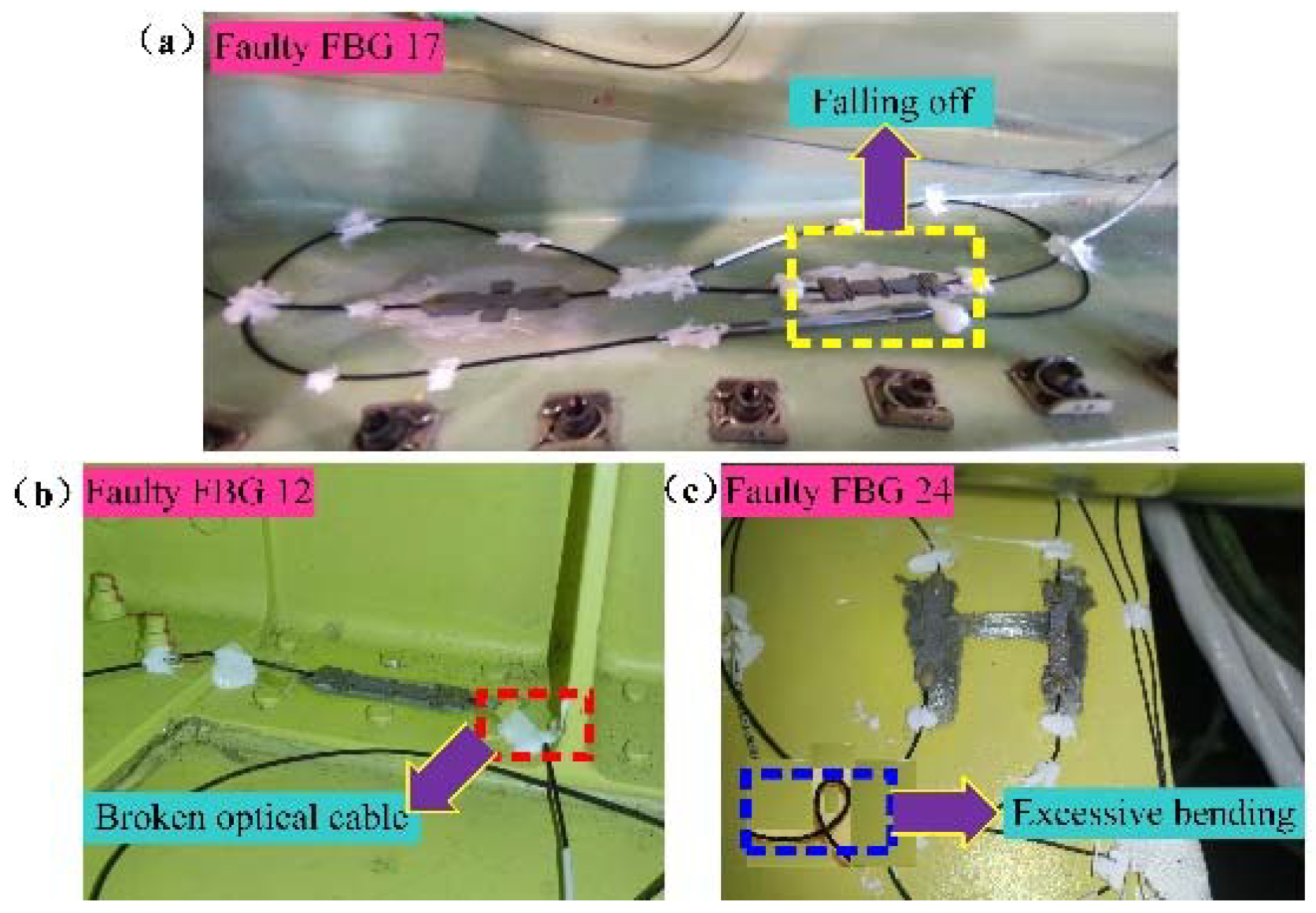

5.2. Fault Detection on 25 FBG Sensors on Airplane

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arcadius, T.C.; Gao, B.; Tian, G. Structural Health Monitoring Framework Based on Internet of Things: A Survey. IEEE Internet Things 2017, 4, 619–635. [Google Scholar] [CrossRef]

- Schenato, L.; Aguilar-López, J.P.; Galtarossa, A.; Pasuto, A.; Bogaard, T.; Palmieri, L. A Rugged FBG-Based Pressure Sensor for Water Level Monitoring in Dikes. IEEE Sens. J 2021, 21, 13263–13271. [Google Scholar] [CrossRef]

- Sarkar, S.J.; Inupakutika, D.; Banerjee, M.; Tarhan, M.; Shadaram, M. Machine Learning Methods for Discriminating Strain and Temperature Effects on FBG-Based Sensors. IEEE Photonics Technol. Lett. 2021, 33, 876–879. [Google Scholar] [CrossRef]

- Qiu, L.; Fang, F.; Yuan, S.F. Improved density peak clustering-based adaptive Gaussian mixture model for damage monitoring in aircraft structure under time-varying conditions. Mech. Syst. Signal Process. 2019, 126, 281–304. [Google Scholar] [CrossRef]

- Gelman, L.; Petrunin, I.; Parrish, C.; Walters, M. Novel health monitoring technology for in-service diagnostics of intake separation in aircraft engines. Struct. Control Health Monit. 2020, 27, e2479. [Google Scholar] [CrossRef] [Green Version]

- Dutta, C.D.; Kumar, J.; Das, T.K.; Sagar, S.P. Recent Advancements in the Development of Sensors for the Structural Health Monitoring (SHM) at High-Temperature Environment: A Review. IEEE Sens. J. 2021, 21, 15904–15916. [Google Scholar] [CrossRef]

- Yu, X.K.; Song, N.F.; Song, J.M. A novel method for simultaneous measurement of temperature and strain based on EFPI/FBG. Opt. Commun. 2020, 459, 125020. [Google Scholar] [CrossRef]

- Jin, J.; Zhu, Y.H.; Zhang, Y.B.; Zhang, D.W.; Zhang, Z.C. Micrometeoroid and Orbital Debris Impact Detection and Location Based on FBG Sensor Network Using Combined Artificial Neural Network and Mahalanobis Distance Method. IEEE Trans. Instrum. Meas. 2021, 70, 7005210. [Google Scholar] [CrossRef]

- Ab-Rahman, M.S.; Ridzuan, A.M.; Kaharudin, I.H.; Hwang, I.S. Real time FTTH network monitoring using binary coded fiber Bragg grating. Optik 2022, 251, 168408. [Google Scholar] [CrossRef]

- Guan, X.; Shi, W.; Rusch, L.A. Ultra-Dense Wavelength-Division Multiplexing with Microring Modulator. J. Lightw. Technol. 2021, 39, 4300–4306. [Google Scholar] [CrossRef]

- Feng, Y.W.; Chang, J.; Chen, X.H.; Zhang, Q.D.; Wang, Z.L.; Sun, J.C.; Zhang, Z.W. Application of TDM and FDM methods in TDLAS based multi-gas detection. Opt. Quantum Electron. 2021, 53, 195. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, J.D.; Shigeno, M. A novel channel-based model for the problem of routing, space, and spectrum assignment. Opt. Switch. Netw. 2022, 43, 100636. [Google Scholar] [CrossRef]

- Maru, K.C. Two-dimensional spatially encoded cross-sectional velocity distribution measurements based on coherent bias-frequency encoding and wavelength-division multiplexing. Opt. Commun. 2021, 485, 126740. [Google Scholar] [CrossRef]

- Zhang, C.B.; Gao, Y.Y.; Zuo, M.Q.; Lei, P.; Liu, R.W.; He, B.B.; Li, J.H.; Chen, Z.Y. Using ASE sources in remote beamforming system with Space-Division-Multiplex fiber. Opt. Commun. 2022, 504, 127477. [Google Scholar] [CrossRef]

- Yin, S.; Chen, Y.D.; Ding, S.C.; Zhang, Z.D.; Huang, S.G. Crosstalk-aware routing, spectrum, and core assignment based on AoD nodes in SDM-EONs with bidirectional multicore fibers. Opt. Switch. Netw. 2022, 43, 100647. [Google Scholar] [CrossRef]

- Mohapatra, A.G.; Talukdar, J.; Mishra, T.C.; Anand, S.; Jaiswal, A. Fiber Bragg grating sensors driven structural health monitoring by using multimedia-enabled iot and big data technology. Multimed. Tools Appl. 2022. [Google Scholar] [CrossRef]

- Soman, R.; Wee, J.; Peters, K. Optical Fiber Sensors for Ultrasonic Structural Health Monitoring: A Review. Sensors 2021, 21, 7345. [Google Scholar] [CrossRef]

- Jinachandran, S.; Rajan, G. Fibre Bragg Grating Based Acoustic Emission Measurement System for Structural Health Monitoring Applications. Materials 2021, 14, 897. [Google Scholar] [CrossRef]

- Tamoghna Ojha, S.M.; Singh, R.N. Wireless sensor networks for agriculture: The state-of-the-art in practice and future challenges. Comput. Electron. Agric. 2015, 118, 66–84. [Google Scholar] [CrossRef]

- Li, D.L.; Wang, Y.; Wang, J.X. Recent advances in sensor fault diagnosis: A review. Sens. Actuators A Phys. 2020, 309, 111990. [Google Scholar] [CrossRef]

- Patton, R.J.; Chen, J. A survey of robustness problems in quantitative model-based fault diagnosis. Appl. Maths. Comput. Sci. 1993, 3, 339–416. [Google Scholar]

- Frank, P.M.; Ding, X. Survey of robust residual generation and evaluation methods in observer-based fault detection systems. J. Process Control 1997, 7, 403–424. [Google Scholar] [CrossRef]

- Kerschen, G.; De, B.P.; Golinval, J.C.; Worden, K. Sensor validation for on-line vibration monitoring. In Proceedings of the European Workshop on Structural Health Monitoring, Munich, Germany, 7–9 July 2004; pp. 819–827. [Google Scholar]

- Cazzulani, G.; Cinquemani, S.; Ronchi, M. A fault identification technique for FBG sensors embedded in composite structures. Smart Mater. Struct. 2016, 25, 055049. [Google Scholar] [CrossRef]

- Cazzulani, G.; Cinquemani, S.; Comolli, L. A technique to evaluate the good operation of FBG sensors embedded in a carbon fiber beam. Proc. SPIE 2013, 8794, 87942S. [Google Scholar]

- Rao, A.R.M.; Kasireddy, V.; Gopalakrishnan, N.; Lakshmi, K. Sensor fault detection in structural health monitoring using null subspace–based approach. J. Intell. Mater. Syst. Struct. 2015, 26, 172–185. [Google Scholar] [CrossRef]

- Huang, H.B.; Yi, T.H.; Li, H.N. Sensor Fault Diagnosis for Structural Health Monitoring Based on Statistical Hypothesis Test and Missing Variable Approach. J. Aerosp. Eng. 2015, B4015003, 1–14. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Kim, J.T.; Ta, Q.B.; Ho, D.D.; Phan, T.T.; Huynh, T.C. Deep learning-based functional assessment of piezoelectric-based smart interface under various degradations. Smart Struct. Syst. 2021, 28, 69–87. [Google Scholar]

- Xu, D.Y.; Tong, J.P.; Gao, J.X.; Wang, F. Fiber Spectrometer Optical Simulation Optimization and Calibration. Chin. J. Lasers 2015, 42, 1–5. [Google Scholar]

- Wen, X.Y. Research on Principle and Technology of Fiber Grating Sensor; Wuhan University of Technology Press: Wuhan, China, 2019; pp. 104–106. [Google Scholar]

| Fault Type | Signal Characteristics |

|---|---|

| Damage or fall off | No change in wavelength and intensity or little change |

| Excessive shock | Abrupt change of signal amplitude or missing |

| Break off optical cable | No signal output |

| Excessive bend optical cable | Weaken the signal or small amplitude variation |

| Sudden power failure and recover | Data missing and data length reduction |

| Feature Parameters | Definition |

|---|---|

| Minimum light intensity I | |

| Signal length L | |

| Standard deviation of original sample σ | |

| Energy value in time-domain P | |

| is the original wavelength data of FBG sensor (N is data points) | |

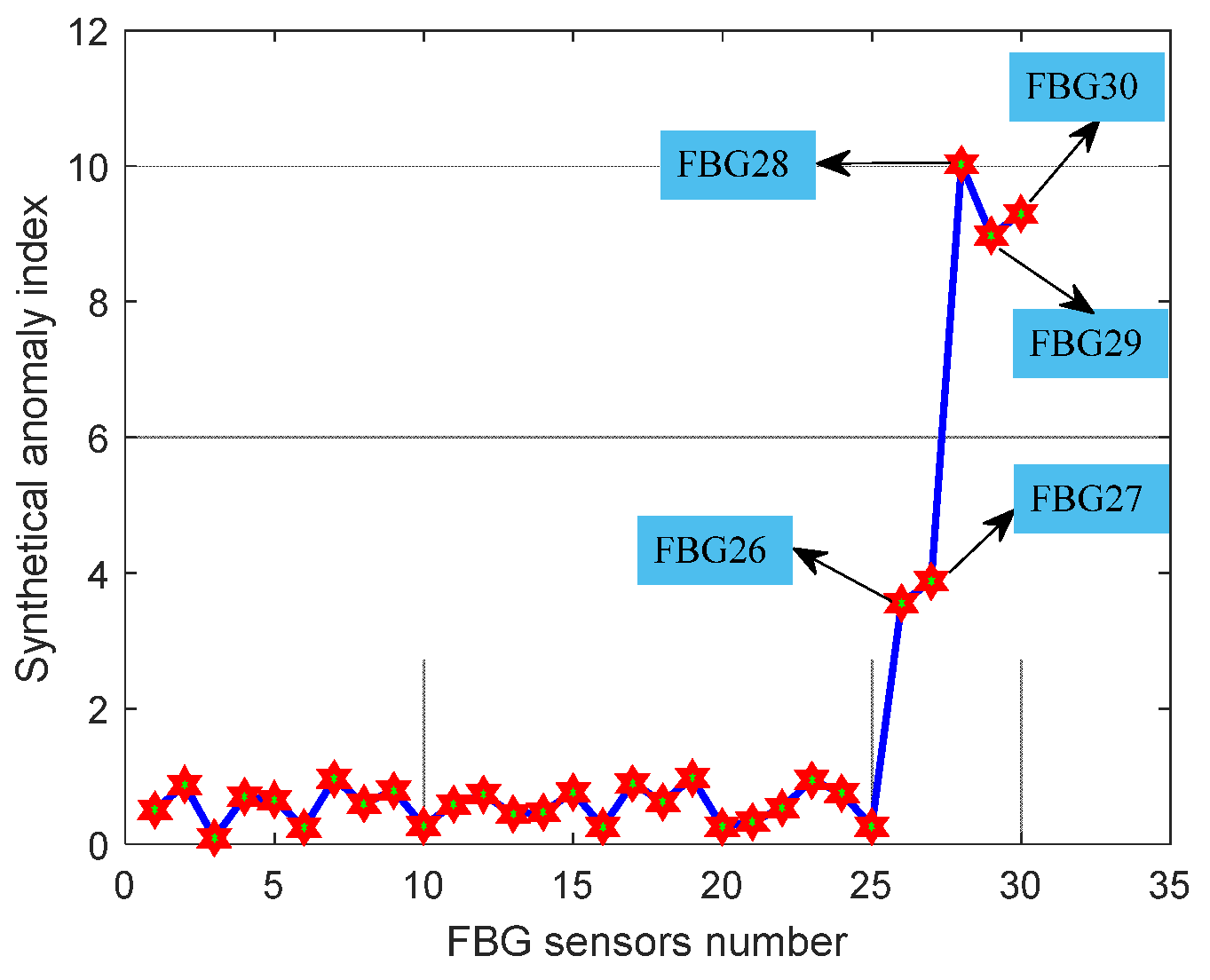

| FBG Sensors Number | Light Intensity I/V | Signal Length L | Standard Deviation σ/nm | Energy Value P/nm2 | Synthetical Anomaly Index |

|---|---|---|---|---|---|

| FBG26 | 1.6 | 267,341 | 0.0718 | 5361.538 | 3.556338 |

| FBG27 | 1.6 | 289,081 | 0.0808 | 6781.024 | 3.881325 |

| FBG28 | 1.6 | 289,081 | 0.2482 | 34,049.181 | 10.02711 |

| FBG29 | 1.6 | 192,679 | 0.0874 | 2741.718 | 8.97647 |

| FBG30 | 1.6 | 227,828 | 0.1883 | 36,879.550 | 9.296857 |

| FBG Sensors Number | Light Intensity I/V | Signal Length L | Standard Deviation σ/nm | Energy Value P/nm2 | Synthetical Anomaly Index |

|---|---|---|---|---|---|

| FBG 10 | 2.56 | 403,581 | 0.2708 | 6985.123 | 7.9565 |

| FBG 12 | 1.60 | 257,562 | 0.1280 | 4909.545 | 16.5480 |

| FBG 17 | 1.60 | 403,581 | 0.2035 | 4293.836 | 19.6785 |

| FBG 21 | 2.79 | 403,581 | 0.0946 | 7290.521 | 6.0214 |

| FBG 24 | 1.65 | 327,890 | 0.1023 | 5031.056 | 17.7976 |

| FBG 25 | 1.71 | 403,581 | 0.1245 | 4986.301 | 15.6780 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, C.; Kong, D.; Xu, C. Development of a Fault Detection Instrument for Fiber Bragg Grating Sensing System on Airplane. Micromachines 2022, 13, 882. https://doi.org/10.3390/mi13060882

Du C, Kong D, Xu C. Development of a Fault Detection Instrument for Fiber Bragg Grating Sensing System on Airplane. Micromachines. 2022; 13(6):882. https://doi.org/10.3390/mi13060882

Chicago/Turabian StyleDu, Cuicui, Deren Kong, and Chundong Xu. 2022. "Development of a Fault Detection Instrument for Fiber Bragg Grating Sensing System on Airplane" Micromachines 13, no. 6: 882. https://doi.org/10.3390/mi13060882

APA StyleDu, C., Kong, D., & Xu, C. (2022). Development of a Fault Detection Instrument for Fiber Bragg Grating Sensing System on Airplane. Micromachines, 13(6), 882. https://doi.org/10.3390/mi13060882