Development of Electrostatic Microactuators: 5-Year Progress in Modeling, Design, and Applications

Abstract

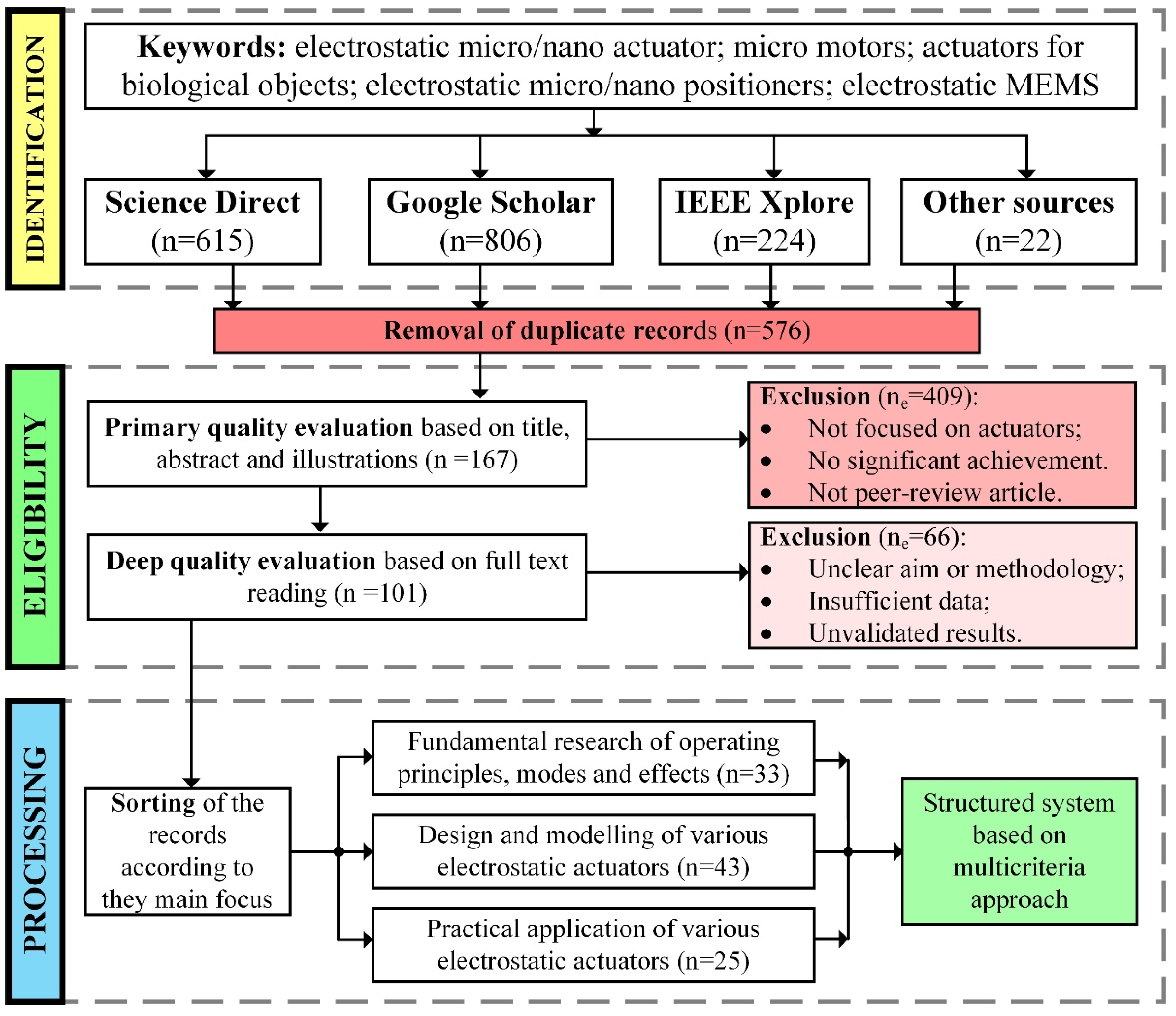

1. Introduction

2. Operating Modes

2.1. Attractive vs. Repulsive Force

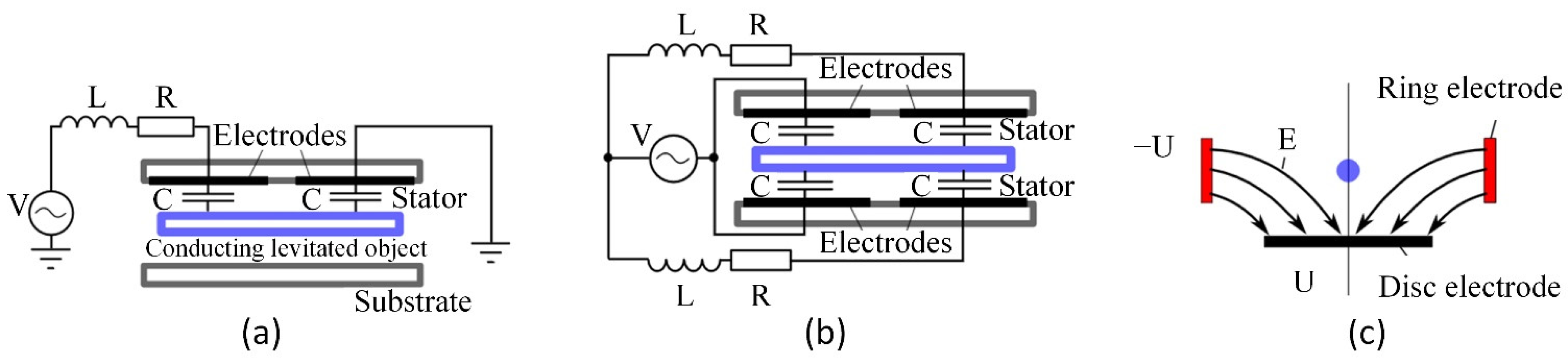

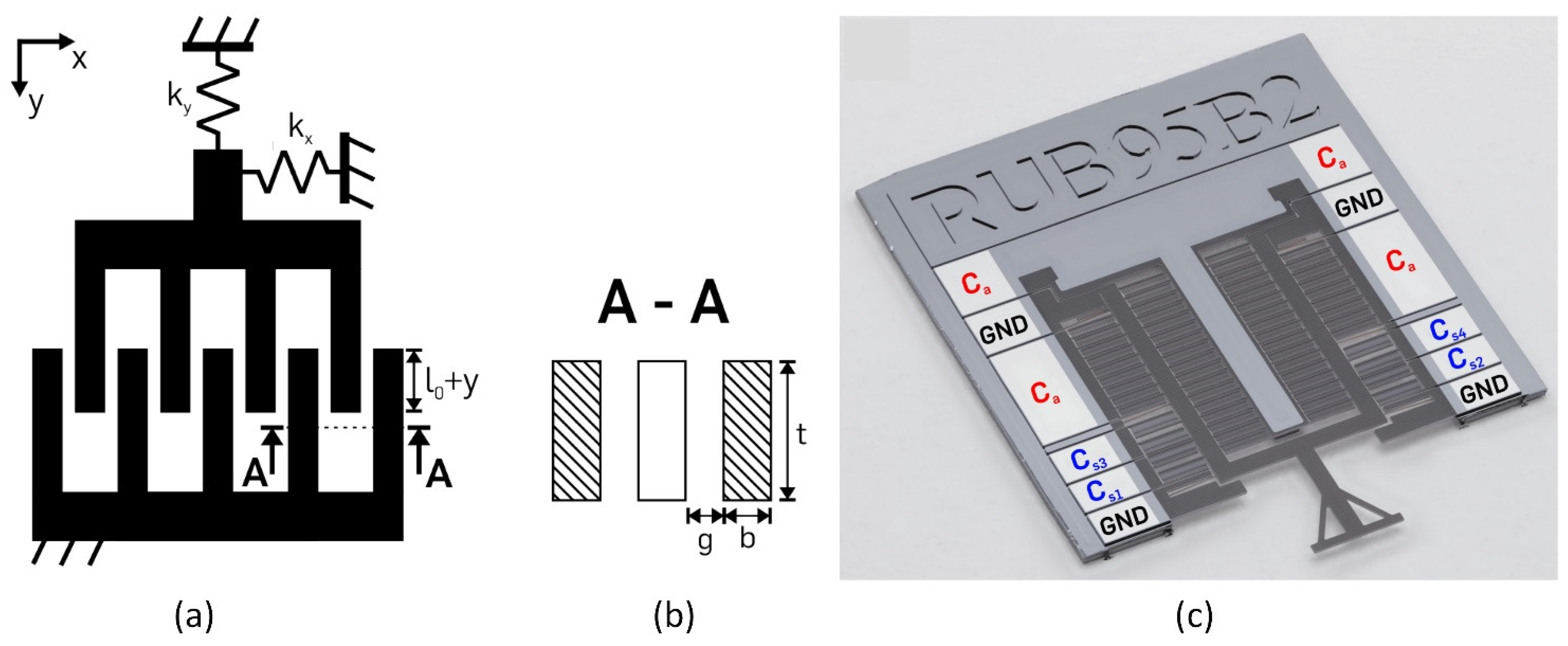

2.2. Electrostatic Levitation

| Design | Voltage | Forces/Displacements | Ref. |

|---|---|---|---|

| MEMS switch using electrostatic levitation | 100 V | 20 µm | [47] |

| MEMS switch using electrostatic levitation | 5.6–150 V | 16 µm | [48] |

| MEMS switch using electrostatic levitation | 6–12 V | 22 µm | [49] |

| MEMS microphone using electrostatic levitation | 40–100 V | - | [54] |

| Pull-in-free MEMS microphone | 200 V; 16.1 mV/Pa | - | [55,61] |

| MEMS pressure sensor | Middle voltage 3.5; side voltage 120 V | - | [59] |

3. Mathematical Modeling and Main Issues

| Object | Model | Voltage | Forces/Displacements | Ref. |

|---|---|---|---|---|

| Mechanical loading and gap influence on the dynamics | Simulink software | 60 V | 1.3 mN/1 µm | [70] |

| Electrostatic actuator made of nanocrystalline material | Mori–Tanaka micromechanical model | - | - | [71] |

| Robust voltage control for an electrostatic microactuator | Non-linear active disturbance rejection controller developed on the electrostatic actuator | 1.31–14.32 V | 2–4 µm | [72] |

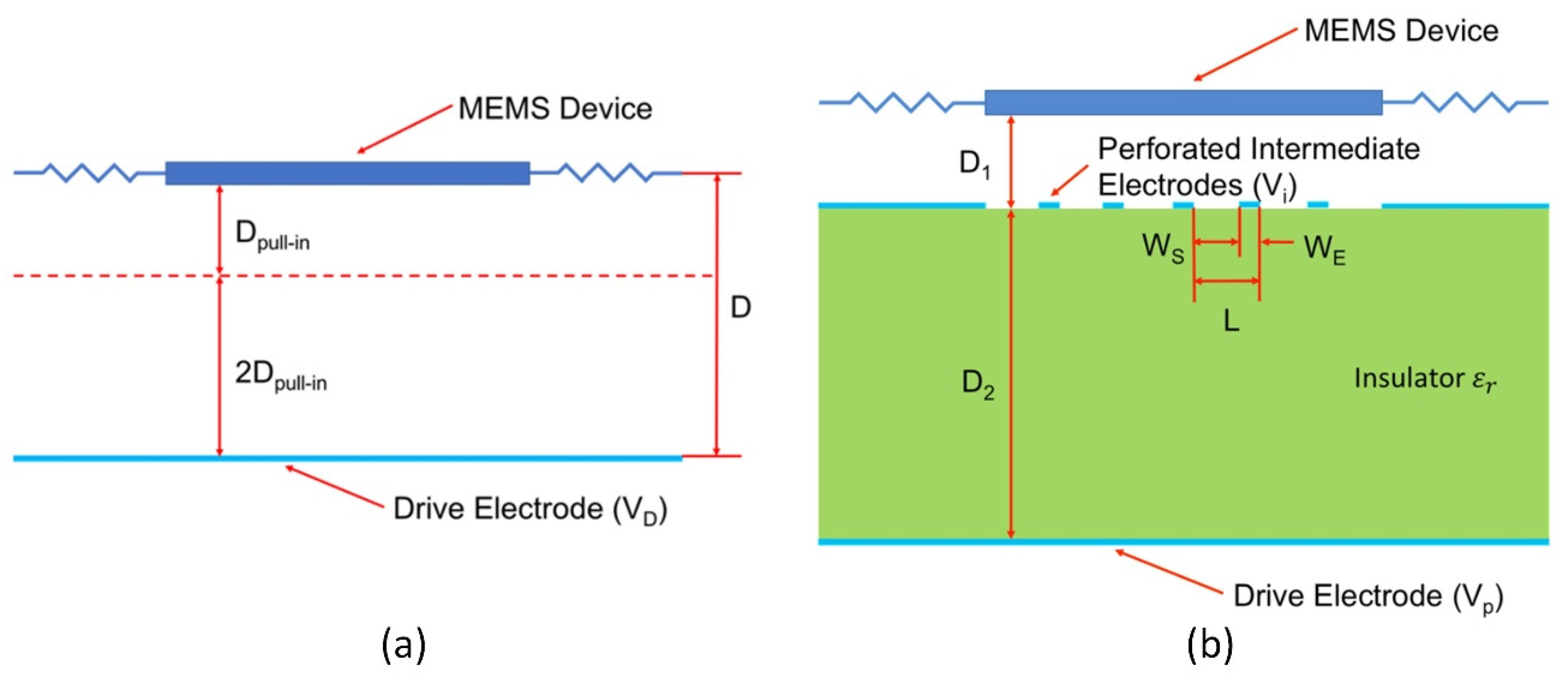

| Tri-electrode actuator | Topology with perforated intermediate electrode | - | - | [73] |

| Electrostatic film actuator | Model of electrostatic film actuator using the method of moment (MoM) | 500 V | 1.125 mN | [61] |

| Synthetic voltage division | Parallel-plate actuator characteristics with and without series capacitor method | 13 V | 10 µm | [74] |

| Fixed–fixed microactuator | Spring mass model, artificial bee colony algorithm | 13–56 V | - | [75] |

| Dimpled electrostatic MEMS actuator | Lumped mass model | 45.4 V short actuator, 9.4 V long actuator | - | [76] |

4. Design

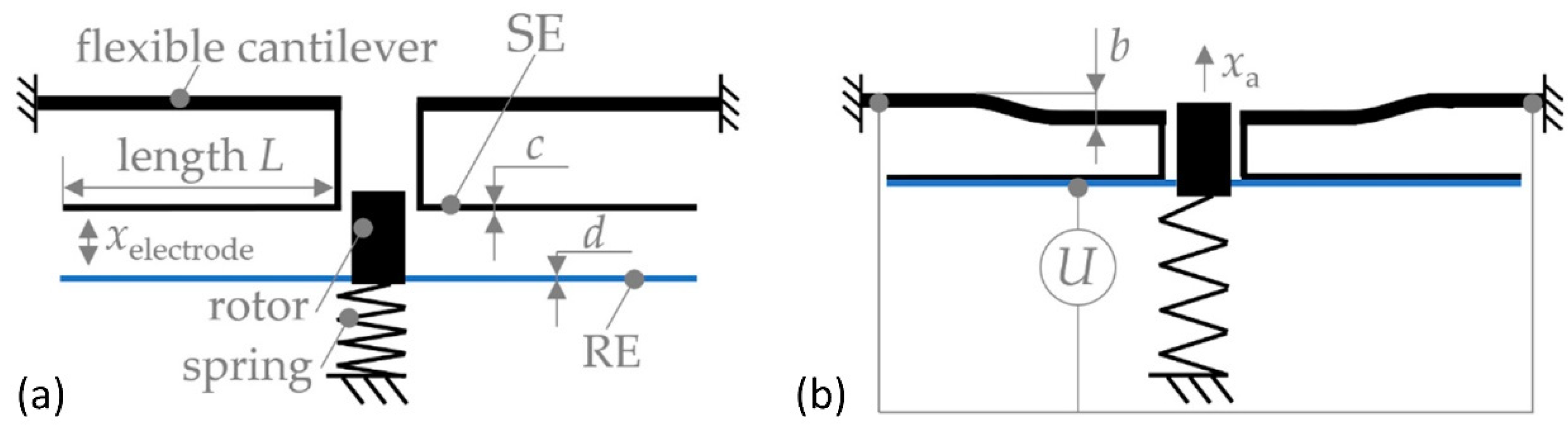

4.1. Parallel-Plate Drives

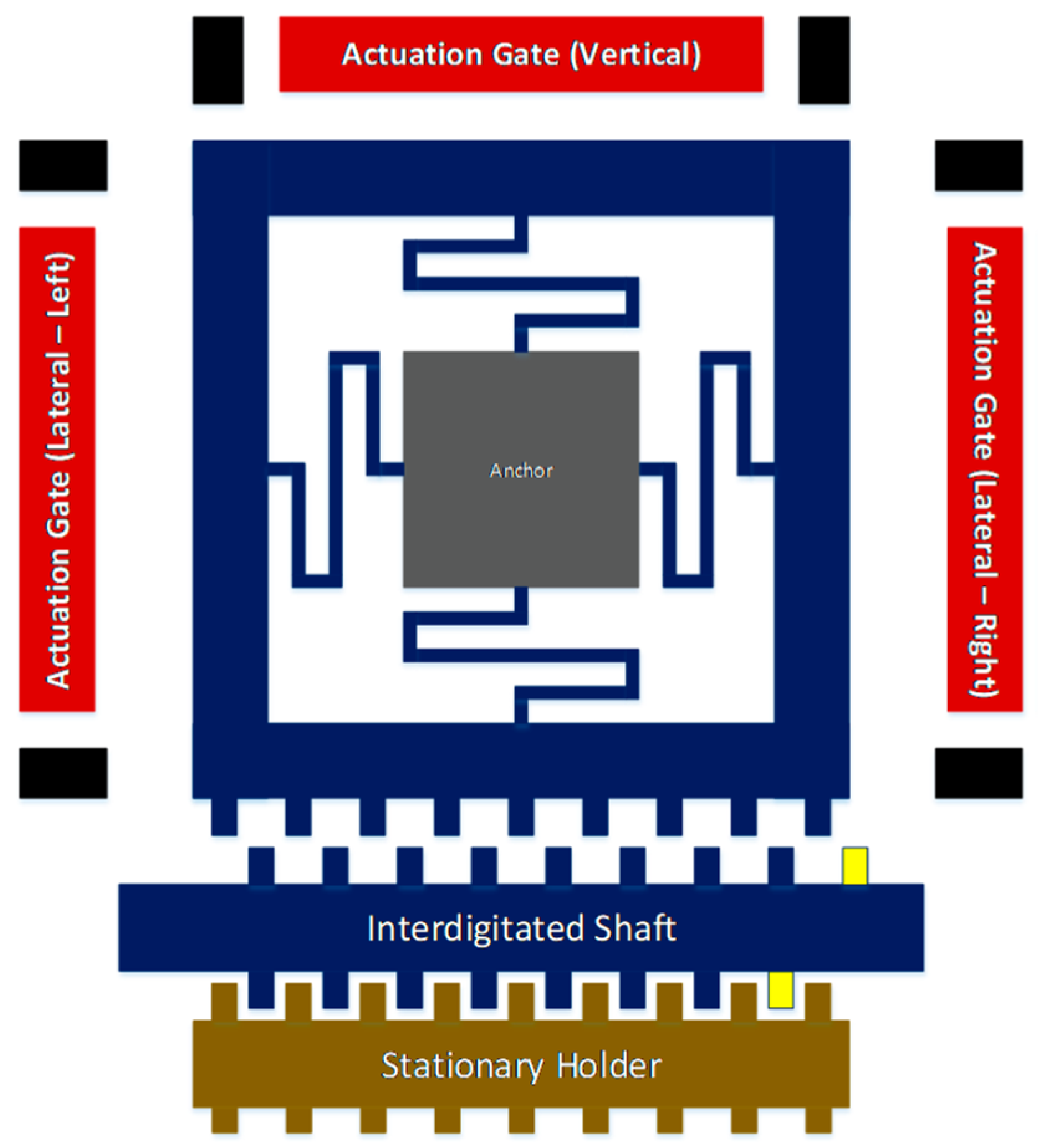

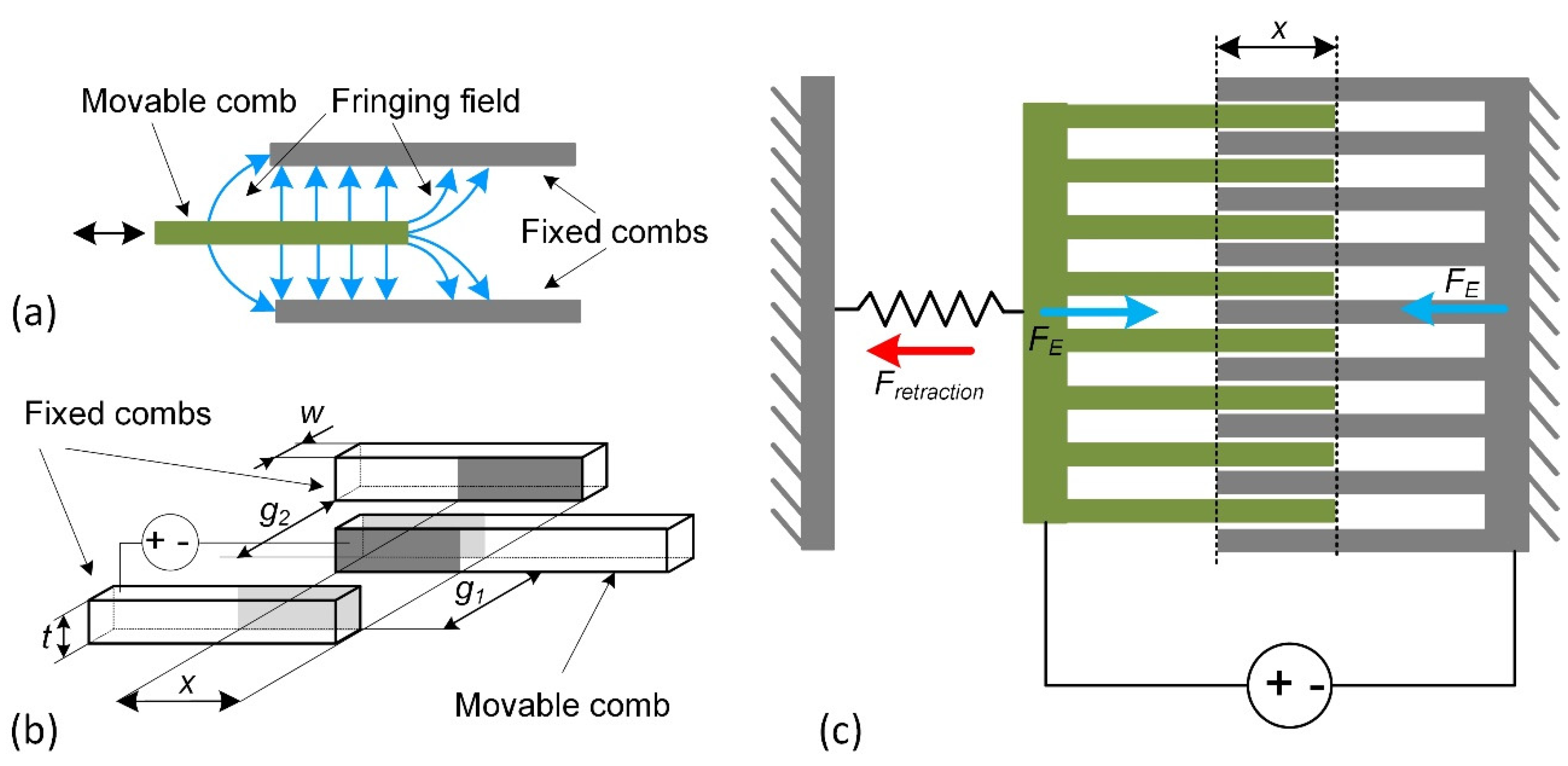

4.2. Comb-Drive Actuators

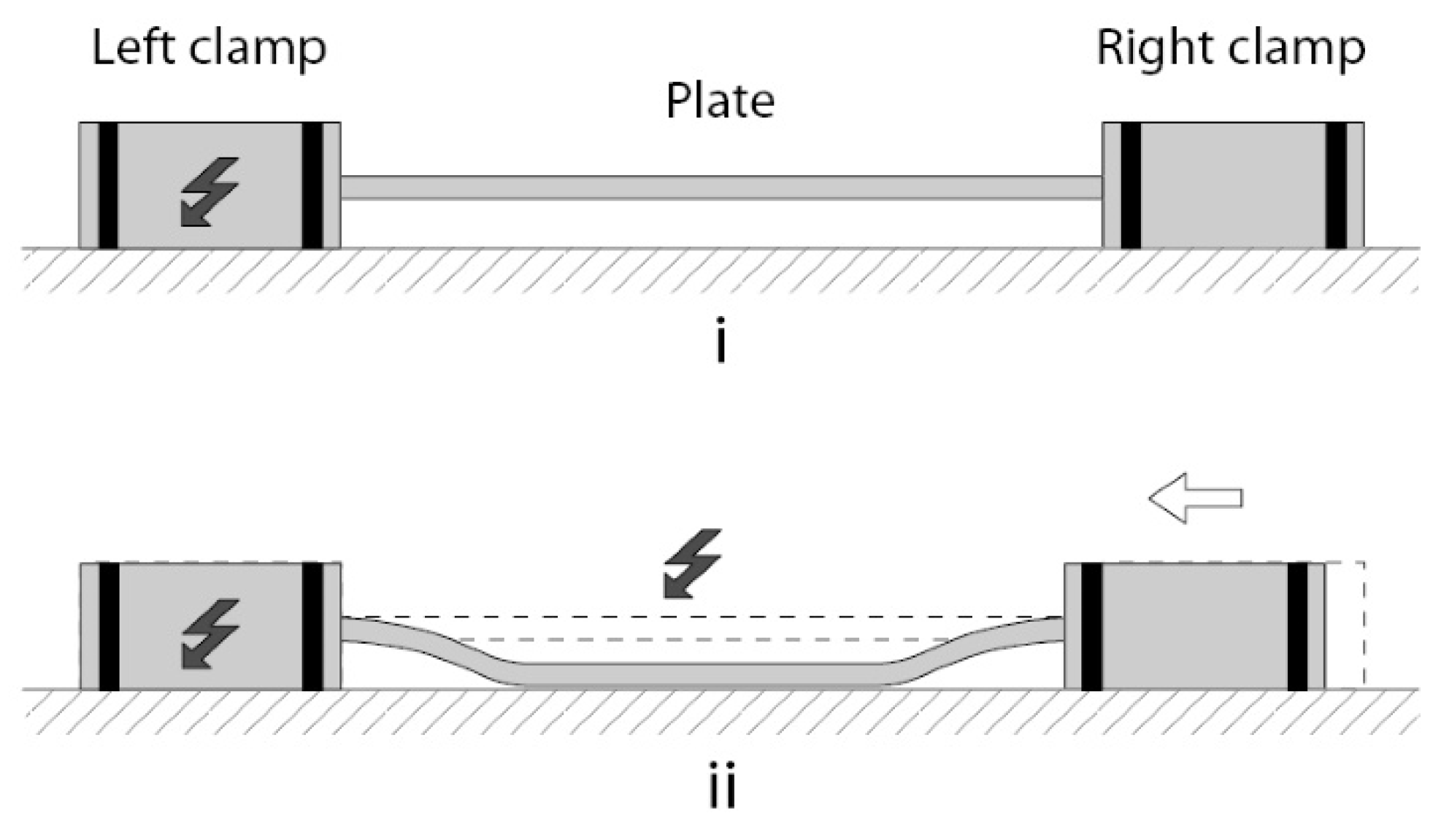

4.3. Scratch-Drive Actuator

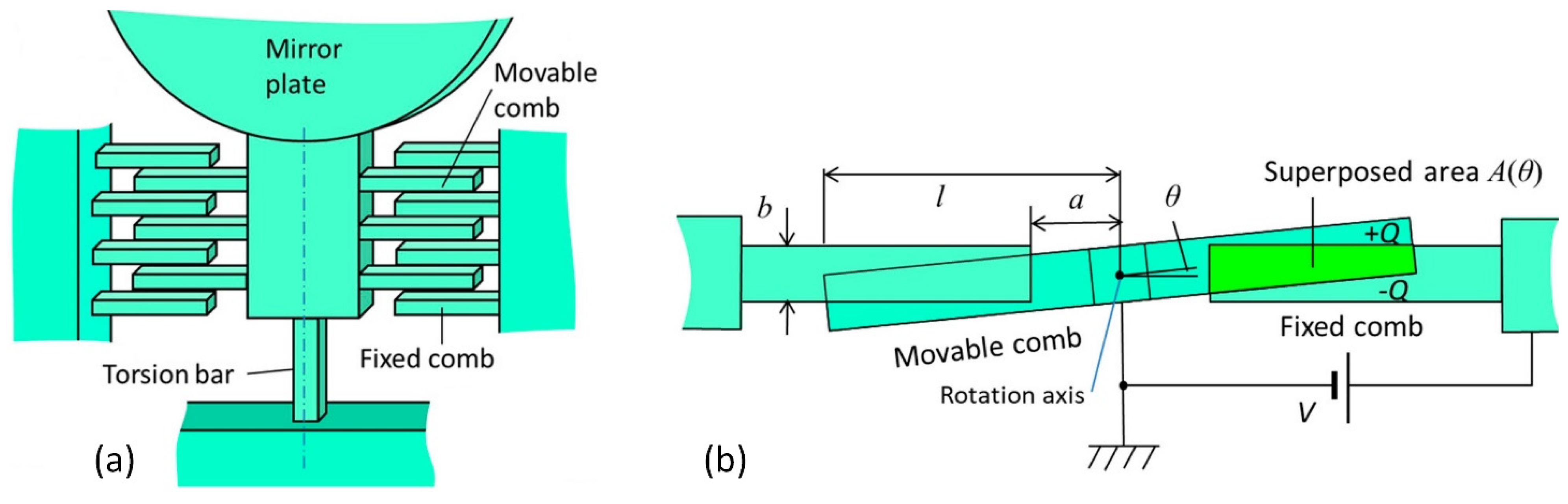

4.4. Rotary Actuators

5. Applications

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bučinskas, V.; Subačiūtė-Žemaitienė, J.; Dzedzickis, A.; Morkvėnaitė-Vilkončienė, I. Robotic micromanipulation: A) actuators and their application. Robot. Syst. Appl. 2021, 1, 2–23. [Google Scholar] [CrossRef]

- Yazdani, M.; Payam, A.F. A comparative study on material selection of microelectromechanical systems electrostatic actuators using Ashby, VIKOR and TOPSIS. Mater. Des. 2015, 65, 328–334. [Google Scholar] [CrossRef]

- Baniukevic, J.; Hakki Boyaci, I.; Goktug Bozkurt, A.; Tamer, U.; Ramanavicius, A.; Ramanaviciene, A. Magnetic gold nanoparticles in SERS-based sandwich immunoassay for antigen detection by well oriented antibodies. Biosens. Bioelectron. 2013, 43, 281–288. [Google Scholar] [CrossRef]

- German, N.; Ramanaviciene, A.; Ramanavicius, A. Dispersed Conducting Polymer Nanocomposites with Glucose Oxidase and Gold Nanoparticles for the Design of Enzymatic Glucose Biosensors. Polymers 2021, 13, 2173. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Conducting Polymers in the Design of Biosensors and Biofuel Cells. Polymers 2021, 13, 49. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Charge Transfer and Biocompatibility Aspects in Conducting Polymer-Based Enzymatic Biosensors and Biofuel Cells. Nanomaterials 2021, 11, 371. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Jagminas, A.; Ramanavicius, A. Advances in Molecularly Imprinted Polymers Based Affinity Sensors (Review). Polymers 2021, 13, 974. [Google Scholar] [CrossRef]

- Wilson, S.A.; Jourdain, R.P.J.; Zhang, Q.; Dorey, R.A.; Bowen, C.R.; Willander, M.; Wahab, Q.U.; Willander, M.; Al-hilli, S.M.; Nur, O.; et al. New materials for micro-scale sensors and actuators: An engineering review. Mater. Sci. Eng. R Rep. 2007, 56, 1–129. [Google Scholar] [CrossRef]

- Esfahani, S.; Esmaeilzade Khadem, S.; Ebrahimi Mamaghani, A. Size-dependent nonlinear vibration of an electrostatic nanobeam actuator considering surface effects and inter-molecular interactions. Int. J. Mech. Mater. Des. 2019, 15, 489–505. [Google Scholar] [CrossRef]

- Srikar, V.T.; Spearing, S.M. Materials selection for microfabricated electrostatic actuators. Sens. Actuators A Phys. 2003, 102, 279–285. [Google Scholar] [CrossRef]

- Zhang, W.M.; Yan, H.; Peng, Z.K.; Meng, G. Electrostatic pull-in instability in MEMS/NEMS: A review. Sens. Actuators A Phys. 2014, 214, 187–218. [Google Scholar] [CrossRef]

- Veroli, A.; Buzzin, A.; Frezza, F.; de Cesare, G.; Hamidullah, M.; Giovine, E.; Verotti, M.; Belfiore, N.P. An approach to the extreme miniaturization of rotary comb drives. Actuators 2018, 7, 70. [Google Scholar] [CrossRef]

- Yang, Q.; Xu, L.; Zhong, W.; Yan, Q.; Gao, Y.; Hong, W.; She, Y.; Yang, G. Recent Advances in Motion Control of Micro/Nanomotors. Adv. Intell. Syst. 2020, 2, 2000049. [Google Scholar] [CrossRef]

- Gao, Y.; You, Z.; Zhao, J. Electrostatic comb-drive actuator for MEMS relays/switches with double-tilt comb fingers and tilted parallelogram beams. J. Micromech. Microeng. 2015, 25, 45003. [Google Scholar] [CrossRef]

- Li, H.; Ruan, Y.; You, Z.; Song, Z. Design and fabrication of a novel MEMS relay with low actuation voltage. Micromachines 2020, 11, 171. [Google Scholar] [CrossRef]

- Ma, B.; You, Z.; Ruan, Y.; Chang, S.; Zhang, G. Electrostatically actuated MEMS relay arrays for high-power applications. Microsyst. Technol. 2016, 22, 911–920. [Google Scholar] [CrossRef]

- Liu, C.-X.; Yan, Y.; Wang, W.-Q. Resonances and chaos of electrostatically actuated arch micro/nanoresonators with time delay velocity feedback. Chaos Solitons Fractals 2020, 131, 109512. [Google Scholar] [CrossRef]

- Alcheikh, N.; Ouakad, H.M.; Mbarek, S.B.; Younis, M.I. Static and dynamic actuations of clamped-clamped V-shaped micro-resonators under electrostatic forces. Mech. Syst. Signal Process. 2021, 155, 107571. [Google Scholar] [CrossRef]

- Schroedter, R.; Yoo, H.W.; Brunner, D.; Schitter, G. Charge-Based Capacitive Self-Sensing With Continuous State Observation for Resonant Electrostatic MEMS Mirrors. J. Microelectromech. Syst. 2021, 30, 897–906. [Google Scholar] [CrossRef]

- Aryal, N.; Emadi, A. A Method to Enhance Stroke Level of a MEMS Micromirror with Repulsive Electrostatic Force. Micromachines 2020, 11, 401. [Google Scholar] [CrossRef]

- Xia, C.; Qiao, D.; Song, X.; Song, X.; Zheng, W.; He, Y.; Wu, B. A time division capacitive feedback method of electrostatic MEMS mirror driven by PWM signal. Sens. Actuators A Phys. 2021, 322, 112631. [Google Scholar] [CrossRef]

- Varghese, V.; Padmanabhan, R. Design and development of an electrostatic-based micropump. Int. J. Biomechatron. Biomed. Robot. 2020, 3, 182–187. [Google Scholar] [CrossRef]

- Wang, K.F.; Wang, B.L.; Lin, K.; Li, J.E.; Liu, Y. Nonlinear dynamics of electrostatically actuated micro-pumps with thermal effects and filled fluids. Int. J. Non-Linear Mech. 2020, 121, 103415. [Google Scholar] [CrossRef]

- Atik, A.C.; Özkan, M.D.; Özgür, E.; Külah, H.; Yıldırım, E. Modeling and fabrication of electrostatically actuated diaphragms for on-chip valving of MEMS-compatible microfluidic systems. J. Micromech. Microeng. 2020, 30, 115001. [Google Scholar] [CrossRef]

- Pallay, M.; Miles, R.N.; Towfighian, S. Towards a high bias voltage MEMS filter using electrostatic levitation. Mech. Syst. Signal Process. 2021, 150, 107250. [Google Scholar] [CrossRef]

- Pallay, M.; Towfighian, S. Feasibility study of a capacitive MEMS filter using electrostatic levitation. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Anaheim, CA, USA, 18–21 August 2019. [Google Scholar] [CrossRef]

- Hafiz, M.A.A.; Kosuru, L.; Hajjaj, A.Z.; Younis, M.I. Highly Tunable Narrow Bandpass MEMS Filter. IEEE Trans. Electron Devices 2017, 64, 3392–3398. [Google Scholar] [CrossRef]

- Schaler, E.W.; Zohdi, T.I.; Fearing, R.S. Thin-film repulsive-force electrostatic actuators. Sens. Actuators A Phys. 2018, 270, 252–261. [Google Scholar] [CrossRef]

- Toshiyoshi, H. Electrostatic Actuation. In Comprehensive Microsystems; Gianchandani, Y.B., Tabata, O., Zappe, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 1–38. [Google Scholar]

- Ozdogan, M.; Daeichin, M.; Ramini, A.; Towfighian, S. Parametric resonance of a repulsive force MEMS electrostatic mirror. Sens. Actuators A Phys. 2017, 265, 20–31. [Google Scholar] [CrossRef]

- Rosa, M.A.; De Bruyker, D.; Völkel, A.R.; Peeters, E.; Dunec, J. A novel external electrode configuration for the electrostatic actuation of MEMS based devices. J. Micromech. Microeng. 2004, 14, 446. [Google Scholar] [CrossRef]

- Qiao, D.-Y.; Yuan, W.-Z.; Li, X.-Y. A two-beam method for extending the working range of electrostatic parallel-plate micro-actuators. J. Electrost. 2007, 65, 256–262. [Google Scholar] [CrossRef]

- Chiou, J.C.; Lin, Y.J. A novel large displacement electrostatic actuator: Pre-stress comb-drive actuator. J. Micromech. Microeng. 2005, 15, 1641. [Google Scholar] [CrossRef][Green Version]

- Wang, W.; Wang, Q.; Ren, H.; Ma, W.; Qiu, C.; Chen, Z.; Fan, B. Electrostatic repulsive out-of-plane actuator using conductive substrate. Sci. Rep. 2016, 6, 35118. [Google Scholar] [CrossRef]

- Zamanzadeh, M.; Azizi, S. Static and dynamic characterization of micro-electro-mechanical system repulsive force actuators. J. Vib. Control 2020, 26, 1216–1231. [Google Scholar] [CrossRef]

- Schaler, E.W.; Jiang, L.; Lee, C.; Fearing, R.S. Bidirectional, Thin-Film Repulsive-/Attractive-Force Electrostatic Actuators for a Crawling Milli-Robot. In Proceedings of the MARSS 2018—International Conference on Manipulation, Automation and Robotics at Small Scales, Nagoya, Japan, 4–8 July 2018; Institute of Electrical and Electronics Engineers Inc.: New York City, NY, USA, 2018. [Google Scholar]

- Pallay, M.; Daeichin, M.; Towfighian, S. Dynamic behavior of an electrostatic MEMS resonator with repulsive actuation. Nonlinear Dyn. 2017, 89, 1525–1538. [Google Scholar] [CrossRef]

- Huang, J.; Jiang, C.; Li, G.; Lu, Q.; Chen, H. Design and analysis of a light-operated microgripper using an opto-electrostatic repulsive combined actuator. Micromachines 2021, 12, 1026. [Google Scholar] [CrossRef]

- Daeichin, M.; Ozdogan, M.; Towfighian, S.; Miles, R. Dynamic response of a tunable MEMS accelerometer based on repulsive force. Sens. Actuators A Phys. 2019, 289, 34–43. [Google Scholar] [CrossRef]

- Nabavi, S.; Menard, M.; Nabki, F. Surface Micromachined Out-of-plane Electrostatic MEMS Actuator Integrated with Displacement Sensor. In Proceedings of the IEEE Sensors, Sydney, Australia, 31 October–4 November 2021; Volume 2021. [Google Scholar]

- Rabenimanana, T.; Walter, V.; Kacem, N.; Le Moal, P.; Bourbon, G.; Lardiès, J. Enhancing the linear dynamic range of a mode-localized MEMS mass sensor with repulsive electrostatic actuation. Smart Mater. Struct. 2021, 30, 07LT01. [Google Scholar] [CrossRef]

- Li, H.; Barnes, P.; Harding, E.; Duan, X.; Wang, T.D.; Oldham, K.R. Large-displacement vertical electrostatic microactuator dynamics using duty-cycled softening/stiffening parametric resonance. J. Microelectromech. Syst. 2019, 28, 351–361. [Google Scholar] [CrossRef]

- Abbasalipour, A.; Palit, P.; Pourkamali, S. High-Energy Density Micro-Machined Cellular Arrays of Electrostatic Actuators. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019; pp. 1870–1873. [Google Scholar]

- Nabae, H.; Ikeda, K. Effect of elastic element on self-excited electrostatic actuator. Sens. Actuators A Phys. 2018, 279, 725–732. [Google Scholar] [CrossRef]

- Poletkin, K. On the static pull-in of tilting actuation in electromagnetically levitating hybrid micro-actuator: Theory and experiment. Actuators 2021, 10, 256. [Google Scholar] [CrossRef]

- Poletkin, K.V.; Asadollahbaik, A.; Kampmann, R.; Korvink, J.G. Levitating micro-actuators: A review. Actuators 2018, 7, 17. [Google Scholar] [CrossRef]

- Pallay, M.; Towfighian, S. A reliable MEMS switch using electrostatic levitation. Appl. Phys. Lett. 2018, 113, 213102. [Google Scholar] [CrossRef]

- Pallay, M.; Ibrahim, A.I.; Miles, R.N.; Towfighian, S. Pairing electrostatic levitation with triboelectric transduction for high-performance self-powered MEMS sensors and actuators. Appl. Phys. Lett. 2019, 115, 133503. [Google Scholar] [CrossRef]

- Pallay, M.; Towfighian, S. A Combined MEMS Threshold Pressure Sensor and Switch. In Proceedings of the 2019 IEEE Sensors, Montreal, QC, Canada, 27–30 October 2019. [Google Scholar] [CrossRef]

- Pallay, M.; Miles, R.N.; Towfighian, S. Merging parallel-plate and levitation actuators to enable linearity and tunability in electrostatic MEMS. J. Appl. Phys. 2019, 126, 014501. [Google Scholar] [CrossRef]

- Pallay, M.; Miles, R.N.; Towfighian, S. A Tunable Electrostatic MEMS Pressure Switch. IEEE Trans. Ind. Electron. 2020, 67, 9833–9840. [Google Scholar] [CrossRef]

- Mousavi, M.; Alzgool, M.; Towfighian, S. Electrostatic levitation: An elegant method to control MEMS switching operation. Nonlinear Dyn. 2021, 104, 3139–3155. [Google Scholar] [CrossRef]

- Mousavi, M.; Alzgool, M.; Towfighian, S. Autonomous shock sensing using bi-stable triboelectric generators and MEMS electrostatic levitation actuators. Smart Mater. Struct. 2021, 30, 065019. [Google Scholar] [CrossRef]

- Ozdogan, M.; Towfighian, S.; Miles, R.N. Fabrication and Experimental Characterization of a MEMS Microphone Using Electrostatic Levitation. In Proceedings of the 2019 IEEE Sensors, Montreal, QC, Canada, 27–30 October 2019. [Google Scholar] [CrossRef]

- Ozdogan, M.; Towfighian, S.; Miles, R.N. Modeling and Characterization of a Pull-in Free MEMS Microphone. IEEE Sens. J. 2020, 20, 6314–6323. [Google Scholar] [CrossRef]

- Hasan, M.N.; Pallay, M.; Towfighian, S. Threshold Pressure Sensing Using Parametric Resonance in Electrostatic MEMS. In Proceedings of the 2019 IEEE Sensors, Montreal, QC, Canada, 27–30 October 2019; pp. 4–7. [Google Scholar] [CrossRef]

- Zamanzadeh, M.; Jafarsadeghi-Pournaki, I.; Ouakad, H.M. A resonant pressure MEMS sensor based on levitation force excitation detection. Nonlinear Dyn. 2020, 100, 1105–1123. [Google Scholar] [CrossRef]

- Poletkin, K. Static Pull-in Behavior of Hybrid Levitation Micro-Actuators: Simulation, Modelling and Experimental Study. IEEE/ASME Trans. Mechatron. 2020, 4435, 1–11. [Google Scholar] [CrossRef]

- Mousavi, M.; Alzgool, M.; Towfighian, S. A MEMS Pressure Sensor Using Electrostatic Levitation. IEEE Sens. J. 2021, 21, 18601–18608. [Google Scholar] [CrossRef]

- Mayberry, M.; Ludois, D.C.; Severson, E.L. Towards Electrostatic Levitation of Rotating Machines. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 270–277. [Google Scholar] [CrossRef]

- Wang, W.; Fan, D.; Zhu, R.; Wang, P.; Zhao, Y.; Wang, H. Modeling and Optimization of Electrostatic Film Actuators Based on the Method of Moments. Soft Robot. 2021, 8, 651–661. [Google Scholar] [CrossRef]

- Zamanzadeh, M.; Jafarsadeghi Pournaki, I.; Azizi, S. Bifurcation analysis of the levitation force MEMS actuators. Int. J. Mech. Sci. 2020, 178, 105614. [Google Scholar] [CrossRef]

- Ryalat, M.; Damiri, H.S.; ElMoaqet, H.; AlRabadi, I. An Improved Passivity-based Control of Electrostatic MEMS Device. Micromachines 2020, 11, 688. [Google Scholar] [CrossRef]

- Nashat, S.E.D.; AbdelRassoul, R.; Abd El Bary, A.E.M. Design and simulation of RF MEMS comb drive with ultra-low pull-in voltage and maximum displacement. Microsyst. Technol. 2018, 24, 3443–3453. [Google Scholar] [CrossRef]

- Daeichin, M.; Miles, R.; Towfighian, S. Lateral pull-in instability of electrostatic MEMS transducers employing repulsive force. Nonlinear Dyn. 2020, 100, 1927–1940. [Google Scholar] [CrossRef]

- Burugupally, S.P.; Perera, W.R. Dynamics of a parallel-plate electrostatic actuator in viscous dielectric media. Sens. Actuators A Phys. 2019, 295, 366–373. [Google Scholar] [CrossRef]

- Nemirovsky, Y.; Bochobza-Degani, O. A methodology and model for the pull-in parameters of electrostatic actuators. J. Microelectromech. Syst. 2001, 10, 601–615. [Google Scholar] [CrossRef]

- Lee, K.B. Closed-form expressions for pull-in parameters of two-degree-of-freedom torsional microactuators. J. Micromech. Microeng. 2007, 17, 1853. [Google Scholar] [CrossRef]

- Aliasghary, M.; Mobki, H.; Ouakad, H.M. Pull-in Phenomenon in the Electrostatically Micro-switch Suspended between Two Conductive Plates using the Artificial Neural Network. J. Appl. Comput. Mech. 2022, 8, 1222–1235. [Google Scholar] [CrossRef]

- Kloub, H. Effect of Mechanical Loading and Increased Gap on the Dynamic Response of Multiple Degree of Freedom Electrostatic Actuator. Proceedings 2020, 64, 18. [Google Scholar] [CrossRef]

- Gholami, R.; Ansari, R. Grain size and nanoscale effects on the nonlinear pull-in instability and vibrations of electrostatic actuators made of nanocrystalline material. Mater. Res. Express 2018, 5, 015012. [Google Scholar] [CrossRef]

- Kandula, P.; Dong, L. Robust Voltage Control for an Electrostatic Micro-Actuator. J. Dyn. Syst. Meas. Control Trans. ASME 2018, 140, 061012. [Google Scholar] [CrossRef]

- Zhou, Y.; Shafai, C. Reduction of Electrostatic Control Voltage with a Tri-Electrode Actuator. Proceedings 2017, 1, 282. [Google Scholar] [CrossRef]

- Li, C.; Dean, R.N.; Flowers, G.T. Analysis and dynamic simulation of the synthetic voltage division controller for extending the parallel plate actuator stable range of motion. Microsyst. Technol. 2017, 23, 1125–1130. [Google Scholar] [CrossRef]

- Ak, C.; Yildiz, A.; Akdagli, A. A novel expression obtained by using artificial bee colony algorithm to calculate pull-in voltage of fixed-fixed micro-actuators. Microsyst. Technol. 2018, 24, 2137–2145. [Google Scholar] [CrossRef]

- Alneamy, A.; Al-Ghamdi, M.; Park, S.; Khater, M.; Abdel-Rahman, E.; Heppler, G. Dimpled electrostatic MEMS actuators. J. Appl. Phys. 2019, 125, 024304. [Google Scholar] [CrossRef]

- Ouakad, H.M. Comprehensive numerical modeling of the nonlinear structural behavior of MEMS/NEMS electrostatic actuators under the effect of the van der Waals forces. Microsyst. Technol. 2017, 23, 5903–5910. [Google Scholar] [CrossRef]

- Moradweysi, P.; Ansari, R.; Hosseini, K.; Sadeghi, F. Application of modified Adomian decomposition method to pull-in instability of nano-switches using nonlocal Timoshenko beam theory. Appl. Math. Model. 2018, 54, 594–604. [Google Scholar] [CrossRef]

- Hajarian, A.; Zand, M.M.; Zolfaghari, N. Effect of Dispersion Forces on Dynamic Stability of Electrostatically Actuated Micro/Nano-Beams in Presence of Mechanical Shocks. Int. J. Appl. Mech. 2019, 11, 1950085. [Google Scholar] [CrossRef]

- Bhojawala, V.M.; Vakharia, D.P. Closed-form solution for static pull-in voltage of electrostatically actuated clamped—Clamped micro/nano beams under the effect of fringing field and van der Waals force Closed-form solution for static pull-in voltage of electrostatically actuated cla. Mater. Res. Express 2017, 4, 126306. [Google Scholar] [CrossRef]

- Admassu, D.; Durowade, T.; Velicu, S.; Sivananthan, S.; Gao, W. Estimation of the mechanical stiffness constant of MEMS-based parallel-plate micro-actuators. Microsyst. Technol. 2021, 27, 2751–2759. [Google Scholar] [CrossRef]

- Sano, C.; Ataka, M.; Hashiguchi, G.; Toshiyoshi, H. An electret-augmented low-voltage MEMS electrostatic out-of-plane actuator for acoustic transducer applications. Micromachines 2020, 11, 267. [Google Scholar] [CrossRef] [PubMed]

- Alcheikh, N.; Ramini, A.; Al Hafiz, M.A.; Younis, M.I. Tunable clamped-guided arch resonators using electrostatically induced axial loads. Micromachines 2017, 8, 14. [Google Scholar] [CrossRef]

- Schmitt, L.; Hoffmann, M. Large stepwise discrete microsystem displacements based on electrostatic bending plate actuation. Actuators 2021, 10, 272. [Google Scholar] [CrossRef]

- Ma, W.; Ma, C.; Wang, W. Surface micromachined MEMS deformable mirror based on hexagonal parallel-plate electrostatic actuator. J. Phys. Conf. Ser. 2018, 986, 012021. [Google Scholar] [CrossRef]

- Elshenety, A.; El-Kholy, E.E.; Abdou, A.F.; Soliman, M.; Elhagry, M.M. A flexible model for studying fringe field effect on parallel plate actuators. J. Electr. Syst. Inf. Technol. 2020, 7, 14. [Google Scholar] [CrossRef]

- Ma, Z.; Jin, X.; Guo, Y.; Zhang, T.; Jin, Y.; Zheng, X.; Jin, Z. Pull-In Dynamics of Two MEMS Parallel-Plate Structures for Acceleration Measurement. IEEE Sens. J. 2021, 21, 17686–17694. [Google Scholar] [CrossRef]

- Zhou, G.; Dowd, P. Tilted folded-beam suspension for extending the stable travel range of comb-drive actuators. J. Micromech. Microeng. 2003, 13, 178–183. [Google Scholar] [CrossRef]

- Izawa, T.; Sasaki, T.; Hane, K. Scanning micro-mirror with an electrostatic spring for compensation of hard-spring nonlinearity. Micromachines 2017, 8, 240. [Google Scholar] [CrossRef]

- Thewes, A.C.; Schmitt, P.; Löhler, P.; Hoffmann, M. Design and characterization of an electrostatic constant-force actuator based on a non-linear spring system. Actuators 2021, 10, 192. [Google Scholar] [CrossRef]

- Ghalandarzadeh, M.; Afrang, S. A new wide tunability MEMS based variable capacitor using two separate electrostatic vertical comb drive actuators. Int. J. Eng. Trans. B Appl. 2021, 34, 2534–2544. [Google Scholar] [CrossRef]

- Velosa-Moncada, L.A.; Aguilera-Cortes, L.A.; González-Palacios, M.A.; Raskin, J.P.; Herrera-May, A.L. Design of a novel MEMS microgripper with rotatory electrostatic comb-drive actuators for biomedical applications. Sensors 2018, 18, 1664. [Google Scholar] [CrossRef]

- Zhao, R.; Qiao, D.; Song, X.; You, Q. The exploration for an appropriate vacuum level for performance enhancement of a comb-drive microscanner. Micromachines 2017, 8, 126. [Google Scholar] [CrossRef]

- Akiyama, T.; Shono, K. Controlled Stepwise Motion in Polysilicon Microstructures. J. Microelectromech. Syst. 1993, 2, 106–110. [Google Scholar] [CrossRef]

- Li, L.; Brown, J.G.; Uttamchandani, D. Study of scratch drive actuator force characteristics. J. Micromech. Microeng. 2002, 12, 736–741. [Google Scholar] [CrossRef]

- Sarajlic, E.; Yamahata, C.; Berenschot, E.; Tas, N.; Fujita, H.; Krijnen, G. High-performance shuffle motor fabricated by vertical trench isolation technology. Micromachines 2010, 1, 48–67. [Google Scholar] [CrossRef]

- Basset, P.; Kaiser, A.; Bigotte, P.; Collard, D.; Buchaillot, L. A large stepwise motion electrostatic actuator for a wireless microrobot. In Proceedings of the Fifteenth IEEE International Conference on Micro Electro Mechanical Systems, Las Vegas, NV, USA, 24 January 2002; pp. 606–609. [Google Scholar] [CrossRef]

- Donald, B.R.; Levey, C.G.; McGray, C.G.; Paprotny, I.; Rus, D. An untethered, electrostatic, globally controllable MEMS micro-robot. J. Microelectromech. Syst. 2006, 15, 1–15. [Google Scholar] [CrossRef]

- Esteves Moreira, E.; Lima, V.; Serra Alves, F.; Cabral, J.; Gaspar, J.; Rocha, L.A. Full-gap tracking system for parallel plate electrostatic actuators using closed-loop control. Sens. Actuators A Phys. 2016, 244, 174–183. [Google Scholar] [CrossRef]

- Woo, J.; Hahn, B.; Ahn, C. Position estimator design for a mems top-drive electrostatic rotary actuator. Sensors 2020, 20, 7081. [Google Scholar] [CrossRef]

- Kedzierski, J.; Chea, H. Multilayer microhydraulic actuators with speed and force configurations. Microsyst. Nanoeng. 2021, 7, 22. [Google Scholar] [CrossRef]

- Kurmendra; Kumar, R. A review on RF micro-electro-mechanical-systems (MEMS) switch for radio frequency applications. Microsyst. Technol. 2021, 27, 2525–2542. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, T. A review of design and fabrication of the bionic flapping wing micro air vehicles. Micromachines 2019, 10, 144. [Google Scholar] [CrossRef]

- Phung, H.; Nguyen, C.T.; Jung, H.; Nguyen, T.D.; Choi, H.R. Bidirectional tactile display driven by electrostatic dielectric elastomer actuator. Smart Mater. Struct. 2020, 29, 035007. [Google Scholar] [CrossRef]

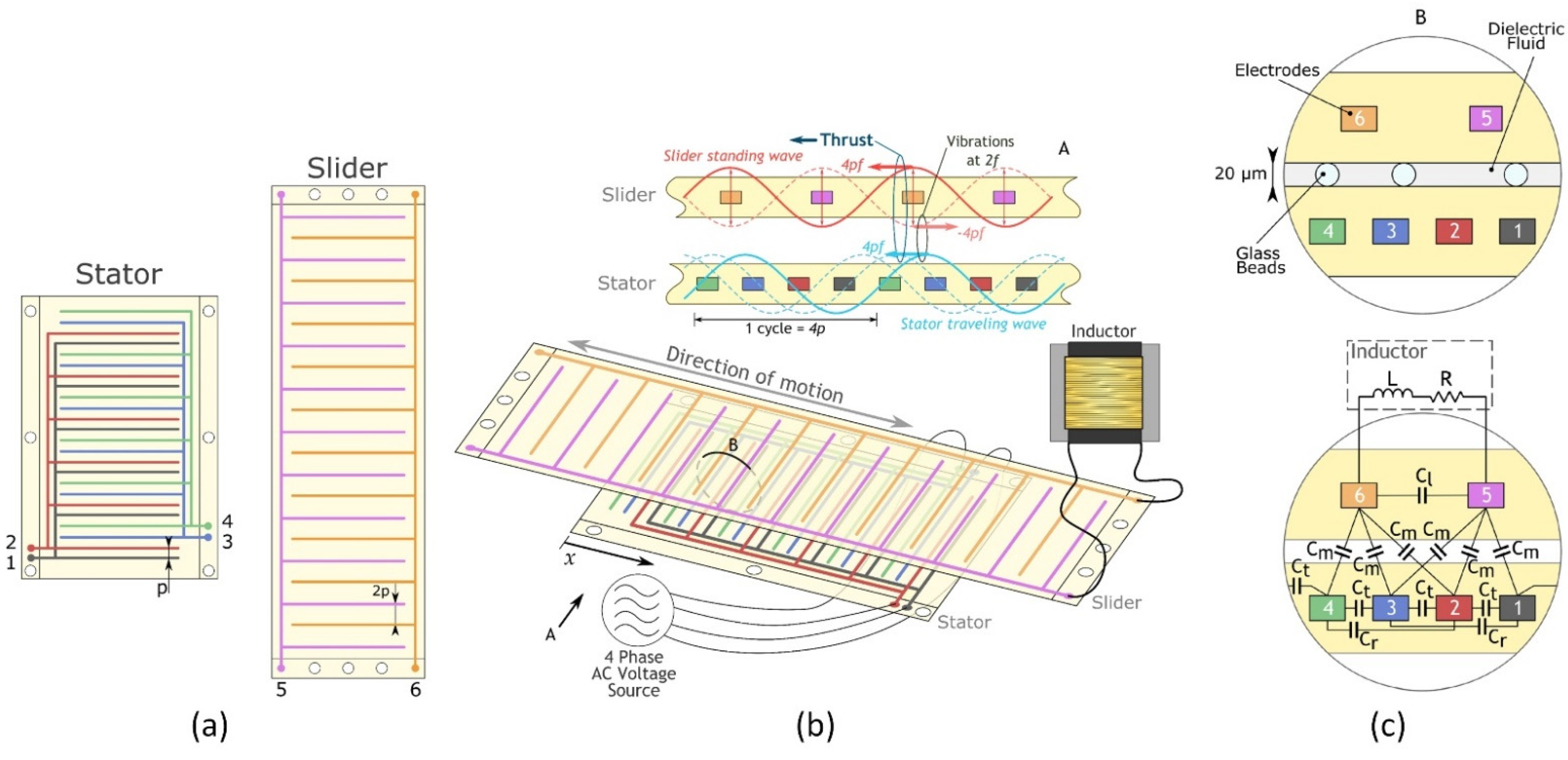

- Carneiro, F.; Zhang, G.; Osada, M.; Yoshimoto, S.; Yamamoto, A. An Extended Model for Ripple Analysis of 2–4 Phase Resonant Electrostatic Induction Motors. Actuators 2021, 10, 291. [Google Scholar] [CrossRef]

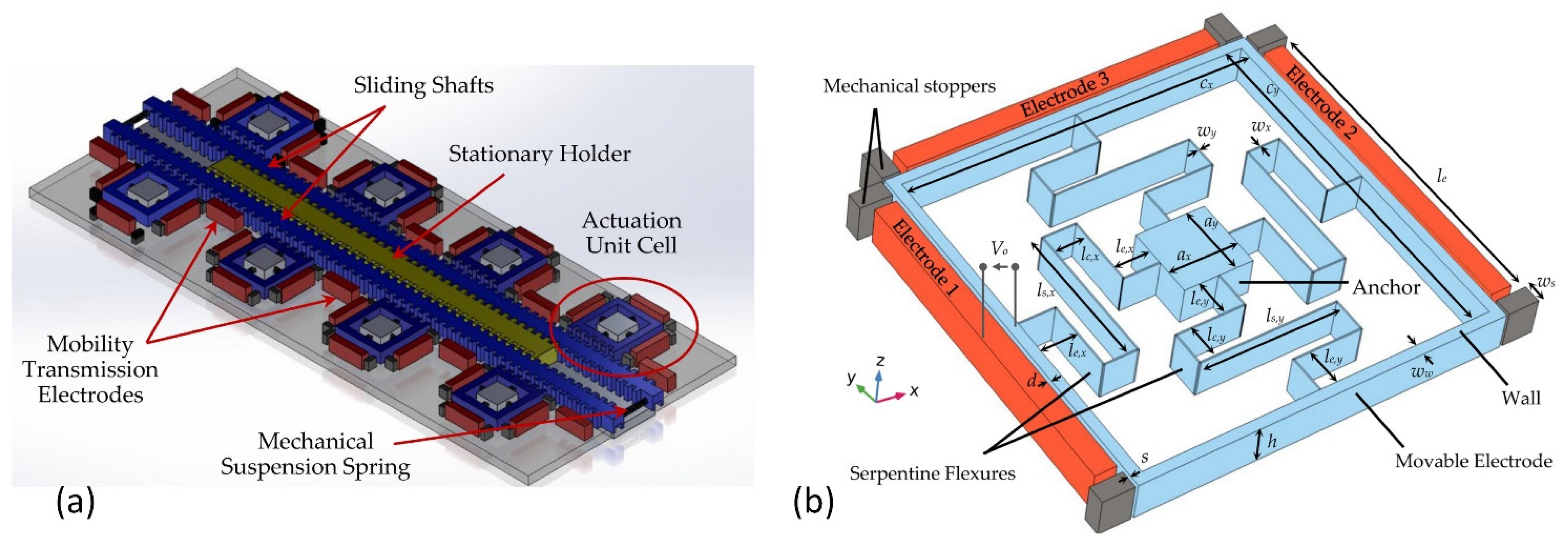

- Albukhari, A.; Mescheder, U. Investigation of the dynamics of a 2-DoF actuation unit cell for a cooperative electrostatic actuation system. Actuators 2021, 10, 276. [Google Scholar] [CrossRef]

- Abbasalipour, A.; Palit, P.; Sheikhlari, S.; Pakdelian, S.; Pourkamali, S. High-Output Micro-Machined Electrostatic Actuators. Res. Sq. 2021; in press. [Google Scholar] [CrossRef]

- Muttikulangara, S.S.; Baranski, M.; Rehman, S.; Hu, L.; Miao, J. Diffraction grating integrated on micromachined stepper motor for diversity implementation in imaging spectroscopy. In Proceedings of the Fifteenth IEEE International Conference on Micro Electro Mechanical Systems, Belfast, Ireland, 21–25 January 2018; pp. 696–699. [Google Scholar] [CrossRef]

- Saito, K.; Contreras, D.S.; Takeshiro, Y.; Okamoto, Y.; Hirao, S.; Nakata, Y.; Tanaka, T.; Kawamura, S.; Kaneko, M.; Uchikoba, F.; et al. Study on Electrostatic Inchworm Motor Device for a Heterogeneous Integrated Microrobot System. Trans. Jpn. Inst. Electron. Packag. 2019, 12, E18-009-1–E18-009-7. [Google Scholar] [CrossRef]

- Shukla, R.; Beera, G.; Dubey, A.; Sharma, V.P.; Sankar, P.R.; Dhawan, R.; Tiwari, P.; Sinha, A.K. Design analysis and fabrication of side-drive electrostatic micromotor by UV-SLIGA. J. Micromanuf. 2021, 251659842110452. [Google Scholar] [CrossRef]

- Jin, C.; Zhang, J.; Xu, Z.; Trase, I.; Huang, S.; Dong, L.; Liu, Z.; Usherwood, S.E.; Zhang, J.X.J.; Chen, Z. Tunable, Flexible, and Resilient Robots Driven by an Electrostatic Actuator. Adv. Intell. Syst. 2020, 2, 1900162. [Google Scholar] [CrossRef]

- Contreras, D.S.; Pister, K.S.J. Dynamics of electrostatic inchworm motors for silicon microrobots. In Proceedings of the International Conference on Manipulation, Automation and Robotics at Small Scales, Montreal, QC, Canada, 17–21 July 2017. [Google Scholar] [CrossRef]

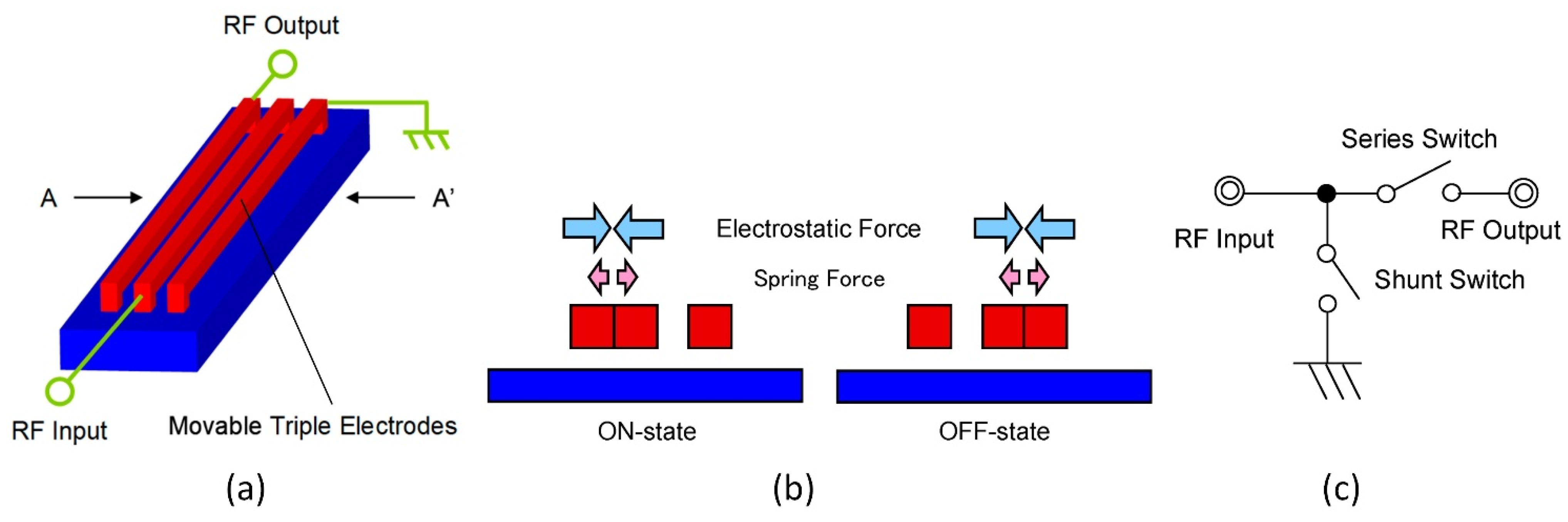

- Naito, Y.; Nakamura, K.; Uenishi, K. Laterally movable triple electrodes actuator toward low voltage and fast response RF-MEMS switches. Sensors 2019, 19, 864. [Google Scholar] [CrossRef]

- Uvarov, I.V.; Kupriyanov, A.N. Stiction-protected MEMS switch with low actuation voltage. Microsyst. Technol. 2019, 25, 3243–3251. [Google Scholar] [CrossRef]

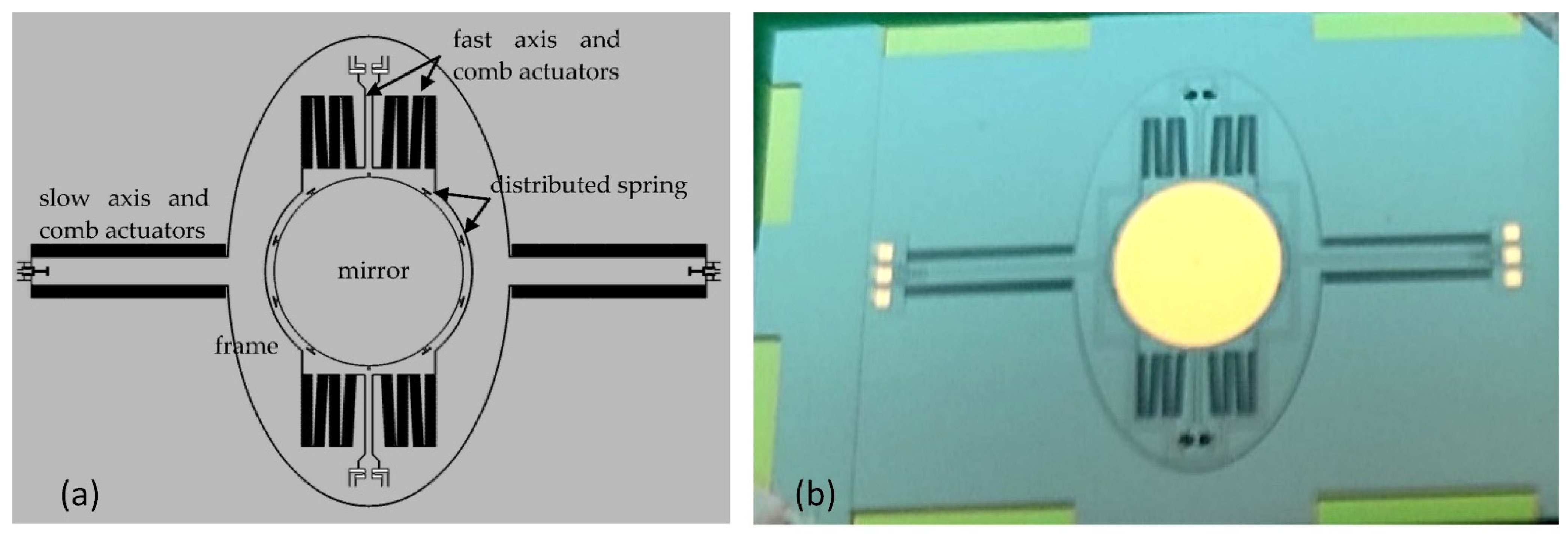

- Wang, Q.; Wang, W.; Zhuang, X.; Zhou, C.; Fan, B. Development of an electrostatic comb-driven mems scanning mirror for two-dimensional raster scanning. Micromachines 2021, 12, 378. [Google Scholar] [CrossRef] [PubMed]

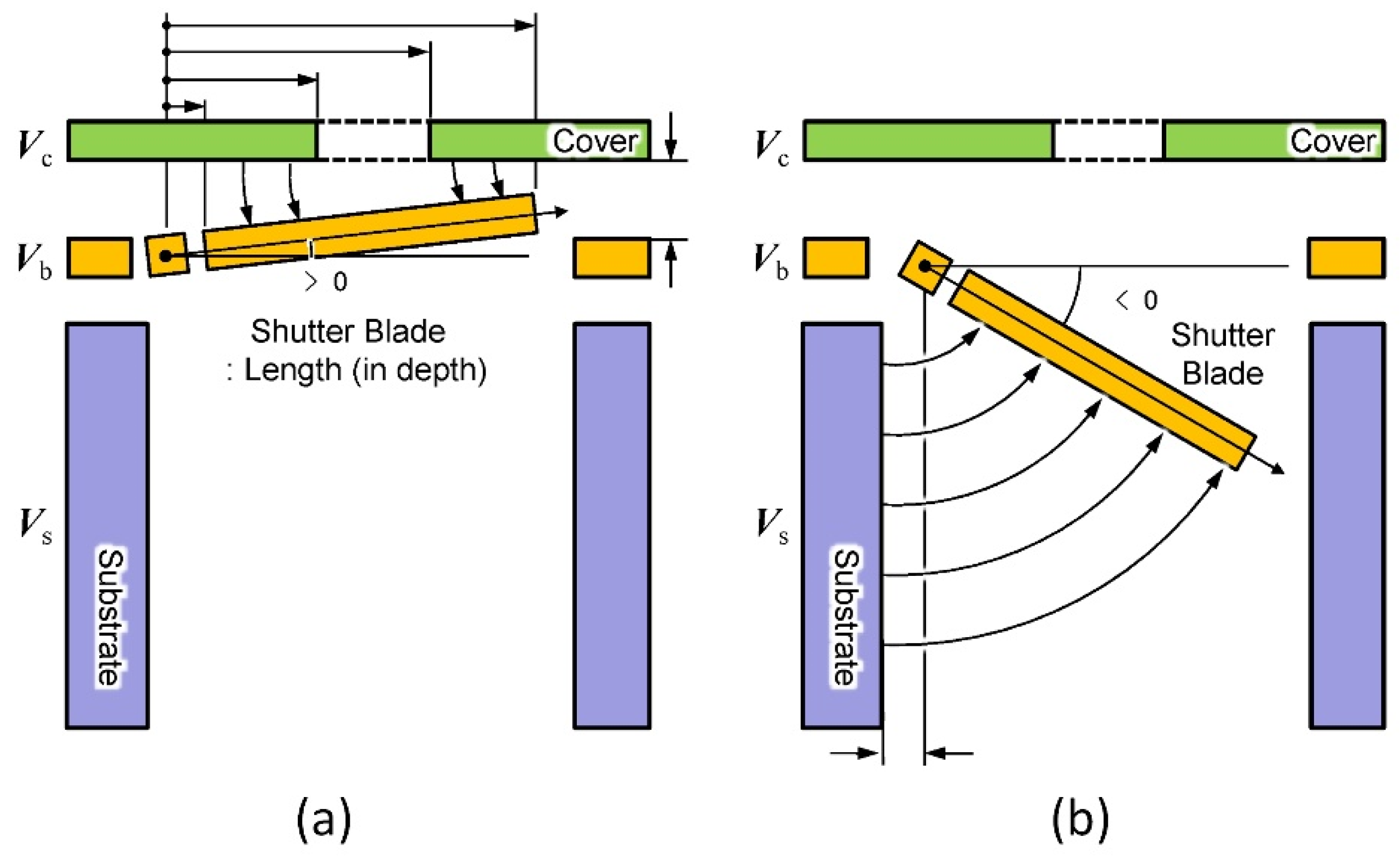

- Liu, X.; Takahashi, T.; Konishi, M.; Motohara, K.; Toshiyoshi, H. Random access addressing of MEMS electrostatic shutter array for multi-object astronomical spectroscopy. Micromachines 2020, 11, 782. [Google Scholar] [CrossRef]

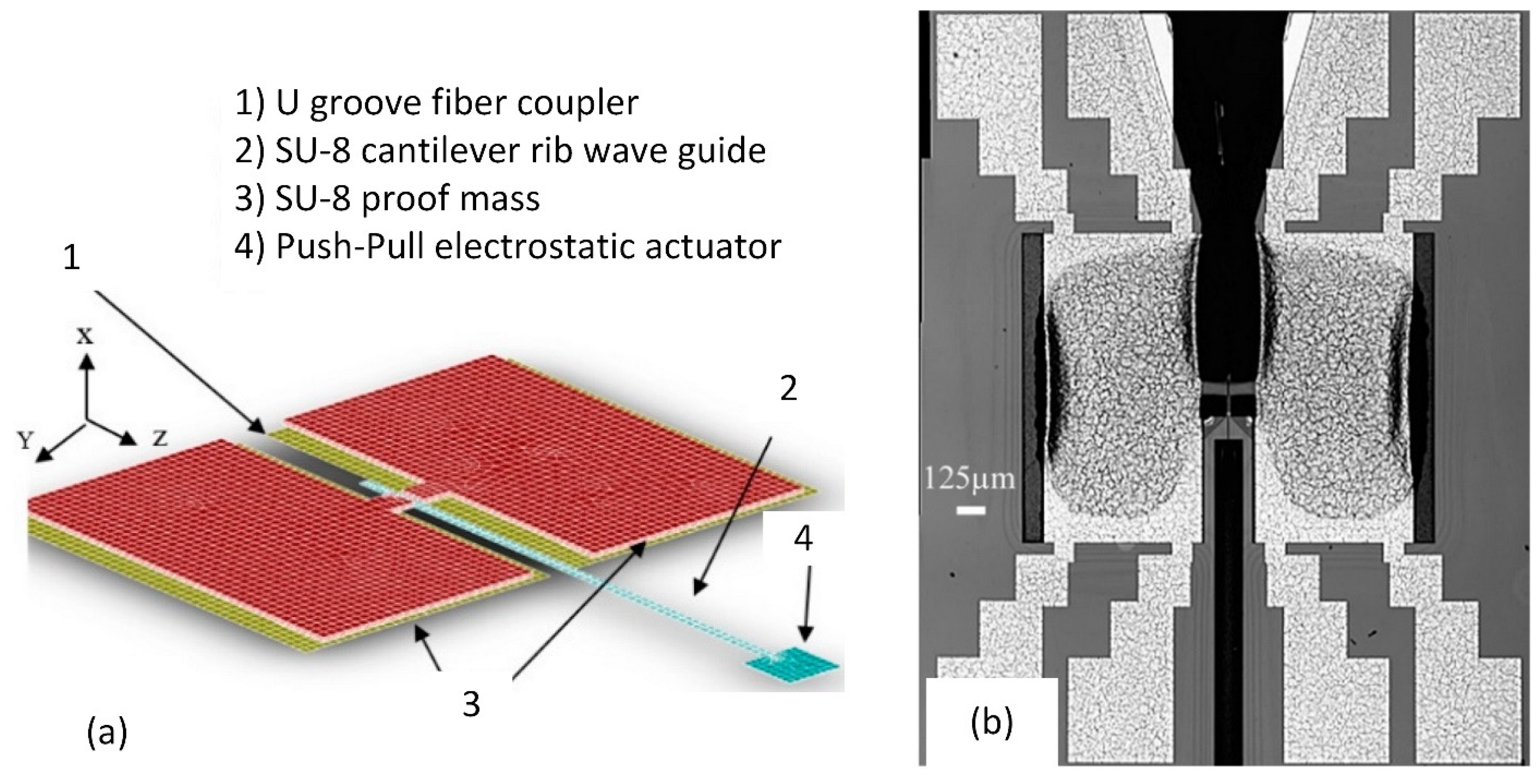

- Wang, W.C.; Gu, K.; Tsui, C.L. Design and fabrication of a push-pull electrostatic actuated cantilever waveguide scanner. Micromachines 2019, 10, 432. [Google Scholar] [CrossRef] [PubMed]

- Leroy, E.; Hinchet, R.; Shea, H. Multimode Hydraulically Amplified Electrostatic Actuators for Wearable Haptics. Adv. Mater. 2020, 32, 2002564. [Google Scholar] [CrossRef] [PubMed]

| Design | Voltage | Forces/Displacements | Ref. |

|---|---|---|---|

| Thin-film repulsive-force electrostatic actuator | 500–1000 V | 9.03 mN/242–511 µm | [28] |

| MEMS mirror driven by the repulsive-force actuator | 95 V | ±43 µm | [30] |

| Thin-film repulsive-force electrostatic actuator for a crawling millirobot | 0–1.2 kV | 156 Pa; | [36] |

| An electrostatic microbeam repulsive-force actuator | 200 V | 2–15 µm | [37] |

| An opto-electrostatic repulsive combined actuator for a microgripper | 0–400 V | 0–750 µm | [38] |

| MEMS accelerometer using repulsive electrostatic force | 0–100 V | 0–13 µm | [39] |

| MEMS micromirror with repulsive electrostatic force | 150 V | 5 µm | [20] |

| Repulsive MEMS actuator with displacement sensing capability | 10–50 V | 0.025–1.8 µm | [40] |

| MEMS mass sensor with repulsive electrostatic actuation | 110 V | 0.3–3.8 µm | [41] |

| Large-displacement vertical electrostatic microactuator | 60 V | 480 ± 30 µm | [42] |

| High-energy density arrays of electrostatic actuators | 90 V | 0.3 mN/230 µm | [43] |

| Self-excited electrostatic actuators | 1.3 kV | ±500 µm | [44] |

| Displacement, µm | Force/Voltage | Width/Thickness/Length of the Beam Electrode, µm | Gaps between Electrodes, µm | Ref. |

|---|---|---|---|---|

| 0.7 | 30 V | 2448/1.5/2448 (hexagon) | 4.53 | [85] |

| 2.4 (stable) | 13 V | 45/5/2000 | 5 | [66] |

| - | 8.2 V (pull-in) | 5/5/125 (beam) 60/1.5/30 (plate) | 2.75 | [86] |

| 3.5 | 7.69 (pull-in) | 60/-/290 (SSPP) | 4.19 and 3.3 | [87] |

| 3.5 | 4.5 (pull-in) | 60/-/290 (DSPP) | 3.95 and 3.98 |

| Displacement, µm | Force/Voltage | Width/ Thickness/Length of the Finger, µm | Gaps between Combs, µm | Overlapping Length, µm | Ref. |

|---|---|---|---|---|---|

| - | 12.42 V | 3/7/480 | - | - | [91] |

| 4.88 degree | 24 V | /0.5/ | 0.6 or 1.8 | - | [12] |

| - | 23.4 V | 2/7/- | 2 | - | [92] |

| ±8 degrees | -/120 V | 5/20/205 | 5 | 190 | [89] |

| 40 | 79 ± 2 µN/25 V | 4/20/200 | 4 | 100 | [90] |

| - | 800 V | 2/2/185.3 | 2 | 20 | [91] |

| scanning angle 44.3 degrees | 30 V | 4/-/- | - | no overlapping | [93] |

| Design | Material | Voltage | Forces/ Displacements | Ref. |

|---|---|---|---|---|

| MEMS-based parallel-plate microactuator | SU-8 | 128 VDC | 9.89 µm | [81] |

| Thin-film repulsive-force actuator | copper foil on a polyimide | 1000 VAC/43 Hz | 9.03 mN 511 µm | [28] |

| Hexagonal parallel-plate actuator | polysilicon | 30 VDC | 0.8 µm | [85] |

| Repulsive-force MEMS electrostatic mirror | - | 40 VDC 1 VAC/1.2 kHz | 43 µm | [30] |

| Micro-machined cellular arrays of electrostatic actuators | silicon polysilicon | 90 VDC | 0.3 mN 230 µm | [43] |

| Bending plate actuator | silicon-on-insulator (SOI) wafers | 54 VDC | 230.7 ± 0.9 µm | [84] |

| Bidirectional, thin-film electrostatic actuator | 0–1.2 kVDC | - | [36] | |

| MEMS-based parallel-plate microactuators | SU-8 | 128 VDC | 33 µm | [81] |

| Multilayer microhydraulic actuators | polyimide layers separated with liquid | 50 VDC | - | [101] |

| Design | Voltage | Forces/Displacements | Ref. |

|---|---|---|---|

| Arrayed cellular actuator | 46 V | 80 mN 678 µm | [107] |

| Parallel-plate MEMS electrostatic microactuator | 95–128 VDC | 8.75–9.89 µm | [81] |

| Three-phase electrostatic actuation mechanism | - | - | [108] |

| Electrostatic inchworm motor | 60 V | 250 µm, 0.05 mN | [109] |

| Side-drive electrostatic micromotor | [110] | ||

| Electromagnetically levitating hybrid microactuator | 27–33 V, 10 MHz | 34–45 µm | [45] |

| Electrostatic actuator in robot | 500 V | 2.7 mm | [111] |

| 800 V | 2.1 mm | ||

| 700 V | 0.1 m | ||

| Electrostatic inchworm motor for microrobots | 80 V, 8 kHz | 1 mN | [112] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morkvenaite-Vilkonciene, I.; Bucinskas, V.; Subaciute-Zemaitiene, J.; Sutinys, E.; Virzonis, D.; Dzedzickis, A. Development of Electrostatic Microactuators: 5-Year Progress in Modeling, Design, and Applications. Micromachines 2022, 13, 1256. https://doi.org/10.3390/mi13081256

Morkvenaite-Vilkonciene I, Bucinskas V, Subaciute-Zemaitiene J, Sutinys E, Virzonis D, Dzedzickis A. Development of Electrostatic Microactuators: 5-Year Progress in Modeling, Design, and Applications. Micromachines. 2022; 13(8):1256. https://doi.org/10.3390/mi13081256

Chicago/Turabian StyleMorkvenaite-Vilkonciene, Inga, Vytautas Bucinskas, Jurga Subaciute-Zemaitiene, Ernestas Sutinys, Darius Virzonis, and Andrius Dzedzickis. 2022. "Development of Electrostatic Microactuators: 5-Year Progress in Modeling, Design, and Applications" Micromachines 13, no. 8: 1256. https://doi.org/10.3390/mi13081256

APA StyleMorkvenaite-Vilkonciene, I., Bucinskas, V., Subaciute-Zemaitiene, J., Sutinys, E., Virzonis, D., & Dzedzickis, A. (2022). Development of Electrostatic Microactuators: 5-Year Progress in Modeling, Design, and Applications. Micromachines, 13(8), 1256. https://doi.org/10.3390/mi13081256