Design and Fabrication of High-Frequency Piezoelectric Micromachined Ultrasonic Transducer Based on an AlN Thin Film

Abstract

:1. Introduction

2. Modeling and Analysis

3. Results and Discussion

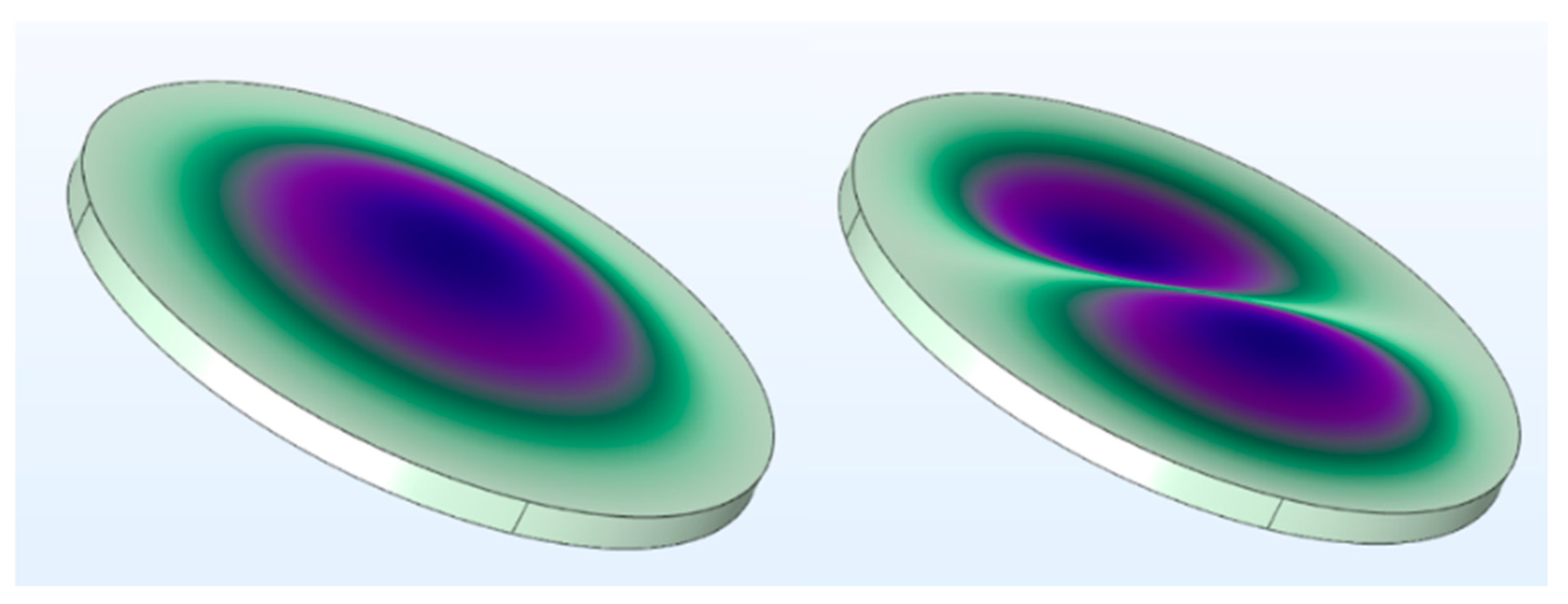

3.1. Simulation Results

3.2. PMUT Fabrication

3.3. PMUT Morphology and Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Leighton, T.G. What is ultrasound? Prog. Biophys. Mol. Biol. 2007, 93, 3–83. [Google Scholar] [CrossRef] [PubMed]

- Zang, J.; Zhou, C.; Xiang, M.; Wang, J.; Wang, H.; Zhang, Z.; Xue, C. Optimum Design and Test of a Novel Bionic Electronic Stethoscope based on the Cruciform Microcantilever with Leaf Microelectromechanical Systems Structure. Adv. Mater. Technol. 2022, 2101501. [Google Scholar] [CrossRef]

- Ali, W.R.; Prasad, M. Piezoelectric MEMS based acoustic sensors: A review. Sensors Actuators A Phys. 2020, 301, 111756. [Google Scholar] [CrossRef]

- Jung, J.; Lee, W.; Kang, W.; Shin, E.; Ryu, J.; Choi, H. Review of piezoelectric micromachined ultrasonic transducers and their applications. J. Micromech. Microeng. 2017, 27, 113001. [Google Scholar] [CrossRef]

- Qu, H. CMOS MEMS Fabrication Technologies and Devices. Micromachines 2016, 7, 14. [Google Scholar] [CrossRef] [PubMed]

- Akhbari, S.; Sammoura, F.; Eovino, B.; Yang, C.; Lin, L. Bimorph Piezoelectric Micromachined Ultrasonic Transducers. J. Microelectromech. Syst. 2016, 25, 326–336. [Google Scholar] [CrossRef]

- Nazemi, H.; Antony Balasingam, J.; Swaminathan, S.; Ambrose, K.; Nathani, M.U.; Ahmadi, T.; Lopez, Y.B.; Emadi, A. Mass Sensors Based on Capacitive and Piezoelectric Micromachined Ultrasonic Transducers-CMUT and PMUT. Sensors 2020, 20, 2010. [Google Scholar] [CrossRef] [PubMed]

- Przybyla, R.J.; Shelton, S.E.; Guedes, A.; Izyumin, I.I.; Kline, M.H.; Horsley, D.A.; Boser, B.E. In-Air Rangefinding With an AlN Piezoelectric Micromachined Ultrasound Transducer. IEEE Sensors J. 2011, 11, 2690–2697. [Google Scholar] [CrossRef]

- Schneider, M.; Dorfmeister, M.; Moll, P.; Kaltenbacher, M.; Schmid, U. Bi-Stable Aluminum Nitride-Based Piezoelectric Micromachined Ultrasonic Transducer (PMUT). J. Microelectromechanical Syst. 2020, 29, 948–953. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, Z.; Chan, J.; Yeow, J.T.W. Capacitive micromachined ultrasound transducers for intravascular ultrasound imaging. Microsyst. Nanoeng. 2020, 6, 73. [Google Scholar] [CrossRef]

- Ding, H.; Yang, D.; Qu, M.; Yang, C.; Chen, X.; Le, X.; Zhu, K.; Xu, J.; Lin, L.; Xie, J. A Pulsed Wave Doppler Ultrasound Blood Flowmeter by PMUTs. J. Microelectromech. Syst. 2021, 30, 680–682. [Google Scholar] [CrossRef]

- Jia, L.; Shi, L.; Liu, C.; Yao, Y.; Sun, C.; Wu, G. Design and Characterization of an Aluminum Nitride-Based MEMS Hydrophone With Biologically Honeycomb Architecture. IEEE Trans. Electron Devices 2021, 68, 4656–4663. [Google Scholar] [CrossRef]

- Chen, Y.-Q.; Li, Y.-X.; Chen, Y.; Ju, Z.-Y.; Tao, L.-Q.; Pang, Y.; Yang, Y.; Ren, T.-L. Large-Scale and High-Density pMUT Array Based on Isolated Sol-Gel PZT Membranes for Fingerprint Imaging. J. Electrochem. Soc. 2017, 164, B377–B381. [Google Scholar] [CrossRef]

- Jiang, X.; Lu, Y.; Tang, H.Y.; Tsai, J.M.; Ng, E.J.; Daneman, M.J.; Boser, B.E.; Horsley, D.A. Monolithic ultrasound fingerprint sensor. Microsyst. Nanoeng. 2017, 3, 17059. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.-Y.; Lu, Y.; Jiang, X.; Ng, E.J.; Tsai, J.M.; Horsley, D.A.; Boser, B.E. 3-D Ultrasonic Fingerprint Sensor-on-a-Chip. IEEE J. Solid-State Circuits 2016, 51, 2522–2533. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, H.; Fung, S.; Wang, Q.; Tsai, J.M.; Daneman, M.; Boser, B.E.; Horsley, D.A. Ultrasonic fingerprint sensor using a piezoelectric micromachined ultrasonic transducer array integrated with complementary metal oxide semiconductor electronics. Appl. Phys. Lett. 2015, 106, 263503. [Google Scholar] [CrossRef]

- Chen, X.; Qu, M.; Zhu, K.; Xie, J. Dual-Frequency Piezoelectric Micromachined Ultrasonic Transducers via Beam-Membrane Coupled Structure. IEEE Electron Device Lett. 2021, 42, 919–922. [Google Scholar] [CrossRef]

- Kazari, H.; Kabir, M.; Mostavi, A.; Ozevin, D. Multi-Frequency Piezoelectric Micromachined Ultrasonic Transducers. IEEE Sens. J. 2019, 19, 11090–11099. [Google Scholar] [CrossRef]

- Liu, X.; Chen, D.; Yang, D.; Chen, X.; Le, X.; Xie, J. A Computational Piezoelectric Micro-Machined Ultrasonic Transducer Toward Acoustic Communication. IEEE Electron Device Lett. 2019, 40, 965–968. [Google Scholar] [CrossRef]

- Liu, X.; Chen, X.; Le, X.; Wang, Y.; Wu, C.; Xie, J. Reducing ring-down time of pMUTs with phase shift of driving waveform. Sens. Actuators A Phys. 2018, 281, 100–107. [Google Scholar] [CrossRef]

- Garcia, A.J.L.; Jalabert, T.; Pusty, M.; Defoor, V.; Mescot, X.; Montanino, M.; Sico, G.; Loffredo, F.; Villani, F.; Nenna, G.; et al. Size and Semiconducting Effects on the Piezoelectric Performances of ZnO Nanowires Grown onto Gravure-Printed Seed Layers on Flexible Substrates. Nanoenergy Adv. 2022, 2, 8. [Google Scholar] [CrossRef]

- Garcia, A.J.L.; Sico, G.; Montanino, M.; Defoor, V.; Pusty, M.; Mescot, X.; Loffredo, F.; Villani, F.; Nenna, G.; Ardila, G. Low-Temperature Growth of ZnO Nanowires from Gravure-Printed ZnO Nanoparticle Seed Layers for Flexible Piezoelectric Devices. Nanomaterials 2021, 11, 1430. [Google Scholar] [CrossRef] [PubMed]

- Fei, C.; Liu, X.; Zhu, B.; Li, D.; Yang, X.; Yang, Y.; Zhou, Q. AlN piezoelectric thin films for energy harvesting and acoustic devices. Nano Energy 2018, 51, 146–161. [Google Scholar] [CrossRef]

- Sammoura, F.; Smyth, K.; Kim, S.G.; Lin, L. An accurate equivalent circuit for the clamped circular multiple-electrode PMUT with residual stress. In Proceedings of the 2013 IEEE International Ultrasonics Symposium (IUS), Prague, Czech Republic, 21–25 July 2013; pp. 275–278. [Google Scholar]

- Leissa, A.W. Vibration of Plates. Scientific and Technical Information Division; National Aeronautics and Space Administration: Washington, DC, USA, 1969. [Google Scholar]

- Ababneh, A.; Schmid, U.; Hernando, J.; Sánchez-Rojas, J.L.; Seidel, H. The influence of sputter deposition parameters on piezoelectric and mechanical properties of AlN thin films. Mater. Sci. Eng. B 2010, 172, 253–258. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, L.; Yang, T.; Liao, Z.; Xue, X.; Wu, B.; Zhang, W.; Zang, J.; Cui, D.; Zhang, Z.; et al. A Mathematical Model of a Piezoelectric Micro- Machined Hydrophone With Simulation and Experimental Validation. IEEE Sens. J. 2021, 21, 13364–13372. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, W.; Wu, Z.; Liu, W.; Sun, C. A Novel Piezoelectric Micromachined Ultrasonic Transducer with Adjustable Broad and Flat Frequency Band. In Proceedings of the 2021 IEEE 16th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xiamen, China, 25–29 April 2021; pp. 656–659. [Google Scholar]

- Williams, M.D.; Griffin, B.A.; Reagan, T.N.; Underbrink, J.R.; Sheplak, M. An AlN MEMS Piezoelectric Microphone for Aeroacoustic Applications. J. Microelectromech. Syst. 2012, 21, 270–283. [Google Scholar] [CrossRef]

- Zhou, X.; Yi, Y.; Cai, G.; Zhang, J.; Huang, H.; Liu, T.; Zhang, J.; Yu, H.; Mu, X. A piezoelectric micromachined ultrasonic transducer with mechanical grooves. J. Micromech. Microeng. 2021, 31, 085009. [Google Scholar] [CrossRef]

- Zhu, W.; Wang, L.; Wu, Z.; Liu, W.; Sun, C. Broadband Piezoelectric Micromachined Ultrasonic Transducer with a Resonant Cavity. IEEE Trans. Ultrason. Ferroelectr. Freq. 2022, 69, 340–349. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.; Wang, Q.; Zhang, Z.; Liao, Z.; Zhao, Y.; Li, Y.; Zang, J.; Gao, R.; Cui, D.; Xue, C. Design and Implementation of 6 × 6 Array Piezoelectric AlN Hydrophone With High Sensitivity. IEEE Sens. J. 2021, 21, 26615–26623. [Google Scholar] [CrossRef]

- Harris, R.A.; Follett, D.H.; Halliwell, M.; Wells, P.N.T. Ultimate limits in ultrasonic imaging resolution. Ultrasound Med. Biol. 1991, 17, 547–558. [Google Scholar] [CrossRef]

- Shung, K.K.; Zippuro, M. Ultrasonic transducers and arrays. IEEE Eng. Med. Biol. Mag. 1996, 15, 20–30. [Google Scholar] [CrossRef]

| Parameters Name | Numerical Value (μm) | Description |

|---|---|---|

| TER | 38 | Top electrode radius |

| TET | 0.2 | Top electrode thickness |

| BER | 55 | Bottom electrode radius |

| BET | 0.2 | Bottom electrode thickness |

| PLR | 55 | Piezoelectric layer radius |

| PLT | 1.2 | Piezoelectric layer thickness |

| SOIT | 5 | SOI-wafer top-layer thickness |

| SOIM | 1 | SOI-wafer middle-layer thickness |

| SOIB | 10 | SOI-wafer bottom-layer thickness |

| BCR | 55 | Back-cavity radius |

| Parameter Name | Parametric Sweep Value (μm) |

|---|---|

| PLR | 30, 35, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90 |

| PLT | 0.6, 0.7, 0.8, 0.9, 1.0, 1.1, 1.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zang, J.; Fan, Z.; Li, P.; Duan, X.; Wu, C.; Cui, D.; Xue, C. Design and Fabrication of High-Frequency Piezoelectric Micromachined Ultrasonic Transducer Based on an AlN Thin Film. Micromachines 2022, 13, 1317. https://doi.org/10.3390/mi13081317

Zang J, Fan Z, Li P, Duan X, Wu C, Cui D, Xue C. Design and Fabrication of High-Frequency Piezoelectric Micromachined Ultrasonic Transducer Based on an AlN Thin Film. Micromachines. 2022; 13(8):1317. https://doi.org/10.3390/mi13081317

Chicago/Turabian StyleZang, Junbin, Zheng Fan, Penglu Li, Xiaoya Duan, Chunsheng Wu, Danfeng Cui, and Chenyang Xue. 2022. "Design and Fabrication of High-Frequency Piezoelectric Micromachined Ultrasonic Transducer Based on an AlN Thin Film" Micromachines 13, no. 8: 1317. https://doi.org/10.3390/mi13081317

APA StyleZang, J., Fan, Z., Li, P., Duan, X., Wu, C., Cui, D., & Xue, C. (2022). Design and Fabrication of High-Frequency Piezoelectric Micromachined Ultrasonic Transducer Based on an AlN Thin Film. Micromachines, 13(8), 1317. https://doi.org/10.3390/mi13081317