Transferability of Diffractive Structure in the Compression Molding of Chalcogenide Glass

Abstract

:1. Introduction

2. Experiments and Discussion

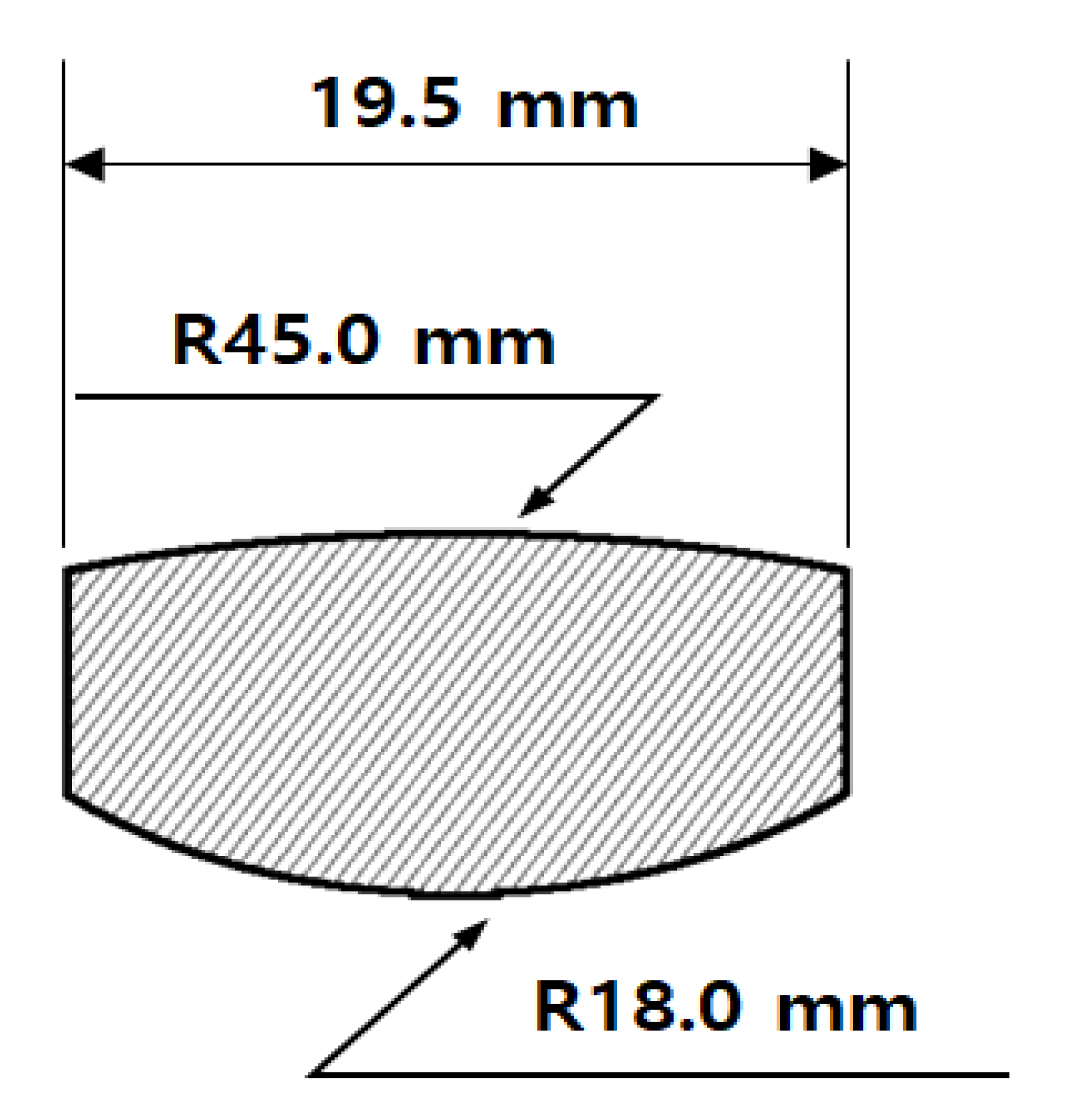

2.1. Optical Design of the Diffractive-Aspheric Lens

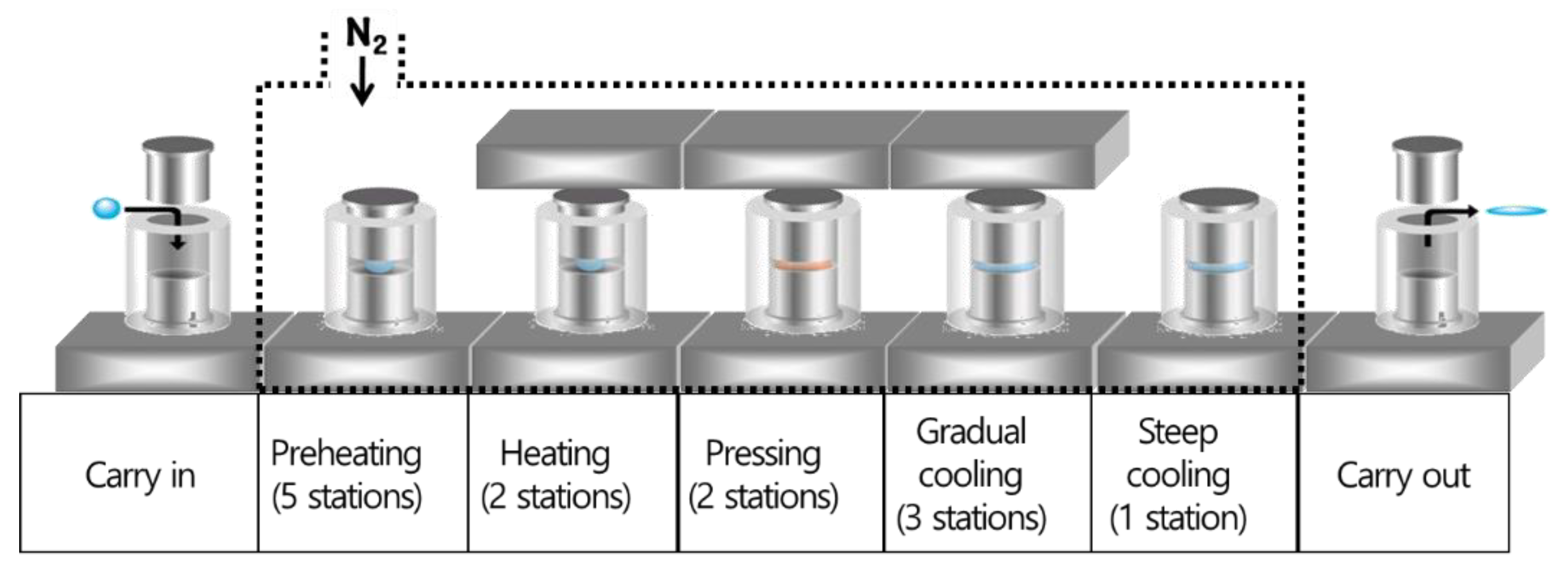

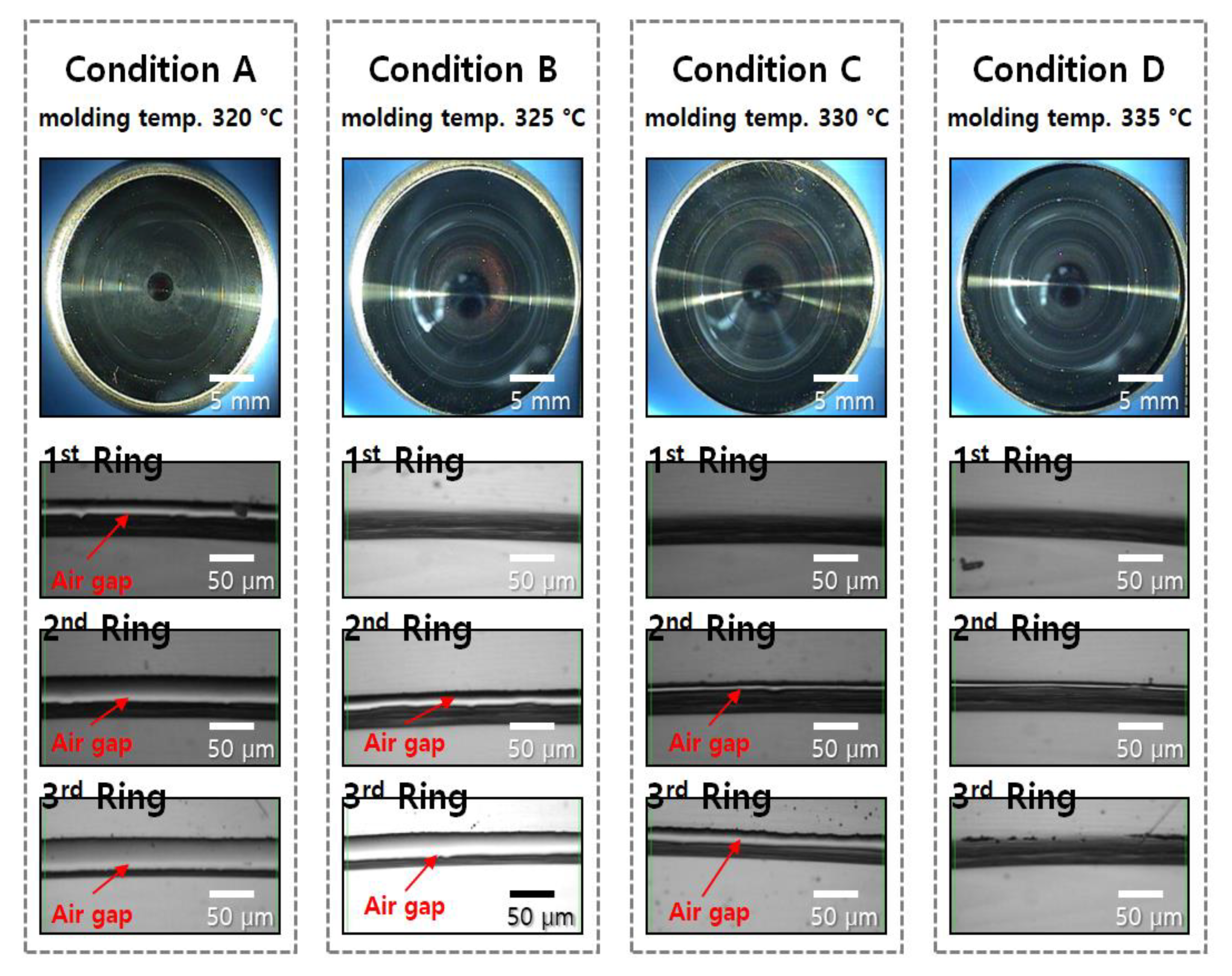

2.2. Mold Fabrication and Molding of Diffractive-Aspheric Lens

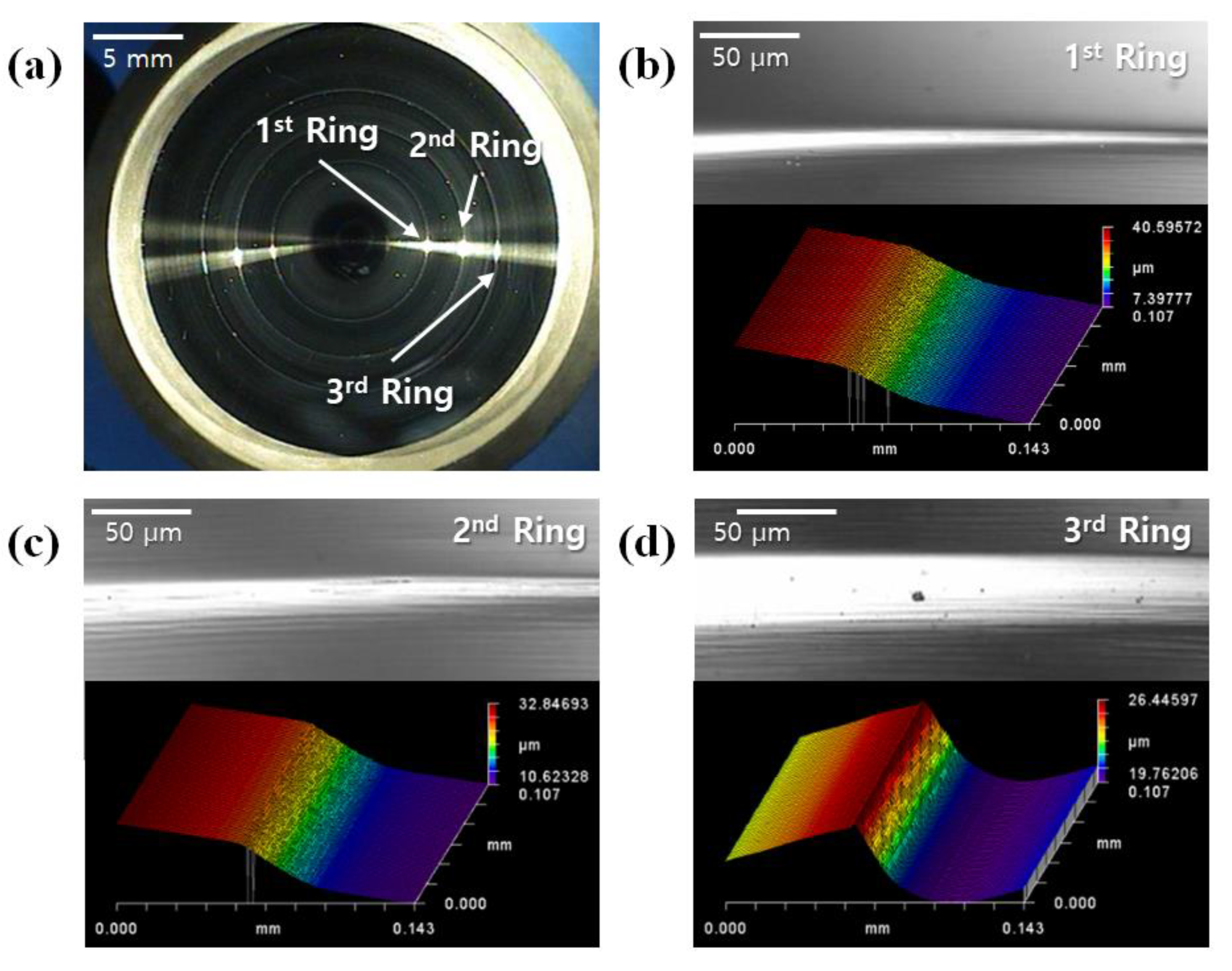

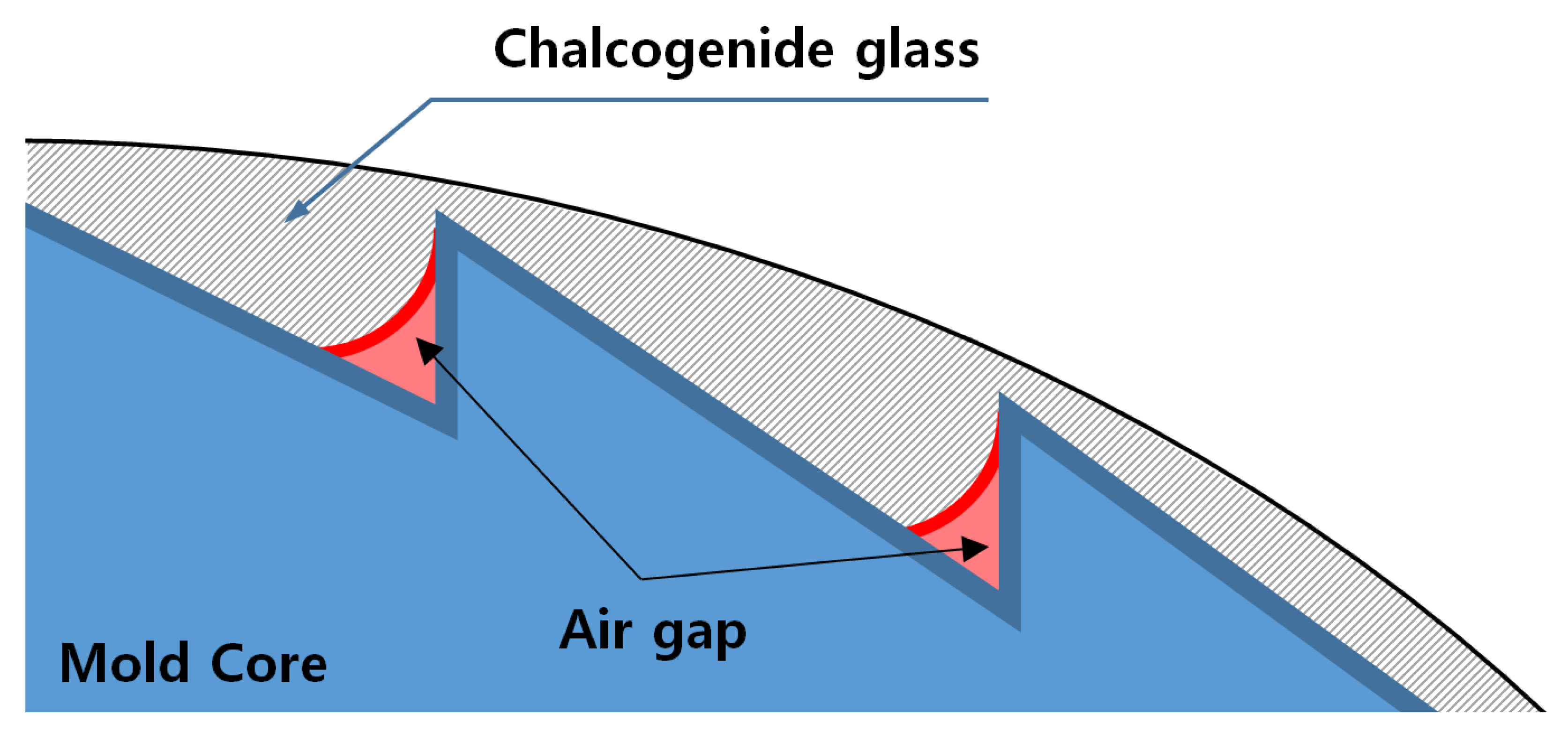

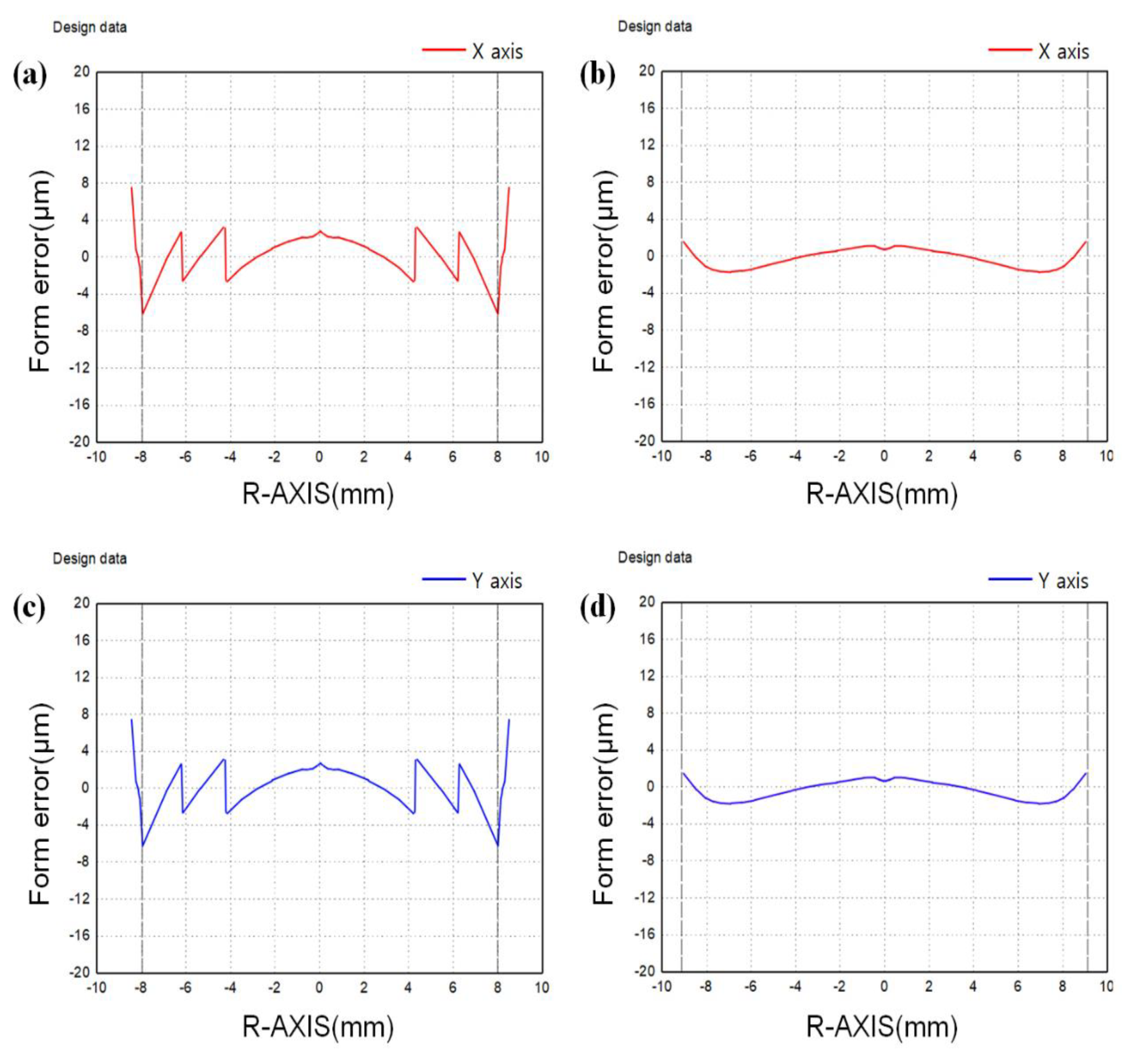

2.3. Results and Discussion

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, B.; Yang, Y.; Fan, Y.; Zhang, L. Barium gallogermanate glass ceramics for infrared applications. J. Mater. Sci. Technol. 2010, 26, 558–563. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, H.; Lucas, J. Applications of chalcogenide glass bulks and fibres. J. Optoelectron. Adv. Mater. 2003, 5, 1327–1333. [Google Scholar]

- Kadono, K.; Kitamura, N. Recent progress in chalcogenide glasses applicable to infrared optical elements manufactured by molding technology. J. Ceram. Soc. Jpn. 2022, 130, 584–589. [Google Scholar] [CrossRef]

- Zhou, T.; Zhu, Z.; Liu, X.; Liang, Z.; Wang, X. A Review of the Precision Glass Molding of Chalcogenide Glass (ChG) for Infrared Optics. Micromachines 2018, 9, 337. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cha, D.H.; Kim, J.; Kim, H.J. Experimental study of the fabrication of chalcogenide glass lenses by using precision glass molding. J. Korean Phys. Soc. 2014, 65, 1675–1681. [Google Scholar] [CrossRef]

- Cha, D.; Kim, H.; Hwang, Y.; Jeong, J.; Kim, J.H. Fabrication of molded chalcogenide-glass lens for thermal imaging applications. Appl. Opt. 2012, 51, 5649–5656. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; He, Y.; Wang, T.; Zhu, Z.; Xu, R.; Yu, Q.; Zhao, B.; Zhao, W.; Liu, P.; Wang, X. A review of the techniques for the mold manufacturing of micro/nanostructures for precision glass molding. Int. J. Extrem. Manuf. 2021, 3, 042002. [Google Scholar] [CrossRef]

- Luo, S.; Huang, F.; Zhan, D.; Wang, M. Development of chalcogenide glasses for infrared thermal imaging system. Laser Infrared 2010, 40, 9–13. [Google Scholar]

- Mehta, N.; Kumar, A. Recent Advances in Chalcogenide Glasses for Multifunctional Applications in Fiber Optics. Mater. Sci. 2013, 6, 59–67. [Google Scholar] [CrossRef]

- Liu, Y.; Xing, Y.; Fu, H.; Li, C.; Yang, C.; Cao, B.; Xue, C. Deformation Analysis of the Glass Preform in the Progress of Precision Glass Molding for Fabricating Chalcogenide Glass Diffractive Optics with the Finite Element Method. Micromachines 2021, 12, 1543. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; Xie, J.; Yan, J.; Tsunemoto, K.; Wang, X. Improvement of glass formability in ultrasonic vibration assisted molding process. Int. J. Precis. Eng. Manuf. 2017, 18, 57–62. [Google Scholar] [CrossRef]

- SCHOTT Advanced Optics. Available online: https://www.schott.com/advanced_optics/english/products/optical-materials/ir-materials/infrared-chalcogenide-glasses/index.html (accessed on 16 January 2023).

- Zhang, L.; Zhou, W.; Naples, N.; Allen, Y. Investigation of index change in compression molding of As40Se50S10 chalcogenide glass. Appl. Opt. 2018, 57, 4245–4252. [Google Scholar] [CrossRef] [PubMed]

- Flores-Ruiz, H.M.; Toledo-Marín, J.; Moukarzel, C.; Naumis, G. Space-time rigidity and viscoelasticity of glass forming liquids: The case of chalcogenides. J. Non-Cryst. Solids 2022, 15, 100117. [Google Scholar] [CrossRef]

- Cha, D.; Kim, H.; Park, H.; Hwang, Y.; Kim, J.; Hong, J.; Lee, K. Effect of temperature on the molding of chalcogenide glass lenses for infrared imaging applications. Appl. Opt. 2010, 49, 1607–1613. [Google Scholar] [CrossRef] [PubMed]

- Kitamura, N. Two types of structural relaxations around the deformation temperature of Ge20Sb15Se65 glass. J. Non-Cryst. Solids 2018, 492, 126–129. [Google Scholar] [CrossRef]

- Kitamura, N.; Suetsugu, T.; Nakano, K.; Higashi, N.; Yamaguro, T. Viscoelastic study of the creep behavior of GeS2-SbS3/2-SnS and GaS3/2-SbS3/2-SnS glasses around their deformation temperatures. J. Non-Cryst. Solids 2019, 517, 44–50. [Google Scholar] [CrossRef]

- Arai, M.; Kato, Y.; Kodera, T. Characterization of the Thermo-Viscoelastic Property of Glass and Numerical Simulation of the Press Molding of Glass Lens. J. Therm. Stress. 2009, 32, 1235–1255. [Google Scholar] [CrossRef]

- Zhu, W.; Lockhart, M.; Aitken, B.; Sen, S. Dynamical rigidity transition in the viscoelastic properties of chalcogenide glass-forming liquids. J. Non-Cryst. Solids 2018, 502, 244–248. [Google Scholar] [CrossRef]

- Kadono, K.; Furukawa, M.; Yamamoto, S.; Wakasugi, T.; Okada, A. The formation and properties of glasses based on Ga2S3-Bi2S3 system. J. Asian Ceram. Soc. 2020, 8, 284–290. [Google Scholar] [CrossRef] [Green Version]

- Chien, H.H.; Kuo, C.; Huang, S.W. Molding of Al2O3-coated chalcogenide glass lenses. Opt. Eng. 2012, 51, 033401. [Google Scholar] [CrossRef]

| Term | Unit | Value |

|---|---|---|

| Transition temperature (Tg) | °C | 285 |

| Softening temperature (Ts) | °C | 310 |

| Thermal conductivity | W/m·K | 0.25 |

| Thermal expansion coefficient | 10−6/K | 14 |

| Process Parameters | |||||

|---|---|---|---|---|---|

| Preheating | Heating | Pressing | Gradual Cooling | ||

| Temp. (°C) | Top plate | - | 320 | 320~335 | 200 |

| Bottom plate | 280 | 320 | 320 | 200 | |

| Pressure (MPa) | - | - | 0.2 | 0.05 | |

| Unit-process time (s) | 300 | ||||

| Molding Conditions | |||||

| Condition no. | A | B | C | D | |

| Temp. (°C) | 320 | 325 | 330 | 335 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, B.-R.; Kim, J.-K.; Choi, Y.-S.; Park, C. Transferability of Diffractive Structure in the Compression Molding of Chalcogenide Glass. Micromachines 2023, 14, 273. https://doi.org/10.3390/mi14020273

Son B-R, Kim J-K, Choi Y-S, Park C. Transferability of Diffractive Structure in the Compression Molding of Chalcogenide Glass. Micromachines. 2023; 14(2):273. https://doi.org/10.3390/mi14020273

Chicago/Turabian StyleSon, Byeong-Rea, Ji-Kwan Kim, Young-Soo Choi, and Changsin Park. 2023. "Transferability of Diffractive Structure in the Compression Molding of Chalcogenide Glass" Micromachines 14, no. 2: 273. https://doi.org/10.3390/mi14020273

APA StyleSon, B.-R., Kim, J.-K., Choi, Y.-S., & Park, C. (2023). Transferability of Diffractive Structure in the Compression Molding of Chalcogenide Glass. Micromachines, 14(2), 273. https://doi.org/10.3390/mi14020273