Ultrasound-Based Real-Time Imaging of Hydrogel-Based Millirobots with Volume Change Capability

Abstract

:1. Introduction

2. Material and Methods

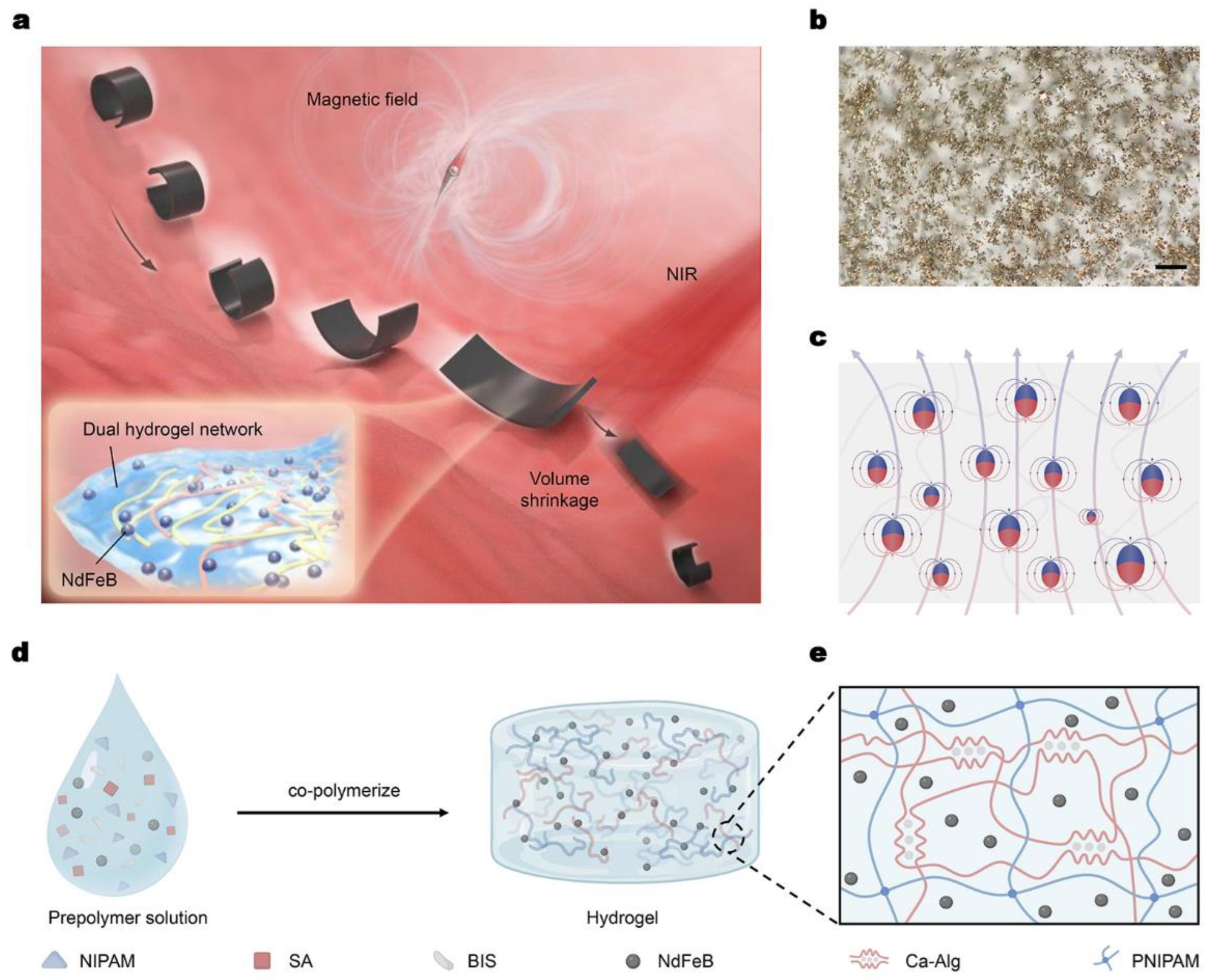

2.1. Fabrication of Dual-Network Hydrogel-Based Millirobot

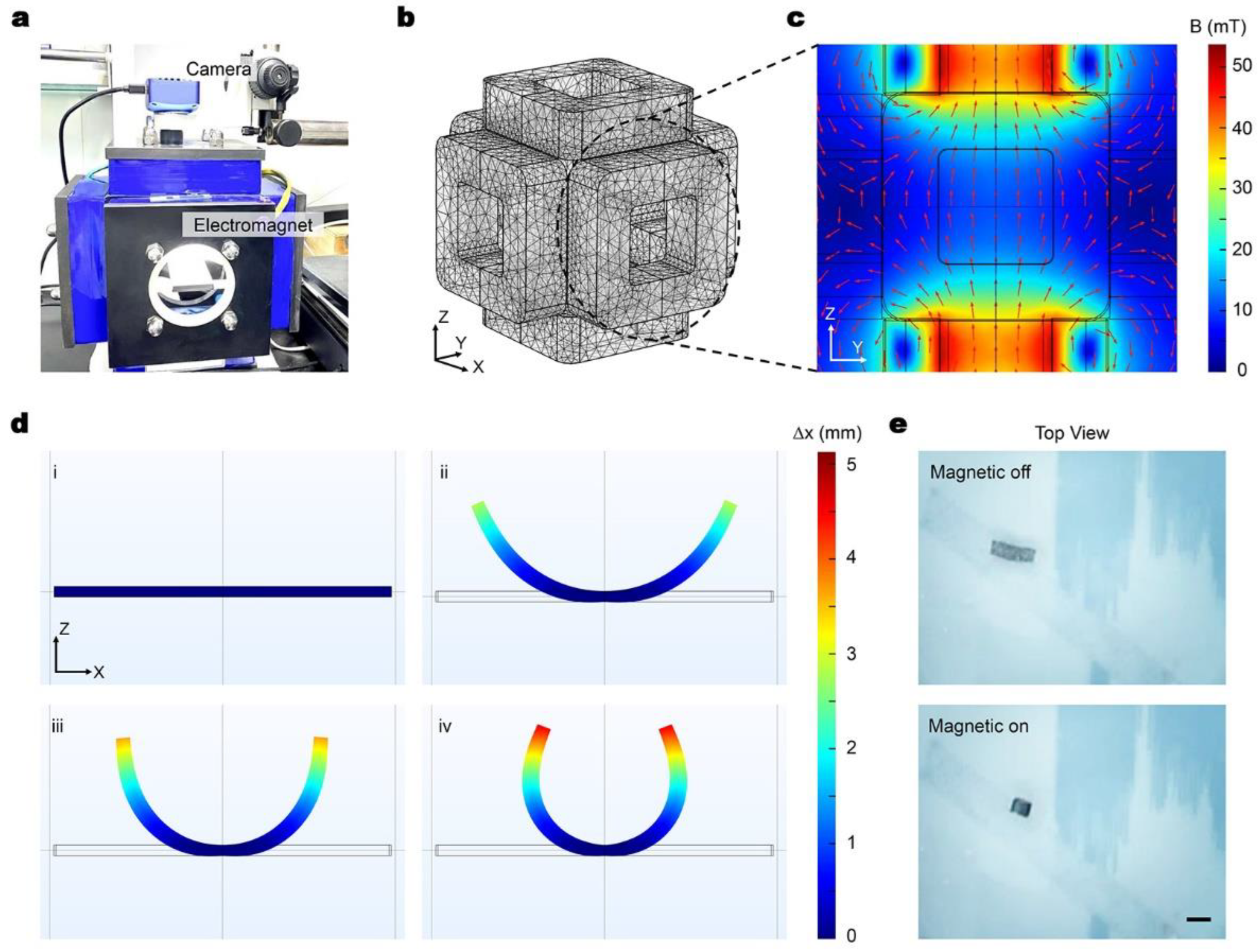

2.2. Simulation Methods

3. Experiments and Results

3.1. Magnetic-Actuated Curve Deformation

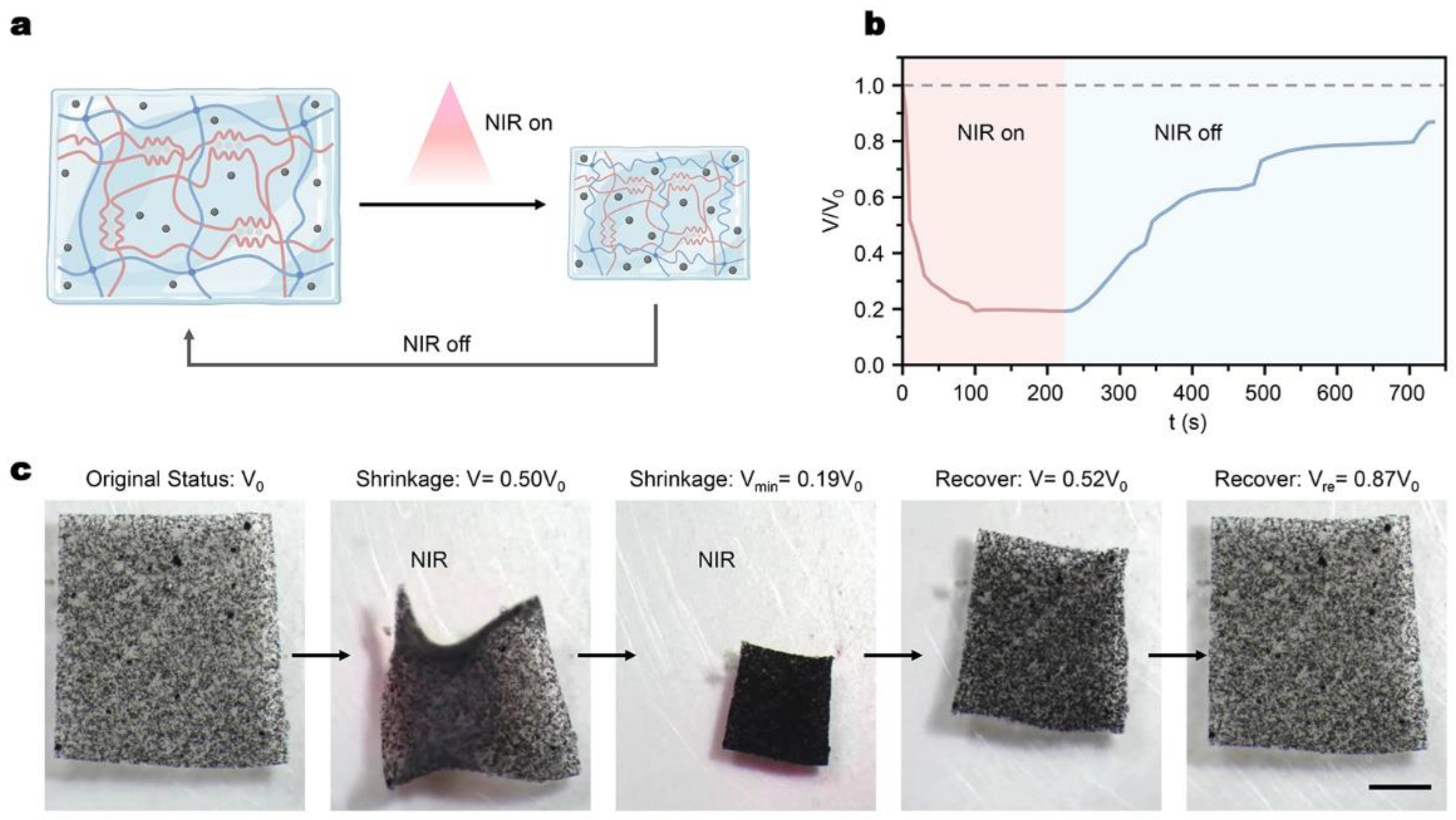

3.2. NIR-Driven Volume Change Capacity

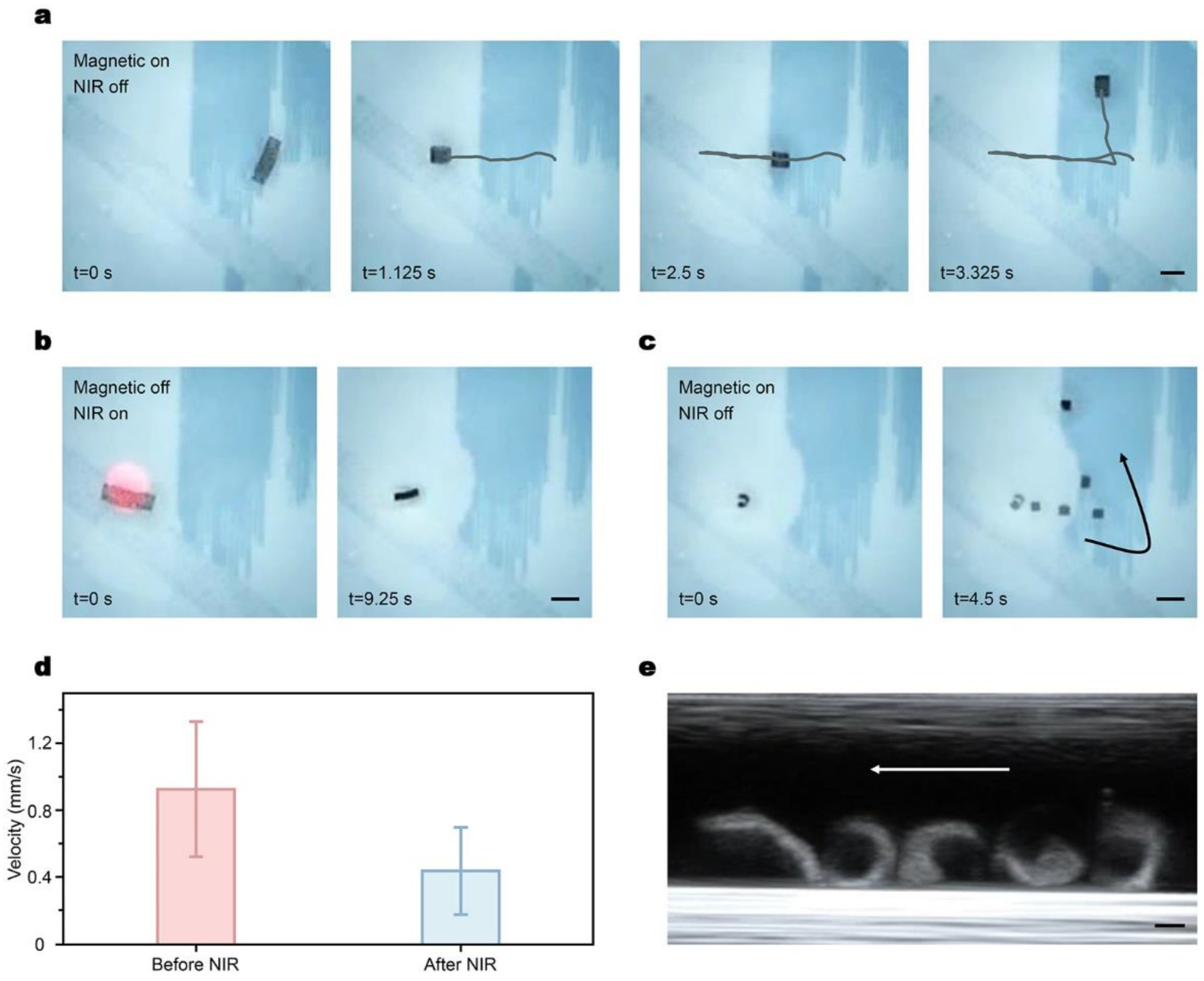

3.3. Dual-Responsive Motility of the Millirobot and Ultrasound Imaging

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, W.Q.; Lum, G.Z.; Mastrangeli, M.; Sitti, M. Small-scale soft-bodied robot with multimodal locomotion. Nature 2018, 554, 81–85. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Zhang, J.; Salehizadeh, M.; Onaizah, O.; Diller, E. Millimeter-scale flexible robots with programmable three-dimensional magnetization and motions. Sci. Robot. 2019, 4, eaav4494. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Wang, H.; Dong, L.; Shi, Q.; Li, J.; Sun, T.; Huang, Q.; Fukuda, T. Ionic shape-morphing microrobotic end-effectors for environmentally adaptive targeting, releasing, and sampling. Nat. Commun. 2021, 12, 411. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Chen, Y.; Majidi, C.; Iida, F.; Askounis, E.; Pei, Q. Controllable and reversible tuning of material rigidity for robot applications. Mater. Today 2018, 21, 563–576. [Google Scholar] [CrossRef]

- Zhuo, S.; Zhao, Z.; Xie, Z.; Hao, Y.; Xu, Y.; Zhao, T.; Li, H.; Knubben, E.M.; Wen, L.; Jiang, L.; et al. Complex multiphase organohydrogels with programmable mechanics toward adaptive soft-matter machines. Sci. Adv. 2020, 6, eaax1464. [Google Scholar] [CrossRef] [PubMed]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef]

- Ren, Z.; Hu, W.; Dong, X.; Sitti, M. Multi-functional soft-bodied jellyfish-like swimming. Nat. Commun. 2019, 10, 2703. [Google Scholar] [CrossRef]

- Wang, T.; Ren, Z.; Hu, W.; Li, M.; Sitti, M. Effect of body stiffness distribution on larval fish–like efficient undulatory swimming. Sci. Adv. 2021, 7, eabf7364. [Google Scholar] [CrossRef]

- Kim, J.; Chung, S.E.; Choi, S.E.; Lee, H.; Kim, J.; Kwon, S. Programming magnetic anisotropy in polymeric microactuators. Nat. Mater. 2011, 10, 747–752. [Google Scholar] [CrossRef]

- Huang, H.-W.; Sakar, M.S.; Petruska, A.J.; Pané, S.; Nelson, B.J. Soft micromachines with programmable motility and morphology. Nat. Commun. 2016, 7, 12263. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef] [PubMed]

- Gu, H.; Boehler, Q.; Cui, H.; Secchi, E.; Savorana, G.; De Marco, C.; Gervasoni, S.; Peyron, Q.; Huang, T.-Y.; Pane, S.; et al. Magnetic cilia carpets with programmable metachronal waves. Nat. Commun. 2020, 11, 2637. [Google Scholar] [CrossRef] [PubMed]

- Gupta, B.; Goudeau, B.; Garrigue, P.; Kuhn, A. Bipolar Conducting Polymer Crawlers Based on Triple Symmetry Breaking. Adv. Funct. Mater. 2018, 28, 1705825. [Google Scholar] [CrossRef]

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft Actuators for Small-Scale Robotics. Adv. Mater. 2017, 29, 1603483. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Zhang, M.; Yang, Y.; Huang, Q.; Fukuda, T.; Wang, Z.; Shen, Y. A bioinspired multilegged soft millirobot that functions in both dry and wet conditions. Nat. Commun. 2018, 9, 3944. [Google Scholar] [CrossRef]

- Ng, C.S.X.; Tan, M.W.M.; Xu, C.; Yang, Z.; Lee, P.S.; Lum, G.Z. Locomotion of Miniature Soft Robots. Adv. Mater. 2021, 33, 2003558. [Google Scholar] [CrossRef]

- Ren, Z.; Zhang, R.; Soon, R.H.; Liu, Z.; Hu, W.; Onck, P.R.; Sitti, M. Soft-bodied adaptive multimodal locomotion strategies in fluid-filled confined spaces. Sci. Adv. 2021, 7, eabh2022. [Google Scholar] [CrossRef]

- Li, C.; Lau, G.C.; Yuan, H.; Aggarwal, A.; Dominguez, V.L.; Liu, S.; Sai, H.; Palmer, L.C.; Sather, N.A.; Pearson, T.J.; et al. Fast and programmable locomotion of hydrogel-metal hybrids under light and magnetic fields. Sci. Robot. 2020, 5, eabb9822. [Google Scholar] [CrossRef]

- Lum, G.Z.; Ye, Z.; Dong, X.G.; Marvi, H.; Erin, O.; Hu, W.Q.; Sitti, M. Shape-programmable magnetic soft matter. Proc. Natl. Acad. Sci. USA 2016, 113, E6007–E6015. [Google Scholar] [CrossRef]

- Dai, Y.; Liang, S.; Chen, Y.; Feng, Y.; Chen, D.; Song, B.; Bai, X.; Zhang, D.; Feng, L.; Arai, F. Untethered Octopus-Inspired Millirobot Actuated by Regular Tetrahedron Arranged Magnetic Field. Adv. Intell. Syst. 2020, 2, 1900148. [Google Scholar] [CrossRef]

- Du, X.; Cui, H.; Xu, T.; Huang, C.; Wang, Y.; Zhao, Q.; Xu, Y.; Wu, X. Reconfiguration, Camouflage, and Color-Shifting for Bioinspired Adaptive Hydrogel-Based Millirobots. Adv. Funct. Mater. 2020, 30, 1909202. [Google Scholar] [CrossRef]

- Xia, N.; Jin, B.; Jin, D.; Yang, Z.; Pan, C.; Wang, Q.; Ji, F.; Iacovacci, V.; Majidi, C.; Ding, Y.; et al. Decoupling and Reprogramming the Wiggling Motion of Midge Larvae Using a Soft Robotic Platform. Adv. Mater. 2022, 34, 2109126. [Google Scholar] [CrossRef] [PubMed]

- Tang, P.; Yan, H.; Chen, L.; Wu, Q.; Zhao, T.; Li, S.; Gao, H.; Liu, M. Anisotropic nanocomposite hydrogels with enhanced actuating performance through aligned polymer networks. Sci. China Mater. 2020, 63, 832–841. [Google Scholar] [CrossRef]

- Niu, F.Z.; Li, J.Y.; Ma, W.C.; Yang, J.; Sun, D. Development of an Enhanced Electromagnetic Actuation System with Enlarged Workspace. IEEE/ASME Trans. Mechatron. 2017, 22, 2265–2276. [Google Scholar] [CrossRef]

- Zheng, J.; Xiao, P.; Le, X.; Lu, W.; Théato, P.; Ma, C.; Du, B.; Zhang, J.; Huang, Y.; Chen, T. Mimosa inspired bilayer hydrogel actuator functioning in multi-environments. J. Mater. Chem. C 2018, 6, 1320–1327. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Y.; Dai, Y.; Zhang, W.; Wang, M.; Zhao, H.; Feng, L. Ultrasound-Based Real-Time Imaging of Hydrogel-Based Millirobots with Volume Change Capability. Micromachines 2023, 14, 422. https://doi.org/10.3390/mi14020422

Hou Y, Dai Y, Zhang W, Wang M, Zhao H, Feng L. Ultrasound-Based Real-Time Imaging of Hydrogel-Based Millirobots with Volume Change Capability. Micromachines. 2023; 14(2):422. https://doi.org/10.3390/mi14020422

Chicago/Turabian StyleHou, Yaxin, Yuguo Dai, Wei Zhang, Minghui Wang, Hanxue Zhao, and Lin Feng. 2023. "Ultrasound-Based Real-Time Imaging of Hydrogel-Based Millirobots with Volume Change Capability" Micromachines 14, no. 2: 422. https://doi.org/10.3390/mi14020422

APA StyleHou, Y., Dai, Y., Zhang, W., Wang, M., Zhao, H., & Feng, L. (2023). Ultrasound-Based Real-Time Imaging of Hydrogel-Based Millirobots with Volume Change Capability. Micromachines, 14(2), 422. https://doi.org/10.3390/mi14020422