Intelligent Device for Harvesting the Vibration Energy of the Automobile Exhaust with a Piezoelectric Generator

Abstract

:1. Introduction

2. Results and Discussion

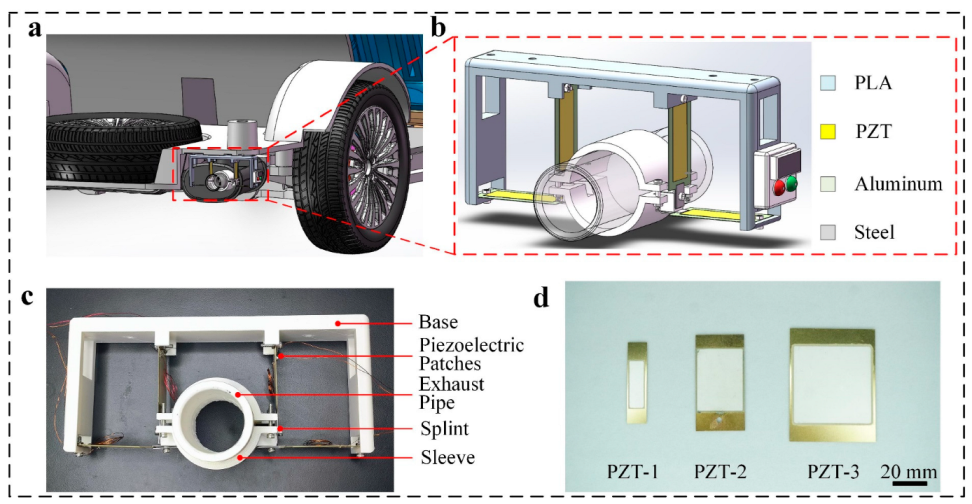

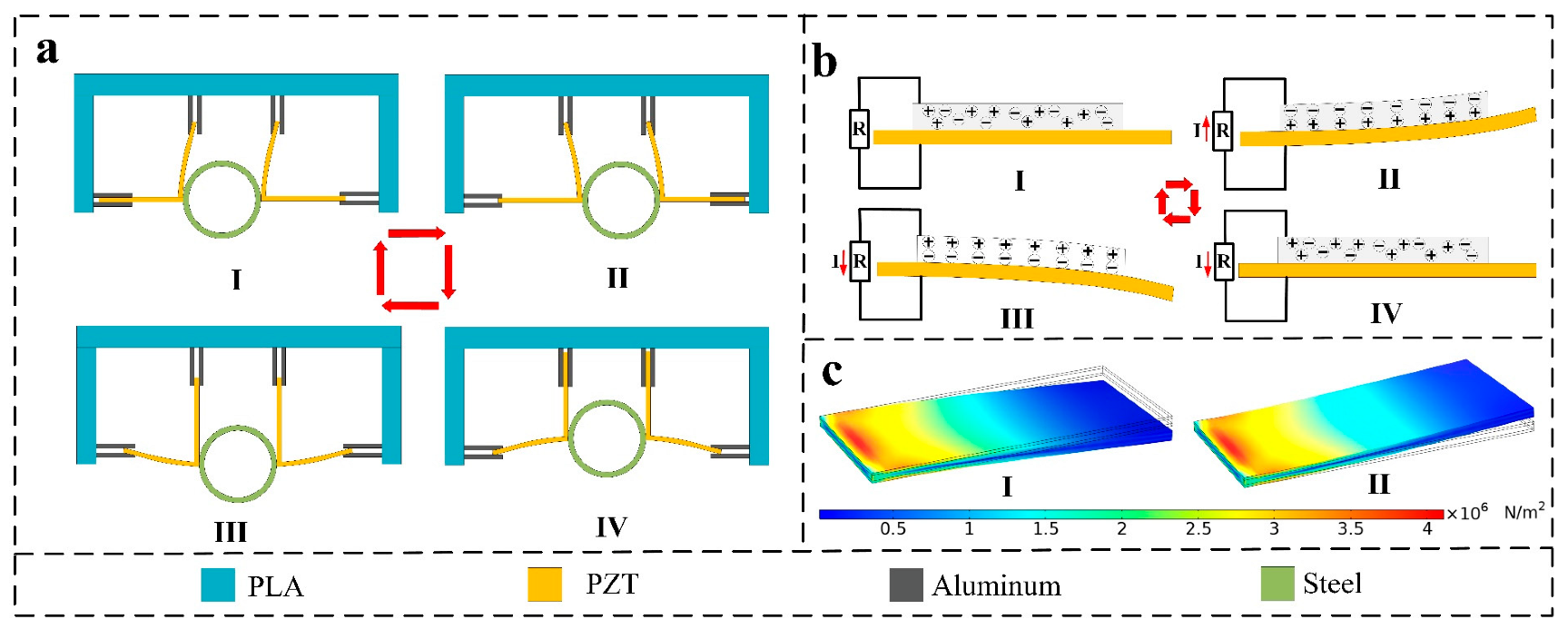

2.1. Structural Design and Working Principle

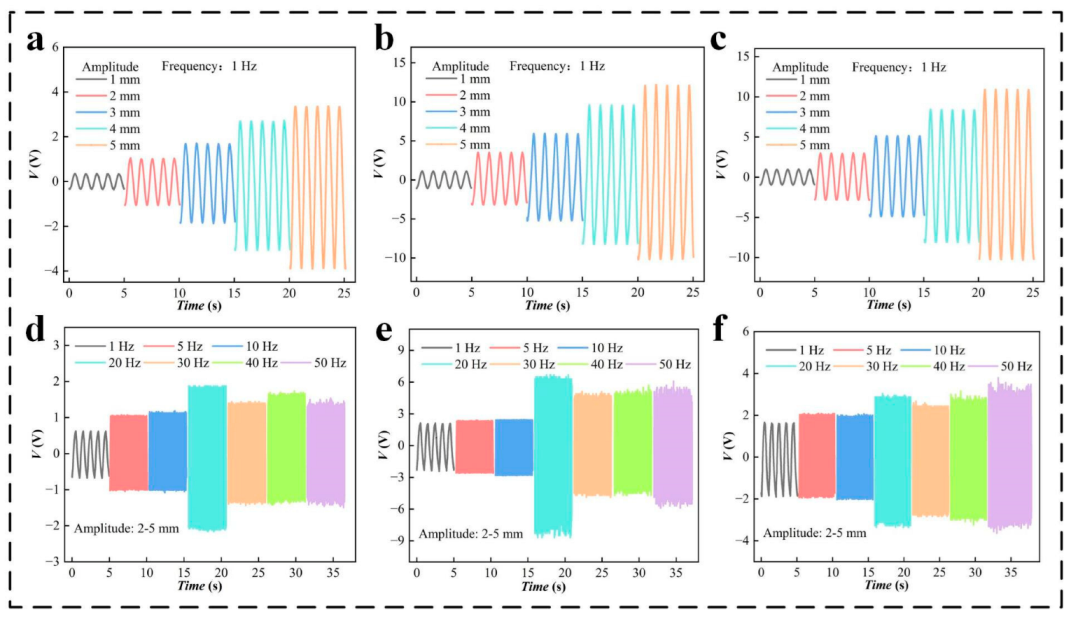

2.2. Output Performance

2.3. Demonstration

3. Experimental

3.1. Fabrication of the SSAS

3.2. Electrical Measurement

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hooftman, N.; Messagie, M.; Van Mierlo, J.; Coosemans, T. A review of the European passenger car regulations–Real driving emissions vs local air quality. Renew. Sustain. Energy Rev. 2018, 86, 1–21. [Google Scholar] [CrossRef]

- Lowe, R.J.; Drummond, P. Solar, wind and logistic substitution in global energy supply to 2050–Barriers and implications. Renew. Sustain. Energy Rev. 2022, 153, 111720. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Abdelkareem, M.A.A.; Gulzar, M.; Elsheikh, A.H. Novel approach of the graphene nanolubricant for energy saving via anti-friction/wear in automobile engines. Tribol. Int. 2018, 124, 209–229. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Fuming, P.; Younus, H.A.; Abdelkareem, M.A.A.; Essa, F.A.; Elagouz, A.; Xianjun, H. Fuel economy in gasoline engines using Al2O3/TiO2 nanomaterials as nanolubricant additives. Appl. Energy 2018, 211, 461–478. [Google Scholar] [CrossRef]

- Wang, H.; Jasim, A.; Chen, X. Energy harvesting technologies in roadway and bridge for different applications—A comprehensive review. Appl. Energy 2018, 212, 1083–1094. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, K.; Wang, D.; Chen, C.; Li, X. Energy conversion mechanism and regenerative potential of vehicle suspensions. Energy 2017, 119, 961–970. [Google Scholar] [CrossRef]

- Qi, L.; Pan, H.; Bano, S.; Zhu, M.; Liu, J.; Zhang, Z.; Liu, Y.; Yuan, Y. A high-efficiency road energy harvester based on a chessboard sliding plate using semi-metal friction materials for self-powered applications in road traffic. Energy Convers. Manag. 2018, 165, 748–760. [Google Scholar] [CrossRef]

- Akkaya Oy, S. A piezoelectric energy harvesting from the vibration of the airflow around a moving vehicle. Int. Trans. Electr. Energy Syst. 2020, 30, 12655. [Google Scholar] [CrossRef]

- Lee, H.; Jang, H.; Park, J.; Jeong, S.; Park, T.; Choi, S. Design of a Piezoelectric Energy-Harvesting Shock Absorber System for a Vehicle. Integr. Ferroelectr. 2013, 141, 32–44. [Google Scholar] [CrossRef]

- Taymaz, I. An experimental study of energy balance in low heat rejection diesel engine. Energy 2006, 31, 364–371. [Google Scholar] [CrossRef]

- Madaro, F.; Mehdipour, I.; Caricato, A.; Guido, F.; Rizzi, F.; Carlucci, A.P.; De Vittorio, M. Available Energy in Cars’ Exhaust System for IoT Remote Exhaust Gas Sensor and Piezoelectric Harvesting. Energies 2020, 13, 4169. [Google Scholar] [CrossRef]

- Tavares, R.; Ruderman, M. Energy harvesting using piezoelectric transducers for suspension systems. Mechatronics 2020, 65, 102294. [Google Scholar] [CrossRef]

- Kim, T.D.; Kim, J.H. Shock-Absorber Rotary Generator for Automotive Vibration Energy Harvesting. Appl. Sci. 2020, 10, 6599. [Google Scholar] [CrossRef]

- Zhang, Z.; Kan, J.; Wang, S.; Wang, H.; Yang, C.; Chen, S. Performance Dependence on Initial Free-End Levitation of a Magnetically Levitated Piezoelectric Vibration Energy Harvester With a Composite Cantilever Beam. IEEE Access 2017, 5, 27563–27572. [Google Scholar] [CrossRef]

- Cheng, T.; Liu, W.; Lu, X.; Wang, Y.; Bao, G.; Liu, M. A Small Magnetic Pre-Stress Based Piezoelectric Diaphragm Generator Induced By Hyperbaric Air. IEEE Access 2018, 6, 26596–26604. [Google Scholar] [CrossRef]

- Yang, W.; Wang, Y.; Li, Y.; Wang, J.; Cheng, T.; Wang, Z.L. Integrated flywheel and spiral spring triboelectric nanogenerator for improving energy harvesting of intermittent excitations/triggering. Nano Energy 2019, 66, 104104. [Google Scholar] [CrossRef]

- Yang, W.; Gao, Q.; Xia, X.; Zhang, X.; Lu, X.; Yang, S.; Cheng, T.; Wang, Z.L. Travel switch integrated mechanical regulation triboelectric nanogenerator with linear–rotational motion transformation mechanism. Extrem. Mech. Lett. 2020, 37, 100718. [Google Scholar] [CrossRef]

- He, J.; Wen, T.; Qian, S.; Zhang, Z.; Tian, Z.; Zhu, J.; Mu, J.; Hou, X.; Geng, W.; Cho, J.; et al. Triboelectric-piezoelectric-electromagnetic hybrid nanogenerator for high-efficient vibration energy harvesting and self-powered wireless monitoring system. Nano Energy 2018, 43, 326–339. [Google Scholar] [CrossRef]

- Liang, H.; Hao, G.; Olszewski, O.Z. A review on vibration-based piezoelectric energy harvesting from the aspect of compliant mechanisms. Sens. Actuators A Phys. 2021, 331, 112743. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Z.L. Reviving Vibration Energy Harvesting and Self-Powered Sensing by a Triboelectric Nanogenerator. Joule 2017, 1, 480–521. [Google Scholar] [CrossRef]

- Han, J.; Hu, J.; Wang, S.X.; He, J. Great enhancement of energy harvesting properties of piezoelectric/magnet composites by the employment of magnetic concentrator. J. Appl. Phys. 2015, 117, 17a304. [Google Scholar] [CrossRef]

- Abed, I.; Kacem, N.; Bouhaddi, N.; Bouazizi, M.L. Multi-modal vibration energy harvesting approach based on nonlinear oscillator arrays under magnetic levitation. Smart Mater. Struct. 2016, 25, 025018. [Google Scholar] [CrossRef]

- Gomes, J.B.A.; Rodrigues, J.J.P.C.; Rabêlo, R.A.L.; Kumar, N.; Kozlov, S. IoT-Enabled Gas Sensors: Technologies, Applications, and Opportunities. J. Sens. Actuator Netw. 2019, 8, 57. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; He, L.; Han, Y.; Zheng, X.; Sun, B.; Cheng, G. A review of rotary piezoelectric energy harvesters. Sens. Actuators A Phys. 2023, 349, 114054. [Google Scholar] [CrossRef]

- Shan, G.; Kuang, Y.; Zhu, M. Design, modelling and testing of a compact piezoelectric transducer for railway track vibration energy harvesting. Sens. Actuators A Phys. 2022, 347, 113980. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, W.; Yu, X.; Li, H.; Cheng, T.; Lu, X.; Wang, Z.L. Real-Time Monitoring System of Automobile Driver Status and Intelligent Fatigue Warning Based on Triboelectric Nanogenerator. ACS Nano 2021, 15, 7271–7278. [Google Scholar] [CrossRef]

- Lin, T.; Pan, Y.; Chen, S.; Zuo, L. Modeling and field testing of an electromagnetic energy harvester for rail tracks with anchorless mounting. Appl. Energy 2018, 213, 219–226. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, J.-H.; Kim, J. A review of piezoelectric energy harvesting based on vibration. Int. J. Precis. Eng. Manuf. 2011, 12, 1129–1141. [Google Scholar] [CrossRef]

- Elahi, H.; Eugeni, M.; Gaudenzi, P. A Review on Mechanisms for Piezoelectric-Based Energy Harvesters. Energies 2018, 11, 1850. [Google Scholar] [CrossRef] [Green Version]

- Shevtsov, S.; Flek, M. Random Vibration Energy Harvesting by Piezoelectric Stack Charging the Battery. Procedia Eng. 2016, 144, 645–652. [Google Scholar] [CrossRef] [Green Version]

- Fan, K.; Liu, S.; Liu, H.; Zhu, Y.; Wang, W.; Zhang, D. Scavenging energy from ultra-low frequency mechanical excitations through a bi-directional hybrid energy harvester. Appl. Energy 2018, 216, 8–20. [Google Scholar] [CrossRef]

- Turkmen, A.C.; Celik, C. Energy harvesting with the piezoelectric material integrated shoe. Energy 2018, 150, 556–564. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Cheng, T.; Song, Z.; Qin, F. Sealed piezoelectric energy harvester driven by hyperbaric air load. Appl. Phys. Lett. 2016, 108, 033902. [Google Scholar] [CrossRef]

- Granstrom, J.; Feenstra, J.; Sodano, H.A.; Farinholt, K. Energy harvesting from a backpack instrumented with piezoelectric shoulder straps. Smart Mater. Struct. 2007, 16, 1810–1820. [Google Scholar] [CrossRef]

- Xie, X.D.; Wang, Q.; Wang, S.J. Energy harvesting from high-rise buildings by a piezoelectric harvester device. Energy 2015, 93, 1345–1352. [Google Scholar] [CrossRef]

- Xie, X.D.; Wang, Q.; Wu, N. Potential of a piezoelectric energy harvester from sea waves. J. Sound Vib. 2014, 333, 1421–1429. [Google Scholar] [CrossRef]

- Wu, N.; Wang, Q.; Xie, X. Wind energy harvesting with a piezoelectric harvester. Smart Mater. Struct. 2013, 22, 095023. [Google Scholar] [CrossRef]

- Krishnamoorthy, K.; Mariappan, V.K.; Pazhamalai, P.; Sahoo, S.; Kim, S.-J. Mechanical energy harvesting properties of free-standing carbyne enriched carbon film derived from dehydrohalogenation of polyvinylidene fluoride. Nano Energy 2019, 59, 453–463. [Google Scholar] [CrossRef]

- Badatya, S.; Bharti, D.K.; Sathish, N.; Srivastava, A.K.; Gupta, M.K. Humidity Sustainable Hydrophobic Poly(vinylidene fluoride)-Carbon Nanotubes Foam Based Piezoelectric Nanogenerator. ACS Appl Mater Interfaces 2021, 13, 27245–27254. [Google Scholar] [CrossRef]

- Yan, M.; Liu, S.; Xu, Q.; Xiao, Z.; Yuan, X.; Zhou, K.; Zhang, D.; Wang, Q.; Bowen, C.; Zhong, J.; et al. Enhanced energy harvesting performance in lead-free multi-layer piezoelectric composites with a highly aligned pore structure. Nano Energy 2023, 106, 108096. [Google Scholar] [CrossRef]

- Wang, B.; Hong, J.; Yang, Y.; Zhao, H.; Long, L.; Zheng, L. Achievement of a giant piezoelectric coefficient and piezoelectric voltage coefficient through plastic molecular-based ferroelectric materials. Matter 2022, 5, 1296–1304. [Google Scholar] [CrossRef]

- Elahi, H.; Israr, A.; Swati, R.; Khan, H. Stability of piezoelectric material for suspension applications. In Proceedings of the 2017 Fifth International Conference on Aerospace Science & Engineering (ICASE), Islamabad, Pakistan, 14–16 November 2017. [Google Scholar]

- Ma, T.; Gao, Q.; Li, Y.; Wang, Z.; Lu, X.; Cheng, T. An Integrated Triboelectric–Electromagnetic–Piezoelectric Hybrid Energy Harvester Induced by a Multifunction Magnet for Rotational Motion. Adv. Eng. Mater. 2019, 22, 1900872. [Google Scholar] [CrossRef]

- Chen, N.; Wei, T.; Ha, D.S.; Jung, H.J.; Lee, S. Alternating Resistive Impedance Matching for an Impact-Type Microwind Piezoelectric Energy Harvester. IEEE Trans. Ind. Electron. 2018, 65, 7374–7382. [Google Scholar] [CrossRef]

- Lafarge, B.; Delebarre, C.; Grondel, S.; Curea, O.; Hacala, A. Analysis and Optimization of a Piezoelectric Harvester on a Car Damper. Phys. Procedia 2015, 70, 970–973. [Google Scholar] [CrossRef]

- Xie, X.; Wang, Q. A mathematical model for piezoelectric ring energy harvesting technology from vehicle tires. Int. J. Eng. Sci. 2015, 94, 113–127. [Google Scholar] [CrossRef]

- Xie, X.D.; Wang, Q. Energy harvesting from a vehicle suspension system. Energy 2015, 86, 385–392. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, T.; Shi, J.; Zhang, B.; Zhang, R.; Li, M.; Wen, Y. Analysis and application of the piezoelectric energy harvester on light electric logistics vehicle suspension systems. Energy Sci. Eng. 2019, 7, 2741–2755. [Google Scholar] [CrossRef] [Green Version]

- Han, C.B.; Jiang, T.; Zhang, C.; Li, X.; Zhang, C.; Cao, X.; Wang, Z.L. Removal of Particulate Matter Emissions from a Vehicle Using a Self-Powered Triboelectric Filter. ACS Nano 2015, 9, 12552–12561. [Google Scholar] [CrossRef]

- Ma, N.; Li, D.; He, W.; Deng, Y.; Li, J.; Gao, Y.; Bao, H.; Zhang, H.; Xu, X.; Liu, Y.; et al. Future vehicles: Interactive wheeled robots. Sci. China Inf. Sci. 2021, 64, 156101:1–156101:3. [Google Scholar] [CrossRef]

- Li, D.; Li, J.; Ma, N.; Gao, Y. Interactive cognition in self-driving. Sci. Sin. Inf. 2018, 48, 1083–1096. [Google Scholar] [CrossRef] [Green Version]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Xu, C.; Ma, N.; Zhou, Q.; Ji, Z.; Jia, C.; Xiao, S.; Wang, P. Intelligent Device for Harvesting the Vibration Energy of the Automobile Exhaust with a Piezoelectric Generator. Micromachines 2023, 14, 491. https://doi.org/10.3390/mi14020491

Huang J, Xu C, Ma N, Zhou Q, Ji Z, Jia C, Xiao S, Wang P. Intelligent Device for Harvesting the Vibration Energy of the Automobile Exhaust with a Piezoelectric Generator. Micromachines. 2023; 14(2):491. https://doi.org/10.3390/mi14020491

Chicago/Turabian StyleHuang, Jie, Cheng Xu, Nan Ma, Qinghui Zhou, Zhaohua Ji, Chunxia Jia, Shan Xiao, and Peng Wang. 2023. "Intelligent Device for Harvesting the Vibration Energy of the Automobile Exhaust with a Piezoelectric Generator" Micromachines 14, no. 2: 491. https://doi.org/10.3390/mi14020491

APA StyleHuang, J., Xu, C., Ma, N., Zhou, Q., Ji, Z., Jia, C., Xiao, S., & Wang, P. (2023). Intelligent Device for Harvesting the Vibration Energy of the Automobile Exhaust with a Piezoelectric Generator. Micromachines, 14(2), 491. https://doi.org/10.3390/mi14020491