Micro-Shaping of Pure Aluminum in Long-Duration Wire Electrochemical Micromachining Using Bipolar Nanosecond Pulses

Abstract

1. Introduction

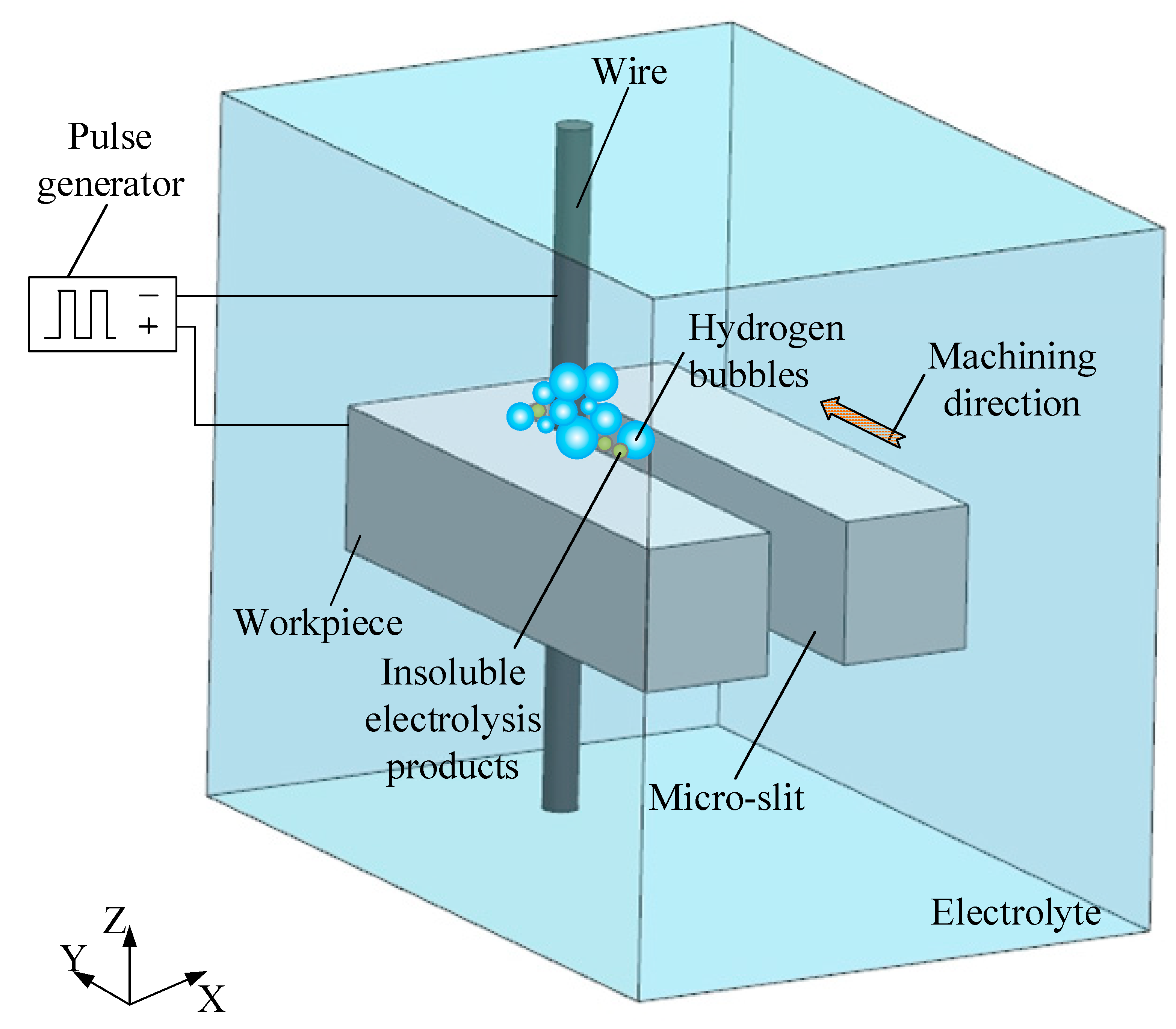

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Experimental

4. Results

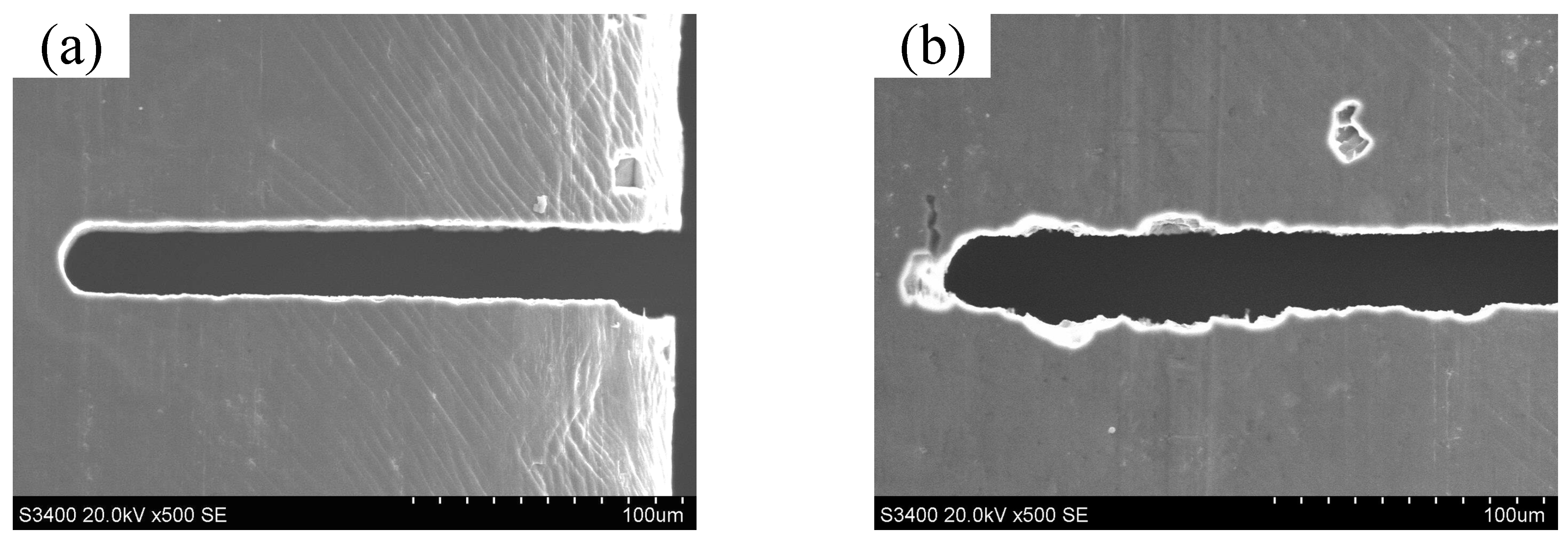

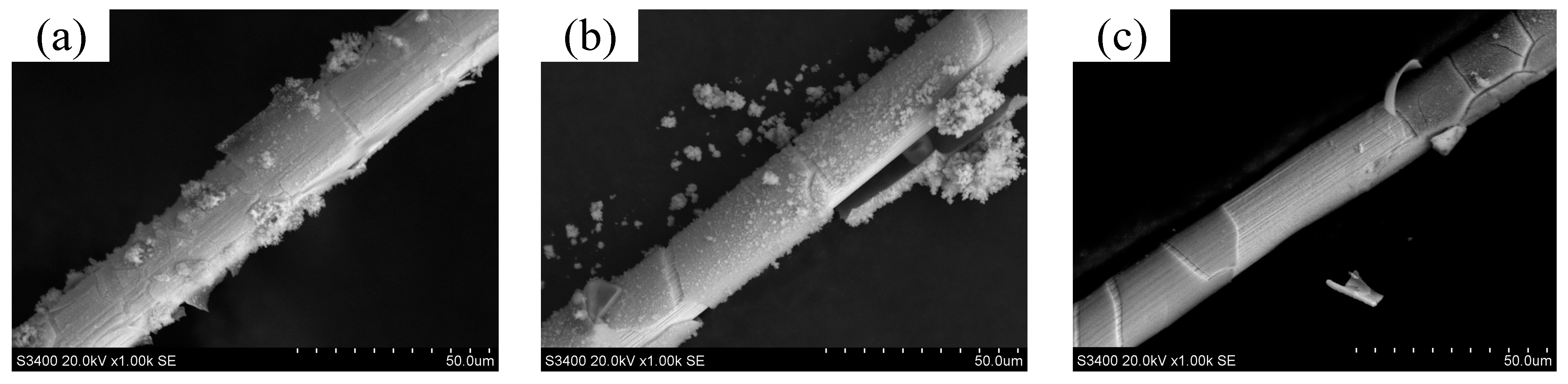

4.1. Comparison between Short- and Long-Duration WECMM

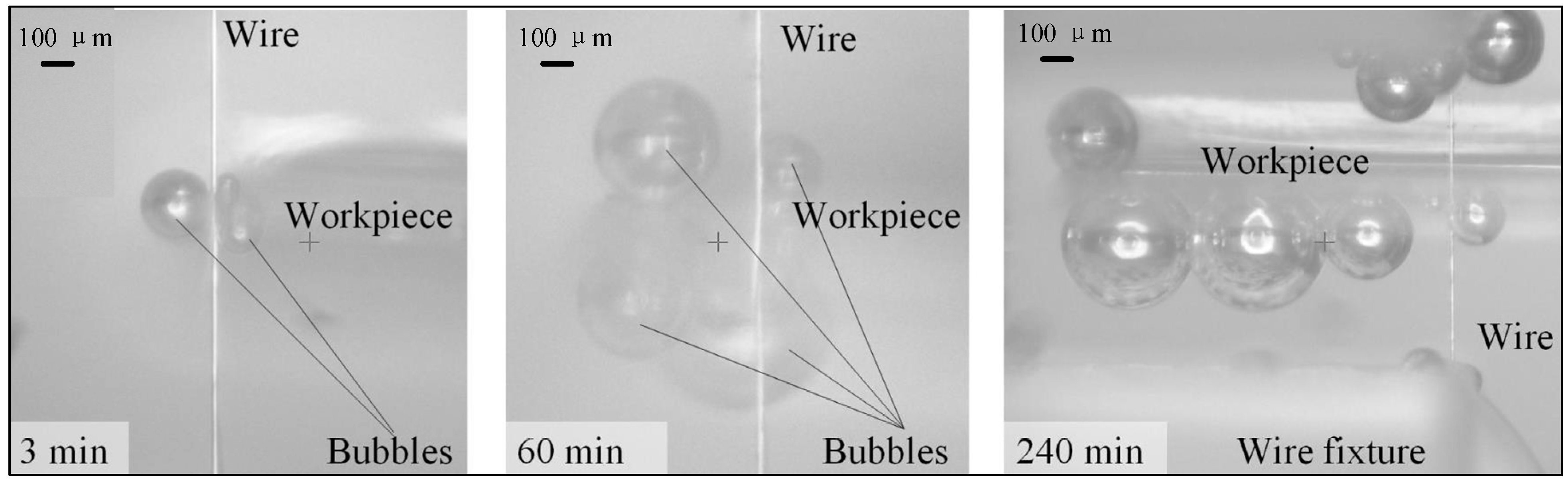

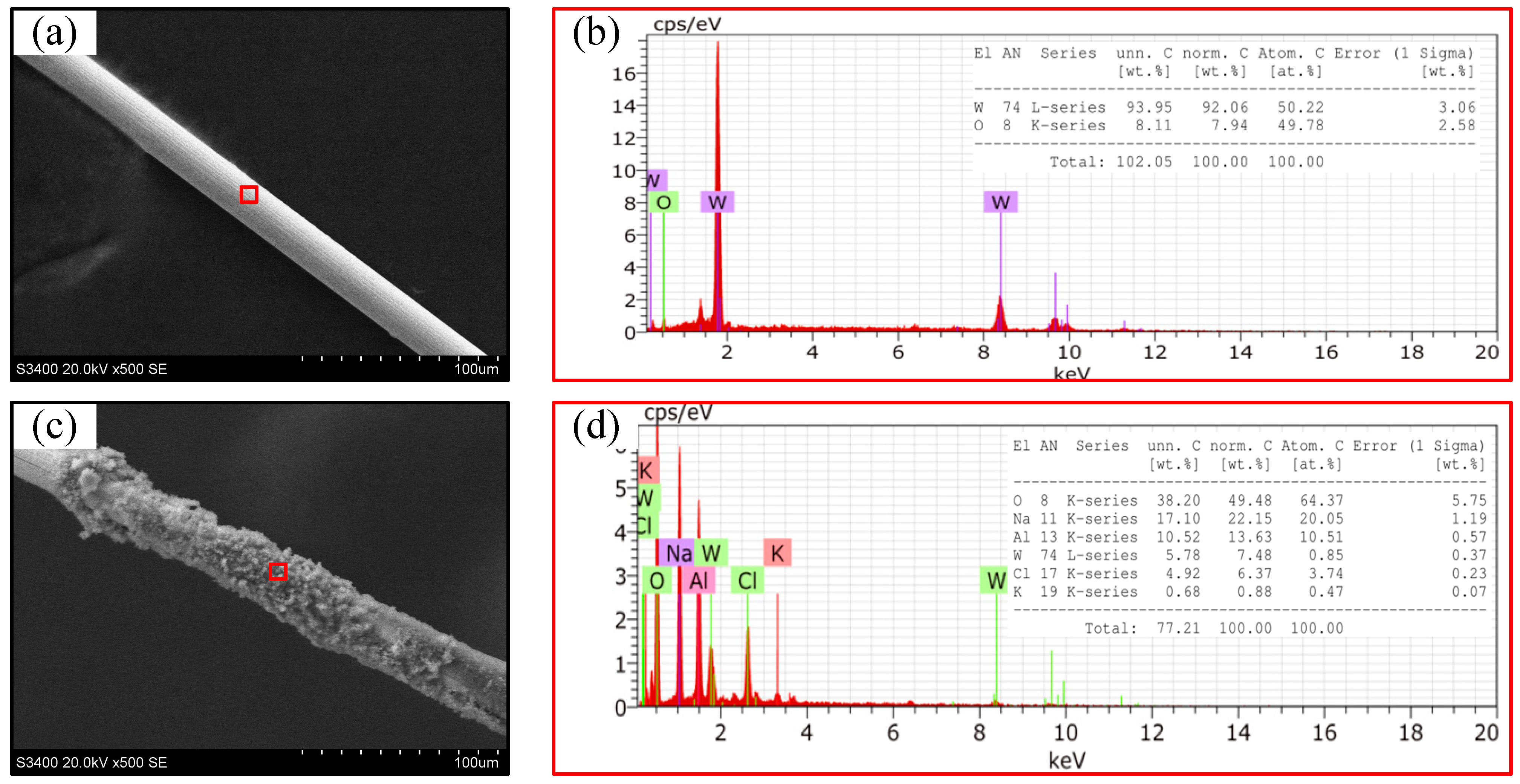

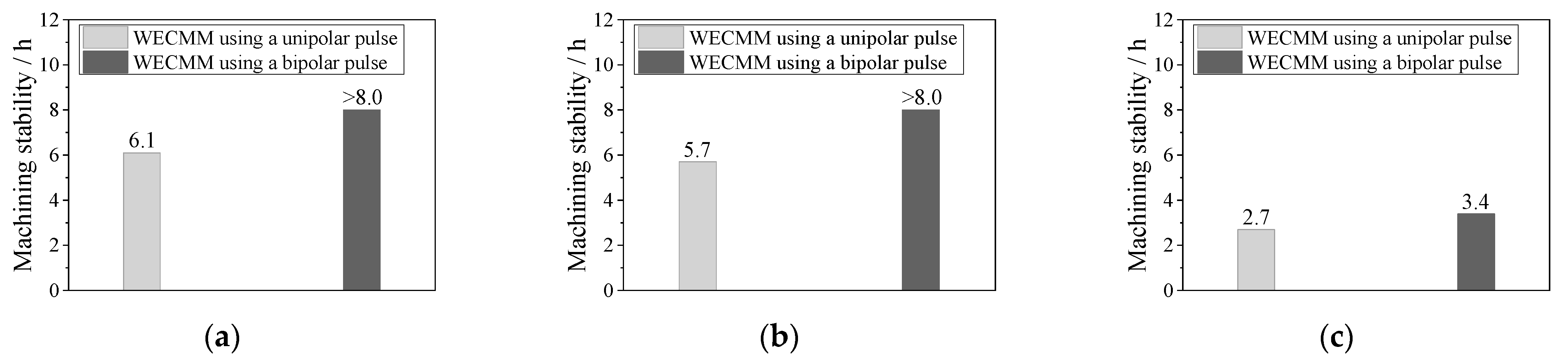

4.2. Improving Machining Stability in Long-Duration WECMM Using Bipolar Nanosecond Pulses

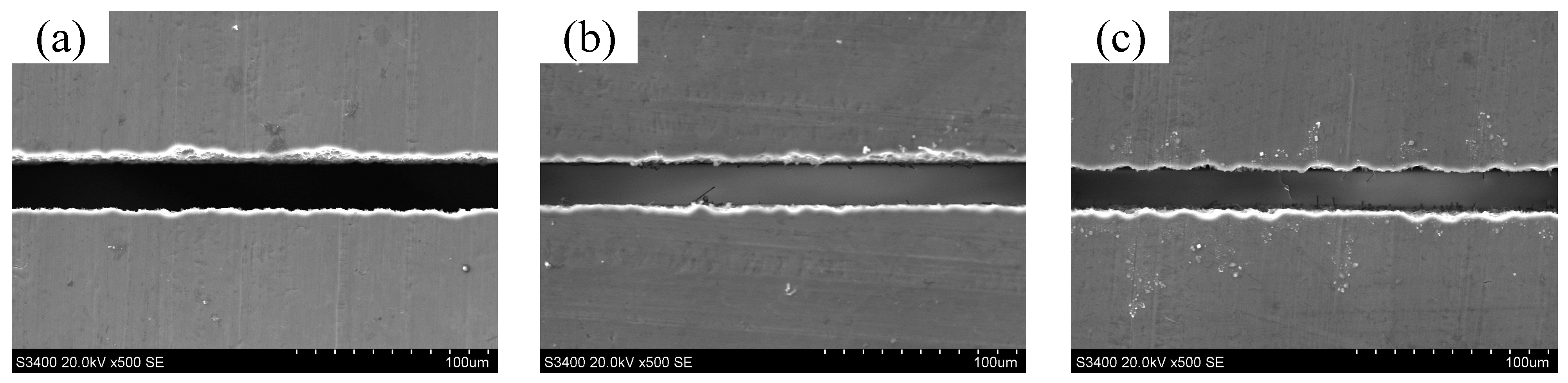

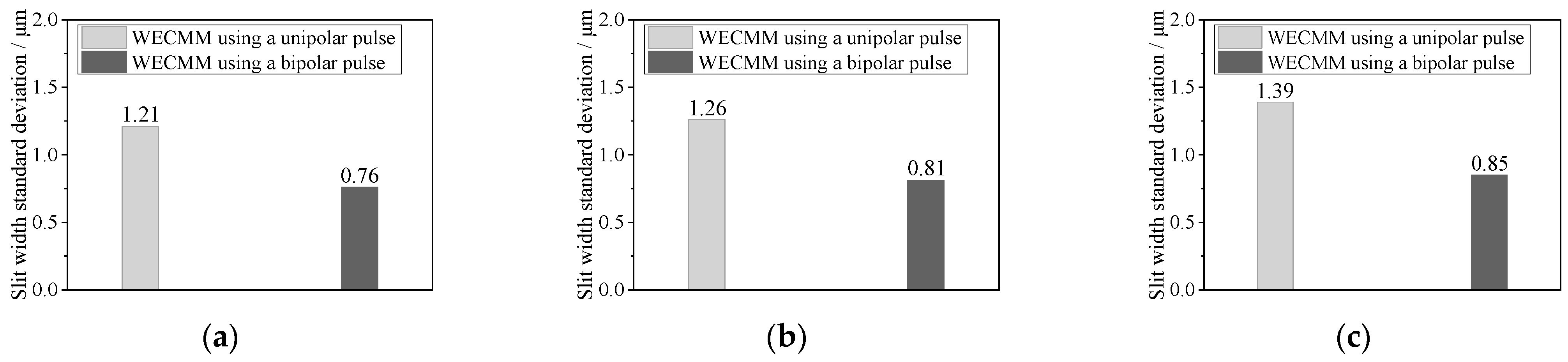

4.3. Improving Machining Accuracy in Long-Duration WECMM Using Bipolar Nanosecond Pulses

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jiang, L.M.; Du, Y.J.; Jia, J.; Lai, L.J.; Zhou, H.; Zhu, L.M.; Tian, Z.W.; Tian, Z.Q.; Zhan, D. Three dimensional micromachining on aluminum surface by electrochemical wet stamping technique. Electrochem. Commun. 2013, 33, 119–122. [Google Scholar] [CrossRef]

- Bi, X.; Zeng, Y.; Qu, N. Micro-Shaping of Pure Aluminum by Intermittent Ultrasonic Oscillation Assisted Wire Electrochemical Micromachining with an Ultra-Low-Concentration Mixed Electrolyte. J. Electrochem. Soc. 2021, 168, 113503. [Google Scholar] [CrossRef]

- Malekian, M.; Mostofa, M.G.; Park, S.S.; Jun, M.B.G. Modeling of minimum uncut chip thickness in micro machining of aluminum. J. Mater. Process. Technol. 2012, 212, 553–559. [Google Scholar] [CrossRef]

- Robinson, G.M.; Jackson, M.J. Femtosecond laser micromachining of aluminum surfaces under controlled gas atmospheres. J. Mater. Eng. Perform. 2006, 15, 155–160. [Google Scholar] [CrossRef]

- Mouralova, K.; Kovar, J.; Klakurkova, L.; Bednar, J.; Benes, L.; Zahradnicek, R. Analysis of surface morphology and topography of pure aluminium machined using WEDM. Meas. J. Int. Meas. Confed. 2018, 114, 169–176. [Google Scholar] [CrossRef]

- Xu, W.; Song, J.; Sun, J.; Dou, Q.; Fan, X. Fabrication of superhydrophobic surfaces on aluminum substrates using NaNO3 electrolytes. J. Mater. Sci. 2011, 46, 5925–5930. [Google Scholar] [CrossRef]

- Sun, J.; Cheng, W.; Song, J.L.; Lu, Y.; Sun, Y.K.; Huang, L.; Liu, X.; Jin, Z.J.; Carmalt, C.J.; Parkin, I.P. Fabrication of superhydrophobic micro post array on aluminum substrates using mask electrochemical machining. Chin. J. Mech. Eng. 2018, 31, 72. [Google Scholar] [CrossRef]

- Yusen, H.; Tao, Y.; Zhengyang, X.; Yongbin, Z. Electrochemical micromachining of ZrCu-based amorphous alloy in ethylene glycol solution. Intermetallics 2021, 132, 107155. [Google Scholar] [CrossRef]

- Gao, C.; Qu, N. A Distinct Perception on Wire Electrochemical Micromachining of Pure Tungsten with Neutral Aqueous Solution. J. Electrochem. Soc. 2019, 166, E465–E472. [Google Scholar] [CrossRef]

- Gao, C.; Qu, N.; Ding, B.; Shen, Y. An insight into cathodic reactions during wire electrochemical micromachining in aque-ous hydrochloric acid solution. Electrochim. Acta 2019, 295, 67–74. [Google Scholar] [CrossRef]

- Bi, X.; Zeng, Y.; Qu, N. Wire electrochemical micromachining of high-quality pure-nickel microstructures focusing on different machining indicators. Precis. Eng. 2020, 61, 14–22. [Google Scholar] [CrossRef]

- Qu, N.; Gao, C. Fabrication of microstructures with mirror surfaces by wire electrochemical micromachining of stainless steel 304 using NaNO3-ethylene glycol. Int. J. Adv. Manuf. Technol. 2021, 112, 261–272. [Google Scholar] [CrossRef]

- Qu, N.; Gao, C. Improving surface processing quality in wire electrochemical micromachining by gas bubble chain. J. Mater. Process. Technol. 2021, 294, 117136. [Google Scholar] [CrossRef]

- Yusen, H.; Yongbin, Z.; Tao, Y.; Zhengyang, X.; Kun, X.; Huimin, W. The microstructure formation of thick Zr-based amorphous alloy with anode vibration in HClO4 solution by WECMM. Int. J. Adv. Manuf. Technol. 2021, 117, 1459–1472. [Google Scholar] [CrossRef]

- Meng, L.; Zeng, Y.; Zhu, D. Wire electrochemical micromachining of Ni-based metallic glass using bipolar nanosecond pulses. Int. J. Mach. Tools Manuf. 2019, 146, 103439. [Google Scholar] [CrossRef]

- Gao, C.; Qu, N.; He, H.; Meng, L. Double-pulsed wire electrochemical micro-machining of type-304 stainless steel. J. Mater. Process. Technol. 2019, 266, 381–387. [Google Scholar] [CrossRef]

- Xu, K.; Zeng, Y.; Li, P.; Zhu, D. Study of surface roughness in wire electrochemical micro machining. J. Mater. Process. Technol. 2015, 222, 103–109. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Wire electrode diameter | 20 μm |

| Workpiece thickness | 90 μm |

| Applied positive voltage | 5 V |

| Applied negative voltage | 0 to −1.5 V |

| Wire vibration amplitude | 150 μm |

| Wire vibration frequency | 2 Hz |

| Feed rate | 0.10, 0.15, and 0.25 μm/s |

| Pulse width and period | 50 ns and 5 μs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, X.; Jia, M.; Meng, L. Micro-Shaping of Pure Aluminum in Long-Duration Wire Electrochemical Micromachining Using Bipolar Nanosecond Pulses. Micromachines 2023, 14, 1046. https://doi.org/10.3390/mi14051046

Bi X, Jia M, Meng L. Micro-Shaping of Pure Aluminum in Long-Duration Wire Electrochemical Micromachining Using Bipolar Nanosecond Pulses. Micromachines. 2023; 14(5):1046. https://doi.org/10.3390/mi14051046

Chicago/Turabian StyleBi, Xiaolei, Meng Jia, and Lingchao Meng. 2023. "Micro-Shaping of Pure Aluminum in Long-Duration Wire Electrochemical Micromachining Using Bipolar Nanosecond Pulses" Micromachines 14, no. 5: 1046. https://doi.org/10.3390/mi14051046

APA StyleBi, X., Jia, M., & Meng, L. (2023). Micro-Shaping of Pure Aluminum in Long-Duration Wire Electrochemical Micromachining Using Bipolar Nanosecond Pulses. Micromachines, 14(5), 1046. https://doi.org/10.3390/mi14051046