Simulation Optimization of AlGaN/GaN SBD with Field Plate Structures and Recessed Anode

Abstract

:1. Introduction

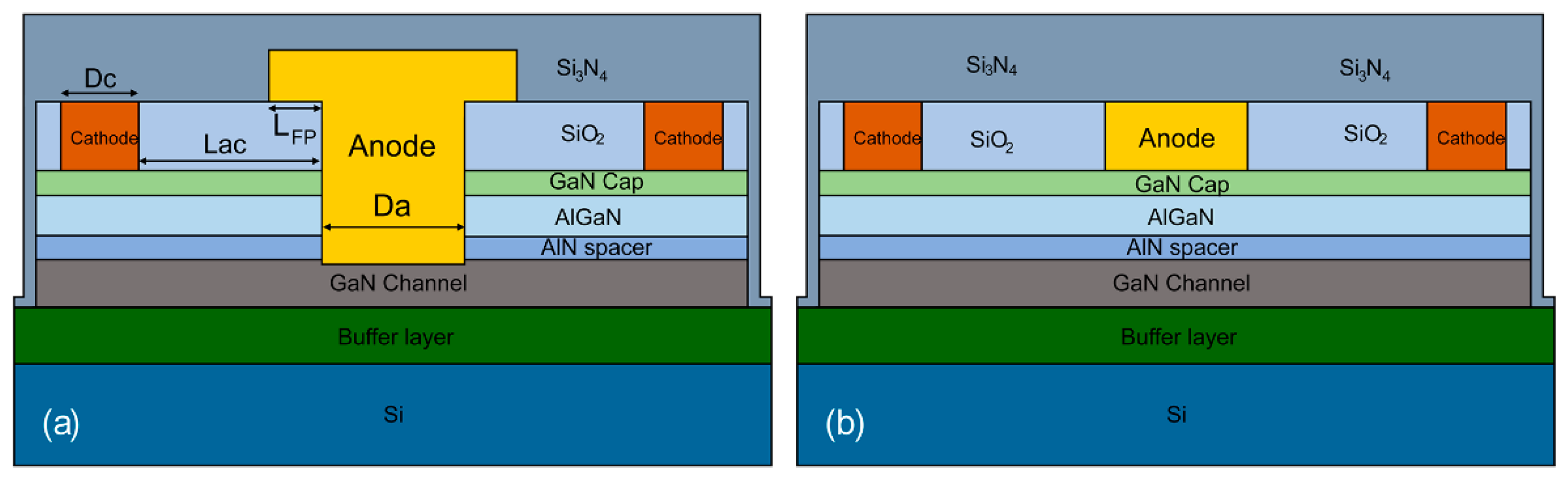

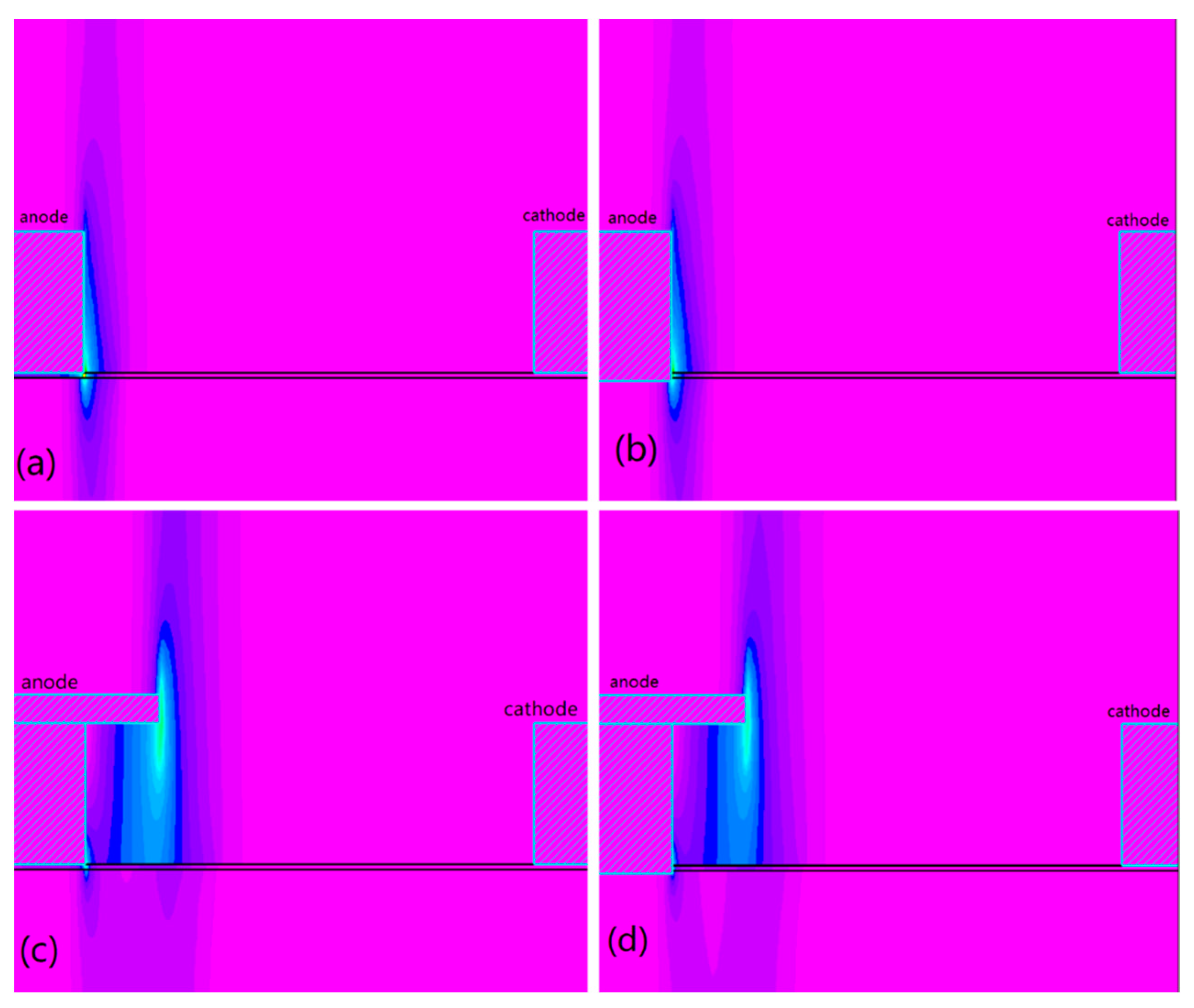

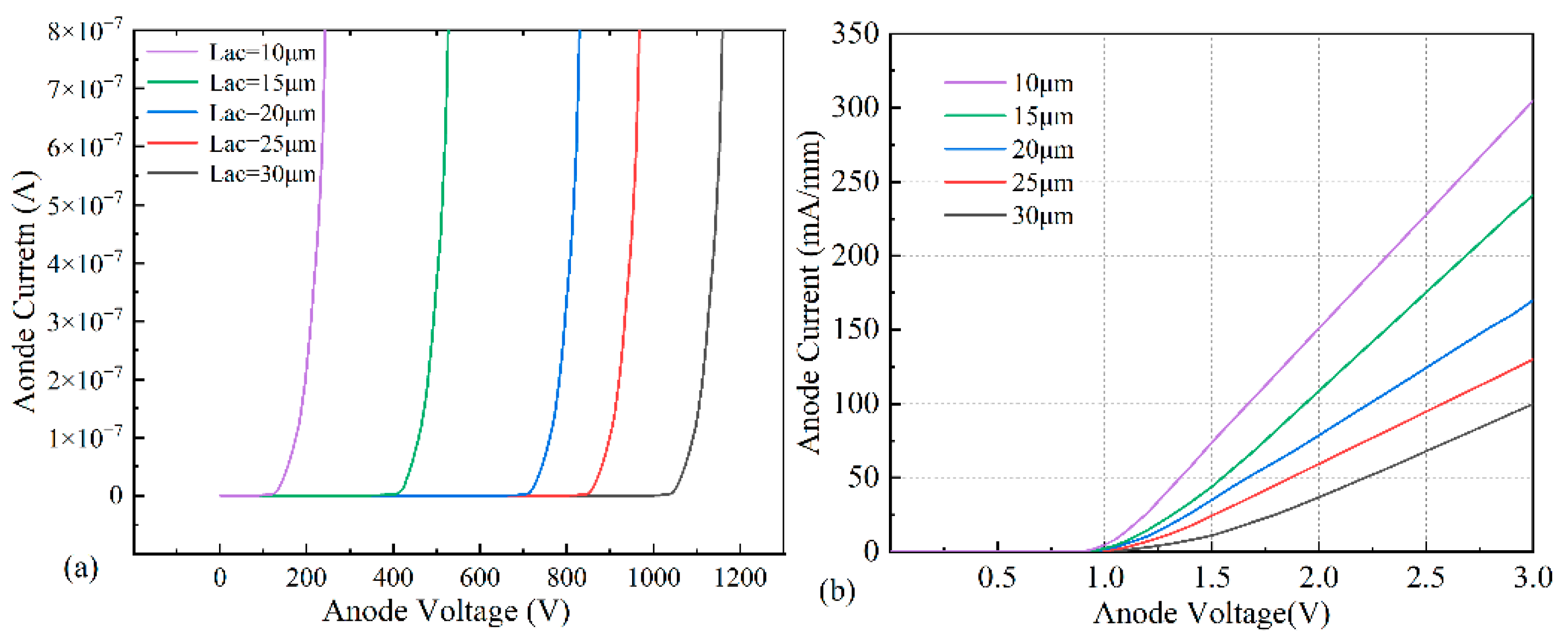

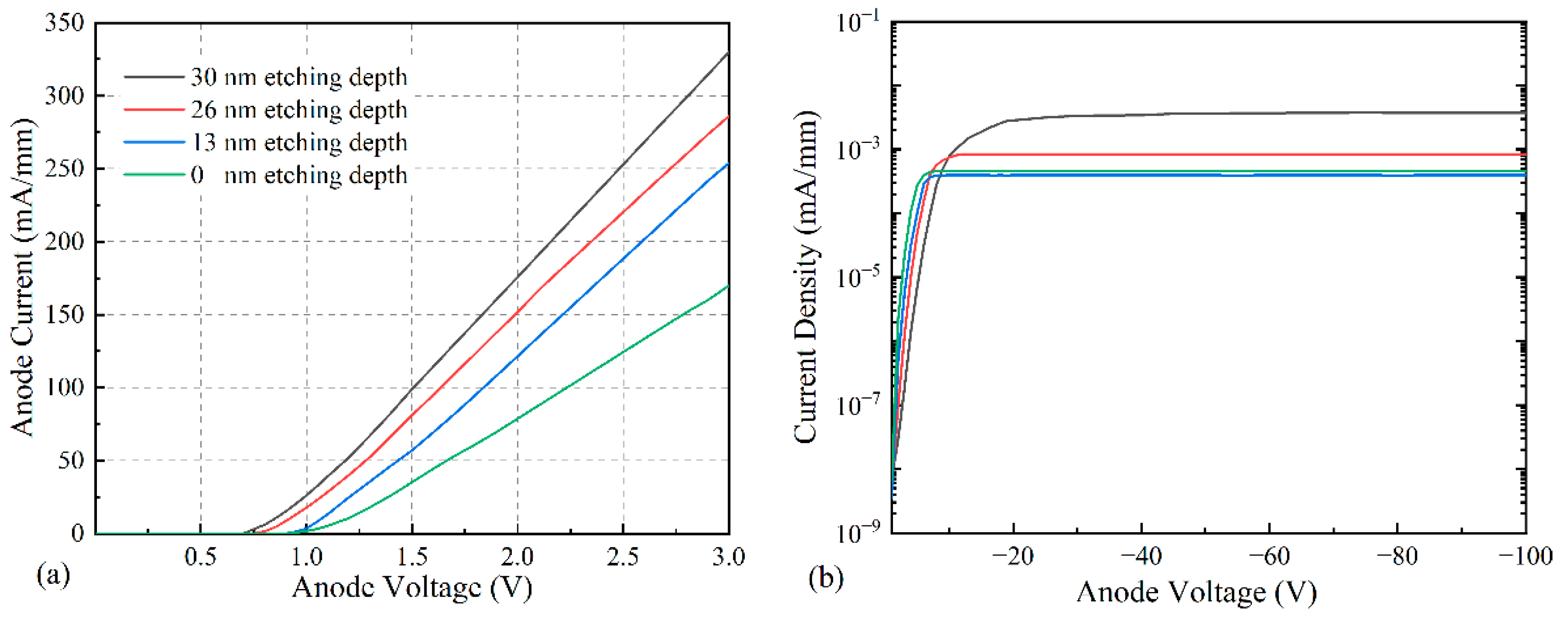

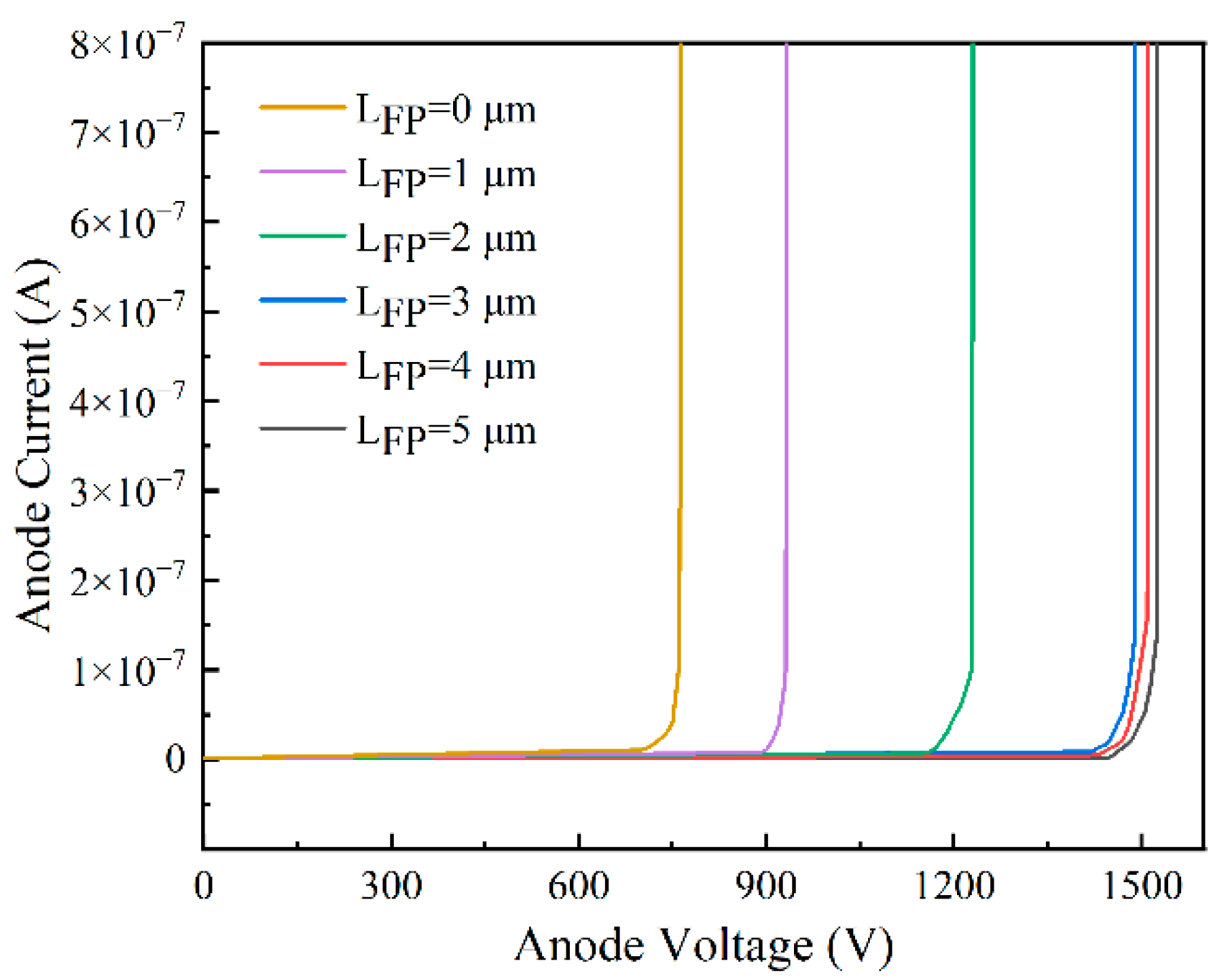

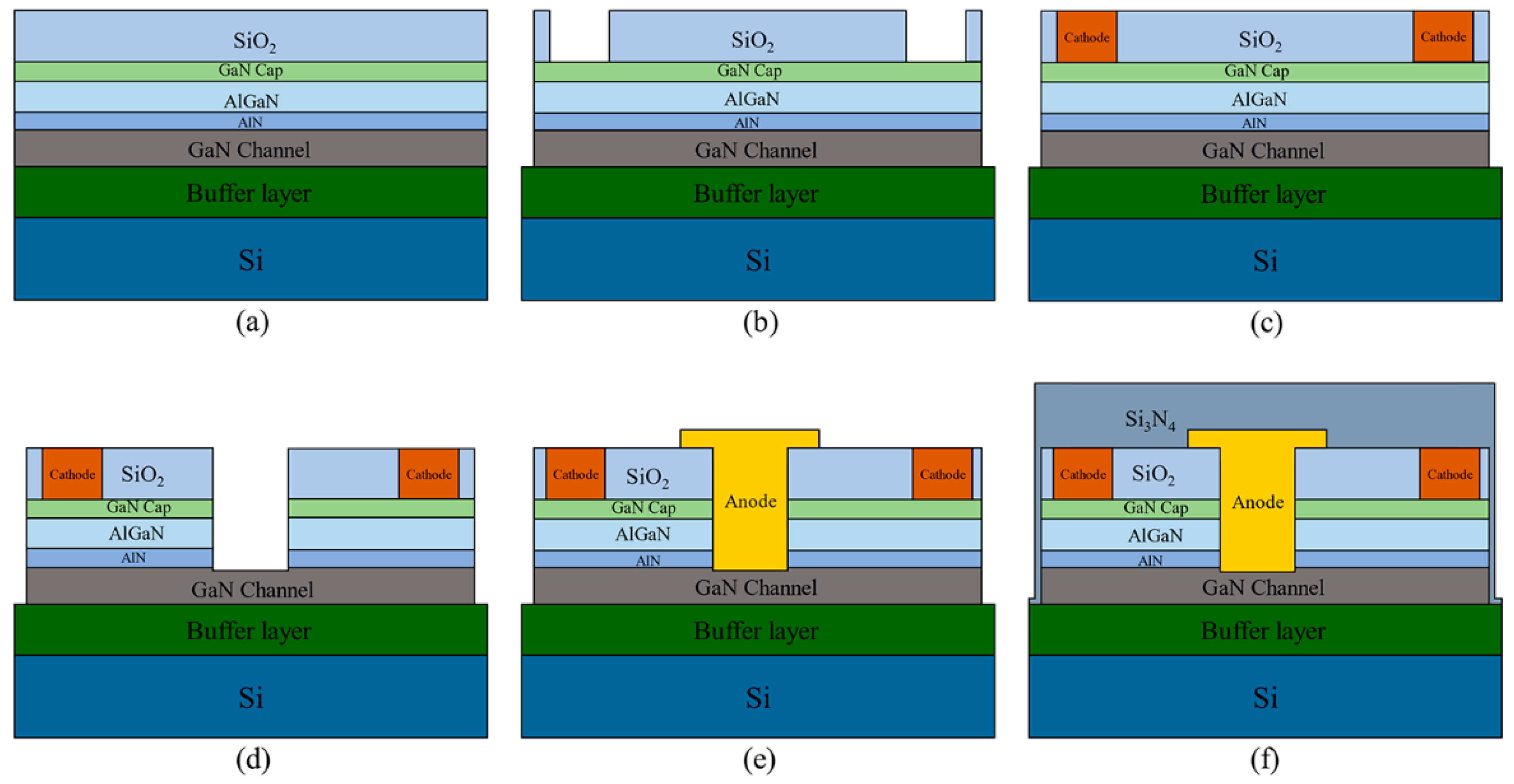

2. Device Design and Simulation Model

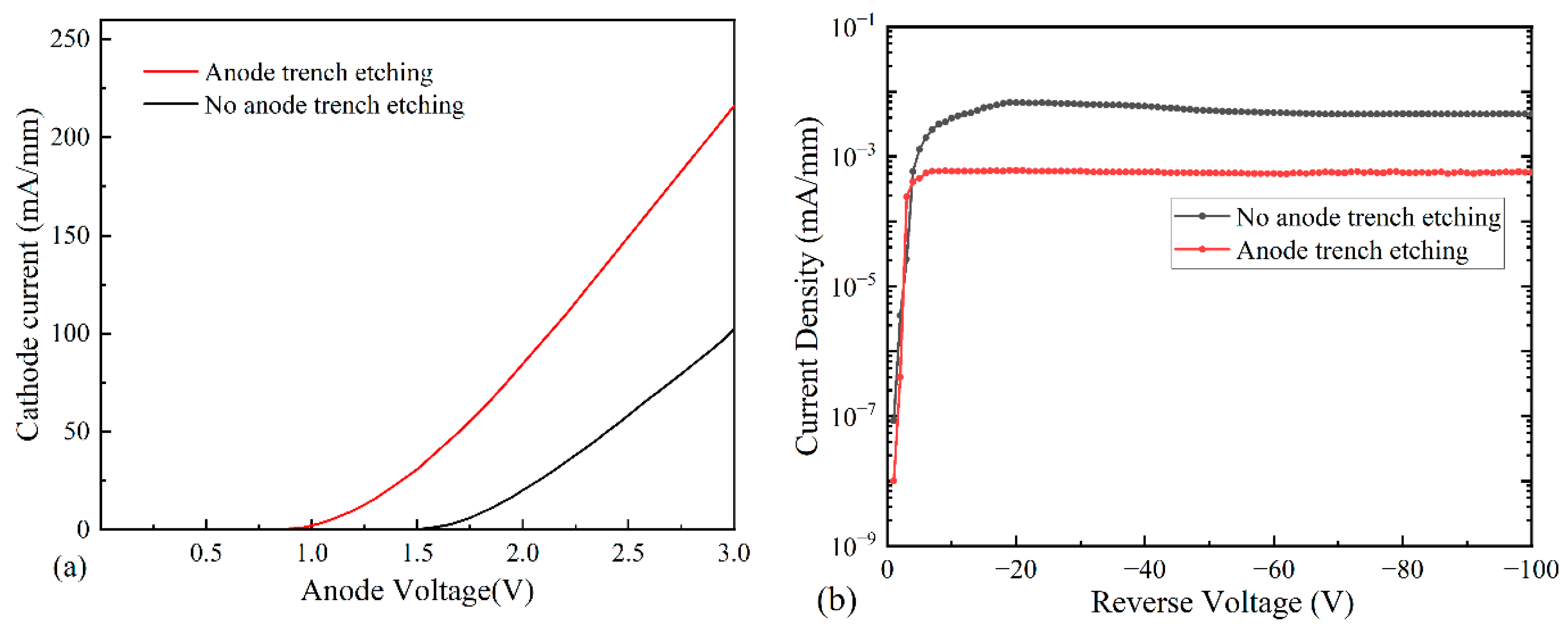

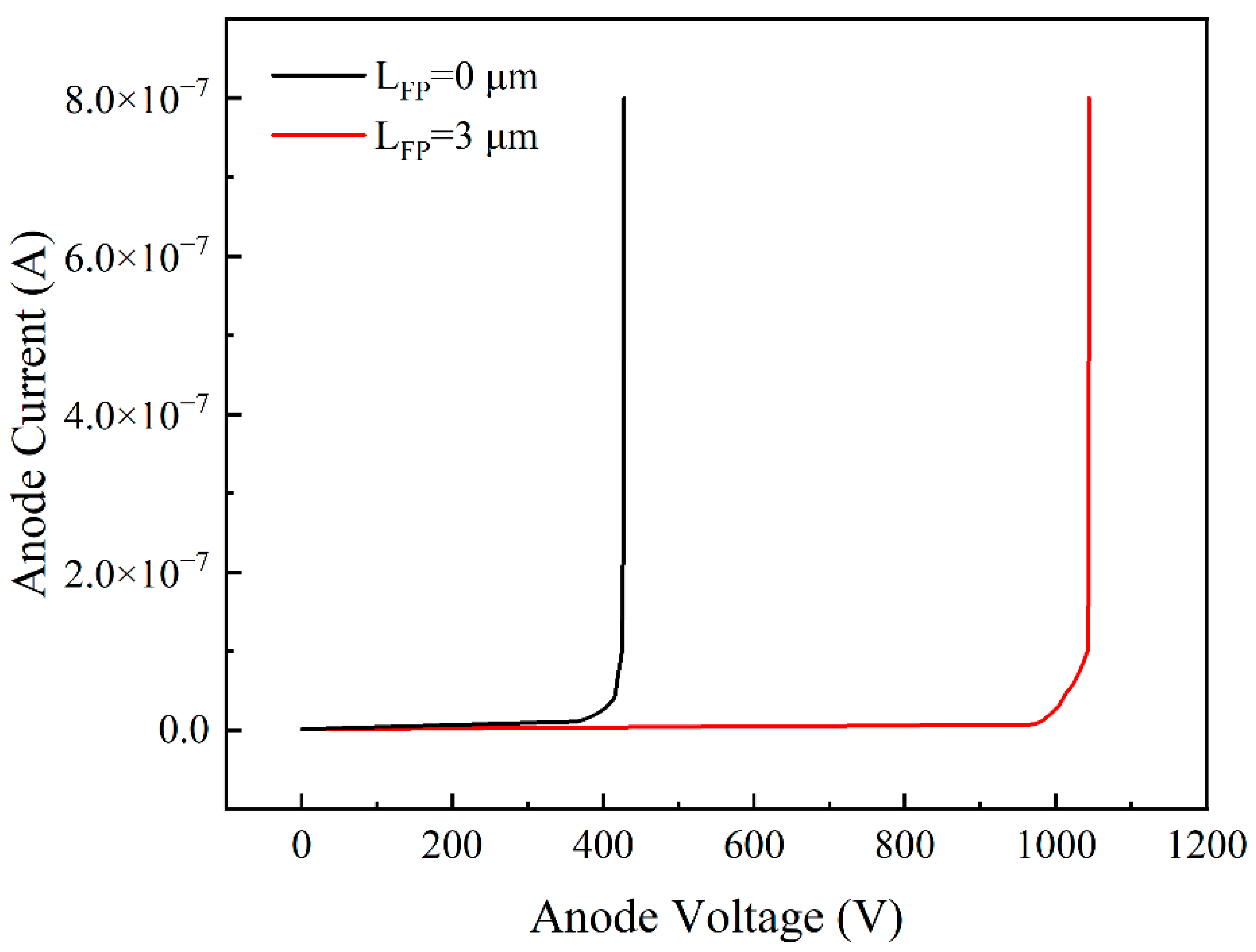

3. Experiments and Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ishida, M.; Ueda, T.; Tanaka, T.; Ueda, D. GaN on Si Technologies for Power Switching Devices. IEEE Trans. Electron Devices 2013, 60, 3053–3059. [Google Scholar] [CrossRef]

- Gui, H.; Zhang, Z.; Chen, R.; Ren, R.; Choi, B.B. Development of High Power High Switching Frequency Cryogenically-Cooled Inverter for Aircraft Applications. IEEE Trans. Power Electron. 2019, 35, 5670–5682. [Google Scholar] [CrossRef]

- Gao, J.; Jin, Y.; Xie, B.; Wen, C.P.; Hao, Y.; Shen, B.; Wang, M. Low ON-Resistance GaN Schottky Barrier Diode With High V-ON Uniformity Using LPCVD Si3N4 Compatible Self-Terminated, Low Damage Anode Recess Technology. IEEE Electron Device Lett. 2018, 39, 859–862. [Google Scholar] [CrossRef]

- Baliga, B.J. Gallium nitride devices for power electronic applications. Semicond. Sci. Technol. 2013, 28, 074011. [Google Scholar] [CrossRef]

- Omura, I.; Tsukuda, M.; Saito, W.; Domon, T. In High Power Density Converter Using SiC-SBD. In Proceedings of the Power Conversion Conference-Nagoya, Nagoya, Japan, 2–5 April 2007. [Google Scholar]

- Zhang, A.P.; Ren, F.; Anderson, T.J.; Abernathy, C.R.; Singh, R.K.; Holloway, P.H.; Pearton, S.J.; Palmer, D.; McGuire, G.E. High-Power GaN Electronic Devices. Crit. Rev. Solid State 2010, 27, 1–71. [Google Scholar] [CrossRef]

- Lian, Y.-W.; Lin, Y.-S.; Yang, J.-M.; Cheng, C.-H.; Hsu, S.S.H. AlGaN/GaN Schottky Barrier Diodes on Silicon Substrates with Selective Si Diffusion for Low Onset Voltage and High Reverse Blocking. IEEE Electron Device Lett. 2013, 34, 981–983. [Google Scholar] [CrossRef]

- Shan, Q.; Meyaard, D.S.; Dai, Q.; Cho, J.; Fred Schubert, E.; Kon Son, J.; Sone, C. Transport-mechanism analysis of the reverse leakage current in GaInN light-emitting diodes. Appl. Phys. Lett. 2011, 99, 253506. [Google Scholar] [CrossRef]

- Bahat-Treidel, E.; Hilt, O.; Zhytnytska, R.; Wentzel, A.; Meliani, C.; Wurfl, J.; Trankle, G. Fast-Switching GaN-Based Lateral Power Schottky Barrier Diodes with Low Onset Voltage and Strong Reverse Blocking. IEEE Electron Device Lett. 2012, 33, 357–359. [Google Scholar] [CrossRef]

- Xu, R.; Chen, P.; Liu, M.; Zhou, J.; Li, Y.; Cheng, K.; Liu, B.; Chen, D.; Xie, Z.; Zhang, R.; et al. 3.4-kV AlGaN/GaN Schottky Barrier Diode on Silicon Substrate with Engineered Anode Structure. IEEE Electron Device Lett. 2021, 42, 208–211. [Google Scholar] [CrossRef]

- Tsou, C.W.; Wei, K.P.; Lian, Y.W.; Hsu, S. 2.07-kV AlGaN/GaN Schottky Barrier Diodes on Silicon with High Baliga’s Figure-of-Merit. IEEE Electron Device Lett. 2015, 37, 70–73. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Tang, J.; Wang, W.; Huang, Y.; Kuang, X. A Breakdown Enhanced AlGaN/GaN Schottky Barrier Diode with the T-Anode Position Deep into the Bottom Buffer Layer. Micromachines 2019, 10, 91. [Google Scholar] [CrossRef] [PubMed]

- Bu, Q.; Cai, Y.; Cui, M.; Wen, H.; Liu, W. Experimental Comparison of AlGaN/GaN-on-Si Schottky Barrier Diode with and without Recessed Anode. In Proceedings of the 2019 International Conference on IC Design and Technology (ICICDT), Suzhou, China, 17–19 June 2019; pp. 1–4. [Google Scholar]

- Zhang, Y.; Zhang, J.; Zhou, H.; Zhang, T.; Wang, H.; Feng, Z.; Hao, Y. Leakage current mechanisms of groove-type tungsten-anode GaN SBDs with ultra low turn-ON voltage and low reverse current. Solid State Electron. 2020, 169, 107807. [Google Scholar] [CrossRef]

- Karmalkar, S.; Mishra, U.K. Enhancement of breakdown voltage in AlGaN/GaN high electron mobility transistors using a field plate. IEEE Trans. Electron Devices 2001, 48, 1515–1521. [Google Scholar] [CrossRef]

- Kang, H.; Wang, Q.; Xiao, H.-L.; Wang, C.-M.; Jiang, L.-J.; Feng, C.; Chen, H.; Yin, H.-B.; Wang, X.-L.; Wang, Z.-G.; et al. High-Voltage AlGaN/GaN-Based Lateral Schottky Barrier Diodes. Chin. Phys. Lett. 2014, 31, 068502. [Google Scholar] [CrossRef]

- Wang, T.T.; Wang, X.; He, Y.; Jia, M.; Ao, J.P. Recessed AlGaN/GaN Schottky Barrier Diodes with TiN and NiN Dual Anodes. IEEE Trans. Electron. Device. 2021, 68, 2867–2871. [Google Scholar] [CrossRef]

- Tang, C.; Xie, G.; Zhang, L.; Guo, Q.; Wang, T.; Sheng, K. Electric field modulation technique for high-voltage AlGaN/GaN Schottky barrier diodes. Chin. Phys. B 2013, 22, 106107. [Google Scholar] [CrossRef]

- Xu, R.; Chen, P.; Liu, M.; Zhou, J.; Yang, Y.; Li, Y.; Ge, C.; Peng, H.; Liu, B.; Chen, D.; et al. 1.4-kV Quasi-Vertical GaN Schottky Barrier Diode with Reverse p-n Junction Termination. IEEE J. Electron Device 2020, 8, 316–320. [Google Scholar] [CrossRef]

- Karmalkar, S.; Mishra, U.K. Very high voltage AlGaN/GaN high electron mobility transistors using a field plate deposited on a stepped insulator. Solid State Electron 2001, 45, 1645–1652. [Google Scholar] [CrossRef]

- Karmalkar, S.; Soudabi, N. A closed-form model of the drain-voltage dependence of the off-state channel electric field in a HEMT with a field plate. IEEE Trans. Electron Device 2006, 53, 2430–2437. [Google Scholar] [CrossRef]

- Zhu, M.; Song, B.; Qi, M.; Hu, Z.; Nomoto, K.; Yan, X.; Cao, Y.; Johnson, W.; Kohn, E.; Jena, D.; et al. 1.9-kV AlGaN/GaN Lateral Schottky Barrier Diodes on Silicon. IEEE Electron Device Lett. 2015, 36, 375–377. [Google Scholar] [CrossRef]

| Parameters | GaN | AlGaN |

|---|---|---|

| Eg300 (eV) | 3.4 | 3.96 |

| Align | 0.8 | 0.8 |

| Permittivity | 9.5 | 9.5 |

| Electron Saturation Velocity (Vsat) | 2 × 107 cm/s | 1.1 × 107 cm/s |

| Electronic Low Field Mobility (Mun) | 900 cm2/Vs | 600 cm2/Vs |

| Hole Low Field Mobility (Mup) | 10 cm2/Vs | 10 cm2/Vs |

| 300K conduction band state density (Nc 300) | 2.07 × 1018 cm3 | 2.07 × 1018 cm3 |

| 300K valance band state density (Nv 300) | 1.16 × 1018 cm3 | 1.16 × 1018 cm3 |

| No Recesed Anode | 30 nm Recessed Anode | ||||

|---|---|---|---|---|---|

| FP = 0 μm | FP = 3 μm | FP = 0 μm | FP = 3 μm | ||

| Von (V) | 1.5 | 1.5 | 0.75 | 0.75 | |

| Ron (Ω·mm) | 14.7 | 14.6 | 8.4 | 8.3 | |

| Ron.sp (mΩ·cm2) | 3.38 | 3.35 | 1.93 | 1.9 | |

| VBV (V) | 427 | 1043 | 427 | 1043 | |

| FOM (MW/cm2) | 53.9 | 324.7 | 94.5 | 572.6 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, T.; Tang, Z.; Zhou, Z.; Zhou, B. Simulation Optimization of AlGaN/GaN SBD with Field Plate Structures and Recessed Anode. Micromachines 2023, 14, 1121. https://doi.org/10.3390/mi14061121

Xu T, Tang Z, Zhou Z, Zhou B. Simulation Optimization of AlGaN/GaN SBD with Field Plate Structures and Recessed Anode. Micromachines. 2023; 14(6):1121. https://doi.org/10.3390/mi14061121

Chicago/Turabian StyleXu, Tao, Ziqi Tang, Ziyou Zhou, and Bing Zhou. 2023. "Simulation Optimization of AlGaN/GaN SBD with Field Plate Structures and Recessed Anode" Micromachines 14, no. 6: 1121. https://doi.org/10.3390/mi14061121