Multi-Layered Bipolar Ionic Diode Working in Broad Range Ion Concentration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication Process for Multi-Layered Bipolar Ionic Diode

2.2. Measuring Ion Current of Multi-Layered Bipolar Ionic Diode

2.3. Numerical Modeling for Simulation

2.4. Ion Current Measurement for Hysteresis

3. Results and Discussion

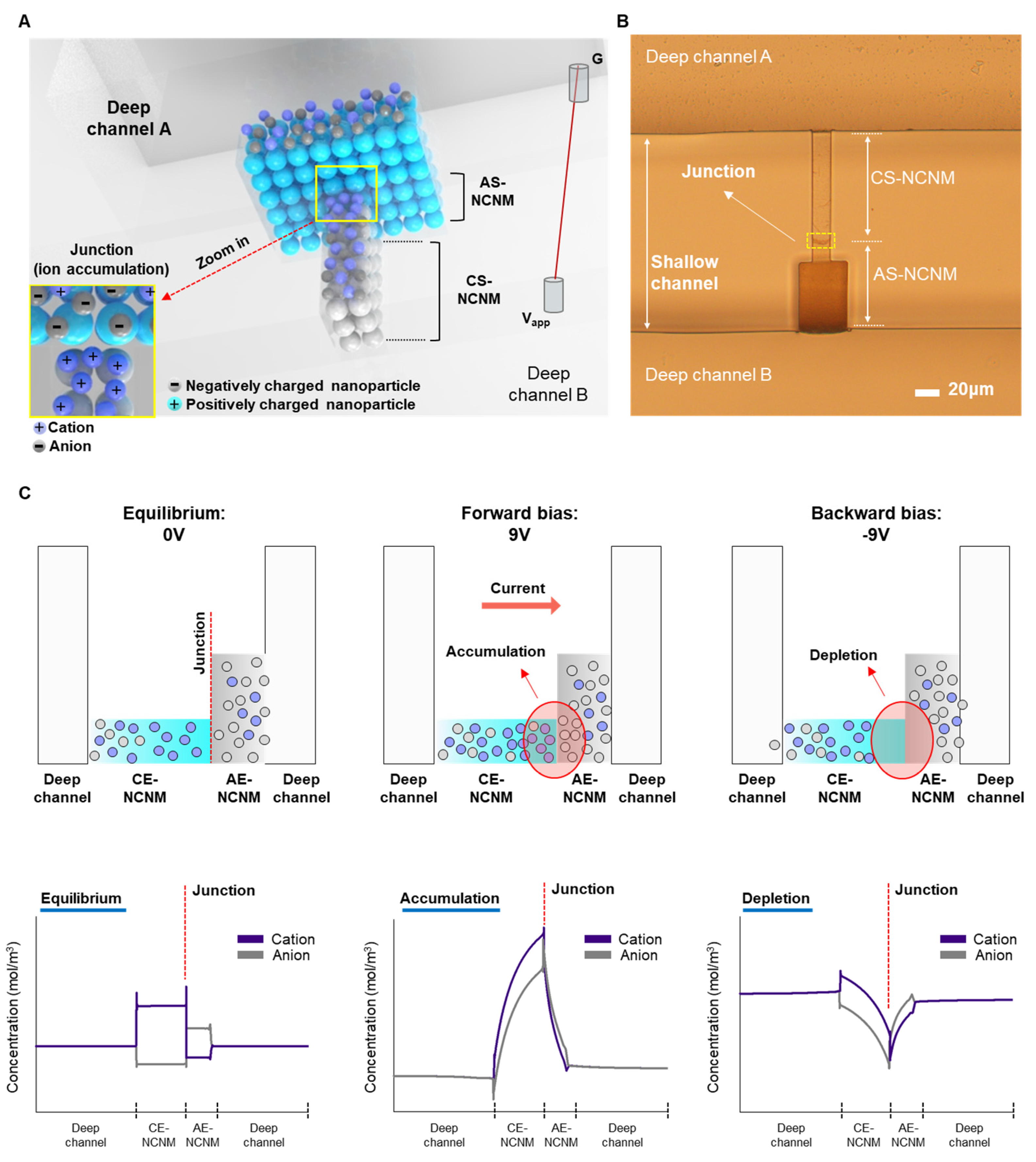

3.1. Working Principle of Multi-Layered Bipolar Ionic Diode Based on NCNM

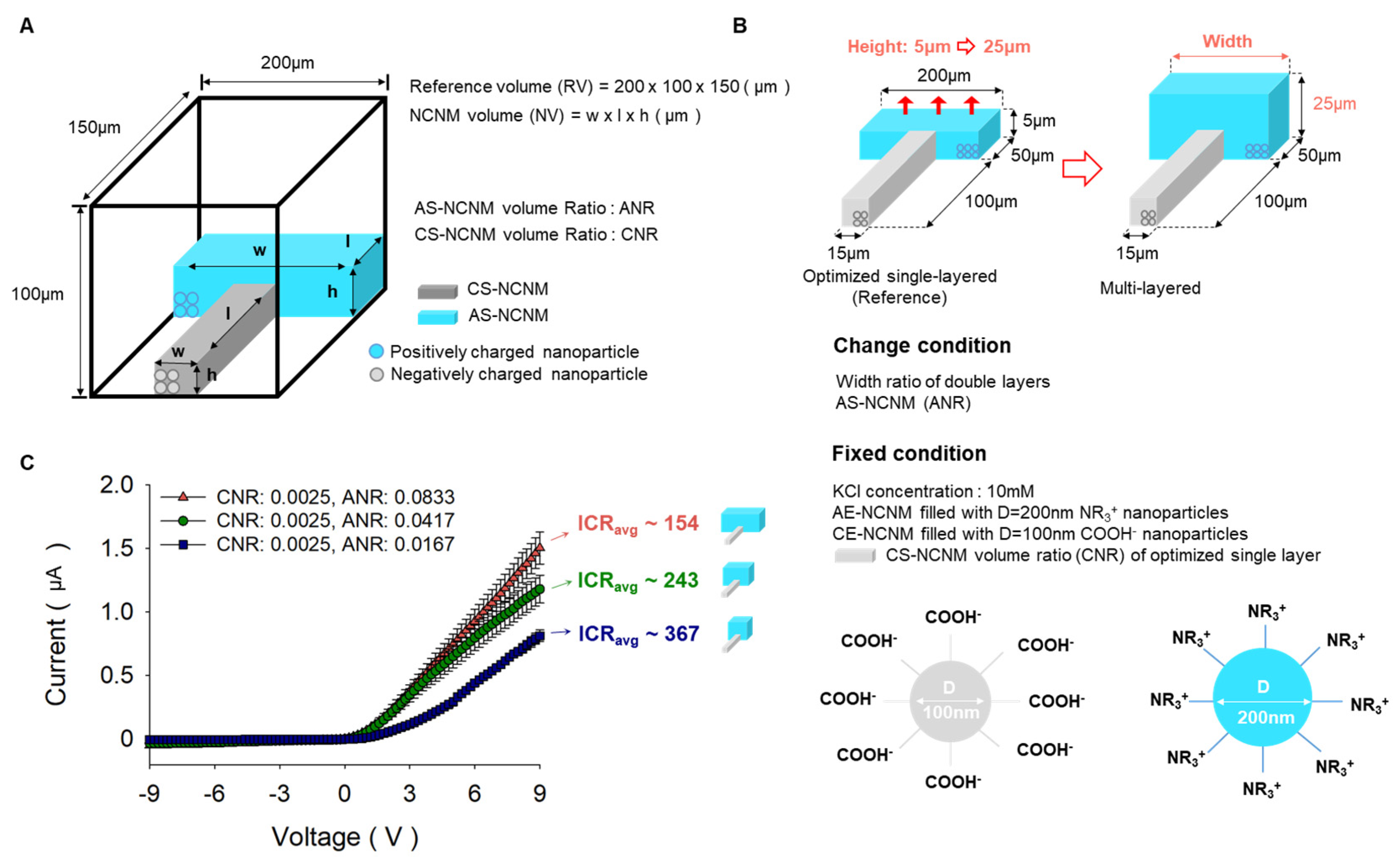

3.2. Characterization of Ionic Rectification According to the Change of Geometry

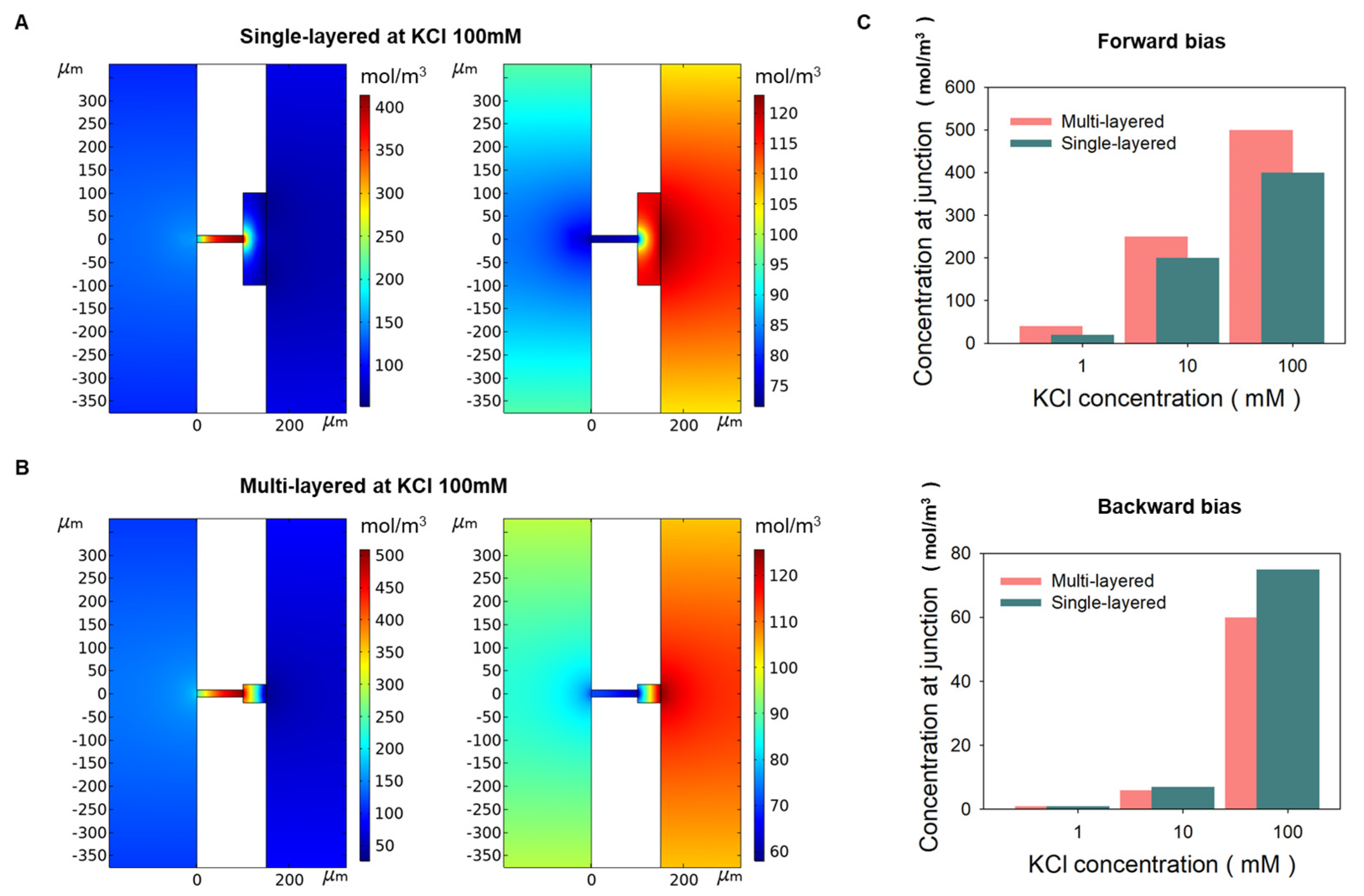

3.3. KCl Concentration Optimization of the Multi-Layered Bipolar Ionic Diode

3.4. Hysteresis Loop of Multi-Layered Bipolar Ionic Diode

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Choi, E.; Kwon, K.; Kim, D.; Park, J. Tunable reverse electrodialysis microplatform with geometrically controlled self-assembled nanoparticle network. Lab Chip 2015, 15, 168–178. [Google Scholar] [CrossRef]

- Han, S.H.; Kwon, S.R.; Baek, S.; Chung, T.D. Ionic Circuits Powered by Reverse Electrodialysis for an Ultimate Iontronic System. Sci. Rep. 2017, 7, 14068. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, L.; Guo, W.; Ma, W.; Wang, L.; Xia, F.; Wang, S.; Wang, Y.; Jiang, L.; Zhu, D. Towards understanding the nanofluidic reverse electrodialysis system: Well matched charge selectivity and ionic composition. Energy Environ. Sci. 2011, 4, 2259–2266. [Google Scholar] [CrossRef]

- Xiao, K.; Jiang, L.; Antonietti, M. Ion Transport in Nanofluidic Devices for Energy Harvesting. Joule 2019, 3, 2364–2380. [Google Scholar] [CrossRef]

- Guo, W.; Cao, L.; Xia, J.; Nie, F.-Q.; Ma, W.; Xue, J.; Song, Y.; Zhu, D.; Wang, Y.; Jiang, L. Energy Harvesting with Single-Ion-Selective Nanopores: A Concentration-Gradient-Driven Nanofluidic Power Source. Adv. Funct. Mater. 2010, 20, 1339–1344. [Google Scholar] [CrossRef]

- Wang, C.; Choi, E.; Park, J. High-voltage nanofluidic energy generator based on ion-concentration-gradients mimicking electric eels. Nano Energy 2018, 43, 291–299. [Google Scholar] [CrossRef]

- Laucirica, G.; Albesa, A.G.; Toimil-Molares, M.E.; Trautmann, C.; Marmisollé, W.A.; Azzaroni, O. Shape matters: Enhanced osmotic energy harvesting in bullet-shaped nanochannels. Nano Energy 2020, 71, 104612. [Google Scholar] [CrossRef]

- Hsu, J.-P.; Su, T.-C.; Lin, C.-Y.; Tseng, S. Power generation from a pH-regulated nanochannel through reverse electrodialysis: Effects of nanochannel shape and non-uniform H+ distribution. Electrochim. Acta 2019, 294, 84–92. [Google Scholar] [CrossRef]

- Dartoomi, H.; Khatibi, M.; Ashrafizadeh, S.N. Importance of nanochannels shape on blue energy generation in soft nanochannels. Electrochim. Acta 2022, 431, 141175. [Google Scholar] [CrossRef]

- Dartoomi, H.; Khatibi, M.; Ashrafizadeh, S.N. Nanofluidic Membranes to Address the Challenges of Salinity Gradient Energy Harvesting: Roles of Nanochannel Geometry and Bipolar Soft Layer. Langmuir 2022, 38, 10313–10330. [Google Scholar] [CrossRef]

- Xie, B.; Xiong, T.; Li, W.; Gao, T.; Zong, J.; Liu, Y.; Yu, P. Perspective on Nanofluidic Memristors: From Mechanism to Application. Chem. Asian J. 2022, 17, e202200682. [Google Scholar] [CrossRef] [PubMed]

- Xiong, T.; Li, C.; He, X.; Xie, O.; Zong, S.; Jiang, Y.; Ma, W.; Wu, F.; Fei, J.; Yu, P.; et al. Neuromorphic functions with a polyelectrolyte-confined fluidic memristor. Science 2023, 379, 156–161. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Ramiah Rajasekaran, P.; Martin, C.R. An Alternating Current Electroosmotic Pump Based on Conical Nanopore Membranes. ACS Nano 2016, 10, 4637–4643. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.; Bard, A.J.; Feldberg, S.W. Current Rectification at Quartz Nanopipet Electrodes. Anal. Chem. 1997, 69, 4627–4633. [Google Scholar] [CrossRef]

- Nguyen, G.; Vlassiouk, I.; Siwy, Z.S. Comparison of bipolar and unipolar ionic diodes. Nanotechnology 2010, 21, 265301. [Google Scholar] [CrossRef]

- Zhang, T.; Bai, H.; Zhao, Y.; Ren, B.; Wen, T.; Chen, L.; Song, S.; Komarneni, S. Precise Cation Recognition in Two-Dimensional Nanofluidic Channels of Clay Membranes Imparted from Intrinsic Selectivity of Clays. ACS Nano 2022, 16, 4930–4939. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Wang, Y.; Yang, D.; Li, C. Ion current rectification in asymmetric charged bilayer nanochannels. Electrochim. Acta 2022, 403, 139706. [Google Scholar] [CrossRef]

- Liu, W.; Ren, Y.; Tao, Y.; Yao, B.; Liu, N.; Wu, Q. A universal design of field-effect-tunable microfluidic ion diode based on a gating cation-exchange nanoporous membrane. Phys. Fluids 2017, 29, 112001. [Google Scholar] [CrossRef]

- Zhang, Z.; Kong, X.-Y.; Xiao, K.; Liu, Q.; Xie, G.; Li, P.; Ma, J.; Tian, Y.; Wen, L.; Jiang, L. Engineered Asymmetric Heterogeneous Membrane: A Concentration-Gradient-Driven Energy Harvesting Device. J. Am. Chem. Soc. 2015, 137, 14765–14772. [Google Scholar] [CrossRef]

- Li, Z.-Q.; Wang, Y.; Wu, Z.-Q.; Wu, M.-Y.; Xia, X.-H. Bioinspired Multivalent Ion Responsive Nanopore with Ultrahigh Ion Current Rectification. J. Phys. Chem. C 2019, 123, 13687–13692. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, H.; Hou, J.; Ou, R.; Zhu, Y.; Li, X.; Jiang, L.; Wang, H. Effect of Anion Species on Ion Current Rectification Properties of Positively Charged Nanochannels. ACS Appl. Mater. Interfaces 2020, 12, 28915–28922. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Liu, Y.; Lu, B.; Wang, Y.; Xu, Y.; Zhai, J.; Fan, X. A high rectification ratio nanofluidic diode induced by an “ion pool”. RSC Adv. 2020, 10, 7377–7383. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, F.F.; Guo, Y.C.; Wang, W.; Chen, Y.M.; Wang, C. In situ synthesis of a MOFs/PAA hybrid with ultrahigh ionic current rectification. Nanoscale 2020, 12, 11899–11907. [Google Scholar] [CrossRef]

- Ali, M.; Ramirez, P.; Nasir, S.; Nguyen, Q.-H.; Ensinger, W.; Mafe, S. Current rectification by nanoparticle blocking in single cylindrical nanopores. Nanoscale 2014, 6, 10740–10745. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.; Gaigalas, P.; Lepoitevin, M.; Plikusiene, I.; Bechelany, M.; Janot, J.-M.; Balanzat, E.; Balme, S. Impact of Polyelectrolyte Multilayers on the Ionic Current Rectification of Conical Nanopores. Langmuir 2018, 34, 3405–3412. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Yan, J.; Li, J. Small-molecule triggered cascade enzymatic catalysis in hour-glass shaped nanochannel reactor for glucose monitoring. Anal. Chem. 2014, 86, 10546–10551. [Google Scholar] [CrossRef]

- Hou, S.; Wang, Q.; Fan, X.; Liu, Z.; Zhai, J. Alumina Membrane with Hour-Glass Shaped Nanochannels: Tunable Ionic Current Rectification Device Modulated by Ions Gradient. J. Nanomater. 2014, 2014, 564694. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Wang, Z.; Su, Z.; Cai, S. Stretchable and transparent ionic diode and logic gates. Extrem. Mech. Lett. 2019, 28, 81–86. [Google Scholar] [CrossRef]

- Xiao, K.; Xie, G.; Zhang, Z.; Kong, X.-Y.; Liu, Q.; Li, P.; Wen, L.; Jiang, L. Enhanced Stability and Controllability of an Ionic Diode Based on Funnel-Shaped Nanochannels with an Extended Critical Region. Adv. Mater. 2016, 28, 3345–3350. [Google Scholar] [CrossRef]

- Nguyen, Q.H.; Ali, M.; Nasir, S.; Ensinger, W. Transport properties of track-etched membranes having variable effective pore-lengths. Nanotechnology 2015, 26, 485502. [Google Scholar] [CrossRef]

- Karimzadeh, M.; Khatibi, M.; Ashrafizadeh, S.N.; Mondal, P.K. Blue energy generation by the temperature-dependent properties in funnel-shaped soft nanochannels. Phys. Chem. Chem. Phys. 2022, 24, 20303–20317. [Google Scholar] [CrossRef] [PubMed]

- Karimzadeh, M.; Seifollahi, Z.; Khatibi, M.; Ashrafizadeh, S.N. Impacts of the shape of soft nanochannels on their ion selectivity and current rectification. Electrochim. Acta 2021, 399, 139376. [Google Scholar] [CrossRef]

- Smirnov, I.V.S.; Siwy, Z. Ionic Selectivity of Single nanochannels. Nano Lett. 2008, 8, 1978–1985. [Google Scholar]

- Choi, E.; Wang, C.; Chang, G.T.; Park, J. High Current Ionic Diode Using Homogeneously Charged Asymmetric Nanochannel Network Membrane. Nano Lett. 2016, 16, 2189–2197. [Google Scholar] [CrossRef]

- Robin, P.; Emmerich, T.; Ismail, A.; Niguès, A.; You, Y.; Nam, G.-H.; Keerthi, A.; Siria, A.; Geim, A.K.; Radha, B.; et al. Long-term memory and synapse-like dynamics in two-dimensional nanofluidic channels. Science 2023, 379, 161–167. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Jeon, J.; Wang, C.; Chang, G.T.; Park, J. Asymmetric Nanochannel Network-Based Bipolar Ionic Diode for Enhanced Heavy Metal Ion Detection. ACS Nano 2022, 16, 8253–8263. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.; Kim, H.-Y.; Kang, J.Y.; Kim, T.S. How the capillary burst microvalve works. J. Colloid Interface Sci. 2007, 306, 379–385. [Google Scholar] [CrossRef] [PubMed]

- Chung, S.; Yun, H.; Kamm, R.D. Nanointerstice-driven microflow. Small 2009, 5, 609–613. [Google Scholar] [CrossRef]

- Wang, D.; Kvetny, M.; Liu, J.; Brown, W.; Li, Y.; Wang, G. Transmembrane potential across single conical nanopores and resulting memristive and memcapacitive ion transport. J. Am. Chem. Soc. 2012, 134, 3651–3654. [Google Scholar] [CrossRef]

- Chen, J.-B.; Guo, T.-T.; Yang, C.-Y.; Xu, J.-W.; Gao, L.-Y.; Jia, S.-J.; Zhang, P.; Chen, J.-T.; Zhao, Y.; Wang, J.; et al. Synaptic Plasticity of a Microfluidic Memristor with a Temporary Memory Function Based on an Ionic Liquid in a Capillary Tube. J. Phys. Chem. C 2023, 127, 3307–3315. [Google Scholar] [CrossRef]

| Author, [Ref] Year | Material, Device Fabrication Method | Voltage Bias | ICR in 0.1 mM and 1 mM | 10 mM | 100 mM |

|---|---|---|---|---|---|

| Zhang et al. [19] 2015 | Poly(ethylene terephthalate) (PET)/track etching technique | From −2 to 2 V | 0.1 mM~100 1 mM~430 | ~1000 | ~200 |

| Li et al. [20] 2019 | Polycarbonate (PC)/track etching technique | From −1 to 1 V | 0.1 mM~5 1 mM~7 | ~100 | ~650 |

| Zhao et al. [21] 2020 | Poly(ethylene terephthalate) (PET)/track etching technique | From −2 to 2 V | 1 mM~10 | ~200 | ~250 |

| Liu et al. [22] 2020 | Anodic aluminum oxide (AAO)/anodization | From −2 to 2 V | 0.1 mM~20 1 mM~80 | ~500 | ~100 |

| Liu et al. [23] 2020 | Polyacrylic acid (PAA)/anodization | From −1 to 1 V | 0.1 mM~300 1 mM~430 | ~160 | ~30 |

| Kim et al. [36] 2022 | Polydimethylsiloxane (PDMS)/soft lithography | From −9 to 9 V | 0.1 mM~50 1 mM~200 | ~370 | ~4 |

| This study | Polydimethylsiloxane (PDMS)/soft lithography | From −9 to 9 V | 0.1 mM~85 1 mM~320 | ~370 | ~100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Wang, C.; Park, J. Multi-Layered Bipolar Ionic Diode Working in Broad Range Ion Concentration. Micromachines 2023, 14, 1311. https://doi.org/10.3390/mi14071311

Kim J, Wang C, Park J. Multi-Layered Bipolar Ionic Diode Working in Broad Range Ion Concentration. Micromachines. 2023; 14(7):1311. https://doi.org/10.3390/mi14071311

Chicago/Turabian StyleKim, Jaehyun, Cong Wang, and Jungyul Park. 2023. "Multi-Layered Bipolar Ionic Diode Working in Broad Range Ion Concentration" Micromachines 14, no. 7: 1311. https://doi.org/10.3390/mi14071311