White Light-Emitting Flexible Displays with Quantum-Dot Film and Greenish-Blue Organic Light-Emitting Diodes

Abstract

1. Introduction

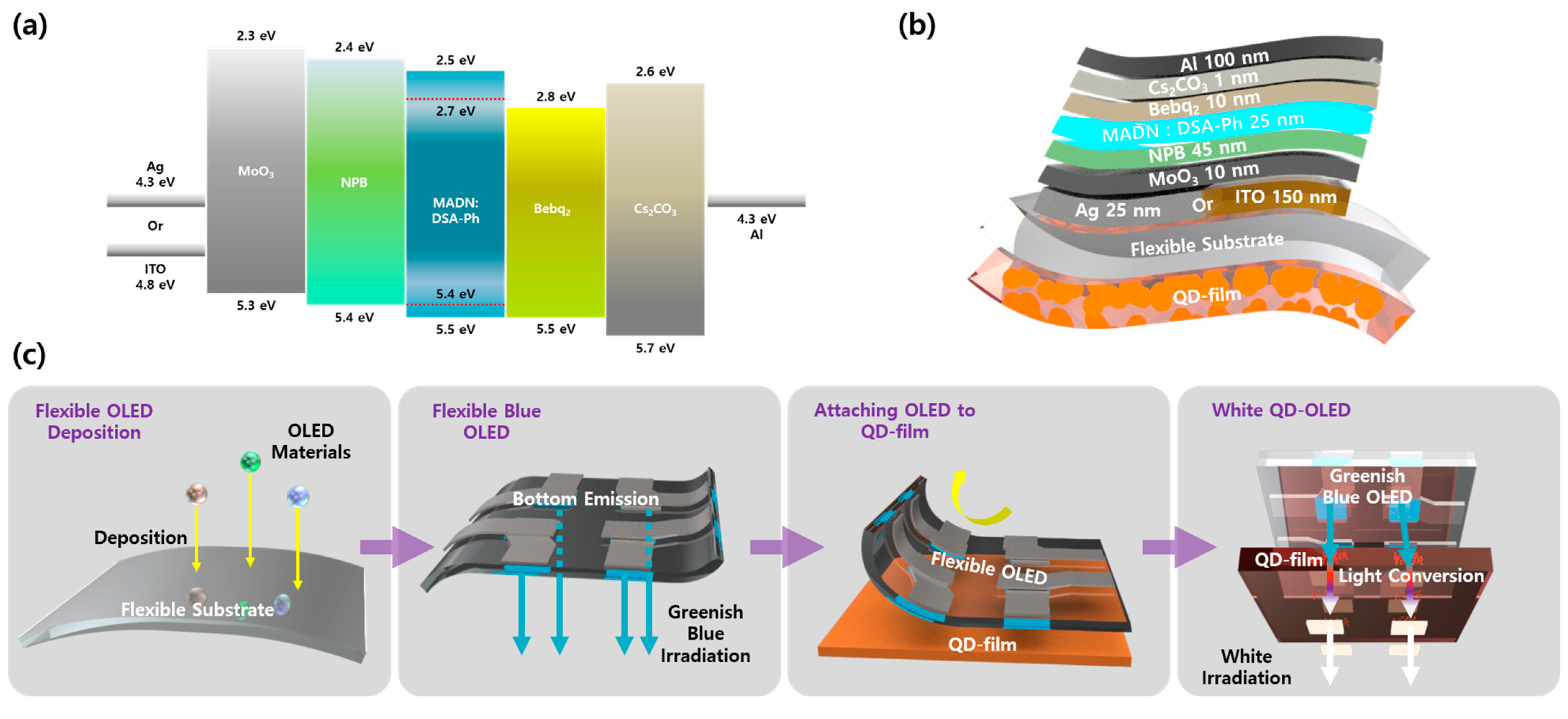

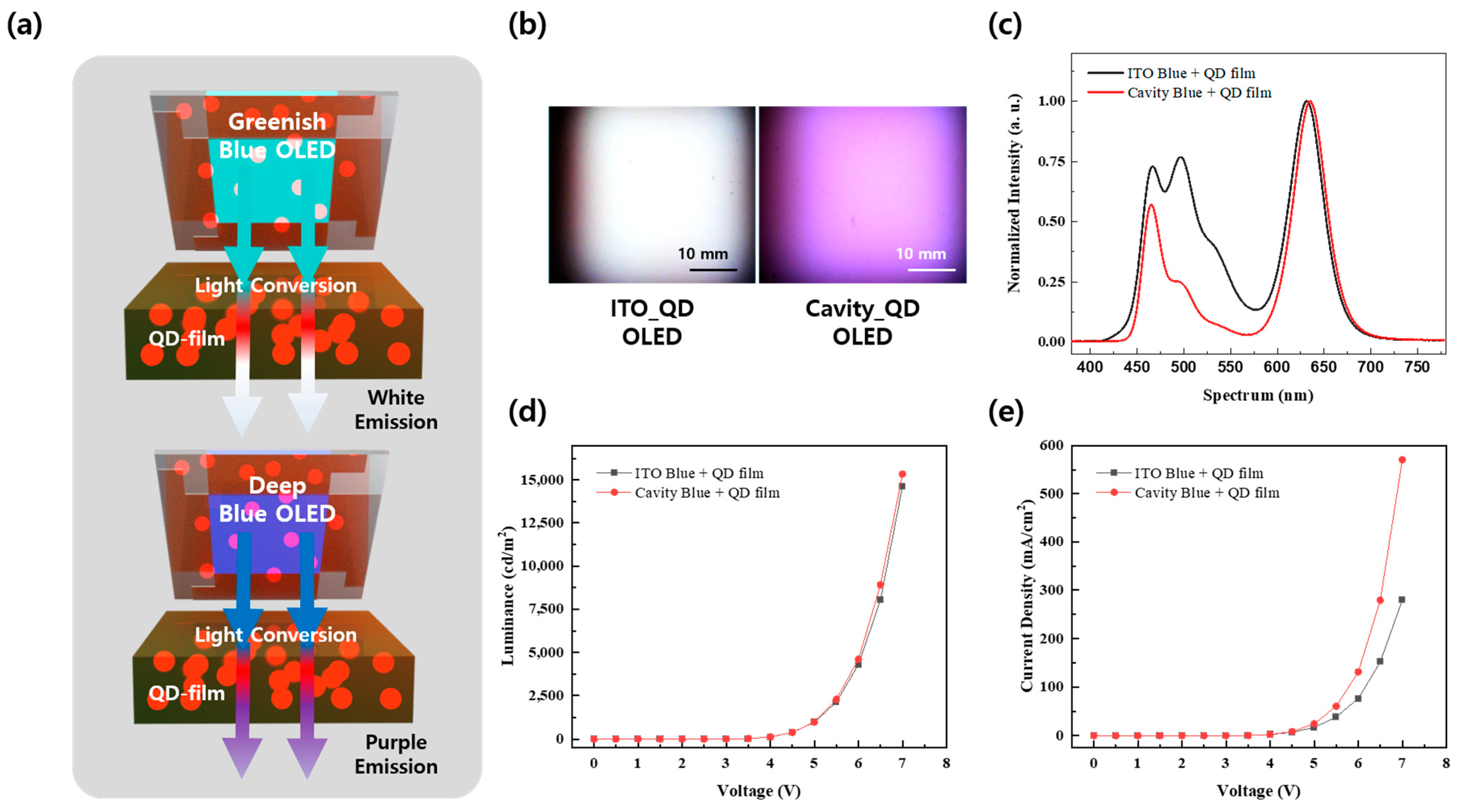

2. Experimental Section

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Salehi, A.; Fu, X.; Shin, D.H.; So, F. Recent advances in OLED optical design. Adv. Funct. Mater. 2019, 29, 1808803. [Google Scholar] [CrossRef]

- Jeon, Y.; Choi, H.-R.; Kwon, J.H.; Choi, S.; Nam, K.M.; Park, K.-C.; Choi, K.C. Sandwich-structure transferable free-form OLEDs for wearable and disposable skin wound photomedicine. Light Sci. Appl. 2019, 8, 114. [Google Scholar] [CrossRef]

- Jeon, Y.; Choi, H.R.; Park, K.C.; Choi, K.C. Flexible organic light-emitting-diode-based photonic skin for attachable phototherapeutics. J. Soc. Inf. Disp. 2020, 28, 324–332. [Google Scholar] [CrossRef]

- Sugimoto, A.; Ochi, H.; Fujimura, S.; Yoshida, A.; Miyadera, T.; Tsuchida, M. Flexible OLED displays using plastic substrates. IEEE J. Sel. Top. Quantum Electron. 2004, 10, 107–114. [Google Scholar] [CrossRef]

- Auch, M.D.J.; Soo, O.K.; Ewald, G.; Soo-Jin, C. Ultrathin glass for flexible OLED application. Thin Solid Film. 2002, 417, 47–50. [Google Scholar] [CrossRef]

- Lee, E. Simulation of the thin-film thickness distribution for an OLED thermal evaporation process. Vacuum 2009, 83, 848–852. [Google Scholar] [CrossRef]

- Villani, F.; Vacca, P.; Nenna, G.; Valentino, O.; Burrasca, G.; Fasolino, T.; Minarini, C.; della Sala, D. Inkjet Printed Polymer Layer on Flexible Substrate for OLED Applications. J. Phys. Chem. C 2009, 113, 13398–13402. [Google Scholar] [CrossRef]

- Gorter, H.; Coenen, M.J.J.; Slaats, M.W.L.; Ren, M.; Lu, W.; Kuijpers, C.J.; Groen, W.A. Toward inkjet printing of small molecule organic light emitting diodes. Thin Solid Film. 2013, 532, 11–15. [Google Scholar] [CrossRef]

- Thejo Kalyani, N.; Dhoble, S.J. Novel materials for fabrication and encapsulation of OLEDs. Renew. Sustain. Energy Rev. 2015, 44, 319–347. [Google Scholar] [CrossRef]

- Fröbel, M.; Schwab, T.; Kliem, M.; Hofmann, S.; Leo, K.; Gather, M.C. Get it white: Color-tunable AC/DC OLEDs. Light Sci. Appl. 2015, 4, e247. [Google Scholar] [CrossRef]

- Bender, V.C.; Marchesan, T.B.; Alonso, J.M. Solid-State Lighting: A Concise Review of the State of the Art on LED and OLED Modeling. IEEE Ind. Electron. Mag. 2015, 9, 6–16. [Google Scholar] [CrossRef]

- Han, K.-H.; Kim, K.; Han, Y.; Kim, Y.-D.; Lim, H.; Huh, D.; Shin, H.; Lee, H.; Kim, J.-J. Highly Efficient Tandem White OLED Using a Hollow Structure. Adv. Mater. Interfaces 2020, 7, 1901509. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, Y.; Zhou, J.; Sun, S.; Luo, W.; He, W.; Wang, J.; Shi, X.; Fung, M.-K. Hybrid Tandem White OLED with Long Lifetime and 150 Lm W−1 in Luminous Efficacy Based on TADF Blue Emitter Stabilized with Phosphorescent Red Emitter. Adv. Opt. Mater. 2020, 8, 2000727. [Google Scholar] [CrossRef]

- Guo, F.; Ma, D. White organic light-emitting diodes based on tandem structures. Appl. Phys. Lett. 2005, 87, 173510. [Google Scholar] [CrossRef]

- Jeon, Y.; Noh, I.; Seo, Y.C.; Han, J.H.; Park, Y.; Cho, E.H.; Choi, K.C. Parallel-Stacked Flexible Organic Light-Emitting Diodes for Wearable Photodynamic Therapeutics and Color-Tunable Optoelectronics. ACS Nano 2020, 14, 15688–15699. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Pfeiffer, M.; Werner, A.; Blochwitz, J.; Leo, K.; Liu, S. Low-voltage organic electroluminescent devices using pin structures. Appl. Phys. Lett. 2002, 80, 139–141. [Google Scholar] [CrossRef]

- Fröbel, M.; Perumal, A.; Schwab, T.; Gather, M.C.; Lüssem, B.; Leo, K. Enhancing the efficiency of alternating current driven organic light-emitting devices by optimizing the operation frequency. Org. Electron. 2013, 14, 809–813. [Google Scholar] [CrossRef]

- Perumal, A.; Fröbel, M.; Gorantla, S.; Gemming, T.; Lüssem, B.; Eckert, J.; Leo, K. Novel Approach for Alternating Current (AC)-Driven Organic Light-Emitting Devices. Adv. Funct. Mater. 2012, 22, 210–217. [Google Scholar] [CrossRef]

- Angioni, E.; Chapran, M.; Ivaniuk, K.; Kostiv, N.; Cherpak, V.; Stakhira, P.; Lazauskas, A.; Tamulevičius, S.; Volyniuk, D.; Findlay, N.J.; et al. A single emitting layer white OLED based on exciplex interface emission. J. Mater. Chem. C 2016, 4, 3851–3856. [Google Scholar] [CrossRef]

- Law, G.-L.; Wong, K.-L.; Tam, H.-L.; Cheah, K.-W.; Wong, W.-T. White OLED with a Single-Component Europium Complex. Inorg. Chem. 2009, 48, 10492–10494. [Google Scholar] [CrossRef]

- Tan, G.; Lee, J.-H.; Lin, S.-C.; Zhu, R.; Choi, S.-H.; Wu, S.-T. Analysis and optimization on the angular color shift of RGB OLED displays. Opt. Express 2017, 25, 33629–33642. [Google Scholar] [CrossRef]

- Xiong, Y.; Xu, W.; Li, C.; Liang, B.; Zhao, L.; Peng, J.; Cao, Y.; Wang, J. Utilizing white OLED for full color reproduction in flat panel display. Org. Electron. 2008, 9, 533–538. [Google Scholar] [CrossRef]

- Wu, X.-M.; Hua, Y.-L.; Wang, Z.-Q.; Yin, S.-G.; Zheng, J.-J.; Deng, J.-C.; Petty, M.C. Pure RGB Emissions Based on a White OLED Combined with Optical Colour Filters. Chin. Phys. Lett. 2006, 23, 1012. [Google Scholar] [CrossRef]

- Patel, K.D.; Juang, F.-S.; Wang, H.-X.; Jian, C.-Z.; Chen, J.-Y. Quantum Dot-Based White Organic Light-Emitting Diodes Excited by a Blue OLED. Appl. Sci. 2022, 12, 6365. [Google Scholar] [CrossRef]

- Lee, H.; Song, S.-W.; Hwang, K.M.; Kim, K.J.; Yang, H.; Kim, Y.K.; Kim, T. Hybrid white quantum dot–organic light-emitting diodes with highly stable CIEx,y coordinates by the introduction of n-type modulation and multi-stacked hole transporting layer. J. Mater. Chem. C 2021, 9, 12248–12254. [Google Scholar] [CrossRef]

- Kwon, H.; Park, S.; Kang, S.; Park, S.; Pu, Y.-J.; Park, J. Three-color white electroluminescence emission using perovskite quantum dots and organic emitters. Appl. Surf. Sci. 2022, 588, 152875. [Google Scholar] [CrossRef]

- Adhikari, G.C.; Vargas, P.A.; Zhu, H.; Grigoriev, A.; Zhu, P. Tetradic phosphor white light with variable CCT and superlative CRI through organolead halide perovskite nanocrystals. Nanoscale Adv. 2019, 1, 1791–1798. [Google Scholar] [CrossRef]

- He, G.; Zheng, L.; Yan, H. LED white lights with high CRI and high luminous efficacy. In Proceedings of the Photonics Asia 2010, Beijing, China, 18–20 October 2010; Volume 7852. [Google Scholar]

- Jou, J.-H.; Wu, M.-H.; Shen, S.-M.; Wang, H.-C.; Chen, S.-Z.; Chen, S.-H.; Lin, C.-R.; Hsieh, Y.-L. Sunlight-style color-temperature tunable organic light-emitting diode. Appl. Phys. Lett. 2009, 95, 013307. [Google Scholar] [CrossRef]

- Xu, Q.; Cai, W.; Li, W.; Sreeprasad, T.S.; He, Z.; Ong, W.-J.; Li, N. Two-dimensional quantum dots: Fundamentals, photoluminescence mechanism and their energy and environmental applications. Mater. Today Energy 2018, 10, 222–240. [Google Scholar] [CrossRef]

- Rossetti, R.; Nakahara, S.; Brus, L.E. Quantum size effects in the redox potentials, resonance Raman spectra, and electronic spectra of CdS crystallites in aqueous solution. J. Chem. Phys. 1983, 79, 1086–1088. [Google Scholar] [CrossRef]

- Kim, H.; Han, J.Y.; Kang, D.S.; Kim, S.W.; Jang, D.S.; Suh, M.; Kirakosyan, A.; Jeon, D.Y. Characteristics of CuInS2/ZnS quantum dots and its application on LED. J. Cryst. Growth 2011, 326, 90–93. [Google Scholar] [CrossRef]

- Deng, D.; Chen, Y.; Cao, J.; Tian, J.; Qian, Z.; Achilefu, S.; Gu, Y. High-Quality CuInS2/ZnS Quantum Dots for In Vitro and In Vivo Bioimaging. Chem. Mater. 2012, 24, 3029–3037. [Google Scholar] [CrossRef]

- Dohnalová, K.; Gregorkiewicz, T.; Kůsová, K. Silicon quantum dots: Surface matters. J. Phys. Condens. Matter 2014, 26, 173201. [Google Scholar] [CrossRef] [PubMed]

- Fauchet, P.M. Light emission from Si quantum dots. Mater. Today 2005, 8, 26–33. [Google Scholar] [CrossRef]

- Mintz, K.J.; Zhou, Y.; Leblanc, R.M. Recent development of carbon quantum dots regarding their optical properties, photoluminescence mechanism, and core structure. Nanoscale 2019, 11, 4634–4652. [Google Scholar] [CrossRef]

- Yuan, F.; Wang, Z.; Li, X.; Li, Y.; Tan, Z.; Fan, L.; Yang, S. Bright Multicolor Bandgap Fluorescent Carbon Quantum Dots for Electroluminescent Light-Emitting Diodes. Adv. Mater. 2017, 29, 1604436. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.W.; Kwon, J.H.; Choi, H.-R.; Choi, J.G.; Kwon, O.K.; Kim, K.H.; Cho, E.H.; Lee, T.-Y.; Cho, E.-S.; Kwon, S.J.; et al. Wearable quantum dots organic light-emitting diodes patch for high-power near infra-red photomedicene with real-time wavelength control. Chem. Eng. J. 2024, 499, 156121. [Google Scholar] [CrossRef]

- Tseng, Z.-L.; Chen, L.-C.; Chao, L.-W.; Tsai, M.-J.; Luo, D.; Al Amin, N.R.; Liu, S.-W.; Wong, K.-T. Aggregation Control, Surface Passivation, and Optimization of Device Structure toward Near-Infrared Perovskite Quantum-Dot Light-Emitting Diodes with an EQE up to 15.4%. Adv. Mater. 2022, 34, 2109785. [Google Scholar] [CrossRef] [PubMed]

- Xue, Q.; Cai, P.; Pu, X.; Ai, Q.; Si, J.; Yao, X.; Bai, G.; Dong, Q.; Liu, Z. Green synthesis of high-quality indium phosphide quantum dots using tripyrrolidine phosphine as a promising phosphorus source for white LED. Mater. Today Nano 2024, 25, 100457. [Google Scholar] [CrossRef]

- Sun, P.; Wang, Z.; Sun, D.; Bai, H.; Zhu, Z.; Bi, Y.; Zhao, T.; Xin, X. pH-guided self-assembly of silver nanoclusters with aggregation-induced emission for rewritable fluorescent platform and white light emitting diode application. J. Colloid Interface Sci. 2020, 567, 235–242. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.W.; Kim, S.; Lee, C.; Jeong, J.H.; Jeong, Y.H.; Bak, Y.; Kim, S.H.; Park, S.J.; Ham, K.E.; Lee, D.; et al. White Light-Emitting Flexible Displays with Quantum-Dot Film and Greenish-Blue Organic Light-Emitting Diodes. Micromachines 2024, 15, 1518. https://doi.org/10.3390/mi15121518

Kim YW, Kim S, Lee C, Jeong JH, Jeong YH, Bak Y, Kim SH, Park SJ, Ham KE, Lee D, et al. White Light-Emitting Flexible Displays with Quantum-Dot Film and Greenish-Blue Organic Light-Emitting Diodes. Micromachines. 2024; 15(12):1518. https://doi.org/10.3390/mi15121518

Chicago/Turabian StyleKim, Young Woo, Seojin Kim, Chaeyeong Lee, Joo Hyun Jeong, Yun Hyeok Jeong, Yuhwa Bak, Seo Hyeon Kim, Sung Jin Park, Ko Eun Ham, Doeun Lee, and et al. 2024. "White Light-Emitting Flexible Displays with Quantum-Dot Film and Greenish-Blue Organic Light-Emitting Diodes" Micromachines 15, no. 12: 1518. https://doi.org/10.3390/mi15121518

APA StyleKim, Y. W., Kim, S., Lee, C., Jeong, J. H., Jeong, Y. H., Bak, Y., Kim, S. H., Park, S. J., Ham, K. E., Lee, D., Song, J., Song, Y., Jung, S.-C., Kwon, O. K., Han, J.-H., Kwon, S. J., Cho, E.-S., & Jeon, Y. (2024). White Light-Emitting Flexible Displays with Quantum-Dot Film and Greenish-Blue Organic Light-Emitting Diodes. Micromachines, 15(12), 1518. https://doi.org/10.3390/mi15121518